Abstract

The construction of large underground caverns fundamentally differs from building and above ground civil infrastructure projects due to their complex geometries and variable geological conditions. These projects are complex and challenging because a large amount of data is generated from dispersed, independent, and heterogeneous sources. The underground construction industry often uses traditional project management techniques to manage complex interactions between these data sources that are hardly linked, and independent decisions are often made without considering all the relevant aspects. In this context, cavern construction exhibits uncertainties and risks due to unforeseen circumstances, an intricate design, and ineffective information management. Existing research has considered general BIM semantic models at the design stage; however, the digital transformation of cavern construction remains underdeveloped and fails to integrate digital construction throughout the project lifecycle. To address that gap, a novel BIM-based multi-model cavern information modeling framework is presented here to improve project management, construction, and delivery by integrating multiple interlinked data models and project performance data for large underground cavern construction. Data models of cavern construction processes are linked to propose an extension of the Industry Foundation Classes (IFC) schema based on the cavern-specific elements, relationships, and property set definitions. To illustrate the potential of the proposed framework, a theoretical application to the powerhouse cavern construction is presented. The results indicate that the framework has significant potential to improve construction efficiency and safety and establish a robust foundation for the digital transformation of underground cavern projects. The theoretical implementation on the Neelum–Jhelum powerhouse cavern showed that the framework enabled a 92 m cavern realignment to avoid fault zones, achieved a 12.4% reduction in rock bolt usage, and a 9.8% reduction in shotcrete volume. These quantitative improvements illustrate its potential to enhance safety, reduce material costs, and optimize construction efficiency compared to conventional workflows.

1. Introduction

With increasing urbanization and infrastructure demands, the utilization of underground space has become an integral part of modern civil engineering infrastructure. These large underground spaces have become vital components of critical infrastructure systems serving diverse functions in energy, urban development, storage, safety, and advanced scientific research, enabling cities to optimize land use while enhancing resilience and sustainability [,]. In contrast to linear tunnel structures, underground caverns are typically characterized by their complex geometries and heterogeneous rock conditions, which require multistage excavation strategies and rigorous geotechnical monitoring protocols. These projects generate vast quantities of data including topographic maps, borehole records, geological sections, and quality assurance documentation that must be consistently interpreted and shared among engineers, geologists, and project managers. Despite the volume and criticality of this information, many projects still rely on conventional documentation methods and isolated data systems, resulting in inefficiencies, coordination gaps, and cost escalations [,].

BIM has emerged as a transformative approach in infrastructure development, offering a centralized digital environment where spatial, temporal, and attribute-based information can be integrated and visualized []. The evolution of BIM into 4D (time-based) and 5D (cost-based) applications has enabled more informed decision-making and lifecycle-oriented project delivery [,]. The shift from building-focused BIM to Infrastructure BIM (I-BIM) has already yielded significant benefits in managing linear infrastructure projects such as railway networks, highway corridors, and metro systems [,,]. However, the digital transformation of cavern construction remains underdeveloped. While I-BIM applications have advanced in tunnel engineering addressing sequential excavation modeling, sensor integration, and geotechnical simulations, these methodologies are not directly scalable to the unique demands of large cavern environments []. The design and execution of cavern structures require specialized digital frameworks that can accommodate excavation staging, rock reinforcement systems, shotcrete applications, and dynamic geotechnical data processing [,].

Recent research trends show a growing focus on BIM-enabled automation and digital twin technologies tailored for underground infrastructure []. Sharafat et al., 2025 [] proposed an integrated stability optimization framework for cavern systems that fuses sensor networks, staged excavation data, and structural analytics into a unified BIM-based digital twin. Similarly, Borrmann et al., 2022 [] advocate for the enhancement of IFC to accommodate the unique elements of tunnel and cavern structures, thereby facilitating standardized, interoperable digital modeling. The adoption of such advanced digital solutions has the potential to significantly improve construction safety, predictive maintenance, and operational resilience, while also enabling more environmentally responsive and risk-informed planning strategies in underground development [,]. Despite these advancements, the distinctive geometric complexity and dynamic construction sequences of large underground caverns remain insufficiently addressed in current BIM applications. Existing methodologies tend to oversimplify cavern geometries and fail to accommodate the multistage excavation and reinforcement strategies essential for large-span subterranean spaces.

The key innovation of this study lies in introducing a cavern-specific, multi-model BIM framework that fundamentally differs from existing research. Previous studies have primarily focused on building-oriented BIM [,] and linear tunnel applications [,], which often oversimplify the geometric complexity and sequential excavation requirements of large-span caverns. Existing methodologies, including tunnel-focused BIM and IFC-Tunnel extensions [], cannot fully integrate geological, excavation, and rock support models for multi-directional cavern environments. To address this challenge of the digital construction of underground caverns throughout the project life cycle, this study introduces a novel multi-model BIM framework for the comprehensive design, construction, and monitoring of underground construction from the design to the construction phase. The proposed framework formalizes a cavern-specific information model by integrating data from multiple sources generated during the feasibility, design, and construction phases. The cavern construction data models are built upon extended IFC standards, and key excavation stages such as pilot tunneling, benching, and rock support installation are explicitly defined to accommodate the unique characteristics of large underground caverns. It integrates diverse datasets, including geological exploration data, geotechnical parameters, structural designs, and construction activities, into a cohesive digital environment. To validate the proposed framework, a theoretical case study is presented using real geological and construction data from the Neelum–Jhelum Hydropower Project’s powerhouse cavern. The proposed framework aims to significantly enhance real-time decision-making and facilitate improved lifecycle management and a foundation for future BIM-based modeling of the cavern infrastructure.

2. Literature Review

2.1. Underground Caverns: Scope and Challenges

The construction of large underground caverns is increasingly integral to modern infrastructure projects, supporting critical sectors such as hydropower generation, hydrocarbon storage, transportation, and specialized research facilities. Their rising popularity is largely due to their efficient land usage, safety enhancements, and environmental benefits, particularly in urban areas facing land scarcity. Hydropower installations often utilize deep underground caverns to achieve geological stability and long-term safety, while the storage of hydrocarbons like hydrogen or natural gas frequently relies on salt caverns or depleted geological formations due to their inherent sealing properties [,].

Despite these advantages, cavern construction is accompanied by significant design and execution challenges. Large cavern spans, varying geological conditions, and phased excavation processes require detailed planning, continuous monitoring, and adaptive support mechanisms [,]. Traditional workflows that depend heavily on 2D drawings and separate, uncoordinated documentation often result in communication gaps, ineffective data integration, and slower decision-making processes, consequently increasing project risks and the likelihood of expensive rework []. Another major limitation in conventional workflows is the isolated management of data. Typically, project stakeholders such as designers, geotechnical specialists, structural engineers, and contractors operate independently, each using separate platforms and repositories. This lack of unified data sharing restricts real-time collaboration, slows down critical decisions, and complicates the management of project versions. Without a centralized information system, valuable project insights remain underutilized, particularly in complex and dynamic construction environments like tunneling and cavern excavations [,]. Hence, digital integration emerges not only as a technological advancement but as an essential strategic measure to mitigate inefficiencies and enhance project adaptability.

2.2. BIM in Construction

BIM has significantly reshaped the construction industry by introducing advanced digital tools that enable the detailed simulation, visualization, and management of construction activities across various project dimensions. BIM has undergone substantial development in recent years, evolving into a comprehensive approach that supports the effective coordination and management of projects across all stages of their lifecycle [,]. BIM represents a transformative shift in how projects are planned, designed, constructed, and managed, facilitating enhanced coordination among architects, engineers, contractors, and other stakeholders. BIM primarily revolves around creating detailed, information-rich digital models capable of effectively organizing, managing, and leveraging project data across every project stage from the early stages of design and construction to ongoing facility operations and maintenance [,]. By consolidating information into a single, centralized platform, BIM provides seamless data access to various stakeholders, such as architects, structural and building service engineers, mechanical, electrical, and plumbing (MEP) contractors, and facilities management teams, greatly enhancing coordination and minimizing communication gaps [].

The integration of BIM with emerging technologies such as virtual reality (VR) and augmented reality (AR) has notably boosted its capabilities in visualizing designs, planning for construction safety, and enabling interactive decision-making processes []. These advancements significantly cut down on construction errors and labor inefficiencies []. In the context of underground construction, BIM’s powerful simulation tools enable project teams to realistically model complex excavation stages, anticipate geological challenges, and continuously track project progress in real-time, thereby fostering more accurate, dependable, and informed project execution [].

