Abstract

The paper focuses on trulli, which are ancient typical drystone constructions with inner hollow largely spread in the Puglia region in the southern part of Italy. The trullo is the cheapest structure that can be built in a calcareous territory using plain stones without using any mortar, and has assumed a number of different forms, initially used as protection for the farm equipment, and later evolving into a house. This paper presents the evolution over time of these structures, as well as their description and treatment from a structural point of view. The simplicity of both the materials and techniques for realizing these structures is currently the basis of many projects for the development and progress in emerging countries, and makes the study of their mechanics very topical.

1. Introduction

Masonry buildings constitute the majority of European architectural heritage [1] and are widely spread around the globe. This is why the topic of the theoretical treatment of the masonry materials [2,3,4,5] and structures [6,7,8] has been widely contributed to from the perspective of many features, besides stability assessment of constructions [9,10,11], analyses of cracks’ spread [12,13] in masonry structures and continua [14,15,16,17]. Over approximately 40 years, the authors have deeply contributed to this subject, with regards, among other things, to stability features of constructions and bridges [10,11], theoretical formulations and setups for limits, operational analyses [5,7], implementation of dynamics [17,18,19], coupling with boost elements [20,21] and protection [22,23,24,25,26] and development of original evolutionary elastic–brittle mechanical models with tensile strength time decay [27,28], also with reference to dynamic control strategies [29,30,31,32,33,34,35,36,37,38,39]. Despite their ancient origin, dry structures are regaining research interest also as methods for the construction of buildings using local materials and techniques as a development tool in emerging countries.

Masonry stone structures without mortar have widely spread in many locations. Many examples may be mentioned around the world referring to dry-stone constructions, such as: the “mitata” in Greece as stables in pasturelands; the multi-tiered “baracas” and the “zahurdas” with the form of flat huts or with nearly hemispherical roofs with eaves projecting above a vertical base in Spain; the special storage huts “cleitean” in Scotland; “the tazotas” made of reddish sandstones for storage in Morocco; the “nawamis” in Egypt; old tombs with rough corbelled domes inside; the ancient tower tombs in Oman with perfect corbelled domes, and sometimes even two domes on top of one another; the storage constructions and stables with corbelled domes in Syria, with clay molded into bricks, serving as building material; and so on.

In the Puglia region in the Italian territory, the presence of compact limestones that form small thick slabs allowed the farmers to build houses by themselves without spending anything in the ancient times [40,41,42,43].

Thus, the more compact stones became the dry-stone walls and the stone slabs became the “chiancarelle” for the roof of the houses [44]. These houses are characteristic of a small area in southern Italy and were called “trulli”, from the Greek word “trullos”, meaning “dome” [45,46,47,48,49,50,51,52,53].

The walls are usually built with calcareous irregular stones and without any mortar, and they are built directly on the ground even if a rock basement is absent. The walls are made of two coupled dry-stone walls, separated by an inner cavity. The inside of the cavity is filled up with numerous stone pieces of different dimensions and forms. The walls with a large thickness are often the basis of repairs for farm equipment, or little houses for the protection of people and animals, where the stones can be arranged according to an elliptic or squared plan. When the wall is the threshold of a property, it is usually transversally closed with large stone blocks.

The smaller stone slabs (called “chiancarelle”) are disposed without mortar by means of an elementary technique in concentric circles to close the conic vault. The conic shape of the roof is obtained with a sequence of circular rings, which start at half-height of the structure and have a decreasing diameter towards the top. Sometimes a large rock closes the roof at the top.

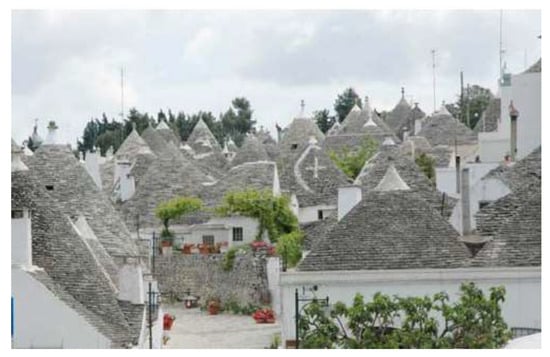

Additionally, although the conic form of the roof remains a primitive structure and the building materials are very simple, the adopted technique is an example of a bright solution to a static equilibrium problem [54]. The trullo was created in the prehistory and over the centuries, its original structure has been modified from a simple shelter to a real house with any comfort. This evolution is particularly evident in some areas of Puglia, as the regions of Alberobello (Figure 1), Locorotondo, Martina Franca and Cisternino within this area, are called the “Murgia dei Trulli”, the land of the trulli. In the following section, the main characteristics and typologies of these constructions, both with reference to technological features, components and their evolution over time, are outlined and discussed.

Figure 1.

Trulli in Alberobello (Puglia, Italy).

2. Historical Background

Alberobello is an Italian town located in the province of Bari, near the hills of the Murgia and the Itria Valley. The historic center with its 2000 trulli was declared a UNESCO World Heritage Site in 1996. Alberobello was officially established at the end of the 1400s, by the will of the Counts of Conversano, who at the time owned the territory and entrusted the work to some farmers. The law at the time, in the Kingdom of Naples, required each new inhabited center to pay specific taxes. For this reason, the Counts charged the peasants to colonize the area by building only precarious houses (the “trulli”), which could have been easily demolished in the event where an inspection had taken place. Only in 1797, towards the end of the feudal dominion, the name of Alberobello was adopted, and the king of Naples, Ferdinand IV of Bourbon, conferred the locality the title of a royal city. After this period, the construction of new trulli fell into decline.

Not far from Alberobello, there is the Itria Valley, with the municipalities of Locorotondo (BA), Cisternino (BR), Ceglie Messapica (BR) and Martina Franca (TA), where there are agglomerations of dozens of trulli on the hills, scattered in the karst ups and downs. The primitive trullo (called “Specchia”) is a simple structure on a circular plan, which rises on concentric circles of stones to constitute the conic roof. In the primitive trullo, four building elements can be identified: the wall, the entrance trilith, the conic vault and the roof. All elements are calcareous and are used without mortar.

