Abstract

It is well known that it takes some time for the solid phase to completely dissolve upon melting, especially inside the defects of insoluble particles, e.g. oxides. Until then the oxides remain active solidification substrates in the case of subsequent solidification. It is also known that ultrasonic melt treatment causes grain refinement through activation and dispersion of solidification substrates (one of the mechanisms) and also accelerates the dissolution of solid metal in the melt. In this study we combine these effects and demonstrate that the introduction of an alloy rod into the matrix melt of the same composition results in significant grain refinement, this effect is increased by the ultrasonic vibration of the rod. The achieved grain size is comparable to that obtained by a standard Al–Ti–B grain refiner. All samples were cast using a standard TP-1 mould to enable correct comparison. The effects of the temperature range of the rod introduction as well as the application of ultrasonic vibrations are discussed.

1. Introduction

The fact that by introducing solid metal into the melt one can achieve structure refinement is rather well known. As early as in the 1930s–1950s a series of papers and patents have been published, showing the benefits for grain refinement when dissolving solid metal in the melt before solidification [1,2]. Later on, this way of structure refinement was developed further and dubbed “suspension casting” or introduction of “internal chills” [3,4]. The solid metal was added in a form of cut wire, cut sheet, or powder, with the resulting grain refining, elimination of columnar grain structure in ingots and castings of steel, copper and aluminium alloys. The underlying mechanisms have been suggested as (1) rapid cooling of the melt due to the latent heat consumption upon melting of the solid metal with the resultant melt undercooling and (2) introduction of many solidification substrates in the form of crystal fragments and active non-metallic inclusions [1,5]. A number of patents have been filed where either the same solid alloy or a master alloy with additions (e.g. Ti for Al alloy) is introduced in the amounts up to 50% (typically less than 10%) into the melt close to the liquidus temperature [6,7,8,9]. The main reason why this technique is not widely used in industry is the possible incomplete dissolution of the solid parts introduced into the melt with ensuing inhomogeneous as-cast structure and potential defects. In addition, the selection of the temperature range where the technology works the best is not clear.

Another well-documented means of controlling the grain structure of as-cast metals is ultrasonic melt processing (USP) [10,11,12,13]. There are well-studied mechanisms through which USP affects the structure, i.e., wetting of non-metallic inclusions, cavitation-assisted heterogeneous nucleation, fragmentation of primary intermetallics and dendrites and enhanced mixing of the liquid volume [13]. Although very powerful in grain refinement, this technology suffers from instrumental issues, i.e., the ultrasonic tool (sonotrode) that is used for direct introduction of high-frequency vibration into the melt is subject to cavitation erosion and (if made of metal) gradual dissolution. The choice of the sonotrode material is, therefore, very important and it has been demonstrated that Nb-based alloys are most stable under cavitation condition in the aluminium melt [10]. But even sonotrodes made from Nb alloys suffer eventually from erosion. At the same time, some schemes that use a “consumable” sonotrode have been suggested in ultrasonic welding (wire feeding) and in electro-slag remelting (vibrating electrode) as reviewed elsewhere [11,12]. Such a scheme opens some new avenues in ultrasonic melt processing as it eliminates the issue of sonotrode material selection. It is also well known that ultrasonic vibrations significantly accelerate the dissolution of solid metals in the melt as well as promote rapid mixing of solutes through accelerated diffusion, eliminating the build-up of the solute-rich layer at and facilitating a better excess of the fresh melt to the solid/liquid phase [10,14].

In this study, we attempted to combine these two technologies to achieve a synergetic effect.

2. Experimental Methods and Materials

An AA6082 alloy was used as a base material (1.16% Si, 0.7% Mg, 0.98% Mn, 0.26% Fe, 0.17% Cr, 0.04% Ti) and a 9-mm rod of the same alloy was used for additions. In some experiments, a standard Al5Ti1B rod (LSM, Rotherham, UK) was used (0.2% addition). A total of 10% of AA6082 rod was introduced in each experiment. The choice of the alloy is due to its wide applicability in automotive applications where extrusions are made from direct-chill case billets, so the grain refinement is an important issue. The liquidus of this alloy is 647 °C, the equilibrium solidus is 593 °C and the nonequilibrium solidus is 533 °C, as calculated by Thermocalc software (version 2019a, TCAL 4 database, Thermo-Calc Software AB, Solna, Sweden).

