Performance Limits of Hydraulic-Binder Stabilization for Dredged Sediments: Comparative Case Studies

Abstract

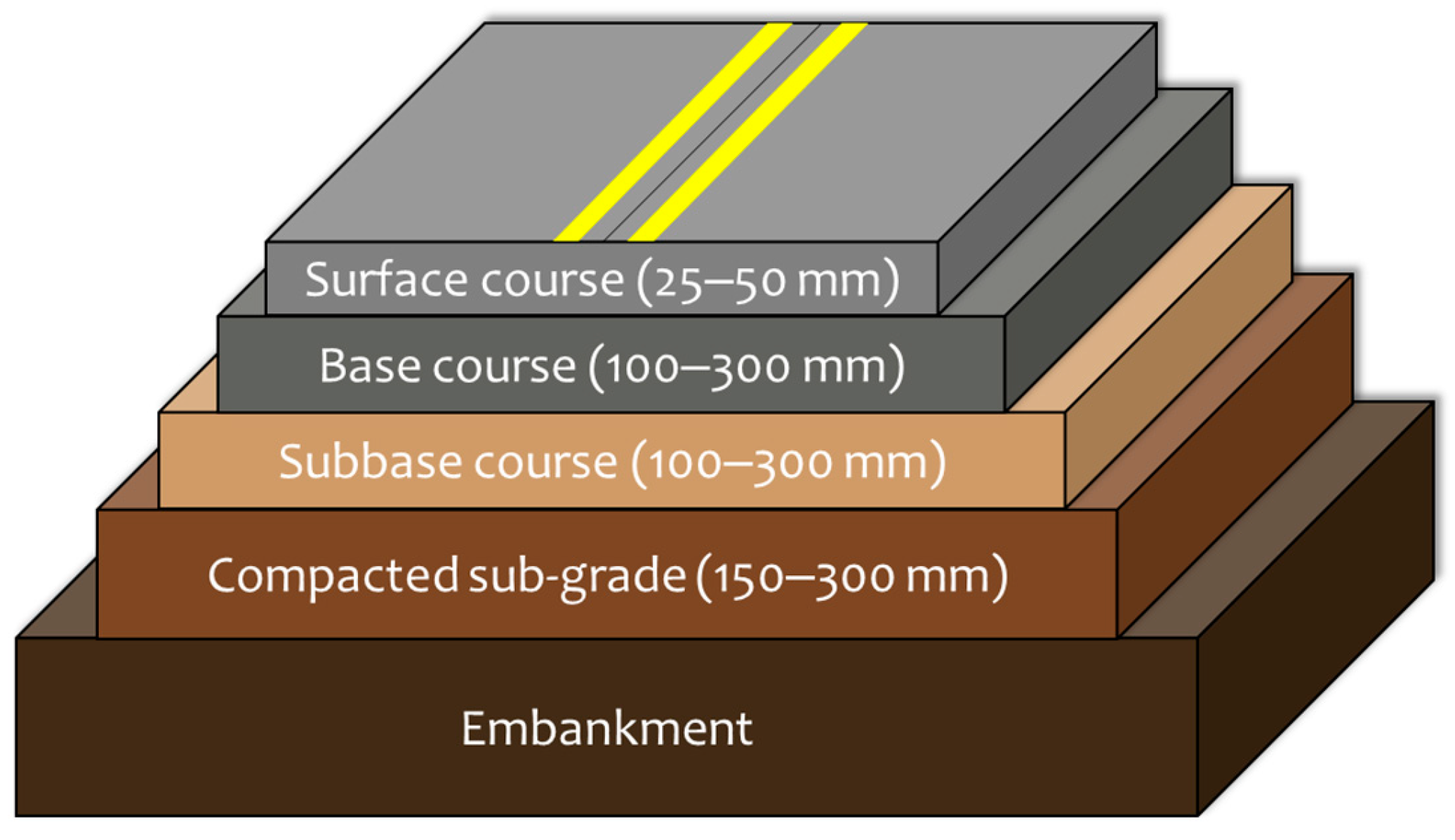

1. Introduction

2. Research Significance

3. Materials and Methods

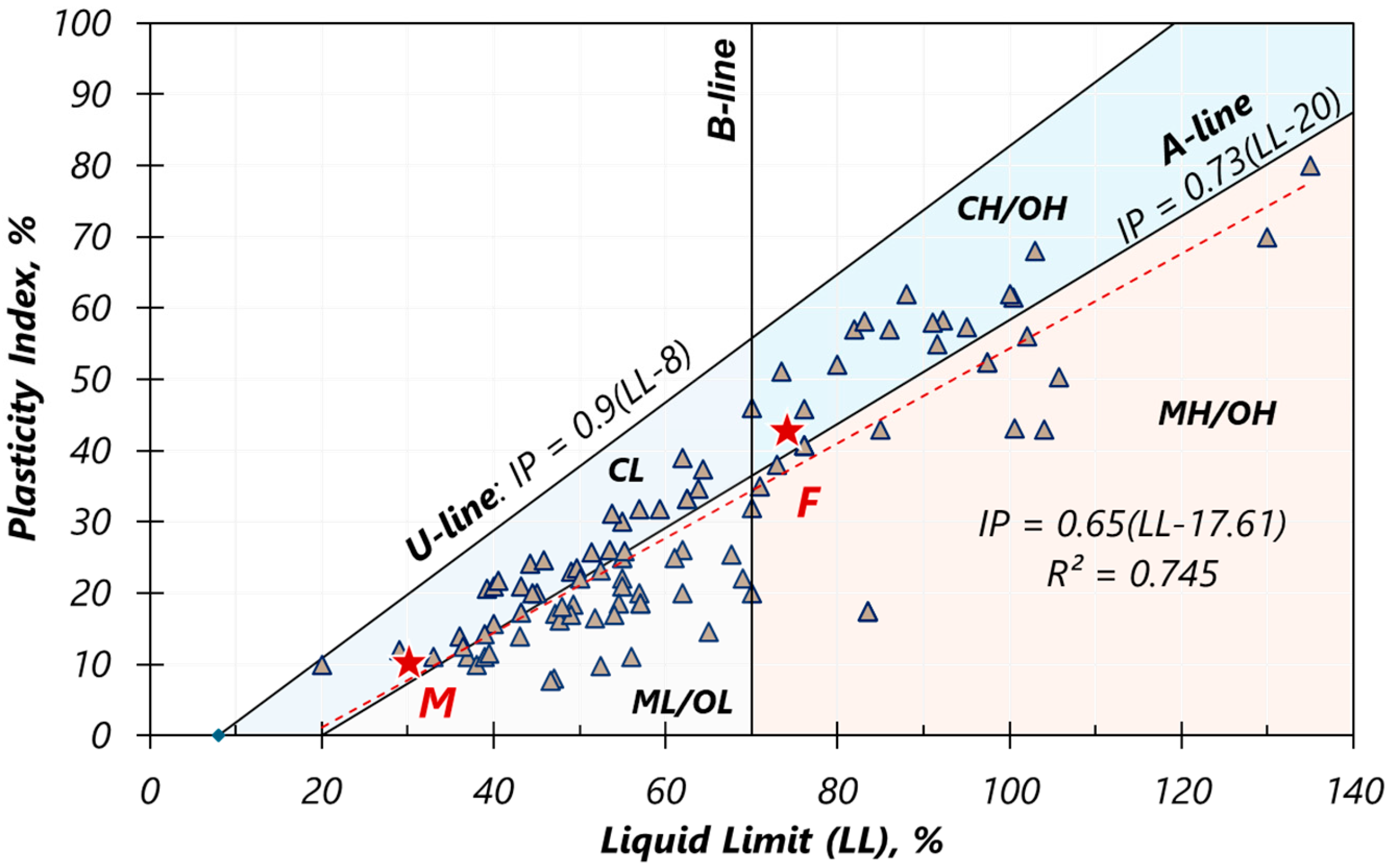

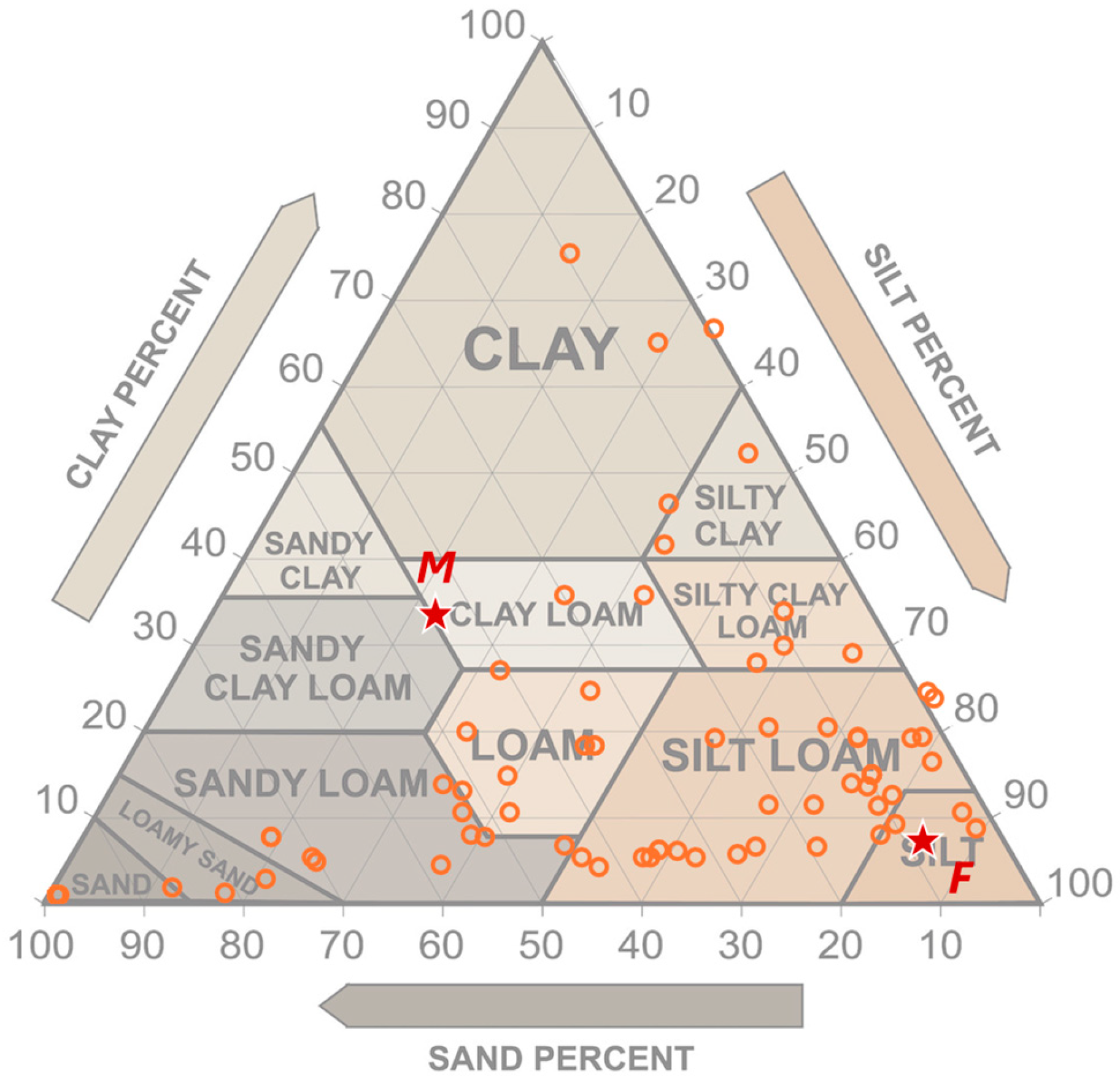

3.1. Dredged Sediments

3.2. Sample Preparation and Compaction Testing

3.3. Specimen Preparation for Strength Testing

3.4. Mechanical Tests and Criteria

4. Results and Discussion

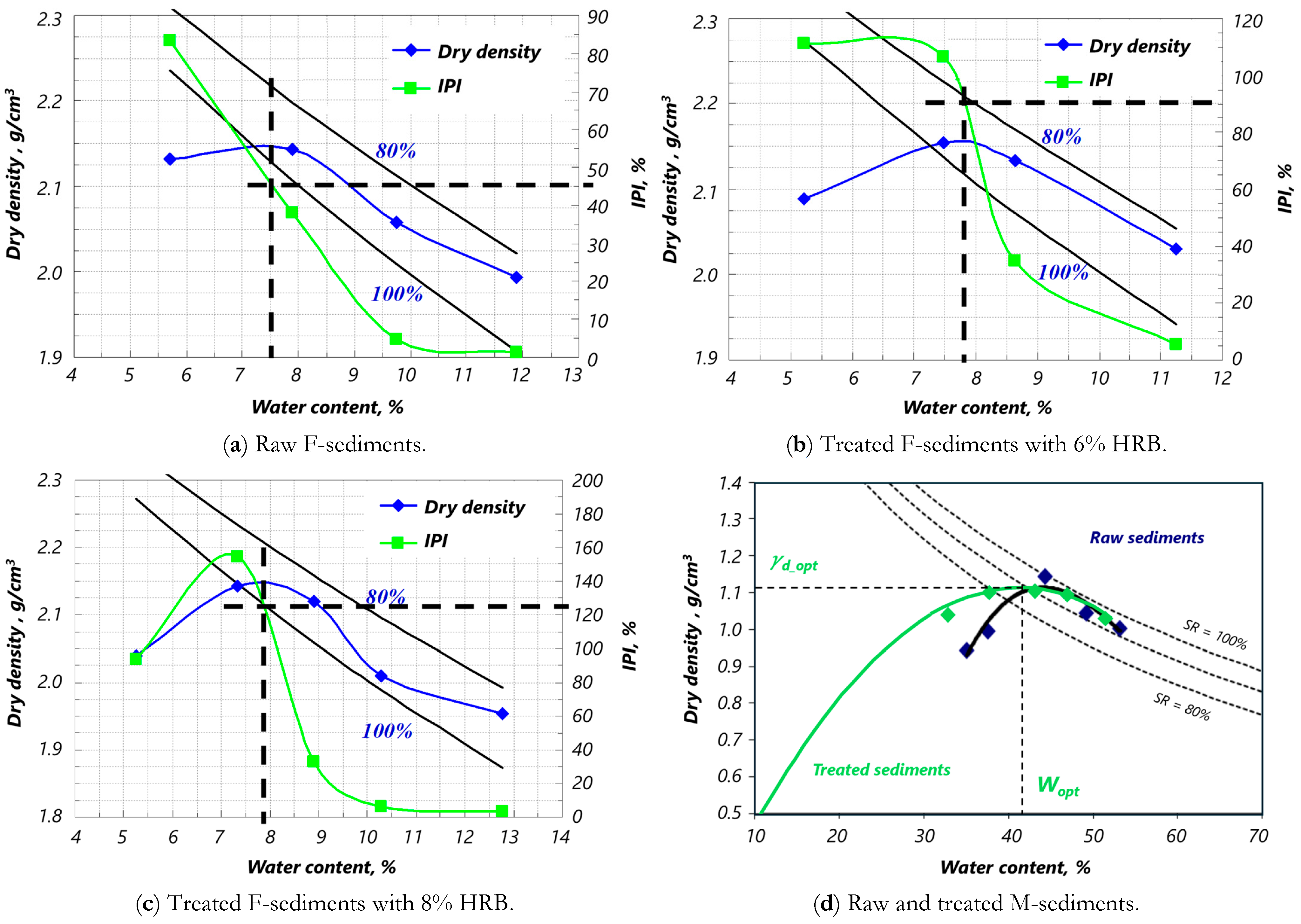

4.1. Compaction Behavior and Immediate Bearing Capacity

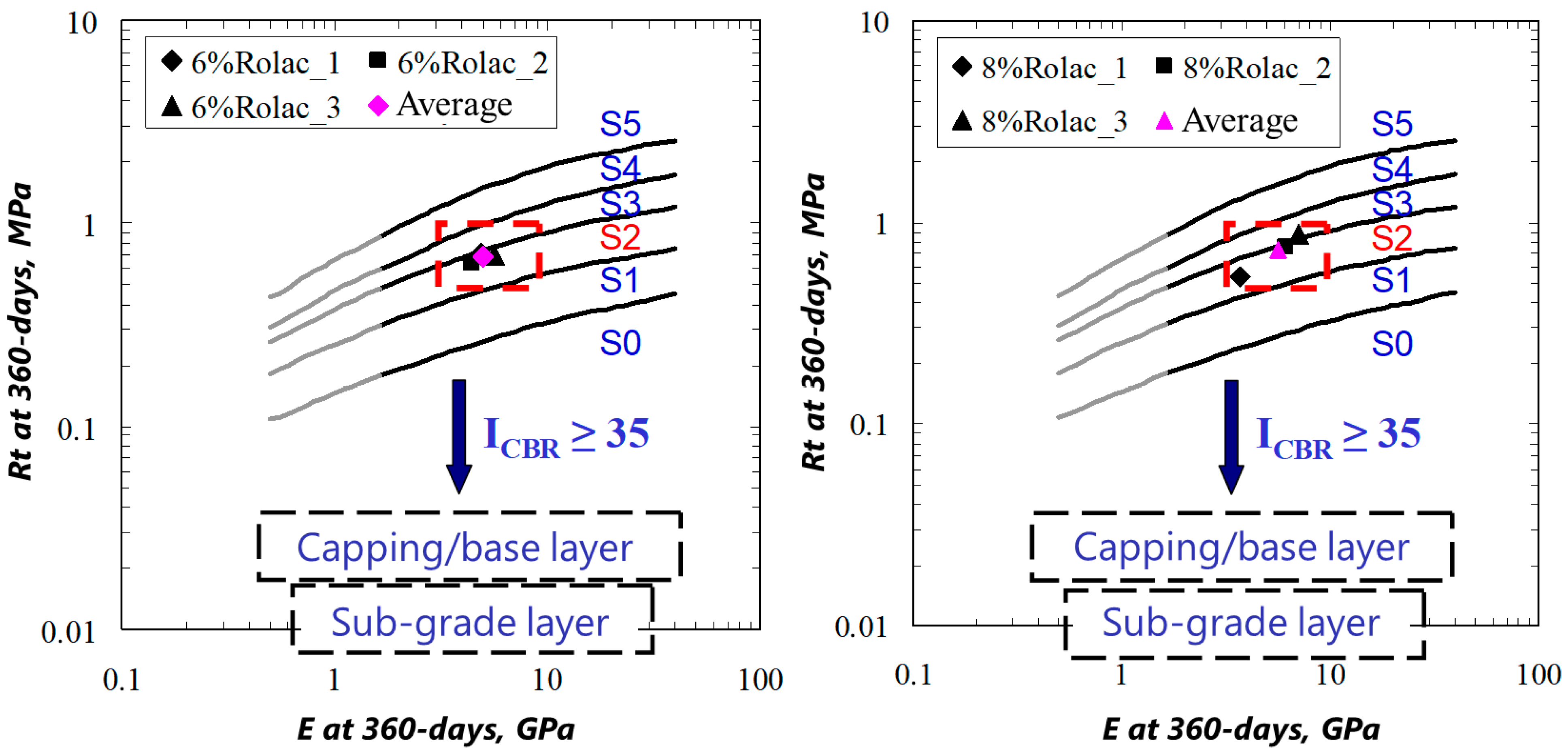

4.2. Strength Development and Criteria Compliance