While using BIM, interoperability among different software and disciplines is achieved through the IFC standards []. IFC serves as a neutral data format that facilitates multidisciplinary collaboration among architectural, structural, and geotechnical domains [,]. However, the existing IFC schema predominantly caters to surface-level or linear infrastructures and lacks detailed definitions necessary for representing cavern-specific features like deformable geological conditions and staged excavation practices. This limitation becomes even more apparent when considering the broader evolution of Infrastructure BIM, where the focus has largely remained on linear and more predictable forms of underground construction. Within the broader context of I-BIM, there has been considerable advancement and application in linear infrastructure such as tunnels, roads, and utilities. Common I-BIM applications include clash detection, finite element method (FEM)-based geotechnical assessments, and detailed construction scheduling [,]. Recent tunneling innovations, like IFC-Tunnel extensions, address phased excavation and support components []. However, substantial gaps remain in applying BIM to large cavern projects due to their multidirectional geometry and complex volumetric nature, areas currently underrepresented in BIM-related research [,].

2.3. Research Challenge and BIM for Underground Caverns

Building Information Modeling (BIM) has been widely adopted for data integration and collaborative workflows in building and linear infrastructure projects, offering centralized platforms for real-time information sharing and multidisciplinary coordination. However, in cavern design and construction, traditional methods such as 2D drawings, reports, and images are still predominantly used for data integration. These methods can often be challenging to interpret and prone to miscommunication, highlighting the need for modern information modeling techniques to streamline the process and enhance accuracy. Similarly, during the design phase, multi-model collaboration in building design using BIM techniques has effectively resolved issues such as design clashes between different disciplines such as MEP, structure and architecture through improved visualization in the construction industry. In contrast, cavern design still relies on independent modeling techniques, which lack integration and are often challenging to interpret when combined with other models. This limitation highlights the need for advanced collaborative modeling approaches to enhance efficiency and accuracy in cavern design. Also, the cavern design and construction rely on schedules, images and reports for project monitoring and control which can be improved by the integration of BIM as has been proven in other complex infrastructure projects.

Significant research and practical gaps persist specifically for large underground caverns. These specialized projects involve complex excavation sequences, highly variable geological conditions, and intensive monitoring demand that current BIM frameworks and schemas do not adequately address. Existing research frequently oversimplifies cavern geometry or overlooks critical features like dynamic rock-support systems and sequential excavation phases [,]. The existing BIM typically lacks built-in geotechnical intelligence. Conventional IFC models do not support the real-time integration of geotechnical sensor data, including stress, deformation, or pore pressure measurements, nor do they adequately enable adaptive decision-making based on live excavation data [,]. Consequently, without tailored extensions, cavern construction modeling remains fragmented and inadequate for managing high-risk underground environments.

Recent studies have further advanced digital approaches for underground cavern construction. A 4D safety information model has been developed to enable the real-time monitoring of underground cavern groups, improving risk management and stability assessment []. Digital twin-driven frameworks have been applied to optimize excavation stability and integrate sensor feedback for underground hydropower caverns []. Lifecycle BIM approaches in hydropower infrastructures highlight challenges in adoption and interoperability []. Multi-LoD BIM frameworks have been proposed for pressurized tunnels, demonstrating scalable modeling across project stages []. Automated BIM-to-FEM workflows have also been validated for large powerhouse caverns, improving stability analysis and design refinement []. Furthermore, BIM has been integrated with multi-information fusion and evidential theory for dynamic risk evaluation under geological uncertainty []. These studies reinforce the need for a domain-specific BIM framework to achieve comprehensive digital transformation in complex underground environments.

To effectively bridge this identified gap, there is a growing emphasis among researchers on developing a cavern-specific BIM framework. Such a framework would enhance existing IFC standards to incorporate specialized functionalities, including the precise modeling of excavation sequencing, rock support installations, and geotechnical monitoring infrastructures within a unified, interoperable digital environment [,]. This enhanced, cavern-specific approach would allow project teams to visualize intricate excavation geometries, simulate phased construction accurately, and integrate real-time monitoring data effectively. The implementation of this specialized framework is expected to promote integrated multidisciplinary collaboration, facilitate real-time, data-driven decision-making during construction phases, and significantly reduce project risks, safety incidents, and related cost overruns [].

3. Methodology

The design and construction of underground caverns involve the integration of a large amount of data, spanning from initial geotechnical and geological investigations during the feasibility stage to complex analysis in the design and construction phase. Traditionally, this integration has been a manual process relying on 2D drawings, site images, progress reports, schedules, lab manuals, design reports, and other documentation, often resulting in inefficiencies, errors, and a lack of real-time collaboration. Conventional workflows also lack the integration of the management of data, where stakeholders like designers, geotechnical specialists, structural engineers, and contractors often work independently using separate platforms, restricting real-time collaboration, slowing down critical decisions, and complicating version management. This highlights the need for modern information modeling techniques to streamline processes and enhance accuracy.

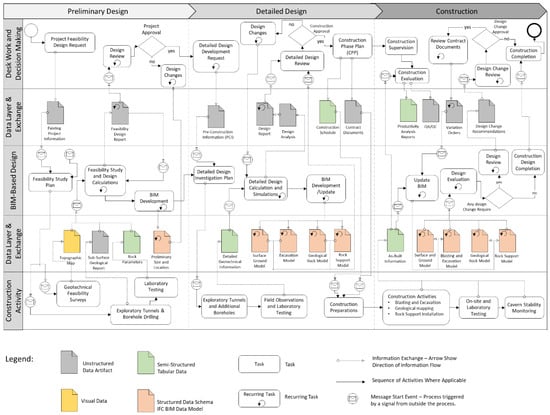

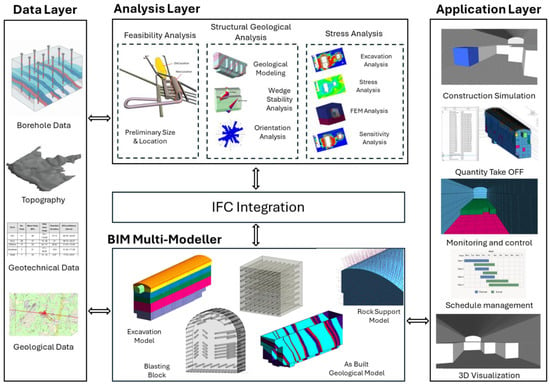

This study introduces a domain-specific, multi-model BIM framework designed for the comprehensive design, construction, and monitoring of large-span underground caverns. The framework’s methodology development process was formalized using the BPMN (Business Process Model and Notation) to standardize iterative revisions throughout the project lifecycle for multi-model integration, and stakeholder collaboration (Figure 1). The proposed multi-model BIM-based framework is structured into four key layers: the Data Layer, BIM Multi-Modeler, Analysis Layer, and Application Layer, facilitating the seamless integration of data, modeling, simulation, and application across the project lifecycle (Figure 2). This structure facilitates seamless collaboration among stakeholders by integrating data generated at various project stages.

Figure 1.

Business Process Model and Notation (BPMN) illustrating data flow and stakeholder interactions in the proposed BIM-based cavern design methodology.

Figure 2.

Overview of the multi-model BIM-based framework for underground cavern design and construction, structured into data, design, and application layers.

The proposed multi-model BIM framework presents several advantages and limitations. Its main advantages include centralized data integration across geological, structural, and construction domains; enhanced visualization through 3D/4D/5D modeling; support for real-time decision-making; and material and cost optimization. The primary limitations are the requirement for specialized software, skilled personnel, and the initial effort to develop an extended IFC schema for cavern-specific applications. The framework is broadly applicable to large underground caverns, hydropower powerhouse caverns, large-span tunnels, and subsurface storage facilities where sequential excavation and complex geometry are critical.

3.1. Data Layer

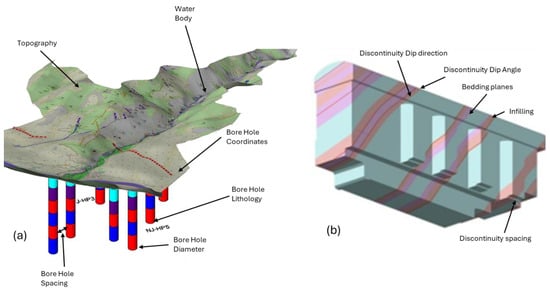

The Data Layer is the foundational component of the proposed framework, it incorporates the diverse data types essential for the comprehensive understanding of site conditions. This step collects and stores vast amounts of data generated throughout the project lifecycle (Figure 3). At the feasibility stage, data from aerial surveys, topographic surveys, hydrographic surveys, geological testing, laboratory and field testing are collected to create geological maps, hydrographic maps, and site topography. This data is stored in various formats such as photographs, survey sheets, and text documents. Building on the feasibility stage data, the design phase incorporates additional information like borehole data, exploratory tunnel, construction codes, and excavation standards. This is used to generate detailed drawings and layouts, rock support designs, blasting designs, excavation schedules, and bills of quantities.