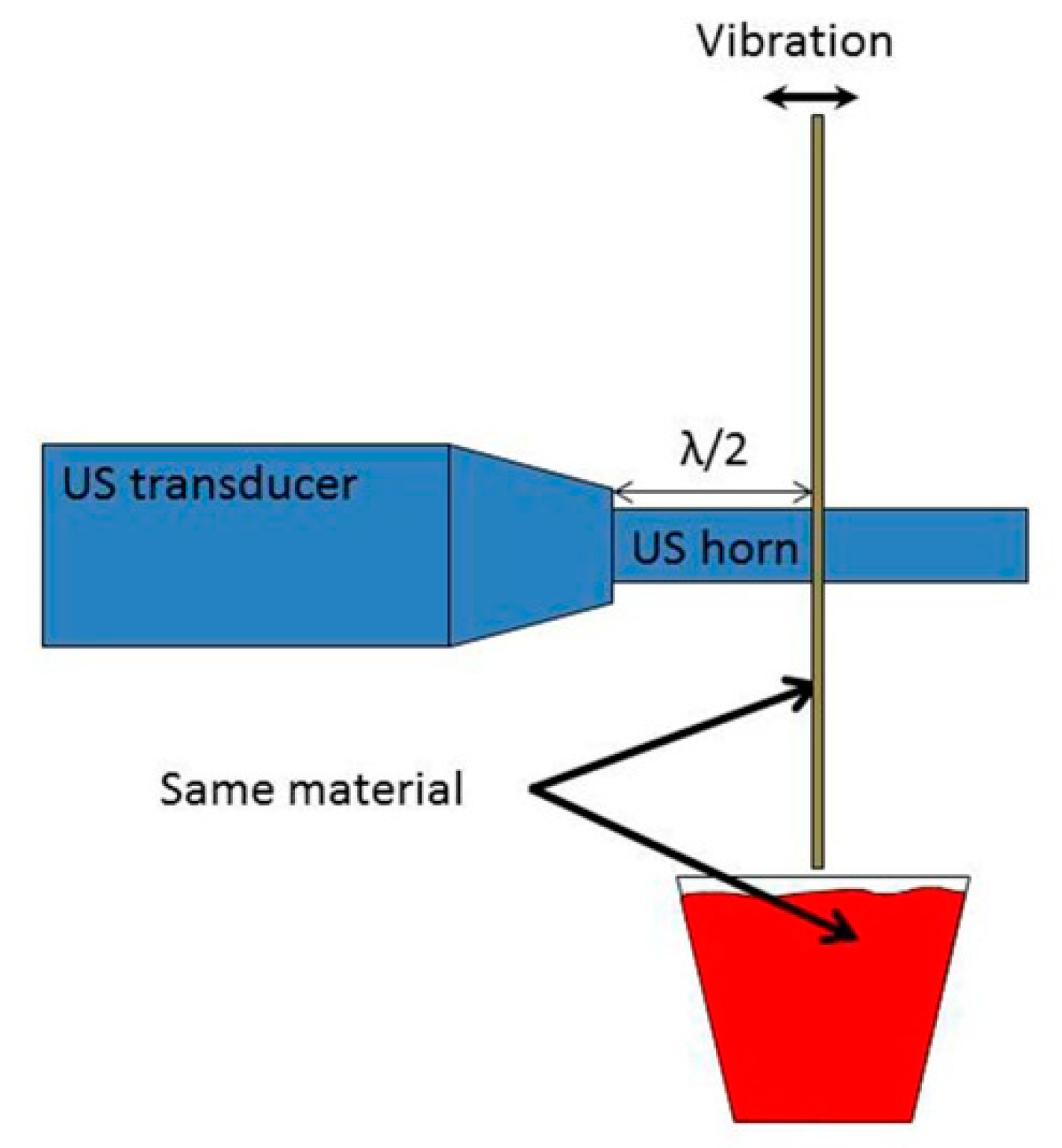

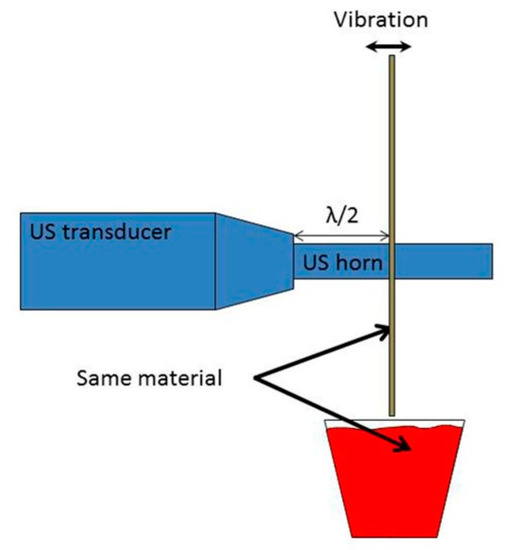

In the experiments with ultrasound, a 5-kW ultrasonic generator and a 5-kW, 17.5-kHz water-cooled transducer (Reltec, Yekaterinburg, Russia) were used at a power of 3 kW (the longitudinal amplitude was ±12 µm). When ultrasound was applied, the rod was inserted tightly into a hole in a steel sonotrode in the half-wavelength position and then fed into the melt while the ultrasonic transducer was on as shown in Figure 1. The sonotrode was not in contact with the melt and was not cooled or heated. As a result of this scheme, the longitudinal oscillations of the sonotrode were transformed into flexural oscillations of the rod with the resultant shorter wavelength and larger amplitudes, up to 25 µm as measured by a contactless vibrometer. Separate experiments in water showed that cavitation conditions were achieved at the tip of the rod as well as in nodes along the rod length. Water is a well-accepted analogue of liquid aluminium with regard to the cavitation behaviour, though the cavitation threshold in liquid Al is about two times higher than in water, 10 µm vs 5 µm peak-to-peak amplitude at 20 kHz [15]. Therefore, the vibration conditions used in these experiments were sufficient to achieve cavitation in liquid Al.

Figure 1.

A schematic of the experiment.