4.3. Comparison with Other Studies and Sustainability Aspects

4.4. Field Realism, Economics and Constructability

- Uniformity. Laboratory mixing yields near-perfect binder dispersion; field re-mixers are less efficient. The SETRA guide therefore applies a 0.8 in situ factor to lab UCS. For the 6% HRB mix (UCS at 28-d ≈ 4.7 MPa), the “design UCS” is 3.8 MPa—still above the 1 MPa trafficability threshold. Three UCS cores per 1000 m2 after 7-days are recommended to confirm compliance.

- Cost-optimization. Material pricing (2025 French averages: HRB = 170 EUR/t, DS handling = 11 EUR/m3) shows that raising the dose from 6% to 8% increases layer cost by 18 EUR/m3 yet boosts IBI only from 90% to 125%. Designers should therefore select the lowest dose that clears LCPC Class S2 (IBI ≥ 80%, UCS ≥ 3 MPa) with a 10% margin.

- Pavement response. Mechanistic–empirical analysis indicates that a subgrade modulus of 900 MPa under a 2800 MPa unbound base yields vertical surface deflection < 350 µm and IRI < 2.3 m/km after 20 years—well within French PF 3 limits. Ride comfort is therefore not jeopardized.

- Site processing. Two French pilots processed 60,000 m3 and 85,000 m3 of DS by windrowing for 7–10 days (to w ≈ 15%) followed by trommel-screening (<20 mm) at ≈4000 m3/day. All-in processing cost was 2.3 EUR/m3, confirming feasibility for medium- to large-scale road-platform works.