Figure 3.

(a) Terrain model integrated with borehole locations, showing surface contours and exploratory drilling points used for geotechnical investigation. (b) Geological model representing subsurface stratigraphy and rock types encountered, visualized through borehole logs and classification of geological units.

Data generated during construction activities include drill and blasting (excavation), as-built construction, rock support installation, machinery used, field testing data, monitoring convergence data, actual schedules, and costs.

A key aspect of the Data Layer involves borehole data, gathered during initial exploration to characterize subsurface conditions. The process includes preliminary site investigation to determine optimal locations, the selection of boring techniques based on rock type (e.g., rotary drilling for hard rock, percussion drilling for softer rock, diamond core drilling for high-quality cores), and the continuous monitoring of drilling parameters. After drilling, rock samples (cores) are extracted, labeled, and analyzed for basic rock type, identification of discontinuities (joints, faults, bedding planes), and the calculation of the Rock Quality Designation (RQD), which indicates fracturing or jointing. In situ tests are also conducted on-site, such as the standard penetration test (SPT) and pressure meter test, alongside geophysical measurements like borehole imaging and seismic/sonic logging to measure elastic properties. Following field work, samples undergo laboratory testing to determine strength properties, elastic properties, durability, and mineralogical composition. The chemical properties of groundwater are also evaluated. This testing supports rock mass classification using systems like the Q-system and calculation of key geotechnical parameters (cohesion, friction angle, modulus of elasticity) for numerical modeling.

Furthermore, a detailed topographic survey maps the project site, highlighting surface features that influence cavern design decisions. This involves reconnaissance, establishing control points, and data collection using tools like total stations and LIDAR. Critical surface features are accurately mapped. This comprehensive data within the Data Layer serves as a robust foundation for the design process, enabling engineers to develop accurate models, assess construction feasibility, and refine design parameters. It reduces uncertainties, enhances design accuracy, and minimizes risks by providing a thorough understanding of site characteristics.

3.2. BIM Multi-Modeler

The BIM-based multi-modeler provides a comprehensive digital representation of underground cavern construction project execution by integrating four critical domain-specific models. This structured approach enables seamless data flow between geological, design, construction, and monitoring disciplines, addressing the key interoperability challenges in underground projects. The intelligent 3D models are developed based on the information from the data and design stages. These models incorporate the 3D geometric data and crucial non-geometric data about the cavern components, adding an extra dimension of information. It is a centralized platform where multiple specific models, each representing a distinct aspect of the project, are developed, updated, and integrated into a cohesive framework. These various models are interconnected within the BIM environment, ensuring that updates in one model, such as geological changes observed during excavation, automatically inform and adjust related models, thereby maintaining consistency and accuracy across the project. This is enabled using interoperable BIM tools such as Autodesk Civil 3D (2025), Leapfrog (2025), Revit (2025), and Navisworks (2025), coordinated via the IFC schema and its proposed extensions. Data is exchanged in IFC-compatible formats, with metadata tags ensuring the proper mapping of attributes across models. Dynamo scripts automate geometry generation, apply design rules, and update models in response to real-time data changes. These mechanisms ensure that geological, structural, and excavation models stay synchronized, reducing manual rework and supporting collaborative decision-making.

Moreover, to manage potential data inconsistencies or conflicts between models, the framework follows a coordination protocol where the model hierarchy is based on the project phase and data reliability. In most cases, geological and excavation models are prioritized, as they reflect actual ground conditions critical to safety and design feasibility. Changes detected during construction, such as updated face mapping or monitoring results, take precedence and trigger updates in related models like support systems or structural layouts. Conflict resolution is further supported by coordination meetings and clash detection workflows within the BIM environment, ensuring interdisciplinary agreement and consistent project delivery.

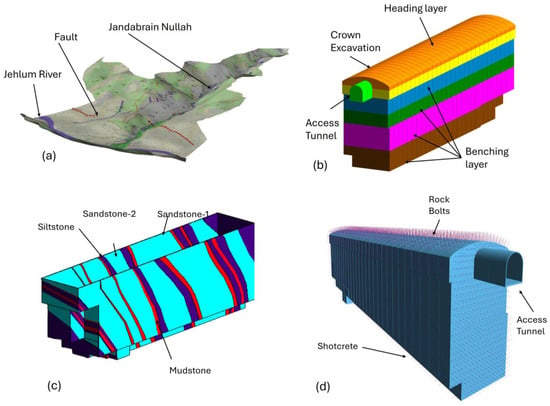

3.2.1. Surface Ground Model

The development of an accurate surface and subsurface ground model represents a critical component in the digital transformation of underground cavern construction. The surface ground model is developed using geographical maps and borehole geological data to provide a comprehensive foundation for the feasibility and design stages of underground cavern construction. This model is essential for understanding excavation conditions, conducting stability assessments, and identifying site-specific geological features, ensuring that the design process is based on actual topographical and subsurface data. By integrating this information, the model helps identify uncertainties and risks associated with excavation, allowing for necessary modifications in the preliminary design phase. In traditional project management, actual ground conditions are typically documented through spreadsheets, images, and text reports, which often lack integration and spatial visualization. However, by incorporating topographic information, geological attributes, and rock mass properties, the surface and ground model developed using Civil 3D (2025) which provides a structured and visual representation of the proposed project, as shown in Figure 3a. Key attributes such as borehole diameter, borehole spacing, rock mass properties, bedding planes, and Young’s modulus are included to define the geological characteristics, structural discontinuities, and material properties of the subsurface as shown in Figure 3b. This model enhances decision-making by improving excavation planning, stability analysis, and support system design, ultimately optimizing the accuracy and efficiency of underground cavern construction.

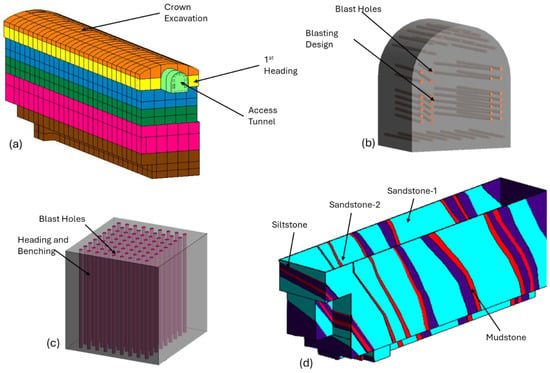

3.2.2. Excavation Model

Excavation constitutes the most critical phase of cavern construction with respect to both safety and efficiency. As cavern excavation commonly follows a cyclic, block-by-block by heading and benching methodology, blast design is customized according to the geological conditions encountered in each excavation cycle (Figure 4a). The mechanical properties of the rock mass influence blasting parameters, necessitating the development and optimization of multiple blast designs throughout the project. In traditional practice, blast design parameters such as intended block size, number and diameter of holes, relief holes, burden spacing, explosive quantities, and delay sequencing are documented in formats such as sheets or paper. This conventional documentation renders interpretation, updating, integration with other construction processes, and adaptation to changing geological conditions challenging.

Figure 4.

(a) Excavation model showing different stages of the planned excavation sequence for the powerhouse cavern. (b) Excavation block model illustrating the access tunnel development used to approach the main cavern. (c) Excavation block model for top heading and benching, representing phased excavation of the cavern cross-section. (d) As-built geological model showing the actual geological conditions encountered during excavation, based on face mapping and borehole data.

The proposed comprehensive 3D digital excavation model integrates multiple blast designs with the geological model, facilitating a data-driven approach for optimizing excavation parameters based on the prevailing geological conditions (Figure 4b,c). This model incorporates essential blasting information, which enhances operational efficiency and contributes to controlling ground vibrations, improving safety, and managing costs. Furthermore, integrating the excavation model with temporal data enables 4D simulation, providing a visual timeline of excavation activities. This assists engineers and project managers to optimize sequencing, identify potential delays, and efficiently allocate resources.

3.2.3. As-Built Geological Model

An as-built geological model is an integral part of underground construction throughout the project lifecycle, influencing ongoing excavation planning and rock support design. Geological mapping is traditionally performed following excavation and before rock support installation, with data typically stored in 2D CAD drawings. While this information is essential for designing appropriate support systems and optimizing the blast design based on actual site conditions, conventional methods lack integration with excavation models, requiring manual interpretation and leading to inefficiencies. The proposed BIM-based solution fundamentally transforms this process by capturing comprehensive geological data, including rock mass characteristics, lithological boundaries, the spatial distribution of rock types, weathering and alteration zones with intensity classification, and Rock Quality Designation (RQD) values mapped to excavation surfaces; structural features such as the 3D orientation of joints, faults, and shear zones, persistence and spacing of discontinuities, and infilling materials in structural discontinuities; and geotechnical anomalies, which include unexpected features like voids, dykes, and weak zones, overbreak and unstable ground conditions, and water ingress points (Figure 4d).

