Abstract

Little research is reported on the properties of Portland cement concrete (PCC) mixtures comprising plastic waste materials. Therefore, this novel study was initiated to evaluate the effects of plastic waste materials on different properties of PCC. Plastic boxes and containers made of polypropylene were cut, grinded, pulverized, and incorporated into PCC mixtures. Sand was partially replaced by plastic waste materials with 0%, 5%, 10%, 15%, and 20% volume ratios. Experiments were conducted using PCC cylinders and prisms to evaluate several unique properties of PCC containing plastic waste. Innovative interactions and contributions of several PCC properties including workability, air content, density, water absorption, mechanical properties, rapid chloride ion penetration, and freeze–thaw deterioration are investigated. The new experimental data indicated that the workability and density of PCC decreased with increasing plastic waste replacement levels. The maximum decreases in workability and density were 23% and 6.2% for the PCC with 20% plastic replacement, respectively. On the other hand, our research has shown that air content and water absorption of PCC increases with increasing plastic waste amount. The maximum increase in air content and water absorption were 78% and 29% for the PCC with 20% plastic waste. This study also shows that the mechanical properties of PCC (e.g., compressive and splitting strengths) after 7 and 28 days of moist curing decreased with increasing plastic waste content. Another new finding is that the rapid chloride permeability of PCC increased and the freeze–thaw durability of PCC decreased with an increase in plastic waste amount. One of the most critical discoveries of this experimental study is that plastic waste increases the durability of PCC, i.e., durability factor of PCC with 20% plastic waste was 9.3% compared to 28.5% for the control PCC without plastic waste materials.

1. Introduction

Plastic is a synthetic polymer material with long chains of carbon and hydrogen molecules produced mainly from crude oil that has become an essential component of contemporary daily life. Plastic may be divided into two main categories: thermoplastics and thermosets. Thermoplastics can soften upon heat and return to their original shape upon cooling with many properties including being less rigid than thermosets and being easily extruded into fibers and films; examples are polyethylene, polypropylene, and polyvinyl chloride. Thermoset plastics are hard and durable and include polyesters, polyurethanes, phenolic resins, and epoxy resins [1].

Plastic finds numerous applications in most areas of modern life such as medicine (gloves, masks, blood bags, syringes, pills, and capsules), households (chairs, tables, food storage, cleaning supplies, and electronics), water supplies (pipes and hoses), etc. [2]. Plastics possess many positive characteristics such as being waterproof, cheap, lightweight, shock resistant, thermally and electrically insulated, and environment resistant. However, plastics also carry some negative properties such as plasticity, low strength, and easy tearing [3]. These negative properties cause most plastic products to be utilized for a short period before being discarded. Additionally, many plastic products are designed to be discarded after a single use. Hence, large amounts of plastic products are thrown away every day after a limited period of utilization [4].

Solid waste management is a vital environmental concern around the world. In 2023 alone, the world produced about 400 million tons of plastic waste annually. Only 30% of the plastic waste is recycled, 30% is utilized to produce energy, and 40% is contained in landfill. Large amounts of plastic waste are sent to the landfills causing negative consequences for the environment [5]. Plastic waste contained in landfill is considered hazardous to the environment since plastic waste is non-biodegradable and non-decomposable [6]. Plastic waste may break down into millions of microplastic particles that never fully dissipate. Microplastic particles may wash away easily causing significant pollution to the environment, water resources, and the food chain [2]. There is also a major concern about the health hazards of microplastic particles [7]. Therefore, there is global need and benefit from sustainable recycling of plastic waste.

Portland cement concrete (PCC) is one of the most essential building and construction materials mainly due to its good properties and economic factors. PCC is composed of aggregate, cement, and water, in addition to some admixtures that may be added during mixing to improve some properties of PCC. The extensive use of PCC all over the globe causes depletion of aggregate resources [8]. Therefore, many by-product waste materials were researched to be utilized as an aggregate replacement in PCC such as tire rubber, olive waste, quarry powder, slag, and plastic waste [9,10,11,12]. Many of these waste materials improved some properties of PCC. For example, employing tire rubber waste in PCC mixtures improved impact resistance, shock absorbance, heat insulation, and vibration damping of PCC [10].