5. Conclusions

- DS-M—despite 3% lime + 6% cement—remained far below the IBI threshold (max = 8%), demonstrating that highly plastic, organic-rich dredging falls outside the cost-effective application window for direct soil–cement stabilization.

- Binder stabilization greatly enhanced the sediment’s properties: A 6–8% addition of road binder roughly doubled to tripled the IBI (from ~45% to >120%) and produced UCS above 4–5 MPa at 28-d. ITS also increased to ~0.4–0.5 MPa. These improvements satisfy all criteria for use in roadbed layers (subgrade or capping layers), including trafficability, water resistance, and frost durability.

- The optimum binder content appears to be around 6%, balancing performance and economy. While an 8% binder yielded higher strength and IBI, the incremental benefit may not be necessary for typical subgrade applications. Even at 6%, the treated DS achieved mechanical class S2, meaning it can serve for foundation layers supporting pavements. The material can be classified as a PF3 platform when properly compacted to ~30 cm thickness, depending on the underlying soil support.

- Comparison with standards and other studies confirms the validity of the approach. The treated DS meets French roadway standards (LCPC-SETRA) and is in line with international findings on soil–binder mixtures. It underscores that dredged fines can be turned into a construction asset with standard stabilization techniques. Minor variations in mix design (e.g., inclusion of FA or slag) could further optimize performance or cost if needed.

- Sustainability impact: Reusing this DS in road construction would divert a substantial quantity of material from waste disposal. It reduces the demand for virgin borrow soils and the environmental disturbances associated with their extraction. Moreover, if the project site is near the dredging location, it cuts down on haulage distance, lowering carbon emissions. The successful application here advocates for the broader adoption of dredge material recycling in coastal regions.

- Future considerations: Prior to field implementation, it is recommended to perform leaching tests to ensure that any contaminants in the DS are securely immobilized by the binder (meeting environmental regulations for reuse). Additionally, a field pilot section would be valuable to monitor the in situ compaction, curing, and performance under actual weather and loading conditions. Long-term monitoring would confirm the durability of the stabilized layer, especially through seasonal cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Failure Mechanisms for DS-M

- High OM inhibition. DS-M contains 17 wt.% OM—more than twice the 7 wt.% limit above which lime fixation is notoriously difficult [46,85]. Humic and fulvic acids preferentially consume Ca(OH)2, preventing an early pH rise and delaying reactions. A stoichiometric estimate (0.8 g CaO per gram of organic carbon) indicates that ≈9 wt.% lime would be needed merely to neutralize the organic acids, three times the dose used here.

- Excessive clay activity and surface area. Although its (MBV = 2.4 g/100 g) appears moderate, 80% of particles are finer than 80 µm. Converting MBV to specific surface (~50 m2/g) yields a binder-to-surface ratio of only 0.15 g binder m−2, compared with 0.46 g/m2 for DS-F. The limited Ca2+ supply could not satisfy the cation-exchange demand, so flocculation and particle bonding remained weak.

- Dilutive w/b ratio. Even at the optimum moisture (≈44%), the paste w/b ratio exceeded 3.5. Hydration products thus formed as isolated nodules that did not percolate into a continuous skeleton, leaving the DS’s original structure essentially intact.

- Low attainable dry density. The organic fraction lowers the specific gravity, capping the maximum dry density despite Modified-Proctor energy. The resulting loose matrix collapses readily under penetration, explaining the persistently low IBI.

References

- Safhi, A.e.M.; Rivard, P.; Yahia, A.; Benzerzour, M.; Khayat, K.H. Valorization of Dredged Sediments in Self-Consolidating Concrete: Fresh, Hardened, and Microstructural Properties. J. Clean. Prod. 2020, 263, 121472. [Google Scholar] [CrossRef]

- Amar, M.; Benzerzour, M.; Kleib, J.; Abriak, N.-E. From Dredged Sediment to Supplementary Cementitious Material: Characterization, Treatment, and Reuse. Int. J. Sediment Res. 2021, 36, 92–109. [Google Scholar] [CrossRef]

- Safhi, A.e.M.; Mejjad, N.; El FadilI, H.; Bortali, M. Dredged Materials in Morocco: Current Practices, Policies, and Roadmap for Sustainable Management. Case Stud. Constr. Mater. 2024, 20, e03045. [Google Scholar] [CrossRef]

- Dorleon, G.; Rigaud, S.; Techer, I. Management of Dredged Marine Sediments in Southern France: Main Keys to Large-Scale Beneficial Re-Use. Environ. Sci. Pollut. Res. 2024, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Crocetti, P.; González-Camejo, J.; Li, K.; Foglia, A.; Eusebi, A.L.; Fatone, F. An Overview of Operations and Processes for Circular Management of Dredged Sediments. Waste Manag. 2022, 146, 20–35. [Google Scholar] [CrossRef] [PubMed]

- Casper, S.T. Regulatory Frameworks for Sediment Management. In Sustainable Management of Sediment Resources; Sediment Management at the River Basin Scale; Owens, P.N., Ed.; Elsevier: Amsterdam, The Netherlands, 2008; Volume 4, pp. 55–81. [Google Scholar]

- Wang, Y.-S.; Lim, J.-Y.; Lim, S.; Lee, B.-S.; Lin, R.; Wang, X.-Y. Alternative Application of Wollastonite in Limestone Calcined Hwangtoh Clay Cement (LC3) Systems: Engineering Properties, Microanalysis and Resistance to Sulfuric Acid Attack. Constr. Build. Mater. 2025, 475, 141214. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Meng, L.-Y.; Chen, L.; Wang, X.-Y. An Innovative Strategy for CO2 Conversion and Utilization: Semi-Wet Carbonation Pretreatment of Wollastonite to Prepare Carbon-Fixing Products and Produce LC3. Cem. Concr. Compos. 2025, 160, 106050. [Google Scholar] [CrossRef]

- Ma, J.; Sun, J.; Yu, Z.; Hou, G.; Xia, B. A Comprehensive Review of Dredged Marine Sediments -Multiple Roles of Utilization in Cement-Based Materials and Construction Products. Mar. Pollut. Bull. 2025, 217, 118079. [Google Scholar] [CrossRef]

- Safhi, A.E.M. Dredged Materials as Construction Resource—Up-to-Date Review. In Valorization of Dredged Sediments as Sustainable Construction Resources; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-00-331555-1. [Google Scholar]

- Bouchikhi, A.; Safhi, A.e.M.; Rivard, P.; Snellings, R.; Abriak, N.-E. Fluvial Sediments as SCMs: Characterization, Pozzolanic Performance, and Optimization of Equivalent Binder. J. Mater. Civ. Eng. 2022, 34, 04021430. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Amar, M.; Arroug, L.; Safhi, A.e.M.; Haddaji, Y. Characterizing Nano-Indentation and Microstructural Properties of Mine Tailings-Based Geopolymers. Case Stud. Constr. Mater. 2024, 21, e03899. [Google Scholar] [CrossRef]

