Determination of Grain Growth Kinetics and Assessment of Welding Effect on Properties of S700MC Steel in the HAZ of Welded Joints

Abstract

:1. Introduction

- Grain growth occurs by moving grain boundaries rather than coalescing.

- The motion of the grain boundary is interrupted, and the direction of motion may suddenly change.

- Grain can grow into another at the expense of its volume.

- Grain consumption rates at the expense of others are often increased when grains are almost consumed.

- The curved border usually migrates to its center of curvature.

- If the grain boundaries of one phase meet at angles other than 120° grains with an acute angle are consumed so that the angle approaches 120°.

- The size of existing grains increases;

- there is the formation of new grains with an initial zero size or with a much smaller initial size than the existing grains in the structure.

2. Materials and Methods

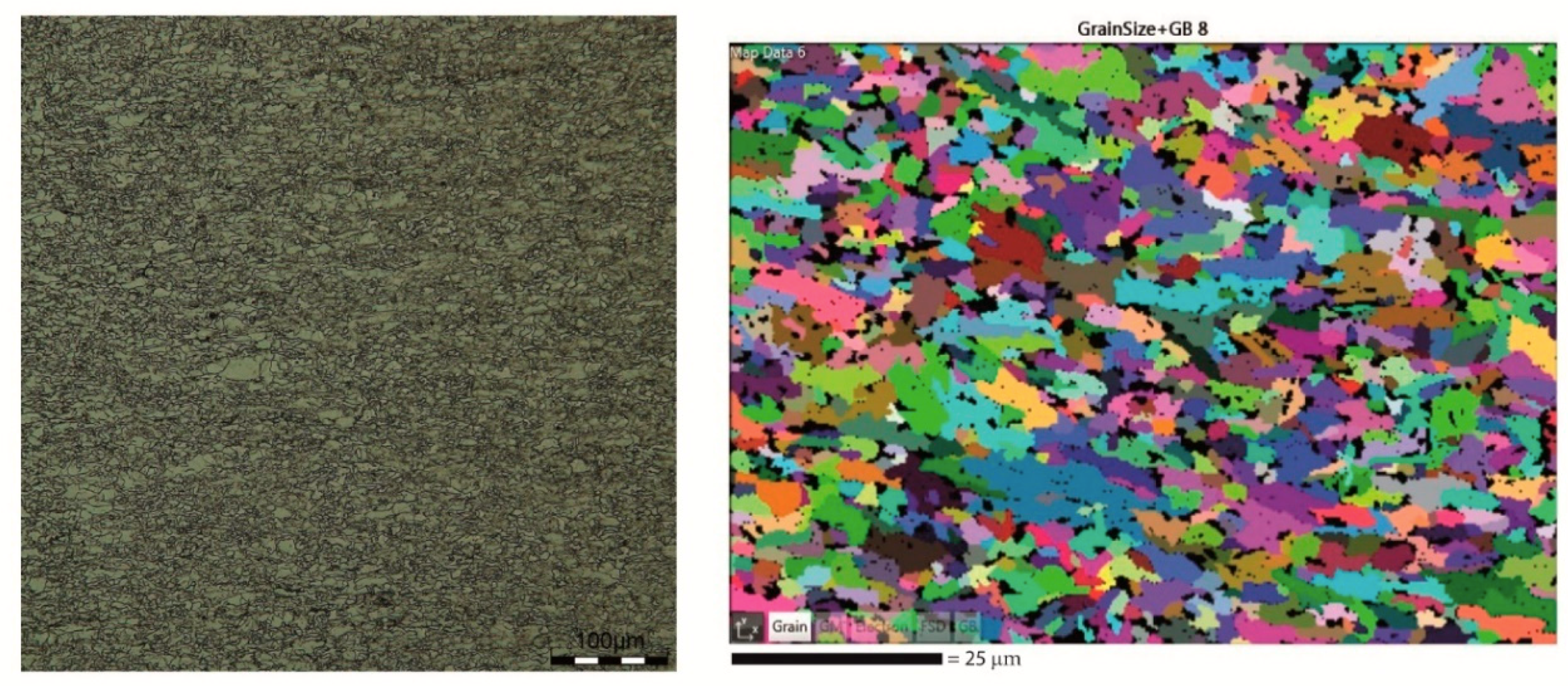

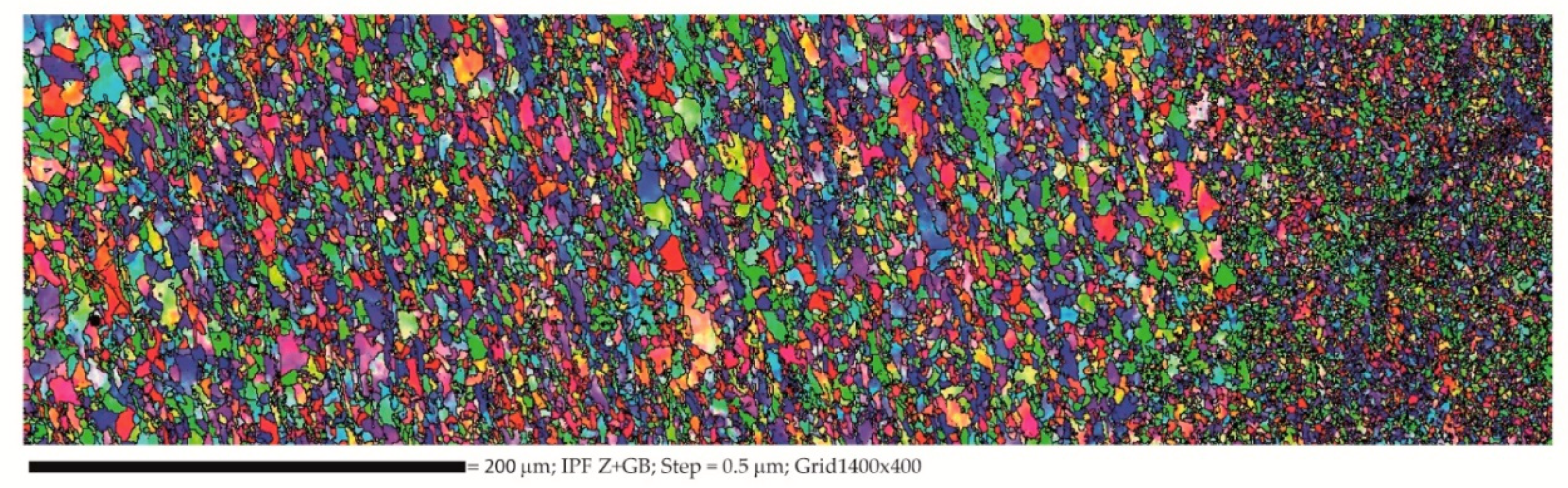

2.1. Experimental S700MC Material

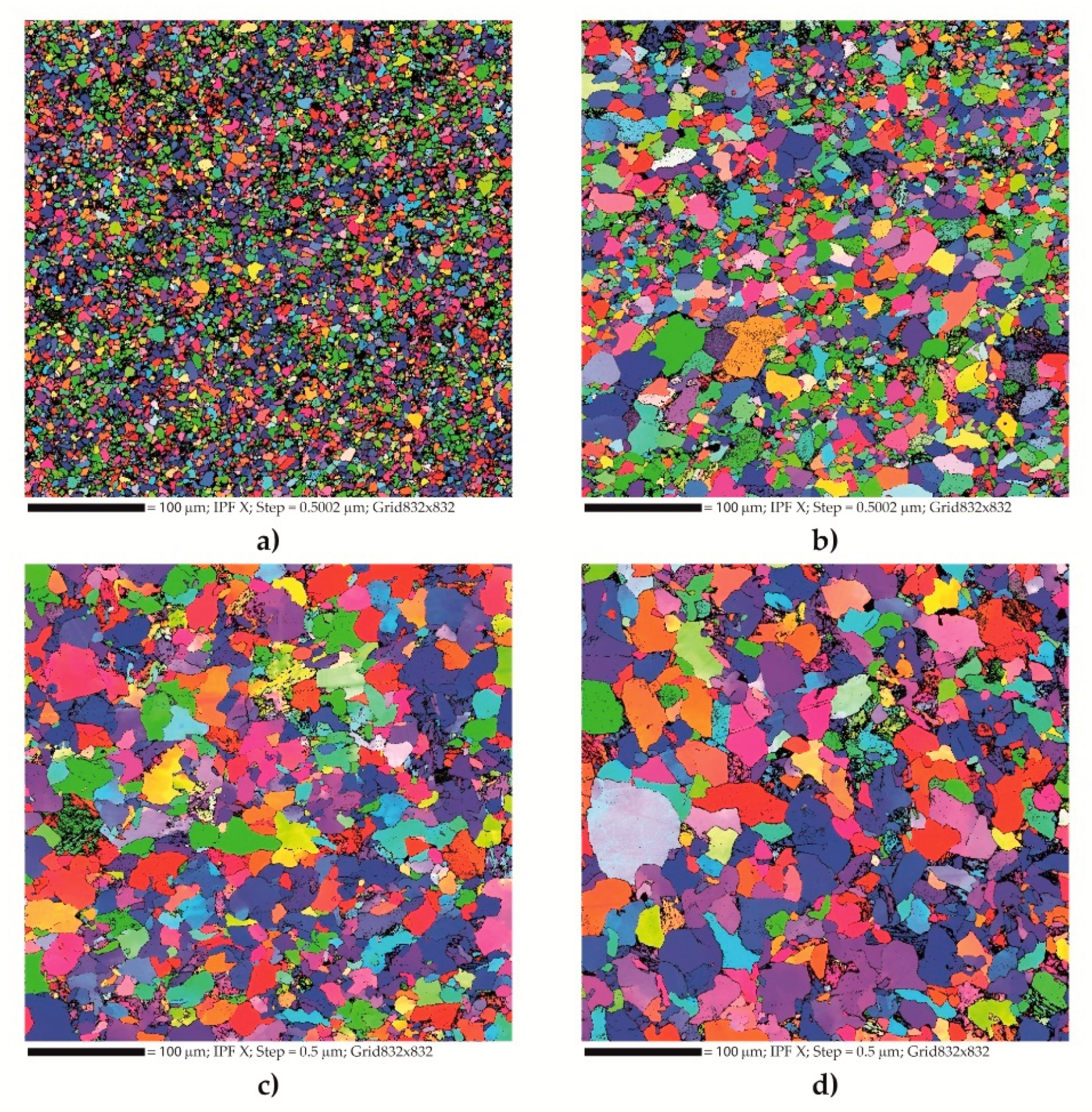

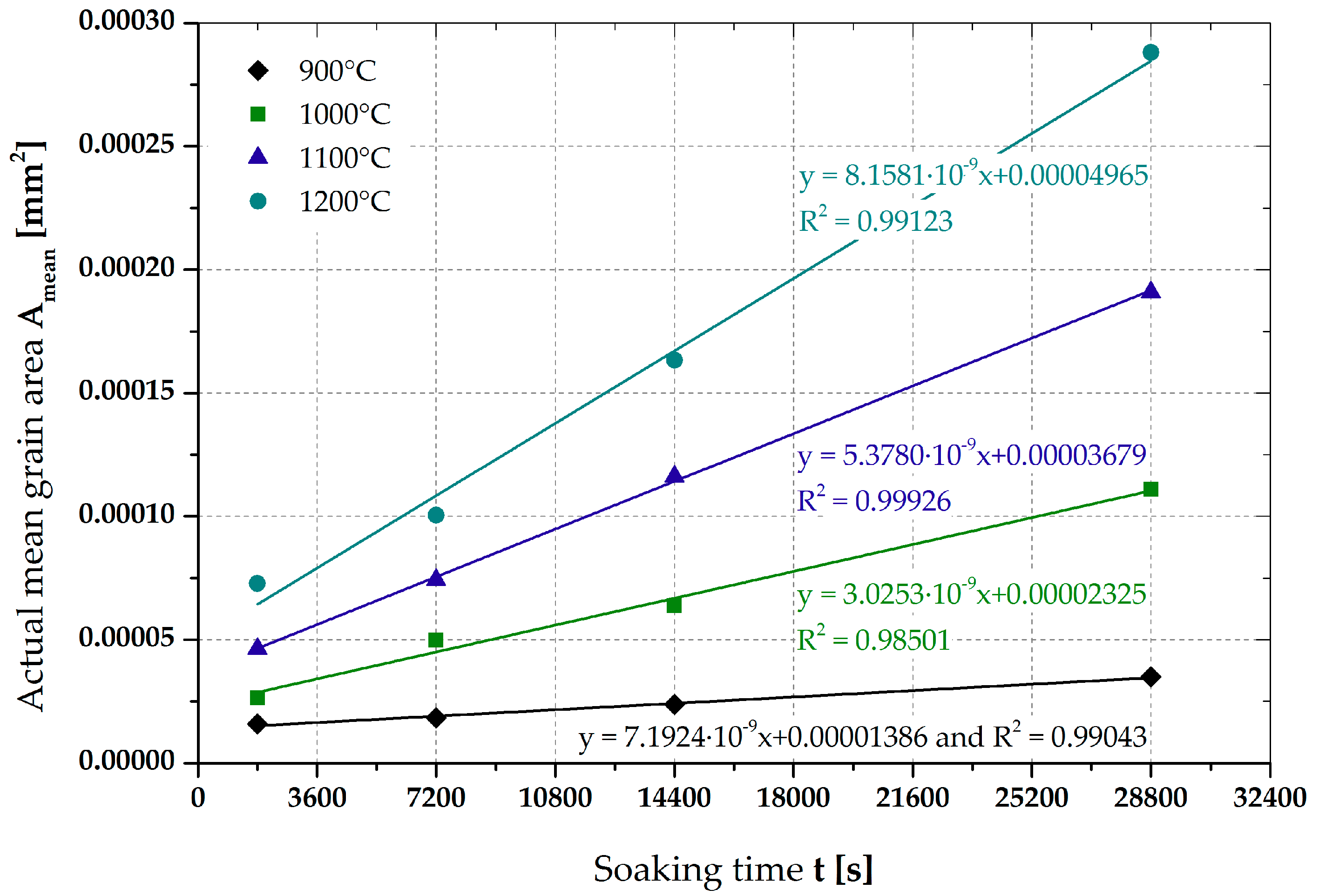

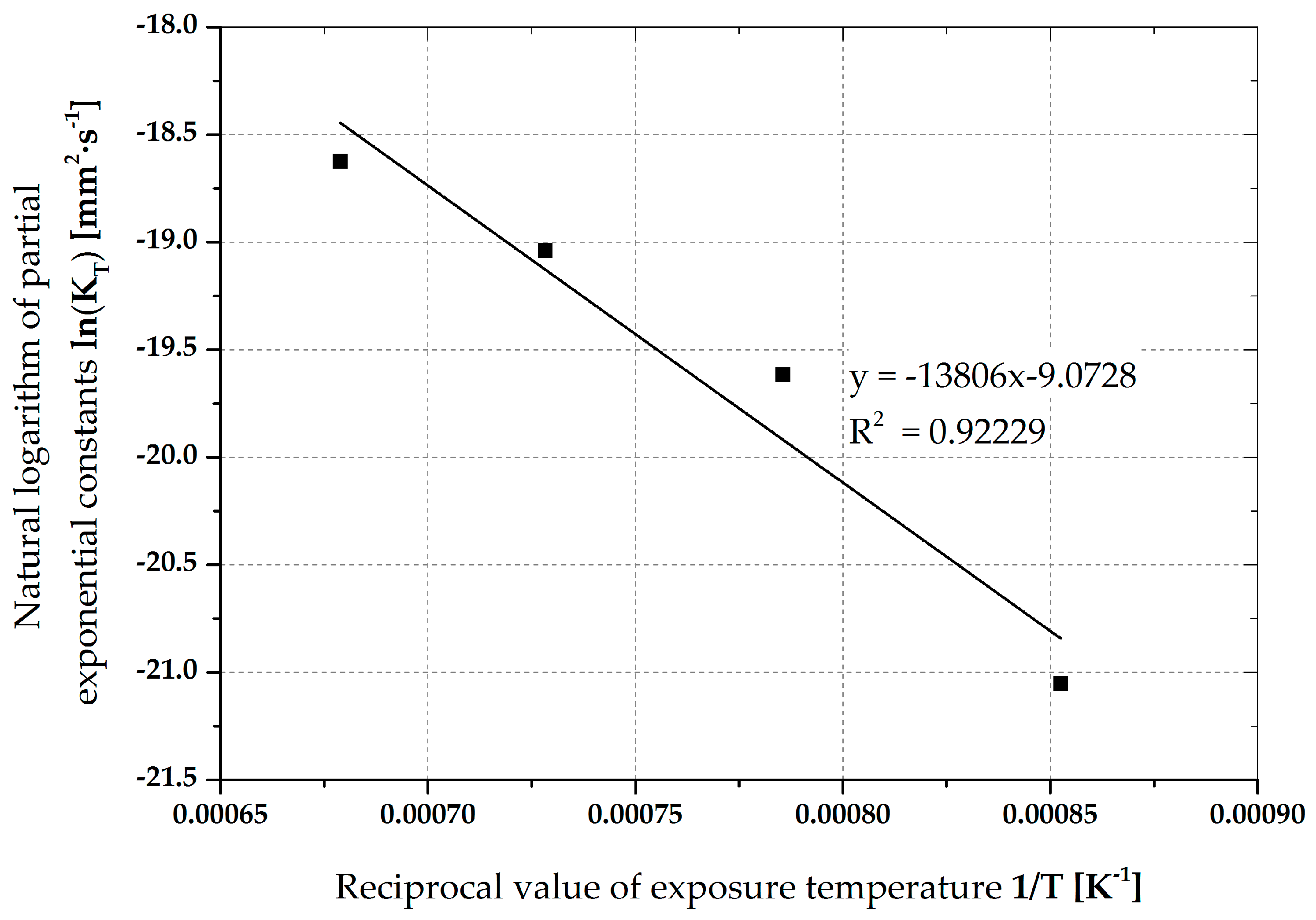

2.2. Methodological Procedure and Experimental Determination of Activation Energy Q Values and Kinetic Constant of Grain Growth K

