The Effect of Laser Peening without Coating on the Fatigue of a 6082-T6 Aluminum Alloy with a Curved Notch

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of the Baseline Material

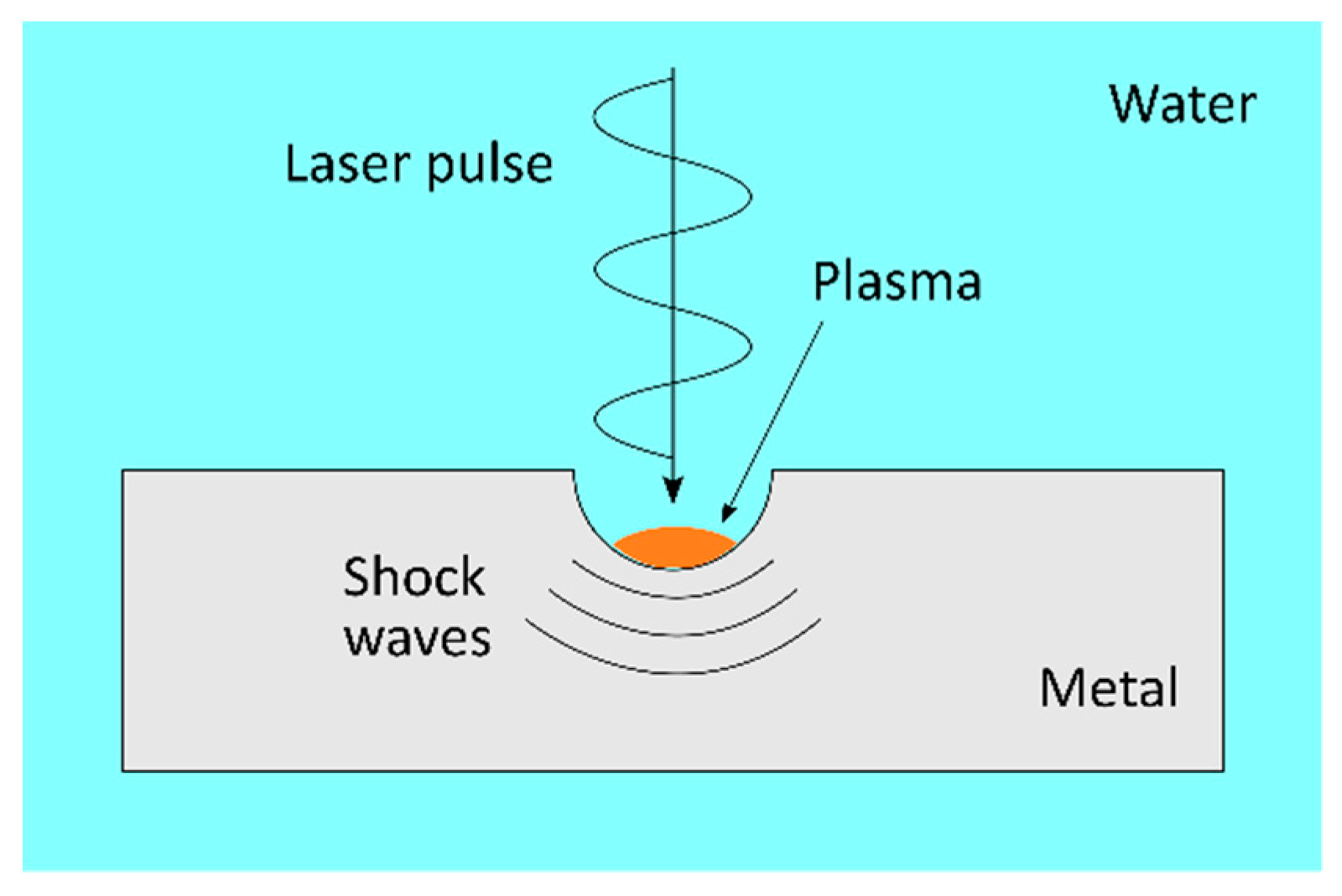

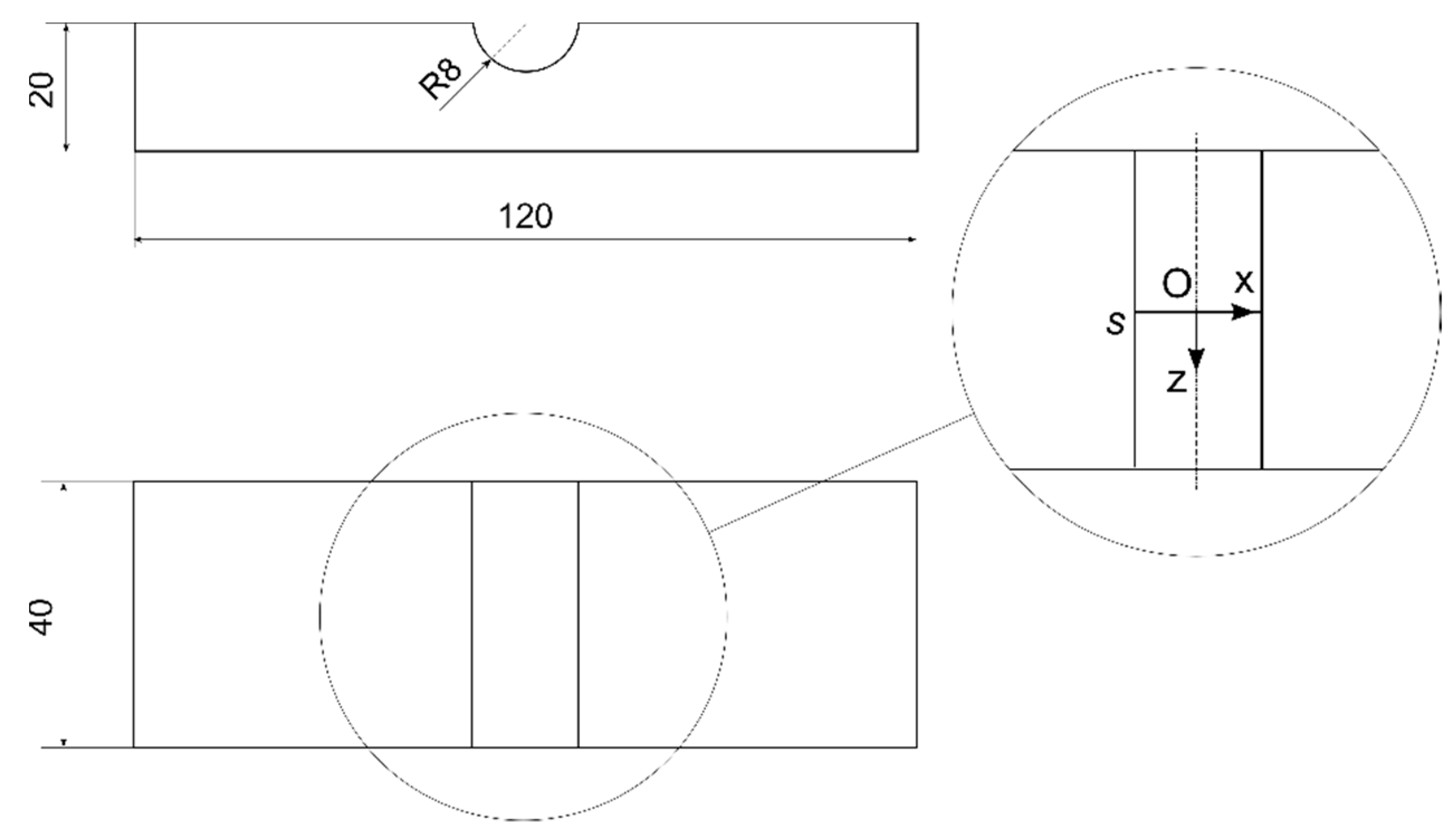

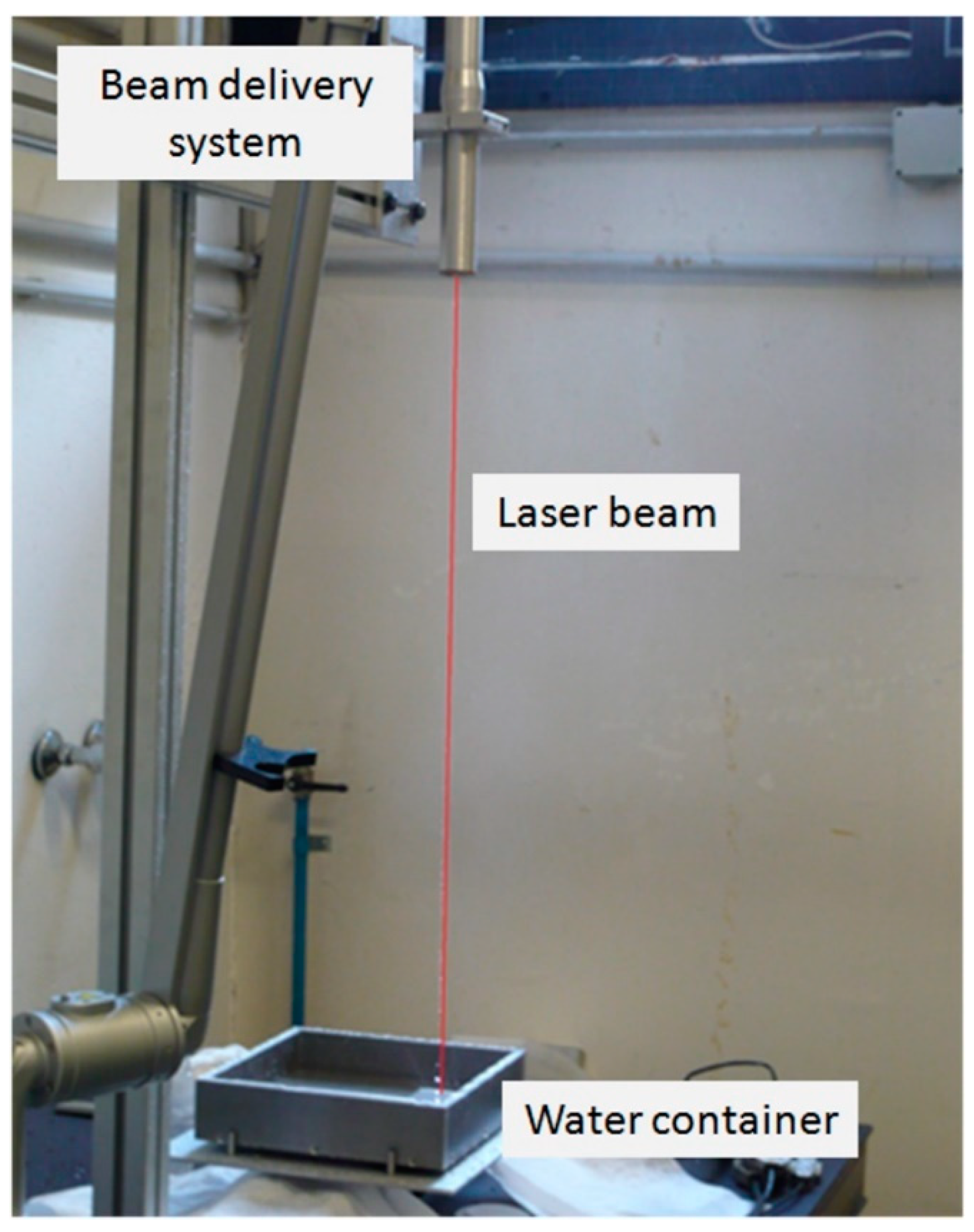

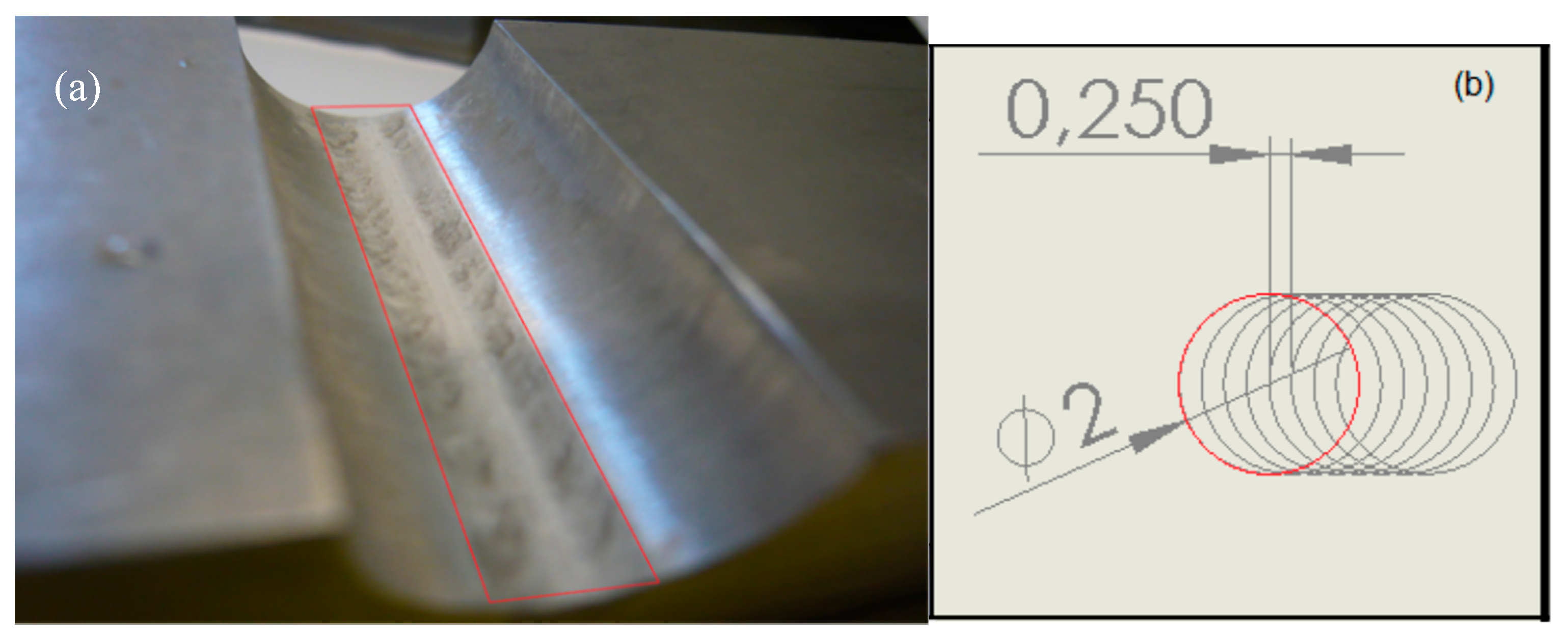

2.2. Laser Peening Treatment

2.3. Fatigue Testing

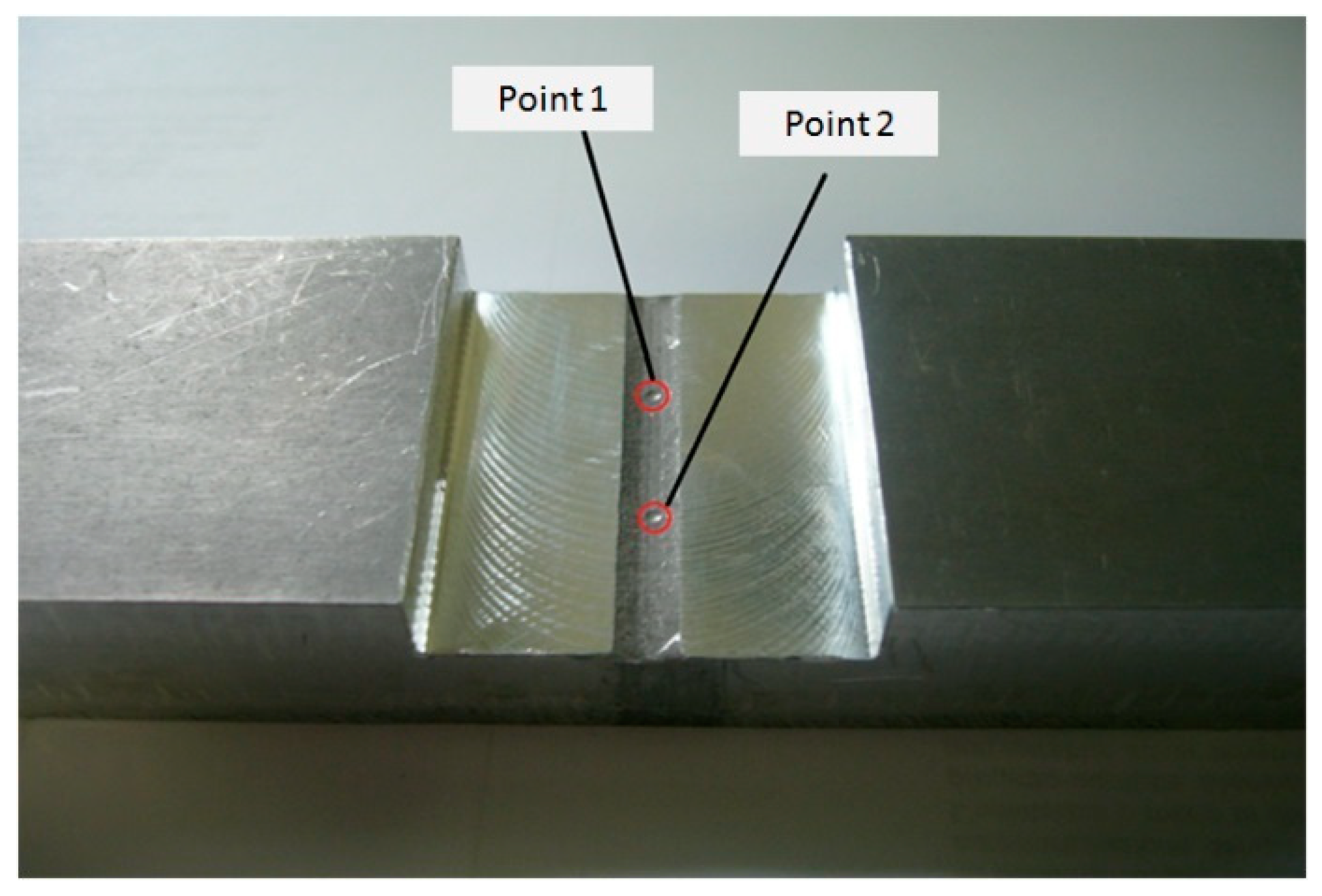

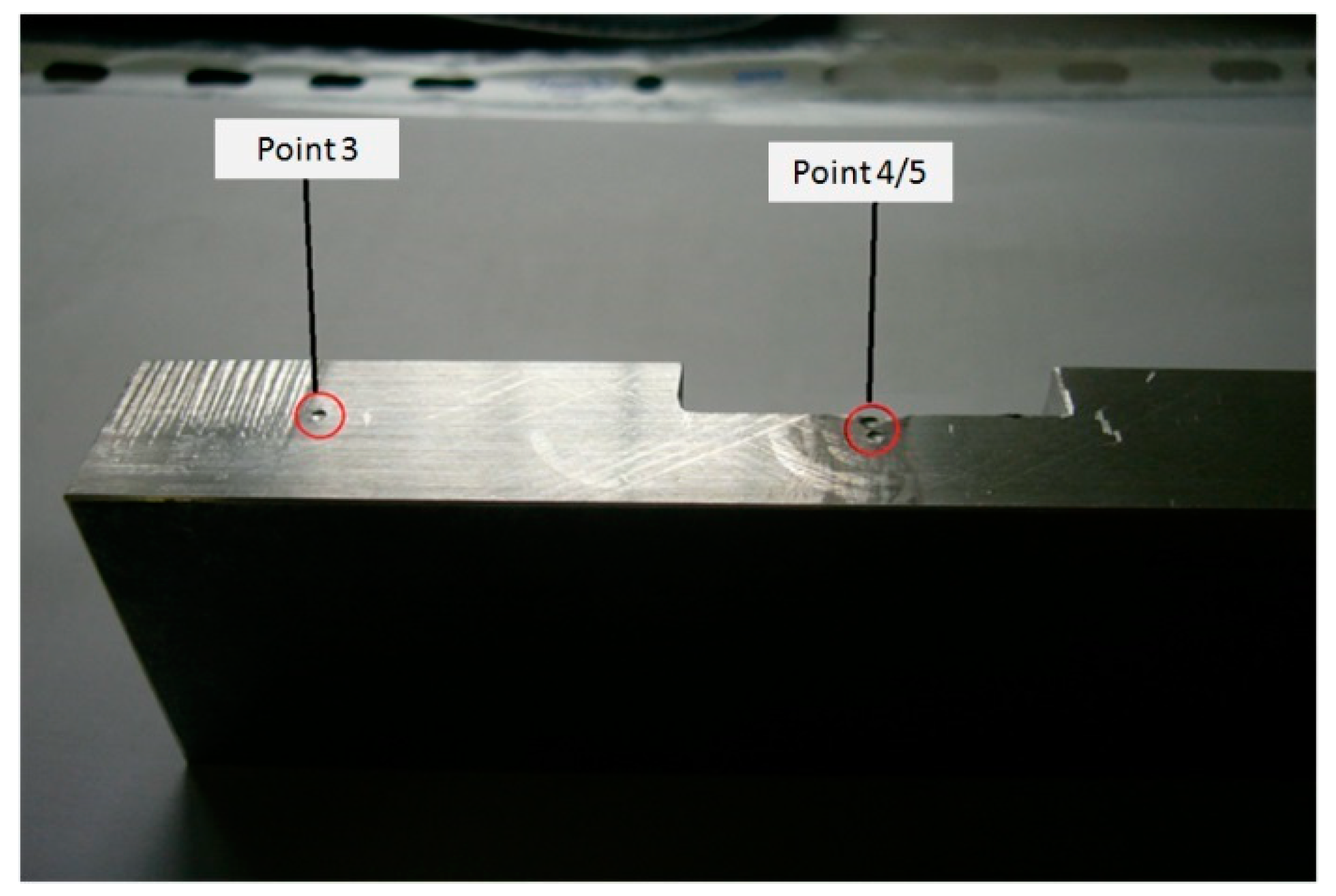

2.4. Hardness Measurement

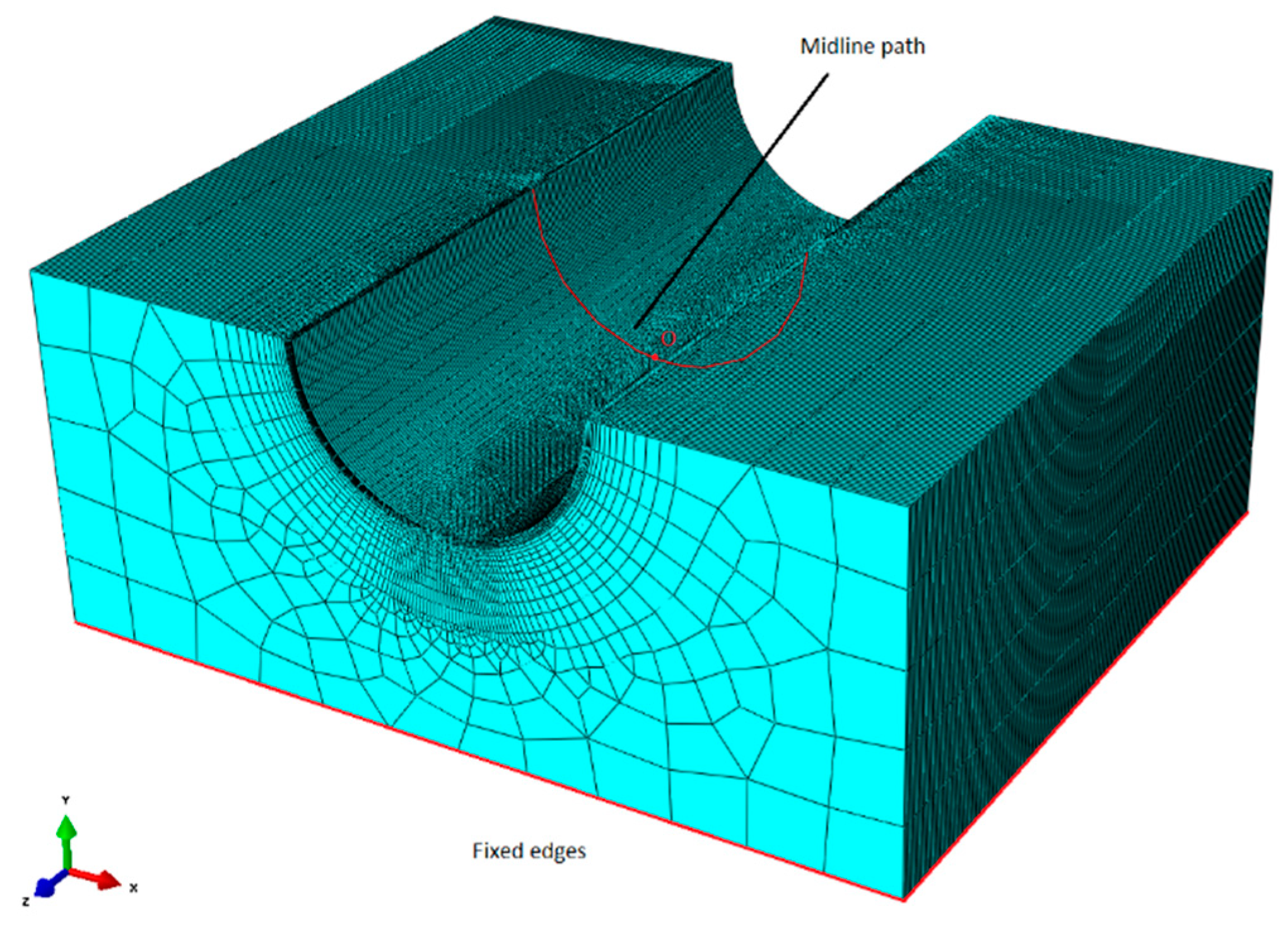

2.5. Numerical Model

3. Results