- Bouzar, B.; Mamindy-Pajany, Y.; Hurel, C. Innovative Reuse of Fly Ashes for Treatment of a Contaminated River Sediment: Synthesis of Layered Double Hydroxides (LDH) and Chemical Performance Assessments. Waste Biomass Valorization 2023, 14, 3923–3945. [Google Scholar] [CrossRef]

- Wan, X.; Ding, J.; Mou, C.; Wang, J.; Zhang, S. Alkali-Activated Red Mud in Stabilizing Marine Dredged Clay with Low Amount of Cement. Eur. J. Environ. Civ. Eng. 2023, 27, 4598–4612. [Google Scholar] [CrossRef]

- Chompoorat, T.; Thanawong, K.; Likitlersuang, S. Swell-Shrink Behaviour of Cement with Fly Ash-Stabilised Lakebed Sediment. Bull. Eng. Geol. Environ. 2021, 80, 2617–2628. [Google Scholar] [CrossRef]

- Chompoorat, T.; Likitlersuang, S.; Thepumong, T.; Tanapalungkorn, W.; Jamsawang, P.; Jongpradist, P. Solidification of Sediments Deposited in Reservoirs with Cement and Fly Ash for Road Construction. Int. J. Geosynth. Ground Eng. 2021, 7, 85. [Google Scholar] [CrossRef]

- Chompoorat, T.; Thepumong, T.; Taesinlapachai, S.; Likitlersuang, S. Repurposing of Stabilised Dredged Lakebed Sediment in Road Base Construction. J. Soils Sediments 2021, 21, 2719–2730. [Google Scholar] [CrossRef]

- Zentar, R.; Wang, H.; Wang, D. Comparative Study of Stabilization/Solidification of Dredged Sediments with Ordinary Portland Cement and Calcium Sulfo-Aluminate Cement in the Framework of Valorization in Road Construction Material. Constr. Build. Mater. 2021, 279, 122447. [Google Scholar] [CrossRef]

- Bazne, M.O.A.; Howard, I.L.; Vahedifard, F. Stabilized Very High–Moisture Dredged Soil: Relative Behavior of Portland-Limestone Cement and Ordinary Portland Cement. J. Mater. Civ. Eng. 2017, 29, 04017110. [Google Scholar] [CrossRef]

- Yoobanpot, N.; Jamsawang, P.; Poorahong, H.; Jongpradist, P.; Likitlersuang, S. Multiscale Laboratory Investigation of the Mechanical and Microstructural Properties of Dredged Sediments Stabilized with Cement and Fly Ash. Eng. Geol. 2020, 267, 105491. [Google Scholar] [CrossRef]

- Brahim, M.; Ndiaye, K.; Aggoun, S.; Maherzi, W. Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder. Buildings 2022, 12, 419. [Google Scholar] [CrossRef]

- Wang, D.X.; Abriak, N.E.; Zentar, R.; Xu, W. Solidification/Stabilization of Dredged Marine Sediments for Road Construction. Environ. Technol. 2012, 33, 95–101. [Google Scholar] [CrossRef]

- Wareham, D.G.; Mackechnie, J.R. Solidification of New Zealand Harbor Sediments Using Cementitious Materials. J. Mater. Civ. Eng. 2006, 18, 311–315. [Google Scholar] [CrossRef]

- Segui, P.; Safhi, A.e.M.; Amrani, M.; Benzaazoua, M. Mining Wastes as Road Construction Material: A Review. Minerals 2023, 13, 90. [Google Scholar] [CrossRef]

- Safhi, A.E.M. (Ed.) Valorization of Dredged Sediments as Sustainable Construction Resources; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-00-331555-1. [Google Scholar]

- AFNOR NF P94-050 ; Sols: Reconnaissance et Essais–Détermination de La Teneur En Eau Pondérale Des Matériaux–Méthode Par Étuvage. Afnor Editions: La Plaine Saint-Denis, France, 1995.

- AFNOR XP P94-041; Soil: Investigation and Testing. Granulometric Description. Wet Sieving Method. Afnor Editions: La Plaine Saint-Denis, France, 1995.

- AFNOR XP P94-047; Soils: Investigation and Testing. Determination of the Organic Matter Content. Ignition Method. Afnor Editions: La Plaine Saint-Denis, France, 1998.

- AFNOR NF P94-068; Soils:Investigation and Testing. Measuring of the Methylene Blue Adsorption Capacity of à Rocky Soil. Determination of the Methylene Blue of à Soil by Means of the Stain Test. Afnor Editions: La Plaine Saint-Denis, France, 1998.

- AFNOR NF EN ISO 17892-3; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 3: Determination of Particle Density. Afnor Editions: La Plaine Saint-Denis, France, 2015.

- ISO 17892-12; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Liquid and Plastic Limits. ISO: Geneva, Switzerland, 2018.

- Zhang, C.L.; Liu, Q.S.; Liu, J.B. Field Plate Load Tests on Dredged Sediment Dump Pond with Cement Solidified Crust Above. Adv. Mater. Res. 2011, 255–260, 2751–2755. [Google Scholar] [CrossRef]

- He, X.; Chen, Y.; Wan, Y.; Liu, L.; Xue, Q. Effect of Curing Stress on Compression Behavior of Cement-Treated Dredged Sediment. Int. J. Geomech. 2020, 20, 04020204. [Google Scholar] [CrossRef]

- Zentar, R.; Dubois, V.; Abriak, N.E. Mechanical Behaviour and Environmental Impacts of a Test Road Built with Marine Dredged Sediments. Resour. Conserv. Recycl. 2008, 52, 947–954. [Google Scholar] [CrossRef]

- Dubois, V.; Abriak, N.E.; Zentar, R.; Ballivy, G. The Use of Marine Sediments as a Pavement Base Material. Waste Manag. 2009, 29, 774–782. [Google Scholar] [CrossRef]

- Zentar, R.; Abriak, N.-E.; Dubois, V.; Miraoui, M. Beneficial Use of Dredged Sediments in Public Works. Environ. Technol. 2009, 30, 841–847. [Google Scholar] [CrossRef]

- Bourabah, M.A.; Abou-Bekr, N.; Taibi, S. Geotechnical Characterization of Dredging Sediments for Valorization in Road Embankments: Case of the Cheurfas Dam (Algeria). In Proceedings of the GeoFlorida 2010, American Society of Civil Engineers, Orlando, FL, USA, 15 February 2010; pp. 2212–2221. [Google Scholar]

- Miraoui, M.; Zentar, R.; Abriak, N.-E. Road Material Basis in Dredged Sediment and Basic Oxygen Furnace Steel Slag. Constr. Build. Mater. 2012, 30, 309–319. [Google Scholar] [CrossRef]

- Zentar, R.; Wang, D.; Abriak, N.E.; Benzerzour, M.; Chen, W. Utilization of Siliceous–Aluminous Fly Ash and Cement for Solidification of Marine Sediments. Constr. Build. Mater. 2012, 35, 856–863. [Google Scholar] [CrossRef]

- Wang, D.; Abriak, N.E.; Zentar, R. Strength and Deformation Properties of Dunkirk Marine Sediments Solidified with Cement, Lime and Fly Ash. Eng. Geol. 2013, 166, 90–99. [Google Scholar] [CrossRef]

