Friction Performance of Aluminum-Silicon Alloy Cylinder Liner after Chemical Etching and Laser Finishing

Abstract

:1. Introduction

2. Experimental Details

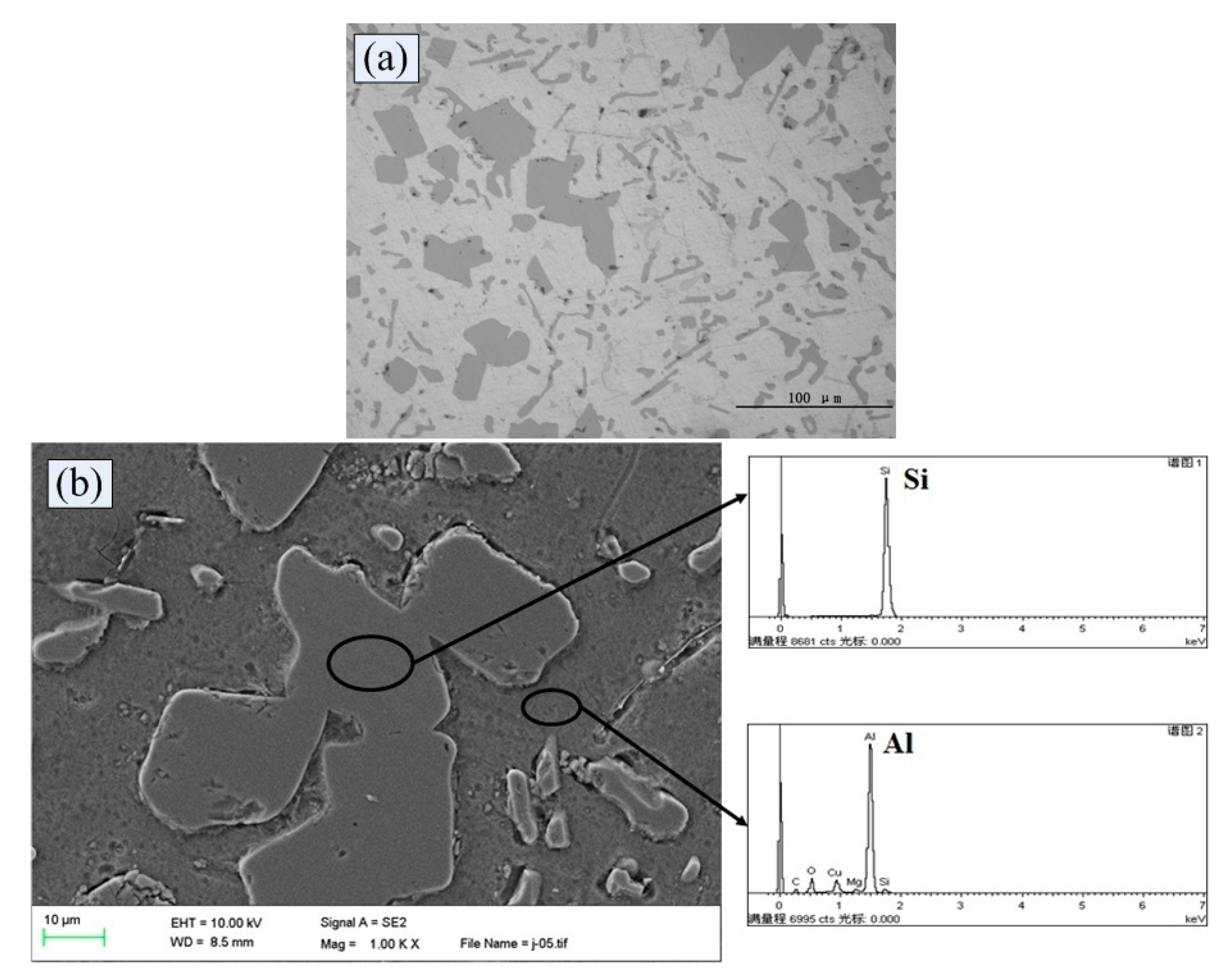

2.1. Materials and Samples

2.2. Chemical Etching