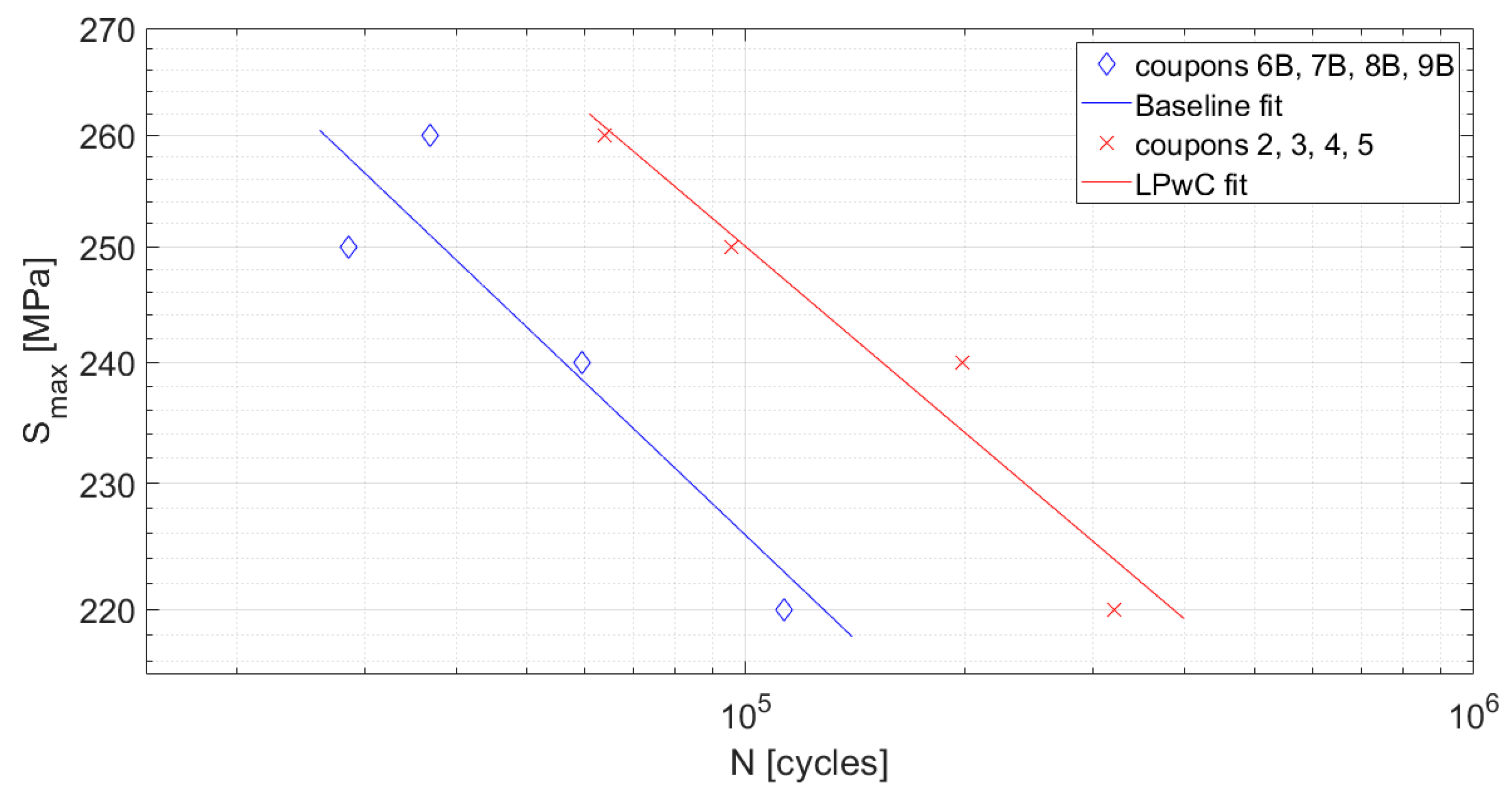

3.1. Fatigue Tests

3.2. Hardness Measurement

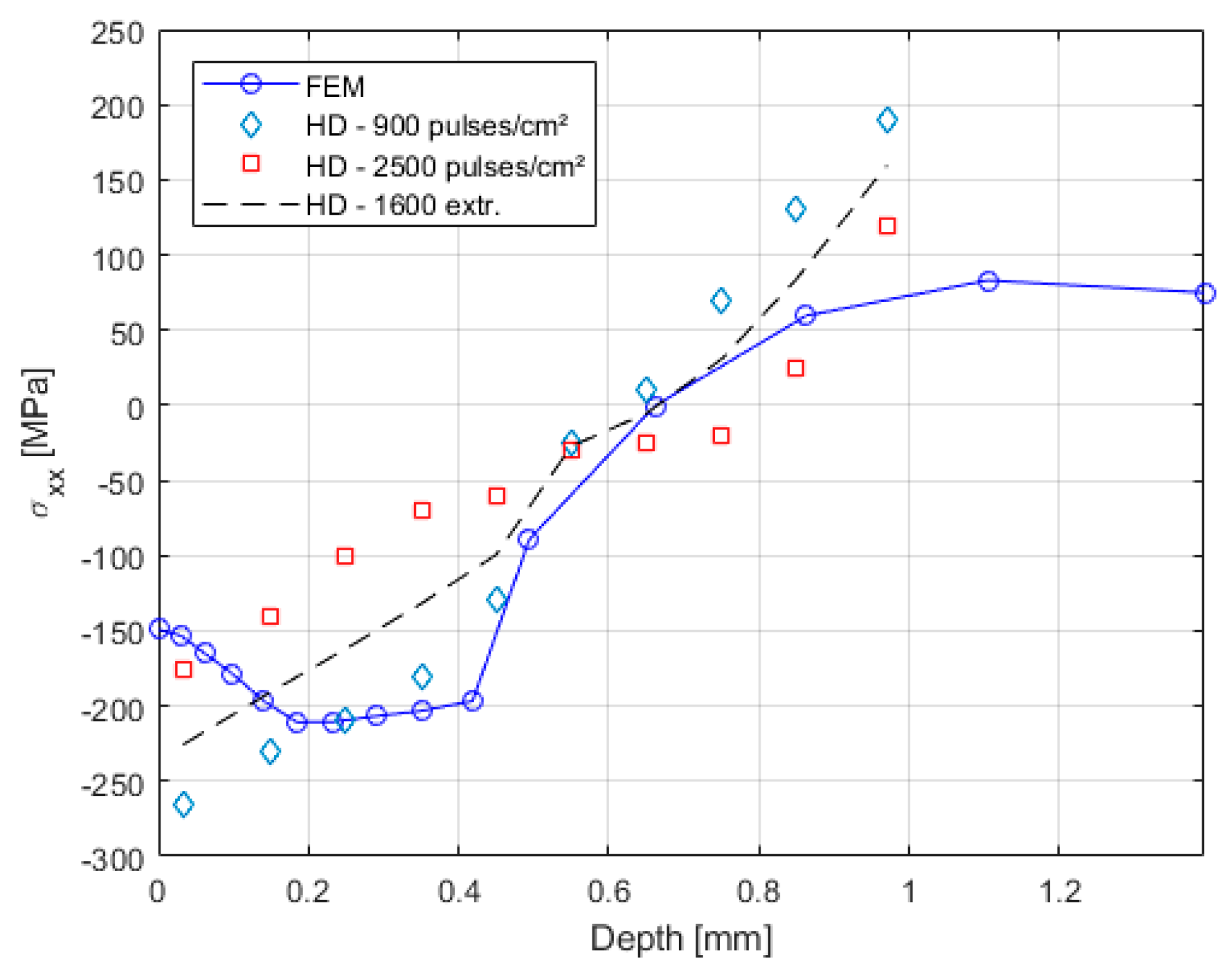

3.3. FEM Results

4. Discussion

5. Conclusions

- The fatigue life of the peened samples shows an improvement over that of the untreated ones, suggesting that laser peening without coating could enhance the fatigue behavior of notched components, similarly to conventional laser shock peening.

- The FEM results indicate that deep compressive residual stresses are induced in the treated area after LPwC, which are known to obstruct fatigue crack growth, and are deemed to be the main reason for the improved fatigue life observed in the tests.

