Abstract

The use of artificial porous aggregates for the production of lightweight cement concrete is widespread and used everywhere. In most cases, lightweight artificial aggregates are used to produce concrete of the standard structure using vibration technology. However, there is currently no knowledge base on the use of these aggregates for the production of concrete using centrifugation technology. The purpose of this work is to develop and obtain a new composition of variotropic concrete with a combined coarse aggregate and microsilica. A total of 17 concrete elements of the annular cross-section were manufactured using centrifugation technology. The optimal ratio of 60% crushed stone (CrS) and 40% expanded clay gravel (EC) was determined. It was found that replacing CrS with EC improves such properties as density and thermal conductivity, and negatively affects the strength of the composite. Modification of lightweight centrifuged concrete on a combined aggregate with microsilica (MS) in dosages from 2% to 10% had a positive effect on its mechanical properties. The most effective MS dosage was 6%. The compressive strength of lightweight concrete increased by 14.75%, from 36.6 MPa to 42.0 MPa, which is comparable to the compressive strength of centrifuged concrete on a heavy aggregate of 43.4 MPa. The density value was 2148 kg/m3. The thermal conductivity coefficient was 1.270 W/m×°C. As a result, a new centrifuged concrete of variotropic structure with reduced material consumption, density, thermal conductivity coefficient, and the required mechanical properties was developed.

1. Introduction

Currently, the construction industry is developing rapidly. Projects are becoming more complex and demanding of budget and time constraints [1]. In this regard, the need for new alternative types of building materials is always relevant. The most popular are cement composite materials modified with various types of chemical and mineral additives based on industrial waste [2,3,4]. One of these approaches is the creation of lightweight concrete by partially or completely replacing heavy natural coarse and fine aggregate with lightweight aggregate. There are many studies proving the effectiveness of this approach. With the correct selection of the recipe, it is possible to obtain a composite with the required mechanical properties, reduced weight, and lower thermal conductivity [5,6]. The reduced weight of such composites is very beneficial in structures where static load is important. The use of lightweight composites allows for reducing the overall load on the building foundation, thereby reducing the percentage of reinforcement and the need for other necessary materials [7]. Lightweight structural concrete with the required performance properties is known, where 30% of the natural coarse aggregate was replaced by a lightweight aggregate made of local clay [8]. The potential of using lightweight expanded clay concrete has already been proven in marine construction [9]. The introduction of 20% of expanded clay gravel encapsulated by bacteria into the concrete mix made it possible to obtain self-healing concrete with improved durability properties [10]. The use of lightweight expanded clay aggregates and slag aggregates made it possible to maintain the strength of the composite at the structural level [11]. The inclusion of basalt fiber in the composition of expanded clay concrete and its enclosure in a polymer network significantly improved the strength of columns [12]. The effectiveness of using lightweight aggregates instead of part of the heavy natural aggregate has already been proven in many studies [13,14,15,16,17]. The main feature of such composites is their lighter weight while maintaining the required mechanical properties.

The uniqueness of centrifuged concrete lies in its non-standard variotropic structure. During the compaction of concrete mix under the action of centrifugal forces, it is divided into zones by the size of the aggregate grains. It is the difference in the drift velocity of particles that determines the specific variotropic state of concrete [18]. The largest and densest grains mainly accumulate near the outer surface of the ring-section product. Less dense grains and a large proportion of the solution part are located in the middle and inner layers of the centrifuged composite [19,20]. Accordingly, the concrete acquires a unique structure that varies in the thickness of the product with distinctive physical and mechanical properties. Previously, the strength and deformation properties of centrifuged concrete structures with various reinforcement options were studied, and the most optimal of them were determined [21]. A detailed study of the features of the heterogeneous structure of concrete made it possible to expand the general understanding of the microstructural features of centrifuged concrete [22,23,24]. Previous studies have assessed the efficiency and cost of centrifugation technology in comparison with vibration technology. Due to the reduction in material and resource intensity, as well as the simplification of transportation and installation processes, centrifugation has an overall advantage over vibration in the range of 12–17% [18,19,20,24]. Centrifuged tubular piles have good corrosion resistance and durability in general [25]. A stochastic model of the relationship between damage and permeability of centrifuged piles allows for a fairly accurate analysis of their technical condition during their driving [26]. The review also revealed a shortage of studies devoted to the modification of concrete with a variotropic structure using various mineral and chemical additives [27,28,29,30]. Microsilica is a popular and effective mineral additive for cement composites [31]. The inclusion of 10% microsilica in concrete on recycled aggregate improves its mechanical properties and reduces permeability [32]. The addition of SiO2 increased the strength of the 28-day-old cement composite by 40%, reduced porosity by 2.68%, and increased its sulfate resistance [33]. The positive effect of SiO2 on the properties of cement composites has already been studied in detail in previous studies [34,35,36,37,38]. Thus, the use of microsilica for modification of the structure of variotropic concrete with combined heavy and light aggregate is a promising direction for conducting experimental studies and will make it possible to fill the knowledge gap in this area. The novelty of the study lies in obtaining new compositions of variotropic concrete obtained by centrifugation technology with lightweight expanded clay aggregate and the addition of microsilica, and new dependencies of the properties of the variotropic composite on the content of lightweight expanded clay aggregate and microsilica, describing the complex effect of a combination of different types of coarse aggregate and modification with production waste.

The objective of this study is to obtain a new composition of variotropic concrete with combined coarse aggregate and modified MS, which has lower density and the required performance properties. The objectives of the study are as follows:

- -

- calculation and selection of the composition of centrifuged concrete with different proportions of heavy and lightweight coarse aggregate and taking into account the actual properties of the raw materials used;

- -

- production of experimental centrifuged concretes of annular cross-section, sawing them into standard-sized samples and conducting laboratory tests; monitoring the density of fresh concrete and the density, compressive strength, and thermal conductivity of the hardened composite;

- -

- selection of a rational dosage of MS for modification of concrete with different proportions of heavy and lightweight coarse aggregate: production of centrifuged concrete samples of annular cross-section, sawing and evaluation of their density, compressive strength, and thermal conductivity;

- -

- study of the structural features of variotropic concretes with combined aggregate and microsilica;

- -

- preparation of practical recommendations for the use of the obtained lightweight centrifuged concrete modified with microsilica.

2. Materials and Methods

2.1. Materials

For the production of samples of variotropic concrete with combined heavy and light aggregate, Portland cement CEM I 42.5N (CEMROS, Moscow, Russia), quartz sand (Don Resurs, Kagalnik, Russia), granite crushed stone Solntsedar-Don (Rostov-on-Don, Russia), and expanded clay gravel (PKF Keramzit, Enem, Russia) were used. Ultrafine microsilica (MS) (NLMK, Lipetsk, Russia) was used as a modifying additive. The main properties of the raw materials are presented in Table 1.

Table 1.

Properties of the raw materials.

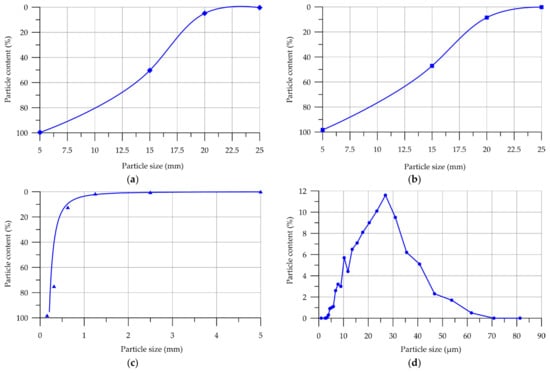

The granulometric curves for the sieving of coarse and fine aggregate are shown in Figure 1.

Figure 1.

Particle size distribution curves: (a) crushed rock; (b) expanded clay gravel; (c) sand; (d) cement.

Crushed rock and expanded clay gravel had grain sizes from 5 to 20 mm (Figure 1a,b), and the fineness modulus of quartz sand was 1.87 (Figure 1c). Cement particles (Figure 1d) in the main volume (88.6%) were in the size range from 8 to 47 μm. The distribution peak of 11.6% fell on particles of 26 μm in size.

