Feasibility Study on Application of Synchrotron Radiation μCT Imaging to Alloy Steel for Non-Destructive Inspection of Inclusions

Abstract

1. Introduction

2. Material and Methods

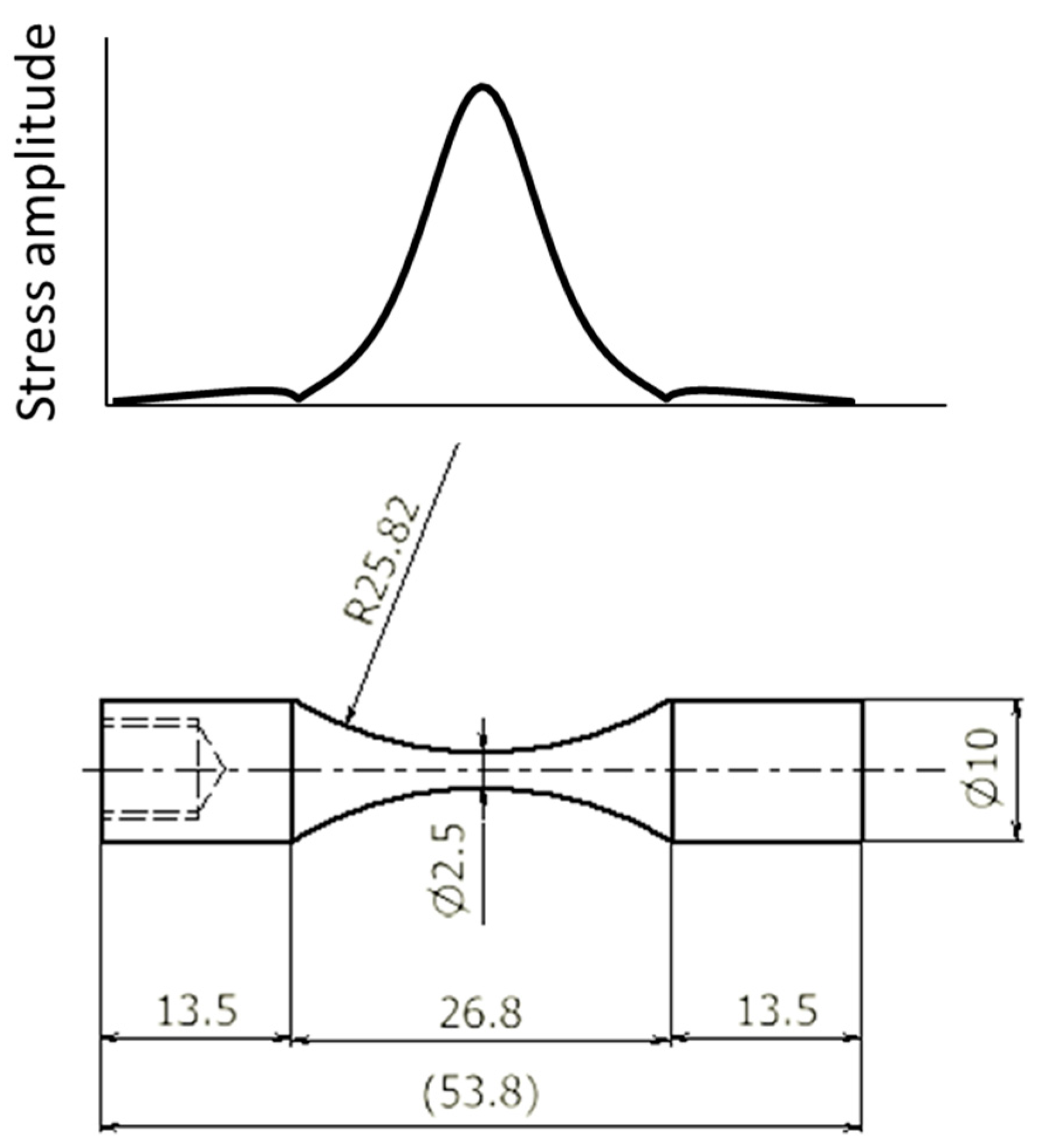

2.1. Material

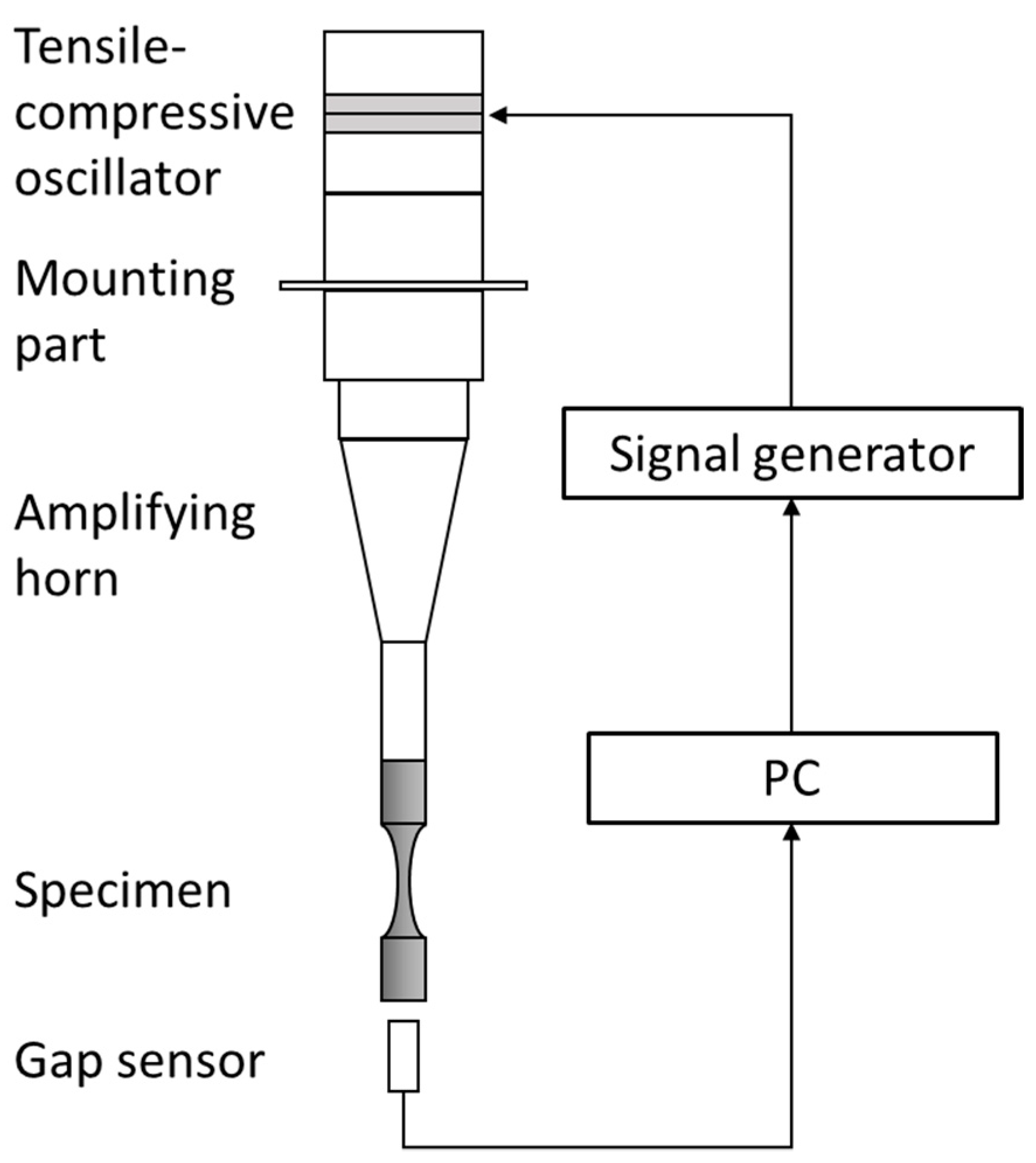

