Abstract

This study aims to examine the latest literature at the intersection of prefabrication, modularity, and the circular economy (CE) through a bibliometric analysis. This systematic review follows five key steps: design and conceptualization, bibliometric data collection via the Scopus database, assessment of the collected data, data visualization, and discussion of the findings. The results are categorized into five main themes: prefabrication and modularity, CE in the construction sector, energy and environmental life cycle assessments, life cycle costing (LCC), and digitalization. The findings reveal that prefabricated and modular systems align with CE principles, supported by strategies such as disassembly and deconstruction design, as well as recycling and reuse. However, the direct connection between prefabrication/modularity and CE remains relatively weak, with environmental life cycle assessment (LCA) and building information modelling (BIM) emerging as the two primary methodologies bridging these concepts. To further advance the integration of prefabrication and modularity in CE, there is a need for the development of reliable guidelines and regulations that establish these practices as core requirements within the construction industry.

1. Introduction

The circular economy (CE) paradigm seeks to foster innovative business models and responsible societies by shifting from the traditional linear “take–make–waste” or “take–make–dispose” economic model to a more sustainable, “close-the-loop”, “regenerative”, and “restorative” approach. CE aims to generate value that benefits businesses, society, and the environment, driving more sustainable economic growth. It also focuses on enhancing the time-value and utility of materials, components, and products [1], while simultaneously reducing material costs, mitigating price volatility, improving supply security, and decreasing environmental pressures and impacts [2,3]. As noted by Tokazhanov et al. [4], the circularity performance of different projects can vary based on factors such as the construction methods and techniques, technologies employed, business models of corporations, and overall practices related to energy and material efficiency. Additionally, Luthin et al. [5] highlighted that the transition to a CE can have both positive and negative impacts on various stakeholders, since some positive impacts for some stakeholders, mainly the social ones, could imply adverse effects for others. Therefore, it is crucial to give special attention to the social dimensions during the transition to a CE. As defined by Meglin et al. [6], the transition to a CE is thus a co-evolutionary process between business models and public policies, marked by high multidimensional complexity and significant changes within a complex socio-technical-economic system. Consequently, it is essential to understand the circularity of products and services to effectively design circular policies and business strategies at the micro, meso, and macro levels. This understanding enables the prioritization of more sustainable solutions grounded in evidence [7].

The study of CE in the construction industry has garnered significant interest, as highlighted by numerous authors (e.g., by Benachio et al. [8], Çimen [9], Antwi-Afari et al. [10], Charef et al. [11], Charef and Lu [12], Norouzi et al. [13], Wijewickrama et al. [14], Joensuu et al. [15], Hossain et al. [16], Pomponi et al. [17], Guerra and Leite [18] and Yu et al. [19]). This is due to the construction sector’s substantial impact on the economy, job creation (both direct and indirect), raw material consumption, water and energy use, waste generation, and greenhouse gas emissions. These studies generally conclude that further research is needed to establish the core principles that drive circularity in construction projects. Key areas for exploration include developing decision-making tools to support the adoption of CE strategies, proposing assessment tools to “quantify” and/or “measure” circularity, and defining monitoring methodologies to evaluate the economic, environmental, and social impacts of CE measures. Additionally, overcoming current barriers hindering the transition to CE in the construction sector is essential. Furthermore, Oorschot and Asselbergs [20] emphasized the importance of fostering CE-based collaborative work among multidisciplinary teams to create more circular, cost-effective construction products and buildings with improved environmental performance.

The literature suggests that prefabrication and modularity align with two of the three CE principles outlined by the Ellen MacArthur Foundation [21]: waste and pollution reduction and the circularity of products and materials. Furthermore, within the 9R circular strategies framework (R0—refuse, R1—rethink, R2—reduce, R3—reuse, R4—repair, R5—refurbish, R6—remanufacture, R7—repurpose, R8—recycle, and R9—recover) proposed by Potting et al. [22] and Kirchherr et al. [23], prefabrication and modularity can facilitate smarter product/building use and manufacturing, contribute to extending the lifespan of buildings and their components, and promote more sustainable material use in the construction industry. However, as noted by Iacovidou et al. [24], the impact of modular construction on the recovery and reuse of materials—therefore enhancing resource efficiency downstream in the construction value chain—remains limited.

The terms “prefabrication” and “modularity” are often used interchangeably, but they do not have the same meaning. Prefabrication is a broad term that refers to a wide range of construction methods where components are manufactured offsite before being transported and assembled at the construction site [25,26]. In contrast, modularity is a more specific subset of prefabricated construction, involving the onsite assembly of individual, repeated units, blocks, or modules that are prefabricated offsite and then transported to the construction site for final assembly.

