A Study on Microstructure and Mechanical Properties of Micro Friction Stir Welded Ultra-Thin Al-1060 Sheets by the Shoulderless Tool

Abstract

1. Introduction

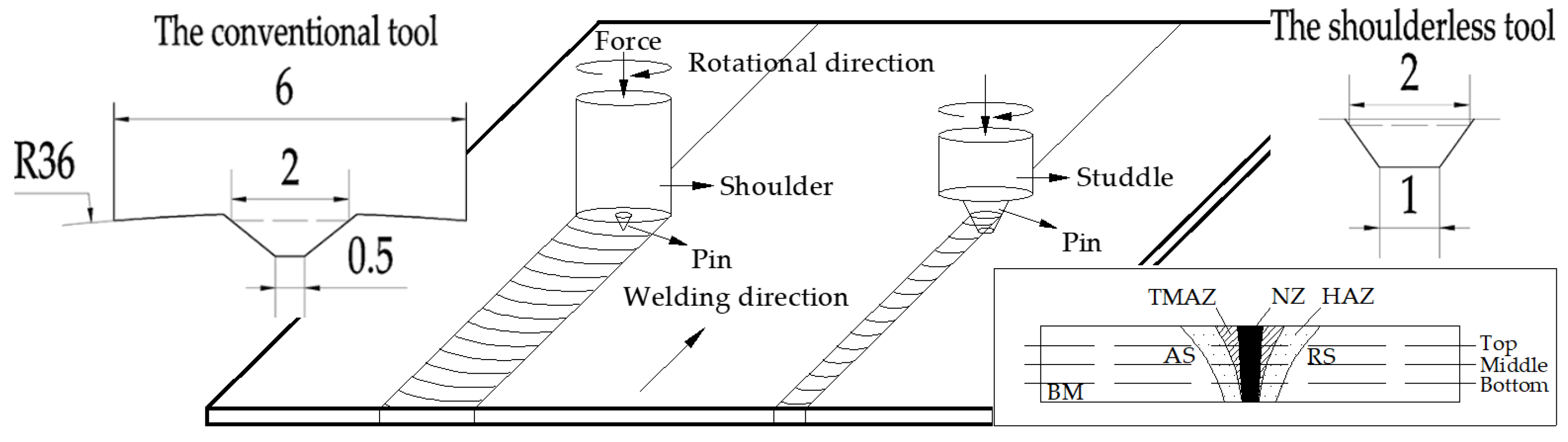

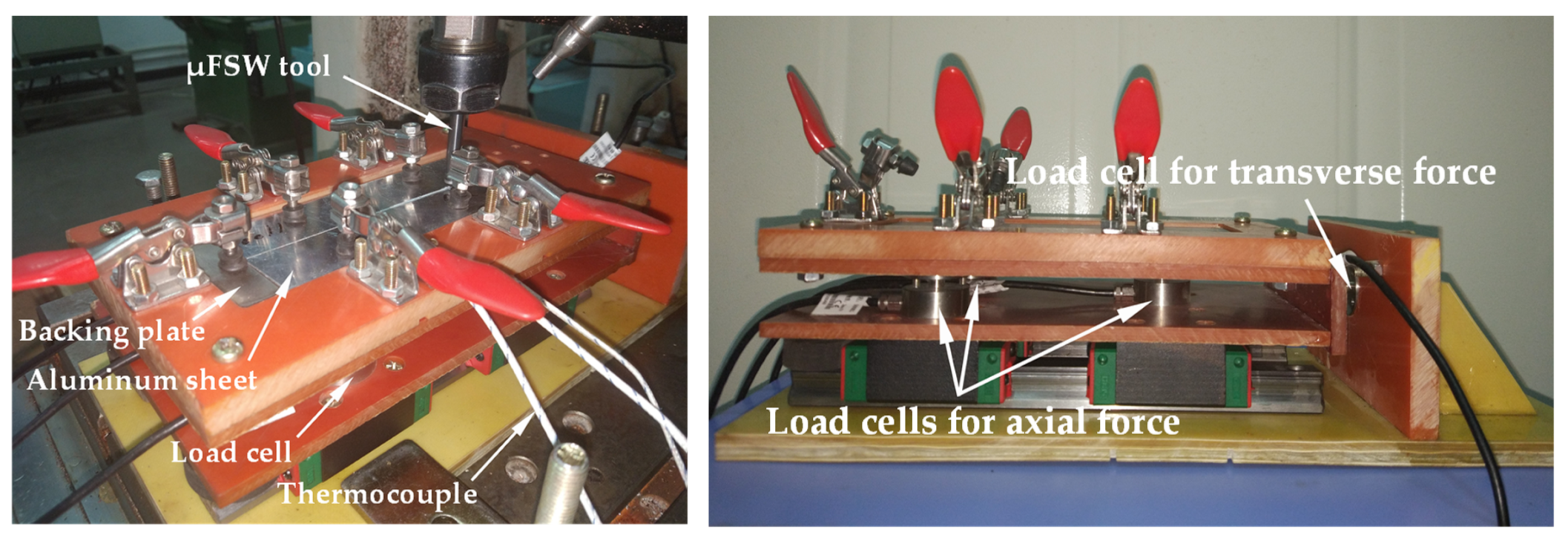

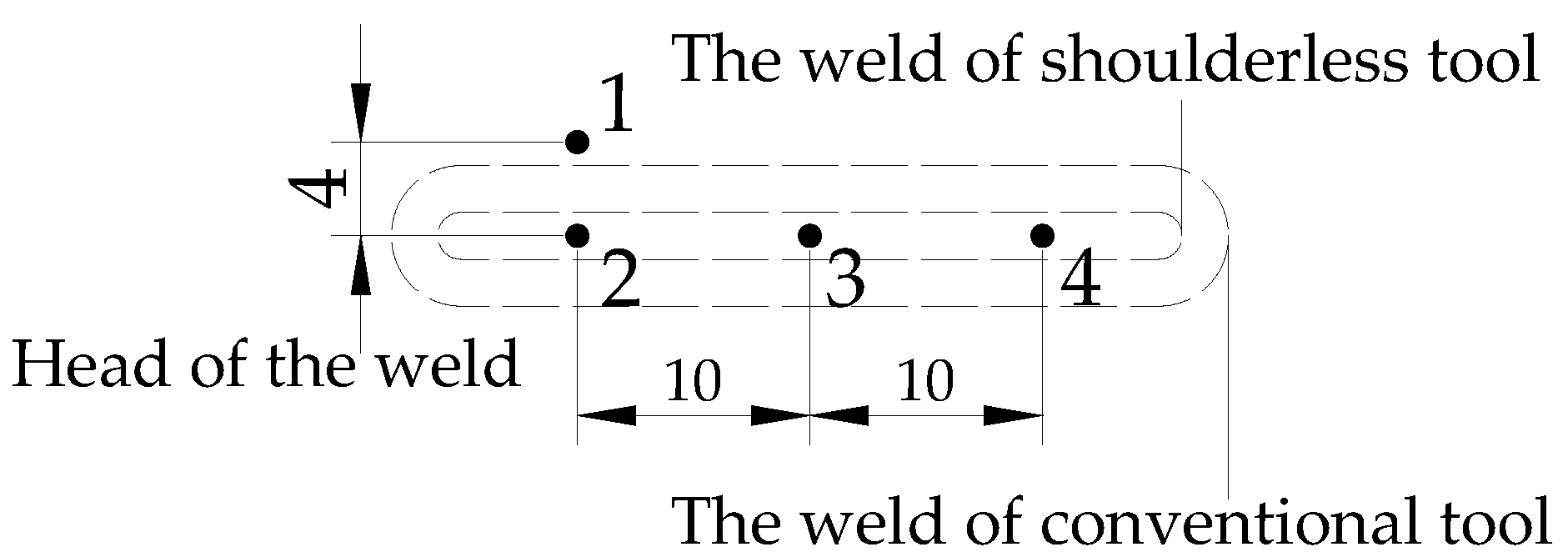

2. Materials and Methods

3. Results and Discussion

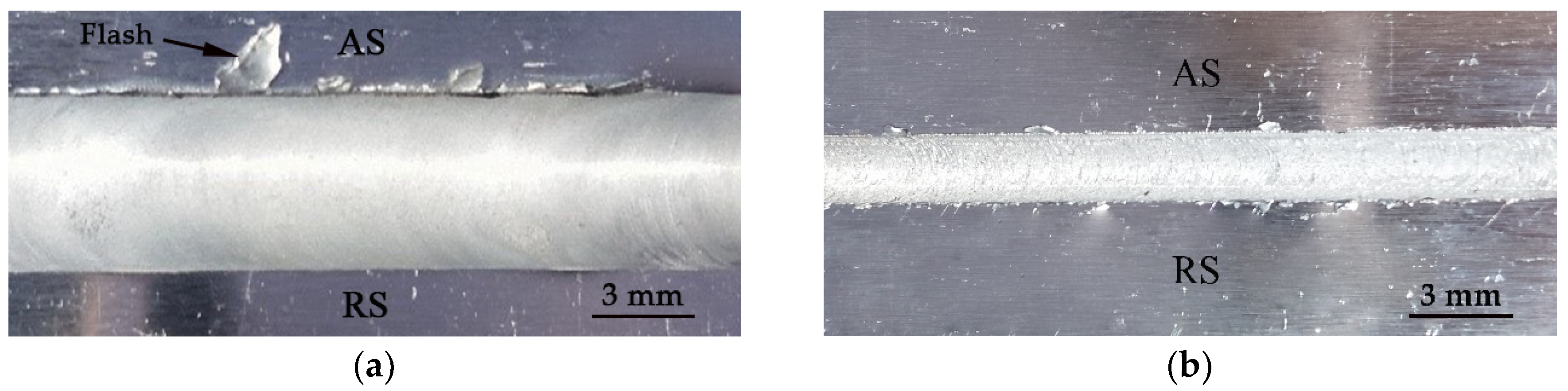

3.1. Weld Surface Appearance

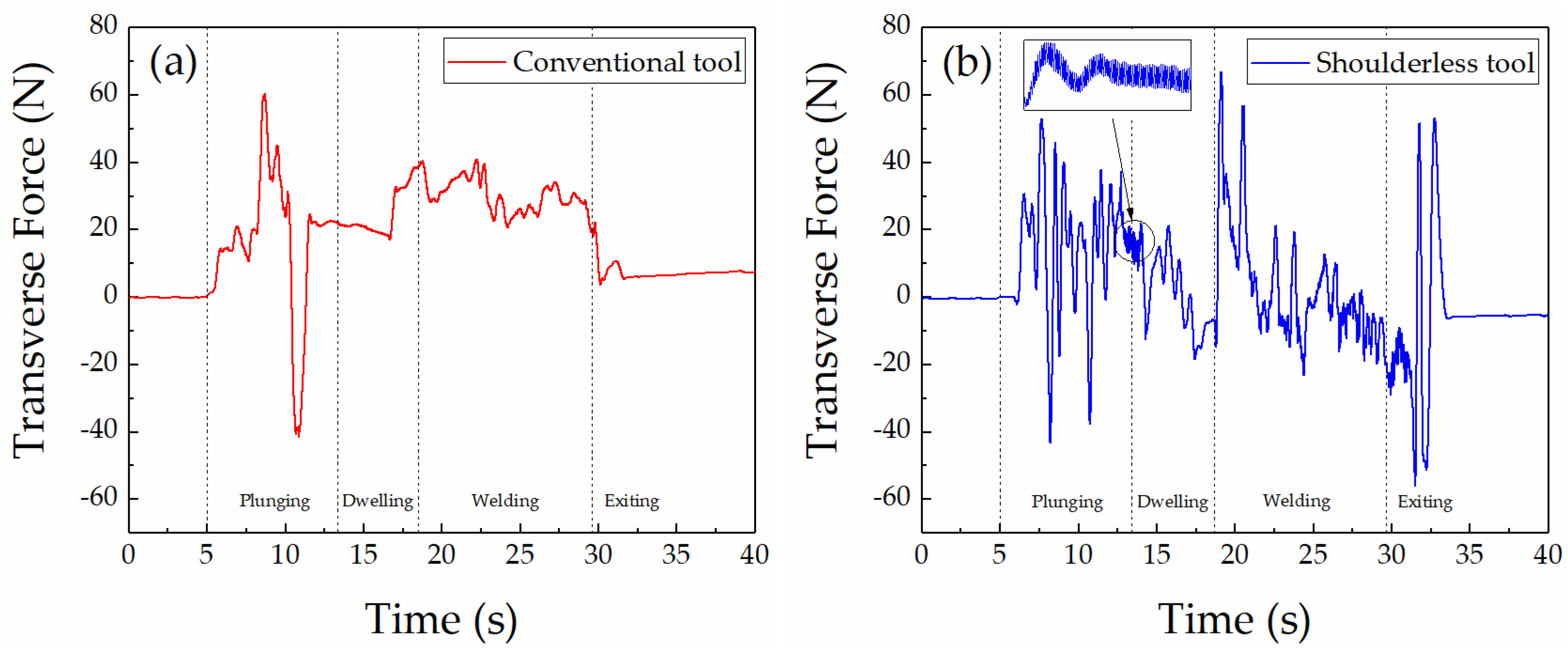

3.2. Welding Force

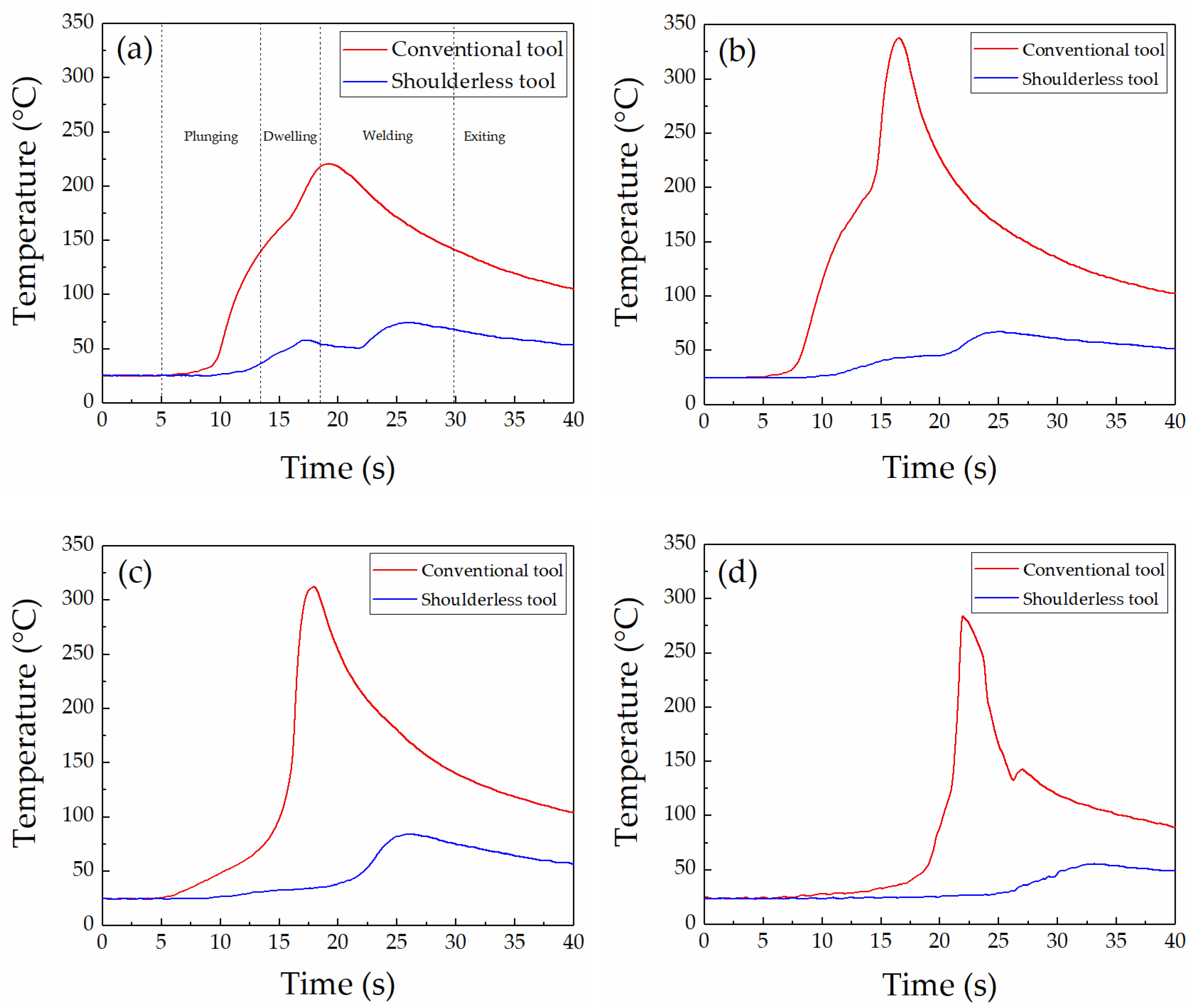

3.3. Weld Temperature

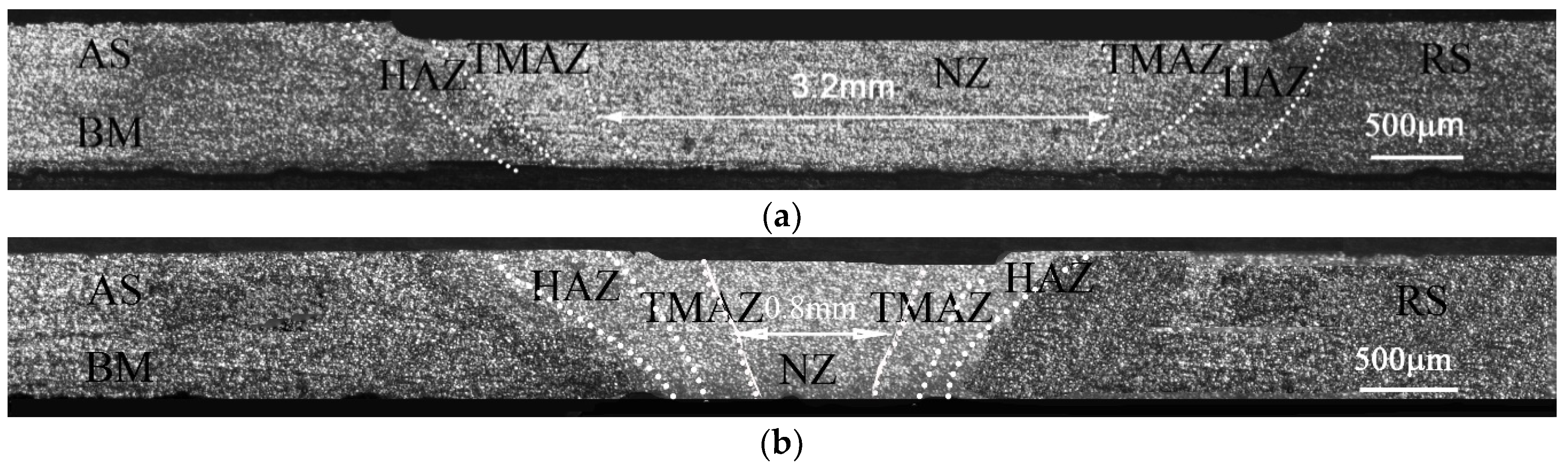

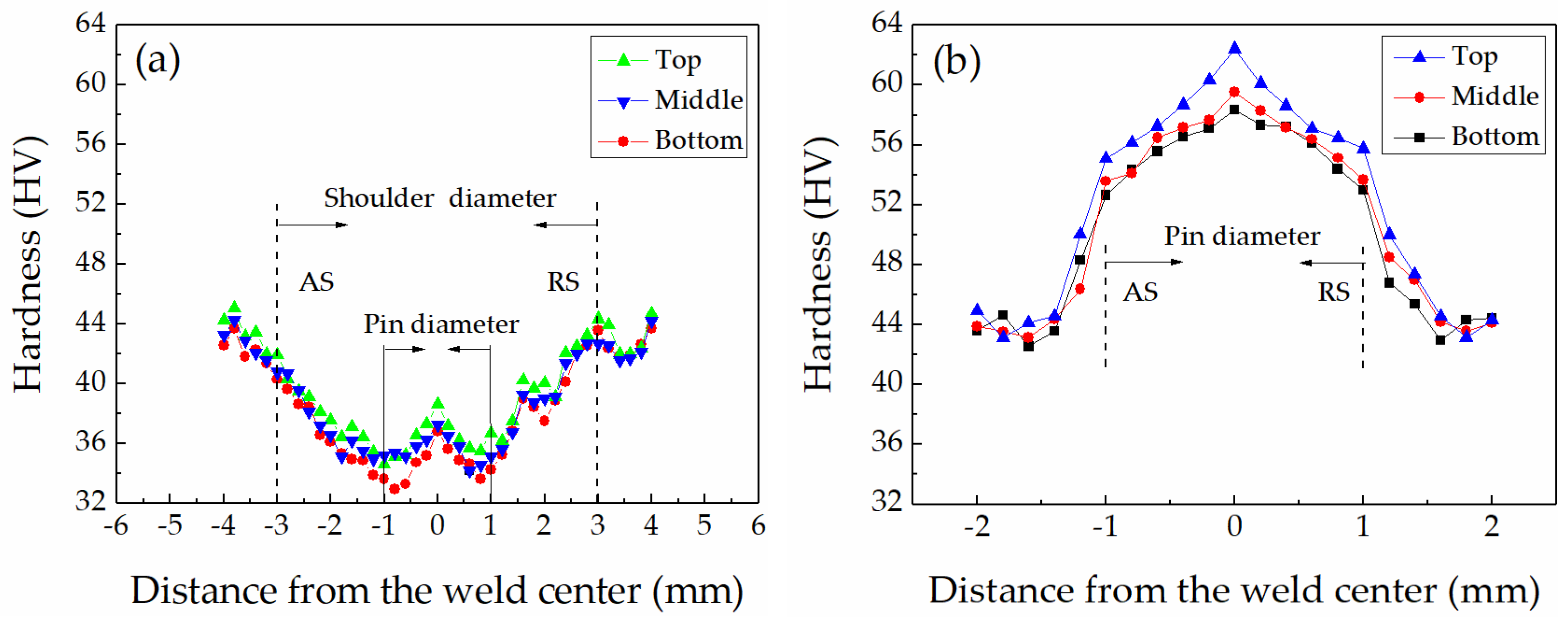

3.4. Macro Morphology and Microhardness

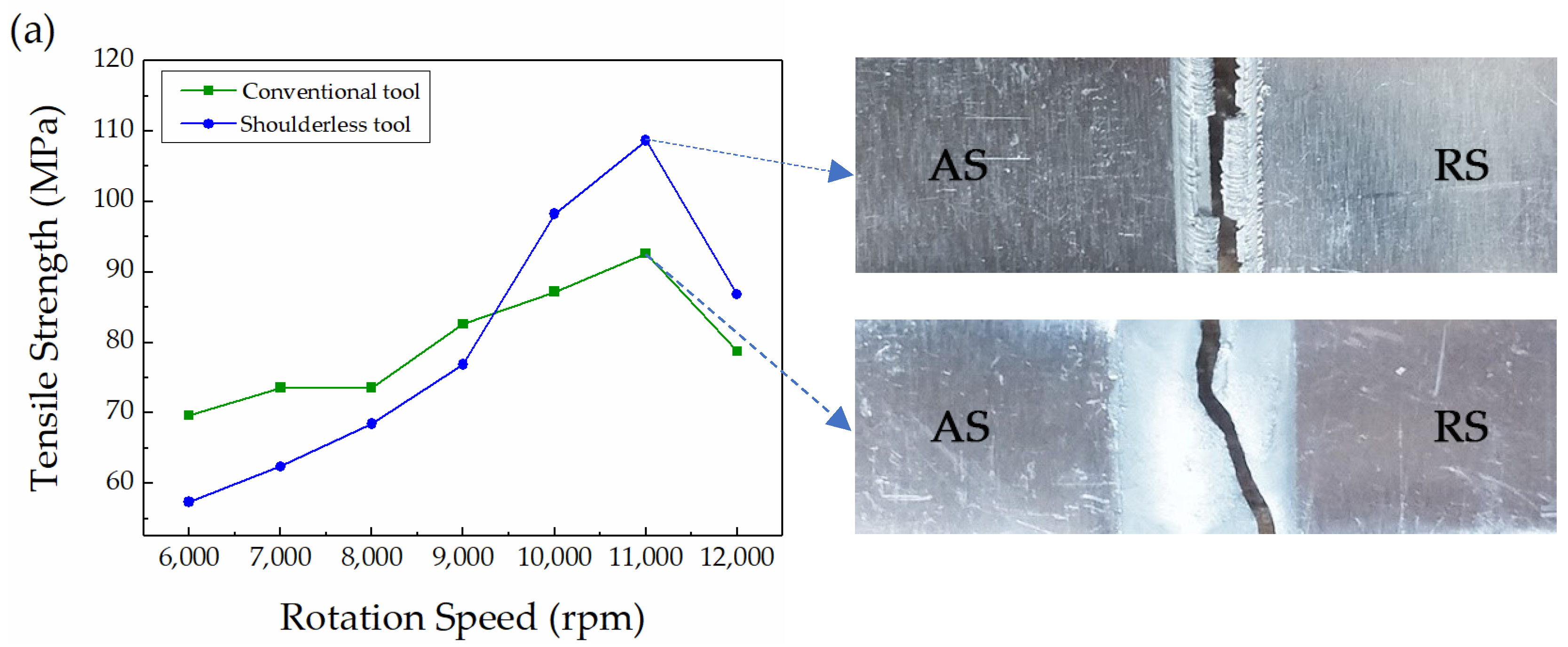