Limited research [13,14,15,16,17,18,19,20,21,22,23,24] is reported on the utilization of plastic waste in PCC mixtures. The recycling of plastic waste in PCC mixtures has many advantages including reducing environmental pollution, producing environmentally friendly PCC, preserving natural resources, and improving some properties of PCC mixtures [12,13,14,15,16,17,18,19,20]. Some recent experimental studies [21,22] reported promising results based on the usage of plastic waste materials different from those considered in this research.

Previous studies on the utilization of plastic waste into PCC mixtures have indicated the following. The compressive and flexural strengths dropped when plastic waste was used from 5% to 15% in PCC mixtures [14,15,16,17]. When polycarbonate particles were utilized in replacing sand from 5% to 20%, PCC with plastic waste showed improved energy-absorbing under impact loading [17,18,19]. Foamed plastic waste was used to replace sand in lightweight mortar using 10% and 25%. Then, the bond improved between plastic and cement paste and the density decreased [19,20,21].

In this study, plastic waste was recycled and utilized in PCC mixtures in different contents (0%, 5%, 10%, 15%, and 20%). These replacement levels were informed by the previous studies [14,15,16] that used similar levels. Different properties of plastic waste PCC were evaluated including workability, density, air content, absorption, mechanical properties (compressive and splitting), and durability aspects (rapid chloride permeability). The significance of this research is its investigation of the incorporation of plastic waste into PCC mixtures, which helps to reduce plastic pollution, produce green concrete, and preserve natural resources. This paper shows that the addition of plastic materials improved several properties of concrete, whereas there were some limited but acceptable negative effects on some other properties of concrete.

2. Experimental Program

2.1. Materials and Test Specimens

Type I ordinary Portland cement was used in the study. The cement had an initial setting time of 110 min, Blaine fineness of 4200 cm2/g, and a specific gravity of 3.15. Crushed limestone coarse and fine aggregates were utilized in preparing the PCC mixtures. The physical properties of the aggregate were as follows. The coarse aggregate had a bulk specific gravity (BSG) based on a saturated surface dry (SSD) of 2.58, water absorption capacity of 2.3%, unit weight of 1570 kg/m3, and maximum aggregate size of 19 mm. The fine aggregate had a BSG based an SSD of 2.56, water absorption capacity of 2.8%, and fineness modulus of 2.4. Superplasticizer was utilized during the mixing of PCC, with 0.7% of the cement weight content, to improve the workability.

The process of preparing the plastic waste to be utilized with PCC mixtures was as follows: (1) Different plastic waste boxes and containers made of polypropylene were collected. (2) The plastic boxes and containers were shredded and cut into smaller pieces using a plastic shredder. (3) The shredded plastic waste was grinded into smaller sizes using a plastic grinder (Figure 1).

Figure 1.

Plastic waste utilized in the PCC mixtures.

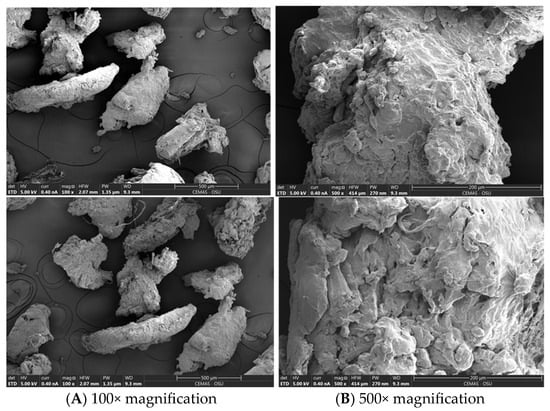

Figure 1 shows the pulverized plastic waste utilized in the study. The plastic waste had a dark color, water absorption of 0.1%, average particle size of 0.3 mm, and specific gravity of 0.95. Scanning electron microscopy images of the plastic waste are presented in Figure 2. The plastic waste particles are irregular in shape (see images on Figure 2A). The width of the plastic samples shown in the images in Figure 2B are approximately 400 μm or 0.4 mm and have a rough texture and spongy structure.

Figure 2.

Scanning electron microscopy images of plastic waste particles (conducted at the Center for Electron Microscopy and Analysis (CEMAS) at Ohio State University).