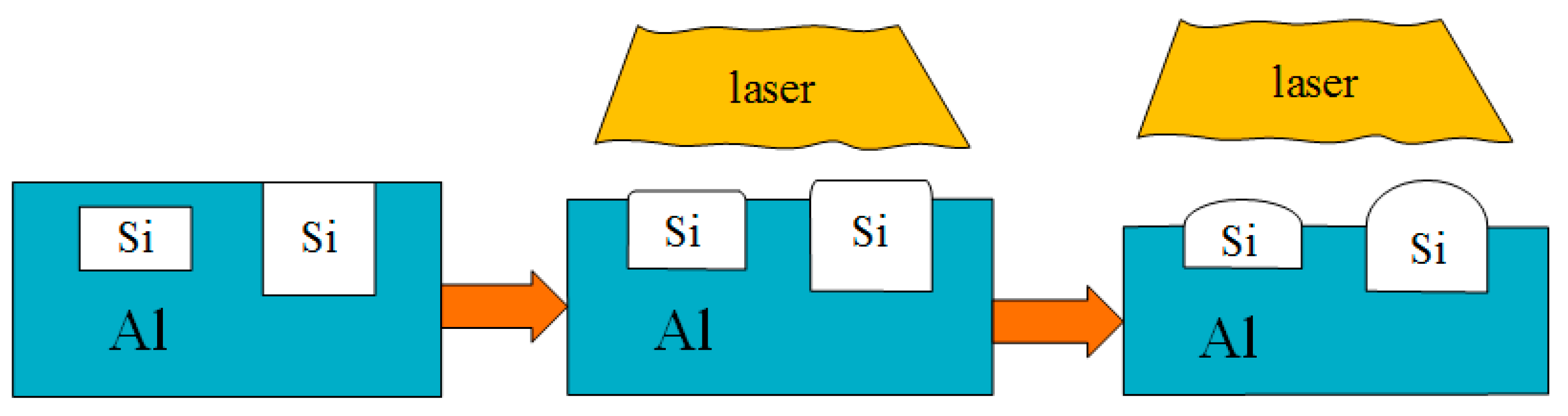

2.3. Laser Finishing

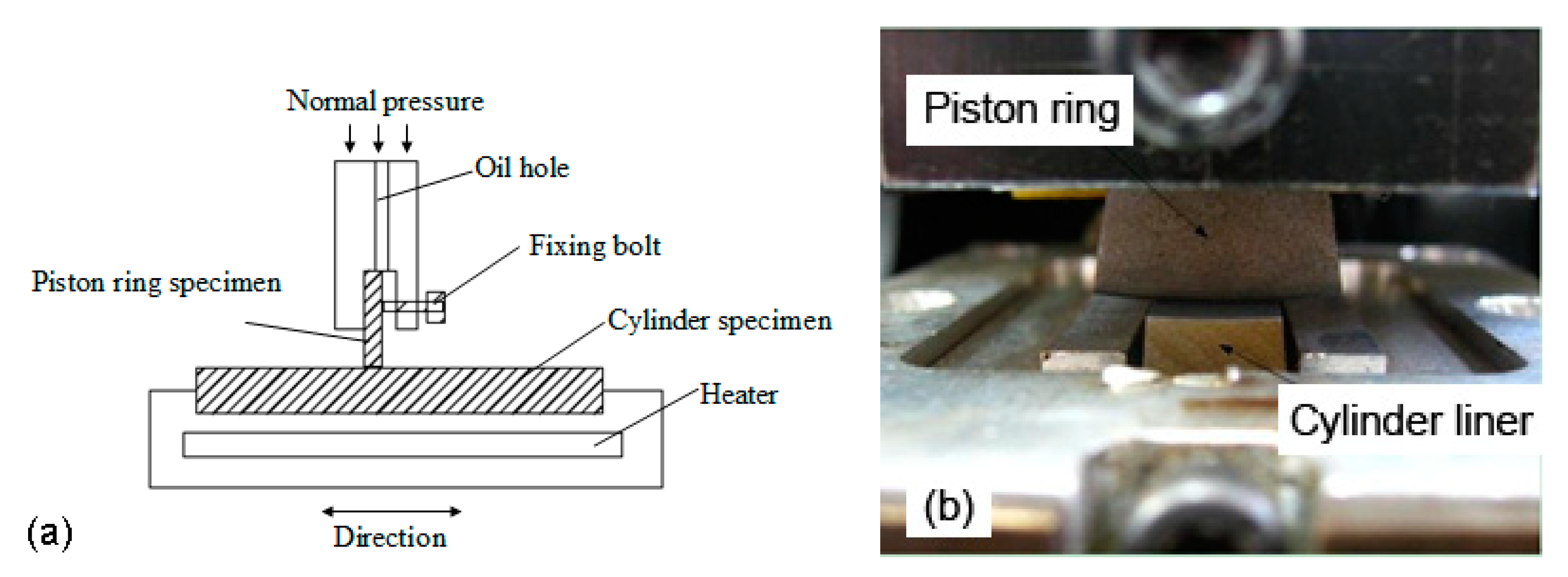

2.4. Wear Tests

3. Experimental Results

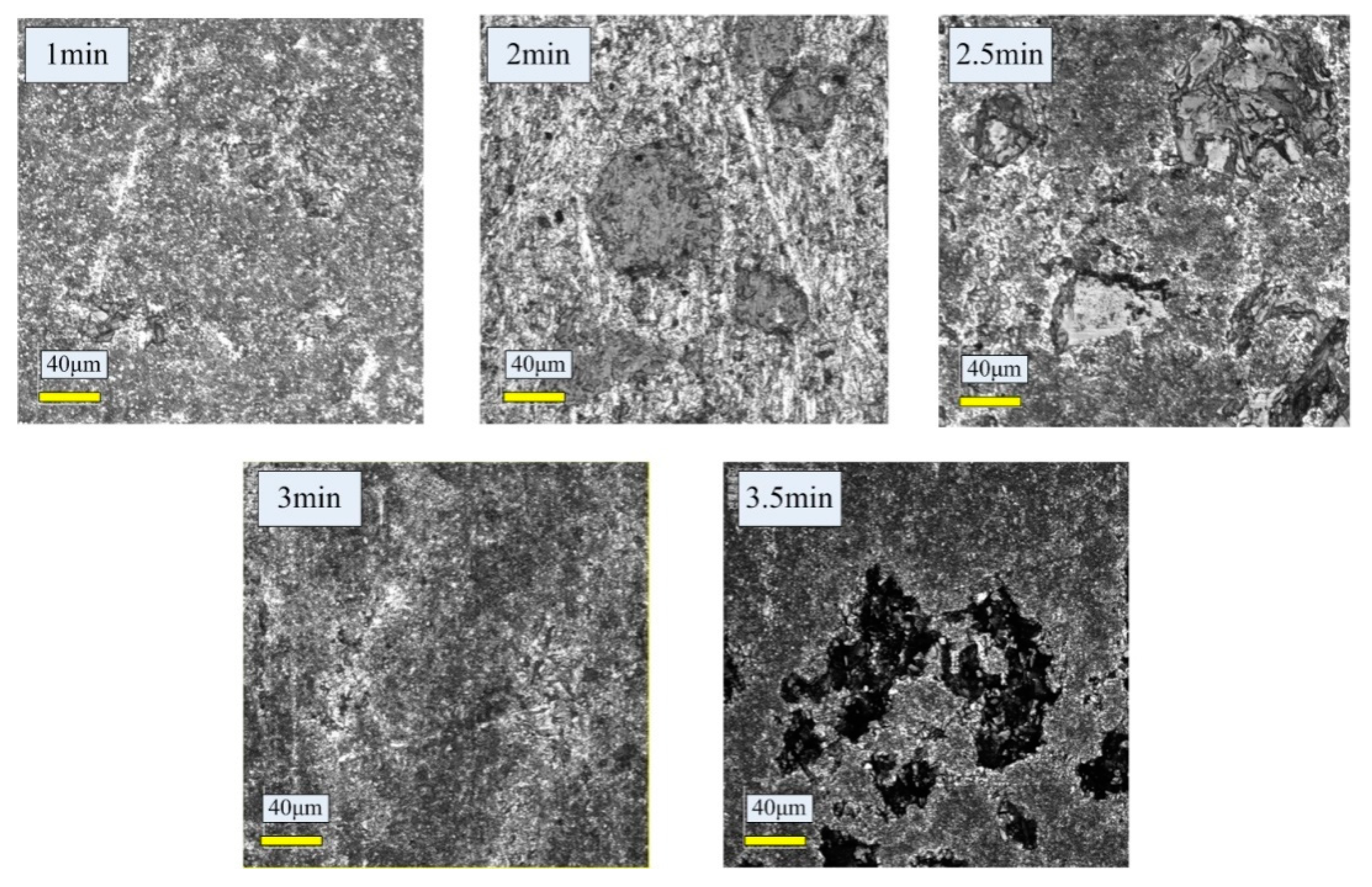

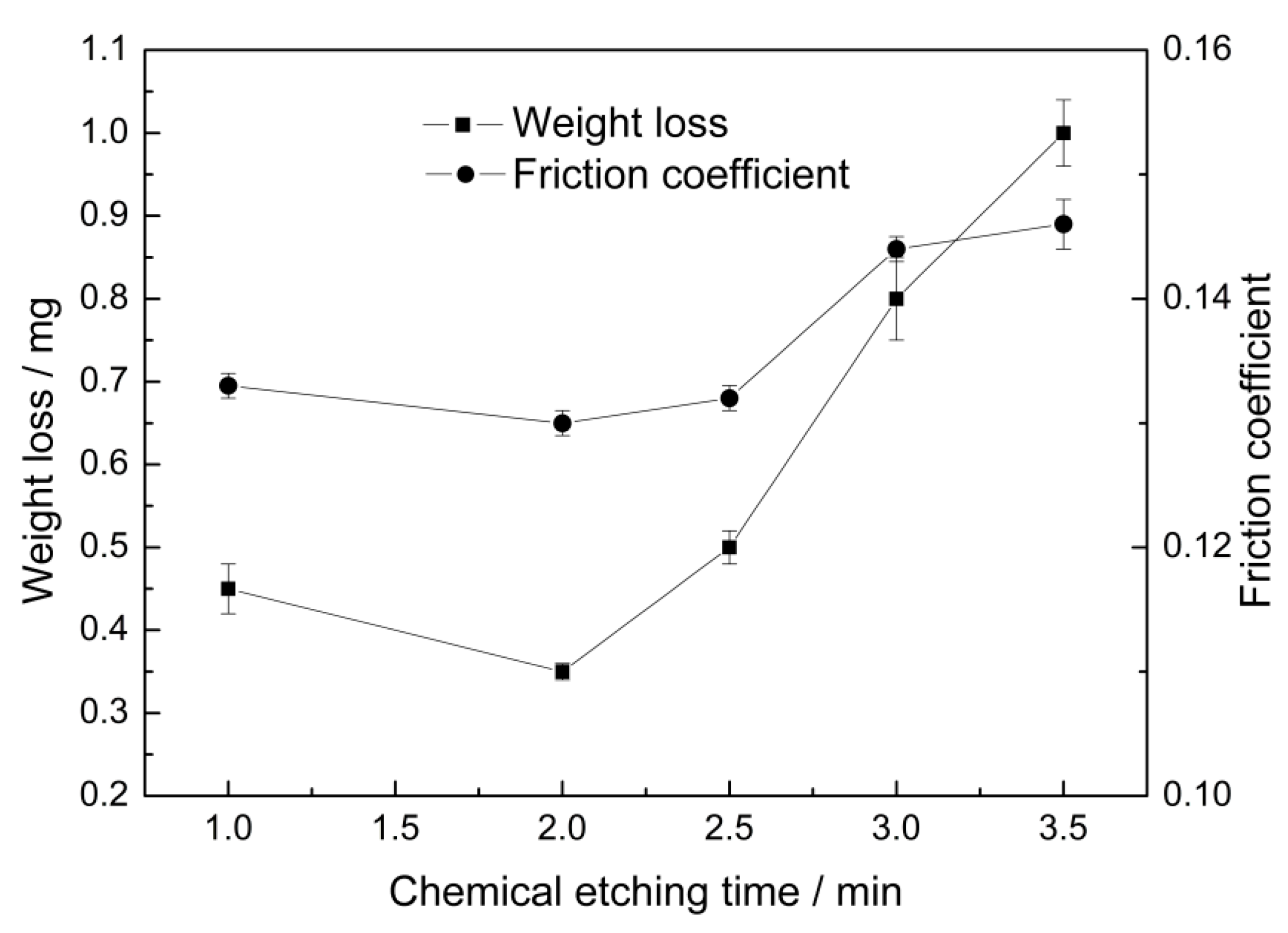

3.1. Friction Performance after Chemical Etching