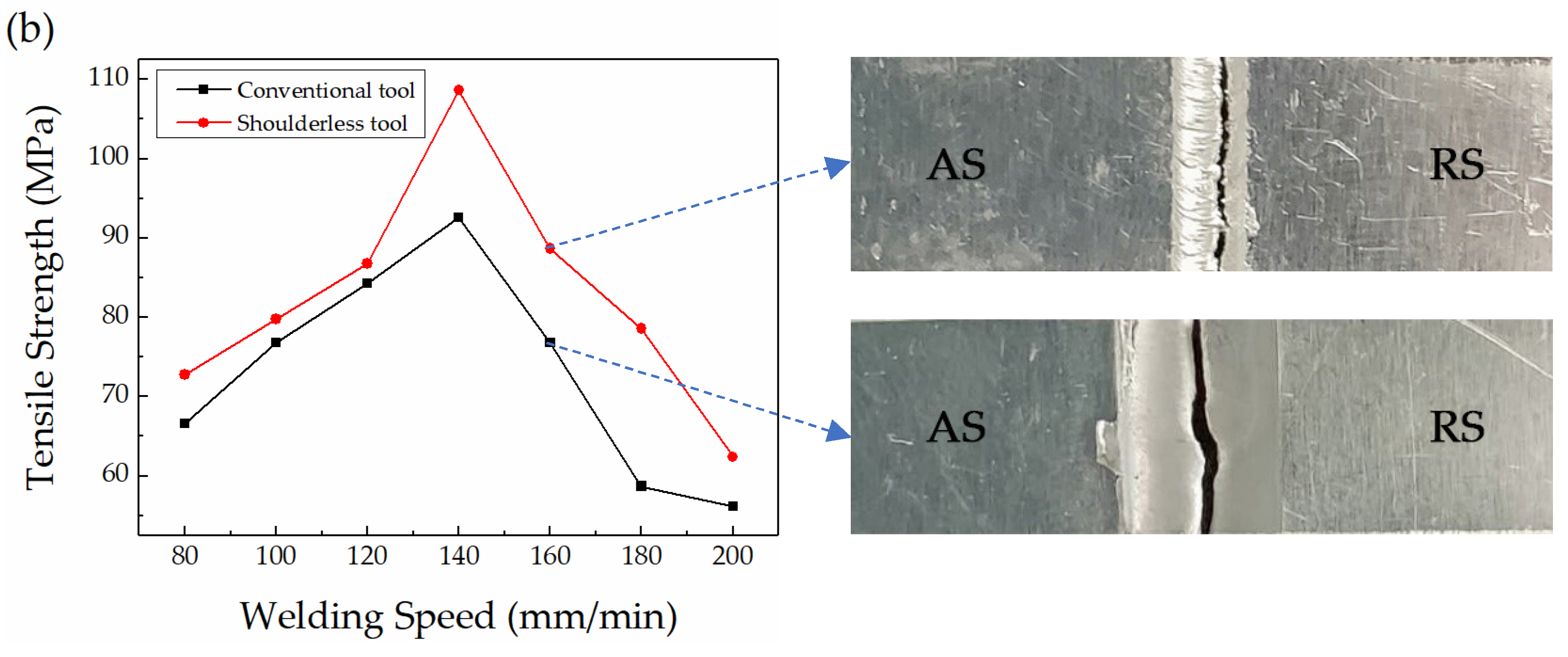

3.5. Tensile Properties of the Joint

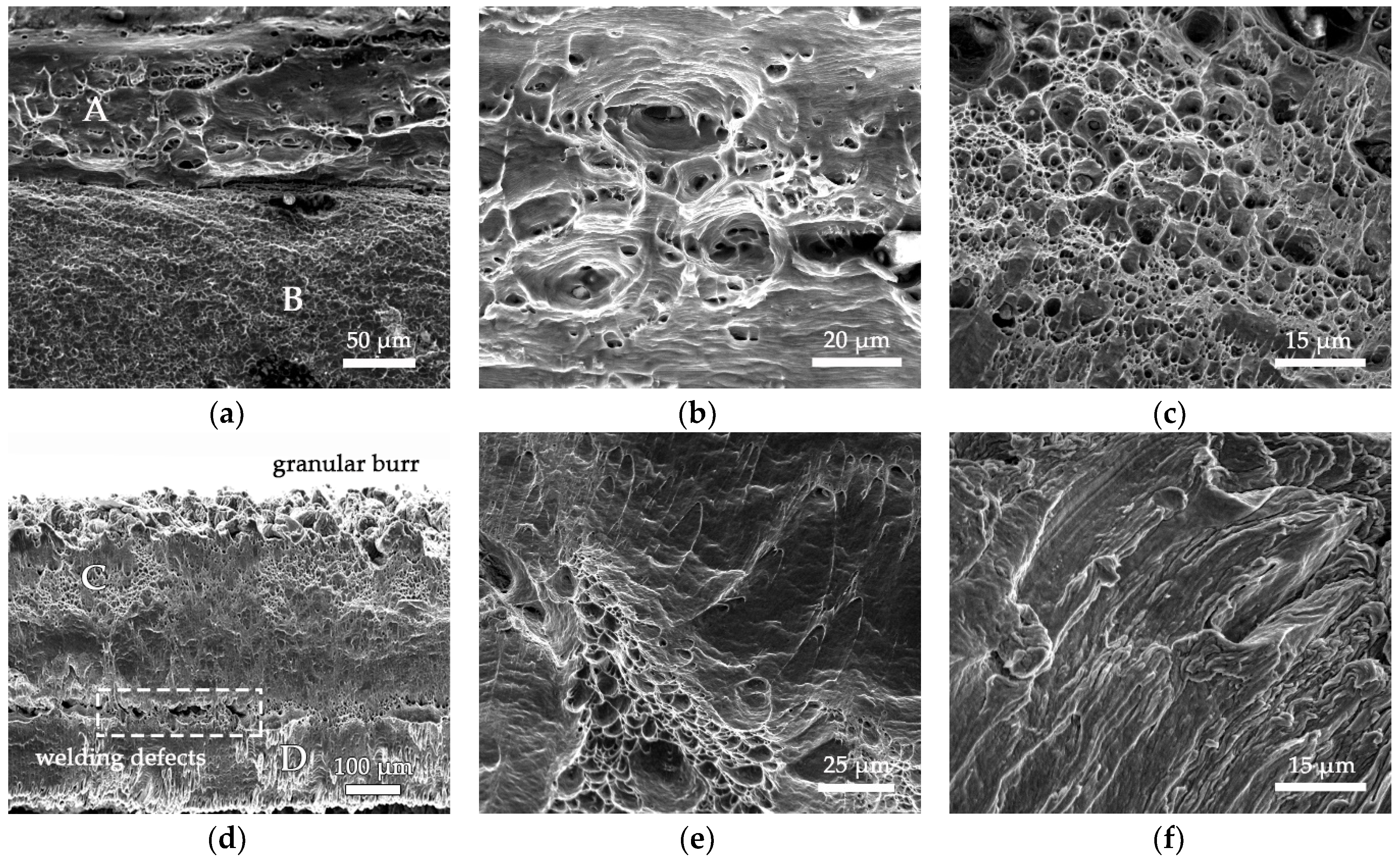

3.6. Morphology of The Tensile Fracture Surface

4. Conclusions

- Compared with the conventional tool, μFSW process with the shoulderless tool has advantages of low heat input, simple process as well as excellent mechanical properties. Thus, it has bright prospects for industrial application.

- The μFSW process of 0.8-mm-thick ultra-thin 1060-H24 aluminum sheets with the shoulderless tool is achieved in this thesis. The joint by the shoulderless tool has small heat input and HAZ because it is only influenced by the tool pin. Among the four zones, the microhardness is as following: NZ > TMAZ > BM > HAZ.