Five PCC mixtures were developed and utilized in the study to evaluate different properties of plastic waste PCC (Table 1). The mixtures were developed using a water-to-cement (w/c) ratio of 0.5, limestone aggregate, and five different plastic waste contents (0%, 5%, 10%, 15%, and 20%). The PCC mixtures were designated by the letter P (referring to plastic waste) followed by a number that represents the plastic waste replacement level, i.e., mixture P0 denotes the control concrete mixture without any plastic waste content. Similarly, mixtures P5 and P20 represent the concrete mixtures with 5% and 20% plastic waste content, respectively. The PCC mixture proportions are listed in Table 2.

Table 1.

Physical properties of plastic waste.

Table 2.

PCC mixture proportions utilized per cubic meter of PCC.

PCC cylinders (100 mm in diameter by 200 mm in height) were used to explore the influence of plastic waste on the compressive strength, splitting strength, absorption, and rapid chloride permeability of PCC. Three specimens were cast and tested, and average measured values were used to investigate each parameter. All PCC ingredients including cement, water, coarse aggregate, fine aggregate, and plastic waste were weighed and placed in containers before mixing. The mixing process was performed as follows: (1) small amount of the mixing water was poured into the mixer to wet its surface; (2) dry ingredients including coarse aggregate, fine aggregate, cement, and plastic waste were added gradually and alternatively; (3) the remaining mixing water was poured gradually while the mixer rotating; (4) PCC mixing continued for 3 min to obtain a homogeneous mixture; and (5) superplasticizer was added to improve the workability of the mix with plastic waste. The same amount of superplasticizer was added to all PCC mixtures. The slump test was performed on fresh PCC to evaluate the consistency and workability of the fresh PCC. The PCC was placed in molds in three layers and consolidated using a vibrating table to reduce the air voids. The molds were covered with plastic sheets to reduce the evaporation of the mixing water. After 24 h, the PCC specimens were removed from the molds and moist cured at ambient temperature of 22 °C to promote the hydration process of the PCC with plastic waste.

2.2. Test Procedures

The specific gravity and absorption of coarse and fine aggregate were conducted according to ASTM C127-15 [25] and ASTM C128-22 [26], respectively. The unit weight of coarse aggregate was measured out using a steel container, rod, and weigh scale in accordance with ASTM C29-23 [27] procedure. The maximum aggregate size of coarse aggregate and fineness modulus of fine aggregate were conducted using the sieve analysis test according to ASTM C136-20 [28]. The fresh density and air content of PCC mixtures were conducted using the pressure meter steel container and pressure method, respectively, following ASTM C138-23 [29] procedure. The slump test of fresh PCC was conducted using the slump steel cone, compacting rod, and square pan according to ASTM C143-20 [30] procedure.

The compressive strength of PCC cylinders was determined using a hydraulic compressive testing machine according to ASTM C39-21 [31] procedure. The splitting strength of PCC cylinders was conducted using a hydraulic compression machine according to ASTM C496-17 [32] procedure. The PCC cylinders were placed horizontally on the testing machine platens and subjected to compressive loading that indirectly produced tensile stress in the perpendicular direction. Hence, the PCC cylinders were ultimately split by tensile stress.

The water absorption of PCC with plastic waste was performed using the saturated surface dry and oven dry weights of PCC cylinders following ASTM C642-97 [33] procedure. PCC specimens were submerged in a water tank for three days, removed from the tank, the surface was dried using a cloth, and weighed to obtain the saturated surface dry weight. Then, the PCC specimens were placed in an oven at 100 °C for three days and weighed to obtain the oven dry weight. The water absorption of PCC was determined from the difference between the saturated surface dry and oven dry weights divided by the oven dry weight.

The rapid chloride penetration test was conducted using 50 mm thick and 100 mm diameter PCC cylinders according to ASTM C1202-22 [34] procedure. The PCC specimens were placed between two plexiglass reservoirs that contain 3% Sodium Chloride in one reservoir and 0.3 M Sodium Hydroxide in the other reservoir. The PCC specimens were subjected to a voltage of 60 V on both ends of the specimen for 6 h. The electrical charge passed through PCC specimens was determined in Coulombs.