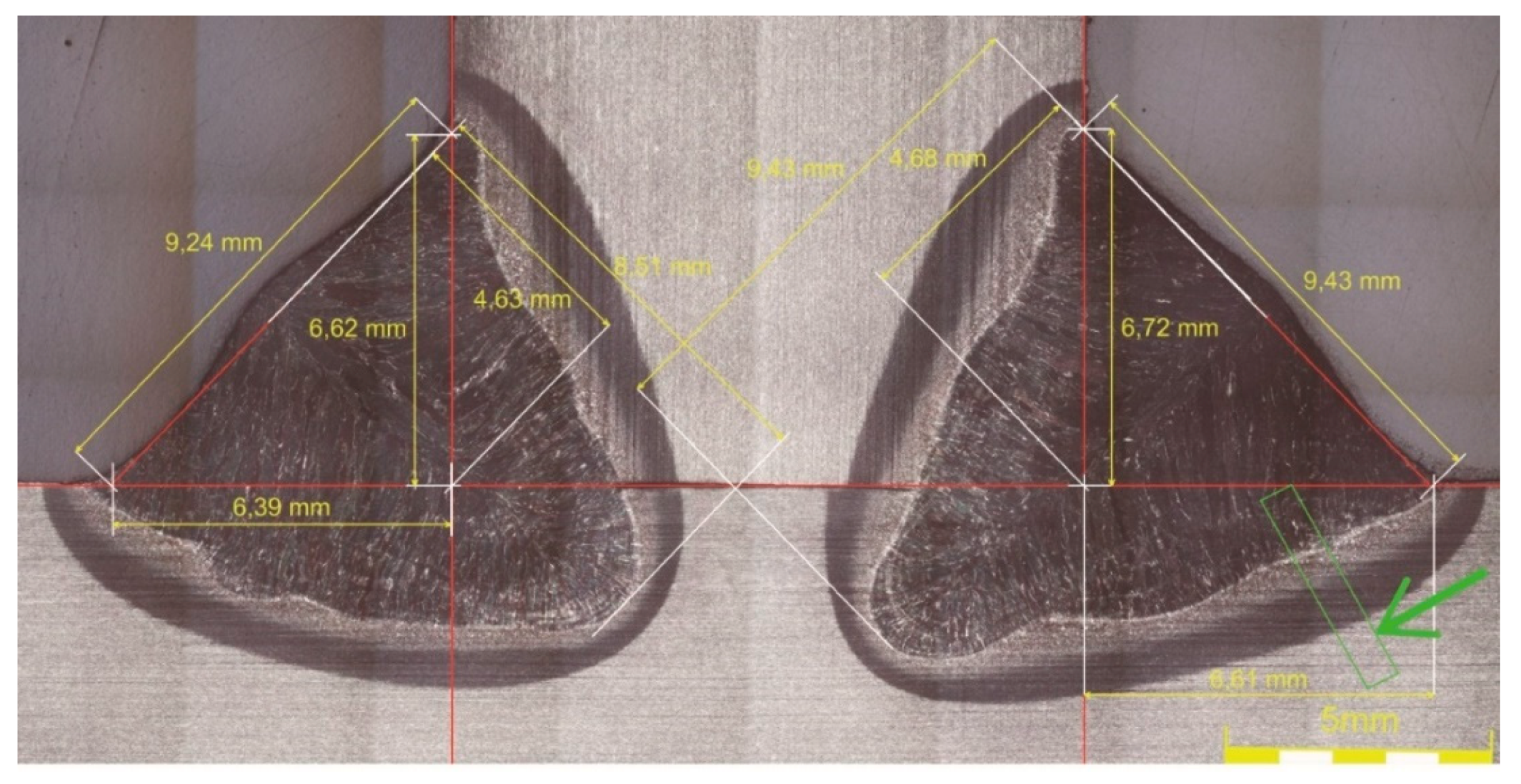

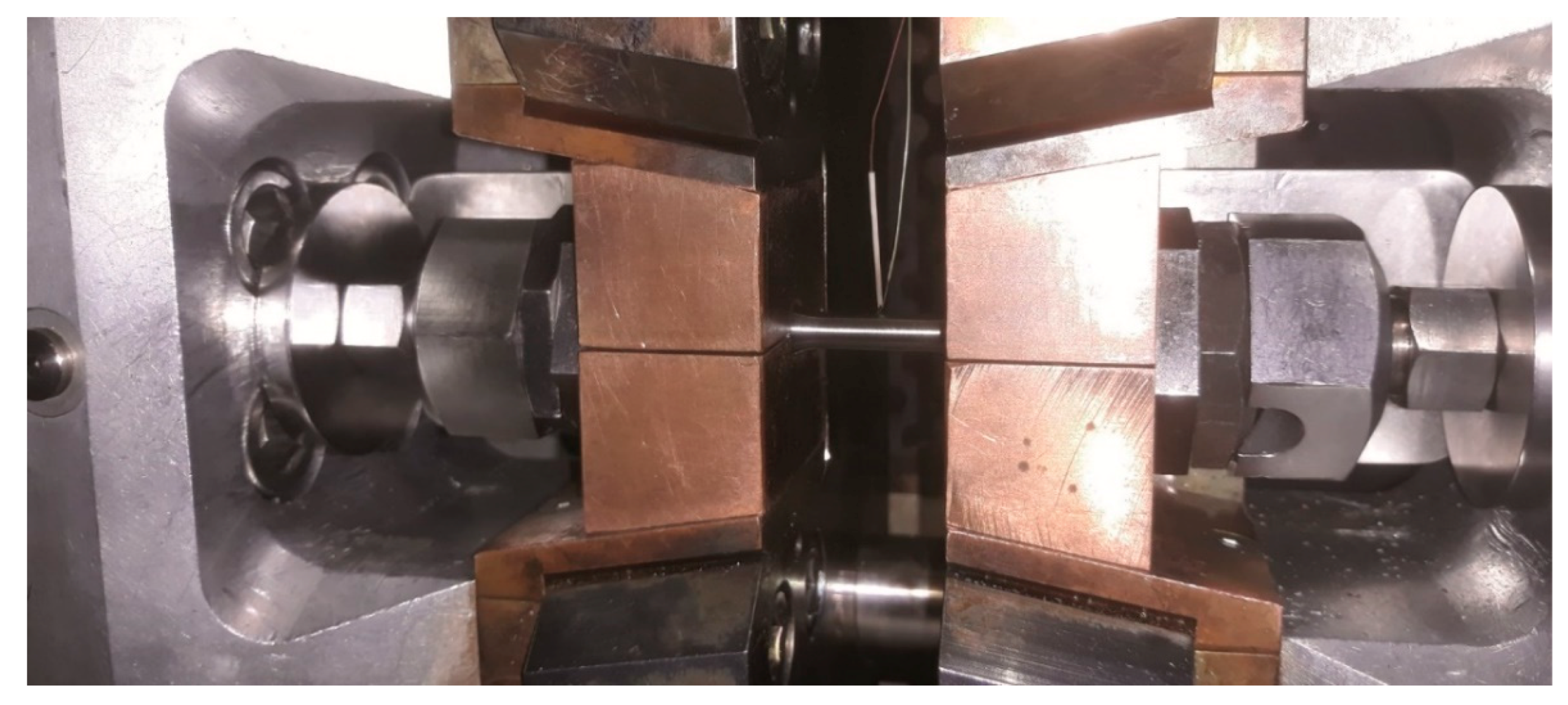

2.3. Welding Experiments

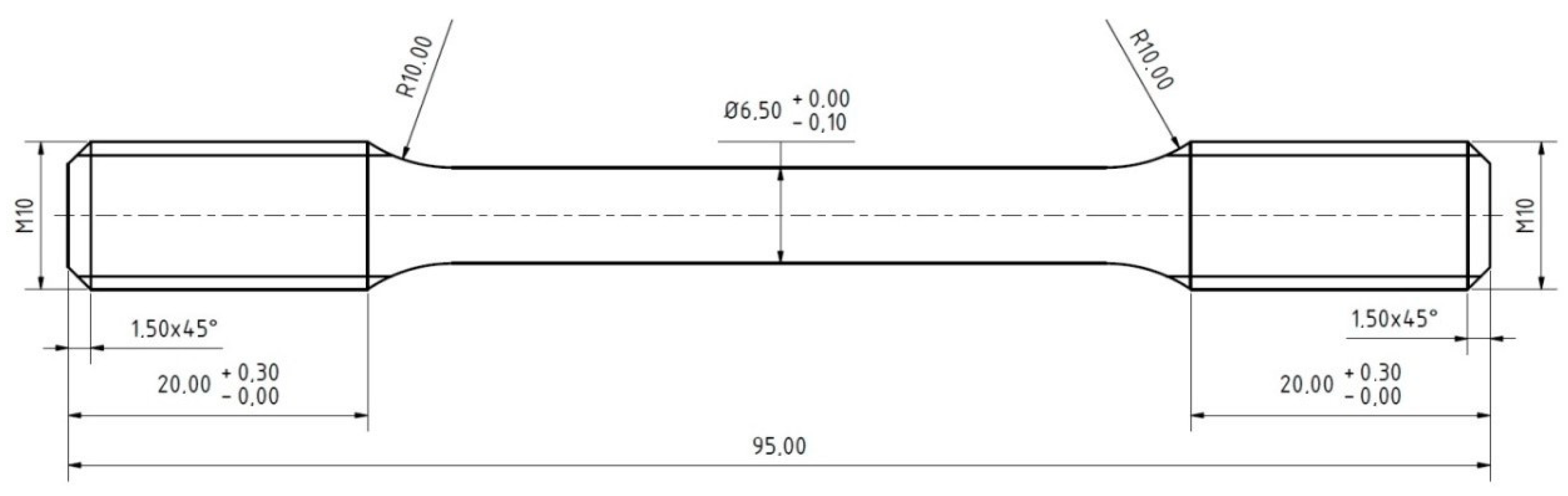

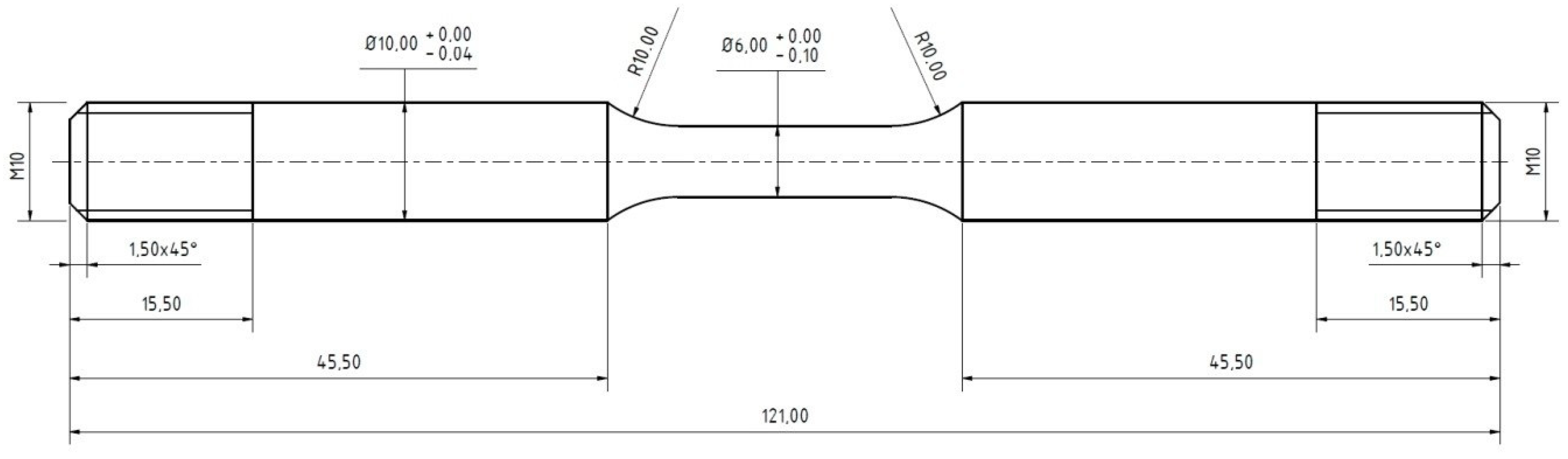

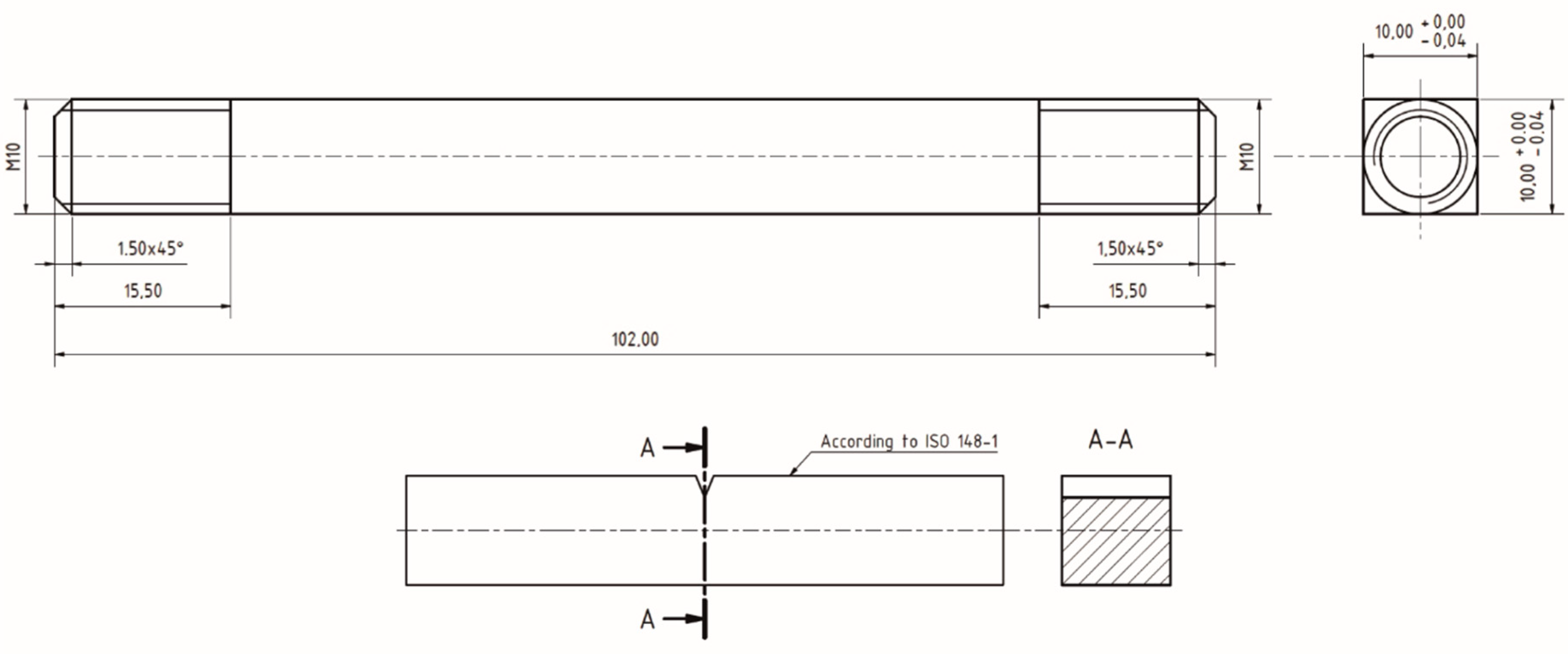

2.4. Preparation of Test Samples for Measurement of Mechanical Properties and KV2 Values in HAZ

3. Results

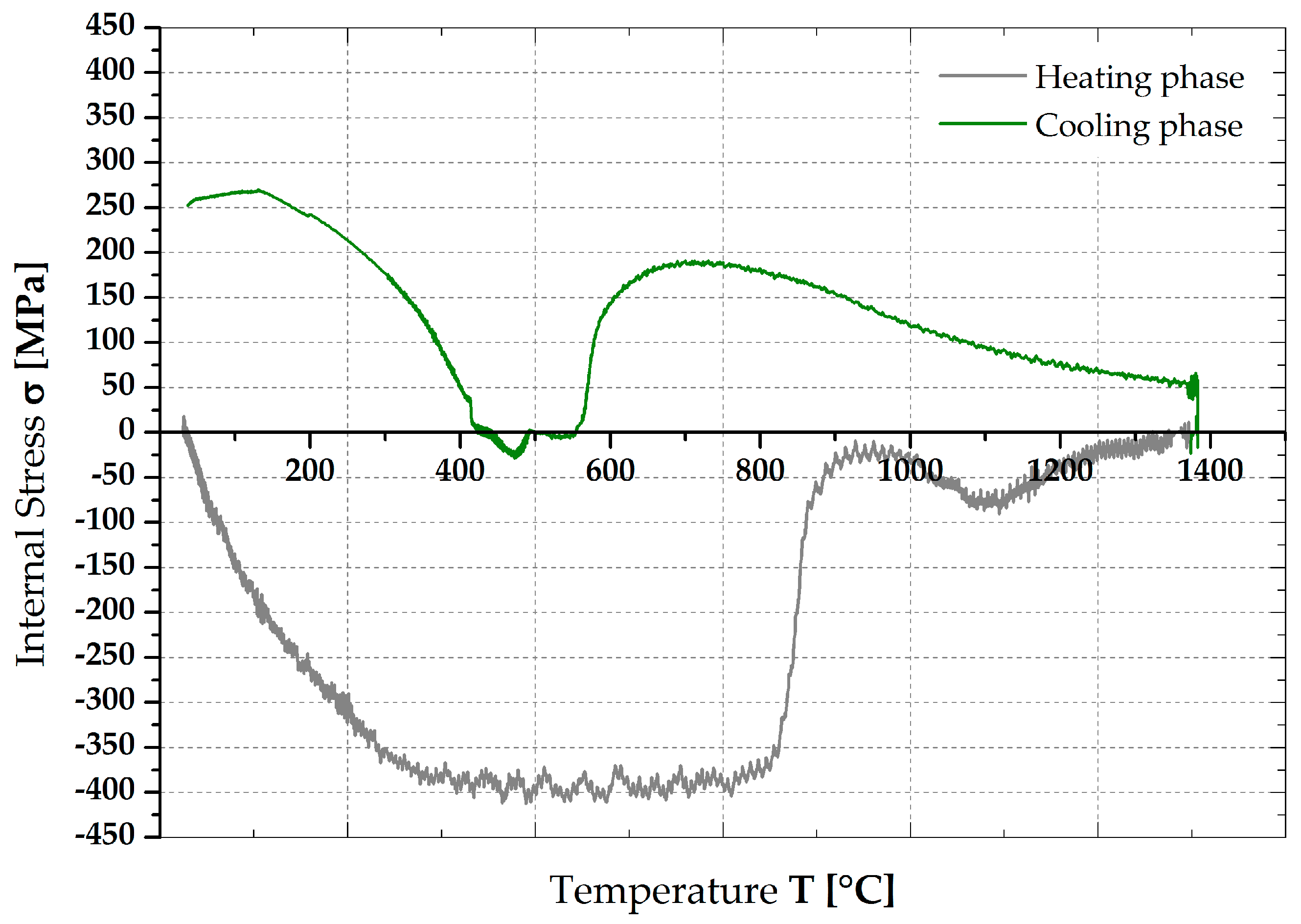

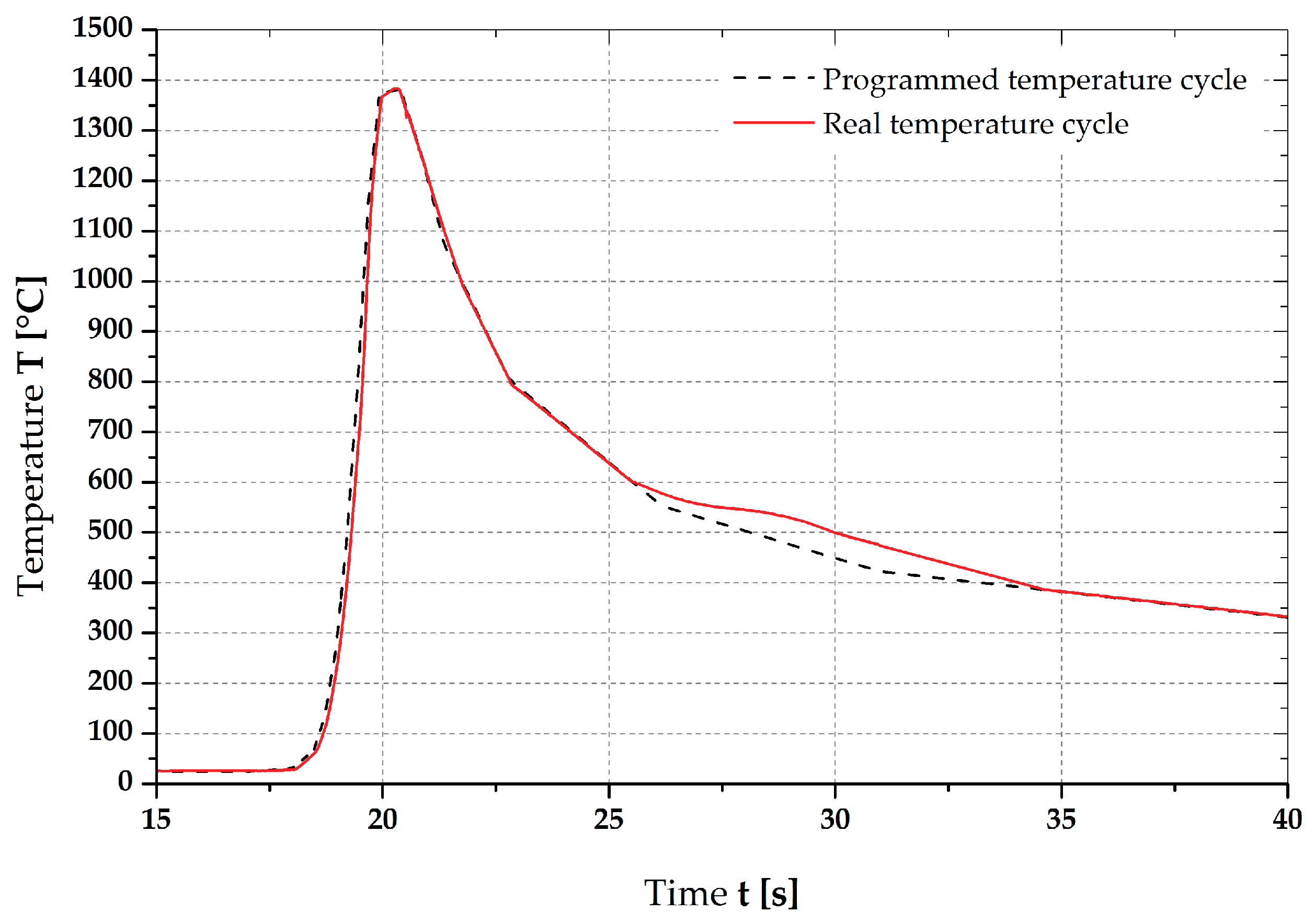

3.1. Evaluation of Welding Experiments and Comparison with Prediction Using the Proportionality Constant K

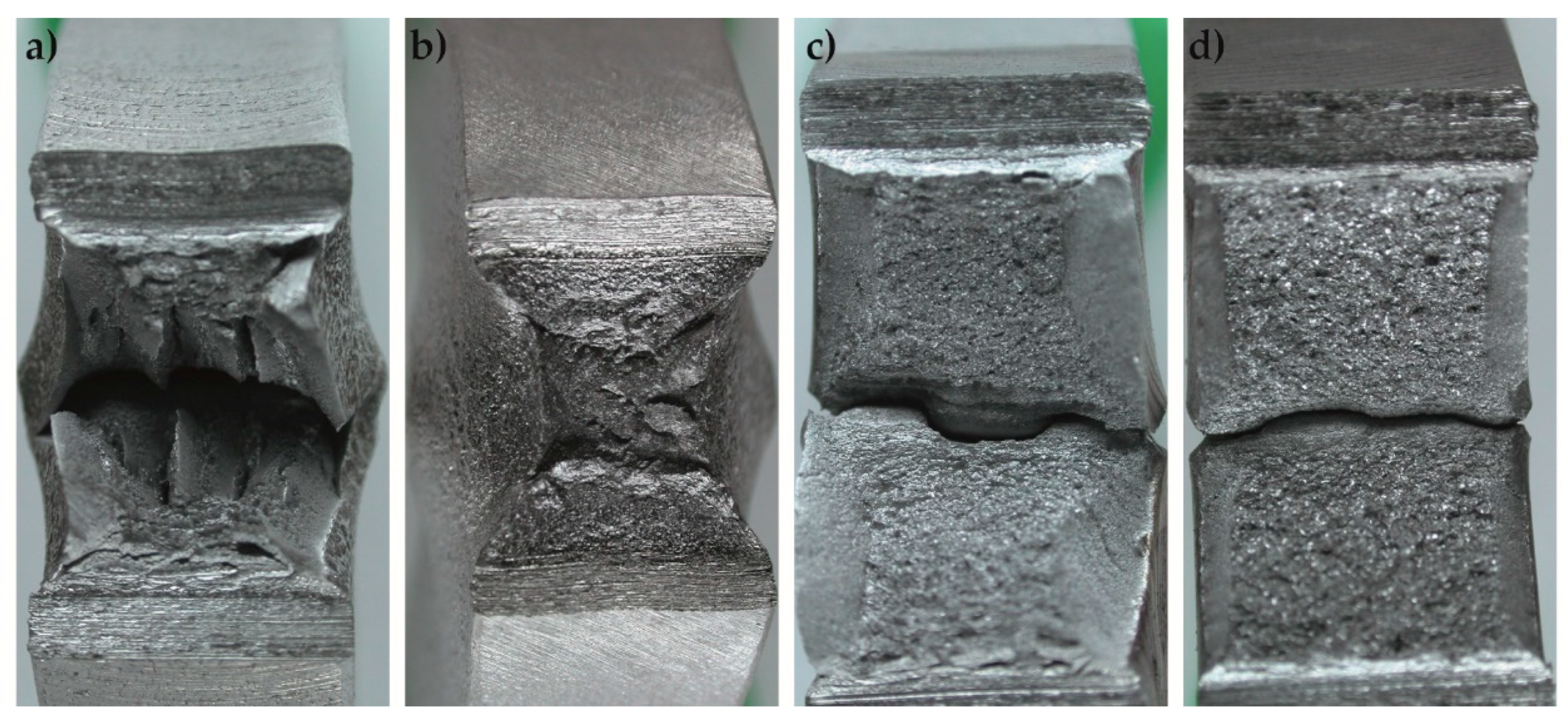

3.2. Evaluation of Welding Influence on Mechanical Properties and Impact Value in a HAZ Area

4. Discussion

4.1. Verification of the Grain Size Determination Method Applicability for Welding Cycles

4.2. Discussion of the Influence of Welding on Mechanical Properties and Impact Value of a HAZ Area

5. Conclusions

- Before the verification experiment, the type of welded joint, the possibilities of its expansion during welding, the method of its clamping, and the rigidity of the parts to be joined should all be defined.

- Consider the Tmax for the temperature cycle applied to the test specimen, especially when it is a thermomechanically fine-grained steel. The effect of grain coarsening is more pronounced in welding cycles at temperatures higher than 1300 °C.