- The μFSW joint of 0.8-mm-thick ultra-thin 1060-H24 aluminum sheets by the shoulderless tool has the best mechanical properties with the welding speed of 140 mm/min and the rotation speed of 11,000 rpm. The highest tensile strength of the joint by the shoulderless tool can reach 108.6 MPa, accounting for 78.6% of the base metal and 117.3% of the joint by the conventional tool. Also, the fracture mode of the joint is ductile fracture. The welding defects have to be overcome for industrial application of the shoulderless tool.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dawes, C.J. An introduction to friction stir welding and its development. Weld. Met. Fabr. 1995, 63, 279–285. [Google Scholar]

- Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Welding and Processing; Springer: Cham, Switzerland, 2010; pp. 13–58. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Joelj, D. The friction stir welding advantage. Weld. J. 2001, 80, 30–34. [Google Scholar]

- Nandan, R.; Debroy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding – Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review. Mater. Sci. Technol. 2017, 34, 1–38. [Google Scholar] [CrossRef]

- Nishibara, T.; Nagasaka, Y. Development of Micro-Friction Stir Welding. In Proceedings of the 5th International Friction Stir Welding Symposium, Metz, France, 14–16 September 2004. [Google Scholar]

- Developments in Micro Applications of Friction Stir Welding. Available online: https://www.twi-global.com/technical-knowledge/published-papers/developments-in-micro-applications-of-friction-stir-welding (accessed on 5 December 2018).

- Scialpi, A.; De Giorgi, M.; De Filippis, L.A.C.; Nobile, R.; Panella, F.W. Mechanical analysis of ultra-thin friction stir welding joined sheets with dissimilar and similar materials. Mater. Des. 2008, 29, 928–936. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Y.; Xue, J.; Ni, R.; Guo, Y.; Dong, J. High Rotation Speed Friction Stir Welding for 2014 Aluminum Alloy Thin Sheets. J. Mater. Eng. Perform. 2017, 26, 1337–1345. [Google Scholar] [CrossRef]