The durability of plastic waste PCC to freezing and thawing cycles was performed using prism specimens following ASTM C666-15 [35] procedure. The freezing and thawing deterioration was evaluated using the relative dynamic modulus of elasticity as follows. The transverse frequency of PCC prisms was measured every 25 cycles of freezing and thawing following ASTM C215-19 [36] procedure. The relative dynamic modulus (RDM) after n cycles of freeze–thaw was calculated by dividing the square of transverse frequency (TFn) of PCC prisms after n cycles by the square of transverse frequency of PCC prisms before exposure to freeze–thaw cycles (TF0) as follows:

RDM = [(TFn)2/(TF0)2] × 100

The PCC specimens were subjected to freezing and thawing cycles until either 300 cycles were completed or the relative dynamic modulus dropped below 60%, whichever occurred first.

3. Results and Discussion

3.1. Effect on Mixture Properties

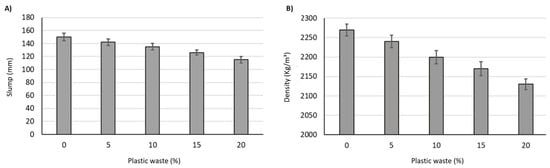

The slump test is widely used to measure the workability of fresh PCC in practice. The slump test was utilized to investigate the influence of plastic waste on the workability of fresh PCC. The slump test provides a good indication of the consistency and homogeneity of the PCC. Figure 3A shows the influence of plastic waste on the slump of PCC with different contents of plastic waste. The workability of PCC decreased with the increase in plastic waste in the PCC mixtures. The slump decreased from 150 mm for the reference P0 mixture (without plastic waste) to 115 mm for the P20 mixture (with 20% plastic waste). The maximum percent decrease in the slump was 23% for the P20 mixture. This behavior may be explained by the irregular shape and rough surface of the plastic waste particles that increased the friction between the fresh PCC particles. Therefore, it is clear that the workability of PCC decreases as the amount of plastic waste increases.

Figure 3.

(A) Influence of plastic waste on the workability of PCC mixtures. (B) Influence of plastic waste on the fresh density of PCC mixtures.

The fresh density of PCC represents an important factor that affects many parameters of PCC such as strength and durability. Generally, for normal weight concrete, as the density of PCC increases, the strength, durability, and the dead load of the concrete increase. As shown in Figure 3B, the fresh density of PCC decreases with increasing plastic waste. The density decreased from 2270 kg/m3 for the P0 mixture to 2130 kg/m3 for the P20 mixture, which represents a 6.2% decrease. This is because the plastic waste was utilized as a partial replacement for sand in the PCC mixtures in this research. The specific gravity of plastic waste (0.95) is significantly lower than the specific gravity of sand (2.56).

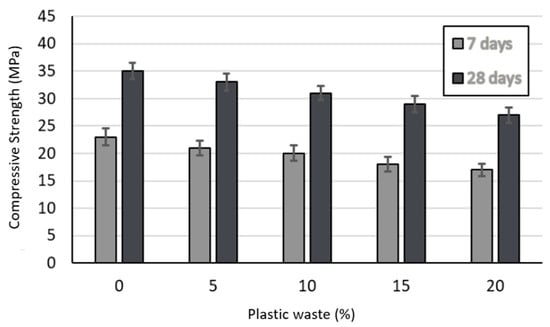

The air content of PCC affects many properties of PCC such as strength and durability. Generally, the increases in the air content of PCC have a negative impact on the strength and durability of PCC but improves the freeze–thaw resistance. The influence of plastic waste on the air content of PCC is illustrated in Figure 4A. The air content increased from 1.8% for the reference PCC without plastic waste to 3.2% (or 78%) for the P20 PCC mixture, which has 20% plastic waste content. The behavior of increasing the air content of PCC with the increase in plastic waste level may be explained from the irregular shape of plastic waste particles (see Figure 2A). Moreover, the hydrophobic nature of plastic waste polymers likely caused air bubble formation on the surface of the plastic [18].

Figure 4.

(A) Influence of plastic waste on the air content of PCC. (B) Influence of plastic waste on the water absorption of PCC.

