Effect of Clearances in Mill Stands on Strip End Motion During Finishing Rolling

Abstract

1. Introduction

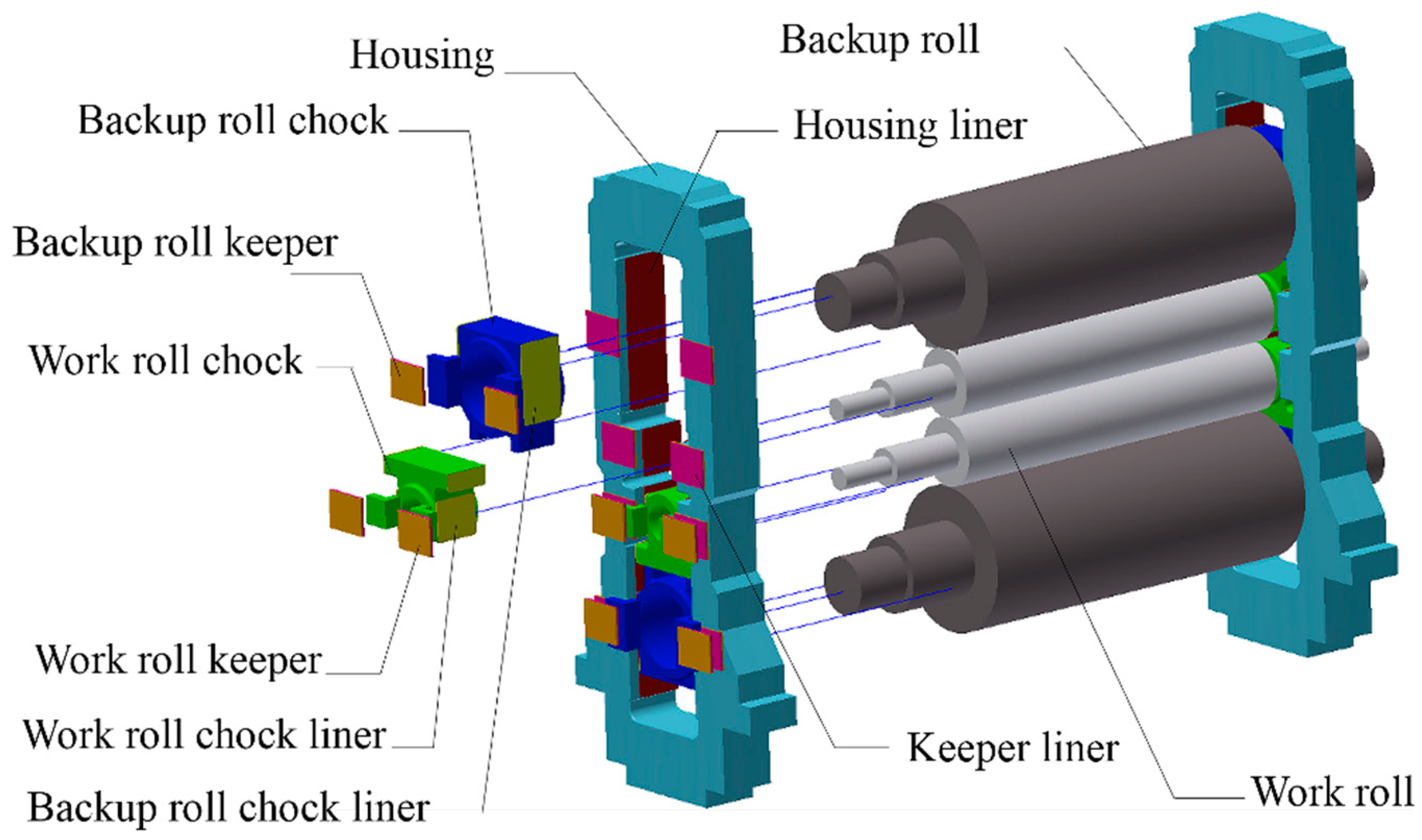

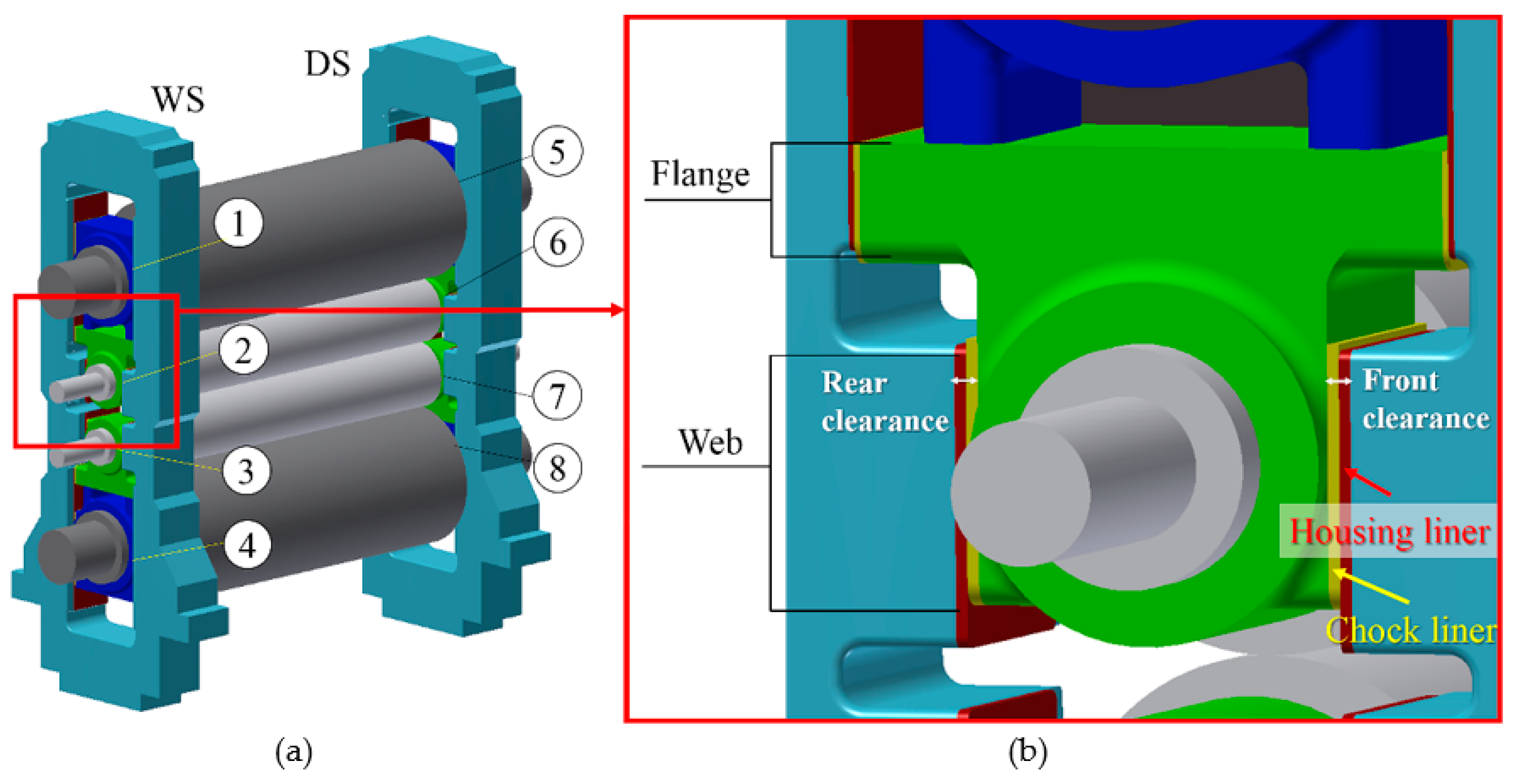

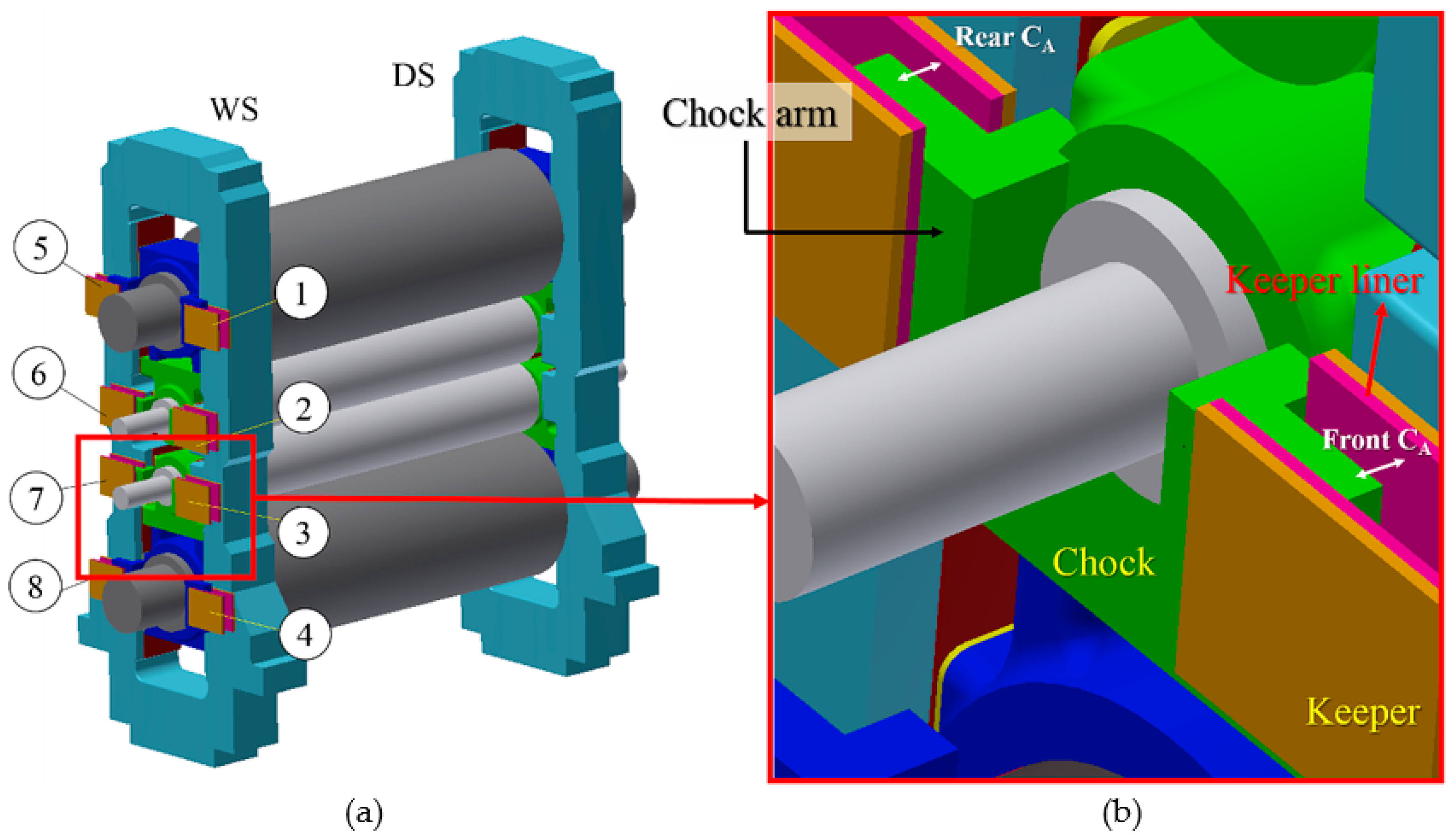

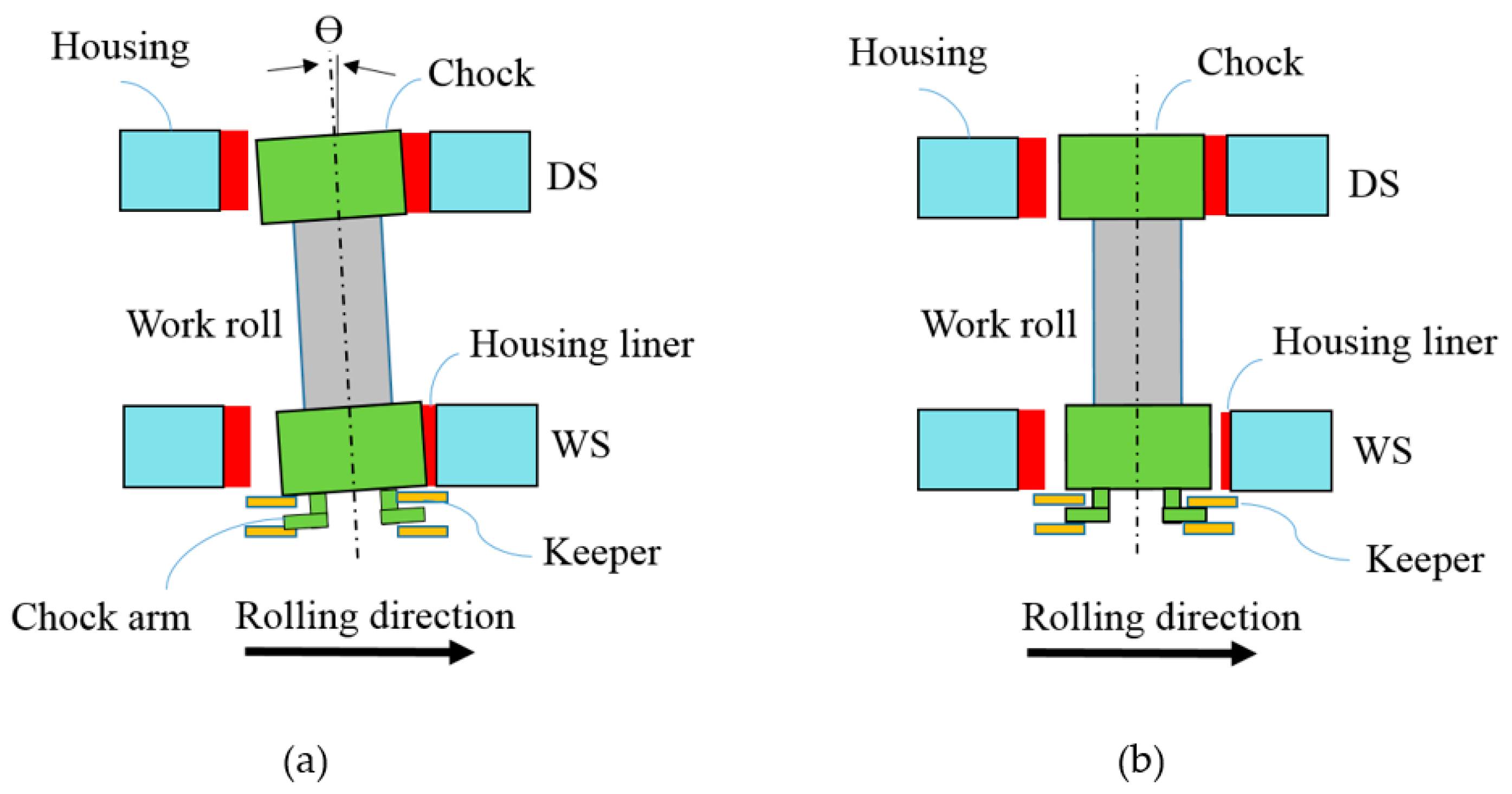

2. Introduction to Assembly of Finishing Mill Stand and Clearances

3. FEM Modeling and Methodology