- Consider the shape of temperature cycles used for samples and simulating the welding process. Essentially start from the real measured temperature cycles characteristic of the used welding method and eventually move to temperature cycles predicted by means of experimentally verified numerical simulations.

- Design the shape and size of the test specimens so that the testing machine applying the temperature cycle to the sample is able to reach the desired Tmax, heating, and cooling rates.

- The values of the temperature dependence of the proportionality constant K, which defines the grain growth kinetics and is obtained experimentally by the isothermal method, can be used with the sufficient precision to predict the grain size both for long-term soaking times at exposure temperatures and for dynamic welding temperature cycles that are characteristic of welding

- While welding parts that are rigidly clamped or have higher rigidity, the thermal expansion of the part is compensated by plastic deformation. In this case, the yield strength Re was reduced by 12%, and the KV2 value was reduced by 32% compared to parts that can dilate freely.

- The value of specific heat introduced into the weld should be limited. In this case, when the cooling time is double extended in the interval Tmax-500 °C (i.e., also for temperature t8/5), the yield strength Re was reduced by 6%, and, above all, the KV2 value decreased by more than 70% compared to the same samples clamped in the same manner.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Burke, J.E.; Turnbull, D. Recrystallization and grain growth. Prog. Met. Phys. 1952, 3, 220–292. [Google Scholar] [CrossRef]

- Zöllner, D.; Streitenberger, P. Three-dimensional Normal Grain Growth: Monte Carlo Potts Model Simulation and Analytical Mean Field Theory. Scr. Mater. 2006, 54, 1697–1702. [Google Scholar] [CrossRef]

- Zöllner, D.; Streitenberger, P. Monte Carlo Potts Model Simulation and Mean-Field Theory of Normal Grain Growth; Shaker Verlag GmbH: Herzogenrath, Germany, 2006; p. 144. [Google Scholar]

- Abbaschian, R.; Abbaschian, L.; Reed-Hill, R.E. Physical Metallurgy Principles; Cengage Learning: Stamford, CT, USA, 2009. [Google Scholar]

- Giumelli, A. Austenite Grain Growth Kinetics and the Grain Size Distribution. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 1995. [Google Scholar]

- Moravec, J. Metodické postupy využitelné kzískání vstupních veličin numerických simulací svařování a tepelného zpracování. Habilitation Thesis, Technical University of Liberec, Liberec, Czech Republic, 2017. [Google Scholar]

- Priadi, D.; Mapitupulu, R.A.M.; Siradj, E.S. Austenite Grain Growth Calculation of 0.028% Nb steel. J. Min. Metall. 2011, 47, 199–209. [Google Scholar] [CrossRef]