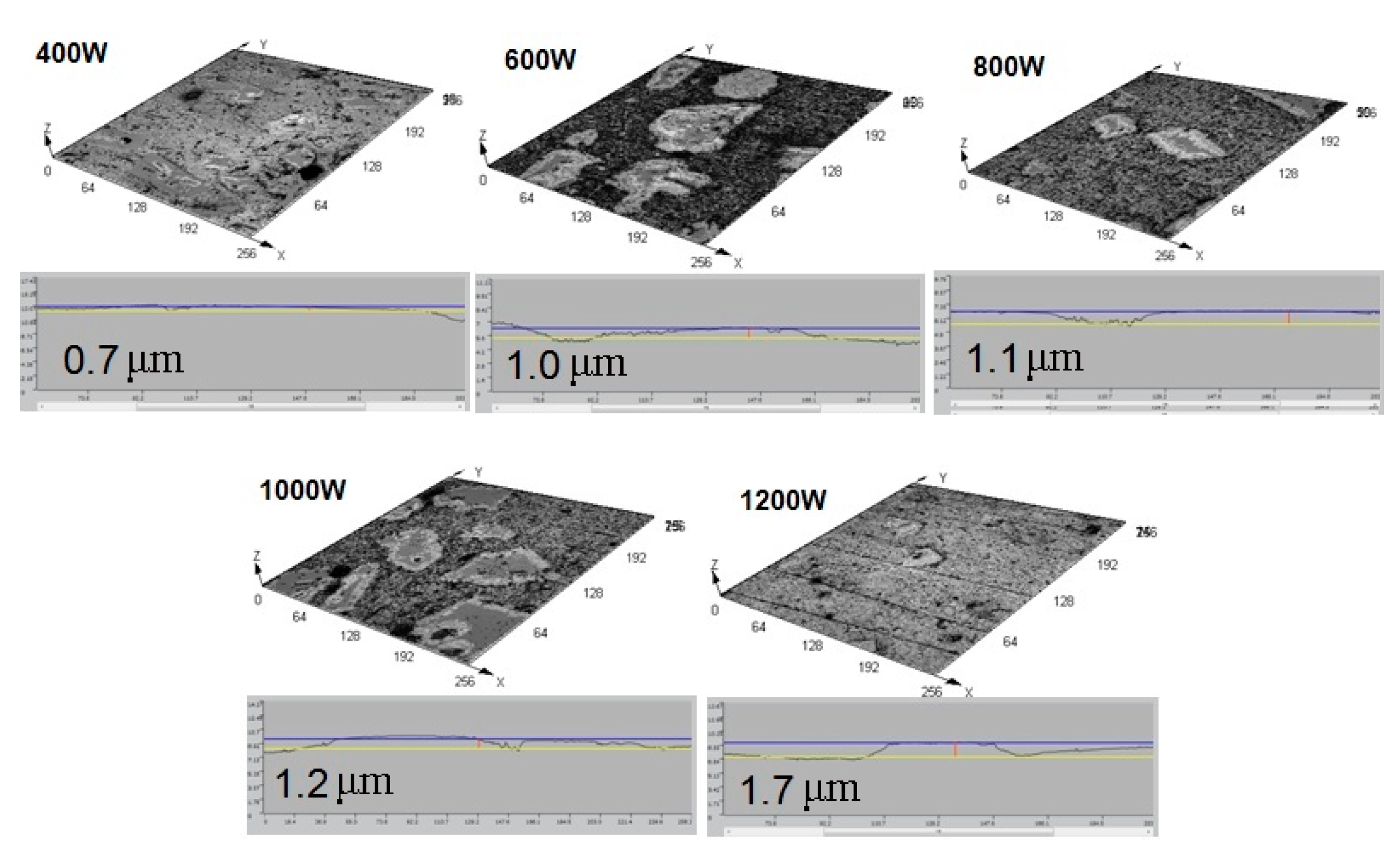

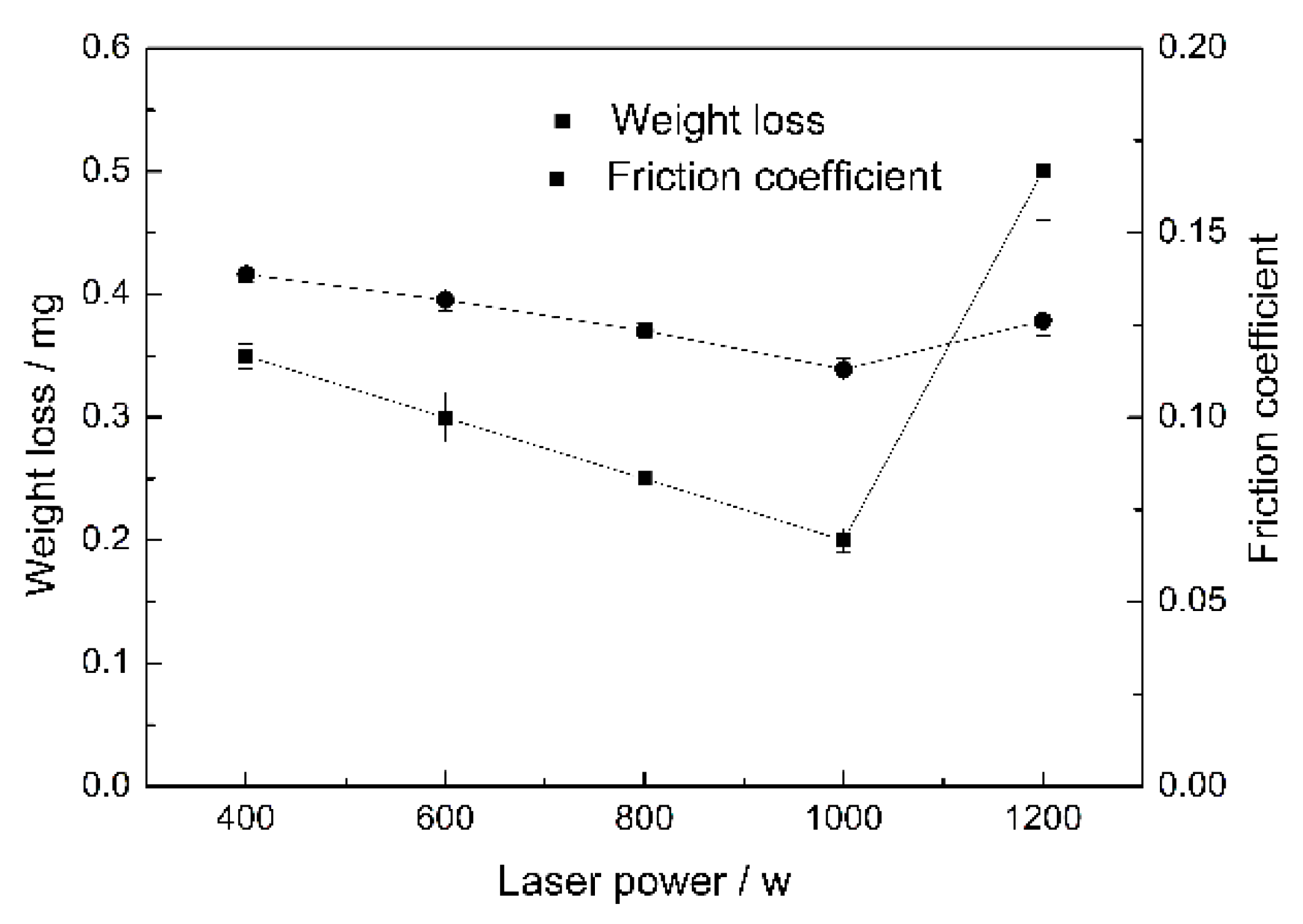

3.2. Friction Performance after Laser Finishing

3.3. Friction Performance of the Two Surface Treatments

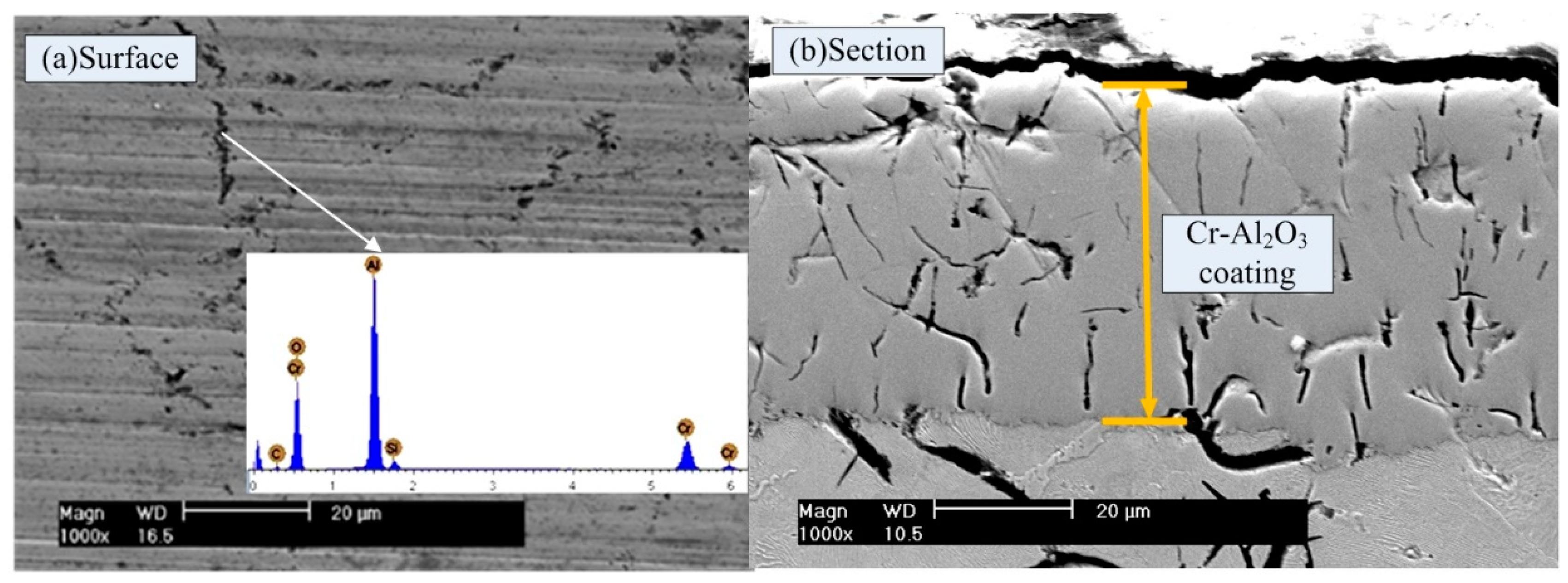

3.4. Surface Morphology of the Piston Ring