To enhance data transfer, risk mitigation, and cost efficiency, the proposed BIM-based as-built geological model links geological properties acquired during construction, enabling real-time updates and improved decision-making. By incorporating geological data into a parametric 3D model, engineers can dynamically adjust support systems based on site conditions, thereby reducing uncertainties and improving construction sequencing. In case unexpected geological anomalies such as weak zones, cavities, or water-bearing layers are encountered, the as-built geological model is updated immediately in the BIM environment. This real-time update capability allows designers and engineers to rapidly reassess excavation sequences, optimize rock support measures, and implement mitigation strategies such as drainage, additional bolting, or shotcrete reinforcement. By incorporating these dynamic updates, the framework ensures that construction decisions remain data-driven and adaptive to changing geological conditions. This approach provides better coordination among stakeholders across the design, construction, and operation phases, resulting in safer and more efficient cavern construction.

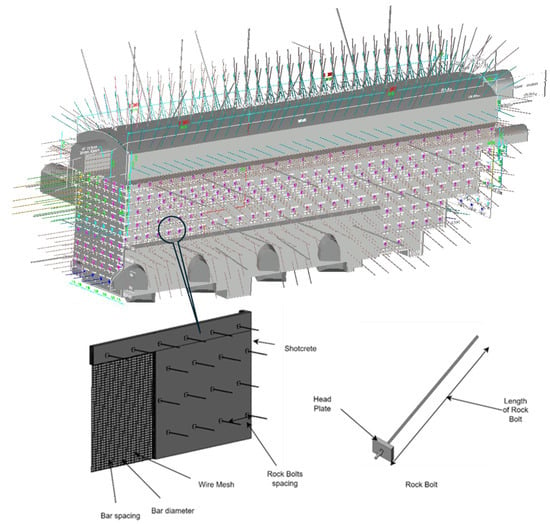

3.2.4. Rock Support Model

The rock support model provides detailed information about the rock support system, which ensures stability after excavation and carries the entire rock mass load. The design of rock support systems is highly dependent on geological conditions, including rock quality, discontinuities, and in situ stress states. The geological model provides essential input for selecting appropriate support measures, reducing uncertainties, and improving overall safety.

Various rock support elements, such as rock bolts, shotcrete, steel ribs, and lattice girders are used to reinforce the surrounding rock mass. These elements help prevent collapse, control deformations, and maintain cavern stability. The effectiveness of the support system depends on accurate design parameters such as rock bolt length, spacing, grout pressure, shotcrete thickness, and the reinforcement of mesh details. Integrating this information into a BIM environment allows for a data-driven approach, improving coordination between design and construction teams.

Traditionally, rock support design has been documented using 2D drawings, which require manual interpretation and increase the risk of errors. A BIM-based framework, however, enables the parametric modeling of rock support elements, allowing for seamless data transfer between excavation, geology, and support systems (Figure 5). This integration helps optimize support installation and ensures that structural analysis results are directly linked to construction planning.

Figure 5.

Rock support model illustrating installed shotcrete, bolts, and reinforcement elements mapped to geotechnical zones and excavation stages.

3.3. Analysis Layer

The design and construction of an underground cavern progress simultaneously, ensuring seamless integration between planning and execution. The analysis layer evolves through multiple stages, starting with the feasibility design to assess the site’s suitability and preliminary size. This is followed by the preliminary design analysis, where conceptual layouts and structural analyses are developed. Finally, the detailed design layer refines these concepts into comprehensive construction plans, addressing all geological, geotechnical, and engineering considerations to effectively guide excavation and support systems. This layer involves multiple stages of evaluation and refinement, progressively ensuring the safety, stability, and efficiency of the cavern throughout its lifecycle. It utilizes site conditions and geological characteristics provided by the Data Layer to facilitate engineering decisions, assess construction feasibility, and fine-tune design parameters, thereby reducing uncertainties, enhancing design accuracy, and minimizing risks during construction.

3.3.1. Feasibility Analysis

The feasibility analysis for an underground cavern is a critical phase that involves evaluating the preliminary size and determining the most probable location based on initial geological data of the site and proposed underground cavern requirements. It uses reconnaissance surveys, including site visits, geological maps, and aerial imagery, to understand surface features and subsurface conditions from the Data Layer. Borehole data and geological surveys play a pivotal role in identifying the rock type, quality, and structural discontinuities such as joints, faults, and bedding planes, which influence the stability and constructability of the cavern. Parameters like Rock Quality Designation (RQD), in situ tests (e.g., Standard Penetration Test), and geophysical measurements (e.g., seismic logging) provide insights into rock strength, elastic properties, and fracture patterns. These factors are analyzed to predict excavation stability, select suitable construction methods, and identify potential risks. Additionally, topographic surveys help map the terrain, align underground features, and evaluate surface constraints such as the existing infrastructure, drainage patterns, and vegetation. Based on this comprehensive dataset, the feasibility study establishes the preliminary dimensions and optimal location of the cavern, balancing geological conditions, engineering requirements, and project objectives while minimizing environmental and structural impacts. The environmental implications assessment during feasibility can include potential groundwater contamination from construction activities, changes in subsurface flow paths, surface water quality deterioration, and local ecosystem disruptions due to blasting or material disposal. Early identification of these risks allows mitigation strategies, such as controlled drainage and protective barriers, to be included in the project plan.

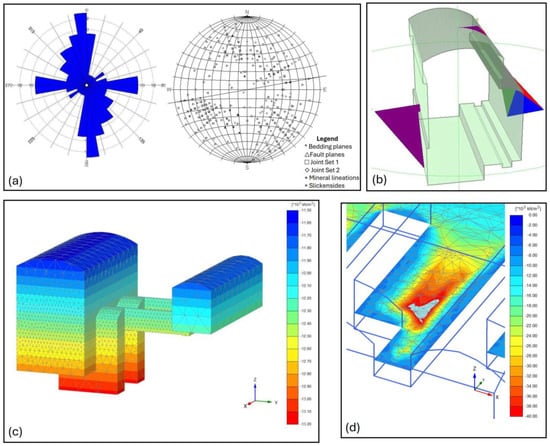

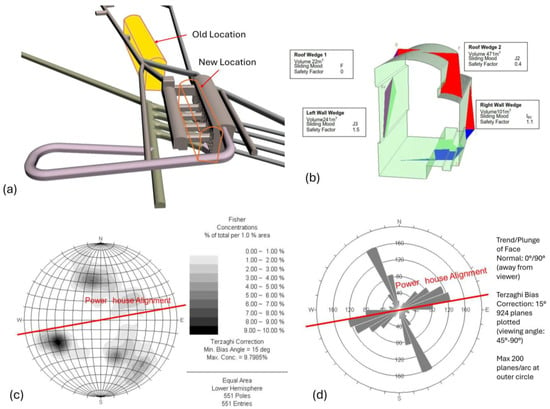

3.3.2. Structural Geological Analysis

The structural geological analysis in the preliminary design phase plays a crucial role in refining the feasibility of an underground cavern by integrating geological data with engineering analyses. It begins with the feasibility design, which defines the preliminary size and proposes a potential location based on initial borehole data. Using this information, a geological model of the cavern is developed using specialized software such as Leapfrog Geo (2025) or Surfer (2024), which help visualize subsurface conditions and structural features. Wedge stability analysis is then performed with tools like Rocscience’s Dips (Version 8.028) or Unwedge (Version 5.019) to assess the number and size of geological wedges formed by discontinuities such as joints, faults, and bedding planes at the proposed location (Figure 6a). This analysis is critical for verifying the cavern’s stability after construction and identifying potential risks. Additionally, orientation analysis is conducted using software such as Stereonet or Roescience’s Dips to ensure the proposed location aligns optimally with geological discontinuities, minimizing the impact of adverse structural features on cavern stability (Figure 6b).

Figure 6.

(a) Rose diagram showing the orientation and strike of bedding planes based on structural measurements taken at the terrain surface in the powerhouse area. (b) Wedge model illustrating the formation of a critical combined wedge in the cavern roof due to intersecting joint sets, posing significant stability concerns. (c) Finite Element Model (FEM) setup representing the cavern geometry and material properties used for stress and deformation analysis. (d) Stress concentration zones identified through FEM results, highlighting areas of potential instability and guiding support design.