- The Brinell tests confirmed the ability of LPwC to increase surface hardness, possibly improving the wear performances of the peened specimens, which, together with the enhanced fatigue properties, could make this treatment appealing for applications such as lugs and bolted joints.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fairand, B.P.; Clauer, A.H.; Jung, R.G.; Wilcox, B.A. Quantitative assessment of laser-induced stress waves generated at confined surfaces. Appl. Phys. Lett. 1974, 25, 431–433. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Sano, Y.; Mukai, N.; Okazaki, K.; Obata, M. Residual stress improvement in metal surface by underwater laser irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 1997, 121, 432–436. [Google Scholar] [CrossRef]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.-W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Rubio-González, C.; Ocaña, J.L.; Gomez-Rosas, G.; Molpeceres, C.; Paredes, M.; Banderas, A.; Porro, J.; Morales, M. Effect of laser shock processing on fatigue crack growth and fracture toughness of 6061-T6 aluminium alloy. Mater. Sci. Eng. A 2004, 386, 291–295. [Google Scholar] [CrossRef]

- Gao, Y.K. Improvement of fatigue property in 7050-T7451 aluminium alloy by laser peening and shot peening. Mater. Sci. Eng. A 2011, 528, 3823–3828. [Google Scholar] [CrossRef]

- Sano, Y.; Masaki, K.; Ochi, Y.; Altenberger, I.; Scholtes, B. Laser Peening without Coating as a Surface Enhancement Technology. J. Laser Micro Nanoeng. 2006, 1, 161–166. [Google Scholar] [CrossRef]

- Ivetic, G.; Meneghin, I.; Troiani, E.; Molinari, G.; Lanciotti, A.; Ristori, V.; Ocaña, J.L.; Morales, M.; Porro, J.A.; Polese, C.; et al. Characterisation of Fatigue and Crack Propagation in Laser Shock Peened