- Wang, D.; Abriak, N.E.; Zentar, R. Co-Valorisation of Dunkirk Dredged Sediments and Siliceous–Aluminous Fly Ash Using Lime. Road Mater. Pavement Des. 2013, 14, 415–431. [Google Scholar] [CrossRef]

- Tang, I.Y.; Yan, D.Y.S.; Lo, I.M.C.; Liu, T. Pulverized Fuel Ash Solidification/Stabilization of Waste: Comparison between Beneficial Reuse of Contaminated Marine Mud and Sediment. J. Environ. Eng. Landsc. Manag. 2015, 23, 202–210. [Google Scholar] [CrossRef]

- Le Guern, M.; Dang, T.A.; Boutouil, M. Implementation and Experimental Monitoring of a Subgrade Road Layer Based on Treated Marine Sediments. J. Soils Sediments 2017, 17, 1815–1822. [Google Scholar] [CrossRef]

- Kasmi, A.; Abriak, N.-E.; Benzerzour, M.; Azrar, H. Environmental Impact and Mechanical Behavior Study of Experimental Road Made with River Sediments: Recycling of River Sediments in Road Construction. J. Mater. Cycles Waste Manag. 2017, 19, 1405–1414. [Google Scholar] [CrossRef]

- Maherzi, W.; Benzerzour, M.; Mamindy-Pajany, Y.; van Veen, E.; Boutouil, M.; Abriak, N.E. Beneficial Reuse of Brest-Harbor (France)-Dredged Sediment as Alternative Material in Road Building: Laboratory Investigations. Environ. Technol. 2018, 39, 566–580. [Google Scholar] [CrossRef]

- Serbah, B.; Abou-Bekr, N.; Bouchemella, S.; Eid, J.; Taibi, S. Dredged Sediments Valorisation in Compressed Earth Blocks: Suction and Water Content Effect on Their Mechanical Properties. Constr. Build. Mater. 2018, 158, 503–515. [Google Scholar] [CrossRef]

- Hamouche, F.; Zentar, R. Effects of Organic Matter on Mechanical Properties of Dredged Sediments for Beneficial Use in Road Construction. Environ. Technol. 2020, 41, 296–308. [Google Scholar] [CrossRef]

- Ho, T.-O.; Tsang, D.C.W.; Chen, W.-B.; Yin, J.-H. Evaluating the Environmental Impact of Contaminated Sediment Column Stabilized by Deep Cement Mixing. Chemosphere 2020, 261, 127755. [Google Scholar] [CrossRef]

- Furlan, A.P.; Razakamanantsoa, A.; Ranaivomanana, H.; Amiri, O.; Levacher, D.; Deneele, D. Effect of Fly Ash on Microstructural and Resistance Characteristics of Dredged Sediment Stabilized with Lime and Cement. Constr. Build. Mater. 2021, 272, 121637. [Google Scholar] [CrossRef]

- Mkahal, Z.; Mamindy-Pajany, Y.; Maherzii, W.; Abriak, N.-E. Recycling of Mineral Solid Wastes in Backfill Road Materials: Technical and Environmental Investigations. Waste Biomass Valorization 2021, 13, 667–687. [Google Scholar] [CrossRef]

- Slama, A.B.; Feki, N.; Levacher, D.; Zairi, M. Valorization of Harbor Dredged Sediment Activated with Blast Furnace Slag in Road Layers. Int. J. Sediment Res. 2021, 36, 127–135. [Google Scholar] [CrossRef]

- Tsuchida, T.; Porbaha, A.; Yamane, N. Development of a Geomaterial from Dredged Bay Mud. J. Mater. Civ. Eng. 2001, 13, 152–160. [Google Scholar] [CrossRef]

- Salehi, M.; Sivakugan, N. Effects of Lime-Clay Modification on the Consolidation Behavior of the Dredged Mud. J. Waterw. Port Coast. Ocean Eng. 2009, 135, 251–258. [Google Scholar] [CrossRef]

- Saussaye, L.; van Veen, E.; Rollinson, G.; Boutouil, M.; Andersen, J.; Coggan, J. Geotechnical and Mineralogical Characterisations of Marine-Dredged Sediments before and after Stabilisation to Optimise Their Use as a Road Material. Environ. Technol. 2017, 38, 3034–3046. [Google Scholar] [CrossRef]

- Wang, D.; Zentar, R.; Abriak, N.E. Temperature-Accelerated Strength Development in Stabilized Marine Soils as Road Construction Materials. J. Mater. Civ. Eng. 2017, 29, 04016281. [Google Scholar] [CrossRef]

- Maher, A.; Bennert, T.; Jafari, F.; Douglas, W.S.; Gucunski, N. Geotechnical Properties of Stabilized Dredged Material from New York-New Jersey Harbor. Transp. Res. Rec. 2004, 1874, 86–96. [Google Scholar] [CrossRef]

- Wang, D.X.; Wang, H.X.; Chen, W.Z. Reinforcement Mechanism of Cement/Lime-Fly Ash Treated Sediments as Road Construction Materials. Appl. Mech. Mater. 2011, 99–100, 924–927. [Google Scholar] [CrossRef]

- Zoubir, W.; Harichane, K.; Ghrici, M. Effect of Lime and Natural Pozzolana on Dredged Sludge Engineering Properties. Electron. J. Geotech. Eng. 2013, 18 C, 589–600. [Google Scholar]

- Azhar, A.; Chan, C.M. Strength Development in Cement Admixed Fine-Grained Dredged Marine Soils. Appl. Mech. Mater. 2015, 802, 272–276. [Google Scholar] [CrossRef]

- Larouci, A.; Yassine, S.; Laïd, L.; Amar, B. Improvement of the Mechanical Performance of Fergoug Dam Sediments Treated for Reuse in Road Engineering. MATEC Web Conf. 2018, 149, 01031. [Google Scholar] [CrossRef][Green Version]

- Jamsawang, P.; Charoensil, S.; Namjan, T.; Jongpradist, P.; Likitlersuang, S. Mechanical and Microstructural Properties of Dredged Sediments Treated with Cement and Fly Ash for Use as Road Materials. Road Mater. Pavement Des. 2020, 22, 2498–2522. [Google Scholar] [CrossRef]

- Poorahong, H.; Wongvatana, N.; Jamsawang, P.; Lueprasert, K.; Tantayopin, K.; Chen, X.B. Unconfined Compressive and Splitting Tensile Strength of Dredged Sediments Stabilized with Cement and Fly Ash. Key Eng. Mater. 2020, 856, 367–375. [Google Scholar] [CrossRef]

- Larouci, A.; Senhadji, Y.; Laoufi, L.; Benazzouk, A. Valorisation of Natural Waste: Dam Sludge for Road Construction. NEPT 2020, 19, 1075–1083. [Google Scholar] [CrossRef]