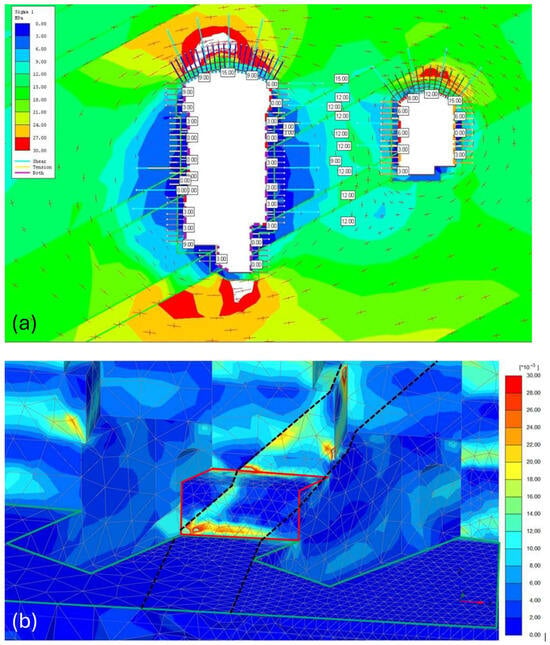

3.3.3. Stress and Excavation Behavior Analysis

This phase ensures the safety, stability, and efficiency of the cavern during the design and construction phase. This phase involves a series of detailed evaluations to refine the design and mitigate potential risks. Excavation analysis is conducted to assess the impact of excavation activities on the surrounding rock mass, aiding in the development of an optimized excavation plan or sequence to minimize stress concentrations and disturbances. Stress analysis evaluates the in situ stresses caused by the excavation process, identifying critical points of stress concentration that may affect cavern stability. Two-dimensional and 3D Finite Element Method (FEM) analysis is performed to model the complex interactions between the cavern structure and the surrounding rock mass, providing insights into deformation and stress distribution (Figure 6c,d). It integrated the complex interactions between excavation activities and the surrounding rock mass. Rock support systems are analyzed and specify rock bolts’ type, length, diameter, and spacing, alongside other reinforcements such as fiber-reinforced shotcrete and steel mesh, ensuring stability under dynamic and static conditions. Sensitivity analysis further complements these efforts by examining the influence of variable parameters, such as material properties and loading conditions, on the overall performance of the cavern, typically conducted using parametric analysis features.

Together, these analyses, supported by state-of-the-art modeling tools, provide a comprehensive understanding of the cavern’s behavior, ensuring robust design and construction practices while minimizing operational risks. Optimized blast designs are developed and evaluated using a simulation to define blast block sizes, drilling patterns, hole diameters, and explosive quantities, enabling controlled fragmentation while minimizing overbreak. Additionally, controlled excavation techniques are optimized through specialized blast pattern simulations that balance fragmentation efficiency with vibration control. By integrating these multifaceted analyses within a unified computational framework, the methodology enables data-driven decision-making throughout the project lifecycle. This integrated approach not only enhances construction safety and efficiency but also provides the flexibility necessary to adapt to unforeseen geotechnical challenges during implementation. The result is a scientifically grounded, yet practical solution for managing the complex behavior of large underground excavations under demanding geological conditions.

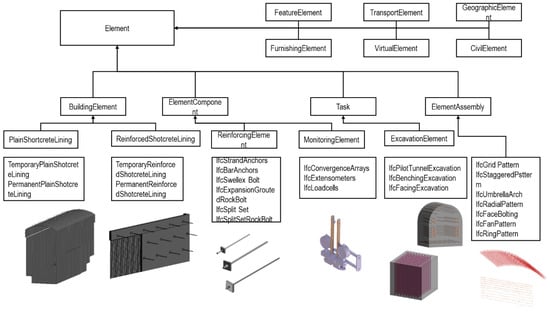

3.4. Interoperability Using IFC and Proposed Schema Extension

The proposed BIM-based framework relies on the IFC, an open, neutral data format to enable seamless data exchange and integration across diverse software platforms used in underground cavern projects. While standard IFC schemas support general building elements, they lack specialized entities for underground excavation and support systems. While tunnels and caverns may share certain construction tools, their workflows diverge significantly. Tunnel construction typically follows a linear heading approach, whereas cavern excavation requires complex staging and continuous support, as shown in the entity breakdown. The larger spans and deformation risks in cavern environments necessitate an IFC schema extension that accurately models these unique requirements—ultimately enabling more effective digital representation, lifecycle analysis, and coordination across stakeholders in underground infrastructure projects.

To address this, the framework introduces an IFC schema extension tailored for cavern construction, ensuring interoperability. An IFC data model specifically for underground caverns that considers the whole process from design to construction has yet to be formalized. An extension of the existing IFC schema originally developed for underground infrastructure is proposed to meet the specialized geometric and semantic exchange requirements of cavern design and construction. The schema in the image illustrates this proposed extension, integrating new domain-specific entities to reflect the complexity of underground excavation and support systems (Figure 7). Table 1 shows a detailed comparison of pre-existing IFC elements and the newly proposed extensions, highlighting their functionalities and significance in BIM-based cavern modeling. The excavation process is modeled under ExcavationElement, introducing entities such as IfcPilotTunnelExcavation, IfcBenchingExcavation, and IfcFacingExcavation. These define key stages in cavern excavation, capturing the sequence and method used—starting with pilot tunnels, progressing through top heading, and followed by staged benching for controlled material removal. Excavation tasks are structured via the Task entity, allowing the representation of process-driven construction steps. Rock support is modeled using ReinforcingElement, extended to include components such as IfcStrandAnchors, IfcBarAnchors, and IfcSwellexBolt, along with other essential support elements like IfcSplitSetRockBolt. The use of shotcrete is represented under BuildingElement via PlainShotcreteLining and ReinforcedShotcreteLining, with both temporary and permanent applications captured to reflect real-world implementation stages. Monitoring systems are incorporated through the MonitoringElement node, which includes entities such as IfcConvergenceArrays, IfcExtensometers, and IfcLoadcells, enabling the integration of geotechnical monitoring tools vital for assessing structural stability. Geological considerations are visually depicted through formations like IfcWeakZone, IfcFaultZone, and IfcRockMass (noted in the conceptual model but implied from geological modeling needs), supporting the simulation of geological heterogeneity. Excavation strategies are further detailed through ElementAssembly, categorizing typical support patterns like IfcGridPattern, IfcUmbrellaArch, and IfcRingPattern, among others. These reflect the practical arrangements of bolts and support needed for large-span cavern stability.

Figure 7.

IFC schema extension for underground cavern modeling, showing new entities for excavation stages, rock support, geological features, and monitoring systems.

Table 1.

Comparison Between Existing IFC Elements and Proposed Extensions for Underground Cavern Modeling.

The backbone of the proposed framework is its interoperability through the use of IFC, both in its standard form and with a proposed extension tailored for underground cavern applications. This open BIM standard enables seamless data exchange and model coordination between a wide array of domain-specific software platforms. For instance, initial terrain and borehole data are processed in CAD to construct surface and subsurface topographies. These geometric and spatial features are exported as IFC-compliant objects and imported into geological modeling software such as Leapfrog Geo or Surfer, where stratigraphic layers, faults, and discontinuities are mapped and classified. The enriched geological models are then integrated with finite element analysis (FEA) enabling stress-deformation simulations and support system design. Using IFC-compatible exports, results from these simulations—such as excavation-induced displacements or factor-of-safety maps—are re-imported into the BIM.

3.5. Application Layer

The application layer of the proposed BIM-based framework demonstrates its extensive utility in enhancing the design, construction, and management of underground caverns. By leveraging the integrated BIM models, this layer facilitates the generation of detailed design information that is accurate and consistent across all stages of the project. The framework enables better visualization by providing 3D representations of geological conditions, excavation sequences, rock support systems, and structural elements, ensuring stakeholders have a clear understanding of the project’s spatial and temporal aspects. Through 4D BIM, construction simulation becomes a powerful tool for planning and visualizing excavation and support installation sequences, helping to identify potential bottlenecks and improving on-site efficiency. The identified bottlenecks include equipment congestion in narrow tunnel sections, sequencing conflicts between excavation and rock support installation, and delays in material transport to the underground site. Early detection of these issues through 4D simulation helps to adjust work scheduling and equipment allocation, reducing the risk of on-site delays. The framework also supports design optimization by iteratively refining designs based on real-time data updates and simulations, ensuring that the most efficient solutions are implemented. Clash detection is another critical application, allowing the identification and resolution of conflicts between different design disciplines, such as structural, geotechnical, and mechanical systems, before construction begins. Efficient cost estimation is achieved by linking the BIM models with material quantities and cost data, providing accurate budget forecasts and enabling better financial control. Scheduling is seamlessly integrated with 4D BIM models, allowing for dynamic construction timelines that adapt to project progress and changes. Additionally, the framework extends beyond construction to facility management, providing a digital repository of all project information for long-term operations and maintenance. By incorporating these applications, the BIM framework enhances stakeholder involvement at every stage, offering a centralized platform for collaboration, transparent communication, and informed decision-making, thereby ensuring the project’s success from inception to operation. As the proposed framework integrates multiple aspects of underground cavern construction, its smooth operation is ensured through modular design and automation. Each layer is modular, allowing independent development and phased implementation. Interoperability is achieved through the extended IFC schema, enabling seamless exchange between Civil 3D, Leapfrog, Revit, Navisworks, and FEM tools without data loss. Automation scripts (e.g., Dynamo) synchronize model updates with real-time geological and excavation data, reducing the risk of human error.