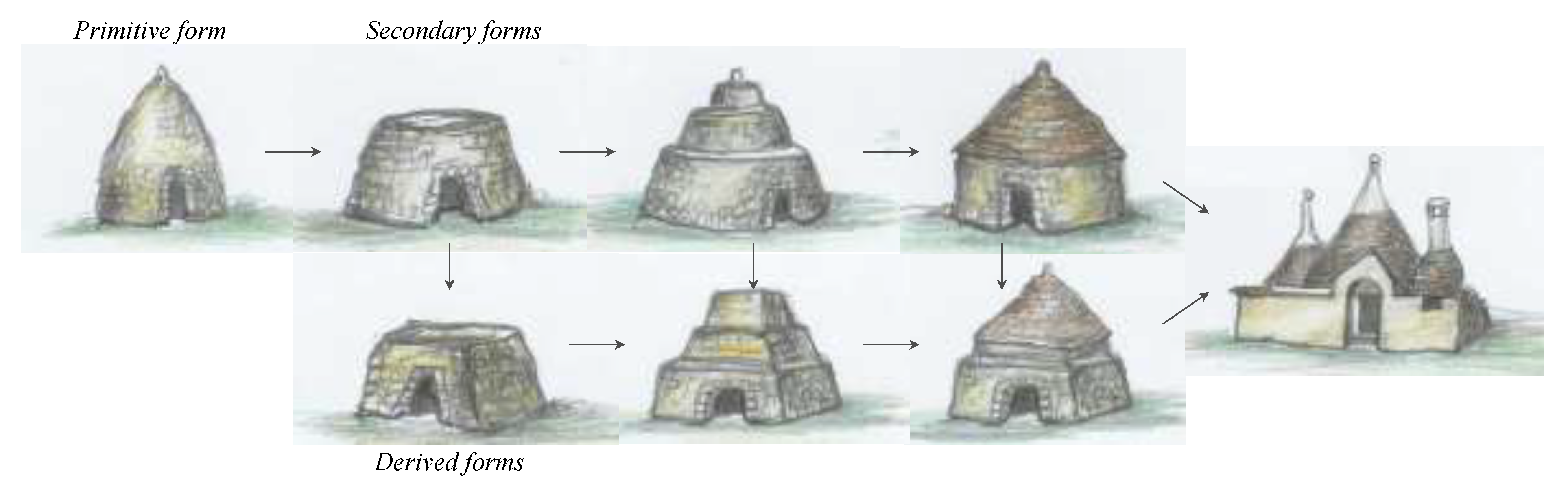

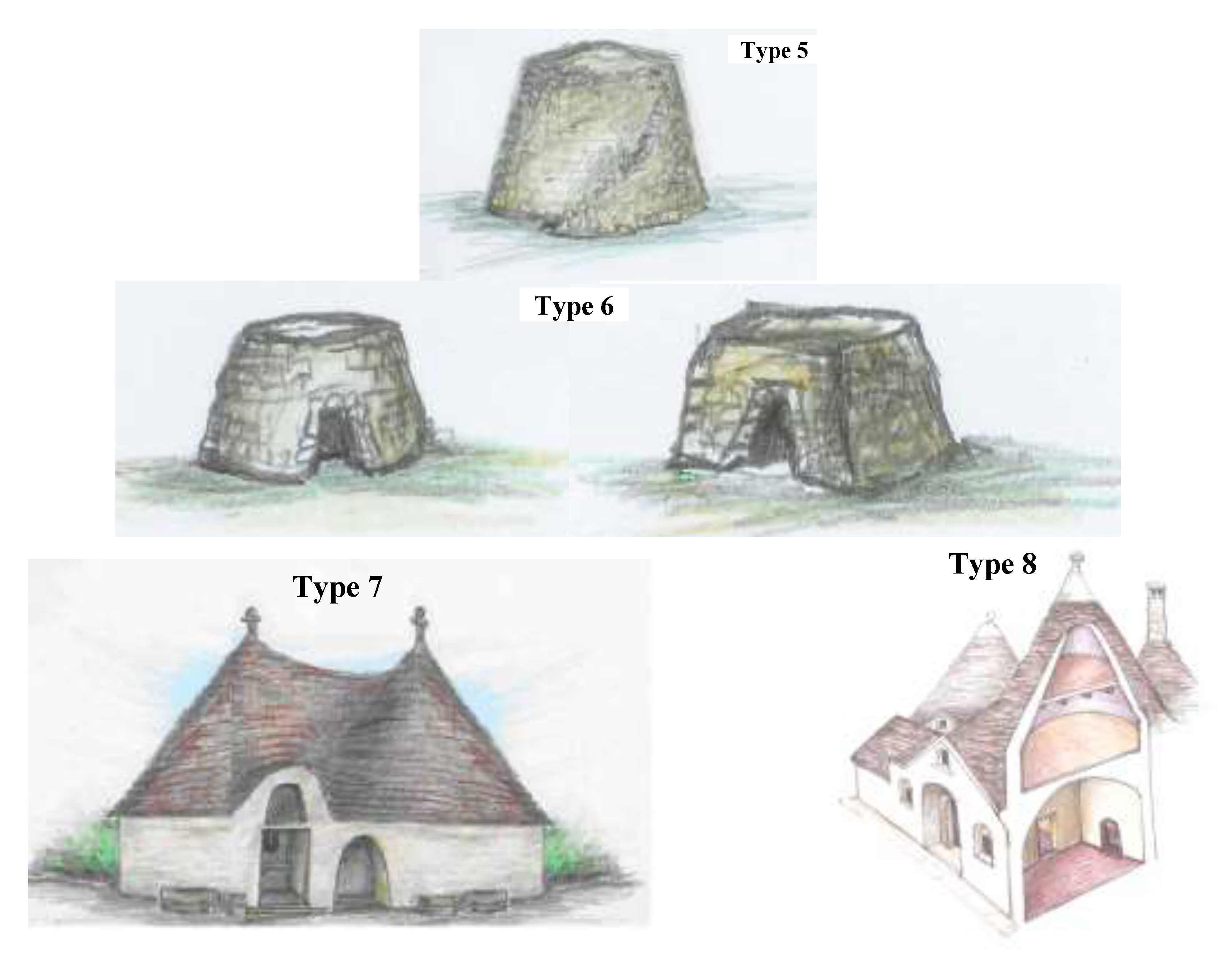

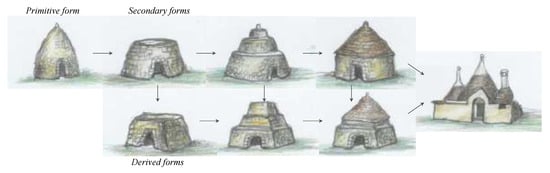

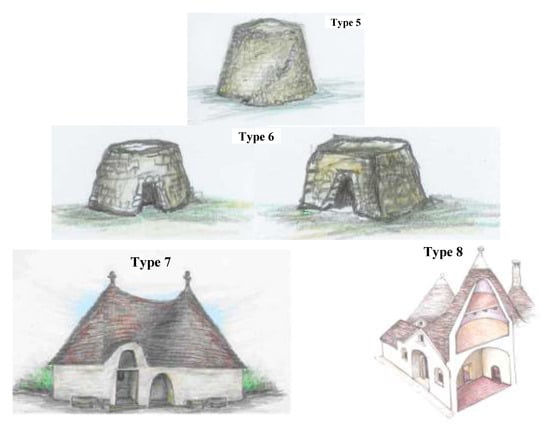

In thousands of years, other shapes were derived from the primitive one with a squared plan and dry-stone walls between the basement and the cone (Figure 2).

Figure 2.

Evolution of the trullo over thousands of years.

From the primitive form, the trullo evolves, absorbing the architectural characteristics of other cultures. Thus, a typical example of that is the substitution of the entrance trilith with a Romanian round arch, surmounted by a triangular tympanum. At the same time it evolves into a house, the primitive form is enriched with architectural and useful details, such as the fireplace, the windows, a floor built with calcareous stones, a water tank realized under the basis of the trullo for the conservation of rain water, etc.

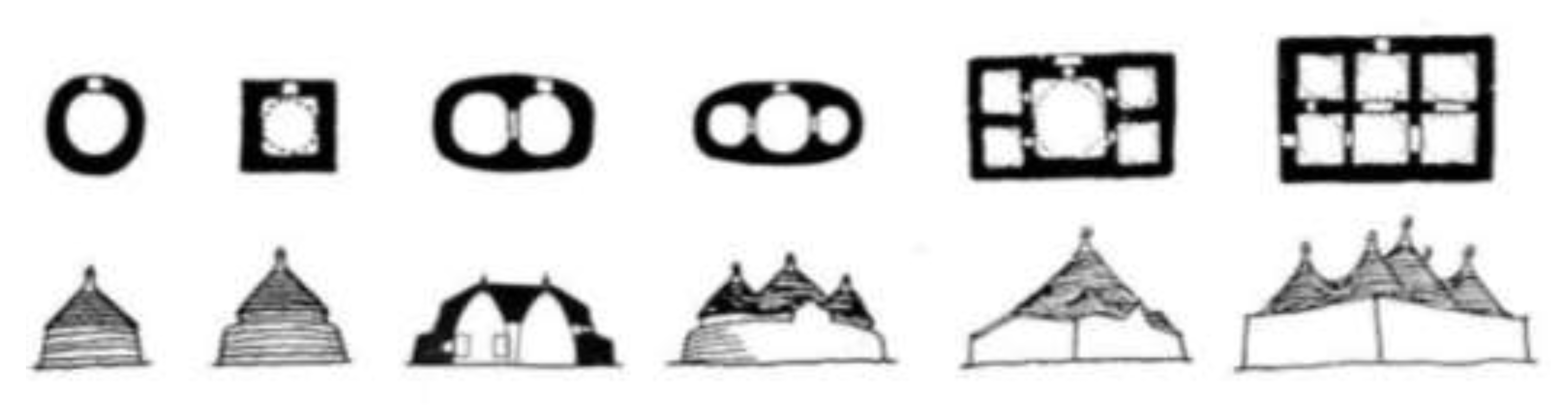

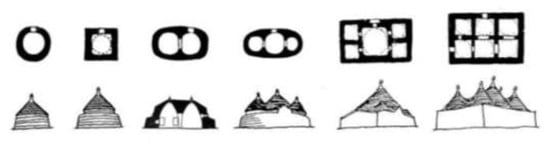

Later, the primitive circular plan becomes a squared one, and more trulli are assembled to realize a detached house with a large central room and lateral dependent rooms (Figure 3).