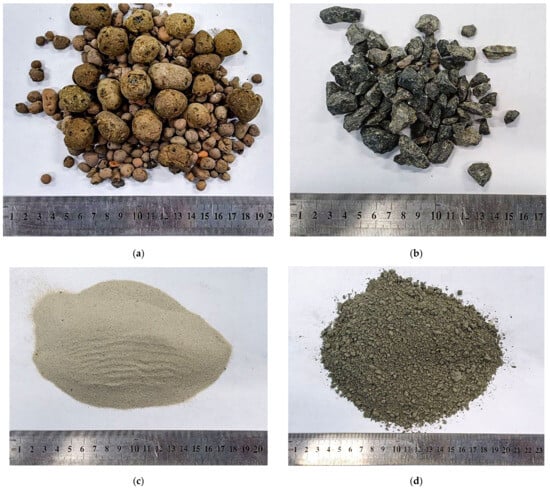

The appearance of the main raw material components is shown in Figure 2.

Figure 2.

Appearance of the main raw materials: (a) expanded clay gravel; (b) crushed granite; (c) sand; (d) cement.

2.2. Methods

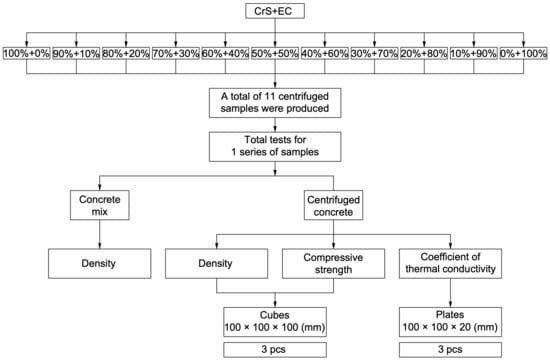

The properties of variotropic concretes with combined heavy and lightweight aggregate were assessed in accordance with the experimental research program presented in Figure 3.

Figure 3.

Experimental research program for variotropic concrete with combined aggregate.

The compositions of the concrete mix of the control composition and mixes with combined aggregate are presented in Table 2.

Table 2.

Compositions of centrifuged concrete with different ratios of dense and porous coarse aggregate.

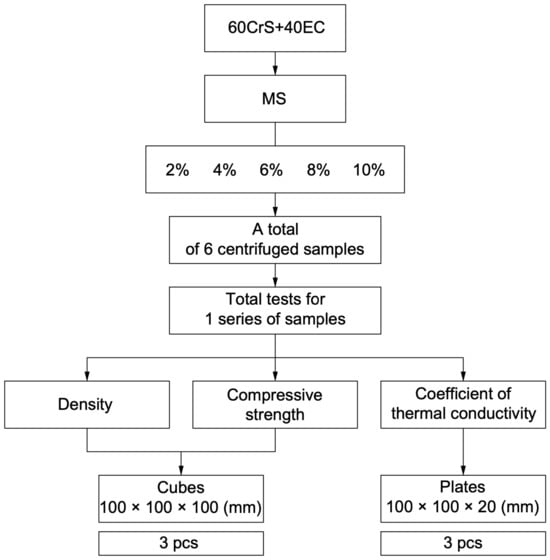

After determining the most rational composition of the concrete mixture, allowing to obtain concrete of a variotropic structure with optimal physical and mechanical properties, the lightweight centrifuged concrete was modified with an active mineral additive MS in order to improve its properties. The selection of the most rational dosage of MS was carried out in accordance with the experimental research program presented in Figure 4.

Figure 4.

Experimental research program for modification of lightweight centrifuged concrete with microsilica.

Experimental compositions of concrete mixtures with combined aggregate and different MS dosages are presented in Table 3.

Table 3.

Compositions of lightweight centrifuged concrete with different MS dosages.

According to the proportions of mixtures with combined aggregate and microsilica presented in Table 3, the percentage ratio of components can be presented as follows (Table 4), taking into account that microsilica was added instead of part of the Portland cement and its share was calculated as a percentage of the binder mass (PC+MS).

Table 4.

Shares of components of concrete mixtures relative to the amount of Portland cement.

In total, 17 centrifuged elements with the following dimensions were made to determine the density, compressive strength, and thermal conductivity coefficient: outer diameter D = 300 mm; inner diameter d = 70 mm; total height h = 500 mm. The production of the control concrete mix was carried out in a standard way. Initially, all raw components were dosed according to the recipe. After dosing, sand and cement were poured into a laboratory concrete mixer BL-10 (ZZBO, Zlatoust, Russia) and mixed dry. Then, water was added, and everything was mixed until a mortar mix of uniform consistency was obtained. Granite crushed stone was added to the mortar mix, and everything was mixed again until a uniform consistency was obtained. The preparation of concrete mixes on a combined aggregate had several differences. All raw components were dosed according to the recipe. At the very beginning, expanded clay gravel and 1/3 of water were loaded into a laboratory concrete mixer and then mixed. This technological method is necessary to reduce the water absorption of expanded clay. At the initial stage of concrete mix preparation, the porous aggregate absorbs some of the water from the mortar mix, which negatively affects its rheological properties [17]. After the porous aggregate was saturated with water, the remaining components were added, including microsilica, and the entire concrete mix was mixed until a uniform consistency was achieved. After the experimental concrete mix compositions were prepared, their density was determined and the process of manufacturing centrifuged elements was carried out, which included the following main stages:

- -

- assembly and lubrication of the metal form for centrifugation;

- -

- loading the concrete mixture into the form;

- -

- compaction of the concrete mixture for 5 min at 800 rpm on a laboratory centrifugation unit (DSTU, Rostov-on-Don, Russia) [39];

- -

- holding the samples in the form and removing them from it after 24 h;

- -

- storing the samples in the KNT-1 normal curing chamber (RNPO RusPribor, St. Petersburg, Russia) for 27 days and sawing.

The curing time of the samples was 28 days under normal conditions (temperature 20 ± 2 °C and relative air humidity 95 ± 5%).

From each centrifuged element, 6 cubes measuring 100 mm × 100 mm × 100 mm were sawn out. The cutting of cube samples from the centrifuged elements was carried out on a CTS-175 «CEDIMA» stone-cutting machine (Cedima GmbH, Celle, Germany) according to the scheme given in the work [19]. In this way, 102 cube samples were made and tested: 51 for determining the density and compressive strength and 51 for determining the thermal conductivity of concrete. Note that to determine the thermal conductivity coefficient, a 2 cm thick plate was cut out of the cube sample. The density of freshly made concrete mixtures was determined in accordance with the standard methodology and calculated using the following formula:

where m is the mass of the measuring vessel with concrete mix (g); m1 is the mass of the measuring vessel without mix (g); and V is the capacity of the measuring vessel (cm3) [40].

The density of the hardened cube samples was determined in accordance with the requirements of the method [41]. Before determining the density, the samples were dried to a constant mass. The average density value was calculated using the following formula:

where m is the mass of the sample (g); and V is the volume of the sample (cm3).

The compressive strength of concrete samples was determined in accordance with the requirements of standards [42,43,44,45,46]. The essence of the method consisted of measuring the minimum forces that destroy specially prepared control concrete specimens when subjected to static loading at a constant rate of load increase and then calculating the stresses under these forces. The temperature in the room for testing the specimens was maintained at 20 ± 5 °C, and the relative air humidity was at least 55%. The specimens were removed from the normal curing chamber and kept in the room for 4 h before testing. The support faces of the specimens to which the force was applied during loading were selected and marked. The support faces of the molded cube specimens were selected so that the compressive force during testing was directed parallel to the layers of concrete mix in the molds. The linear dimensions of the specimens were measured with an error of no more than 1%. All specimens were tested at the estimated age for no more than 1 h. The specimens were loaded continuously at a constant rate of load increase until their destruction. In this case, the specimen loading time until its destruction was at least 30 s. The maximum force achieved during the test was taken as the breaking load. All samples were tested on a P-50 hydraulic machine (PKC ZIM, Armavir, Russia) at a constant load increase rate of (0.6 ± 0.2) MPa/s. Compressive strength was calculated using the following formula:

where F is the breaking load (N); A is the area of the working cross-section of the sample (mm2); and α is the scaling factor for converting the concrete strength to the concrete strength in samples of the basic size and shape, for cubes with an edge length of 100 mm α = 0.95.