Open Hole 7075-T73 Aluminium Specimens. In ICAF 2011 Structural Integrity: Influence of Efficiency and Green Imperatives, Proceedings of the 26th Symposium of the International Committee on Aeronautical Fatigue, Montreal, QC, Canada, 1–3 June 2011; Komorowski, J., Ed.; Springer: Dordrecht, The Netherlands, 2011; pp. 855–866. [Google Scholar]

- Karthik, D.; Swaroop, S. Laser peening without coating—An advanced surface treatment: A review. Mater. Manuf. Process. 2017, 32, 1565–1572. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Horstmann, M.; Chupakhin, S.; Riekehr, S.; Falck, R.; Maawad, E.; Staron, P.; Schell, N.; Huber, N. Effects of laser shock peening on the microstructure and fatigue crack propagation behaviour of thin AA2024 specimens. Int. J. Fatigue 2017, 98, 223–233. [Google Scholar] [CrossRef]

- Troiani, E.; Taddia, S.; Meneghin, I.; Molinari, G. Fatigue Crack Growth in Laser Shock Peened Thin Metallic Panels. Adv. Mater. Res. 2014, 996, 775–781. [Google Scholar] [CrossRef]

- Yang, J.-M.; Her, Y.C.; Han, N.; Clauer, A. Laser shock peening on fatigue behaviour of 2024-T3 Al alloy with fastener holes and stopholes. Mater. Sci. Eng. A 2001, 298, 296–299. [Google Scholar] [CrossRef]