Figure 3.

Evolution from mono-cell to multi-cell constructions [52].

Some other transformations and adjustments for the domestic use of the trullo are realized as niches and brackets in the walls for the preservation of any types of objects, the plastering of the internal and external walls and the top of the roof near the pinnacles. By preserving the primitive structure, the evolution of the trulli makes them particularly characteristic buildings, so that the Apulian trulli represent a monumental and artistic heritage unique in the world. In December of 1996, UNESCO has added the Alberobello trulli to the World Heritage List.

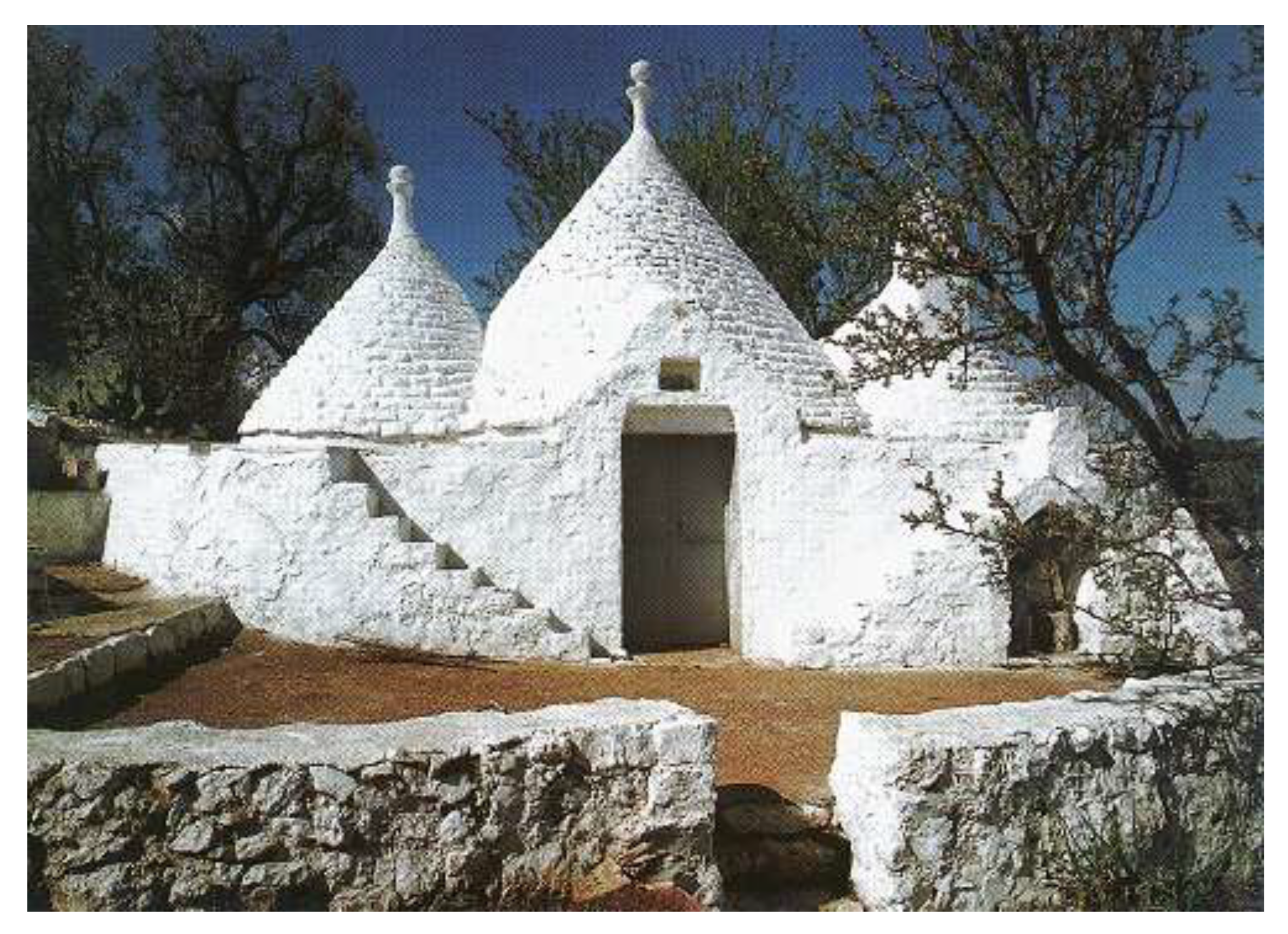

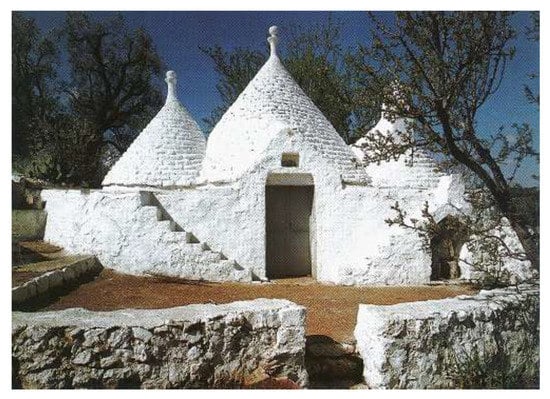

The construction technology of the trulli originated many centuries ago and it is nowadays also being adopted for solving some economic problems of buildings in emerging countries, because it uses local materials and poor technologies. The trulli present an optimal adaptability to the climatic conditions because of the thermal inertia due to the building dimensions and the used materials [48,49]. The custom to whitewash the external walls increases the reflection of the sun radiation (Figure 4). The comfort is improved by a good ventilation guaranteed by the “fireplace effect”, due to the conic form of the structure and the permeability of the walls that allow the external air to filter through the walls’ bricks. The use of baked clay or stabilized earth bricks allows a recovery in modern key of the ancient building technique of trulli for improving the characteristics of the traditional huts, without using corrugated iron roofs which are disadvantageous, especially for the rooms’ air-conditioning.

Figure 4.

Whitewash complex trullo.

Moreover, the easiness to realize these structures allows a large participation of the population to the building works, under the direction of few masons with experience.

A sample of a relatively modern application of this type of architecture was adopted in the late 1970s in Angola (southern Africa) by the Brazilian architect Fabricio Pedroza, who applied the technique of trulli for building some scholastic houses. For the roof, he used a single layer of perforated bricks, made with a light and resistant material which is abundant in that country. The internal space is similar to the traditional one, enriched with the advantages of the building being made with stable materials, and an excellent air-conditioning [55,56].

3. Trulli Typologies

Trulli have spread in the areas where the geological characteristics of soils assure an availability of the raw materials for the building. In the same way, the different forms of trulli are strictly connected to the physical and mechanical properties of the used materials.