As highlighted by Chippagiri et al. [25] and Turner et al. [27], the growing interest in prefabrication is largely driven by the enhanced efficiency achieved in the production of prefabricated components within factory settings, where quality control and safer conditions are prioritized. Prefabrication enables faster construction, ensuring that project complexity and timelines are met while also achieving cost savings [28]. It can also promote the sustainable mass production of housing, increase flexibility and material efficiency, and reduce labor, waste, energy, and water consumption in construction [25]. These benefits align with CE principles, which can be further integrated into modular construction projects by identifying key success factors [29]. Prefabrication has significant potential to advance Industry 4.0 within the building sector [27]. This can be achieved through the integration of advanced technologies such as building information modelling (BIM), which enables the creation of centralized repositories of organized digital project data, as well as the adoption of additive manufacturing [30], 3D printing [31], digital twins (DTs), robotics, artificial intelligence (AI), and the internet of things (IoT) [32]. Prefabrication can also significantly improve systematic lean construction by streamlining workflows, minimizing inventory, and reducing waste. It also helps shorten lead times, enhance stakeholder value, boost engagement, improve safety, and empower employees across all levels [33,34]. Additionally, prefabricated components, particularly in modular construction, support key design strategies such as design for disassembly (DfDy), design for adaptability (DfAd) [35,36,37], and design for manufacture and assembly (DfMA) [38,39,40,41], while driving the digitalization of the construction industry [42]. These strategies facilitate the future modification, reuse, reconfiguration, and dismantling of all or part of a building, allowing components to be recovered and extending their lifespan. As noted by several researchers, prefabricated and modular homes offer the potential for comfortable, flexible, regenerative, reusable, and adaptable post-disaster temporary housing, with reduced construction time and lower costs [43,44,45,46]. Kamali and Hewage [47] also conducted a review of the key benefits and challenges of modular construction. The primary advantages, as highlighted earlier, include time and cost savings, enhanced onsite safety, improved product quality, better workmanship, increased productivity, and superior environmental performance. However, the authors also identify some key drawbacks, such as transportation limitations, project planning complexities, negative perceptions, site constraints, coordination and communication challenges, and higher initial costs. In particular, additional stages (such as prefabrication), extra activities (like transportation to the site), and materials (e.g., additional resources needed for module or part transport) can introduce impacts that may offset some of the initial benefits of prefabrication, necessitating further research.

The literature identifies various degrees of prefabrication based on factors such as size, complexity, configuration, and installation [48,49,50,51,52,53]. These range from buildings with low levels of prefabrication that only incorporate certain prefabricated components or parts to fully prefabricated structures with the highest level of prefabrication. Accordingly, prefabricated components can be categorized into component sub-assemblies, non-volumetric pre-assemblies (or panelized systems), volumetric pre-assemblies, modular construction, hybrid structures, and unitized whole-building prefabrication [54]. Notably, standardization plays a crucial role in facilitating modularity within the building industry. In this regard, Anastasiades et al. [55] recently reviewed the key drivers for standardization to enable the circular reuse of construction components, contributing to a more sustainable construction industry.

Despite extensive recent research on these topics, the relationship between prefabrication, modularity, and CE remains underexplored, creating a significant gap in the literature. While prefabrication and modularity are recognized as key strategies for promoting CE in the construction sector, their interconnections with CE have not been sufficiently mapped. This study aims to address this gap by conducting a bibliometric analysis and systematic review of the existing literature at the intersection of prefabrication, modularity, and CE. The goal is to identify research trends, gaps, and emerging areas of focus, as well as to explore the connections between these concepts and other relevant fields. In doing so, this study seeks to uncover pivotal topics, tools, and methodologies that can accelerate the adoption of circular practices in the construction industry. Additionally, the bibliometric analysis will help outline a roadmap for future research on leveraging prefabrication and modularity to enhance CE across the various life cycle phases of buildings.

2. Framework: Bibliometric Analysis and Systematic Review

A systematic review of the literature is designed to address a specific research question and aims to identify, select, analyze, and synthesize relevant evidence in a structured, transparent, and replicable manner. It involves a methodical process of systematically gathering documents and presenting the results, which may also include a bibliometric analysis of the selected studies to further enrich the findings.

Bibliometric analysis is recognized as an effective, reproducible, objective, and systematic method for collecting and organizing large volumes of data on specific research topics within the literature. This methodology allows for the clear illustration of current research progress, impact, trends, and gaps by leveraging title, keyword, abstract, and citation databases from peer-reviewed literature. Through bibliometric analysis, a quantitative evaluation of various parameters can be swiftly conducted, including keyword relationships, annual publication rates, the geographical distribution of publications and authorship, research area linkages through data clustering, author and institution collaborations, citation trends, and more. This “big picture” approach is invaluable for positioning specific research topics, mapping out research branches within particular fields, identifying emerging areas of focus, recognizing research gaps, and generating innovative ideas for future exploration. As such, bibliometric analysis enables a rapid overview of the state-of-the-art in scientific knowledge on a given topic, supports theoretical discussions, and lays the groundwork for conducting a systematic review of the literature.

Table 1 provides a summary of bibliometric studies and systematic reviews published up until August 2023, which have explored and discussed the key pillars, drivers, actors, technologies, methodologies, actions, challenges, and barriers in the transition to a more CE in the building industry. These studies have employed a systematic approach to analyze the topic.

Table 1.

Bibliometric studies and systematic reviews that have examined the key pillars, drivers, actors, technologies, methodologies, actions, challenges, and barriers in advancing a CE within the building industry.

3. Methodology

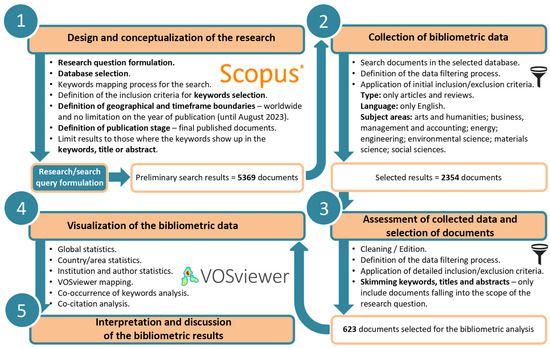

The methodology adheres to the procedure outlined by Norouzi et al. [13] and Aria and Cuccurullo [96], as depicted in Figure 1. It consists of five key stages: (i) research design and conceptualization; (ii) collection of bibliometric data; (iii) assessment and selection of relevant documents; (iv) visualization of the bibliometric data; and (v) interpretation and discussion of the bibliometric findings.

Figure 1.

Sketch of the methodological framework.

In the first stage, the research question is formulated and the search process is defined. This includes selecting the appropriate database, developing the search query, choosing relevant keywords, and establishing inclusion and exclusion criteria for keyword selection. The following research question was formulated to guide this systematic review: “What are the main research trends in global studies on prefabrication and modularity to promote CE in the construction sector?”