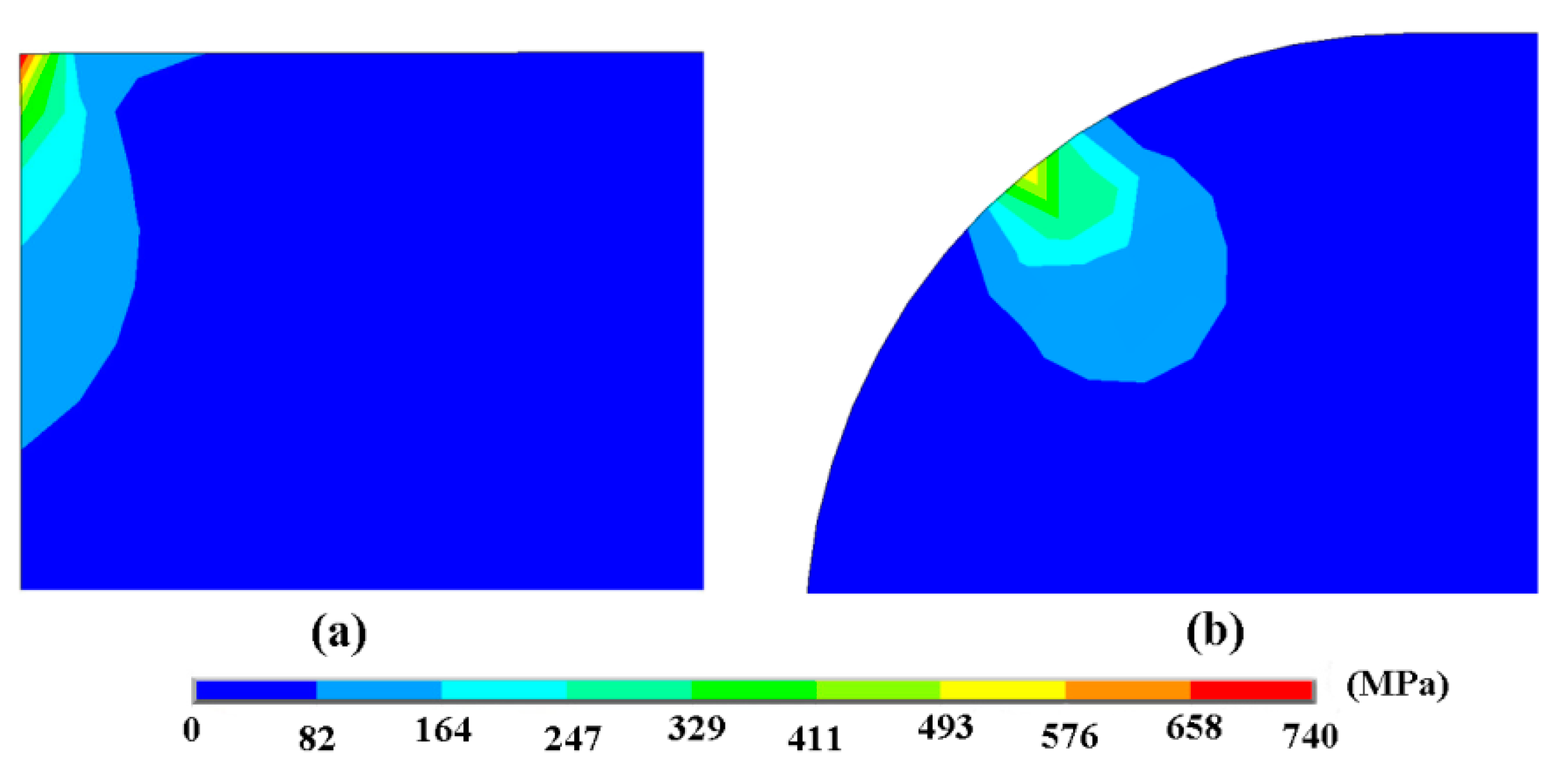

4. Simulation

- The asperity of the piston ring only contacts the silicon particles.

- The piston ring/silicon particle contact is rigid to flexible so that the piston ring elements cannot penetrate the silicon.

- The wear depth is the same for the two cases and a given downward displacement of 0.05 μm is applied to the piston ring.

- The bottom nodes of the silicon particle are fixed:where Ux and Uy are the degrees of freedom along the x- and y-direction.Ux = Uy = 0

- The downward displacement of the piston ring is:Uy = −0.05 μm

5. Wear Mechanism

6. Conclusions

- The friction coefficient and weight loss of the Al-Si cylinder liner tend to decrease first and then increase with the increase in the chemical etching time; the optimum etching time is 2 min.