- Cerri, E.; Xiang, W.; Embury, J.D. Mechanical Properties and Microstructural Evolution of Friction-Stir-Welded Thin Sheet Aluminum Alloys. Metall. Mater. Trans. A 2011, 42, 1283–1295. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Effect of Tool Pin Profile and Tool Rotational Speed on Mechanical Properties of Friction Stir Welded AA6061 Aluminium Alloy. Adv. Manuf. Process. 2008, 23, 251–260. [Google Scholar] [CrossRef]

- Biswas, P. Effect of tool pin profile on the material flow characteristics of AA6061. J. Manuf. Process. 2017, 26, 382–392. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Loureiro, A.; Leitao, C.; Leal, R.M.; Chaparro, B.M.; Vilaça, P. Influence of friction stir welding parameters on the microstructural and mechanical properties of AA 6016-T4 thin welds. Mater. Des. 2009, 30, 1913–1921. [Google Scholar] [CrossRef]

- Lammlein, D.H.; Delapp, D.R.; Fleming, P.A.; Strauss, A.M.; Cook, G.E. The application of shoulderless conical tools in friction stir welding: An experimental and theoretical study. Mater. Des. 2009, 30, 4012–4022. [Google Scholar] [CrossRef]

- Galvão, I.; Leal, R.M.; Rodrigues, D.M.; Loureiro, A. Influence of tool shoulder geometry on properties of friction stir welds in thin copper sheets. J. Mater. Process. Technol. 2013, 213, 129–135. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, H. Effect of pin shapes on material deformation and temperature field in friction stir welding. Trans. China Weld. Inst. 2011, 32, 5–8. [Google Scholar] [CrossRef]