The Scopus database [97] was used to gather and export data, followed by the use of VOSviewer [98] for network visualization. Scopus is a leading scientific database, known for its extensive content and powerful citation analysis capabilities. However, other databases are often used, as shown in Table 1; e.g., Web of Science, ScienceDirect, Google Scholar, etc. VOSviewer (v. 1.6.18) [98], on the other hand, is a free software tool designed to create bibliometric maps based on network data from a selected set of documents, allowing users to visualize and explore these maps. This tool facilitates the presentation of large bibliometric networks in a clear, accessible, and easily interpretable format [98]. Other software programs are very often used in the literature, such as Bibliometrix R—R Studio, CiteSpace, SciMAT, etc.

Initially, the literature search was confined to documents containing the keywords “circular economy”, “prefabrication”, “modular construction”, and “construction sector” in their title, keywords, or abstract. However, it became apparent that various alternative terms are often used to describe these concepts. For example, “circular economy” is frequently associated with terms like “circularity”, “closed loop economy”, or “zero waste economy”; “prefabrication” is sometimes referred to as “offsite production” or “offsite construction”; “modular construction” is often used interchangeably with “modular buildings” or “modularity”; and “construction sector” is sometimes expressed as “built environment” or “buildings”.

Thus, given the significant impact of keyword selection on bibliometric results, semantically different terms with the same meaning were incorporated into an extended keyword collection for the literature search, as shown in Table 2. This collection includes terminology referenced by Charef et al. [11], Nobre and Tavares [13], Kalmykova et al. [2], Norouzi et al. [13], Hossain et al. [16], Munaro et al. [69], and Yu et al. [19], expanding the scope to include broader topics related to CE. Additionally, keywords from Norouzi et al. [13], Yu et al. [19], and Cabeza et al. [99] were used to encompass topics related to the construction sector and various building types. Terms from Yevu et al. [63] and Tavares et al. [100] were included to cover different concepts related to prefabrication and modular construction, as well as construction methods commonly associated with these approaches, such as lightweight steel framing (LSF), cross-laminated timber (CLT), wood framing, precast manufacturing, and structural insulated panels (SIPs). In the absence of a consistent, up-to-date taxonomy for “circular economy”, “modularity”, and “prefabrication” in the literature, the search query was further enriched with additional terms and concepts identified during the preliminary publication retrieval and from the papers listed in Table 1.

Table 2.

Taxonomy and expanded keyword collection for the literature search, categorized by research topic.

It is important to note that this study only includes well-established, expert-driven, semantically related terms that are widely recognized in the literature and cited in the documents listed in Table 1. Context-specific terms found in the literature but not comprehensively addressing the full spectrum of CE are excluded from the search query. For example, while the taxonomy for the EoL strategies of buildings, which includes terms starting with the prefix “Re” (e.g., reduce, reuse, repair, recycle, recover, refuse, reorganize, refurbish, etc.), is well-established, these isolated terms do not necessarily cover the entire CE scope of a project, and therefore are excluded. The only exception is the inclusion of the combined 3R’s (reduce, reuse, recycle), as these terms form the foundation of numerous earlier CE studies [13,91]. Additionally, the term “nR” was included in the search to capture several other well-established CE strategies.

As noted by Jaillon and Poon [101], prefabrication has seen increasing use in the building industry. However, it remains crucial to identify the primary DfD barriers and the obstacles hindering the development of more industrialized, flexible, and demountable building systems. To address this, several additional keywords were incorporated into the search query, including: “design for manufacture”, “design for assembly”, “design for disassembly and deconstruction”, “design for disassembly”, “design for deconstruction”, “design for reuse”, “design for adaptation”, “design for flexibility”, and “design for reassembly”.

Construction and demolition waste management (CDWM) is also included in the search query, as it underpins several symbiotic and synergistic CE strategies within the construction sector. Similarly, the lean construction philosophy is incorporated into the CE framework, as it aims to enhance productivity, profitability, and innovation in the construction industry while minimizing waste. While the terms “sustainability” and “sustainable” are included in some definitions of CE by various authors [13], they are considered too broad for the purposes of this study and are therefore excluded from the search query. However, several tools commonly used to assess the environmental and economic impacts of construction projects, along with their sustainability, are included in the CE framework search. These tools include LCA, LCC, and material flow analysis (MFA). These methodologies focus on mapping material, energy, service, and emission flows across the different phases of a construction project’s life cycle, enabling better identification of efficiency opportunities and resource recovery [17]. Moreover, these tools are valuable for supporting decision-making toward a more sustainable built environment. It is important to note that MFA is a reliable method for understanding material flows in complex, large-scale systems [17], and it is particularly effective for evaluating CE strategies at the city, regional, or national levels (e.g., urban metabolism). For example, Meglin et al. [6] and Meglin et al. [102] utilized this method within an integrated assessment model to evaluate the environmental and economic aspects of the regional building materials industry in Switzerland. Similarly, Böckin et al. [103] explored resource efficiency measures that could reduce physical flows and environmental impacts, depending on the characteristics of products and their life cycles. Although the social life cycle assessment (S-LCA), the third pillar of sustainability evaluation, is not directly included in the search query, the “social sciences” subject area is considered for data collection, as illustrated in Figure 1.

The final search query was formulated as shown in Figure 2, and bibliometric data were collected using the Scopus database, with the last access on August 2023. Boolean operators “AND” and “OR” were used to link and combine the research topics listed in Table 2. Several wildcards (asterisks) were employed to represent different variations of terms, automatically including all possible forms of a given word (e.g., plural, -ing form, etc.) and any noun phrases related to the term. Initially, a total of 5369 documents worldwide were identified, with no restrictions on the year of publication. The bibliometric data were then filtered according to the inclusion and exclusion criteria outlined in Figure 1. Only peer-reviewed articles and reviews published in English were considered. Additionally, the search was restricted to the following subject areas: arts and humanities; business, management, and accounting; energy; engineering; environmental science; materials science; and social sciences. After applying these filtering criteria, the document count was reduced to 2354.