The water absorption of PCC influences the water transport and durability of PCC. Most durability problems in PCC arise from the water ingress into the PCC. Most water penetrating PCC carries many dissolved salts such as sulfate and chloride, etc., that cause durability problems such as sulfate attack and the corrosion of reinforcing steel. Figure 4B shows that water absorption increased by increasing plastic waste amounts. Water absorption increased from 5.6% for the reference PCC mixture (P0) to 7.2% for the P20 mixture that contains 20% plastic waste, which corresponds to a 29% increase. The increase in water absorption of PCC with the increase in plastic waste may be explained by the increase in the air content, which tends to facilitate and boost water absorption.

3.2. Effect on Strength Properties

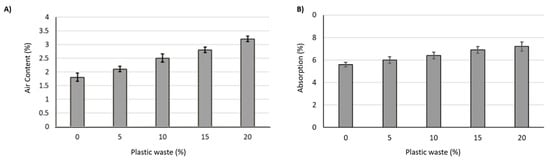

The compressive strength of PCC is considered one of the most vital properties and is related to other critical properties such as permeability, durability, abrasion resistance, shrinkage, creep, and bond with reinforcement, etc. The effect of plastic waste on the compressive strength of PCC after 7 and 28 days of moist curing is illustrated in Figure 5. The compressive strength decreased with the increase in plastic waste contents from 23 and 35 MPa for P0 mixture without plastic waste at 7 and 28 days, respectively, to 17 and 27 MPa for P20 mixture with 20% plastic waste level. The maximum percentage decrease in compressive strength of PCC after 7 and 28 days were 26% and 23%, respectively. The strength reduction was 11% (from 35 MPa to 31 MPa) at 28 days when 10% plastic was added to concrete. This high compressive strength reduction can be tolerable in many structural design applications given the environmental benefits of using plastics in concrete, as discussed above.

Figure 5.

Influence of plastic waste on the compressive strength of PCC mixtures.

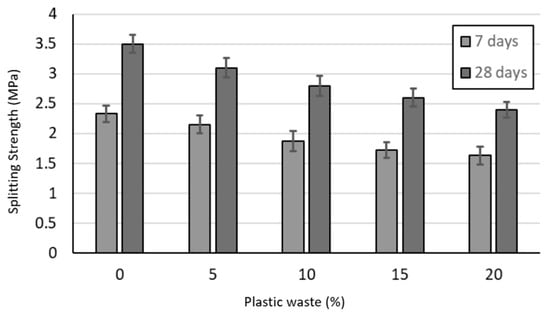

The splitting strength of PCC is important for crack control when structural elements, such as beams, slabs, columns, and footings, are subjected to tensile stress. The split tensile strength of PCC is a good indirect measure of the tensile strength, which is difficult to measure in the laboratory. Typically, the splitting tensile strength ranges from 8% to 12% of the compressive strength of concrete, which is calculated according to ACI 318 [37], which defines splitting tensile strength as 0.56 times the square root of compressive strength.

Figure 6 shows that the splitting strength of PCC at the age of 7 and 28 days decreased with increasing plastic waste content. The splitting strength (after 7 and 28 days) of moist curing decreased (from 2.33 and 3.5 MPa) for the P0 reference mixture (to 1.63 and 2.4 MPa) for the P20 mixture. Therefore, the maximum percent decrease in the splitting strength at the age of 7 and 28 days was 30% and 31%, respectively, for the P20 mixture. The percentage decrease in the splitting strength of PCC containing plastic waste after 7 and 28 days of moist curing was higher than the percent decrease in the compressive strength. This behavior may be explained by the increase in air content and voids of PCC with the increase in plastic waste. The air voids present in the PCC with plastic waste facilitate splitting strength failure more than compressive strength failure. It should also be noted that the plastic size used in this research was small.

Figure 6.

Influence of plastic waste on the splitting strength of PCC mixtures.