The melt was prepared in clay-graphite crucibles (0.5 kg charge) in an electric resistance furnace (Carbolite, Hope Valley, UK) with melt temperature up to 770 °C. Rod introduction was made either without or with ultrasonic vibrations applied into the melt in a temperature range with the final pouring temperature 670 °C, i.e., the rod was started to be introduced at a certain given melt temperature and then, while the rod was dissolving, the melt was naturally cooled down to the pouring temperature. Reference samples were prepared by adding the same amount of rod into the melt that was then superheated to 750 °C, left in the furnace for 30 min and then cooled in air and cast at 670 °C. The rod was not preheated before the introduction. Casting was done in a standard TP-1 mould [16].

The castings were then sectioned along the vertical centre plane and etched for structure examination. Macroetching was done in a 10% NaOH water solution after grinding. To reveal grain microstructure smaller samples were cut, ground and polished using standard procedures and then anodised in a 5% HFB4 water solution at 20 VDC. The grain structure was subsequently examined in an optical microscope Zeiss Axioscope (Zeiss, Cambridge, UK) in polarised light. For the grain size measurement, the sections in the middle of the sample cross-section were used (see Figure 1a for detail). The grain size was measured using a random linear intercept method with at least 50 grains measured. Statistical analysis of the measured grain size was performed and the average values are reported.