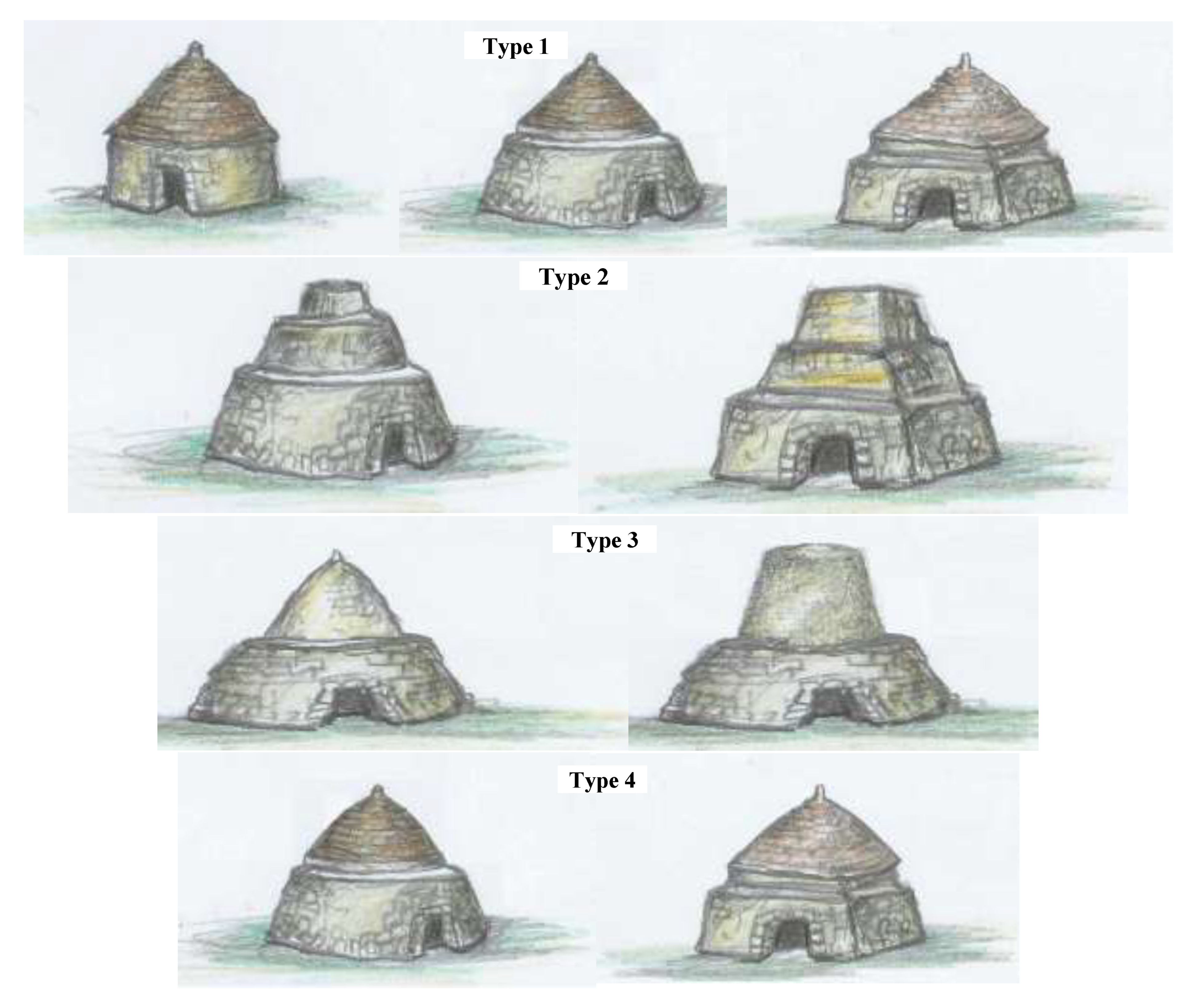

As shown in Figure 2 and Figure 3, primitive forms of trulli refer to uni-cell plans with circular shapes, that evolve towards more complex plans with a multi-cell layout and also squared shapes of the basements surmounted by a similar conic roofing system, or sometimes, by degrading squared roofing. Squared typologies are usually adopted for increasing available spaces and derive [57] from the original circular plan as depicted in Figure 5.

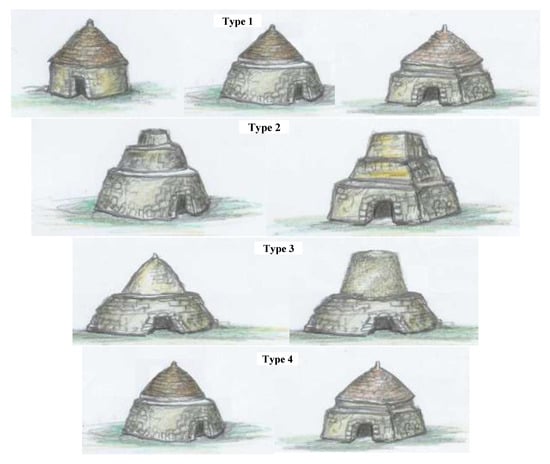

Figure 5.

Overview of the trulli typologies.

In the following section, the main typologies and forms trulli in Puglia are described in their basic characteristics (Figure 5).

In this regard, one should emphasize that, although the architectural typology of trulli derives from an ancient construction tradition related to the Mycenaeum Tholoi [58,59] and presents some similarity with other constructions [60] (like African Tucul or Sardinian Pinnettas, where circular plans and conical roofs made of clay and straw, or of dry stones arranged in layers, may be found), the main difference lies in its technical and morphological evolution, where technique was combined with functionality towards the development of a unique and singular aesthetic appearance.

This clearly appears from the outline of the typologies examined below, represented in Figure 5.

Type 1. The trullo is largely widespread in the Murge area. The roof is covered by thin slabs of stones, called “chiancarelle”, and has a perfectly conic form with a slope of 45 degrees. The basement has a circular or a squared plan (right side); it can be whitewash and may or may not be connected to the roof through a whitewash tambour. The multiple form is given by more trulli connected together. From this typology derives the more known form of the trulli in Alberobello.

Type 2. The trulli have largely spread along the coastline from Barletta to Bari, and in the Modugno area. The trullo is characterized by buttresses arranged around the dome and having a thickness so that the dome is completely hidden. The plan can be circular or squared (the second element in the row “type 2” of Figure 5, surmounted by a degrading square roof). The rise from the ground presents four or five large steps with the shape of truncated cones or pyramids, so that the trullo appears like a “multi-tiered cake”. The thickness of the wall at the basement is about 4 m. The cliff is usually one meter high. On the top, the central hole is covered by a large slab of stone, which can be occasionally removed. Because of the porosity of the calcareous bricks used during building, the trulli are covered by plaster on the horizontal surfaces. The door is small and of low height. The internal space is smaller because the trullo originates as a poor shed, which the shepherds built with the stones found in the area where they lived for a short time.

Type 3. The trullo is made by particularly irregular and unworkable materials, so that it is totally covered by plaster until it has a uniform surface. The structure consists of a circular basement, surmounted by a circular dome or by a truncated cone. Many trulli can be built together in multiple forms.

Type 4. The trullo type 4 is similar to the trullo type 1; the difference consists of a larger slope of the dome generated in the space by a soft curve. The tambour may or may noy be present. Many trulli can be built together in multiple forms. Additionally, this type may present a square plan of the basement, as shown in Figure 5.

Type 5. The trullo is not strictly a dry-stone building, because the basement is made of masonry composed of stones, and poor mortar made with soil and water. The dome is built by means of a very different technique with respect to other trullo types, since the trullo has buttresses as external walls, by which only the dome overhangs. The trullo can be totally plastered.

Type 6. The trullo has largely spread in the Salentine peninsula. These trulli look very different from the classical trulli; thus, they are called “Pagghiari”, “Furneddhi” or “Caseddhe”. The mixed technique adopted for the building of these trulli requires the presence of buttresses to contain horizontal stresses. The form is a truncated cone or pyramid. The trullo is not plastered, but the horizontal surfaces are covered with calcareous slabs or a thick layer of earth and stubble.

Type 7. The Siamese Trullo is largely widespread in the Alberobello area. This typology derives from the trullo type 1 having the difference of a squared plan, without the feeder tambour, and a whitewash basement. The structure is usually made of twin trulli, with only one basic perimeter and one masonry wall. The two domes are connected to each other by a solid body of large stones called “chianche”. It has no windows, and two arched doors open on the façade.