The thermal conductivity coefficient of centrifuged concrete was determined according to the method [47] on the ITP-MG4 device (Stroypribor, Chelyabinsk, Russia). Sample plates with dimensions of 100 × 100 × 20 mm were dried to constant weight, placed in the device, and tested in the stationary mode. The operating principle in this mode is based on the creation of a stationary heat flow passing through a flat sample of a certain thickness and directed perpendicular to the front faces of the sample, measuring the thickness of the sample, the density of the heat flow, and the temperature of the opposite front faces. The stationary installation of the device consists of a heater control unit and a refrigerator made on Peltier elements, a heat meter, platinum temperature sensors, a device for converting primary sensor signals, and a power source. Cooling of the Peltier elements is carried out by a fan. The sample was placed in the device to determine its thermal resistance, the device began measuring. After the measurement was complete, the device emitted a corresponding signal and the display showed the value of the thermal conductivity coefficient of the sample. The time of one measurement was no more than 2 h.

The structure of the composites was studied on an MBS-10 optical microscope (Measuring equipment, Moscow, Russia)

3. Results and Discussion

3.1. Results of the Influence of Combining Heavy and Light Aggregate on the Properties of Variotropic Concrete

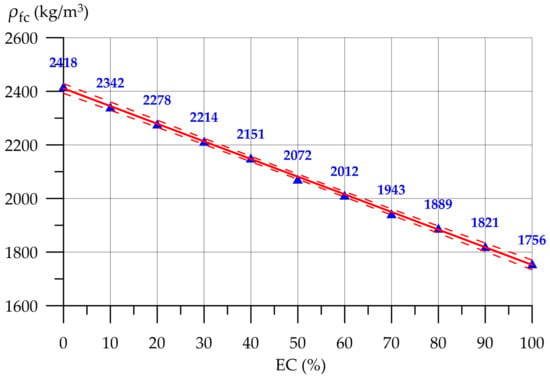

The results of determining the density of fresh concrete are shown in Figure 5.

Figure 5.

Concrete mix density (ρfc) versus EC content.

As can be seen from Figure 5, the density is linearly dependent on the EC content and can be described by the following equation:

According to the density determination data (Figure 5), it is evident that with an increase in the EC content introduced instead of part of the CrS, the density decreases. The higher the EC share, the lower the density of fresh concrete. This dependence is primarily explained by the lower density of expanded clay gravel compared to granite crushed stone. The maximum density value was 2418 kg/m3, and the minimum was 1756 kg/m3. The percentage decrease in the density of fresh concrete on combined aggregate compared to concrete on heavy aggregate is shown in Table 5.

Table 5.

Change in the density of concrete mixtures on combined aggregate.

The density of the concrete mix on EC is 27.4% less than the density of the mix made on CrS.

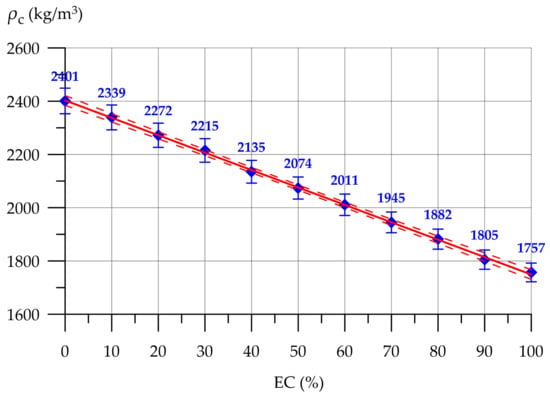

Figure 6 shows the dependence of the density of centrifuged concrete on the EC content.

Figure 6.

Density of centrifuged concrete (ρc) versus EC content (the dotted line shows the confidence limits).

It is evident that the dependence of concrete density on EC content also has a linear character.

As with density in Figure 5, the density of centrifuged concrete decreases as the content of lightweight coarse aggregate (EC) increases. The maximum density of 2401 kg/m3 is for centrifuged concrete on coarse heavy aggregate. The minimum density of 1747 kg/m3 is for centrifuged concrete on lightweight aggregate. The percentage decrease in the density of centrifuged concrete on combined aggregate compared to centrifuged concrete on heavy aggregate is shown in Table 6.

Table 6.

Change in the density of centrifuged concrete on combined aggregate.

The density of centrifuged concrete on EC is 26.8% less than the density of concrete on CrS.

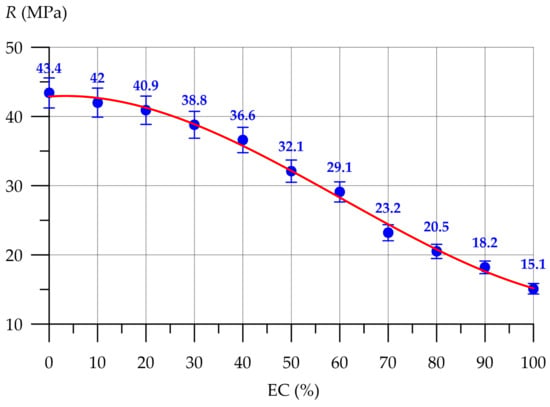

Figure 7 shows the results of determining the compressive strength of variotropic centrifuged concrete depending on the percentage of EC and CrS.

Figure 7.

Dependence of compressive strength of centrifuged concrete (R) on the EC content.

The dependence of the compressive strength of concrete on the EC content has the form of a descending curve and is well approximated by a third-degree polynomial.

As can be seen from Figure 7, the compressive strength of centrifuged concrete decreases with increasing EC content introduced instead of CrS. With the introduction of EC up to 40%, a smooth decrease in compressive strength by 15.7% is observed compared to the control composition (EC = 0). Starting from 50% EC and more, the compressive strength decreases more rapidly. The compressive strength of centrifuged concrete on heavy granite aggregate was 43.4 MPa. The compressive strength of centrifuged concrete on lightweight expanded clay aggregate was 15.1 MPa. The standard deviation of compressive strength values was up to 5.5%. The percentage decrease in compressive strength of centrifuged concrete on combined aggregate compared to centrifuged concrete on heavy aggregate is shown in Table 7.

Table 7.

Change in the compressive strength of centrifuged concrete on combined aggregate.

With the complete replacement of CrS with EC, centrifuged concrete significantly loses strength. The reduction in compressive strength was 65.2%.

Figure 8 shows photographs of destroyed centrifuged concrete samples with different coarse aggregates after compression testing.

Figure 8.

Determination of compressive strength of centrifuged concrete: concrete with combined coarse aggregate 50% CrS/50% EC (a) before collapse, (c) after collapse; concrete with lightweight coarse aggregate 100% EC (b) before collapse, (d) after collapse.

From Figure 8, it is evident that the nature of concrete failure on the combined aggregate is somewhat different from that of concrete on expanded clay gravel. The failure of the sample (a), (c) was more brittle, with instant cracking and splitting of concrete fragments than that of the sample (b), (d). This may indicate that the sample with the combined aggregate has a denser and stronger structure than the sample with lightweight aggregate, which is also confirmed by the visual assessment of the samples presented in the figure. The macrostructure of the sample with the combined aggregate (c) is more organized and uniform than that of the sample with 100% EC (d).

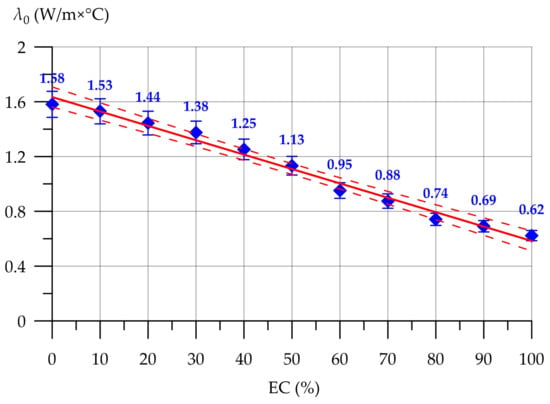

Figure 9 shows the graphical dependence of the thermal conductivity of centrifuged concrete on the content of expanded clay gravel in it.

Figure 9.

Dependence of the thermal conductivity coefficient of centrifuged concrete (λ0) on the EC content (the dotted line shows the confidence limits).

It is evident that the dependence of the thermal conductivity coefficient of centrifuged concrete (λ0) on the EC content is close to linear.

Replacing CrS with EC, as can be seen from Figure 9, helps to reduce the thermal conductivity coefficient. The highest value of the thermal conductivity coefficient of 1.58 W/m×°C was recorded for centrifuged concrete on heavy aggregate. Further, with an increase in the EC content, a decrease in the thermal conductivity coefficient is observed. Centrifuged concrete made exclusively on lightweight expanded clay aggregate has the lowest value of the thermal conductivity coefficient of 0.623 W/m×°C. The decrease in the thermal conductivity coefficient is primarily explained by the fact that the dense granite aggregate is partially and completely replaced by porous expanded clay gravel. The standard deviation of thermal conductivity values was up to 6.1%. The reduction in thermal conductivity of centrifuged concrete depending on the EC content in percentage is presented in Table 8.