- Gueffaf, N.; Rabehi, B.; Boumchedda, K. Recycling Dam Sediments for the Elaboration of Stabilized Blocks. Int. J. Eng. Res. Afr. 2020, 50, 131–144. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, Y.; Chen, G.; Li, B. Characterization and Prediction for the Strength Development of Cement Stabilized Dredged Sediment. Mar. Georesources Geotechnol. 2021, 39, 1015–1024. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Li, D. Effect of Nano-Modification and Fiber-Reinforcement on Mechanical Behavior of Cement-Stabilized Dredged Sediment. Mar. Georesources Geotechnol. 2021, 40, 1–17. [Google Scholar] [CrossRef]

- Zhou, Y.; Cai, G.; Cheeseman, C.; Li, J.; Poon, C.S. Sewage Sludge Ash-Incorporated Stabilisation/Solidification for Recycling and Remediation of Marine Sediments. J. Environ. Manag. 2022, 301, 113877. [Google Scholar] [CrossRef]

- Grubb, D.G.; Malasavage, N.E.; Smith, C.J.; Chrysochoou, M. Stabilized Dredged Material. II: Geomechanical Behavior. J. Geotech. Geoenviron. Eng. 2010, 136, 1025–1036. [Google Scholar] [CrossRef]

- Kim, Y.T.; Ahn, J.; Han, W.J.; Gabr, M.A. Experimental Evaluation of Strength Characteristics of Stabilized Dredged Soil. J. Mater. Civ. Eng. 2010, 22, 539–544. [Google Scholar] [CrossRef]

- Kasmi, A.; Abriak, N.-E.; Benzerzour, M.; Azrar, H. Effect of Dewatering by the Addition of Flocculation Aid on Treated River Sediments for Valorization in Road Construction. Waste Biomass Valorization 2017, 8, 585–597. [Google Scholar] [CrossRef]

- Yu, H.; Yin, J.; Soleimanbeigi, A.; Likos, W.J. Effects of Curing Time and Fly Ash Content on Properties of Stabilized Dredged Material. J. Mater. Civ. Eng. 2017, 29, 04017199. [Google Scholar] [CrossRef]

- Zelleg, M.; Said, I.; Missaoui, A.; Lafhaj, Z.; Hamdi, E. Dredged Marine Sediment as Raw Material in Civil Engineering Applications. In Proceedings of the Contemporary Issues in Geoenvironmental Engineering, Sharm El Sheikh, Egypt, 15–19 July 2017; Singh, D.N., Galaa, A., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 407–418. [Google Scholar]

- Zelleg, M.; Said, I.; Hamdi, E.; Lafhaj, Z. Experimental Testing for Zarzis Port Sediments (Tunisia) in Road Materials. Geotech. Res. 2018, 5, 13–21. [Google Scholar] [CrossRef]

- Mohammad, S.; Akram, W.; Mirza, S.A. Geotechnical Characterization of Dredged Material and Effect of Lime Stabilisation on Its Strength Characteristics. Appl. Mech. Mater. 2018, 877, 289–293. [Google Scholar] [CrossRef]

- Smith, B.T.; Howard, I.L.; Vahedifard, F. Lightly Cemented Dredged Sediments for Sustainable Reuse. Environ. Geotech. 2018, 5, 324–335. [Google Scholar] [CrossRef]

- Nguyen, T.T.M.; Rabbanifar, S.; Brake, N.A.; Qian, Q.; Kibodeaux, K.; Crochet, H.E.; Oruji, S.; Whitt, R.; Farrow, J.; Belaire, B.; et al. Stabilization of Silty Clayey Dredged Material. J. Mater. Civ. Eng. 2018, 30, 04018199. [Google Scholar] [CrossRef]

- Lei, H.; Xu, Y.; Li, X.; Zheng, G.; Liu, G. Effects of Polyacrylamide on the Consolidation Behavior of Dredged Clay. J. Mater. Civ. Eng. 2018, 30, 04018022. [Google Scholar] [CrossRef]

- Huang, H.; Burns, S.E.; Kurtis, K.E. Beneficial Use of Savannah River Dredged Material in Large-Scale Geotechnical Applications. Jpn. Geotech. Soc. Spec. Publ. 2021, 9, 245–248. [Google Scholar] [CrossRef]

- Houlihan, M.; Bilgen, G.; Dayioglu, A.Y.; Aydilek, A.H. Geoenvironmental Evaluation of RCA-Stabilized Dredged Marine Sediments as Embankment Material. J. Mater. Civ. Eng. 2021, 33, 04020435. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B. Stabilization of Dredged Sediment Using Activated Binary Cement Incorporating Nanoparticles. J. Mater. Civ. Eng. 2022, 34, 04021381. [Google Scholar] [CrossRef]

- Khayat, K.H.; Assaad, J.; Daczko, J. Comparison of Field-Oriented Test Methods to Assess Dynamic Stability of Self-Consolidating Concrete. Munic. J. 2004, 101, 13066. [Google Scholar] [CrossRef]

- Wang, D.; Xiao, J.; Gao, X. Strength Gain and Microstructure of Carbonated Reactive MgO-Fly Ash Solidified Sludge from East Lake, China. Eng. Geol. 2019, 251, 37–47. [Google Scholar] [CrossRef]

- El-Shinawi, A.; Kramarenko, V. Assessment of Stabilized Dredged Sediments Using Portland Cement for Geotechnical Engineering Applications along Hurghada Coast, Red Sea, Egypt. Asian J. Appl. Sci. 2015, 3, 819–830. [Google Scholar]

- Kang, G.; Tsuchida, T.; Tang, T.X.; Kalim, T.P. Consistency Measurement of Cement-Treated Marine Clay Using Fall Cone Test and Casagrande Liquid Limit Test. Soils Found. 2017, 57, 802–814. [Google Scholar] [CrossRef]

- Rosman, M.Z.; Chan, C.-M.; Anuar, N.M. Compressibility and Permeability of Solidified Dredged Marine Soils (DMS) with the Addition of Cement and/or Waste Granular Materials (WGM). J. Sci. Technol. 2018, 10, 13–20. [Google Scholar] [CrossRef]

- Liu, Y.; Ong, D.E.L.; Oh, E.; Liu, Z.; Hughes, R. Sustainable Cementitious Blends for Strength Enhancement of Dredged Mud in Queensland, Australia. Geotech. Res. 2022, 9, 65–82. [Google Scholar] [CrossRef]

- Silitonga, E.; Levacher, D.; Mezazigh, S. Utilization of Fly Ash for Stabilization of Marine Dredged Sediments. Eur. J. Environ. Civ. Eng. 2010, 14, 253–265. [Google Scholar] [CrossRef]

- Maherzi, W.; Abdelghani, F.B. Dredged Marine Sediments Geotechnical Characterisation for Their Reuse in Road Construction. Eng. J. 2014, 18, 27–37. [Google Scholar] [CrossRef]

- Wang, D.; Abriak, N.E.; Zentar, R. Dredged Marine Sediments Used as Novel Supply of Filling Materials for Road Construction. Mar. Georesources Geotechnol. 2017, 35, 472–480. [Google Scholar] [CrossRef]

- Silitonga, E. Experimental Research of Stabilization of Polluted Marine Dredged Sediments by Using Silica Fume. MATEC Web Conf. 2017, 138, 01017. [Google Scholar] [CrossRef]