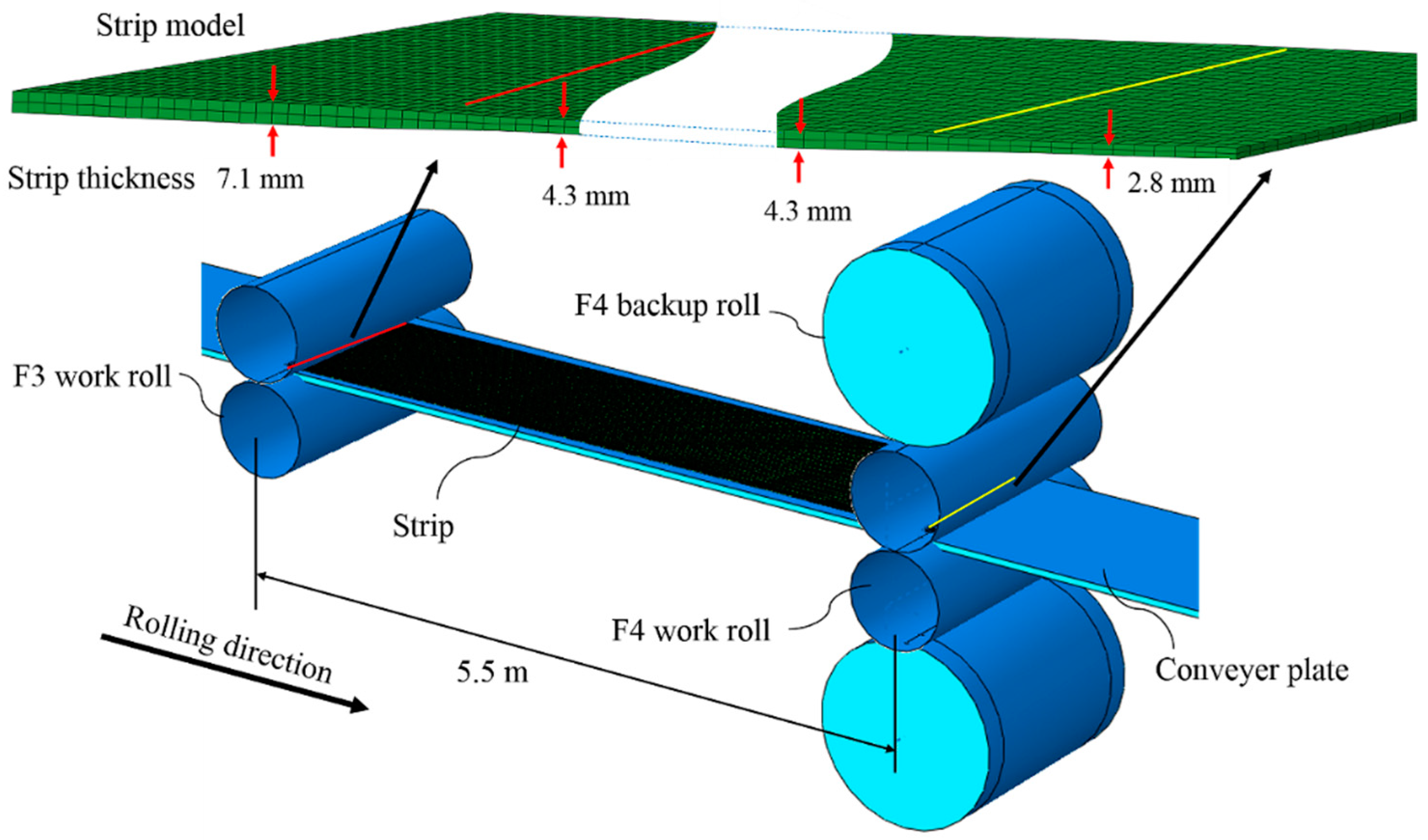

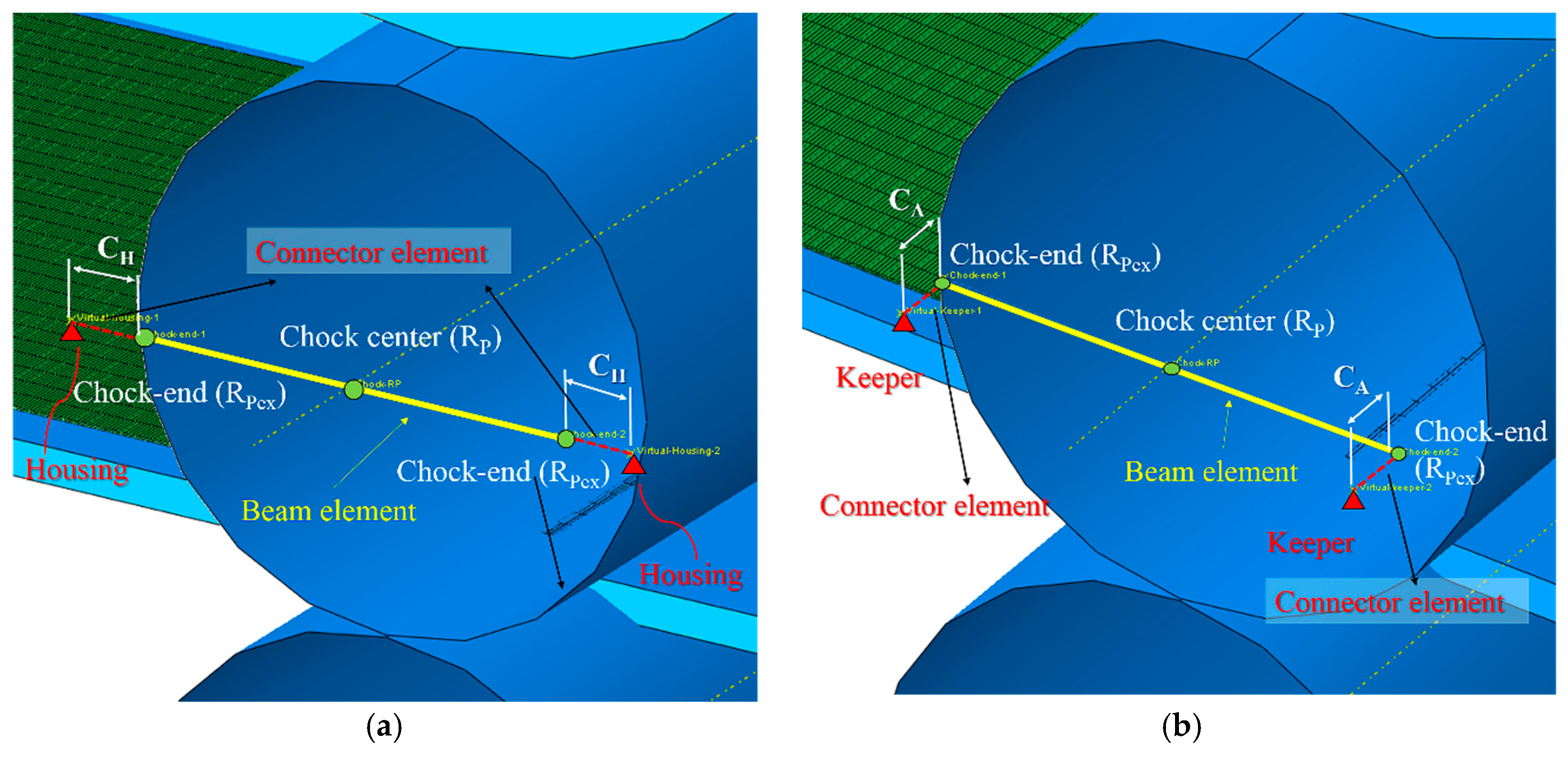

3.1. Finishing Mill and Clearance Model

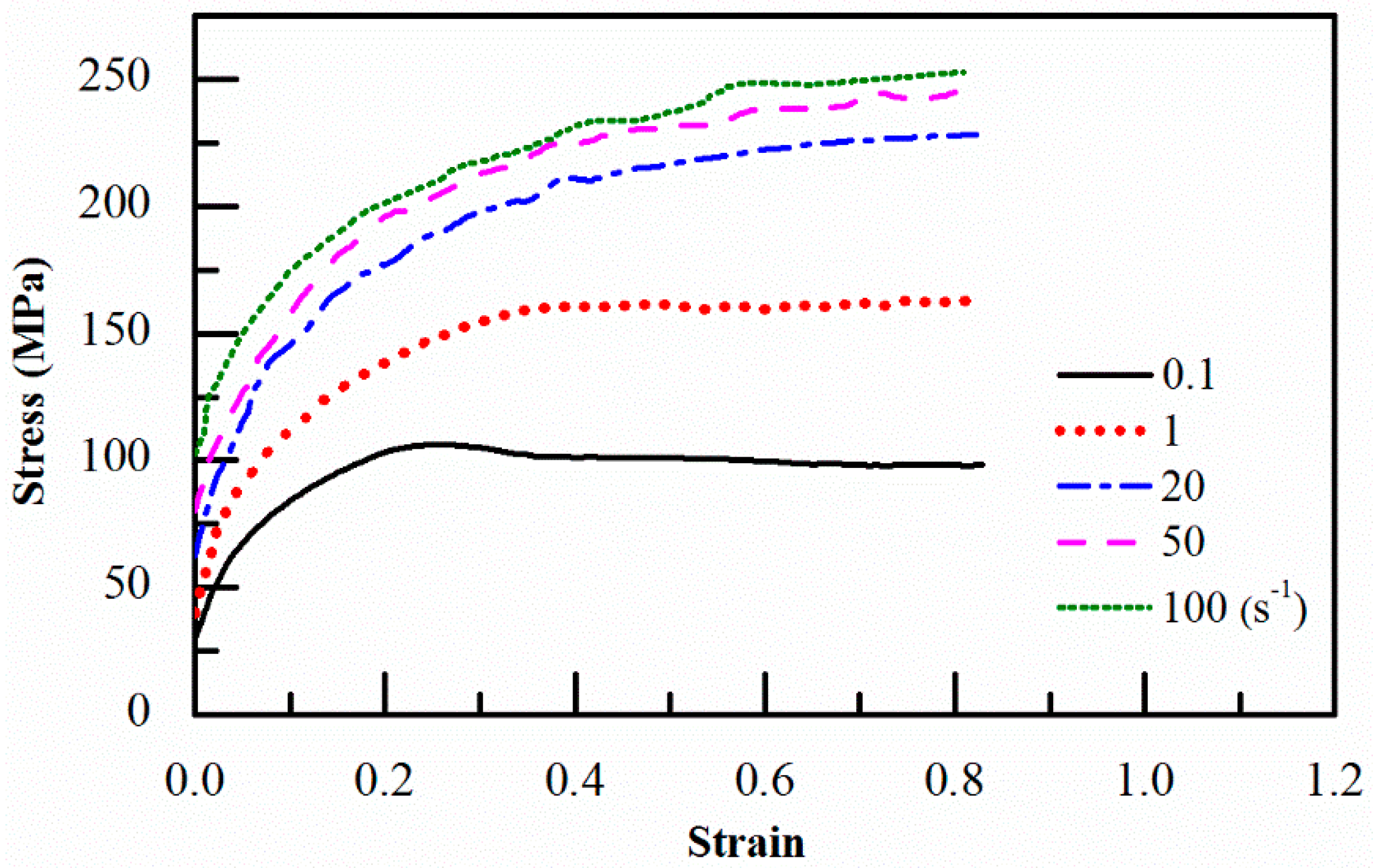

3.2. Strip Modeling

4. Results and Discussion

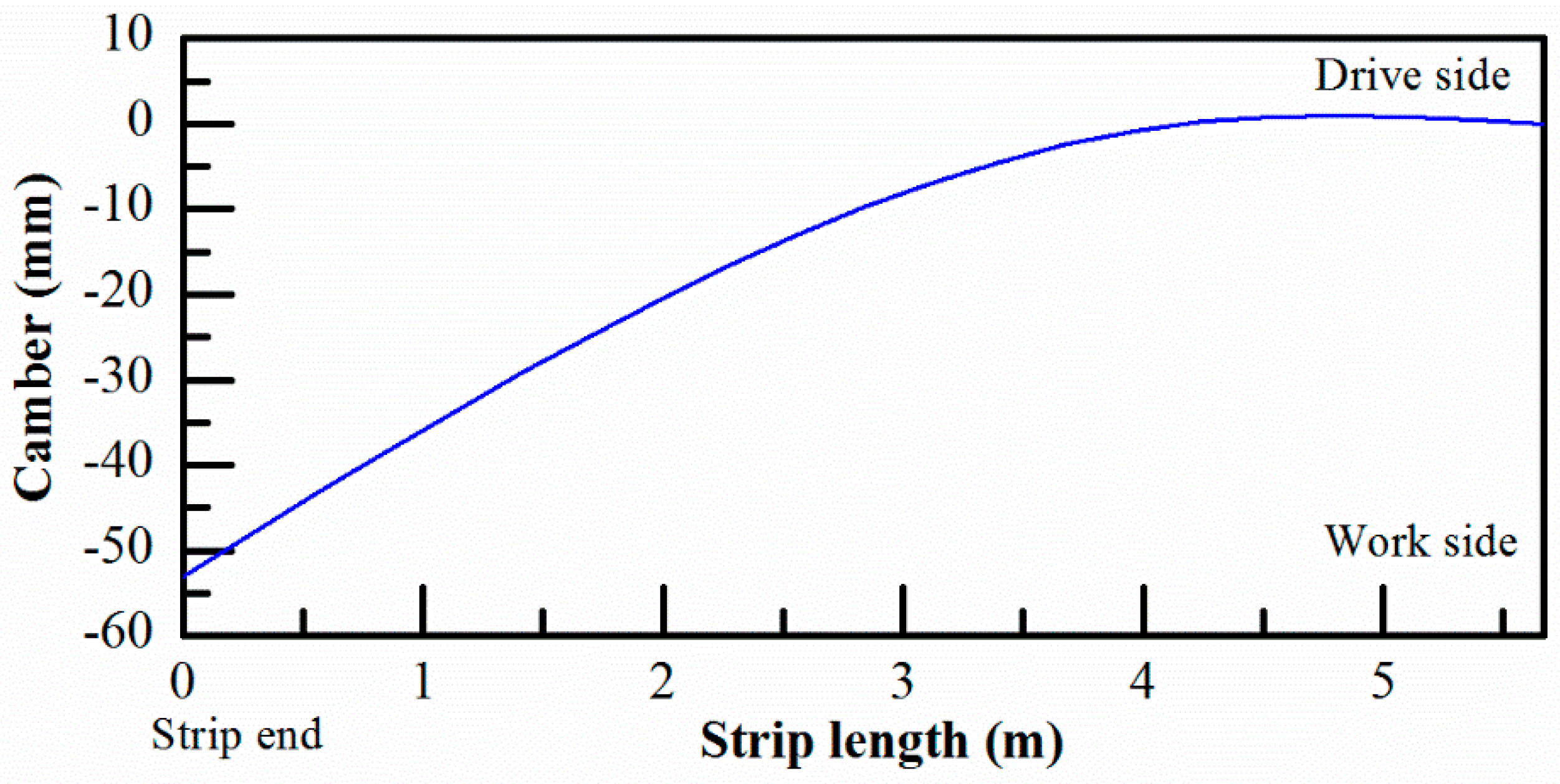

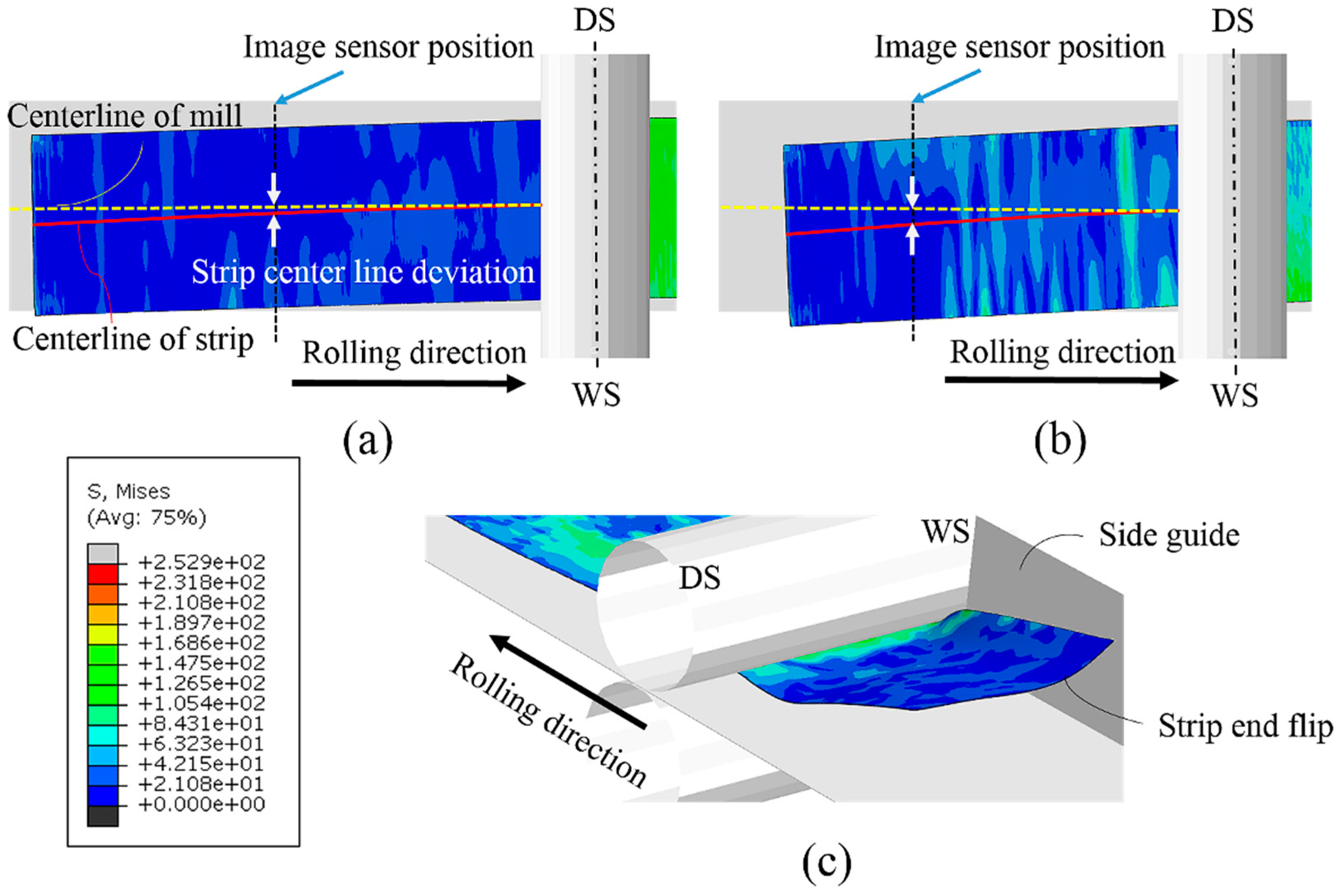

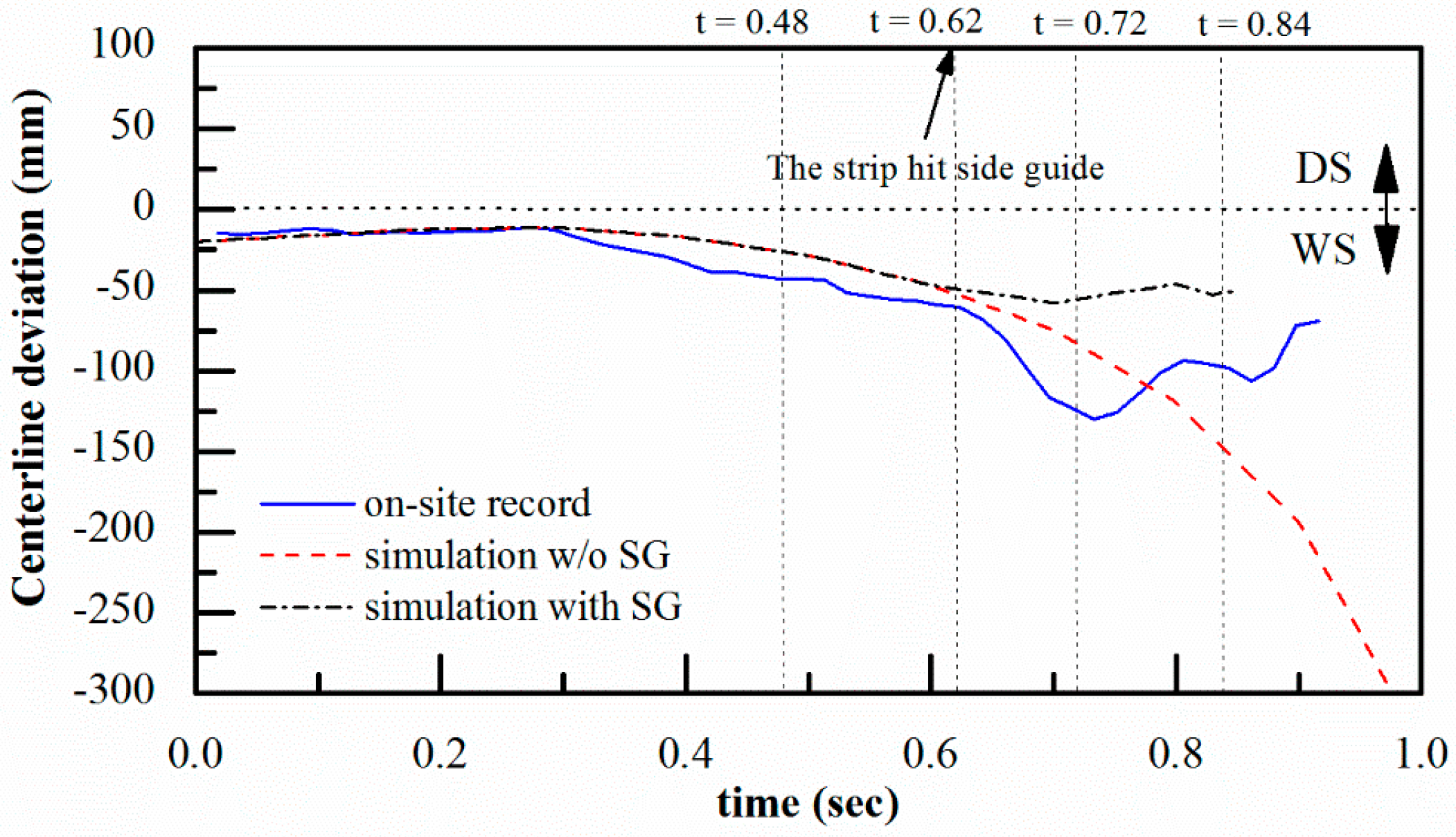

4.1. Strip End Motion Simulation

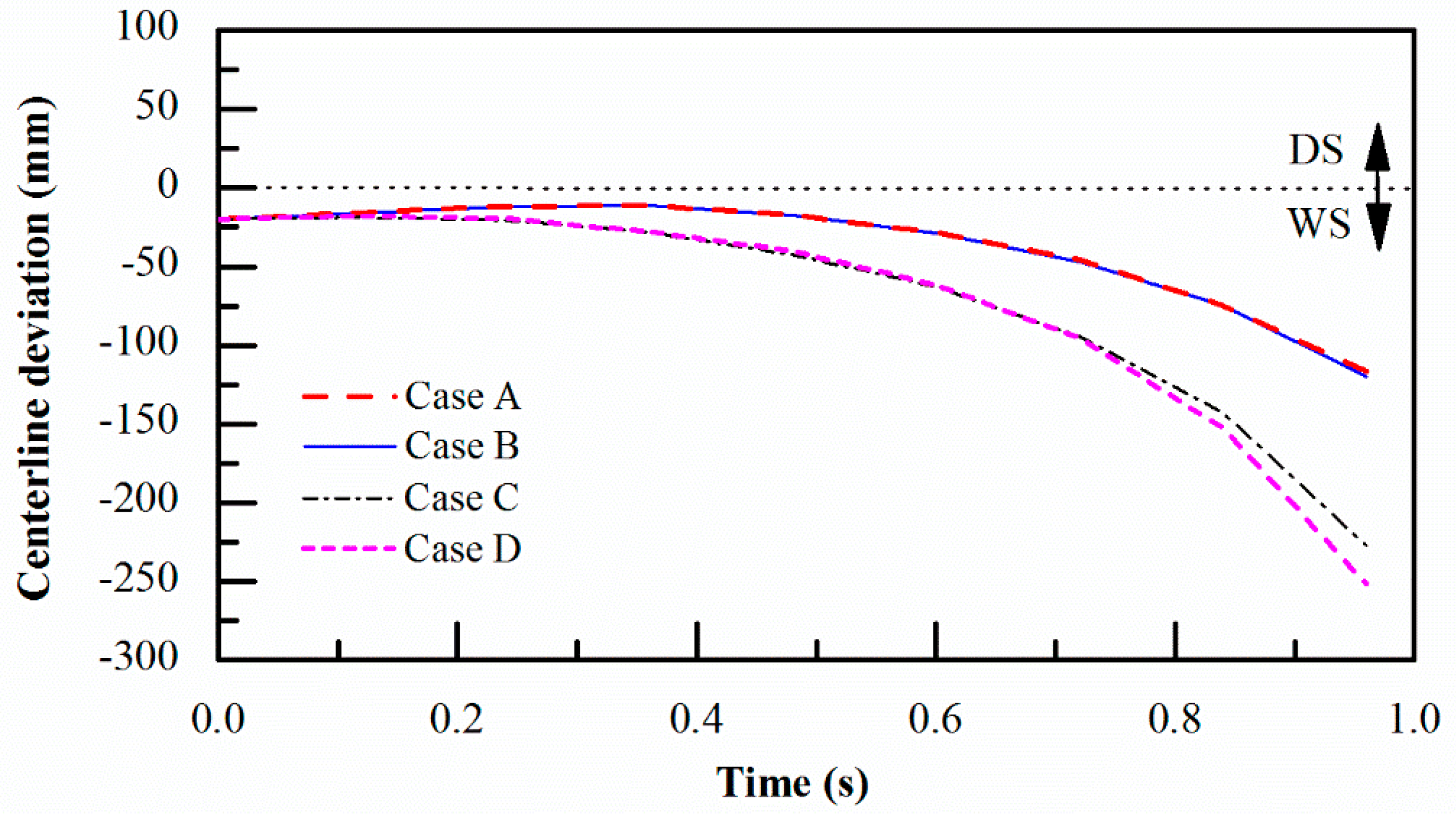