3. Results and Discussion

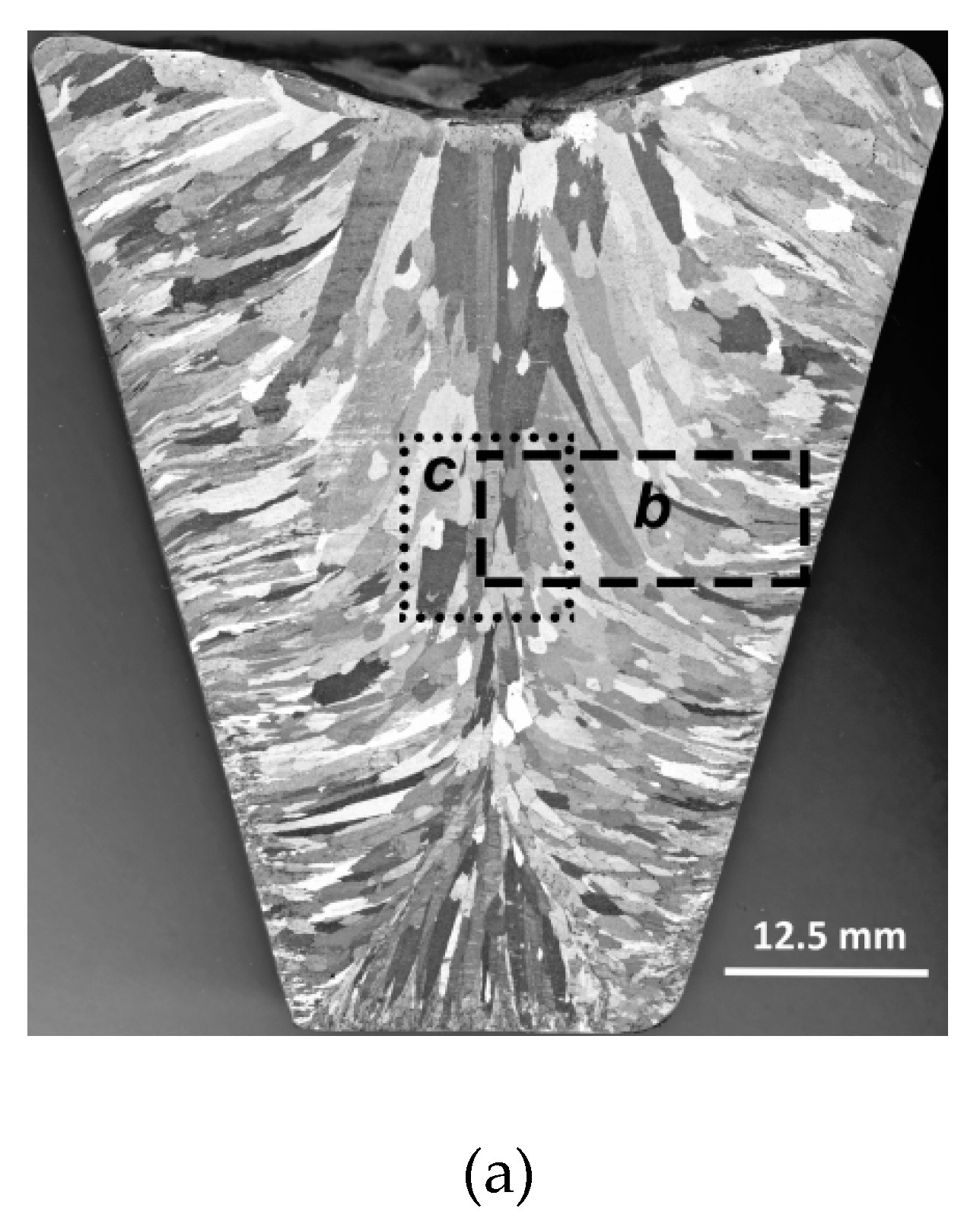

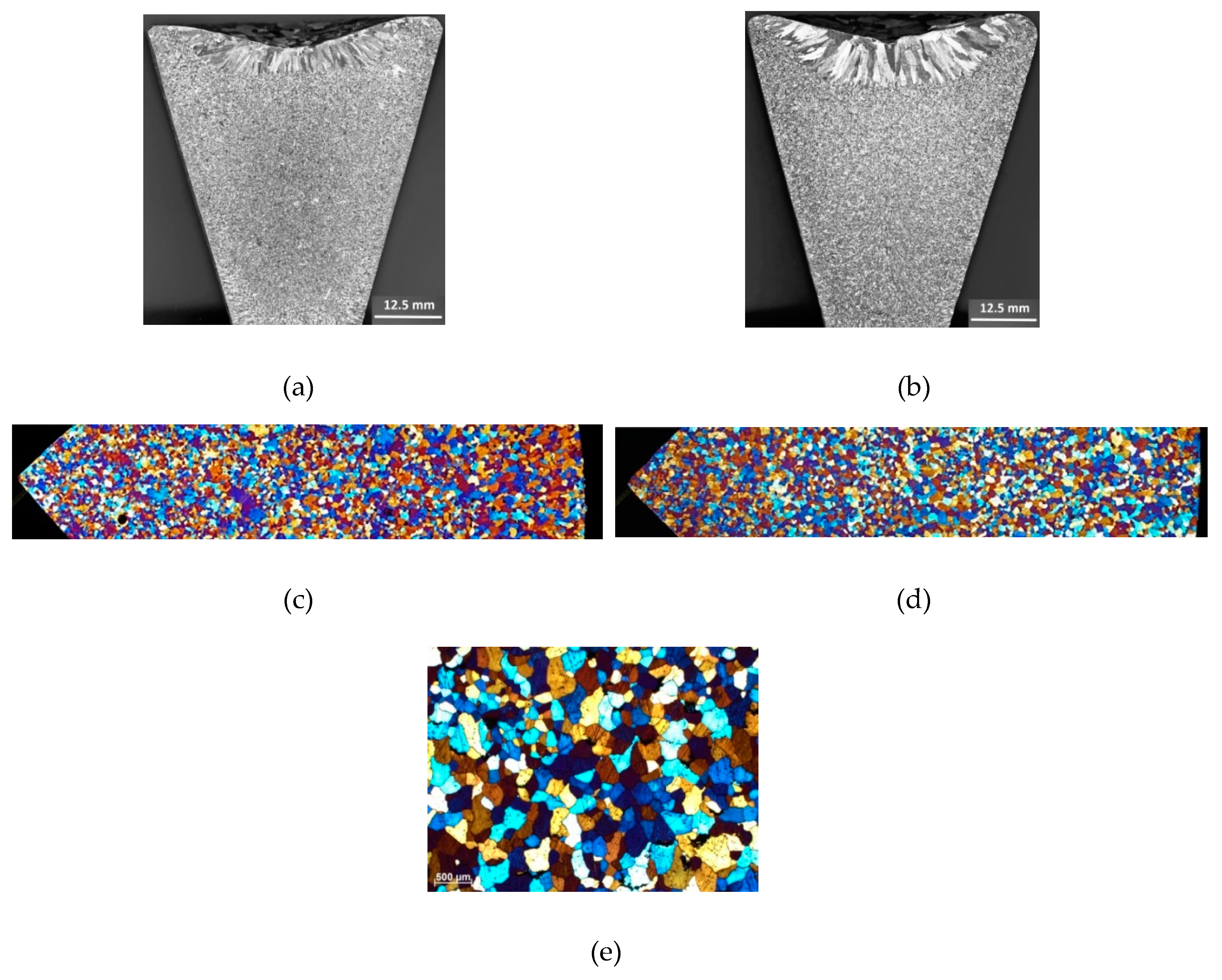

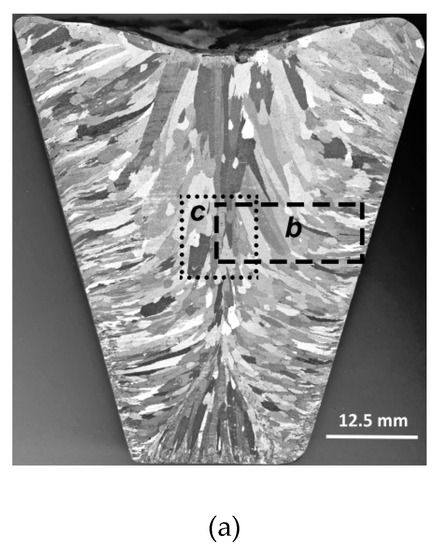

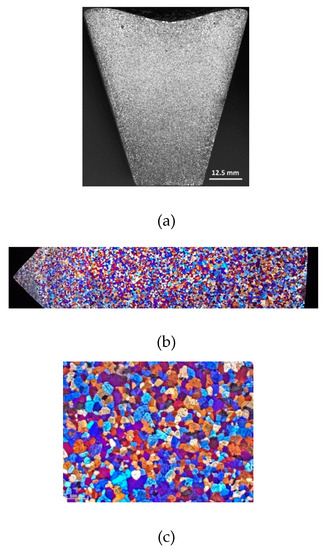

Reference samples (a number of those had been produced) showed a coarse columnar grain structure as shown in Figure 2 with the average grain size 630 µm.

Figure 2.

Macro (a) and micro (b,c) grain structure of a reference sample cast at 670 °C in a TP1 mould. The positions of photos in (b) and (c) with respect to the sample cross-section are marked in (a) (same positions have been used hereafter).

First experiments when the rod was introduced without or with ultrasound in the temperature ranges 740 to 715 °C and 740 to 710 °C did not produce any significant results with a very coarse mixed columnar and equiaxed structure formed (these results are not presented here). This confirmed the importance of the temperature range needed for the desired effect. Although the introduced rod was quick to dissolve, the relatively high temperature apparently prevented the survival of solid fragments as well as facilitated deactivation of solid inclusions (only 10–15 °C above liquidus is needed for that [9]).