Figure 2.

Scopus search query.

The collected documents underwent further assessment before finalizing the selection for the bibliometric analysis. The inclusion process involved evaluating the relevance of each document by reviewing their titles, keywords, and abstracts. Duplicate entries were excluded, and only documents that specifically linked CE principles in the construction sector with concepts of prefabrication and/or modularity were retained in the final selection. Documents that focused on unrelated topics, such as food waste and food chain supply, household waste management, urban solid waste management, wastewater treatment, energy communities, or the urban environment, were excluded. Similarly, papers that addressed mechanical systems (e.g., ventilation, air-conditioning, or domestic hot water), the assessment of asphalt-based materials, polymer processing and recycling, the valorization of plastic wastes, thermophysical or mechanical properties of specific materials, the environmental or economic impacts of materials, or specific construction types were also excluded. Additionally, studies that dealt with particular refurbishment or retrofitting actions, thermal and energy performance assessments, or seismic performance evaluations were not included. The bibliometric data were also cleaned and edited to correct any typos or missing information before mapping. Following this refinement process, a total of 623 documents were included in the final portfolio for the bibliometric analysis.

The bibliometric data were then imported into VOSviewer for graphical plotting and analysis. In the bibliometric maps, connections between items are represented by lines, with the thickness of these lines indicating the strength of the relationship. This strength can be interpreted in different ways depending on the analysis type. For example, in a co-authorship analysis by countries, connection strength reflects the total number of collaborative publications between those countries. In keyword co-occurrence analysis, connection strength denotes the frequency with which two keywords appear together in the same publication. Another key indicator in the bibliometric maps is the size of the circle representing each item. The size of the circle reflects the relative importance of that item in the literature, with larger circles indicating greater relevance. For co-authorship by countries, the circle size corresponds to the total number of documents published by each country. In keyword co-occurrence, it shows how frequently a specific keyword appears in the literature. VOSviewer offers two types of visualizations. The first is a standard visualization, where items are grouped into clusters based on their overall connections within the network, with each cluster assigned a distinct color. The second visualization maintains the same cluster distribution but adds an overlay color scale to indicate the average publication year for each item. In the case of country co-authorship, this overlay represents the average year of publication for documents from that country, while in keyword co-occurrence, it indicates the average year of reference for that keyword in the literature.

4. General Mapping of the Bibliometric Results

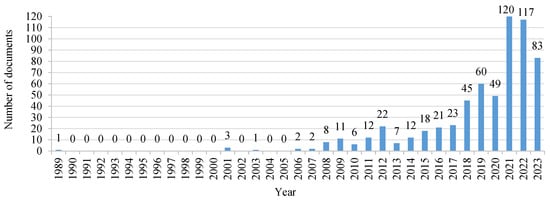

Figure 3 illustrates the annual trend in the number of publications, starting with the first document by Sarja [104] identified in the selected literature. Prior to 2007, the number of publications per year was relatively low. However, from 2008 onward, there was a noticeable increase in the volume of publications, with a substantial surge beginning in 2020. This upward trend highlights the growing prominence of the emerging “circular economy” research field. It is important to note that, as of the time of this study (August 2023), the Scopus database only includes documents published up to that point. Consequently, the number of publications for 2023 is not fully representative of the total number of publications for that year.

Figure 3.

Annual publication trends in the selected literature.

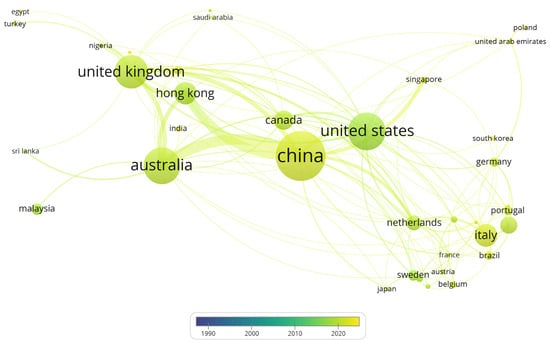

A total of 68 countries have contributed publications to the selected research fields. Among them, China (excluding Hong Kong, as Hong Kong is classified as a special administrative region of China for statistical purposes) leads with 98 publications, followed by the USA with 74 and Australia with 72. Figure 4 displays the co-authorship network of countries, including the average year of publication for each country. A minimum threshold of five documents per country was used for mapping the bibliometric results, and 36 countries of the 68 met this criterion. The findings indicate that the topics under investigation are highly current, reflecting a surge of interest in these research areas, particularly since 2020. In terms of co-authorship networks, strong collaborative links were identified between China and Australia; China and Hong Kong; China and the UK; China and the USA; China and Singapore; China and the Netherlands; the UK and Australia; the UK and the Netherlands; the UK and Hong Kong; and Australia and Hong Kong. Geographically, Europe has the highest share of publications, accounting for 41.1%, followed by Asia at 31.3%, North America at 13.3%, Australia at 9.2%, South America at 3.1%, and Africa at 2%. In total, 1304 organizations have contributed to the research areas.

Figure 4.

Network of countries with the average publication year per country between 1989 and August 2023 (co-authorship analysis), with a minimum threshold of five documents per country.