Type 8. A particular type of trullo is represented as the King Trullo, which is a two-storied trullo in Alberobello. In Figure 5, the cross-section is depicted for emphasizing its main feature related to the two-storey structure. Originally it was built by the Perta family in the middle of the 1700s, when the building technique of dry-stone walls was used. The King Trullo represents a unique and optimal example to propose the trullo as an architectural monument; it has twelve cones and the central dome is 14 m high. After the King Trullo, other two-storied trulli were built in Alberobello.

Another typical form of the trullo is represented through a construction made up of a group of trulli placed around a central courtyard (Figure 6).

Figure 6.

Group of trulli around an inner courtyard.

A further classification of trulli can be made based on the intended use. Thus, the trulli can be distinguished according to whether they are used as houses or as shelters, haylofts or sheds.

Mono-cell or supporting trullo. The circular form is characteristic, also if it is not exclusive, of the older trulli (Figure 7a). The older trulli were generally low-rise constructions since the used stones were lifted by arms. The trulli had a “bell” shape, since the internal walls had no vertical base, but were vaulted on the basement. The roof is characterized by numerous steps obtained by removing some “chiancarelle” from the roof and realizing some suitable niches to climb by feet. The trulli have no pinnacles when the staircase is present on the conic roof, and are characterized by a large stone that can be removed when it is necessary to ventilate the internal rooms.

Figure 7.

(a) A mono-cell rural trullo, with steps on the roof and (b) some city trulli.

City trullo. Unlike the country trullo, city trullo is always coupled with other trulli (Figure 7b). The house structure is made of a lot of rooms, which had various fabrics added for satisfying different needs. The roof of the trullo house is closed at the top with a large stone slab.

4. The Trullo Structure

The main material used for the trullo building comes from the same soil where the trullo is edified. The building material has different dimensions and thickness, because being the trullo built without any mortar, the best adhesion and contrast between the stony wedges is favored. For the geological origin of the Puglia region, the trulli in this area are usually built with calcareous rocks, a material largely widespread throughout the country. The calcareous rocks are sedimentary rocks, made mainly of calcite and with different forms, color and other properties in relation to their genesis and transformations acquired during the thousands of years.

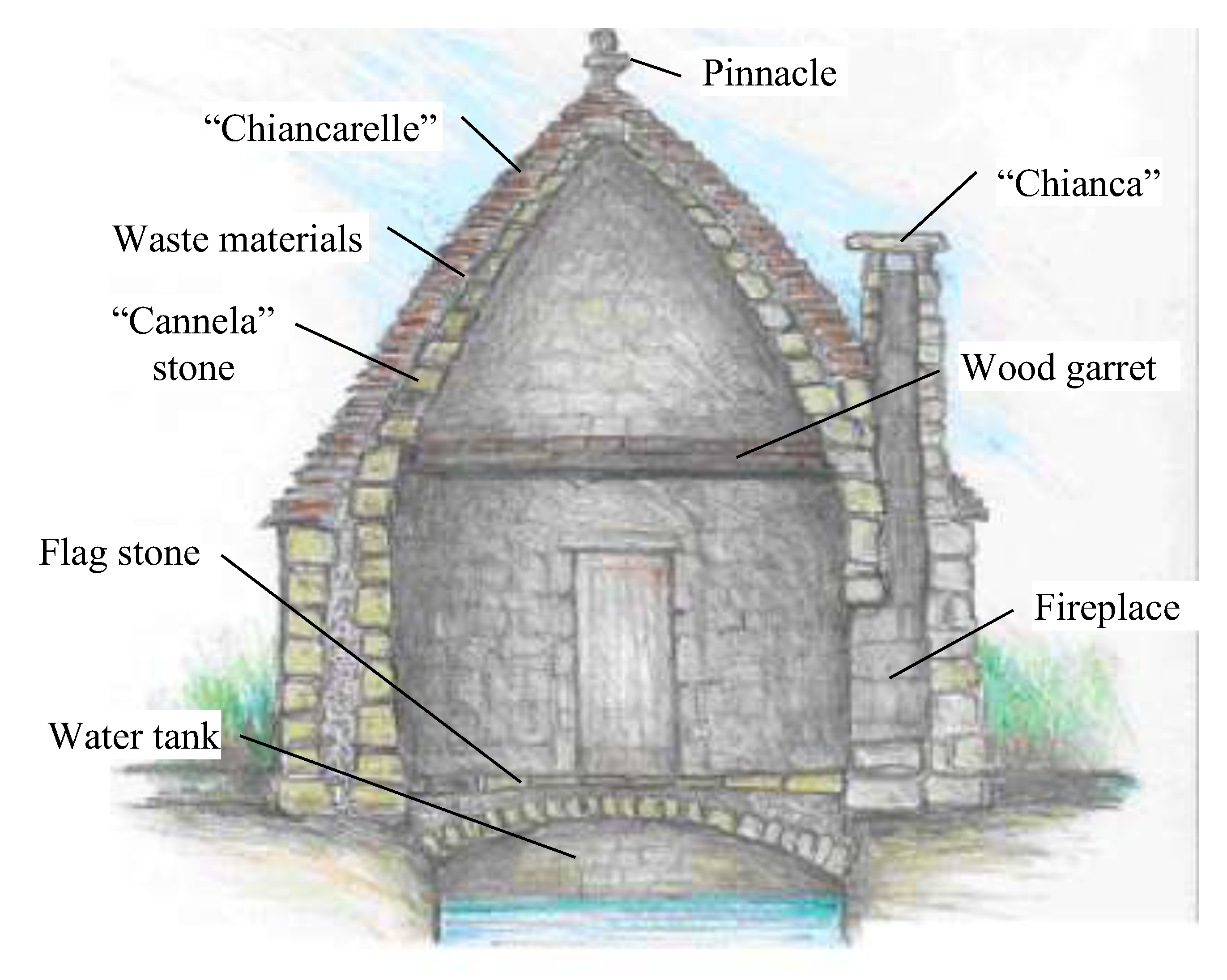

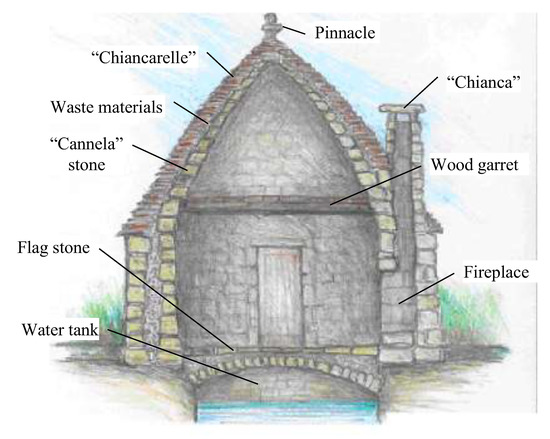

The typical structure of the trullo is represented by the following fundamental structural elements: foundations, floor, water tank, outer walls and dome (Figure 8).

Figure 8.

Structure of a trullo.

4.1. The Foundations and the Water Tank

The foundations are dug 5060 cm deep in the same rock from which the stones used in the trullo-building process are caved. They are then covered by a cemented lime with a local pozzolana.

In the cavity under the building, suitably treated in order to have a high capacity, a water tank is obtained for the deposit of the water which is carried in the subsoil by the particularly round forms of the roof stones (Figure 7). The water tank is built before the upper main structure of the trullo, and consists of a square or rectangular cavity with both length and depth, four or six meters large. On the base of the water tank, there is always a basin towards which the floor slopes, with the double function of a dirty deposit and conservation of water.

The floor of the trullo stands on the boundary of a loose, stone foundation 40 cm high; the central part stands on the roof of the water tank, which is usually a barrel vault. The rocks used for the building the floor are initially rough, and then become smooth, through wear, and assume brightness with a beige or soft pink color.