3.3. Effect on Durability

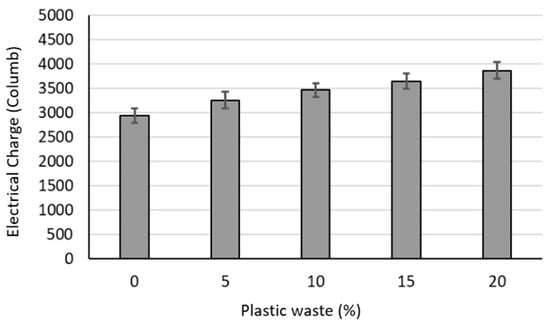

The penetration of chloride ions into PCC is the main cause of the corrosion of reinforced steel in reinforced concrete elements. The corrosion process of steel is a very slow process and may take more than ten years in the field. The rapid chloride permeability test gives an indication of the susceptibility of chloride ions to penetrate PCC, and hence the corrosion susceptibility of the PCC. Figure 7 shows the electrical charge (in Coulomb) of the rapid chloride permeability test. The electrical charge passed through the PCC specimens increased with the increase in plastic waste content, which indicates higher chloride penetration and more corrosion susceptibility. The electrical charge was increased from 2940 Columb for the reference PCC without plastic waste (P0) to 3870 Coulomb for the P20 mixture that contains 20% plastic waste. The maximum percentage increase in the electrical charge was 24% for the PCC with 20% plastic waste content. This indicates that plastic waste concrete is more susceptible to chloride penetration and corrosion. The higher permeability of concrete with more plastic materials can be explained by the increase in the water absorption and air content of the PCC with plastic waste, as discussed in Section 3.1. The increase in the water absorption of the plastic waste PCC (Figure 4B) causes an increase in the chloride ions penetrating into the PCC.

Figure 7.

Influence of plastic waste on the electrical charge passing through PCC.

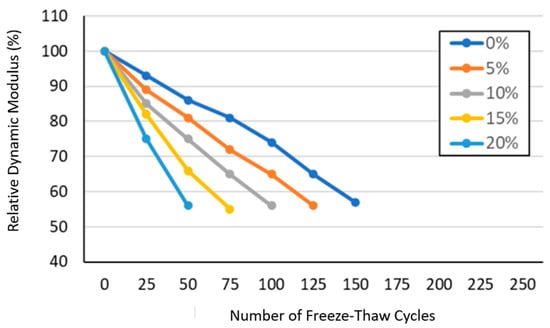

Freeze–thaw deterioration of PCC is common in regions with cold weather, particularly where temperatures drop below −12 °C. The freezing of the capillary water inside the PCC pores exerts internal pressure and tensile stresses on the cement paste matrix of the PCC, causing deterioration of the PCC that progressively increases with repeated cycles of freezing and thawing. The main approach to reduce the freeze–thaw deterioration in the PCC is to introduce air-entrained bubbles inside the cement paste matrix that reduces the pressure resulting from freezing of the capillary water. Figure 8 shows the variations in the relative dynamic modulus of elasticity (calculated from Equation (1)) with the number of freeze–thaw cycles for the PCC containing plastic waste. The relative dynamic modulus decreased significantly for all PCC mixtures investigated as the number of freeze–thaw cycles increased, demonstrating the deterioration caused by freeze–thaw in PCC containing plastic waste.

Figure 8.

Relative dynamic modulus of elasticity with the number of freeze–thaw cycles.

The P0 mixture (control PCC without plastic waste) reached a 57% relative dynamic modulus after 150 cycles of freeze–thaw, indicating medium durability to freeze–thaw cycles. However, the plastic waste PCC mixtures showed lower durability to freeze–thaw cycles. The PCC containing plastic waste reached 125, 100, 75, and 50 cycles of freeze–thaw for PCC with 5%, 10%, 15%, and 20% plastic waste, respectively. The behavior of decreasing durability with increasing plastic waste can be explained by the following. The inclusion of plastic waste into PCC mixtures significantly decreased the compressive and splitting strength of the PCC, as shown in Figure 5 and Figure 6. The tensile strength or splitting strength is directly related to the durability or resistance of PCC with plastic waste to freeze–thaw cycles.

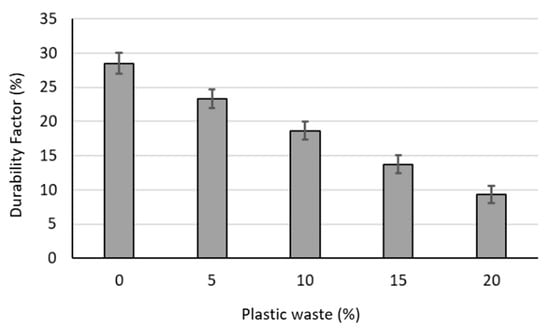

The durability factor (DF) of the PCC exposed to freeze–thaw cycles is defined as follows:

where RDM represents the relative dynamic modulus of the PCC prism at the end of freeze–thaw exposure, while N denotes the number of freeze–thaw cycles at which the test was terminated.