Table 8.

Effect of EC content on thermal conductivity of centrifuged concrete.

Centrifuged concrete on expanded clay has a thermal conductivity coefficient value that is 60.6% lower than that of concrete on granite aggregate. Expanded clay has a low density and a porous structure, which helps to reduce heat transfer through the material [48].

Thus, the following was determined during experimental studies on the selection of the composition of variotropic concrete with EC:

- (1)

- The introduction of lightweight coarse aggregate allows reducing the density of fresh concrete. This indicator decreases as the expanded clay content increases. The density of fresh concrete on CrS was 2418 kg/m3, and for concrete on expanded clay aggregate, the density was 1756 kg/m3.

- (2)

- Replacing CrS with EC up to 40% is the most optimal and allows the production of centrifuged concrete with high mechanical properties. The decrease in compressive strength was 15.7%. The density of centrifuged concrete on the combined aggregate was 2135 kg/m3. With a higher content of expanded clay, the compressive strength begins to decrease more rapidly. The compressive strength of centrifuged expanded clay concrete was 15.1 MPa with a density of 1757 kg/m3. The decrease in the density of the composite when replacing part of the CrS with EC is logical and is due to the fact that EC grains have a lower density and strength compared to CrS grains.

- (3)

- The thermal conductivity coefficient of variotropic concrete decreases with an increase in the content of lightweight aggregate. The thermal conductivity coefficient of the control concrete on CrS was 1.581 W/m×°C. The thermal conductivity coefficient of centrifuged concrete on the combined aggregate of 60% CrS and 40% EC decreased by 20.8% and was 1.252 W/m×°C. Concrete on EC had the lowest value of thermal conductivity coefficient of 0.623 W/m×°C.

The results obtained in this study have good convergence with other similar studies [49,50,51,52,53]. For example, the use of 20% pumice allowed the production of effective high-strength concrete with a compressive strength of 52 MPa with a lower density and good corrosion resistance [49]. Replacing coarse dense aggregate with expanded clay led to a decrease in the mechanical properties of the composite as its proportion increased [50]. The introduction of 50% expanded clay allowed the production of lightweight self-compacting concrete with acceptable performance properties [51]. In addition, in previous works, it was found that a rational content of lightweight aggregate introduced instead of a part of heavy aggregate allows the production of a lightweight cementitious composite with the required characteristics [52,53]. For further research, the most optimal composition of centrifuged lightweight concrete with 40% EC and 60% CrS with a compressive strength of 36.6 MPa was selected. MS modification of lightweight centrifuged concrete was carried out in order to increase its strength properties while maintaining lower values of density and thermal conductivity.

3.2. Results of the Effect of Microsilica Modification of Centrifuged Concrete on Combined Aggregate on Its Properties

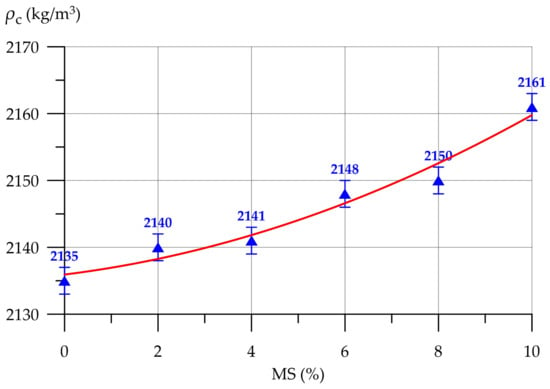

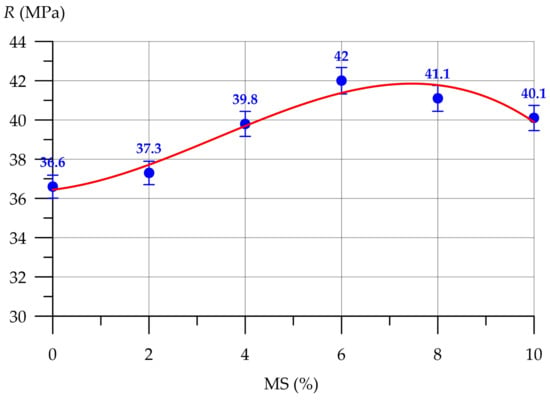

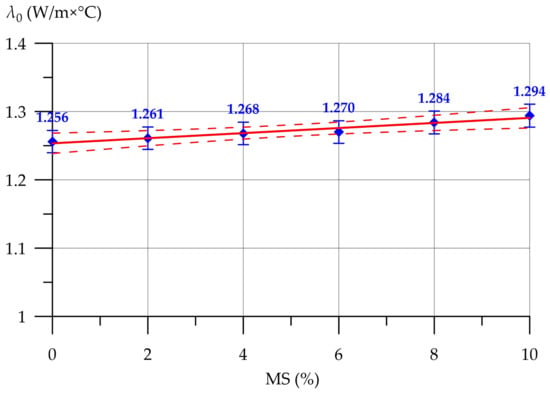

The results of determining the density (Figure 10), compressive strength (Figure 11), and thermal conductivity (Figure 12) of lightweight centrifuged concrete modified with MS additive are presented below.

Figure 10.

Dependence of the density of lightweight centrifuged concrete (ρc) on the MS content.

Figure 11.

Compressive strength of lightweight centrifuged concrete (R) as a function of MS content.

Figure 12.

Dependence of the thermal conductivity coefficient of lightweight centrifuged concrete (λ0) on the MS content (the dotted line shows the confidence limits).

Figure 10 shows that the dependence of lightweight centrifuged concrete (ρc) on the MS content is nonlinear, although not clearly expressed. The dependence is well approximated by a second-degree polynomial and has the following form:

As can be seen from Figure 10, the density of centrifuged concrete on a combined aggregate, regardless of the content of the MS additive, fluctuates slightly and ranges from 2135 kg/m3 to 2161 kg/m3. With an increase in the dosage of the modifying additive, a slight increase in density to 1.22% at 10% MS is observed. Accordingly, the use of MS with a maximum dosage of 10% does not have a significant effect on the change in the density of the centrifuged composite.

The dependence of the compressive strength of lightweight centrifuged concrete (R) as a function of MS content has a clearly expressed nonlinear character and can be represented by a third-degree polynomial.

The introduction of up to 10% MS into the variotropic composite increases its compressive strength (Figure 11). In the 2–6% MS range, there is a steady increase in compressive strength with a maximum value of 42 MPa at 6% MS. At higher dosages, the efficiency of MS modification decreases. The compressive strength values at 8% and 10% MS were 41.1 MPa and 40.1 MPa, respectively. Thus, the introduction of 6% MS into the variotropic lightweight centrifuged composite will increase its strength by 14.75% compared to the compressive strength of variotropic concrete without MS. The standard deviation of compressive strength values was up to 4.4%.

The dependence of the thermal conductivity coefficient of lightweight centrifuged concrete (λ0) on the MS content has a form close to linear.

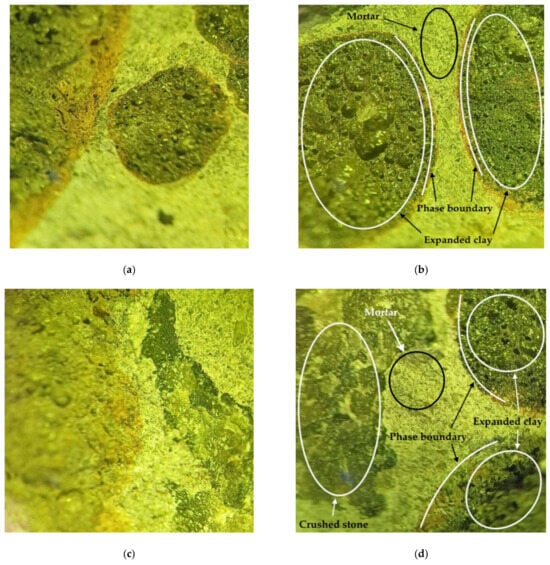

Based on the results of determining the thermal conductivity coefficient (Figure 12), it was found that the inclusion of MS does not significantly affect the change in the thermal conductivity of lightweight centrifuged concrete. With an increase in the MS dosage from 2% to 10%, a small increase in thermal conductivity to 3.0% is observed. The standard deviation of thermal conductivity values was up to 4.2%. Further, Figure 13 shows an analysis of the structure of lightweight centrifuged concrete on a combined aggregate modified with MS. Fragments of test samples were selected to study the structure of variotropic concrete.