4. Case Study: Theoretical Implementation on Powerhouse Cavern Construction

The Neelum–Jhelum Hydroelectric Project (NJHEP) is a major run-of-the-river hydropower facility located near Muzaffarabad in Azad Jammu and Kashmir, Pakistan. The project was developed to divert water from the Neelum River to the Jhelum River via a complex network of tunnels, utilizing the natural elevation drop between the two rivers to generate electricity. The plant has an installed capacity of 969 MW, consisting of four units of 242.25 MW each.

A key component of the NJHEP is its underground powerhouse complex, which houses all four turbine-generator units. The powerhouse cavern is constructed approximately 420 m below the surface and is designed to withstand high overburden stresses. The powerhouse cavern itself is 137.1 m long, 23.5 m wide, and 47 m high. Adjacent to it lies the transformer hall cavern, measuring 168.2 m in length, 16.8 m in width, and 20.98 m in height, connected via access galleries and bus bar tunnels. All major structures, including the headrace tunnel (28.6 km), surge shafts, penstocks, and the tailrace tunnel (3.6 km), were excavated through challenging geological conditions using both Tunnel Boring Machines (TBMs) and conventional drill-and-blast methods.

The proposed BIM-based methodology was successfully implemented as a theoretical implementation case study in the design and planning stages of the powerhouse cavern for the NJP Hydropower Project. It includes the construction of a large underground powerhouse cavern. With its intricate layout and complex geological environment, this project offered a unique opportunity to illustrate the theoretical case study for the application of a multi-model BIM-based framework for the integrated digital transformation from the design to construction of underground structures. The BIM framework developed in this study integrates multidisciplinary data models and introduces schema extensions to the Industry Foundation Classes (IFC), enabling enhanced interoperability and project performance tracking throughout the lifecycle.

4.1. Data Layer

Data collection commenced at the feasibility stage and continued through the design and construction phase, capturing critical geological, geotechnical, and engineering parameters that informed decision-making and model development. During feasibility, data collection included terrain surveys, geological mapping, and geophysical investigations such as seismic refraction and resistivity to assess subsurface conditions. Exploratory boreholes, including a 270 m horizontal borehole, provided core samples for the RQD, fracture logging, and hydrogeological evaluation. As the project advanced to the design stage, in situ stress measurements and Q-system rock mass classifications were carried out to evaluate stability and determine appropriate support systems. Geometric data like tunnel alignments and overburden profiles were captured through total stations and laser scanning. Core samples underwent laboratory tests to determine the UCS, triaxial strength, and durability. Data collected during these stages were stored in structured formats: geological logs and test results in Excel spreadsheets and CSV files, survey data in DXF and DWG formats, and geophysical data in SEG and LAS file formats. All the data and elements of the project are available as 2D representations in the form of spreadsheets, 2D CAD files, text documents, scanned PDF files, and images. To implement the proposed method of the digitalization of the underground cavern construction process, all that information was modeled, interpolated, and extracted. The Autodesk BIM software Civil 3D (2025), Revit (2025), Dynamo (v. 3.4.1), and Navisworks (2025) were used and integrated with scheduling and tunnel analysis software.

4.2. BIM-Based Integrated Models

Four interconnected models were developed to address spatial, geological, and construction-specific requirements. These models, including the Surface Ground Model, Excavation Model, As-Built Geological Model, and Rock Support Model, formed the foundation of an integrated digital representation of the entire construction process.

The surface ground model was constructed using topographic maps, aerial imagery, and borehole data to provide a comprehensive spatial context for the underground cavern layout (Figure 8a). This model helped visualize terrain elevations, access adits, and surface infrastructure, and allowed the evaluation of overburden conditions, fault traces, and potential surface constraints. It included key parameters like borehole locations, ground elevations, and geological cross-sections, which supported the alignment and siting of the cavern during the feasibility phase. The excavation model represented the theoretical excavation sequence, staged profiles, and structural boundaries of the powerhouse cavern and associated tunnels. Developed from construction staging plans and design cross-sections, it visualized each excavation phase including pilot tunnel development, benching strategy, and heading advance (Figure 8b). The model incorporated data such as round lengths, blast sequences, and excavation volumes, providing a clear framework for planning, monitoring, and updating excavation progress.

Figure 8.

(a) Surface geological model showing key geological features derived from terrain mapping and borehole interpretation. (b) Excavation model illustrating different layers and stages of the planned excavation process. (c) As-built geological model showing the different geologies encountered during excavation based on face mapping and ground investigation. (d) Rock support model representing the placement of shotcrete, rock bolts, and other reinforcements applied during construction.

Based on geological observations during excavation—such as tunnel face mapping, rock mass classification (Q-system), and fault/fracture data—the as-built geological model captured the actual ground conditions encountered (Figure 8c). The model was updated regularly with data from geologists, core logs, and structural discontinuity measurements. It reflected zones of weakness, lithological changes, and areas requiring modified support strategies. This real-time model was critical for validating design assumptions and adapting engineering decisions during construction. This model documented the types, locations, and installation parameters of rock support systems applied across various tunnel sections. It included 3D representations of fully grouted rock bolts, wire mesh, shotcrete layers, lattice girders, and anchors (Figure 8d). Support types were assigned based on geotechnical zones derived from the geological model. Parameters such as bolt spacing, shotcrete thickness, and support class boundaries were embedded into the model. This allowed the analysis of support performance, planning of support logistics, and visualization of support coverage across the cavern. During the theoretical implementation, multiple aspects of the powerhouse cavern construction were systematically tracked to validate model accuracy and optimize planning through a developed Multi-model BIM-based Framework. Three key metrics were monitored throughout the proposed method: (i) Excavation Progress Tracking, where each blast round and bench advancement was linked to the 4D construction schedule using Navisworks Timeliner, enabling the visual simulation of actual versus planned progress; (ii) Support System Installation, where quantities of installed shotcrete, rock bolts, and reinforcement mesh were automatically extracted through Revit quantity take-offs, allowing comparison with design specifications and the identification of material savings; and (iii) Geological Condition Updates, where tunnel face mapping, fault zone identification, and Q-system classifications were dynamically updated in the as-built geological model to reflect real ground behavior. These metrics facilitated data-driven adjustments to support designs, minimized overbreak, and improved safety through the real-time visualization of structural and geological conditions.

4.3. Technical Analysis

The technical analysis examines feasibility, geological, and stress behavior assessments. These analyses are conducted using linked models and datasets to validate design assumptions, assess risks, and guide decisions across excavation stages. During the early project stages, feasibility analysis focused on evaluating potential cavern locations based on overburden conditions, geological hazards, and accessibility. Using pilot borehole data and surface ground models, the team identified high-stress zones and faulted rock masses. A critical outcome of this phase was the relocation of the powerhouse cavern approximately 90 m eastward from its initially proposed position (Figure 9a–d). This shift was informed by geophysical data, stress trajectories, and safety considerations, and led to a more stable and feasible cavern alignment. The digital ground model was used to simulate terrain profiles, overburden thickness, and surface-to-underground access constraints, supporting optimal design and reducing long-term excavation risk.

Figure 9.

(a) Original and optimized powerhouse cavern locations and surrounding access tunnels, showing spatial adjustments made based on geological and geotechnical analysis. (b) Wedge stability analysis of the cavern roof and walls indicating critical wedge volumes, sliding modes, and safety factors for different failure surfaces. (c) Stereographic projection illustrating the distribution of joint orientations and the concentration of discontinuities influencing cavern alignment. (d) Rose diagram of joint strike directions with a statistical representation of the dominant structural orientations, used to assess optimal cavern orientation relative to geological discontinuities.