4.2. The Outer Walls

The bearing wall is the classical interstice-wall made of two stone walls, separated by an inner cavity (Figure 8). The cavity is filled with small pieces of grossly carved stone. The final wall is usually 1 m thick, even if, sometimes, the final thickness of the wall is about 3 m in older trulli. The significant thickness of the walls allows for maintaining a constant temperature inside the building and a comfortable room-temperature, too, if the permeability of the water tank and the roof is not significant. The stones are worked in various sizes and dry-assembled to form the entrance arch and the frames for the window openings, which remain limited, in any case, to reduce heat loss. The basement has the function of retaining the horizontal stresses that are generated by the presence of the dome, even if the dome is built so that the stresses transmitted to the wall below are minimum.

4.3. The Dome

The dome is built gradually; circle by circle starting from the walls with a cavity, which increases from the pinnacle to the basis of the dome, and is filled with waste materials (Figure 8). Once a ring has been completed, the next one is built superposing to the previous one until the roof is completed, without the use of any auxiliary wooden repayment. Finally the stones placed in concentric rings and staggered in height generate a vault that does not need internal supports. The internal cone is made of stones, called “cannele”, arranged according to concentric rings with an overhang of approximately 1–2 cm. The ring diameter reduces going to the top of the dome, which is closed with a large stone slab (Figure 9b). The equilibrium of the cone is guaranteed by the lateral mutual contrast of the bricks and through wedges of stones that can be locally added.

Figure 9.

(a) A trullo roof covered by “chiancarelle” stones and (b) an internal view of the roof closed with a central stone slab.

The external cone, which covers the internal one, consists of thin stone slabs, called “chiancarelle” (Figure 9a), arranged in the form of flakes with a slight tilt outwards.

In modern trulli, the dome starts at 1.80 m in height. On the contrary, in older trulli it starts at 1 m in height. For the equilibrium of the dome, well-squared stones, with different thicknesses and widths, can be used only when the stones with different width and the same height are arranged in the same ring. It is possible to have two contiguous rings with different heights too. Going up to the top of the trullo, the diameter of the stone rings gradually reduces. The final shape is not the perfect form of the dome, which is usually realized with squared stones, having a truncated pyramid form and a direction towards the centre of the dome. Therefore, the cone of the trullo is more properly a pseudo-dome.

During the building phases, the internal part of the dome is built at first by means of a series of little tricks, such as introducing an angle-key stone in the room angles, which is a stone able to cancel the base angles and give the necessary roundness to the wall for supporting the upper cone. After building, the bearing structure of the cone, the cover of the dome, is made of two layers: waste materials or irregular little stones are used in the first layer, while the second layer is made of dry stones (“chiancarelle”) which are assembled and sloped outwards. The trullo’s cones are characterized by a grey colour because they are usually not whitewashed.

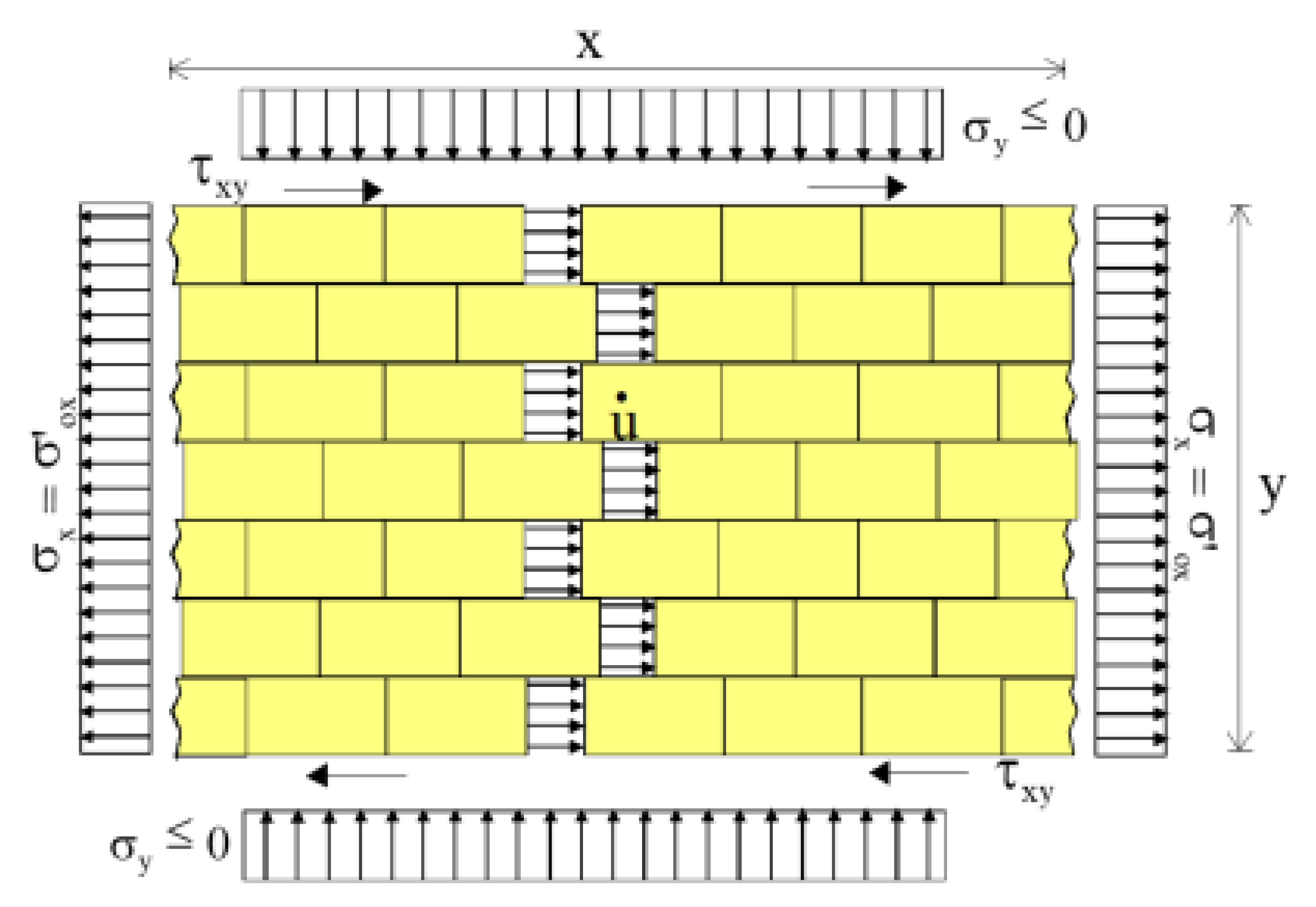

4.4. Structural Features of Bearing Walls and the Roofing System

Because of their constituent materials, the static analysis of the trulli and of any component requires reference to analytical tools for treating masonry, which may be handled through the NT treatment for modelling the mechanical behavior of the material. In regards to the roofing system, its construction does not require any careful preparatory work, being a pseudo-vault, which does not require any finishing of the ashlars or wooden ribs, since it is built by overlapping circles. Although the behavior of such a pseudo-vaulted roofing system differs from traditional vaults, where the forces are to be completely absorbed by the lateral piers and friction forces are generated between the ashlars ensuring the stability of the structure mainly by the weight of the mass (earth or stone) placed on the extrados, further checks are needed.

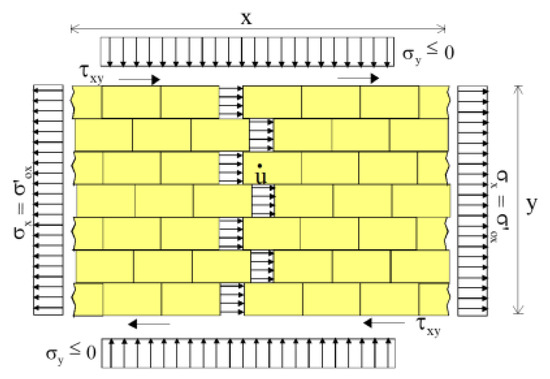

The vertical panels of these dry constructions, being realized without mortar and having a bearing function of the roofing system, may experience failure mechanisms because of the horizontal tractions in the masonry of the type, shown in Figure 10. The thrust of the roof on the load-bearing structures can cause tensile stresses in the masonry, which must be carefully checked also in relation to the absence of mortar between the brick joints.