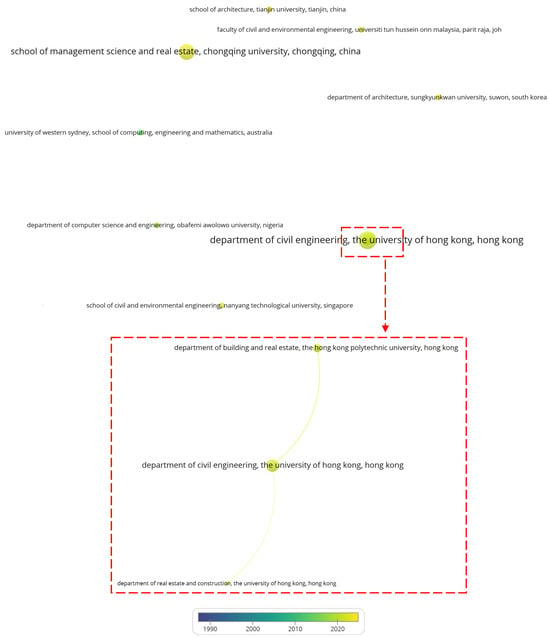

Figure 5 shows the co-authorship network of institutions, including the average year of publication for each institution. A minimum threshold of three documents per institution was used for mapping, and only 10 of the 1300 institutions met this criterion. The leading institution is the Department of Civil Engineering of the University of Hong Kong, with nine publications, followed by the School of Management Science and Real Estate of the Chongqing University and the Department of Building and Real Estate of the Hong Kong Polytechnic University, with eight and six publications, respectively. Figure 5 demonstrates the near-absence of notable co-authorship links among the institutions. This may be explained by the relatively recent emergence of research in these areas.

Figure 5.

Network of institutions with the average publication year per institution between 1989 and August 2023 (co-authorship analysis), with a minimum threshold of three documents per institution.

Figure 6 displays the co-authorship network of authors—a minimum threshold of six documents per author was used for mapping the bibliometric results, and only 16 authors of the 1833 met this criterion. Among the most prominent authors who have published in these areas, the most prolific author is Lu W. (H-index of 55), followed by Li Z. and Wang J. These results are based on the bibliometric data, where all co-authors are attributed equal value.

Figure 6.

Network of authors with the average publication year per author between 1989 and August 2023 (co-authorship analysis), with a minimum threshold of six documents per author.

Figure 7 maps the co-occurrence of author keywords, using a threshold of 10 occurrences per keyword (out of the 1456 keywords, 44 met this criterion). This visualization highlights the key research topics and the connections between them. Table 3 provides a detailed summary of the information presented in Figure 7, including descriptions of the terms (with similar meaning keywords grouped together as explained earlier), along with the number of co-occurrences and total link strength. To reduce ambiguity, keywords with synonymous meanings were clustered before mapping. As a result, the original 1734 author keywords in the selected documents were consolidated into 1457 distinct keywords. For example, variations such as “Life cycle assessment (LCA)”, “Lifecycle assessment”, “LCA”, “(LCA)”, “Life cycle assessment”, “Lifecycle assessment”, “Life-cycle assessment”, “Life-cycle assessment (LCA)” and “LCA method” were unified under the single term “Life cycle assessment”.

Figure 7.

Co-occurrence map of author keywords with a minimum frequency of 10 occurrences per keyword.

Table 3.

Description of the terms presented in Figure 5, including their co-occurrence frequency and total link strength.

The keyword “Life cycle assessment” stands out with the highest total occurrence and link strength, indicating its centrality and high frequency of use in the literature. It is closely followed by the keywords “Circular economy” and “Prefabrication”. However, it is important to note that the direct connection between “Circular economy” and “Prefabrication” remains relatively weak, suggesting that this relationship may evolve into a prominent research topic in the near future.

The results are grouped into five distinct clusters, each represented by a different color:

- The red cluster (cluster #1) focuses on prefabrication and modularity, including terms such as “Prefabrication”, “Offsite construction”, “Modularity”, “Modular construction”, “Industrialized building system”, “Lean construction”, and “Lean production”.

- The green cluster (cluster #2) centers on strategies for CE in the construction sector, with terms like “Circular economy”, “Building information modeling”, “Design for disassembly”, “Design for deconstruction”, “Reuse”, and “Recycling”.

- The blue cluster (cluster #3) is concerned with energy and environmental LCA, including terms such as “Life cycle assessment”, “Carbon footprint”, “Embodied carbon”, “Embodied energy”, “Global warming”, “Climate change”, and “Greenhouse gas emissions”.

- The yellow cluster (cluster #4) is primarily associated with “Life cycle costing”.

- Lastly, the purple cluster (cluster #5) includes terms related to “3D printing” and “Additive manufacturing”.

These clusters highlight the main thematic areas in the research, with some terms bridging multiple topics within the construction industry’s CE framework.

Table 4 lists the 25 most-cited studies found in the selected literature at the time this paper was written. The 623 documents selected for the final portfolio of documents were cited 18,588 times.

Table 4.

Top 25 most-cited documents in the research areas under investigation (as of August 2023).

5. Conclusions

This paper conducted a bibliometric analysis to explore the key relationships between prefabrication and/or modularity and CE research in the building industry. The primary objective was to determine the extent to which prefabrication and modularity serve as core strategies for advancing CE in construction or whether they are merely treated as supplementary approaches. To achieve this, documents published before August 2023 were selected from the Scopus database and VOSviewer was used to visualize the bibliometric findings.

It was concluded that, while prefabrication and modularity are frequently recognized as key strategies for enhancing the CE in buildings, the direct connection between these concepts remains weak. Instead, environmental LCA and BIM have emerged as the primary tools linking prefabrication, modularity, and CE. In other words, although prefabrication and modularity are acknowledged as CE strategies, they are rarely considered the primary drivers of circularity in buildings. Additionally, the bibliometric analysis identified five main thematic categories: prefabrication and modularity, CE in the construction sector, LCA, LCC, and digitalization.