DF = (RDM × N)/300

The durability factors for PCC with different plastic waste contents are shown in Figure 9. The durability factor decreased with the increase in the plastic waste in the PCC mixtures, indicating lower durability to freeze–thaw deterioration. The durability factor decreased from 28.5% for the control PCC without plastic waste to 9.3% for the P20 mixture that contained 20% plastic waste.

Figure 9.

Durability factors for PCC contain different plastic waste contents.

4. Conclusions

This study investigates different properties of PCC containing different amounts of plastic waste (0%, 5%, 10%, 15%, and 20%). The evaluated PCC properties include workability, density, absorption, air content, compressive strength, splitting strength, rapid chloride permeability, and freeze–thaw performance. One of the most important conclusions of this research is that the compressive strength of concrete was reduced by only 11% at 28 days when 10% plastic waste was added to the concrete (Figure 5). This relatively low compressive strength reduction can be tolerated in many field applications given the environmental benefits of diverting plastic waste from the landfill.

Based on the results of this study, the following conclusions were made:

- 1.

- The workability of PCC containing plastic waste decreased with the increase in plastic waste content mainly due to sharp edges or the irregular shape of plastic materials (Figure 1). The slump decreased by 10% when PCC included 10% of plastic, which is not a significant reduction, and by 23% for the PCC with 20% plastic waste.

- 2.

- The density of PCC with plastic waste decreased with the increase in plastic waste level. The maximum decrease in density was 6.2% for the mixture with 20% plastic waste content.

- 3.

- The air content of PCC with plastic waste increased with increasing plastic waste amounts. The air content increased by 39% and 78% for the mixtures with 10% and 20% plastic waste content, respectively.

- 4.

- The absorption of concrete increased as the amount of plastic waste increased. The maximum percentage of water absorption was 29% for the PCC mixture containing a 20% plastic waste level.

- 5.

- The mechanical properties (compressive and splitting strength) decreased with the increase in the plastic waste substitution level. The decrease in the compressive strength after 7 and 28 days of moist curing were 26% and 23%, respectively, for the mixture with 20% plastic replacement. Moreover, the maximum decrease in the splitting strength after 7 and 28 days of moist curing were 30% and 31%, respectively, for the same mixture. The compressive strength reduction was only 11% when the PCC included 10% plastic waste, indicating that an addition of 10% plastic waste in concrete can be practical.

- 6.

- The electrical charge passing through PCC specimens using the rapid chloride permeability test increased with an increasing amount of plastic waste. The maximum increase in the electrical charge was 24% for the mixture with 20% plastic waste.

- 7.

- The durability of PCC under freeze–thaw cycles decreased as the plastic waste content increased. The durability factor decreased from 29% for the control mixture without plastic waste to 9% for the mixture with a 20% plastic waste level.

Author Contributions

Conceptualization, N.A.-A. and H.S.; methodology, N.A.-A. and H.S.; validation, N.A.-A. and H.S.; formal analysis, N.A.-A.; investigation, N.A.-A.; resources, N.A.-A. and H.S.; data curation, N.A.-A.; writing—original draft preparation, N.A.-A.; writing—review and editing, N.A.-A. and H.S.; visualization, N.A.-A.; supervision, N.A.-A. and H.S.; project administration, N.A.-A.; funding acquisition, N.A.-A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Deanship of Scientific Research at the Jordan University of Science and Technology, grant number 352-2023.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PCC | Portland Cement Concrete |

| ASTM | American Standards for Testing and Materials |

| RDM | Relative Dynamic Modulus |

| N | Number of Freeze–Thaw Cycles |

| TFn | Transverse Frequency After n Cycles of Freeze–Thaw |

| TF0 | Transverse Frequency Before Freeze-Thaw |

| DF | Durability Factor |

References

- Guerra, E.; Lima, E. Handbook of Polymer Synthesis, Characterization, and Processing, 1st ed.; 222 Rosewood Drive: Danvers, MA, USA, 2013. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Singh, P.; Sharma, V. Integrated plastic waste management: Environmental and improved health approaches. Procedia Environ. Sci. 2016, 35, 692–700. [Google Scholar] [CrossRef]