Figure 10.

Stress state and failure mechanisms with activation of fractures.

For this aim, the masonry characterized by the offset “s” of the bricks between one row and another, and the coefficient “f” of friction that is exerted between adjacent ashlars for dry masonry or between the ashlar and the mortar should be considered. Usually, experimentally, this coefficient is between 0.3 and 0.8.

Analysing the fracture mechanism caused by the tension σx in the “x” direction depicted in Figure 9, after denoting the stress component in the “y” direction with σy, the tangential stress with τxy, the limit horizontal stress with σ’o, the horizontal row drift with “u” and its time derivative with a superimposed dot, the equilibrium equation between the energy developed by the tensile stresses and dissipated due to friction is

where ω is the joint density (given by the number of joints in the row per unit height), “s” is the offset and “f” the friction coefficient, one gets

and the material admissibility conditions can be written in the form of the following inequalities.

Going off this premise, stresses may be inferred once implemented in the problem under the admissibility conditions set by the above Equation (3), and through a suitably built numerical model with the relevant mesh, analysed by the authors also through a compilation of adhoc calculus codes, as referred to literature [5,7,8].

5. Conclusions

The paper focuses on a special type of dry constructions built in the Puglia region, in Italy, over thousands of years by shepherds: the trulli. The paper presents the evolution over time of these structures, as well as their description and treatment from a structural point of view. A classification of these constructions by typology (type 1–type 9) is also presented and the main advantages of these structures are highlighted, providing an important documentary material regarding the trulli-type limestone structures. This type of construction is characterized by walls with an internal hollow and a roofing system, realized through concentric masonry rings. The main technological, functional and structural features of these constructions, which have been recognized among the UNESCO World Heritage sites, are discussed together with their components, construction features and classification, as a tool for deepening the main characteristics of these kinds of spontaneous and poor architectures, using local materials without any specialized workers, but nevertheless, resisting over time.

Author Contributions

Conceptualization, I.C. and A.B.; methodology, I.C. and A.B.; software, I.C.; validation, O.C. and H.L.; formal analysis, I.C.; investigation, I.C.; resources, O.C.; writing—original draft preparation, I.C. and O.C.; writing—review and editing, O.C. and H.L.; visualization, I.C.; supervision, I.C.; project administration, all authors; funding acquisition, I.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Italian Ministry of University, Research MUR and the Laboratory network ReLuis, supported by the national civil protection.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Huerta, S. The Analysis of Masonry Architecture: A Historical Approach. Archit. Sci. Rev. 2008, 51, 297–328. [Google Scholar] [CrossRef]

- Heyman, J. The stone skeleton. J. Solids Struct. 1966, 2, 269–279. [Google Scholar] [CrossRef]

- Heyman, J. The safety of masonry arches. J. Mech. Sci. 1969, 2, 363–384. [Google Scholar] [CrossRef]

- Heyman, J. The Stone Skeleton: Structural Engineering of Masonry Architecture; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Baratta, A.; Corbi, O. Relationships of LA theorems for NRT structures by means of duality. Theor. Appl. Fract. Mech. 2005, 44, 263–274. [Google Scholar] [CrossRef]

- Lau, W.; Ochsendorf, J.; Zessin, J. Equilibrium of cracked masonry domes. Proc. ICE Eng. Comput. Mech. 2010, 163, 135–145. [Google Scholar]

- Baratta, A.; Corbi, O. Heterogeneously Resistant Elastic-Brittle Solids under Multi-Axial Stress: Fundamental Postulates and Bounding Theorems. J. Acta Mech. 2015, 226, 2077–2087. [Google Scholar] [CrossRef]

- Baratta, A.; Corbi, I.; Corbi, O. Analytical Formulation of Generalized Incremental Theorems for 2D No-Tension Solids. Acta Mech. 2015, 226, 2849–2859. [Google Scholar] [CrossRef]

- Benvenuto, E.; Corradi, M. La statica delle false volte. Archit. Pietra Secco 1987, 93–106. (In Italian) [Google Scholar]

- Corbi, I.; Corbi, O.; Tropeano, F. Stability assessment of an historical masonry bridge through the LA kinematic theorem for NT structures. Int. J. Mech. 2016, 10, 305–311. [Google Scholar]

- Baratta, A.; Corbi, O. Contribution of the fill to the static behaviour of arched masonry structures: Theoretical formulation. Acta Mech. 2014, 225, 53–66. [Google Scholar] [CrossRef]

- Bazant, Z.P. Is no-tension design of concrete or rock structures always safe? Fracture analysis. J. Struct. Eng. ASCE 1996, 122, 2–10. [Google Scholar] [CrossRef]

- Broberg, K.B. Cracks and fracture. Appl. Mech. Rev. 2000, 53. [Google Scholar]

- Corbi, I.; Corbi, O. Combinational optimization for shaping discrete tensile boost elements in continuum structures. Acta Mech. 2018, 229, 3575–3584. [Google Scholar] [CrossRef]

- Cambou, B.; Di Prisco, C. Constitutive modelling of geomaterials. Appl. Mech. Rev. 2022, 55. [Google Scholar] [CrossRef]

- Khludnev, A.M.; Kovtunenko, V.A. Analysis of Cracks in Solids; WIT Press: Southampton, UK, 2000; p. 386. [Google Scholar]

- Li, V.C.; Bazant, Z.P. Fracture Mechanics: Applications to Concrete; Special Publ. SP-118; American Concrete Institute: Indianapolis, IN, USA, 1996. [Google Scholar]

- Baratta, A.; Corbi, I.; Corbi, O. Rocking Motion of Rigid Blocks and their Coupling with Tuned Sloshing Dampers. In Proceedings of the CC09, 12th International Conference on Civil, Structural and Environmental Engineering Computing, Madeira, Portugal, 1–4 September 2009; Topping, B.H.V., Costa Neves, L.F., Barros, R.C., Eds.; Civil Comp-Press: Stirlingshire, UK, 2009; p. 175. [Google Scholar]

- Corbi, I.; Corbi, O.; Li, H. A Constrained Energy Minimum Approach to Modal Dynamic Control of Vibrations in Ancient Nonlinear Structures. Int. J. Struct. Stab. Dyn. 2019, 19, 1950054. [Google Scholar] [CrossRef]

- Corbi, I.; Corbi, O. Analysis of bi-dimensional solids with internal unilateral constraint coupled to structural elements with different degree of connection. Acta Mech. 2016, 228, 607–616. [Google Scholar] [CrossRef]

- Baratta, A.; Corbi, I.; Corbi, O. Bounds on the Elastic Brittle solution in bodies reinforced with FRP/FRCM composite provisions. J. Compos. Part B Eng. 2015, 68, 230–236. [Google Scholar] [CrossRef]

- Corbi, O.; Zaghw, A.H.; Elattar, A.; Saleh, A. Preservation provisions for the environmental protection of egyptian monuments subject to structural vibrations. Int. J. Mech. 2013, 7, 172–179. [Google Scholar]

- Baratta, A.; Corbi, I.; Corbi, O.; Mastorakis, N. Strategies for the protection from structural failures under seismic events. Int. J. Mech. 2015, 9, 69–75. [Google Scholar]

- Corbi, I.; Corbi, O. Development and implementation of a control system for the dynamic mitigation of 3-D masonry structures with feedback on the drifts in the horizontal plan. J. Struct. Control Health Monit. 2018, 25, e2176. [Google Scholar] [CrossRef]

- Corbi, I.; Corbi, O. Macro-mechanical modelling of pseudo-elasticity in shape memory alloys for structural applications. J. Acta Mech. 2016, 27, 2171–2179. [Google Scholar] [CrossRef]