2.2. Ultrasonic Fatigue Testing Machine

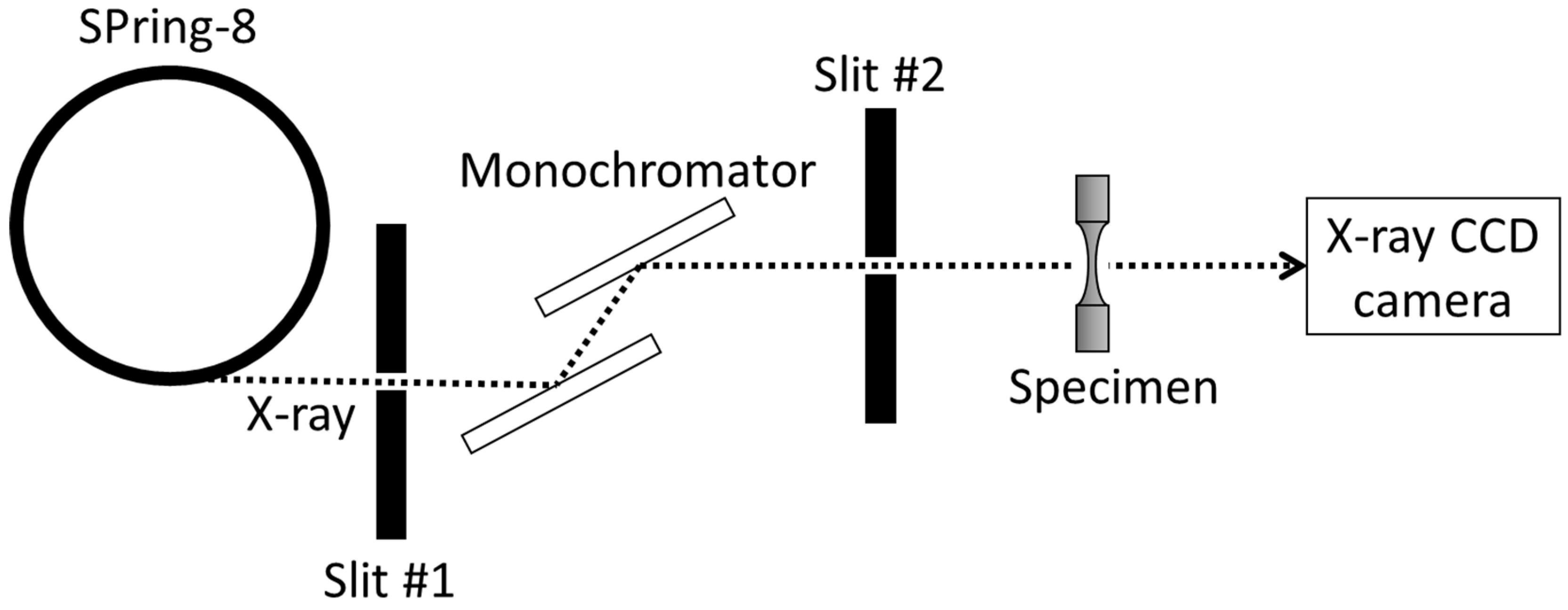

2.3. Synchrotron Radiation μCT Imaging

2.4. Determination of Fatigue Life of the Specimen Used for the Repeated μCT Imaging

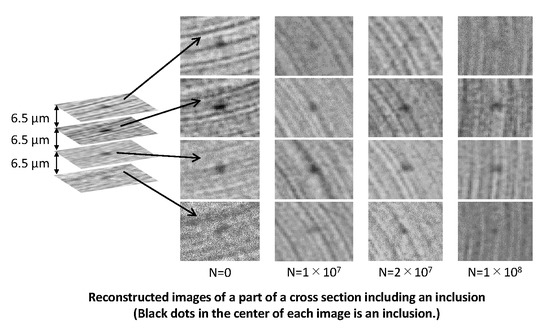

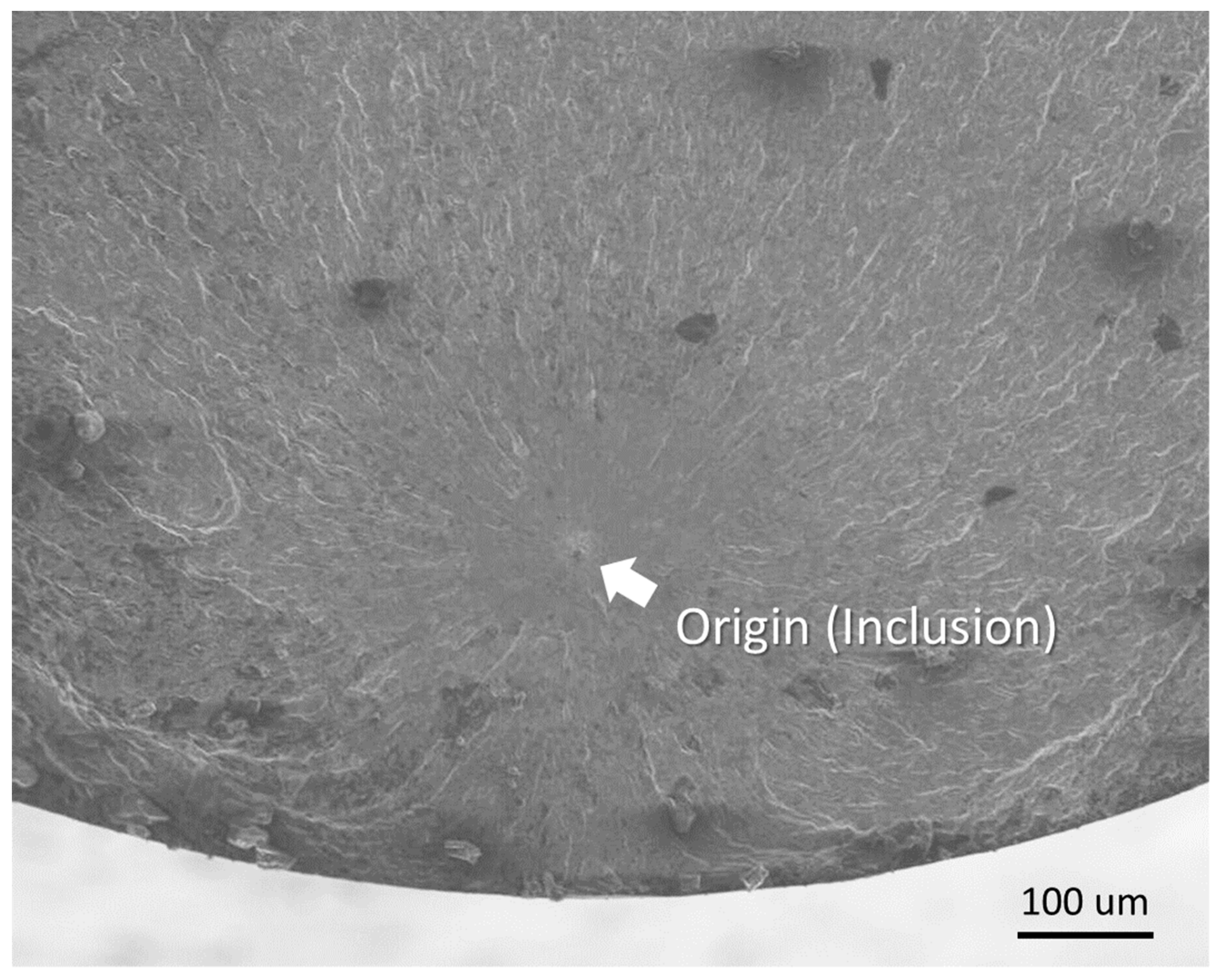

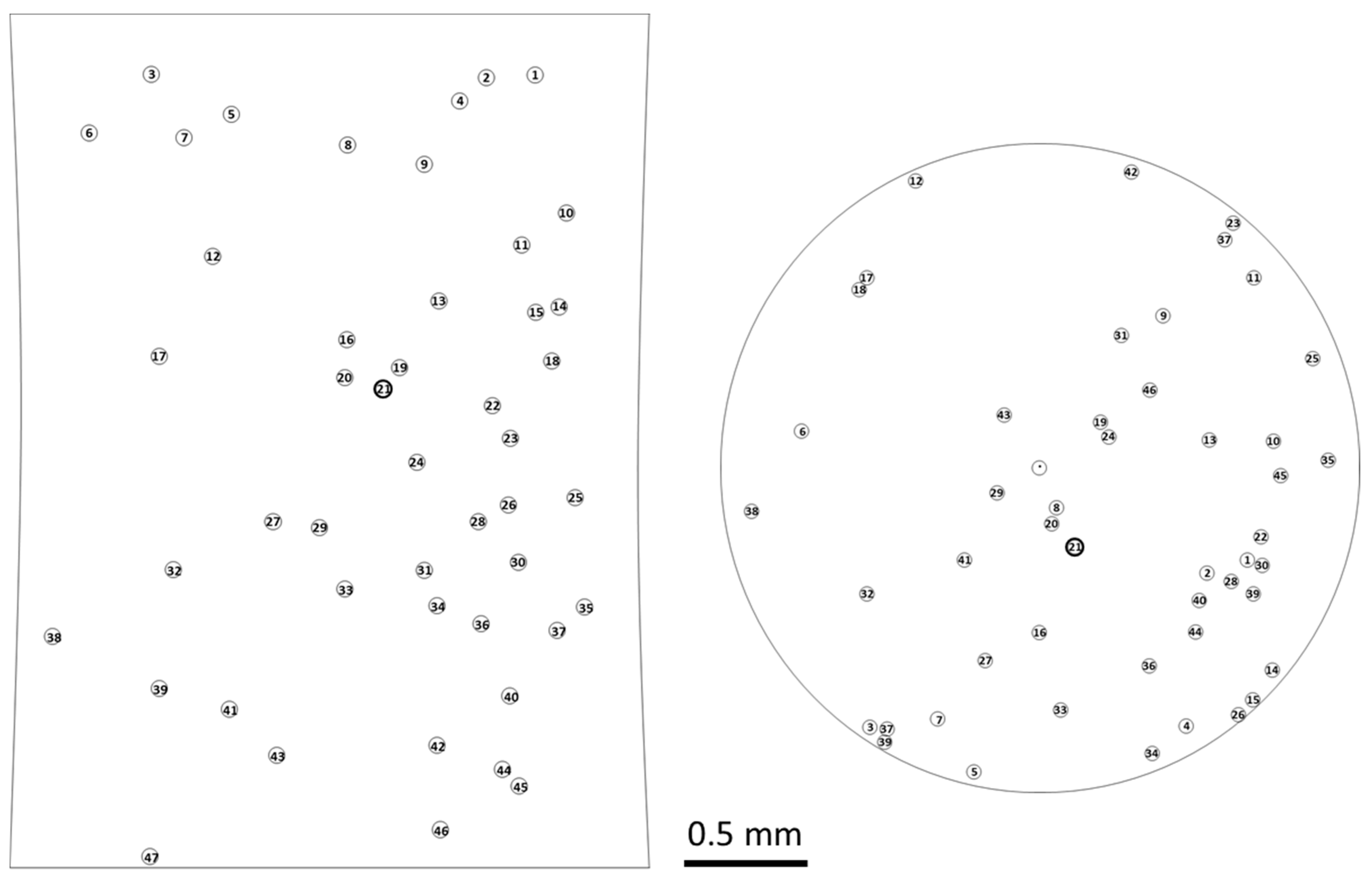