As excavation progressed, a structural geological analysis was conducted using data from geological face mapping, borehole logs, and geophysical investigations. Key structural features—such as bedding planes, joint sets, shears, and fault intersections—were captured in the as-built geological model. Face mapping was performed after each blast round and was used to update Q-system rock mass classification values. These classifications (ranging from Q2 to Q5 in various cavern sections) were linked to rock support strategies, with direct implications on safety and construction methods. Discontinuity data and stereographic projections were analyzed to assess the wedge failure potential and inform the rock support model design.

Stress and excavation behavior analysis was performed using numerical simulations based on in situ stress measurements, geological conditions, and staged excavation plans Finite element models were developed to predict the rock mass response to excavation, focusing on deformation patterns, stress redistribution, and potential failure zones (Figure 10a,b). Excavation was carried out in seven benches, and each stage was evaluated against predicted convergence and displacement thresholds. Vibration monitoring using geophones at selected locations validated the impact of drill-and-blast operations. Data from convergence stations and extensometers were fed back into the model to adjust the support classes and evaluate the time-dependent deformation behavior of rock masses. The integrated analysis allowed timely adjustments to excavation sequences and support installation, reducing overbreak and enhancing overall cavern stability.

Figure 10.

(a) Principal stress distribution around the powerhouse cavern, illustrating stress concentration zones in the central pillar and relatively lower stresses along the cavern periphery. (b) Shear strain distribution in the buttress and pillar area between draft tube niches, highlighting deformation patterns. The buttress is shown in red, the powerhouse floor in green, and the siltstone/mudstone interface is indicated by black dashed lines.

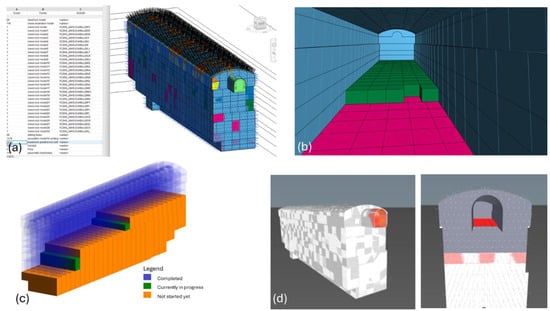

4.4. Application Layer

It enables multidisciplinary collaboration, real-time visualization, simulation, and decision-making by delivering integrated outputs from the data, analysis, and modeling layers in a user-centric environment. This layer transformed static design data into interactive and dynamic construction tools. Using Autodesk platforms like Navisworks and Revit, combined with custom visual programming scripts in Dynamo, the 3D BIM models were enriched with 4D (time) and 5D (cost) components (Figure 11a). The 4D simulation was created by linking construction schedule data with BIM elements using Navisworks Timeliner, enabling the visualization of excavation and support installation over time. For 5D integration, material quantities embedded in the BIM model were associated with unit cost data using Revit and cost management tools, allowing the automated calculation of project costs at each construction stage (Figure 11b–d). This integration supported the dynamic updating of time and budget forecasts as the project evolved. Construction sequences were simulated to align excavation stages, support installations, and logistics operations with the actual project timeline. This simulation capability provided engineers and planners with foresight into potential spatial conflicts, schedule mismatches, and resource bottlenecks.

Figure 11.

(a) Integrated BIM model incorporating rock support, shotcrete, and excavation elements along with quantity take-off data. (b) Figures visually illustrating excavation progress at different construction stages. (c) Excavation model highlighting planned, ongoing, and completed excavation zones. (d) Four-dimensional construction simulation combining spatial and temporal data to represent excavation and support installation over time.

For instance, support system installations such as rock bolts, shotcrete layers, and lattice girders were visualized alongside the excavation stages, allowing for clash detection and sequencing optimization. Through linked metadata and parametric properties, elements within the BIM model could be queried for material quantities, installation status, and compliance with design thresholds. This supported automated quantity take-offs and progress tracking, essential for cost estimation and procurement planning. In addition to that, the framework also ensures continuity into the operation and maintenance stage by retaining detailed construction metadata, including element identifiers, installation timelines, and material specifications. This data is exported in open formats such as the IFC and COBie, which are compatible with facility management platforms. As a result, the as-built BIM models serve as intelligent digital twins that support asset tracking, inspection planning, and long-term maintenance scheduling throughout the infrastructure’s lifecycle.

4.5. Evaluation Metrics

The effectiveness of the proposed multi-model BIM-based framework was systematically evaluated using a combination of quantitative and qualitative metrics. These metrics assessed the framework’s capability to enhance data integration, visualization, simulation, collaboration, and decision-making processes during the design and construction of large underground caverns. The theoretical implementation on the Neelum–Jhelum Powerhouse Cavern Project (NJHPP) served as the validation platform, leveraging real-world geological and engineering data.

The evaluation metrics in Table 2 provide a comprehensive assessment of the proposed multi-model BIM-based framework for underground cavern design and construction. Results demonstrate significant improvements in data centralization, decision-making, visualization, and interdisciplinary collaboration. By integrating geological, structural, and excavation data into a centralized BIM environment, the framework ensured 100% data accessibility, eliminated silos, and enhanced traceability across phases. Six domain-specific models—geology, excavation, structural, support, monitoring, and surface—were unified using an extended IFC schema, allowing synchronized updates and model consistency. Three-dimensional and 4D simulations supported the intuitive understanding of the excavation stages and support systems, aiding planning and stakeholder communication. These visualizations proved valuable in non-technical presentations and project coordination. Quantitative evaluation showed a 92 m shift in cavern alignment to avoid fault zones, improving safety. Iterative design feedback resulted in a 12.4% reduction in rock bolts and 9.8% less shotcrete, contributing to cost savings and construction efficiency. To compute the reported reduction values in shotcrete and rock bolts, a comparative analysis was conducted between the initial support system quantities and the optimized values derived from integrated BIM simulations. Initial support quantities were estimated using conventional empirical methods based on generalized rock mass classifications. These were embedded into the preliminary BIM model. Following detailed wedge stability analysis and finite element stress-deformation simulations, support layouts were iteratively refined in the model. The updated model incorporated geologically adaptive support zones and precise rock classification data obtained during excavation. Quantity take-offs were automatically generated using Revit and Navisworks tools linked to parametric BIM elements. The percentage reduction was then computed by comparing the revised quantities to the initial baseline, validating both material savings and enhanced structural reliability.

Table 2.

Evaluation of the Proposed Multi-Model BIM-Based Framework for Underground Cavern Design and Construction.

The shared BIM model improved cross-team collaboration, reduced revision cycles, and provided a clear audit trail through version control and model tracking. Risk mitigation was strengthened through the early identification of 83% of instability zones, enabling proactive support planning. The early identification of instability zones was achieved through the integration of three key models in the BIM framework: (i) the As-Built Geological Model, which incorporated real-time face-mapping data (e.g., joint orientation, the RQD, and fault zones) and geologist surveys; (ii) the Wedge Stability Analysis Model, which simulated failure mechanisms using discontinuity sets from the geological model; and (iii) the Finite Element Model (FEM), which predicted stress-redistribution zones after each excavation stage. Discrepancies between predicted (FEM) and observed (monitoring data) deformations triggered automated alerts in the BIM environment, flagging high-risk zones. For example, intersecting joint sets with dips >60° were automatically classified as unstable when combined with FEM-predicted stress concentrations exceeding 2 MPa. This multi-model approach reduced false negatives by cross-validating instability signals across datasets, enabling proactive support installation in 37 of 45 critical zones (83%). Expert reviews confirmed the framework’s scalability across other subsurface structures such as tunnels and shafts, supported by its modular IFC extension. Overall, the framework establishes a robust foundation for digital transformation in underground construction, enhancing accuracy, collaboration, and safety while enabling scalable, data-driven project delivery.

5. Conclusions

Constructing large underground caverns involves navigating complex geometries, variable geological conditions, and the integration of multidisciplinary data. This paper presented a comprehensive multi-model BIM-based framework that addresses these challenges by facilitating integrated data flow across the design and construction lifecycle. This research presents a BIM framework specifically designed to address these challenges by extending the IFC schema to include cavern-specific components.

The proposed framework is structured into four interoperable layers: Data, BIM Multi-Modeler, Analysis, and Application, enabling seamless collaboration among geologists, designers, and engineers. It formalizes cavern-specific elements, supports real-time updates from construction feedback, and integrates diverse data types, including geological models, excavation sequences, support systems, and monitoring tools. The framework facilitates the seamless integration of diverse datasets, enhancing real-time decision-making and improving collaboration among stakeholders. The theoretical case study of the Neelum–Jhelum Hydropower Project’s powerhouse cavern demonstrated the framework’s potential to reduce design-to-execution gaps, enhance visualization, and optimize support system usage. Specific outcomes include the following: (i) a 92 m cavern realignment based on wedge and stress analysis, (ii) a 12.4% reduction in rock bolt use, and (iii) a 9.8% reduction in shotcrete volume, highlighting cost and material efficiency through simulation-driven refinements. It illustrates the framework’s capability to model intricate excavation sequences, incorporate real-time geotechnical monitoring, and optimize rock support systems within a cohesive digital environment.