The research question—“What are the main future research trends in global studies on prefabrication and modularity to promote CE in the construction sector?”—encompasses four key research categories: circular tools, circular strategies, construction types, and degree of prefabrication. Within the circular tools category, LCA, LCC, MFA, and S-LCA emerge as the primary methods for evaluating building circularity across environmental, economic, and social dimensions. However, most studies focus on the manufacturing and construction stages, with insufficient attention to operation and EoL phases. Additionally, further research is needed to integrate CE strategies at the social level. The circular strategies category includes CE principles that can be enhanced by prefabrication and modular construction. Key strategies include closed-loop systems, stronger circularity regulations and incentives, standardization, stakeholder awareness, economic impact maximization, and support for the local economy. Design considerations play a crucial role, such as long-life design, material durability, maintenance, repair, and flexibility. Digital and technological advancements—including offsite construction, lean construction, BIM, material passports, EPDs, additive manufacturing, robotics, IoT, and automation—also contribute to CE adoption. Further strategies involve designing for adaptability, reuse, disassembly, and recycling, as well as prioritizing energy efficiency, renewable energy integration, water and waste reduction, and minimizing CDW. The construction types that align best with prefabrication and modularity principles include LSF, CLT, wood framing, and precast concrete. Regarding the degree of prefabrication, various classification scales have been identified, primarily encompassing component sub-assembly, non-volumetric pre-assembly, volumetric pre-assembly, modular construction, hybrid structures, and unitized whole-building prefabrication.

Finally, this study concluded that establishing reliable guidelines and regulations is essential to directly support the integration of prefabrication and modularity as key requirements for advancing the CE in the construction sector.

Author Contributions

Conceptualization, N.S. and V.T.; methodology, N.S. and V.T.; investigation, N.S. and V.T.; writing—original draft preparation, N.S. and V.T.; writing—review and editing, N.S. and V.T.; visualization, N.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in part by the Fundação para a Ciência e a Tecnologia, I.P. (FCT, https://ror.org/00snfqn5816) under Grant https://doi.org/10.54499/UIDB/50022/2020, https://doi.org/10.54499/UIDP/50022/2020, https://doi.org/10.54499/LA/P/0079/2020. For the purpose of Open Access, the author has applied a CC-BY public copyright license to any Author‘s Accepted Manuscript (AAM) version arising from this submission.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AEC | architecture, engineering and construction |

| AI | artificial intelligence |

| BIM | building information modelling |

| CAM | computer-aided manufacture |

| CDW | construction and demolition waste |

| CDWM | construction and demolition waste management |

| CE | circular economy |

| CLT | cross-laminated timber |

| DfA | design for assembly |

| DfAd | design for adaptability |

| DfD | design for deconstruction |

| DfDy | design for disassembly |

| DT | digital twin |

| EoL | end-of-life |

| GIS | geographic information system |

| ICT | information and communication technology |

| IoT | internet of things |

| LCA | environmental life cycle assessment |

| LCC | life cycle costing |

| LSF | lightweight steel framing |

| MFA | material flow analysis |

| MMC | modern method of construction |

| PfD | planning for deconstruction |

| S-LCA | social life cycle assessment |

| SIP | structural insulated panels |

References

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Sher, W.; Egbelakin, T. Circular economy pillars: A semi-systematic review. Clean Technol. Environ. Policy 2021, 23, 899–914. [Google Scholar] [CrossRef]

- Tokazhanov, G.; Galiyev, O.; Lukyanenko, A.; Nauyryzbay, A.; Ismagulov, R.; Durdyev, S.; Turkyilmaz, A.; Karaca, F. Circularity assessment tool development for construction projects in emerging economies. J. Clean. Prod. 2022, 362, 132293. [Google Scholar] [CrossRef]

- Luthin, A.; Traverso, M.; Crawford, R.H. Assessing the social life cycle impacts of circular economy. J. Clean. Prod. 2023, 386, 135725. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Uncertainty, variability, price changes and their implications on a regional building materials industry: The case of Swiss canton Argovia. J. Clean. Prod. 2022, 330, 129944. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A review of the circularity gap in the construction industry through scientometric analysis. J. Clean. Prod. 2021, 298, 126870. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W.; Hall, D. The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W. Factor dynamics to facilitate circular economy adoption in construction. J. Clean. Prod. 2021, 319, 128639. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Wijewickrama, M.K.C.S.; Rameezdeen, R.; Chileshe, N. Information brokerage for circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2021, 313, 127938. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Yu, Y.; Yazan, D.M.; Junjan, V.; Iacob, M.E. Circular economy in the construction industry: A review of decision support tools based on Information & Communication Technologies. J. Clean. Prod. 2022, 349, 131335. [Google Scholar] [CrossRef]

- Oorschot, L.; Asselbergs, T. New housing concepts: Modular, circular, biobased, reproducible, and affordable. Sustainability 2021, 13, 13772. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The Circular Economy in Detail. Available online: https://www.ellenmacarthurfoundation.org/the-circular-economy-in-detail-deep-dive (accessed on 21 November 2023).

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P.; Tsavdaridis, K.D.; Poologanathan, K. Digitally enabled modular construction for promoting modular components reuse: A UK view. J. Build. Eng. 2021, 42, 102820. [Google Scholar] [CrossRef]

- Chippagiri, R.; Bras, A.; Sharma, D.; Ralegaonkar, R.V. Technological and sustainable perception on the advancements of prefabrication in construction industry. Energies 2022, 15, 7548. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, T.; Zhou, X.; Li, Z.; Jia, Y.; Ren, K.; Xu, T.; Li, C.; Hong, J. Life cycle environmental and cost assessment of prefabricated components manufacture. J. Clean. Prod. 2023, 415, 137888. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Stergioulas, L.K. Distributed manufacturing: A new digital framework for sustainable modular construction. Sustainability 2021, 13, 1515. [Google Scholar] [CrossRef]

- Chauhan, K.; Peltokorpi, A.; Lavikka, R.; Seppänen, O. The monetary and non-monetary impacts of prefabrication on construction: The effects of product modularity. Buildings 2022, 12, 459. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Developing critical success factors for integrating circular economy into modular construction projects in Hong Kong. Sustain. Prod. Consum. 2022, 29, 574–587. [Google Scholar] [CrossRef]