- Manohar, P.A.; Dunne, D.P.; Chandra, T.; Killmore, C.R. Grain Growth Predictions in Microalloyed Steels. ISIJ Int. 1995, 36, 194–200. [Google Scholar] [CrossRef]

- Górka, J. Microstrukture and Properties of the High-Temperature (HAZ) of Thermo-Mechanically Treated S700MC High-Yield-Strength Steells. Mater. Technol. 2016, 50, 617–621. [Google Scholar]

- Górka, J. Influence of the maximum temperature of the thermal cycle on the properties and structure of the HAZ of steel S700MC. IOSR J. Eng. 2013, 3, 22–28. [Google Scholar] [CrossRef]

- Górka, J. An Influence of Welding Thermal Cycles on Properties and HAZ Structure of S 700MC Steel Treated Using Thermomechanical Method. In Proceedings of the Scientific Proceedings IX. International Congress “Machines, Technologies, Materials”, Varna, Bulgaria, 19–21 September 2012; Volume 3, pp. 41–44. [Google Scholar]

- Górka, J.; Stano, S. Microstructure and Properties of Hybrid Laser Arc Welded Joints (Laser Beam-MAG) in Thermo-Mechanical Control Processed S700MC Steel. Metals 2018, 8, 132. [Google Scholar] [CrossRef]

- Górka, J. Assessment of Steel Subjected to the Thermomechanical Control Process with Respect to Weldability. Metals 2018, 8, 169. [Google Scholar] [CrossRef]