4.2. Effect of Horizontal Clearances on the Centerline Deviation

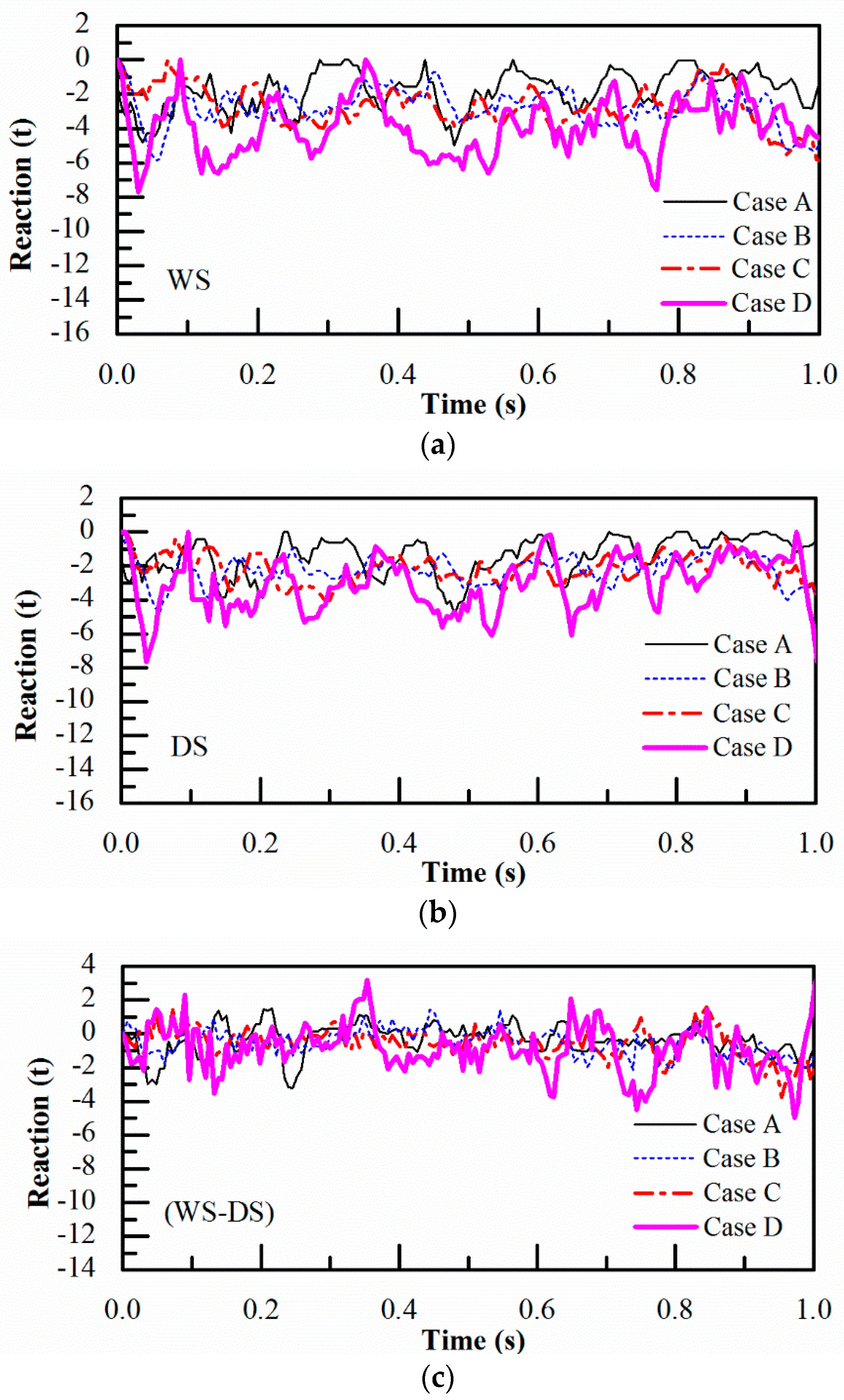

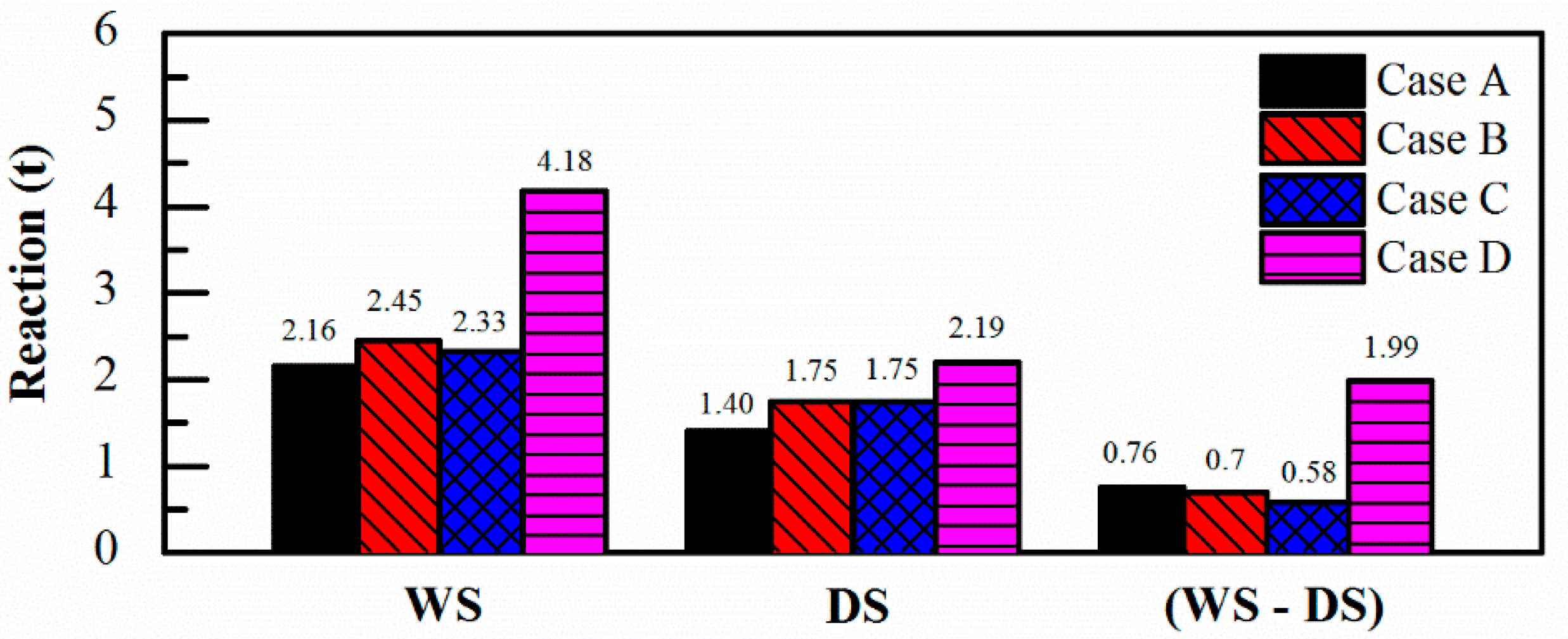

4.3. Effect of Horizontal Clearance on the Reactions between Roll Chocks and Housing

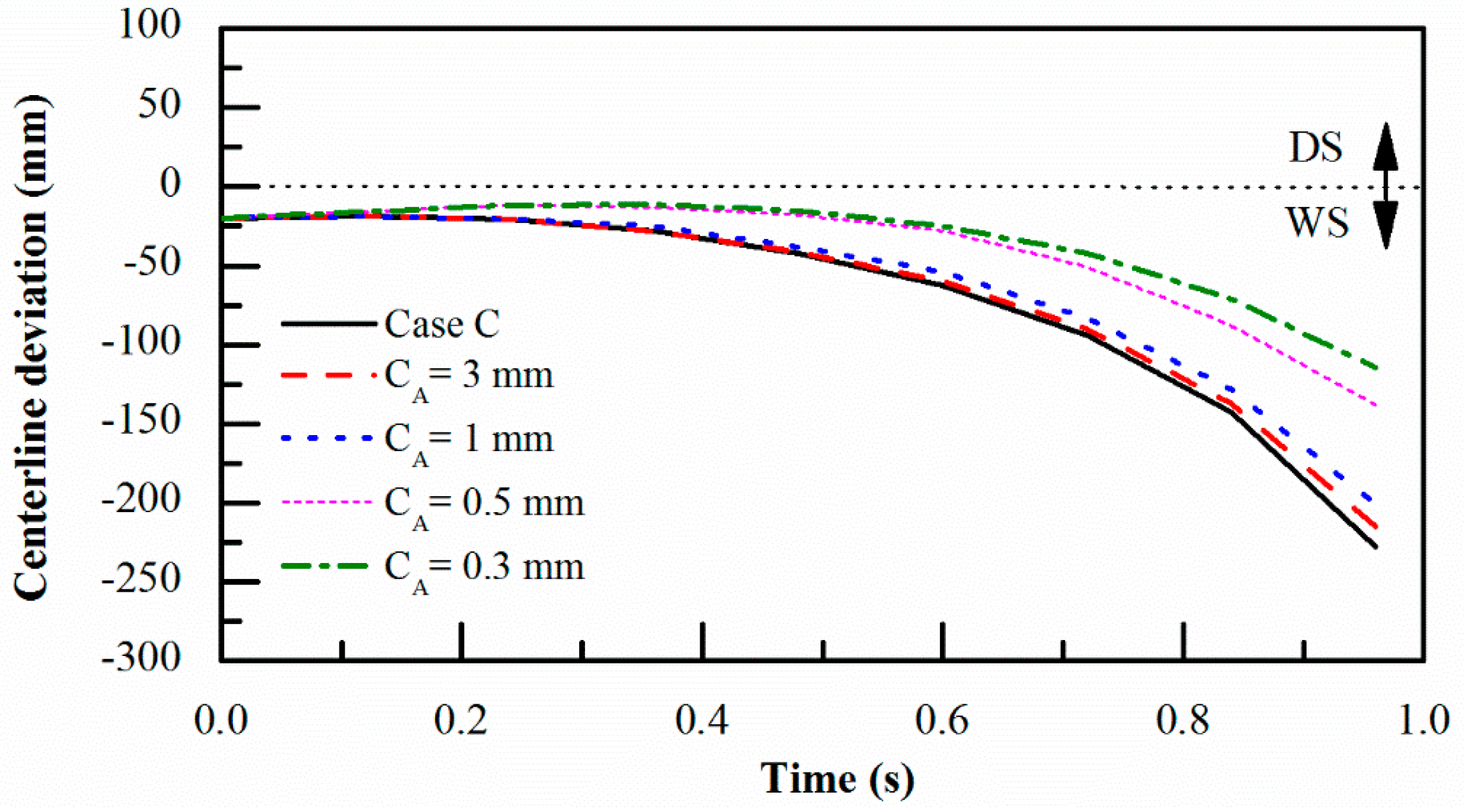

4.4. Effect of AxialClearance on the Centerline Deviation

5. Conclusions

- A numerical model of the finishing mill has been created, consisting of the third and fourth finishing stand and incorporating a strip end model. The ability of the numerical tool in predicting the strip end motion was verified by successfully duplicating a strip end flip phenomenon under identical clearance configuration adopted from on-site data of a particular strip in finish rolling.

- The instantaneous strip end motion, including the strip end flip between the mill stands, was numerically visualized at different times. The effect of the clearance on the centerline deviation of the strip was predicted.

- The effect of horizontal clearance on the strip motion and the reaction between the housing and chock was investigated by examining the strip centerline deviation under conditions where the work roll and backup roll had different degrees of asymmetry. The centerline deviation of the strip end and the strip end flip were susceptible to the degradation of the horizontal clearance level of the work rolls. In contrast, the asymmetry of the backup roll alone had only a minor effect on the centerline deviation. The degradation of clearance level also resulted in a higher reaction to the liners, which would accelerate the wear of liners.

- Tight axial clearances imposed a restraint at the roll ends and had the effect of reducing or suppressing the misalignment of the work roll caused by the asymmetric horizontal clearance levels. As a result, the centerline deviation of strip and the incidence of strip end flip could be significantly reduced.