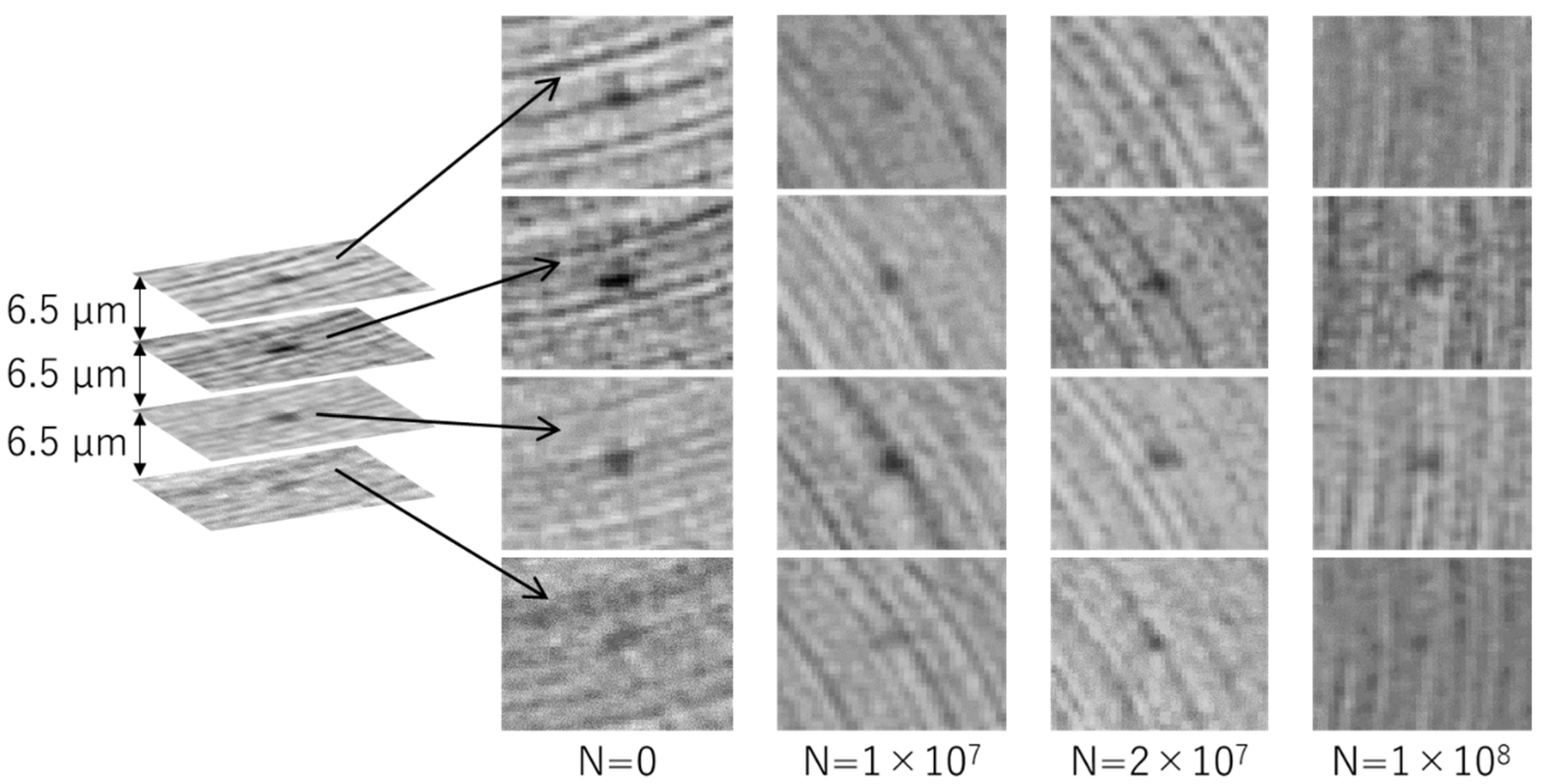

3. Results

4. Discussion

5. Conclusions

- The proposed experimental set-up allows us to observe inclusions of more than 10 μm nondestructively, one of which is the potential origin of an internal fatigue crack.

- No identifiable internal damage was observed within the imaging volume at least up to 70% of the fatigue life. For more detailed in-situ-inspection of ODA formation, improvements of resolution and experimental set-up should be required.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sakai, T. Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use. J. Solid Mech. Mater. Eng. 2009, 3, 425–439. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T.; Murakami, Y. On the Mechanism of Fatigue Failure in the Superlong Life Regime (N > 107 cycles). Part I: Influence of Hydrogen Trapped by Inclusions. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 893–902. [Google Scholar] [CrossRef]

- Sakai, T.; Sato, Y.; Oguma, N. Characteristic S–N property of high carbon chromium bearing steel under axial loading in long life fatigue. Trans. Jpn. Soc. Mech. Eng. A 2001, 67, 1980–1987. [Google Scholar] [CrossRef][Green Version]