- Pasco, J.; Lei, Z.; Aranas, C. Additive manufacturing in off-site construction: Review and future directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building envelope prefabricated with 3D printing technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. Effects of Lean construction on sustainability of modular homebuilding. J. Archit. Eng. 2012, 18, 155–163. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. An empirical examination of the relationship between lean construction and safety in the industrialized housing industry. Lean Constr. J. 2009, 1–12. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Saari, R. A selective disassembly multi-objective optimization approach for adaptive reuse of building components. Resour. Conserv. Recycl. 2020, 154, 104605. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Wasim, M.; Vaz Serra, P.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction—A review. Int. J. Constr. Manag. 2022, 22, 3014–3022. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Hartmann, T. A framework for BIM-based disassembly models to support reuse of building components. Resour. Conserv. Recycl. 2021, 175, 105825. [Google Scholar] [CrossRef]

- Atmaca, N. Life-cycle assessment of post-disaster temporary housing. Build. Res. Inf. 2017, 45, 524–538. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Comparative life cycle energy and cost analysis of post-disaster temporary housings. Appl. Energy 2016, 171, 429–443. [Google Scholar] [CrossRef]

- Arslan, H. Re-design, re-use and recycle of temporary houses. Build. Environ. 2007, 42, 400–406. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Porras-Pereira, P.; Levinton, C. Circular economy and regenerative sustainability in emergency housing: Eco-efficient prototype design for subasi refugee camp in Turkey. Sustainability 2021, 13, 8100. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Wong, R.W.M.; Loo, B.P.Y. Sustainability implications of using precast concrete in construction: An in-depth project-level analysis spanning two decades. J. Clean. Prod. 2022, 378, 134486. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Gibb, A. Pre-Assembly in Construction (CRISP): A Review of Recent and Current Industry and Research Initiatives on Pre-Assembly in Construction. 2001. Available online: https://hdl.handle.net/2134/25702 (accessed on 1 August 2023).

- Lu, W.; Lee, W.M.W.; Xue, F.; Xu, J. Revisiting the effects of prefabrication on construction waste minimization: A quantitative study using bigger data. Resour. Conserv. Recycl. 2021, 170, 105579. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Tavares, V.; Calheiros, C.S.C.; Martins, I.B.; Maia, J.; Tsikaloudaki, K.; Fonseca, M.; Marchesi, M.; Laban, M.; Soares, N.; Santos, P.; et al. Modularity and Prefabrication. In Circular Economy Design and Management in the Built Environment; Springer: Berlin/Heidelberg, Germany, 2025; pp. 215–256. [Google Scholar] [CrossRef]

- Anastasiades, K.; Goffin, J.; Rinke, M.; Buyle, M.; Audenaert, A.; Blom, J. Standardisation: An essential enabler for the circular reuse of construction components? A trajectory for a cleaner European construction industry. J. Clean. Prod. 2021, 298, 126864. [Google Scholar] [CrossRef]

- Aziminezhad, M.; Taherkhani, R. BIM for deconstruction: A review and bibliometric analysis. J. Build. Eng. 2023, 73, 106683. [Google Scholar] [CrossRef]

- Allam, A.S.; Nik-Bakht, M. From demolition to deconstruction of the built environment: A synthesis of the literature. J. Build. Eng. 2023, 64, 105679. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.; Castro-Lacouture, D.; Hu, Y. Lean manufacturing applications in prefabricated construction projects. Autom. Constr. 2023, 150, 104790. [Google Scholar] [CrossRef]

- Barkhausen, R.; Rostek, L.; Miao, Z.C.; Zeller, V. Combinations of material flow analysis and life cycle assessment and their applicability to assess circular economy requirements in EU product regulations. A systematic literature review. J. Clean. Prod. 2023, 407, 137017. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P. Adopting artificial intelligence for enhancing the implementation of systemic circularity in the construction industry: A critical review. Sustain. Prod. Consum. 2023, 35, 509–524. [Google Scholar] [CrossRef]

- Kręt-Grześkowiak, A.; Baborska-Narożny, M. Guidelines for disassembly and adaptation in architectural design compared to circular economy goals—A literature review. Sustain. Prod. Consum. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Salvador, R.; Barros, M.V.; Pieroni, M.; Lopes Silva, D.A.; Freire, F.; De Francisco, A.C. Overarching Business Models for a Circular Bioeconomy: Systematising archetypes. Sustain. Prod. Consum. 2023, 43, 349–362. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Oti-Sarpong, K.; Wuni, I.Y.; Tetteh, M.O. Systematic review on the integration of building information modelling and prefabrication construction for low-carbon building delivery. Build. Res. Inf. 2023, 51, 279–300. [Google Scholar] [CrossRef]

- Khan, A.A.; Yu, R.; Liu, T.; Gu, N.; Walsh, J. Volumetric modular construction risks: A comprehensive review and digital-technology-coupled circular mitigation strategies. Sustainability 2023, 15, 7019. [Google Scholar] [CrossRef]

- Hamida, M.B.; Jylhä, T.; Remøy, H.; Gruis, V. Circular building adaptability and its determinants—A literature review. Int. J. Build. Pathol. Adapt. 2022, 41, 47–69. [Google Scholar] [CrossRef]

- López-Guerrero, R.E.; Vera, S.; Carpio, M. A quantitative and qualitative evaluation of the sustainability of industrialised building systems: A bibliographic review and analysis of case studies. Renew. Sustain. Energy Rev. 2022, 157, 112034. [Google Scholar] [CrossRef]

- Horn, E.; Proksch, G. Symbiotic and regenerative sustainability frameworks: Moving towards circular city implementation. Front. Built Environ. 2022, 7, 780478. [Google Scholar] [CrossRef]