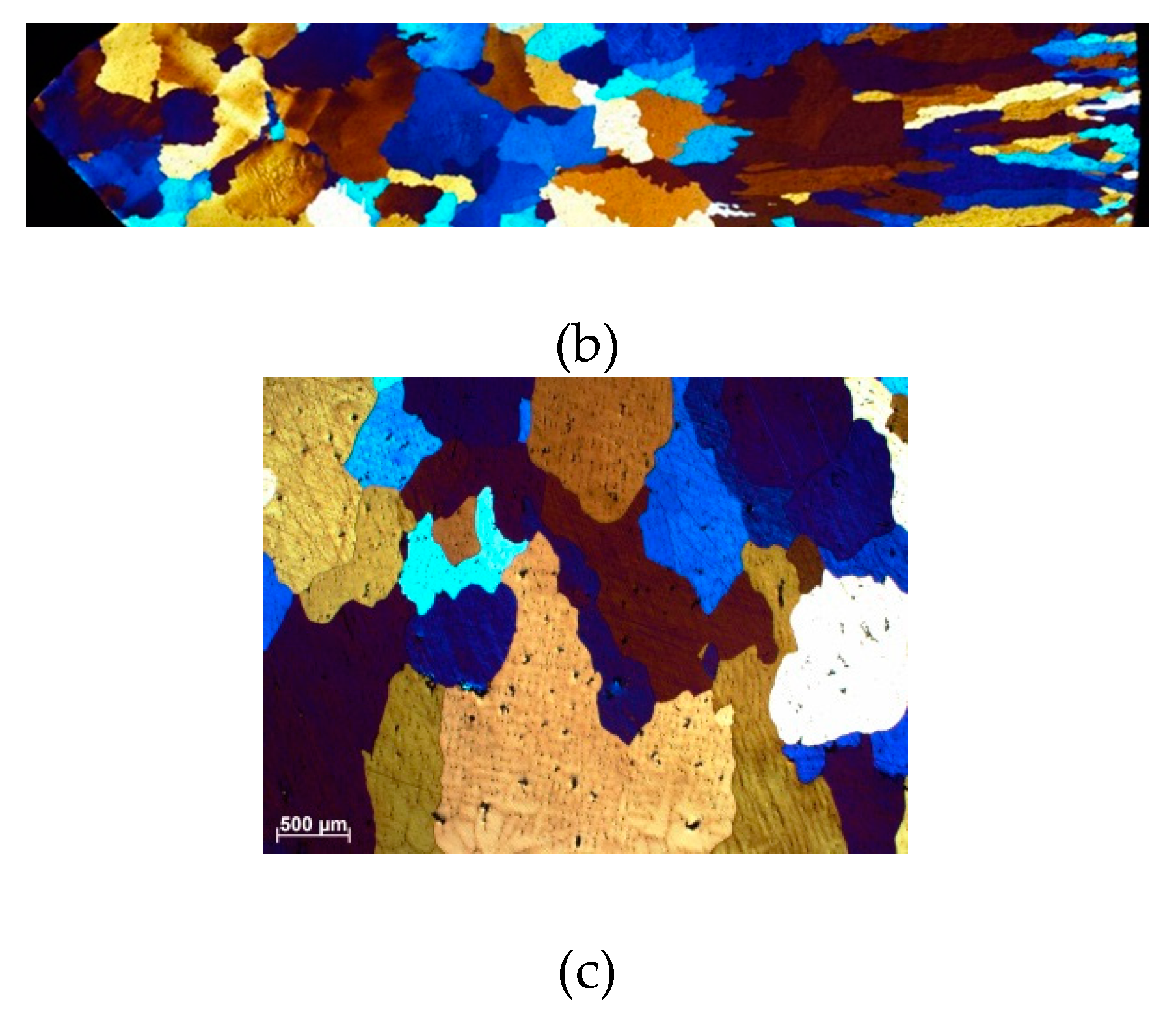

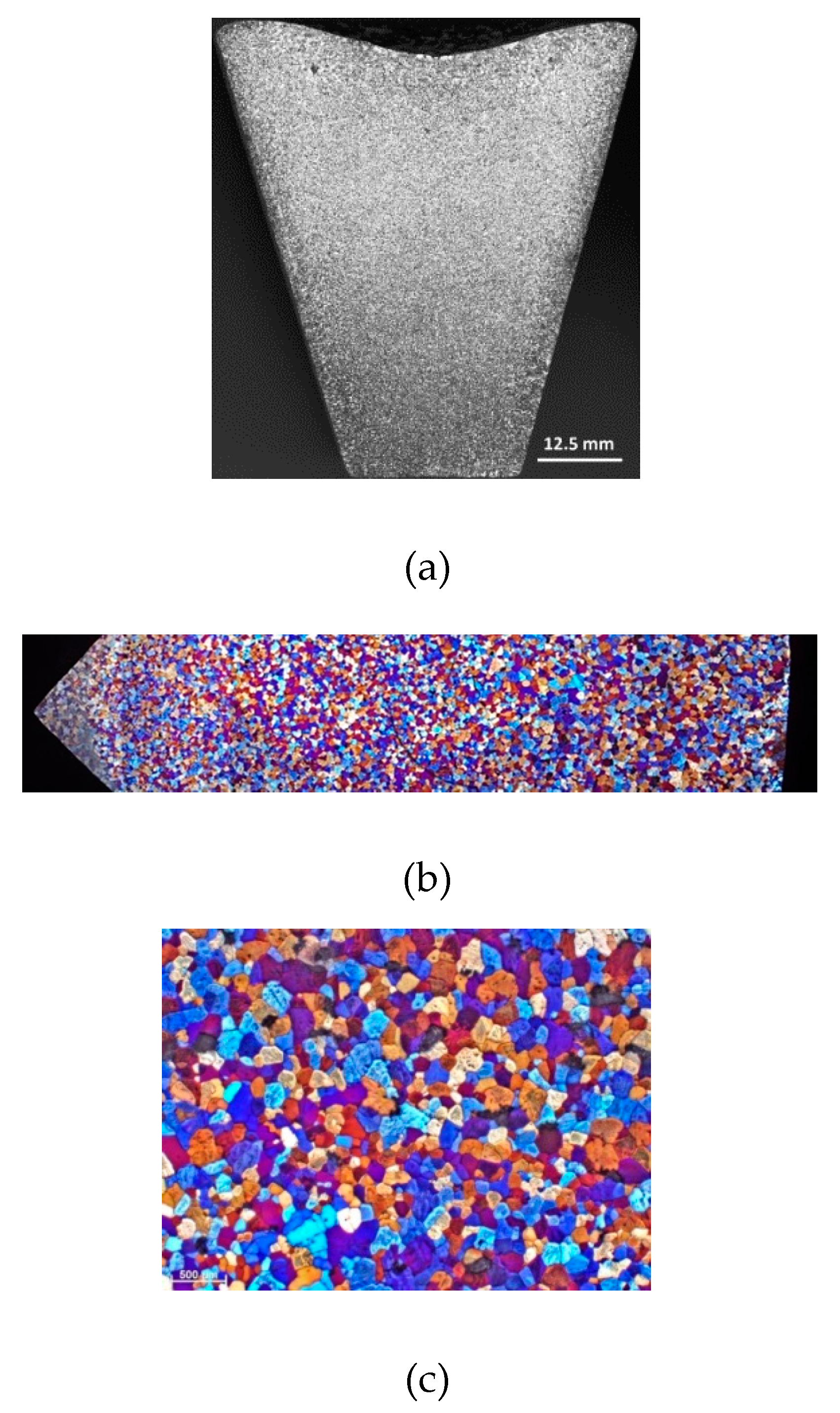

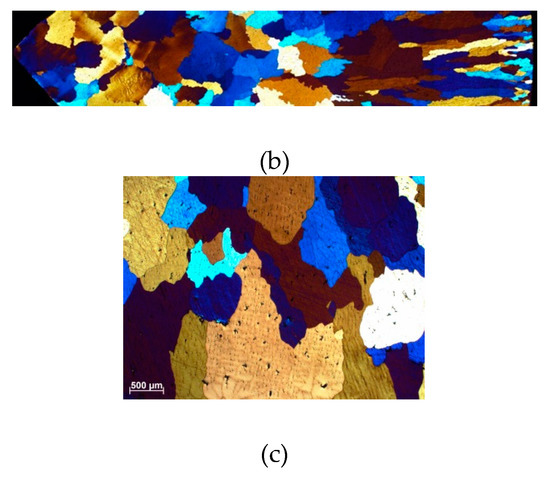

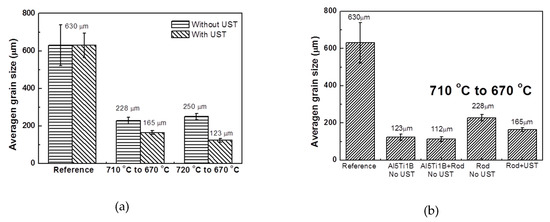

Following experiments were performed in the temperature ranges 720 to 670 °C and 710 to 670 °C. The decrease in the introduction temperature yielded a remarkable change in the grain structure even when the rod was introduced without ultrasonic vibrations, with the average grain size 250 µm, Figure 3. It can be noted that a slight decrease in the starting melt temperature gives some additional grain refining effect (228 µm), most probably due to the better survival chances of crystal fragments and active inclusions.