The framework enabled the real-time tracking of the excavation progress, geotechnical updates, and support installation using 4D/5D BIM tools, ensuring timely adaptations to changing geological conditions. Its modular IFC schema extensions further ensure scalability to similar underground infrastructure such as tunnels and shafts. This integrated approach not only enhances construction efficiency and safety but also sets a precedent for future advancements in subterranean infrastructure development. As the underground construction industry moves toward digitalization, the adoption of such domain-specific BIM frameworks will be essential to achieving sustainable, data-driven, and resilient project delivery.

This study has limitations, including the reliance on a theoretical case study and the need for specialized BIM software and skilled personnel for full implementation. However, the research significantly advances digital transformation for underground cavern construction by integrating geological, excavation, and support models into a unified, interoperable framework. Future work should focus on full-scale deployment, integration with IoT-based monitoring systems, and validation through multiple real-world cavern projects. As the underground construction industry continues to evolve, adopting such tailored BIM frameworks will be instrumental in achieving sustainable and resilient infrastructure solutions.

Author Contributions

Conceptualization, A.U., A.S., W.A.T. and E.M.H.I.; Methodology, A.U., A.S. and W.A.T.; Software, A.U. and A.S.; Validation, A.S. and A.U.; Formal analysis, A.U., A.S. and W.A.T.; Investigation, A.U., A.S. and W.A.T.; Resources, A.U. and E.M.H.I.; Data curation, A.U. and A.S.; Writing—original draft preparation, A.U. and A.S.; Writing—review and editing, A.S. and W.A.T.; Visualization, A.U.; Supervision, A.S., W.A.T. and E.M.H.I.; Project administration, A.S. and E.M.H.I.; Funding acquisition, W.A.T. and E.M.H.I. All authors contributed equally to manuscript preparation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia. Grant No. KFU252836.

Data Availability Statement

The dataset used and analyzed during the current study is available from the corresponding authors upon reasonable request. The data are not publicly available due to privacy and confidentiality agreements with the construction site operators involved in the data collection.

Acknowledgments

This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (Grant No. KFU252836). The authors hereby acknowledge the incorporation of AI-assisted instruments, specifically Grammarly (Version 8.932) and ChatGPT (GPT-4o, developed by OpenAI), to augment linguistic precision and rectify grammatical inaccuracies. The authors reviewed and edited the content as needed and take full responsibility for the content of the published article. The utilization of AI is in accordance with the journal’s stipulations regarding transparency and ethical standards in authorship practices.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, N.; Guo, D.; Song, Z.; Zhong, S.; Hu, R. BIM-Based Digital Platform and Risk Management System for Mountain Tunnel Construction. Sci. Rep. 2023, 13, 7585. [Google Scholar] [CrossRef] [PubMed]

- Muhammad Waleed, Q.; Azfar Khan, R.W.; Sharafat, A.; Arshad Tanoli, W.; Zubair, M.U.; Qureshi, H.J. Development of BIM-Based Tunnel Information Modeling Prototype for Tunnel Design. Adv. Civ. Eng. 2024, 2024, 8118578. [Google Scholar] [CrossRef]

- Li, L.; Jiang, Q.; Huang, Q.; Xiang, T.; Liu, J. Advances in Stability Analysis and Optimization Design of Large Underground Caverns under High Geostress Condition. Deep. Resour. Eng. 2024, 1, 100113. [Google Scholar] [CrossRef]

- Huang, M. BIM for Underground Stations: Supporting Decision Making on Lifecycle Stages. Ph.D. Thesis, Monash University, Victoria, Australia, 2022. [Google Scholar]

- Lee, S.; Sharafat, A.; Kim, I.S.; Seo, J. Development and Assessment of an Intelligent Compaction System for Compaction Quality Monitoring, Assurance, and Management. Appl. Sci. 2022, 12, 6855. [Google Scholar] [CrossRef]

- Cerovsek, T. A Review and Outlook for a ‘Building Information Model’(BIM): A Multi-Standpoint Framework for Technological Development. Adv. Eng. Inform. 2011, 25, 224–244. [Google Scholar] [CrossRef]

- Latif, K.; Sharafat, A.; Park, S.; Seo, J. Digital Twin-Based Hybrid Approach to Visualize the Performance of TBM. In Proceedings of the KSCE, Busan, Republic of Korea, 19 October 2022; pp. 3–4. [Google Scholar]

- Bradley, A.; Li, L.; Dunn, R.; Bradley, M.A.; Li, H.; Lark, R.; Dunn, S. BIM for Infrastructure: An Overall Review and Constructor Perspective. Autom. Constr. 2016, 71, 139–152. [Google Scholar] [CrossRef]

- Fabozzi, S.; Biancardo, S.A.; Veropalumbo, R.; Bilotta, E. I-BIM Based Approach for Geotechnical and Numerical Modelling of a Conventional Tunnel Excavation. Tunn. Undergr. Space Technol. 2021, 108, 103723. [Google Scholar] [CrossRef]

- Marzouk, M.; Othman, A. Planning Utility Infrastructure Requirements for Smart Cities Using the Integration between BIM and GIS. Sustain. Cities Soc. 2020, 57, 102120. [Google Scholar] [CrossRef]

- Wang, M.; Yin, X. Construction and Maintenance of Urban Underground Infrastructure with Digital Technologies. Autom. Constr. 2022, 141, 104464. [Google Scholar] [CrossRef]

- Li, H.; Chen, W.Z.; Tan, X.J.; Chen, E.Y. Digital Design and Stability Simulation for Large Underground Powerhouse Caverns with Parametric Model Based on BIM-Based Framework. Tunn. Undergr. Space Technol. 2022, 123, 104375. [Google Scholar] [CrossRef]

- Kontothanasis, P.; Krommyda, V.; Roussos, N. BIM and Advanced Computer-Based Tools for the Design and Construction of Underground Structures and Tunnels. In Tunnel Engineering—Selected Topics; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Sharafat, A.; Latif, K.; Park, S.; Seo, J. Digital Twin-Driven Optimization of Blast Design for Underground Construction. In Proceedings of the KSCE, Yeosu, Republic of Korea, 19 October 2022; pp. 1–2. [Google Scholar]

- Sharafat, A.; Tanoli, W.A.; Zubair, M.U.; Mazher, K.M. Digital Twin-Driven Stability Optimization Framework for Large Underground Caverns. Appl. Sci. 2025, 15, 4481. [Google Scholar] [CrossRef]

- Borrmann, A.; Rives, M.; Muhic, S.; Wikström, L.; Weil, J. The IFC-Tunnel Project–Extending the IFC Standard to Enable High-Quality Exchange of Tunnel Information Models. In Advances in Information Technology in Civil and Building Engineering; Springer: Cham, Switzerland, 2022; pp. 487–516. [Google Scholar] [CrossRef]

- Muir, J.; Mather, D. Preparing a Tunnelling Professional for the Future. In Proceedings of the 16th Australasian Tunnelling Conference, Sydney, NSW, Australia, 30 October–1 November 2017. [Google Scholar]

- Zou, Y.; Dong, X.; Feng, T.; Xu, Z.; He, H.; Wu, Z. Research on Spatial Prediction Technology for Mitigating Tunnel Inrush Disasters under Complex Geological Conditions in China’s Hengduan Mountain Range. Sci. Rep. 2025, 15, 1850. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wang, T.; Chen, H. Theoretical and Technological Challenges of Deep Underground Energy Storage in China. Engineering 2023, 25, 168–181. [Google Scholar] [CrossRef]

- Sadkhan, R.A.; Al-Mudhafar, W.J. Key Aspects of Underground Hydrogen Storage in Depleted Hydrocarbon Reservoirs and Saline Aquifers: A Review and Understanding. Energy Geosci. 2024, 5, 100339. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, X.; Fan, J.; Li, Y.; Wang, L. Evaluation of Potential for Salt Cavern Gas Storage and Integration of Brine Extraction: Cavern Utilization, Yangtze River Delta Region. Nat. Resour. Res. 2020, 29, 3275–3290. [Google Scholar] [CrossRef]

- Qin, B.; Li, H.; Wang, Z.; Jiang, Y.; Lu, D.; Du, X.; Space, Q.Q.-U. New Framework of Low-Carbon City Development of China: Underground Space Based Integrated Energy Systems. Undergr. Space 2024, 14, 300–318. [Google Scholar] [CrossRef]