- As the laser power increases, the friction coefficient and weight loss also decrease first and then increase; the optimum laser power is 1000 W.

- Chemical etching and laser finishing both remove the surface aluminum layer and result in the protrusion of the silicon particles, which bear the load. Under the boundary lubrication state, the lubricating oil retained in the concave surface could help to form oil film to enhance the lubrication.

- Unlike chemical etching, laser finishing results in rounded edges of the silicon particles, which decreases the stress concentration. As a result, the surface friction performance of the Al-Si cylinder liner is better when laser finishing is used.

Author Contributions

Funding

Conflicts of Interest

References

- Dwivedi, D.K. Adhesive wear behaviour of cast aluminium-silicon alloys: Overview. Mater. Des. 2010, 31, 2517–2531. [Google Scholar] [CrossRef]

- Shahrbabaki, Z.K.M.; Pahlevani, F.; Gorjizadeh, N.; Hossain, R.; Ghasemian, M.B.; Gaikwad, V.; Sahajwalla, V. Direct transformation of metallized paper into Al-Si nano-rod and Al nano-particles using thermal micronizing technique. Materials 2018, 11, 1964. [Google Scholar] [CrossRef]

- Ni, J.Q.; Yu, M.H.; Han, K.Q. Debinding and sintering of an injection-moulded hypereutectic Al-Si alloy. Materials 2018, 11, 807. [Google Scholar] [CrossRef] [PubMed]

- Chiang, K.T.; Tsai, D.C. Effect of silicon particles on the rapidly resolidified layer of Al-Si alloys in the electro discharge machining process. Int. J. Adv. Manuf. Technol. 2008, 36, 707–714. [Google Scholar] [CrossRef]

- Chen, C.; Lu, C.Y.; Feng, X.M.; Shen, Y.F. Effects of annealing on Al-Si coating synthesised by mechanical alloying. Surf. Eng. 2017, 33, 548–558. [Google Scholar] [CrossRef]

- Burkinshaw, M.; Neville, A.; Morina, A.; Sutton, M. ZDDP and its interactions with an organic antiwear additive on both aluminium-silicon and model silicon surfaces. Tribol. Int. 2014, 69, 102–109. [Google Scholar] [CrossRef]

- Ye, H.Z. An overview of the development of Al-Si-Alloy based material for engine applications. J. Mater. Eng. Perform. 2003, 12, 288–297. [Google Scholar] [CrossRef]

- Elmadagli, M.; Perry, T.; Alpas, A.T. A parametric study of the relationship between microstructure and wear resistance of Al-Si alloys. Wear 2007, 262, 79–92. [Google Scholar] [CrossRef]

- Chen, M.; Meng-Burany, X.; Perry, T.A.; Alpas, A.T. Micromechanisms and mechanics of ultra-mild wear in Al-Si alloys. Acta. Mater. 2008, 56, 5605–5616. [Google Scholar] [CrossRef]

- Slattery, B.E.; Perry, T.; Edrisy, A. Microstructural evolution of a eutectic Al-Si engine subjected to severe running conditions. Mat. Sci. Eng. A. 2009, 512, 76–81. [Google Scholar] [CrossRef]

- Slattery, B.E.; Edrisy, A.; Perry, T. Investigation of wear induced surface and subsurface deformation in a linerless Al-Si engine. Wear 2010, 269, 298–309. [Google Scholar] [CrossRef]

- Zandrahimi, M.; Rezvanifar, A. Investigation of dislocation characterisation in worn Al-Si alloys with different sliding speeds using X-Ray diffraction. Tribol. Lett. 2012, 46, 255–261. [Google Scholar] [CrossRef]

- Dwivedi, D.K. Wear behaviour of cast hypereutectic aluminium silicon alloys. Mater. Des. 2006, 27, 610–616. [Google Scholar] [CrossRef]

- Shen, Y.; Lv, Y.T.; Li, B.; Huang, R.X.; Yu, B.H.; Wang, W.W.; Li, C.D.; Xu, J.J. Reciprocating electrolyte jet with prefabricated-mask machining micro-dimple arrays on cast iron cylinder liner. J. Mater. Process. Tech. 2019, 266, 329–338. [Google Scholar] [CrossRef]

- Mansuri, M.; Hadavi, S.M.M.; Zare, E.; Nabi, M.M. Thermal fatigue behaviour of Al-Si coated Inconel 713LC. Surf. Eng. 2016, 32, 201–206. [Google Scholar] [CrossRef]

- Viswanathan, A.; Sastikumar, D.; Kamachimudali, U.; Kumar, H.; Nath, A.K. TiC reinforced composite layer formation on Al-Si alloy by laser processing. Surf. Eng. 2007, 23, 123–128. [Google Scholar] [CrossRef]

- Meng, X.C.; Liu, B.; Luo, L.; Ding, Y.; Rao, X.X.; Hu, B.; Liu, Y.; Lu, J. The Portevin-Le Chatelier effect of gradient nanostructured 5182 aluminum alloy by surface mechanical attrition treatment. J. Mater. Sci. Technol. 2018, 34, 2307–2315. [Google Scholar] [CrossRef]

- Li, C.D.; Li, B.; Shen, Y.; Jin, M.; Xu, J.J. Effect of surface chemical etching on the lubricated reciprocating wear of honed Al–Si alloy. Proc. IMechE. Part J J. Eng. Tribol. 2018, 232, 722–731. [Google Scholar] [CrossRef]