- Ivetic, G.; Meneghin, I.; Troiani, E.; Molinari, G.; Ocaña, J.; Morales, M.; Porro, J.; Lanciotti, A.; Ristori, V.; Polese, C.; et al. Fatigue in laser shock peened open-hole thin aluminium specimens. Mater. Sci. Eng. A 2012, 534, 573–579. [Google Scholar] [CrossRef]

- Dorman, M.; Toparli, M.B.; Smyth, N.; Cini, A.; Fitzpatrick, M.E.; Irving, P.E. Effect of laser shock peening on residual stress and fatigue life of clad 2024 aluminium sheet containing scribe defects. Mater. Sci. Eng. A 2012, 548, 142–151. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H.P. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Vasu, A.; Grandhi, R.V. Effects of curved geometry on residual stress in laser peening. Surf. Coat. Technol. 2013, 218, 71–79. [Google Scholar] [CrossRef]

- ASTM International. ASTM E10-18 Standard Test Method for Brinell Hardness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar] [CrossRef]

- Peyre, P.; Sollier, A.; Chaieb, I.; Berthe, L.; Bartnicki, E.; Braham, C.; Fabbro, R. FEM simulation of residual stresses induced by laser Peening. Eur. Phys. J. Appl. Phys. 2003, 23, 83–88. [Google Scholar] [CrossRef]

- Angulo, I.; Cordovilla, F.; García-Beltrán, A.; Smyth, N.S.; Langer, K.; Fitzpatrick, M.E.; Ocaña, J.L. The effect of material cyclic deformation properties on residual stress generation by laser shock processing. Int. J. Mech. Sci. 2019, 156, 370–381. [Google Scholar] [CrossRef]

- Chaboche, J.L. Time-independent constitutive theories for cyclic plasticity. Int. J. Plast. 1986, 2, 149–188. [Google Scholar] [CrossRef]

- Chen, Y.; Clausen, A.H.; Hopperstad, O.S.; Langseth, M. Stress–strain behaviour of aluminium alloys at a wide range of strain rates. Int. J. Solids Struct. 2009, 46, 3825–3835. [Google Scholar] [CrossRef]

- Chen, X.; Peng, Y.; Peng, S.; Yao, S.; Chen, C.; Xu, P. Flow and fracture behaviour of aluminium alloy 6082-T6 at different tensile strain rates and triaxialities. PLoS ONE 2017, 12, e0181983. [Google Scholar] [CrossRef]

- Langer, K.; Olson, S.; Brockman, R.; Braisted, W.; Spradlin, T.; Fitzpatrick, M.E. High strain-rate material model validation for laser peening simulation. J. Eng. 2015, 13, 150–157. [Google Scholar] [CrossRef]

- Trdan, U.; Porro, J.A.; Ocaña, J.L.; Grum, J. Laser shock peening without absorbent coating (LSPwC) effect on 3D surface topography and mechanical properties of 6082-T651 Al alloy. Surf. Coat. Technol. 2012, 208, 109–116. [Google Scholar] [CrossRef]

- Berthe, L.; Fabbro, R.; Peyre, P.; Tollier, L.; Bartnicki, E. Shock waves from a water-confined laser-generated plasma. J. Appl. Phys. 1997, 82, 2826–2832. [Google Scholar] [CrossRef]

- Benedetti, M.; Bortolamedi, T.; Fontanari, V.; Frendo, F. Bending fatigue behaviour of differently shot peened Al 6082 T5 alloy. Int. J. Fatigue 2004, 26, 889–897. [Google Scholar] [CrossRef]

- Trdan, U.; Skarba, M.; Ocaña, J.L. Laser shock peening effect on the dislocation transitions and grain refinement of Al–Mg–Si alloy. Mater. Character. 2014, 97, 57–68. [Google Scholar] [CrossRef]

- Hfaiedh, N.; Peyre, P.; Song, H.; Popa, I.; Ji, V.; Vignal, V. Finite element analysis of laser shock peening of 2050-T8 aluminium alloy. Int. J. Fatigue 2015, 70, 480–489. [Google Scholar] [CrossRef]

[MPa] | [MPa s] | [s] | [MPa] | [–] |

|---|---|---|---|---|

| 319 | 3211.7 | 25 | 64.5 | 24.3 |

| Measurement Point | Surface State | Brinell Hardness |

|---|---|---|

| 1 | LSP-treated | 178 HB |

| 2 | LSP-treated | 185 HB |

| 3 | As machined | 123 HB |

| 4 | As machined | 117 HB |

| 5 | As machined | 120 HB |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Troiani, E.; Zavatta, N. The Effect of Laser Peening without Coating on the Fatigue of a 6082-T6 Aluminum Alloy with a Curved Notch. Metals 2019, 9, 728. https://doi.org/10.3390/met9070728

Troiani E, Zavatta N. The Effect of Laser Peening without Coating on the Fatigue of a 6082-T6 Aluminum Alloy with a Curved Notch. Metals. 2019; 9(7):728. https://doi.org/10.3390/met9070728

Chicago/Turabian StyleTroiani, Enrico, and Nicola Zavatta. 2019. "The Effect of Laser Peening without Coating on the Fatigue of a 6082-T6 Aluminum Alloy with a Curved Notch" Metals 9, no. 7: 728. https://doi.org/10.3390/met9070728

APA StyleTroiani, E., & Zavatta, N. (2019). The Effect of Laser Peening without Coating on the Fatigue of a 6082-T6 Aluminum Alloy with a Curved Notch. Metals, 9(7), 728. https://doi.org/10.3390/met9070728