- Lahtinen, T.; Vilaça, P.; Peura, P.; Mehtonen, S. MAG Welding Tests of Modern High Strenght Steels with Minimum Yeild Stenght of 700 MPa. Appl. Sci. 2019, 9, 1031. [Google Scholar] [CrossRef]

- Rahman, M.; Albu, M.; Enzinger, N. On the Modelling of Austenite Grain Growth in Micro-Alloyed Steel S700MC. In Proceedings of the 10th International Seminar on Numerical Analysis of Weldability, Mathematical Modelling of Weld Phenomena, Schloss Seggau, Germany, 24–26 September 2012; Volume 9, pp. 623–636. [Google Scholar]

- Kik, T.; Górka, J. Numerical Simulations of Laser and Hybrid S700MC T-Joint Welding. Materials 2019, 12, 516. [Google Scholar] [CrossRef] [PubMed]

- ESI Group. Reference Manual Sysweld 2019; ESI Group: Paris, France, 2019; p. 366. [Google Scholar]

- Schmidová, E.; Bozkurt, F.; Culek, B.; Kumar, S.; Kuchariková, L.; Uhríčik, M. Influence of Welding on Dynamic Fracture Toughness of Strenx 700MC Steel. Metals 2019, 9, 494. [Google Scholar] [CrossRef]

- Spanos, G.; Fonda, R.W.; Vandermeer, R.A.; Matuszeski, A. Microstructural changes in HSLA-100 steel thermally cycled to simulate the heat-affected zone during welding. Metall. Mater. Trans. A 1995, 26, 3277–3293. [Google Scholar] [CrossRef]

- Welding of Strenx. Available online: https://ssabwebsitecdn.azureedge.net/-/media/files/en/strenx/ssab-strenx-welding-brochure-2018.pdf (accessed on 29 May 2019).