- Ahn, N.; Dodoo, A.; Riggio, M.; Muszynski, L.; Schimleck, L.; Puettmann, M. Circular economy in mass timber construction: State-of-the-art, gaps and pressing research needs. J. Build. Eng. 2022, 53, 104562. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. The ecodesign methodologies to achieve buildings’ deconstruction: A review and framework. Sustain. Prod. Consum. 2022, 30, 566–583. [Google Scholar] [CrossRef]

- Díaz-López, C.; Bonoli, A.; Martín-Morales, M.; Zamorano, M. Analysis of the scientific evolution of the circular economy applied to construction and demolition waste. Sustainability 2021, 13, 9416. [Google Scholar] [CrossRef]

- Arumugam, G.; Priya, L.K.P.; Kusumo, C.M.L.; Mari, T. A Systematic Review and Analysis of 3D Printed Building Envelopes Inspired By Nature. J. Eng. Sci. Technol. 2021, 58–73. [Google Scholar]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Camana, D.; Manzardo, A.; Toniolo, S.; Gallo, F.; Scipioni, A. Assessing environmental sustainability of local waste management policies in Italy from a circular economy perspective. An overview of existing tools. Sustain. Prod. Consum. 2021, 27, 613–629. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, H.; Wang, Q.; Hua, T.; Xue, H. A review and scientometric analysis of global research on prefabricated buildings. Adv. Civ. Eng. 2021, 2021, 8869315. [Google Scholar] [CrossRef]

- O’Grady, T.; Minunno, R.; Chong, H.Y.; Morrison, G.M. Design for disassembly, deconstruction and resilience: A circular economy index for the built environment. Resour. Conserv. Recycl. 2021, 175, 105847. [Google Scholar] [CrossRef]

- Machado, N.; Morioka, S.N. Contributions of modularity to the circular economy: A systematic review of literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Charef, R.; Morel, J.C.; Rakhshan, K. Barriers to implementing the circular economy in the construction industry: A critical review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Zairul, M. The recent trends on prefabricated buildings with circular economy (CE) approach. Clean. Eng. Technol. 2021, 4, 100239. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Jin, R.; Hong, J.; Zuo, J. Environmental performance of off-site constructed facilities: A critical review. Energy Build. 2020, 207, 109567. [Google Scholar] [CrossRef]

- Akbarieh, A.; Jayasinghe, L.B.; Waldmann, D.; Teferle, F.N. BIM-based end-of-lifecycle decision making and digital deconstruction: Literature review. Sustainability 2020, 12, 2670. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Li, X.; Wu, G. A review of global lean construction during the past two decades: Analysis and visualization. Eng. Constr. Archit. Manag. 2019, 26, 1192–1216. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Ji, L.; Liu, C.; Huang, L.; Huang, G. The evolution of resources conservation and recycling over the past 30 years: A bibliometric overview. Resour. Conserv. Recycl. 2018, 134, 34–43. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Sonego, M.; Echeveste, M.E.S.; Galvan Debarba, H. The role of modularity in sustainable design: A systematic review. J. Clean. Prod. 2018, 176, 196–209. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and internet of things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- “Scopus”. Elsevier. Available online: http://www.scopus.com (accessed on 1 August 2023).

- “VOSviewer—Visualizing Scientific Landscapes”. Available online: https://www.vosviewer.com/ (accessed on 1 August 2023).

- Cabeza, L.F.; Chàfer, M.; Mata, É. Comparative analysis of web of science and scopus on the energy efficiency and climate impact of buildings. Energies 2020, 13, 409. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, P.S.; Habert, P.G. Regional environmental-economic assessment of building materials to promote circular economy: Comparison of three Swiss cantons. Resour. Conserv. Recycl. 2022, 181, 106247. [Google Scholar] [CrossRef]

- Böckin, D.; Willskytt, S.; André, H.; Tillman, A.M.; Ljunggren Söderman, M. How product characteristics can guide measures for resource efficiency—A synthesis of assessment studies. Resour. Conserv. Recycl. 2020, 154, 104582. [Google Scholar] [CrossRef]

- Sarja, A. Principles and Solutions of the New System Building Technology (TAT); Valtion teknillinen tutkimuskeskus. Tutkimuksia—Research Reports No. 662; VTT Technical Research Centre of Finland: Espoo, Finland, 1989. [Google Scholar]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input-output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Tam, V.W.Y. On the effectiveness in implementing a waste-management-plan method in construction. Waste Manag. 2008, 28, 1072–1080. [Google Scholar] [CrossRef] [PubMed]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, M.; Tam, V.W.Y.; Yi, G.; Tran, C.N.N. A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. J. Clean. Prod. 2018, 176, 676–692. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W.Y. Critical factors in effective construction waste minimization at the design stage: A Shenzhen case study, China. Resour. Conserv. Recycl. 2014, 82, 1–7. [Google Scholar] [CrossRef]

- Shadram, F.; Johansson, T.D.; Lu, W.; Schade, J.; Olofsson, T. An integrated BIM-based framework for minimizing embodied energy during building design. Energy Build. 2016, 128, 592–604. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Bilal, M.; Ajayi, S.O.; Owolabi, H.A.; Alaka, H.A.; Bello, S.A. Waste minimisation through deconstruction: A BIM based Deconstructability Assessment Score (BIM-DAS). Resour. Conserv. Recycl. 2015, 105, 167–176. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the impact of prefabrication on construction waste reduction: An empirical study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction matters: Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Design issues of using prefabrication in hong kong building construction. Constr. Manag. Econ. 2010, 28, 1025–1042. [Google Scholar] [CrossRef]

- Dong, Y.H.; Jaillon, L.; Chu, P.; Poon, C.S. Comparing carbon emissions of precast and cast-in-situ construction methods—A case study of high-rise private building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).