- Siddiqua, A.; Hahladakis, J.; Al-Attiya, W. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef]

- Cudjoe, D.; Zhu, B. Gasification of medical plastic waste into hydrogen: Energy potential, environmental benefits and economic feasibility. Fuel 2024, 371, 132150. [Google Scholar] [CrossRef]

- Babaremu, K.; Oladijo, O.; Akinlabi, E. Biopolymers: A suitable replacement for plastics in product packaging. Adv. Ind. Eng. Polym. Res. 2023, 6, 333–340. [Google Scholar] [CrossRef]

- Awoyera, P.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Choudhary, A.; Shah, V.; Bishnoi, S. Effect of Low-Cost Fillers on Cement Hydration. Constr. Build. Mater. 2016, 124, 533–543. [Google Scholar] [CrossRef]

- Tejaswini, M.; Pathak, P.; Gupta, D. Sustainable approach for valorization of solid wastes as a secondary resource through urban mining. J. Environ. Manag. 2022, 319, 115727. [Google Scholar] [CrossRef]

- Lin, R.; Wang, X.; Zhang, G. Effects of Quartz Powder on the Microstructure and Key Properties of Cement Paste. Sustainability 2018, 10, 3369. [Google Scholar] [CrossRef]

- Akbar, M.; Hussain, Z.; Imran, M.; Bhatti, S.; Anees, M. Concrete matrix based on marble powder, waste glass sludge, and crumb rubber: Pathways towards sustainable concrete. Front. Mater. 2024, 10, 1329386. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Enhancing sustainability in concrete construction: A comprehensive review of plastic waste as an aggregate material. Sustain. Mater. Technol. 2024, 40, e00877. [Google Scholar] [CrossRef]

- Li, X.; Ling, T.; Mo, K. Functions and Impacts of Plastic/Rubber Wastes as Eco-Friendly Aggregate in Concrete: A Review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- Cordoba, L.; Barrera, G.; Diaz, C.; Nunez, F.; Yanez, A. Effects on Mechanical Properties of Recycled PET in Cement-Based Composite. Int. J. Polym. Sci. 2013, 2013, 763–776. [Google Scholar] [CrossRef]

- Dawood, A.; Al-khazrahi, H.; Falih, R. Physical and Mechanical Properties of Concrete Containing PET Wastes as a Partial Replacement for Fine Aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Islam, M.; Meherier, M.; Islam, A. Effects of Waste PET as Coarse Aggregate on the Fresh and Harden Properties of Concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Caputo, D.; Colangelo, F.; Cioffi, R. Recycled plastic aggregate in mortars composition: Effect on physical and Mechanical Properties. Mater. Des. 2013, 52, 916–922. [Google Scholar] [CrossRef]

- Jacob-Vaillancourt, C.; Sorelli, L. Characterization of concrete composites with recycled plastic aggregates from postconsumer material streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.; Allahyari, H.; Nikbin, I. On the Mechanical Properties of Concrete Containing Waste PET Particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J. Use of plastic Waste as Aggregate in Cement Mortar and Concrete Preparation: A Review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Yang, S.; Yue, Z.; Liu, X.; Tong, Y. Properties of Self-Compacting Lightweight Concrete Containing Recycled Plastic Particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Zulkernain, N.; Gani, P.; Chuan, N.; Uvarajan, T. Utilization of Plastic Waste as Aggregate in Construction Materials: A Review. Constr. Build. Mater. 2021, 296, 123669. [Google Scholar] [CrossRef]

- Abduallah, R.; Burris, L.; Castro, J.; Sezen, H. Utilization of Different Types of Plastics in Concrete Mixtures. Constr. Mater. 2025, 5, 39. [Google Scholar] [CrossRef]

- Ammari, M.; Sezen, H.; Castro, J. Effect of Different Plastics on Mechanical Properties of Concrete. Constr. Mater. 2025, 5, 60. [Google Scholar] [CrossRef]

- ASTM Standard C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM Standard C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM Standard C29; Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM Standard C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM Standard C138; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM Standard C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM Standard C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM Standard C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM Standard C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM Standard C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM Standard C666; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM Standard C215; Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 1997.

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).