| Elements | C | Si | Mn | P | S | Al | Nb | V |

| EN 10149-2 | max. 0.12 | max. 0.6 | max. 2.2 | max. 0.025 | max. 0.010 | min. 0.015 | max. 0.09 | max. 0.2 |

| Experiment | 0.051 | 0.197 | 1.916 | 0.006 | 0.006 | 0.038 | 0.063 | 0.072 |

| Ti | Mo | B | N | Ni | Cr | W | ||

| EN 10149-2 | max. 0.25 | max. 1 | max. 0.005 | - | - | - | - | |

| Experiment | 0.056 | 0.113 | 0 | 0.013 | 0.154 | 0.036 | 0.035 |

| S700MC | Soaking Time at Relevant Temperature | ||||

|---|---|---|---|---|---|

| 0.5 h | 2 h | 4 h | 8 h | ||

| Exposure temperature | 900 °C | 3.99 | 4.29 | 4.87 | 5.91 |

| 1000 °C | 5.15 | 7.06 | 7.98 | 10.53 | |

| 1100 °C | 6.81 | 8.62 | 10.78 | 13.82 | |

| 1200 °C | 8.53 | 10.02 | 12.78 | 16.97 | |

| S700MC | Exposure Temperature (°C) | |||

|---|---|---|---|---|

| 900 | 1000 | 1100 | 1200 | |

| KT (mm2 s−1) | 7.1924 × 10−10 | 3.0253 × 10−9 | 5.3780 × 10−9 | 8.1581 × 10−9 |

| D0 (mm) | 0.00001386 | 0.00002325 | 0.00003679 | 0.00004965 |

| Temperature (°C) | 20 | 100 | 200 | 300 | 400 | 500 |

| K (mm2·s−1) | 9.839 × 10−52 | 1.224 × 10−41 | 8.019 × 10−34 | 9.825 × 10−29 | 3.702 × 10−25 | 1.657 × 10−22 |

| Temperature (°C) | 600 | 700 | 800 | 900 | 1000 | 1100 |

| K (mm2·s−1) | 1.832 × 10−20 | 7.698 × 10−19 | 1.612 × 10−17 | 2.009 × 10−16 | 1.685 × 10−15 | 1.035 × 10−14 |

| Temperature (°C) | 1200 | 1300 | 1400 | 1500 | ||

| K (mm2·s−1) | 4.982 × 10−14 | 1.961 × 10−13 | 6.555 × 10−13 | 1.912 × 10−12 |

| Sample No. | Diameter (mm) | Re (MPa) | Rm (MPa) | Ag (%) | A20 (%) |

|---|---|---|---|---|---|

| BMT-01 | 6.52 | 749 | 851 | 10.97 | 23.91 |

| BMT-02 | 6.53 | 748 | 852 | 12.33 | 25.22 |

| BMT-03 | 6.50 | 731 | 849 | 10.72 | 23.62 |

| Average value | 743 | 851 | 11.01 | 24.25 | |

| GT-FD-01 | 6.48 | 708 | 834 | 8.64 | 23.85 |

| GT-FD-02 | 6.51 | 712 | 826 | 8.36 | 22.97 |

| GT-FD-03 | 6.50 | 699 | 829 | 9.02 | 23.68 |

| GT-FD-04 | 6.51 | 704 | 822 | 8.58 | 23.33 |

| Average value | 706 | 828 | 8.65 | 23.46 | |

| GT-D0-01 | 6.50 | 617 | 785 | 5.49 | 23.38 |

| GT-D0-02 | 6.48 | 626 | 797 | 5.32 | 23.63 |

| GT-D0-03 | 6.51 | 621 | 783 | 5.12 | 21.78 |

| GT-D0-04 | 6.50 | 634 | 790 | 4.94 | 24.21 |

| Average value | 625 | 789 | 5.22 | 23.25 | |

| VFT-FD-01 | 6.51 | 301 | 448 | 13.24 | 37.65 |

| VFT-FD-02 | 6.49 | 306 | 452 | 13.45 | 38.63 |

| VFT-FD-03 | 6.48 | 311 | 446 | 13.52 | 38.16 |

| VFT-FD-04 | 6.51 | 304 | 457 | 13.09 | 37.93 |

| Average value | 306 | 451 | 13.33 | 38.09 | |

| Sample No. | KCV2 (J/cm2) | Absorbed Energy KV2 (J) | Fmax (N) | Actual Impact Speed [m·s−1] | Ductile Fracture [%] |

|---|---|---|---|---|---|

| BMCH-01 | 294.7 | 235.8 | 25119 | 5.529 | 100 |

| BMCH-02 | 367.1 | 293.7 | 25536 | 5.478 | 100 |

| BMCH-03 | 336.1 | 268.9 | 25343 | 5.426 | 100 |

| BMCH-04 | 327.3 | 261.8 | 25413 | 5.429 | 100 |

| BMCH-05 | 306.4 | 245.1 | 25323 | 5.426 | 100 |

| Average value | 326.3 | 261.1 | |||

| GCH-FD-01 | 254.7 | 187.8 | 25714 | 5.439 | 62.5 |

| GCH-FD-02 | 237.5 | 174.0 | 25649 | 5.426 | 59.8 |

| GCH-FD-03 | 263.2 | 194.6 | 25803 | 5.511 | 63.3 |

| GCH-FD-04 | 271.8 | 201.4 | 25852 | 5.442 | 63.9 |

| Average value | 256.8 | 205.4 | |||

| GCH-D0-01 | 166.3 | 133.0 | 26094 | 5.512 | 35.3 |

| GCH-D0-02 | 174.1 | 139.3 | 25927 | 5.426 | 33.6 |

| GCH-D0-03 | 187.6 | 150.1 | 25973 | 5.431 | 36.1 |

| GCH-D0-04 | 170.9 | 136.7 | 26011 | 5.473 | 37.0 |

| Average value | 174.7 | 139.8 | |||

| VFCH-FD-01 | 466.6 | 373.3 | 18694 | 5.426 | 100 |

| VFCH-FD-02 | 473.9 | 379.1 | 18670 | 5.426 | 100 |

| VFCH-FD-03 | 432.3 | 345.8 | 18434 | 5.684 | 100 |

| VFCH-FD-04 | 458.9 | 367.2 | 18030 | 5.383 | 100 |

| Average value | 457.9 | 366.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moravec, J.; Novakova, I.; Sobotka, J.; Neumann, H. Determination of Grain Growth Kinetics and Assessment of Welding Effect on Properties of S700MC Steel in the HAZ of Welded Joints. Metals 2019, 9, 707. https://doi.org/10.3390/met9060707

Moravec J, Novakova I, Sobotka J, Neumann H. Determination of Grain Growth Kinetics and Assessment of Welding Effect on Properties of S700MC Steel in the HAZ of Welded Joints. Metals. 2019; 9(6):707. https://doi.org/10.3390/met9060707

Chicago/Turabian StyleMoravec, Jaromir, Iva Novakova, Jiri Sobotka, and Heinz Neumann. 2019. "Determination of Grain Growth Kinetics and Assessment of Welding Effect on Properties of S700MC Steel in the HAZ of Welded Joints" Metals 9, no. 6: 707. https://doi.org/10.3390/met9060707

APA StyleMoravec, J., Novakova, I., Sobotka, J., & Neumann, H. (2019). Determination of Grain Growth Kinetics and Assessment of Welding Effect on Properties of S700MC Steel in the HAZ of Welded Joints. Metals, 9(6), 707. https://doi.org/10.3390/met9060707