Figure 13.

Photographs of the structure of centrifuged concrete modified with 6% MS: (a) structure at the interface between the mortar part and the expanded clay grain; (b) structure at the interface between the mortar part and the expanded clay grain (with markings); (c) structure at the interface between the mortar part and the crushed stone grain; (d) structure at the interface between the mortar part and the crushed stone grain (with markings).

Expanded clay and crushed stone grains are surrounded by a matrix of hydrated cement formations and sand particles. The phase boundary between the mortar part and the expanded clay grain (Figure 13a,b) is more clearly visible than the phase boundary between the mortar part and the crushed stone grain (Figure 13c,d). A good bond between the expanded clay grains and the mortar part (cement paste + fine aggregate) is also visible. The mortar part penetrates into the upper layer of the porous structure of the expanded clay grain, forming CSH there, which strengthens the zone at the phase boundary, resulting in a positive effect on the final strength of the concrete composite. The insignificant effect of the MS modification on such properties as density and thermal conductivity and the significant increase in compressive strength of lightweight centrifuged concrete are determined by the properties of MS and its interaction with the components of the concrete mix. MS has high pozzolanic activity and high dispersion, which gives it the properties of an ultrafine aggregate filling the space between the cement particles [54]. Microsilica is also an active mineral additive that participates in the formation of additional hydration products. MS interacts with free Ca(OH)2, which is released during the hydration of Portland cement. The products of this interaction are calcium hydrosilicates (CSH). Accordingly, the specific surface area of the hydration products increases, which leads to an increase in the strength of the composite and a decrease in its capillary porosity [55,56,57]. A slight increase in the density and thermal conductivity coefficient is also associated with the increased specific surface area of CSH. The high reactivity of MS is primarily determined by the amount of SiO2: the more it is, the more CSH is formed. The chemical reaction of SiO2 with Ca(OH)2 can be represented as follows:

SiO2 + Ca(OH)2 → CaSiO3 + H2O

These reactions are especially active during the first day of hardening. SiO2 particles react very quickly with Ca(OH)2, released during cement hydration, forming dense CSH. This gel mainly accumulates around cement particles and Ca(OH)2 particles, which causes the rate of CSH formation to decrease over time. CSH formed during the first day of hardening has a denser structure than CSH formed after 28 days. It is also worth noting that, in addition to MS, there are other active mineral additives containing SiO2, which actively interact with Ca(OH)2 and form an additional CSH gel, which then strengthens the structure of the concrete composite and reduces its capillary porosity. For example, such additives include fly ash and ground blast furnace granulated slag. They are actively used in the cement industry, and their positive effect on the properties of concrete is proven by a number of the following studies [58,59,60,61]. According to these studies and studies conducted by us earlier [37,62], microsilica, all other things being equal, leads to the best effect and a composite with the highest and most stable characteristics, which is confirmed by a detailed study of the mechanism of its behavior in concrete and, in particular, in variotropic concrete.

Similar results, where an increase in the mechanical properties of cement composites with the introduction of MS into their composition was recorded, are confirmed by a number of other studies and have good convergence with the results of experimental studies obtained in this work [63,64,65,66,67,68]. For example, the introduction of MS into a solution on recycled aggregates made it possible to increase its compressive strength by more than 20% [63]. The addition of 5% microsilica provided an increase in compressive strength by 14.55% [64]. The solution with MS content of up to 10% had higher strength and sulfate resistance compared to the unmodified solution [65]. The positive effect, expressed in the increase in mechanical and physical properties with the introduction of MS instead of part of the cement up to 10%, was also studied in other previous studies [66,67]. Thus, in the course of this study, new effective compositions of lightweight variotropic centrifuged concretes were developed. It was proven that replacing CrS with EC up to and including 40% will allow obtaining concrete with a lightweight and required compressive strength. Additional modification with ultrafine MS in the amount of 6% increases the strength of lightweight centrifuged concrete from 36.6 MPa to 42.0 MPa (by 14.8%), which is comparable to the strength of centrifuged concrete on heavy aggregate 43.4 MPa. Below is an analysis of the structure of variotropic concrete with large heavy and combined aggregate, which it acquires during centrifugal compaction. A schematic representation of the structure of variotropic concrete on large heavy and combined aggregate is shown in Figure 14.

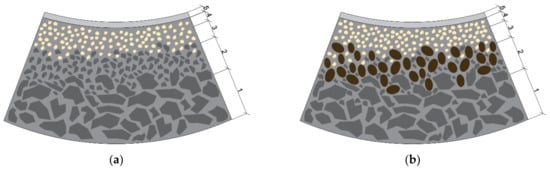

Figure 14.

Schematic diagram of the structure of variotropic concrete: (a) on large heavy aggregate; (b) on combined aggregate.

As mentioned earlier, the coarse-grained conglomerate with a greater mass moves to the outer surface of the product, while the one with a smaller mass moves closer to the inner surface. The rate of separation of particles occurs faster, the denser and larger the aggregate, and the higher the rotation speed of the mold. Variotropic concrete on large heavy aggregate acquires a structure (Figure 14a), which can be conditionally divided into five parts. Zone 1 is a coarse-grained conglomerate consisting of the largest grains of crushed stone and a solution part binding these grains. Zone 2 includes a conglomerate consisting of smaller grains of crushed stone and a solution part. Zone 3 is a fine-grained conglomerate consisting of small grains of crushed stone, on average 5 mm, and a solution part. Zone 4 consists mainly of the mortar part with single inclusions of small grains of crushed stone. Zone 5 is made up of a thin layer of cement slurry (water squeezed out during the centrifugation process with a highly dispersed cement fraction). The structure of variotropic concrete on a combined aggregate (Figure 14b) has a number of differences compared to the structure of variotropic concrete on a heavy aggregate. The outer layer of concrete (Zone 1), as in the first case, is mainly represented by a coarse-grained conglomerate, in which large grains of crushed stone are concentrated, and connected by a mortar part. Zone 2 mainly consists of gravel grains with a small amount of smaller grains of crushed stone. Zone 3 is a fine-grained conglomerate consisting of small grains of gravel 5 mm and a mortar part. Zones 4 and 5 have a similar structure, which is represented by a mortar part and cement slurry.

This order of transition from one layer to another is explained by the effect of centrifugal forces on the concrete mixture. The concrete mixture consists of several raw materials that have different densities. Accordingly, the outer layer (Zone 1) will consist of heavier components, namely the largest and heaviest crushed stone grains, bonded with a small amount of the solution part. As you approach the inner layer (Zones 3, 4, 5), the amount of large aggregate will decrease, and the amount of the solution part will increase. The inner layer is represented by the least dense component in the form of cement slurry separated during the compaction of water and cement particles. As a rule, due to this difference, each layer of concrete will have different physical and mechanical properties. The outer layer will have the highest density and higher strength properties, and the middle layer (Zone 2) will have a lower density and lower strength properties. Accordingly, the inner layer will have the lowest density and the lowest mechanical properties. This difference in the physical and mechanical properties of each layer was proven in previous studies [18,20]. It is this feature that opens up great opportunities in managing the properties of the variotropic structure due to various formulations and technological solutions that will improve each of the layers and the entire structure as a whole [18,19,37].

The type and size of aggregate significantly affect concrete properties; this is important to note. Thus, a rationally selected formulation of poly fractional aggregates leads to the creation of the densest packing of particles, and, consequently, to the most perfect structure of the concrete conglomerate. Quantitatively, this phenomenon does not differ from the mono-fractional approach to combining aggregates. That is, the ratio of the types of aggregates to each other remains unchanged, and the fractional size is selected for each specific case, based on the set technological and design tasks [20,51].

Centrifuged concrete compares favorably with simple vibrated concrete. This is due to the more perfect structure of centrifuged variotropic concrete, increased density and increased protective capacity of its outer layer, and, consequently, increased resistance of structures made of it. Positive consequences of the proposed variotropic concrete structures for seismic resistance in construction are predicted. This is due to the fact that the nature of concrete destruction changes from brittle to more viscous. This allows concrete to become more resistant to chaotic tremors.