- Kuroshima, Y.; Ikeda, T.; Harada, M.; Harada, S. Subsurface crack growth behavior on high cycle fatigue of high strength steel. Trans. Jpn. Soc. Mech. Eng. A 1998, 64, 2536–2541. [Google Scholar] [CrossRef][Green Version]

- Luo, L.; Shiozawa, K. Effect of two-step load variation on super-long life fatigue and internal crack growth behavior of high carbon-chromium bearing steel. Trans. Jpn. Soc. Mech. Eng. A 2002, 68, 1666–1673. [Google Scholar] [CrossRef][Green Version]

- Ogawa, T.; Stanzal-Tschegg, S.E.; Shönbaue, B.M. A fracture mechanics approach to interior fatigue crack growth in the very high cycle regime. Eng. Fract. Mech. 2014, 115, 241–254. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Nakamura, T.; Nakayama, S.; Shiozawa, D.; Nakai, Y.; Uesugi, K. Non-destructive observation of internal fatigue crack growth in Ti-6Al-4V by using synchrotron radiation μCT imaging. Int. J. Fatigue 2016, 93, 397–405. [Google Scholar] [CrossRef]

- Kasahara, R.; Nishikawa, M.; Shimamura, Y.; Tohgo, K.; Fujii, T. Evaluation of very high cycle fatigue properties of β-titanium alloy by using an ultrasonic fatigue testing machine. Key Eng. Mater. 2016, 725, 366–371. [Google Scholar] [CrossRef]

- Nakai, Y.; Shiozawa, D.; Morinaga, Y.; Kurimura, T.; Okada, H.; Miyashita, T. Observation of inclusions and defects in steels by micro computed-tomography using ultrabright synchrotron radiation. In Proceedings of the Fourth International Conference on Very High Cycle Fatigue, Ann Arbor, MI, USA, 19–22 August 2007; Allison, J.E., Jones, J.W., Larsen, J.M., Ritche, R.O., Eds.; TMS: Warrendale, PA, USA, 2007; pp. 67–72. [Google Scholar]

- Murakami, R. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusion; Yukendo Ltd.: Tokyo, Japan, 1993; p. 90. ISBN 978-4842593029. [Google Scholar]

- WES 1112: Standard Method for the Ultrasonic Fatigue Test in Metallic Materials; The Japan Welding Engineering Society: Tokyo, Japan, 2017; p. 7.

- Computed Tomography in SPring-8 (SP-μCT). Available online: http://www-bl20.spring8.or.jp/xct/index-e.html (accessed on 15 March 2019).

- Mayer, H. Recent Developments in Ultrasonic Fatigue. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 3–29. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cu | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.18 | 0.8 | 0.02 | 0.02 | 0.01 | 1.12 | 0.01 | 0.19 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimamura, Y.; Matsushita, S.; Fujii, T.; Tohgo, K.; Akita, K.; Shobu, T.; Shiro, A. Feasibility Study on Application of Synchrotron Radiation μCT Imaging to Alloy Steel for Non-Destructive Inspection of Inclusions. Metals 2019, 9, 527. https://doi.org/10.3390/met9050527

Shimamura Y, Matsushita S, Fujii T, Tohgo K, Akita K, Shobu T, Shiro A. Feasibility Study on Application of Synchrotron Radiation μCT Imaging to Alloy Steel for Non-Destructive Inspection of Inclusions. Metals. 2019; 9(5):527. https://doi.org/10.3390/met9050527

Chicago/Turabian StyleShimamura, Yoshinobu, Shinya Matsushita, Tomoyuki Fujii, Keiichiro Tohgo, Koichi Akita, Takahisa Shobu, and Ayumi Shiro. 2019. "Feasibility Study on Application of Synchrotron Radiation μCT Imaging to Alloy Steel for Non-Destructive Inspection of Inclusions" Metals 9, no. 5: 527. https://doi.org/10.3390/met9050527

APA StyleShimamura, Y., Matsushita, S., Fujii, T., Tohgo, K., Akita, K., Shobu, T., & Shiro, A. (2019). Feasibility Study on Application of Synchrotron Radiation μCT Imaging to Alloy Steel for Non-Destructive Inspection of Inclusions. Metals, 9(5), 527. https://doi.org/10.3390/met9050527