- Fourvel, G.; Vidal-Beaudet, L.; Le Bocq, A.; Brochier, V.; Théry, F.; Landry, D.; Kumarasamy, T.; Cannavo, P. Early Structural Stability of Fine Dam Sediment in Soil Construction. J. Soils Sediments 2018, 18, 2647–2663. [Google Scholar] [CrossRef]

- Bellara, S.; Hidjeb, M.; Maherzi, W.; Mezazigh, S.; Senouci, A. Optimization of an Eco-Friendly Hydraulic Road Binders Comprising Clayey Dam Sediments and Ground Granulated Blast-Furnace Slag. Buildings 2021, 11, 443. [Google Scholar] [CrossRef]

- Jan, O.; Mir, B. Strength Behaviour of Cement Stabilised Dredged Soil. Int. J. Geosynth. Ground Eng. 2018, 4, 16. [Google Scholar] [CrossRef]

- Wang, D.; Zentar, R.; Abriak, N.E. Durability and Swelling of Solidified/Stabilized Dredged Marine Soils with Class-F Fly Ash, Cement, and Lime. J. Mater. Civ. Eng. 2018, 30, 04018013. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Y.; Wang, Q.; Xue, Q.; Poon, C.S. Development of a Novel Binder Using Lime and Incinerated Sewage Sludge Ash to Stabilize and Solidify Contaminated Marine Sediments with High Water Content as a Fill Material. J. Mater. Civ. Eng. 2019, 31, 04019245. [Google Scholar] [CrossRef]

- Sherwood, P. Soil Stabilization with Cement and Lime; National Academies: Washington, DC, USA, 1993. [Google Scholar]

- AFNOR NF P94-078; Sols: Soils: Investigation and Tests. CBR After immersion. Immediate CBR. Immediate Bearing Ratio. Measurement on Sample Compacted in CBR Mould. Afnor Editions: La Plaine Saint-Denis, France, 1997.

- Boutouil, M.; Levacher, D. Traitement et Valorisation Des Vases de Dragages Par Solidification/Stabilisation: État de l’art. In Proceedings of the VI Journées Nationales Génie Civil- Génie Côtier, Caen, France, 17–19 May 2000; Editions Paralia: Nantes, France, 2000; pp. 367–375. [Google Scholar]

| Property | Standard | DS-M | DS-F |

|---|---|---|---|

| Water content (%) | NF P94-050 [26] | 256 | 15.9 |

| Fines < 80 µm (%) | XP P94-041 [27] | 80 | 17 |

| OM at 450 °C (%) | XP P94-047 [28] | 17.1 | 1.5 |

| MBV (g/100 g) | NF P94–068 [29] | 2.4 | 2.0 |

| Specific gravity (g/cm) | ISO 17892-3 [30] | 2.35 | 2.67 |

| LL (%) | ISO 17892-12 [31] | 76 | 30 |

| PI (%) | ISO 17892-12 [31] | 41 | 10 |

| Test | Modified-Proctor Compaction and IBI | UCS and Tangent Modulus E | Brazilian ITS | Immersion Durability Ratio |

|---|---|---|---|---|

| Mixes/Binder dosage | F-0, F-6, and F-8; M-0, M-LC | F-6, F-8 only (DS-F) | F-6, F-8 only | F-6, F-8 |

| Specimen geometry and preparation | 152 Ø 126 mm in CBR/Proctor mold; mixed to target moisture | Cylinders 50 Ø 100 mm; static press compaction to ρdmax | Discs 50 Ø 50 mm sawn from UCS cylinders | Same UCS cylinders |

| Compaction/mold energy | 2.7 MJ/m3 (56 blows × 2.5 kg rammer) | Static press ≈ 10 MPa | — | — |

| Curing regime before test | none (IBI measured immediately after compaction, sample still in mold) | 4-d humid air (20 °C, RH > 90%) → 7-d water (40 °C) → humid air (20 °C) until test; additional set 32-d water immersion for 60-d “soaked” UCS | Same as UCS (air + water curing) | 28-d humid air → 32-d water (20 °C) |

| Test ages (days) | 0 | 7, 14, 28, 60, and 90 | 28 | 60 |

| Loading rate | Penetration 1.27 mm/min | Axial strain ≈ 1%/min | Diametral load 0.5 mm/min | Axial strain ≈ 1%/min |

| Replicates (n) | 3 | 3 | 3 | 3 |

| Reference standard | NF P94-093 (compaction) NF P94-078 (IBI) | NF P94-251-1 (loading) NF P94-100 (curing) | NF P98-232-3 | NF P94-100 |

| Property | Standard | DS-M | DS-F |

|---|---|---|---|

| F-0 | 2.147 | 7.5 | 45.3 |

| F-6 | 2.155 | 7.8 | 90.1 |

| F-8 | 2.148 | 7.9 | 124.6 |

| M-0 | 1.150 | 44 | 5.0 |

| M-LC | 1.090 | 44 | 8.0 |

| Criterion | Requirement (Subgrade/Foundation) | Achieved (F-6/F-8) |

|---|---|---|

| Immediate bearing index (IBI) | ≥25% (subgrade); ≥35% (foundation) | 90%/125% (conform) |

| UCS at 7–28 days | ≥1.0 MPa (to allow construction traffic) | 4.7 MPa/5.9 MPa (conform) |

| Immersion strength ratio 60-d | ≥0.8 | ~0.9/~0.95 (conform) |

| Indirect tensile Rt (28 d) | ≥0.25 MPa (for frost resistance) | ~0.4/~0.5 MPa (conform) |

| Class (tensile strength and modulus | ≥S1 for subgrade; ≥S2 for foundation | S2/S2–S3 (conform) |

| Platform class outcome | PF2–PF3 (depending on roadbed support) | PF3–PF4 (with 30–40 cm layer) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zri, A.; Abriak, N.-E.; Safhi, A.e.M.; Pilehvar, S.; Kioumarsi, M. Performance Limits of Hydraulic-Binder Stabilization for Dredged Sediments: Comparative Case Studies. Buildings 2025, 15, 2484. https://doi.org/10.3390/buildings15142484

Zri A, Abriak N-E, Safhi AeM, Pilehvar S, Kioumarsi M. Performance Limits of Hydraulic-Binder Stabilization for Dredged Sediments: Comparative Case Studies. Buildings. 2025; 15(14):2484. https://doi.org/10.3390/buildings15142484

Chicago/Turabian StyleZri, Abdeljalil, Nor-Edine Abriak, Amine el Mahdi Safhi, Shima Pilehvar, and Mahdi Kioumarsi. 2025. "Performance Limits of Hydraulic-Binder Stabilization for Dredged Sediments: Comparative Case Studies" Buildings 15, no. 14: 2484. https://doi.org/10.3390/buildings15142484

APA StyleZri, A., Abriak, N.-E., Safhi, A. e. M., Pilehvar, S., & Kioumarsi, M. (2025). Performance Limits of Hydraulic-Binder Stabilization for Dredged Sediments: Comparative Case Studies. Buildings, 15(14), 2484. https://doi.org/10.3390/buildings15142484