The effectiveness of the formulation solutions proposed in this paper in the form of partial replacement of large heavy aggregate (CrS) with a lighter porous one (EC) and modification with microsilica was confirmed by the results of experimental studies. The subject of research devoted to improving the properties of variotropic concretes manufactured using centrifugal compaction technology is a promising direction, and currently, the authors’ team is conducting laboratory studies to study the durability properties of centrifuged composites with a variotropic structure on a combined aggregate and are developing other types of formulation solutions to improve the properties of this type of concrete. The authors have previously established improved resistance of centrifuged concrete to long-term cyclic effects such as freeze-thaw [69], wetting-drying [70], chloride attack [71], and sulfate attack [72]. The study of each of these effects on lightweight centrifuged concrete is the goal of the following series of articles. The long-term durability of centrifuged lightweight concrete with combined aggregates will be higher than the durability of traditional vibrated concrete. This is due to the more advanced structure of centrifuged variotropic concrete, increased density and increased protective capacity of its outer layer, and, consequently, increased durability of structures made from it. It is expected that the addition of microsilica in an optimal dosage will help to reduce the permeability of variotropic concrete and, thus, improve its long-term characteristics due to the improvement of the microstructure and reduction of capillary porosity of the composite [37]. Using expanded clay gravel as a lightweight aggregate in variotropic concrete will reduce the weight of products and structures and, therefore, simplify their transportation and installation. This will have a positive effect on the environment, because of the reduction in the amount of harmful emissions. Thus, the developed centrifuged concrete on a combined aggregate, modified with MS, is a promising modern building material. Ring-section structures made of lightweight concrete have reduced material consumption, light weight, reduced thermal conductivity, and competitive compressive strength. In real construction practice, ring-section structures can be used as supports for power transmission lines and columns for the construction of civil and industrial buildings [22,23,63,64,65,66,67,68].

The adaptability of the methodology for creating variotropic concrete to other types of building materials can be projected onto the technologies of ceramic and polymeric materials, taking into account the implementation of a full range of relevant studies.

4. Conclusions

The properties and structure of lightweight variotropic centrifuged concrete with a combined aggregate and modified with microsilica were studied. The following conclusions were made based on the results obtained.

- (1)

- Replacing coarse heavy aggregate with lightweight porous aggregate reduces the density of the centrifuged composite. The most optimal replacement is considered to be up to 40%. When replacing more than 40%, the strength of concrete is significantly reduced. The density of lightweight centrifuged concrete with a ratio of granite crushed stone and expanded clay gravel of 60% to 40% decreased by 11.1% and amounted to 2135 kg/m3. Compressive strength decreased by 15.7% and amounted to 36.6 MPa. The thermal conductivity coefficient decreased by 20.8% and amounted to 1.252 W/m×°C.

- (2)

- Modification of lightweight centrifuged concrete on combined aggregate with microsilica in a dosage of up to 10% allowed to significantly improve its compressive strength. The greatest increase in compressive strength was recorded at 6% MS. The strength of the composite increased by 14.75% and amounted to 42.0 MPa, which is comparable to the compressive strength of centrifuged concrete on granite crushed stone (43.4 MPa). The density and thermal conductivity coefficient remained virtually unchanged and amounted to 2148 kg/m3 and 1.270 W/m×°C. Ultrafine microsilica is a mineral additive with a SiO2 content of 94.3% and, due to active interaction with the hydration products of Portland cement clinker, forms additional CSH, which subsequently contributes to an increase in compressive strength.

- (3)

- Structural analysis showed that crushed stone and expanded clay grains have a good bond with the mortar part. Near the expanded clay grains, a clearer phase boundary “mortar part—expanded clay grain” is observed than the phase boundary near granite grains. Lightweight expanded clay aggregate has good adhesion to the mortar part, which partially penetrates its pores, providing good adhesion.

- (4)

- The main result of the study is a new optimal composition of lightweight concrete with a variotropic structure, manufactured using centrifugal compaction technology and modified with microsilica. The resulting composite meets all regulatory requirements and has a light weight. Thanks to the centrifugation technology, less raw material is used to manufacture concrete elements of annular cross-section, which makes them more economical and advantageous for use in the construction industry.

- (5)

- One of the limitations of the study is related to the fact that the obtained concrete is applicable only for the manufacture of products using centrifugal compaction technology. Factory testing of the proposed composition of centrifuged concrete showed its complete readiness for scaling for industrial use. Regarding the overall economic efficiency of centrifugation technology compared to traditional vibration technology of concrete production, industrial partners noted advantages in resource, material, and energy consumption. The overall difference is about 17% in favor of centrifugation, according to preliminary estimates. A limitation of centrifuged concrete is the impossibility of obtaining it on the construction site. Future research directions are related to studying the durability properties of centrifuged composites with a variotropic structure on a combined aggregate and other types of formulation solutions to improve the properties of this type of concrete. Future recommendations for researchers also include studying the influence of various micro- and nano-additives on the structure and properties of lightweight variotropic concretes. Practical application of ring-section structures can be implemented in the form of power transmission line support posts and columns for the construction of civil and industrial buildings.

Author Contributions

Conceptualization, S.A.S., E.M.S., L.R.M. and N.S.; methodology, S.A.S., E.M.S. and D.E.; software, A.C.; validation, S.A.S., E.M.S., A.L.M. and A.C.; formal analysis, A.N.B., S.A.S. and E.M.S.; investigation, S.A.S., E.M.S., A.N.B., N.S., A.C. and D.E.; resources, S.A.S., E.M.S. and D.E.; data curation, S.A.S. and E.M.S.; writing—original draft preparation, S.A.S., E.M.S. and A.N.B.; writing—review and editing, S.A.S., E.M.S. and A.N.B.; visualization, S.A.S., E.M.S. and A.N.B.; supervision, A.N.B. and L.R.M.; project administration, A.N.B. and L.R.M.; funding acquisition, E.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

The research was supported by the Russian Science Foundation, grant No. 23-79-10289, https://rscf.ru/en/project/23-79-10289/ (accessed on 2 January 2025).

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to acknowledge the administration of Don State Technical University for their resources and financial support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Akbulut, Z.F.; Yavuz, D.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review. Sustainability 2024, 16, 4905. [Google Scholar] [CrossRef]

- Lu, J.-X. Recent advances in high strength lightweight concrete: From development strategies to practical applications. Constr. Build. Mater. 2023, 400, 132905. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Slobodchikova, N.A.; Saidumov, M.S.; Abumuslimov, A.S.; Mezhidov, D.A.; Khezhev, T.A. Application of ash and slag waste from coal combustion in the construction of the earth bed of roads. Constr. Mater. Prod. 2024, 7, 3. [Google Scholar] [CrossRef]

- Kang, M.; Jia, Y.; Guo, P.; Ju, Y.; Zhang, H. Influence of Fly Ash Content on Macroscopic Properties and Microstructure of High-Performance Concrete. Buildings 2024, 14, 3844. [Google Scholar] [CrossRef]

- Shcherban, E.M.; Beskopylny, A.N.; Stel’makh, S.A.; Mailyan, L.R.; Shilov, A.A.; Hiep, N.H.; Song, Y.; Chernil’nik, A.A.; Elshaeva, D.M. Study of thermophysical characteristics of variatropic concretes. Constr. Mater. Prod. 2024, 7, 2. [Google Scholar] [CrossRef]

- Khodjaev, A.A.; Karimjonov, I.S. Modern Lightweight Energy-Saving Frame-Sheathing Exterior Walls and Possibilities of Using Thereof in Construction of the Multi-Storey Reinforced Concrete Frame Buildings in Uzbekistan. Mod. Trends Constr. Urban Territ. Plan. 2024, 3, 17–25. [Google Scholar] [CrossRef]

- Uysal, O.; Uslu, İ.; Aktaş, C.B.; Chang, B.; Yaman, İ.Ö. Physical and Mechanical Properties of Lightweight Expanded Clay Aggregate Concrete. Buildings 2024, 14, 1871. [Google Scholar] [CrossRef]

- Islam, S.; Ara, G.; Akhtar, U.S.; Haque, I.; Samad, A. Development of lightweight structural concrete with artificial aggregate manufactured from local clay and solid waste materials. Heliyon 2024, 10, e34887. [Google Scholar] [CrossRef]

- Dao, P.-L.; Thai, K.-C.; Pham, D.-T.; Vu, M.-N.; Nguyen-Sy, T.; Le, Q.-V.; Tran, T.-T. Chloride diffusivity of lightweight expanded clay aggregate concretes under compressive stress. Mater. Today Commun. 2023, 35, 105917. [Google Scholar] [CrossRef]