- Corbi, O.; Zaghw, A.H. Properties and design of dissipative viscorecentring SMA members for civil structures. Int. J. Mech. 2013, 7, 285–292. [Google Scholar]

- Baratta, A.; Corbi, I.; Corbi, O. Stability of evolutionary brittle-tension 2D solids with heterogeneous resistance. J. Comput. Struct. 2016, 174, 133–138. [Google Scholar] [CrossRef]

- Corbi, I.; Corbi, O. Theorems for masonry solids with brittle time-decaying tensile limit strength. Acta Mech. 2017, 228, 837–849. [Google Scholar]

- Baratta, A.; Corbi, I.; Corbi, O. Algorithm design of a hybrid system embedding influence of soil for dynamic vibration control. Soil Dyn. Earthq. Eng. 2015, 74, 79–88. [Google Scholar] [CrossRef]

- Corbi, I.; Corbi, O.; Li, H. Optimum design of dynamic modal control algorithm using non-linear structural mathematical modeling. Soil Dyn. Earthq. Eng. 2018, 114, 548–554. [Google Scholar] [CrossRef]

- Corbi, I.; Corbi, O.; Li, H. Convolutive PD controller for hybrid improvement of dynamic structural systems. J. Soil Dyn. Earthq. Eng. 2020, 137, 106255. [Google Scholar] [CrossRef]

- Di Cesare, A.; Ponzo, F.C. Seismic Retrofit of Reinforced Concrete Frame Buildings with Hysteretic Bracing Systems: Design Procedure and Behaviour Factor. J. Shock Vib. 2017, 2017, 2639361. [Google Scholar] [CrossRef]

- Gallipoli, M.R.; Mucciarelli, M.; Ponzo, F.; Dolce, M.; D’Alema, E.; Maistrello, M. Buildings as a seismic source: Analysis of a release test at Bagnoli, Italy. Bull. Seismol. Soc. Am. 2006, 96, 2457–2464. [Google Scholar] [CrossRef]

- Ponzo, F.C.; Di Cesare, A.; Lamarucciola, N.; Nigro, D. Seismic Design and Testing of Post-tensioned Timber Buildings with Dissipative Bracing Systems. J. Frontiers Built Environ. 2019, 5, 104. [Google Scholar] [CrossRef]

- Iacovino, C.; Ditommaso, R.; Ponzo, F.C.; Limongelli, M.P. The Interpolation Evolution Method for damage localization in structures under seismic excitation. Earthq. Eng. Struct. Dyn. 2018, 47, 2117–2136. [Google Scholar] [CrossRef]

- Mazza, F. Nonlinear seismic analysis of unsymmetric-plan structures retrofitted by hysteretic damped braces. Bull. Earthq. Eng. 2016, 14, 1311–1331. [Google Scholar] [CrossRef]

- Mazza, F. Displacement-based seismic design of hysteretic damped braces for retrofitting in-plan irregular r.c. framed structures. J. Soil Dyn. Earthq. Eng. 2014, 66, 231–240. [Google Scholar] [CrossRef]

- Mazza, F.; Vulcano, A. Nonlinear seismic analysis to evaluate the effectiveness of damped braces designed for retrofitting r.c. framed structures. Int. J. Mech. 2013, 7, 251–261. [Google Scholar]

- Mazza, F.; Vulcano, A. Control of the along-wind response of steel framed buildings by using viscoelastic or friction dampers. Int J. Wind Struct. 2007, 10, 233–247. [Google Scholar] [CrossRef]

- Allen, E. Pietre di Puglia: Dolmen, Trulli e Insediamenti Rupestri; Adda Editore: Bari, Italy, 1984. (In Italian) [Google Scholar]

- Dal Sasso, P.; Caliandro, L.P. The role of historical agro-industrial buildings in the study of rural territory. Landsc. Urban Plan. 2010, 96, 146–162. [Google Scholar] [CrossRef]

- Pagano, G.; Guarniero, D. Architettura Rurale Italiana; Hoepli Ed.: Milano, Italy, 1936. (In Italian) [Google Scholar]

- Stefanelli, G. Costruzioni Rurali; Edizioni Agricole: Bologna, Italy, 1956; pp. 9–11. (In Italian) [Google Scholar]

- Merico, A.; Bellopede, R.; Fiorucci, A.; Marini, P. Itria Valley (Apulia, Italy): Comparison of limestones for the construction and restoration of “Trulli” roofing. Resour. Policy 2022, 76, 102630. [Google Scholar] [CrossRef]

- Marzulli, M.T. Meravigliose Architetture nel Contesto dei Muri a Secco; Artebaria: Martina Franca, Italy, 2019; p. 176. [Google Scholar]

- Banks, I.; MacGregor, G. Townships to Farmsteads: Rural Settlement Studies in Scotland, England and Wales, British Series: 293; British Archaeological Reports: Oxford, UK, 2000. [Google Scholar]

- Maggiulli, P. Specchie e Trulli in Terra d’Otranto; Tipografia Editrice Leccese: Lecce, Italy, 1909. (In Italian) [Google Scholar]

- Chiaramonte, F. Materiali Nella Costruzione Edilizia; Edizioni Marcri: Firenze, Italy, 1950; pp. 4–7. (In Italian) [Google Scholar]

- Dragone, M. L’architettura in Pietra a Secco Della Puglia in Italia; Materiali, Forme e Cultura: Fasano, Italy, 2012. (In Italian) [Google Scholar]

- Esposito, G. Architettura e Storia dei Trulli: Alberobello, un Paese da Conservare, Casa del Libro, Roma; Gangemi editore; De Gruyter Saur: Munich, Germany, 1984; p. 160. (In Italian) [Google Scholar]

- Notarnicola, G. I Trulli di Alberobello; Unione Editori d’Italia: Roma, Italy, 1940. (In Italian) [Google Scholar]

- Simoncini, G. Architettura Contadina di Puglia; Vitali e Ghianda: Genova, Italy, 1960; p. 139. (In Italian) [Google Scholar]

- Di Mizio, E.T. Pietra, Vita da Trullo. Descrizione, Problemi, Risposte; Vito Radio: Putignano, Italy, 1983. (In Italian) [Google Scholar]

- Fraddosio, A.; Lepore, N.; Piccioni, M.D. Further refinement of the Corbelling Theory for the equilibrium analysis of corbelled domes. Curved Layer. Struct. 2019, 6, 30–40. [Google Scholar] [CrossRef]

- Stefanizzi, P.; Fato, I.; Di Turi, S. Energy and Environmental Performance of Trullo Stone Building. An Experimental and Numerical Survey. Int. J. Heat Technol. 2016, 34, S396–S402. [Google Scholar] [CrossRef]

- Bodach, S.; Lang, W.; Hamhaber, J. Climate responsive building design strategies of vernacular architecture in Nepal. Energy Build. 2014, 81, 227–242. [Google Scholar] [CrossRef]

- Battaglia, R. Osservazioni Sulla Distribuzione e Sulla Forma dei Trulli Pugliesi. In Atti del II Congresso Storico Pugliese e del Convegno Internazionale di Studi Salentini, Terra d’Otranto 25–31 ott; Archivio Storico Pugliese, C.E., Ed.; Alfredo Cressati: Bari, Italy, 1952; pp. 33–44. [Google Scholar]

- Cavanagh, W.G.; Laxton, R.R. The structural mechanics of the Mycenaean Tholos Tombs. Annu. Br. Sch. Athens 1981, 76, 109–140. [Google Scholar] [CrossRef]

- Rovero, L.; Tonietti, U. Structural behaviour of earthen corbelled domes in the Aleppo’s region. Mater. Struct. 2012, 45, 171–184. [Google Scholar] [CrossRef]

- Lobbecke, R. Corbelled Domes; Verlag der Buchhandlung, Walther Konig: Walther König, Köln, 2013; p. 384. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).