- Papahn, H.; Haghpanahi, M.; Bahemmat, P. Using a novel fixture to study of temperature and applied forces during friction stir welding. J. Braz. Soc. Mech. Sci. Eng. 2015, 39, 531–541. [Google Scholar] [CrossRef]

- Amini, S.; Amiri, M.R. Pin axis effects on forces in friction stir welding process. Int. J. Adv. Manuf. Technol. 2015, 78, 1795–1801. [Google Scholar] [CrossRef]

- Paoletti, A.; Lambiase, F.; Di Ilio, A. Analysis of forces and temperatures in friction spot stir welding of thermoplastic polymers. Int. J. Adv. Manuf. Technol. 2015, 83, 1395–1407. [Google Scholar] [CrossRef]

- Zhao, S.; Bi, Q.; Wang, Y. An axial force controller with delay compensation for the friction stir welding process. Int. J. Adv. Manuf. Technol. 2015, 85, 2623–2638. [Google Scholar] [CrossRef]

- Kim, K.-H.; Bang, H.-S.; Ro, C.-S.; Bang, H.-S. Influence of preheating source on mechanical properties and welding residual stress characteristics in ultra thin ferritic stainless steel hybrid friction stir welded joints. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 393–400. [Google Scholar] [CrossRef]

- Jain, R.; Pal, S.K.; Singh, S.B. A study on the variation of forces and temperature in a friction stir welding process: A finite element approach. J. Manuf. Process. 2016, 23, 278–286. [Google Scholar] [CrossRef]

- Shukla, A.K.; Chelladurai, H.; Tiwari, S. Effect of Pre-Heat Time on Force During Friction Stir Welding of Aluminium 1050 Alloy. Mater. Today Proc. 2017, 4, 3618–3626. [Google Scholar] [CrossRef]

- Das, B.; Pal, S.; Bag, S. Design and development of force and torque measurement setup for real time monitoring of friction stir welding process. Measurement 2017, 103, 186–198. [Google Scholar] [CrossRef]

- Forcellese, A.; Simoncini, M.; Casalino, G. Influence of Process Parameters on the Vertical Forces Generated during Friction Stir Welding of AA6082-T6 and on the Mechanical Properties of the Joints. Metals 2017, 7, 350. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, A.P.; Ren, J.L.; Sato, Y.S.; Kokawa, H.; Miyake, M.; Yan, D.Y. Temperature and force response characteristics of friction stir welding on Invar 36 alloy. Sci. Technol. Weld. Join. 2013, 18, 232–238. [Google Scholar] [CrossRef]

- Schmidt, H.; Hattel, J.; Wert, J. An analytical model for the heat generation in friction stir welding. Model. Simul. Mater. Sci. Eng. 2004, 12, 143. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Zhang, Y.; Cao, J.; Feng, J. Micro friction stir welding of ultra-thin Al-6061 sheets. J. Mater. Process. Technol. 2017, 250, 313–319. [Google Scholar] [CrossRef]

- Liu, F.; Li, F.U.; Zhang, W.; Meng, Q.; Dong, C.; Luan, G. Interface structure and mechanical properties of friction stir welding joint of 2099-T83/2060-T8 dis-similar Al-Li alloys. Acta Metall. Sin. 2015, 51, 281–288. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S.; Wang, J.; Wang, P.; Xia, J. Influences of pin shape on a high rotation speed friction stir welding joint of a 6061-t6 aluminum alloy sheet. Metals 2018, 8, 987. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mg | Mn | Zn | Ti | V | Al |

|---|---|---|---|---|---|---|---|---|

| 0.15 | 0.20 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | margin |

| Used Tools | Rotation Speed (rpm) | Welding Speed (mm/min) | Plunging Rate (mm/min) |

|---|---|---|---|

| Conventional tool | 6000–12,000 | 140 | 5 |

| 11,000 | 80–200 | ||

| Shoulderless tool | 6000–12,000 | 140 | 5 |

| 11,000 | 80–200 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Wang, W.; Jin, X.; Rong, C.; Qin, Z. A Study on Microstructure and Mechanical Properties of Micro Friction Stir Welded Ultra-Thin Al-1060 Sheets by the Shoulderless Tool. Metals 2019, 9, 507. https://doi.org/10.3390/met9050507

Zhang C, Wang W, Jin X, Rong C, Qin Z. A Study on Microstructure and Mechanical Properties of Micro Friction Stir Welded Ultra-Thin Al-1060 Sheets by the Shoulderless Tool. Metals. 2019; 9(5):507. https://doi.org/10.3390/met9050507

Chicago/Turabian StyleZhang, Changqing, Weijie Wang, Xin Jin, Chen Rong, and Zhuo Qin. 2019. "A Study on Microstructure and Mechanical Properties of Micro Friction Stir Welded Ultra-Thin Al-1060 Sheets by the Shoulderless Tool" Metals 9, no. 5: 507. https://doi.org/10.3390/met9050507

APA StyleZhang, C., Wang, W., Jin, X., Rong, C., & Qin, Z. (2019). A Study on Microstructure and Mechanical Properties of Micro Friction Stir Welded Ultra-Thin Al-1060 Sheets by the Shoulderless Tool. Metals, 9(5), 507. https://doi.org/10.3390/met9050507