- Shivanshi, S.; Chakraborti, G.; Upadhyaya, K.S.; Kannan, N. A study on bacterial self-healing concrete encapsulated in lightweight expanded clay aggregates. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Sobhani, J.; Komijani, S.; Shekarchi, M.; Ghazban, F. Durability of concrete mixtures containing Iranian electric arc furnace slag (EAFS) aggregates and lightweight expanded clay aggregates (LECA). Constr. Build. Mater. 2023, 400, 132597. [Google Scholar] [CrossRef]

- Chiadighikaobi, P.C.; Muritala, A.A.; Abu Mahadi, M.I.; Noor, A.A.A.; Ibitogbe, E.M.; Niazmand, A.M. Mechanical characteristics of hardened basalt fiber expanded clay concrete cylinders. Case Stud. Constr. Mater. 2022, 17, e01368. [Google Scholar] [CrossRef]

- Onuralp Özkılıç’, Y.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Chernil’nik, A.; Ananova, O.; Aksoylu, C.; Madenci, E. Lightweight expanded-clay fiber concrete with improved characteristics reinforced with short natural fibers. Case Stud. Constr. Mater. 2023, 19, e02367. [Google Scholar] [CrossRef]

- Mahmmod, L.M.R.; Dulaimi, A.; Bernardo, L.F.A.; Andrade, J.M.d.A. Characteristics of Lightweight Concrete Fabricated with Different Types of Strengthened Lightweight Aggregates. J. Compos. Sci. 2024, 8, 144. [Google Scholar] [CrossRef]

- Ahmad, I.; Shokouhian, M.; Jenkins, M.; McLemore, G.L. Quantifying the Self-Healing Efficiency of Bioconcrete Using Bacillus subtilis Immobilized in Polymer-Coated Lightweight Expanded Clay Aggregates. Buildings 2024, 14, 3916. [Google Scholar] [CrossRef]

- Uslu, İ.; Uysal, O.; Aktaş, C.B.; Chang, B.; Yaman, İ.Ö. Dematerialization of Concrete: Meta-Analysis of Lightweight Expanded Clay Concrete for Compressive Strength. Sustainability 2024, 16, 6346. [Google Scholar] [CrossRef]

- Ramezani, A.M.; Khajehdezfuly, A.; Poorveis, D. Structural Lightweight Concrete Containing Basalt Stone Powder. Buildings 2024, 14, 1904. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.; Elshaeva, D.; Beskopylny, N. Analytical Review of the Current State of Technology, Structure Formation, and Properties of Variatropic Centrifugally Compacted Concrete. Materials 2024, 17, 1889. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.; Elshaeva, D.; Beskopylny, N. Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete. Polymers 2024, 16, 642. [Google Scholar] [CrossRef] [PubMed]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Khalyushev, A.K.; Smolyanichenko, A.S.; Sysoev, A.K.; Parinov, I.A.; Cherpakov, A.V. Investigation of Integral and Differential Characteristics of Variatropic Structure Heavy Concretes by Ultrasonic Methods. Appl. Sci. 2021, 11, 3591. [Google Scholar] [CrossRef]

- Kliukas, R.; Lukoševičienė, O.; Jaras, A.; Jonaitis, B. The Mechanical Properties of Centrifuged Concrete in Reinforced Concrete Structures. Appl. Sci. 2020, 10, 3570. [Google Scholar] [CrossRef]

- Michałek, J.; Sobótka, M. Assessment of Internal Structure of Spun Concrete Using Image Analysis and Physicochemical Methods. Materials 2020, 13, 3987. [Google Scholar] [CrossRef] [PubMed]

- Michałek, J.; Pachnicz, M.; Sobótka, M. Application of Nanoindentation and 2D and 3D Imaging to Characterise Selected Features of the Internal Microstructure of Spun Concrete. Materials 2019, 12, 1016. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban, E.M.; Zherebtsov, Y.V.; Al-Tulaikhi, M.M. Research of physicomechanical and design characteristics of vibrated, centrifuged and vibro-centrifuged concretes. Adv. Eng. Res. (Rostov-on-Don) 2021, 21, 5–13. [Google Scholar] [CrossRef]

- Han, X.; Wei, D.; Wang, P.; Wang, M.; Du, Z.; Ling, Z. Microstructure characteristics and evolution of pipe pile concrete under centrifugation and steam curing. Constr. Build. Mater. 2024, 450, 138554. [Google Scholar] [CrossRef]

- He, J.; Tang, M.; Gao, R.; Hu, H.; Hong, J. Damage—Permeability analysis of pretensioned spun high strength concrete pipe piles based on stochastic damage model. Eng. Fail. Anal. 2022, 140, 106578. [Google Scholar] [CrossRef]

- Qiu, J.; Huo, Y.; Feng, Z.; Li, L.; Wang, J.; Zhang, Y.; Guan, X. Study on the Modification Effect and Mechanism of a Compound Mineral Additive and Basalt Fiber on Coal Gangue Concrete. Buildings 2023, 13, 2756. [Google Scholar] [CrossRef]

- Aleksandrova, O.V.; Quang, N.D.V.; Bulgakov, B.I.; Fedosov, S.V.; Lukyanova, N.A.; Petropavlovskaya, V.B. The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete. Materials 2022, 15, 8851. [Google Scholar] [CrossRef]

- Dvorkin, L.; Zhitkovsky, V.; Sitarz, M.; Hager, I. Cement with Fly Ash and Metakaolin Blend—Drive towards a More Sustainable Construction. Energies 2022, 15, 3556. [Google Scholar] [CrossRef]

- Nafees, A.; Javed, M.F.; Khan, S.; Nazir, K.; Farooq, F.; Aslam, F.; Musarat, M.A.; Vatin, N.I. Predictive Modeling of Mechanical Properties of Silica Fume-Based Green Concrete Using Artificial Intelligence Approaches: MLPNN, ANFIS, and GEP. Materials 2021, 14, 7531. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Cui, L.; Wu, J.; Xu, H.; Zhang, Z.; Zhang, Y.; Qin, G.; Meng, Q.; Li, H.; Wang, K. Mineral Additives to Enhance Early-Age Crack Resistance of Concrete under a Large-Temperature-Difference Environment. Appl. Sci. 2021, 11, 9338. [Google Scholar] [CrossRef]

- Ali, B.; Ahmed, H.; Ali Qureshi, L.; Kurda, R.; Hafez, H.; Mohammed, H.; Raza, A. Enhancing the Hardened Properties of Recycled Concrete (RC) through Synergistic Incorporation of Fiber Reinforcement and Silica Fume. Materials 2020, 13, 4112. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Yang, Y. Unveiling the Effects of Quicklime on the Properties of Sulfoaluminate Cement–Ordinary Portland Cement–Mineral Admixture Repairing Composites and Their Sulphate Resistance. Materials 2023, 16, 4026. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; He, Y.; Ji, D.; Tang, J.; Li, C. Experimental Research on the Mechanical Properties and Autogenous Shrinkage of Precast Members Joint Concrete. Buildings 2022, 12, 373. [Google Scholar] [CrossRef]

- Dilbas, H.; Güneş, M.Ş. Mineral Addition and Mixing Methods Effect on Recycled Aggregate Concrete. Materials 2021, 14, 907. [Google Scholar] [CrossRef] [PubMed]

- Ali, B.; Kurda, R.; Herki, B.; Alyousef, R.; Mustafa, R.; Mohammed, A.; Raza, A.; Ahmed, H.; Fayyaz Ul-Haq, M. Effect of Varying Steel Fiber Content on Strength and Permeability Characteristics of High Strength Concrete with Micro Silica. Materials 2020, 13, 5739. [Google Scholar] [CrossRef]

- Shcherban, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.A.; Elshaeva, D.M.; Beskopylny, N.A. Structure and Properties of Variatropic Concrete Combined. Modified with Nano- and Micro-silica. Constr. Mater. Prod. 2024, 7, 3. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhuang, J.; Lin, W.; Xu, W.; Hu, R. Creep and Shrinkage Properties of Nano-SiO2-Modified Recycled Aggregate Concrete. Materials 2024, 17, 1904. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Kholodnyak, M.G.; Shcherban, E.M.; Nazhuev, M.P.; Chernil’nik, A.A. Device for the Manufacture of Products from Centrifuged Concrete. Russian. Federation Patent RU 192 492 U1, 23 May 2019. Available online: https://yandex.ru/patents/doc/RU192492U1_20190918 (accessed on 22 January 2025).