- Riahi, A.R.; Perry, T.; Alpas, A.T. Scuffing resistances of Al-Si alloys: effects of etching condition, surface roughness and particle morphology. Mater. Sci. Eng. A. 2003, 343, 76–81. [Google Scholar] [CrossRef]

- Das, S.; Perry, T.; Biswas, S.K. Effect of surface etching on the lubricated sliding wear of an eutectic aluminium-silicon alloy. Tribol. Lett. 2006, 21, 193–204. [Google Scholar] [CrossRef]

- Cai, Z.H.; He, J.W.; Di, Y.L.; Zhang, P. Microstructure and high temperature wear resistance of laser quenching and ion sulphidizing composite layer on cylinder inwall. Heat. Treat. Metal. 2011, 36, 55–59. [Google Scholar]

- Ghosh, K.; Mccay, M.H.; Dahotre, N.B. Formation of a wear resistant surface on Al by laser aided in-situ synthesis of MoSi2. J. Mater. Process. Tech. 1999, 88, 169–179. [Google Scholar] [CrossRef]

- Tomida, S.; Nakata, K.; Shibata, S. Improvement in wear resistance of hyper-eutetic Al-Si cast alloy by laser surface remelting. Surf. Coat. Technol. 2003, 169, 468–471. [Google Scholar] [CrossRef]

- Sušnik, J.; Šturm, R.; Grum, J. Influence of laser surface remelting on Al-Si alloy properties. Strojniški vestnik-J. Mech. Eng. 2012, 58, 614–620. [Google Scholar] [CrossRef]

- Gao, J.F.; Suo, J.P. Preparation and characterization of the electrodeposited Cr–Al2O3/SiC composite coating. Appl. Surf. Sci. 2011, 257, 9643–9648. [Google Scholar] [CrossRef]

- Jang, J.H.; Joo, B.D.; Lee, J.H.; Moon, Y.H. Effect of hardness of the piston ring coating on the wear characteristics of rubbing surfaces. Met. Mat. Int. 2009, 15, 903–908. [Google Scholar] [CrossRef]

- Zhu, F.; Xu, J.J.; Han, X.G.; Shen, Y.; Jin, M. Tribological performance of three surface-modified piston rings matched with chromium-plated cylinder liner. Ind. Lubr. Tribol. 2017, 69, 276–281. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, B.H.; Lv, Y.T.; Li, B. Comparison of heavy-duty scuffing behavior between chromium-based ceramic composite and nickel-chromium-molybdenum-coated ring sliding against cast iron liner under starvation. Materials 2017, 10, 1176. [Google Scholar] [CrossRef]

- Shen, Y.; Xu., J.J.; Jin, M.; Yuan, X.S.; Wang, J.P.; Liu, Y.; Zhu, F.; Wang, Z.Q. Scuffing behavior of CKS piston ring with alloy cast iron cylinder liner. Lubr. Eng. 2014, 39, 40–43. [Google Scholar]

- Liu, W.Q.; Zhang, J.H.; Hong, J.; Zhu, L.B. Elastic contact model of elliptical parabolic asperity. J. Xi’an Jiaotong. Univ. 2015, 49, 34–40. [Google Scholar]

- Zhao, Y.W.; Maietta, D.M.; Chang, L. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J. Tribol. 2000, 122, 86. [Google Scholar] [CrossRef]

- Sun, T.F.; Guo, M.X.; Zhu, H.Y.; Chen, D.H.; Sun, Y.H.; Wang, F.D. The friction wearing properties research of high-silicon aluminium alloy cylinder sleeve. Vehicle. Power. Tech. 2007, 2, 14–18. [Google Scholar]

| Element | Al | Si | Fe | Cu | Mg | Zn |

|---|---|---|---|---|---|---|

| wt.% | 71 | 20.1 | 0.9 | 5 | 0.6 | 1.0 |

| Material | Elasticity Modulus (GPa) | Poisson’s Ratio | Density (g/cm3) |

|---|---|---|---|

| Si | 190 | 0.28 | 2.33 |

| Al | 71.7 | 0.33 | 2.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Li, C.; Mi, Z.; Huang, R.; Han, X.; Shen, Y.; Xu, J. Friction Performance of Aluminum-Silicon Alloy Cylinder Liner after Chemical Etching and Laser Finishing. Metals 2019, 9, 431. https://doi.org/10.3390/met9040431

Du F, Li C, Mi Z, Huang R, Han X, Shen Y, Xu J. Friction Performance of Aluminum-Silicon Alloy Cylinder Liner after Chemical Etching and Laser Finishing. Metals. 2019; 9(4):431. https://doi.org/10.3390/met9040431

Chicago/Turabian StyleDu, Fengming, Chengdi Li, Zetian Mi, Ruoxuan Huang, Xiaoguang Han, Yan Shen, and Jiujun Xu. 2019. "Friction Performance of Aluminum-Silicon Alloy Cylinder Liner after Chemical Etching and Laser Finishing" Metals 9, no. 4: 431. https://doi.org/10.3390/met9040431

APA StyleDu, F., Li, C., Mi, Z., Huang, R., Han, X., Shen, Y., & Xu, J. (2019). Friction Performance of Aluminum-Silicon Alloy Cylinder Liner after Chemical Etching and Laser Finishing. Metals, 9(4), 431. https://doi.org/10.3390/met9040431