- The numerical results provided a qualitative guideline for designing a suitable maintenance strategy for clearances.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Corts, J. Linear Bearing Plate for Rolling Mill. U.S. Patent No. US 8,353,192 B2, 15 January 2013. [Google Scholar]

- Zheng, T.; Li, M. Development of statically determinate plate rolling mills that maintain the rolls parallel. J. Manuf. Sci. Eng. 2013, 135, 031014:1–031014:8. [Google Scholar]

- Ishikawa, T.; Tozawa, Y.; Nishizawa, J. Fundamental study on snaking in strip rolling. Trans. ISIJ 1998, 28, 485–490. [Google Scholar] [CrossRef][Green Version]

- Washikita, Y.; Isei, Y.; Buei, Y.; Aihara, Y.; Takeda, M. Strip Walking Control Technology in Hot Strip Rolling; Technical Report, No. 111; Control Research Lab, Process Research Laboratories: Futtsu, Japan, 2016. [Google Scholar]

- Kiyota, T.; Matsumoto, H.; Adachi, Y.; Kondo, E.; Tsuji, Y.; Aso, S. Tail crash control in hot strip mill by LQR. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; pp. 3049–3054. [Google Scholar]

- Choi, Y.J.; Min, C.L. PID sliding mode control for steering of lateral moving strip in hot strip rolling. Int. J. Control Autom. Syst. 2009, 7, 399–407. [Google Scholar] [CrossRef]

- Costa, A.; Dornelas, F.; Costa, R.; Fontes, L.; Salles, A. CST Arcelor Brasil HSM Tail-end Crashing Reduction Using Six Sigma Methodology. In Proceedings of the Iron & Steel Technology Conference, Indianapolis, IN, USA, 7–10 May 2007. [Google Scholar]

- Kiyota, T.; Matsumoto, H.; Adachi, Y.; Tsuji, Y.; Kondo, E. Improved linear model of hot strip mill for tail crash control. Trans. JSME 2004, 190, 70–695. [Google Scholar]

- Abdelkhalek, S.; Montmitonnet, P.; Legrand, N.; Buessler, P. Coupled approach for flatness prediction in cold rolling of thin strip. Int. J. Mech. Sci. 2011, 53, 661–675. [Google Scholar] [CrossRef]

- Aoh, J.N.; Hsu, H.K.; Chen, M.F. Numerical approach on the reproduce of a strip end flip phenomenon in finishing mill. In Proceedings of the 12th International Conference on Technology of Plasticity ICTP, Cambridge, UK, 17–22 September 2017. [Google Scholar]

- Furumoto, F.; Kanemori, S.; Takeguchi, T. Reduction of off centering at tail end caused by unstable work roll position with mill stabilizing device in hot rolling. In Proceedings of the 12th International Conference on Technology of Plasticity ICTP, Cambridge, UK, 17–22 September 2017. [Google Scholar]

- Shen, G.; Li, M. Statically determinate characteristics of micro displacement in a four-high mill. J. Mater. Process. Technol. 2009, 209, 5002–5007. [Google Scholar] [CrossRef]

- Shen, G.; Yu, C.; Ren, Z.; Xing, J.; Xiao, H. Mechanism generating deviations in the rolling load and strip camber on the plate rolling mill. Ironmak. Steelmak. 2017, 44, 707–711. [Google Scholar] [CrossRef]

- Wang, X.; Li, F.; Li, B.; Dong, L.; Zhang, B. Design and application of an optimum backup roll contour configured with CVC work roll in hot strip mill. ISIJ Int. 2012, 52, 1637–1643. [Google Scholar] [CrossRef]

- Hsu, H.K.; Aoh, J.N. The Mechanism of Position-Mode Side Guide in Correcting Camber in Roughing Process of a Hot Strip Mill. Metals 2019, 9, 504. [Google Scholar] [CrossRef]

| Components | Dimensions |

|---|---|

| 3rd and 4th stand work roll | Length 2.03 m/Diameter 0.73 m |

| 4th standbackup roll | Length 1.73 m/Diameter 1.4 m |

| Work roll/chock | Mass 6 ton/10 ton |

| Backup roll/chock | Mass 30 ton/15 ton |

| Finishing Parameters | Value |

|---|---|

| F3 traverse speed | 3.93 m/s |

| F4 traverse speed | 5.96 m/s |

| F3 reduction | 0.39 |

| F4 reduction | 0.34 |

| F3 friction coefficient | 0.24 |

| F4 friction coefficient | 0.24 |

| Tension on strip | 10 t |

| CH | Work Side (WS) (mm) | Drive Side (DS) (mm) |

|---|---|---|

| Top backup roller | 2.58 | 2.63 |

| Top work roller | 1.69 | 1.26 |

| Bottom work roller | 1.88 | 1.84 |

| Bottom backup roller | 1.32 | 1.81 |

| CA | Front (mm) | Rear (mm) |

|---|---|---|

| Top backup roller | 1.51 | 1.35 |

| Top work roller | 0.82 | 0.46 |

| Bottom work roller | 1.79 | 2.53 |

| Bottom backup roller | 1.81 | 2.68 |

| CH | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Top backup roll (mm) | <2.0 | 2.0–2.5 | 2.5–3.0 | 3.0–4.0 |

| Top work roll (mm) | <1.5 | 1.4–2 | 2.0–2.5 | 2.5–3.0 |

| Bottom work roll (mm) | <1.5 | 1.4–2 | 2.0–2.5 | 2.5–3.0 |

| Bottom backup roll (mm) | <2.0 | 2.0–2.5 | 2.5–3.0 | 3.0–4.0 |

| Location of CH | Side | Case A | Case B | Case C | Case D | ||||

|---|---|---|---|---|---|---|---|---|---|

| CH | Level | CH | Level | CH | Level | CH | Level | ||

| Top backup roll (mm) | WS | 0.7 | 1 | 0.7 | 1 | 0.7 | 1 | 0.7 | 1 |

| DS | 0.5 | 1 | 0.5 | 1 | 0.5 | 1 | 0.5 | 1 | |

| Top work roll (mm) | WS | 0.5 | 1 | 0.5 | 1 | 0.5 | 1 | 0.5 | 1 |

| DS | 0.2 | 1 | 0.2 | 1 | 0.2 | 1 | 0.2 | 1 | |

| Bottom work roll (mm) | WS | 0.5 | 1 | 0.5 | 1 | 3.0 | 4 | 3.0 | 4 |

| DS | 0.2 | 1 | 0.2 | 1 | 0.2 | 1 | 0.2 | 1 | |

| Bottom backup roll (mm) | WS | 0.7 | 1 | 3.0 | 4 | 0.7 | 1 | 3.0 | 4 |

| DS | 0.5 | 1 | 0.5 | 1 | 0.5 | 1 | 0.5 | 1 | |

| CA | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Top backup roll (mm) | <2.0 | 2.0–3.0 | 3.0–4.0 | 4.0–5.0 |

| Top work roll (mm) | <1.5 | 1.5–2.0 | 2.0–2.7 | 2.5–3.0 |

| Bottom work roll (mm) | <1.5 | 1.5–2.0 | 2.0–2.7 | 2.5–3.0 |

| Bottom backup roll (mm) | <2.0 | 2.0–3.0 | 3.0–4.0 | 4.0–5.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, H.-K.; Aoh, J.-N. Effect of Clearances in Mill Stands on Strip End Motion During Finishing Rolling. Metals 2019, 9, 727. https://doi.org/10.3390/met9070727

Hsu H-K, Aoh J-N. Effect of Clearances in Mill Stands on Strip End Motion During Finishing Rolling. Metals. 2019; 9(7):727. https://doi.org/10.3390/met9070727

Chicago/Turabian StyleHsu, Han-Kai, and Jong-Ning Aoh. 2019. "Effect of Clearances in Mill Stands on Strip End Motion During Finishing Rolling" Metals 9, no. 7: 727. https://doi.org/10.3390/met9070727

APA StyleHsu, H.-K., & Aoh, J.-N. (2019). Effect of Clearances in Mill Stands on Strip End Motion During Finishing Rolling. Metals, 9(7), 727. https://doi.org/10.3390/met9070727