- GOST R 57813-2017/EN 12350-6:2009; Testing Fresh Concrete. Part 6. Density. Standartinform: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200157335 (accessed on 23 December 2024).

- EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/811a0cf3-55e3-495a-b06e-5c302d5f2806/en-12390-7-2019 (accessed on 23 December 2024).

- GOST 10180-2012; Concretes. Methods for Strength Determination Using Reference Specimens. Standartinform: Moscow, Russia, 2018. Available online: https://docs.cntd.ru/document/1200100908 (accessed on 23 December 2024).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 23 December 2024).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 23 December 2024).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 23 December 2024).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 23 December 2024).

- GOST 7076-99; Building Materials and Products. Method of Determination of Steady-State Thermal Conductivity and Thermal Resistance. Gost Standard: Moscow, Russia, 2000. Available online: https://docs.cntd.ru/document/1200005006 (accessed on 23 December 2024).

- Augonis, A.; Ivanauskas, E.; Bocullo, V.; Kantautas, A.; Vaičiukynienė, D. The Influence of Expanded Glass and Expanded Clay on Lightweight Aggregate Shotcrete Properties. Materials 2022, 15, 1674. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Rodríguez, F.J.; Elizondo-Villareal, N.; Verástegui, L.H.; Arato Tovar, A.M.; López-Perales, J.F.; Contreras de León, J.E.; Gómez-Rodríguez, C.; Fernández-González, D.; Verdeja, L.F.; García-Quiñonez, L.V.; et al. Effect of Mineral Aggregates and Chemical Admixtures as Internal Curing Agents on the Mechanical Properties and Durability of High-Performance Concrete. Materials 2020, 13, 2090. [Google Scholar] [CrossRef] [PubMed]

- Desai, M.; Pandya, S.; Peddinti, P.R.T. 6—Experimental study on the use of lightweight expanded clay aggregate as coarse aggregate for light traffic, medium traffic, and light weight concrete application. In Sustainable Materials in Civil Infrastructure; Woodhead Publishing: Cambridge, UK, 2024; pp. 111–135. [Google Scholar] [CrossRef]

- Nahhab, A.H.; Ketab, A.K. Influence of content and maximum size of light expanded clay aggregate on the fresh, strength, and durability properties of self-compacting lightweight concrete reinforced with micro steel fibers. Constr. Build. Mater. 2020, 233, 117922. [Google Scholar] [CrossRef]

- Mohammad, S.; Shea, A. Performance Evaluation of Modern Building Thermal Envelope Designs in the Semi-Arid Continental Climate of Tehran. Buildings 2013, 3, 674–688. [Google Scholar] [CrossRef]

- Shafigh, P.; Hafez, M.A.; Che Muda, Z.; Beddu, S.; Zakaria, A.; Almkahal, Z. Influence of Different Ambient Temperatures on the Thermal Properties of Fiber-Reinforced Structural Lightweight Aggregate Concrete. Buildings 2022, 12, 771. [Google Scholar] [CrossRef]

- Karlina, A.I.; Karlina, Y.I.; Gladkikh, V.A. Analysis of Experience in the Use of Micro- and Nanoadditives from Silicon Production Waste in Concrete Technologies. Minerals 2023, 13, 1525. [Google Scholar] [CrossRef]

- Foti, D.; Lerna, M.; Sabbà, M.F.; Vacca, V. Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions. Appl. Sci. 2019, 9, 1279. [Google Scholar] [CrossRef]

- Salah Uddin, K.M.; Izadifar, M.; Ukrainczyk, N.; Koenders, E.; Middendorf, B. Dissolution of β-C2S Cement Clinker: Part 1 Molecular Dynamics (MD) Approach for Different Crystal Facets. Materials 2022, 15, 6388. [Google Scholar] [CrossRef] [PubMed]

- Izadifar, M.; Ukrainczyk, N.; Salah Uddin, K.M.; Middendorf, B.; Koenders, E. Dissolution of β-C2S Cement Clinker: Part 2 Atomistic Kinetic Monte Carlo (KMC) Upscaling Approach. Materials 2022, 15, 6716. [Google Scholar] [CrossRef] [PubMed]

- Anjos, M.A.S.d.; Camões, A.; Malheiro, R.; Maia Pederneiras, C.; Peixoto, L.K.S. Experimental Study of Carbonation and Chloride Resistance of Self-Compacting Concretes with a High Content of Fly Ash and Metakaolin, with and Without Hydrated Lime. Materials 2025, 18, 422. [Google Scholar] [CrossRef]

- Szcześniak, A.; Siwiński, J.; Stolarski, A.; Piekarczuk, A.; Nasiłowska, B. The Influence of the Addition of Microsilica and Fly Ash on the Properties of Ultra-High-Performance Concretes. Materials 2025, 18, 28. [Google Scholar] [CrossRef] [PubMed]

- Kowshika, V.R.; Bhaskaran, V.; Natarajan, R.; Faridmehr, I. Enhancing Strength and Corrosion Resistance of Steel-Reinforced Concrete: Performance Evaluation of ICRETE Mineral Additive in Sustainable Concrete Mixes with PFA and GGBS. Infrastructures 2024, 9, 228. [Google Scholar] [CrossRef]

- Hema, P.; Revathi, V. Durability Evaluation of GGBS-RHA-Based Geopolymer Concrete Along with Lightweight Expanded Clay Aggregate Using SEM Images and EDAX Analysis. Buildings 2024, 14, 3355. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; Varavka, V.; Beskopylny, N. Nano-Modified Vibrocentrifuged Concrete with Granulated Blast Slag: The Relationship between Mechanical Properties and Micro-Structural Analysis. Materials 2022, 15, 4254. [Google Scholar] [CrossRef]

- Mazilu, C.; Deju, R.; Georgescu, D.P.; Apostu, A.; Barbu, A. Effects of Micro- and Nanosilica on the Mechanical and Microstructural Characteristics of Some Special Mortars Made with Recycled Concrete Aggregates. Materials 2024, 17, 2791. [Google Scholar] [CrossRef] [PubMed]

- Amini, M.M.; Ghanepour, M.; Rezaifar, O. Experimental analysis of the impact of alternating magnetic fields on the compressive strength of concrete with various silica sand and microsilica compositions. Case Stud. Constr. Mater. 2024, 21, e03487. [Google Scholar] [CrossRef]

- Li, L.G.; Zhu, J.; Huang, Z.H.; Kwan, A.K.H.; Li, L.J. Combined effects of micro-silica and nano-silica on durability of mortar. Constr. Build. Mater. 2017, 157, 337–347. [Google Scholar] [CrossRef]

- Jalal, M.; Mansouri, E.; Sharifipour, M.; Pouladkhan, A.R. Mechanical, rheological, durability and microstructural properties of high performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater. Des. 2012, 34, 389–400. [Google Scholar] [CrossRef]

- Beskopylny, A.; Kadomtseva, E.; Strelnikov, G.; Morgun, L.; Berdnik, Y.; Morgun, V. Model of heterogeneous reinforced fiber foam concrete in bending. IOP Conf. Ser. Mater. Sci. Eng. 2018, 365, 032023. [Google Scholar] [CrossRef]

- Afzali-Naniz, O.; Mazloom, M.; Karamloo, M. Effect of nano and micro SiO2 on brittleness and fracture parameters of self-compacting lightweight concrete. Constr. Build. Mater. 2021, 299, 124354. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Chernil’nik, A.; El’shaeva, D. Influence of Variatropy on the Evaluation of Strength Properties and Structure Formation of Concrete under Freeze-Thaw Cycles. J. Compos. Sci. 2023, 7, 58. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Chernil’nik, A.; El’shaeva, D.; Pogrebnyak, A. Influence of Variotropy on the Change in Concrete Strength under the Impact of Wet–Dry Cycles. Appl. Sci. 2023, 13, 1745. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Chernil’nik, A.; Elshaeva, D.; Ananova, O. The Influence of Recipe-Technological Factors on the Resistance to Chloride Attack of Variotropic and Conventional Concrete. Infrastructures 2023, 8, 108. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Elshaeva, D.; Chernil’nik, A. Physical and Mechanical Characteristics of Variotropic Concrete during Cyclic and Continuous Sulfate Attack. Appl. Sci. 2023, 13, 4386. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).