Figure 3.

Effect of rod introduction into the melt in the temperature range 720 to 670 °C (a,c) and 710 to 670 °C (b–e) on the grain structure of the alloy cast in a TP1 mould.

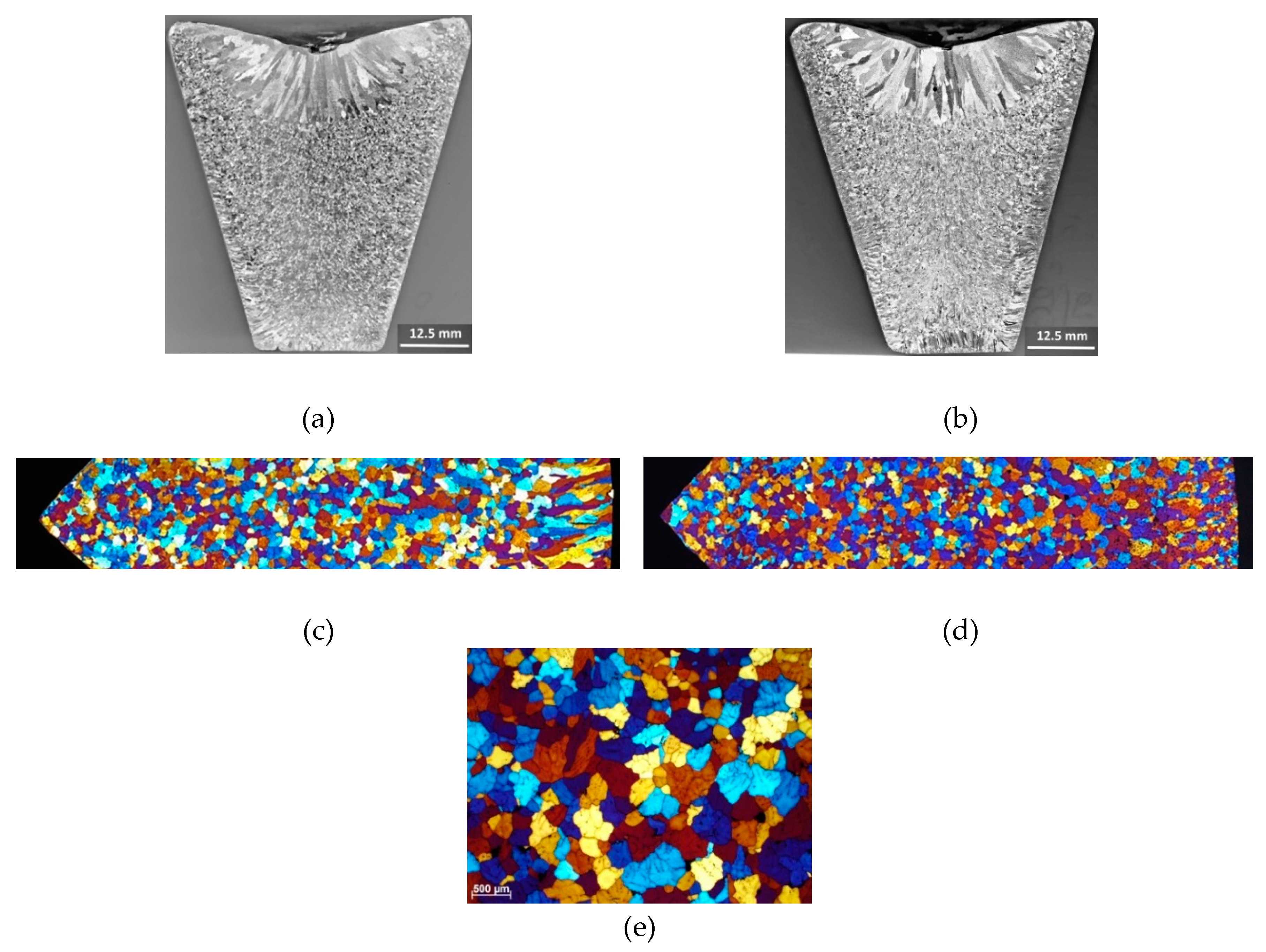

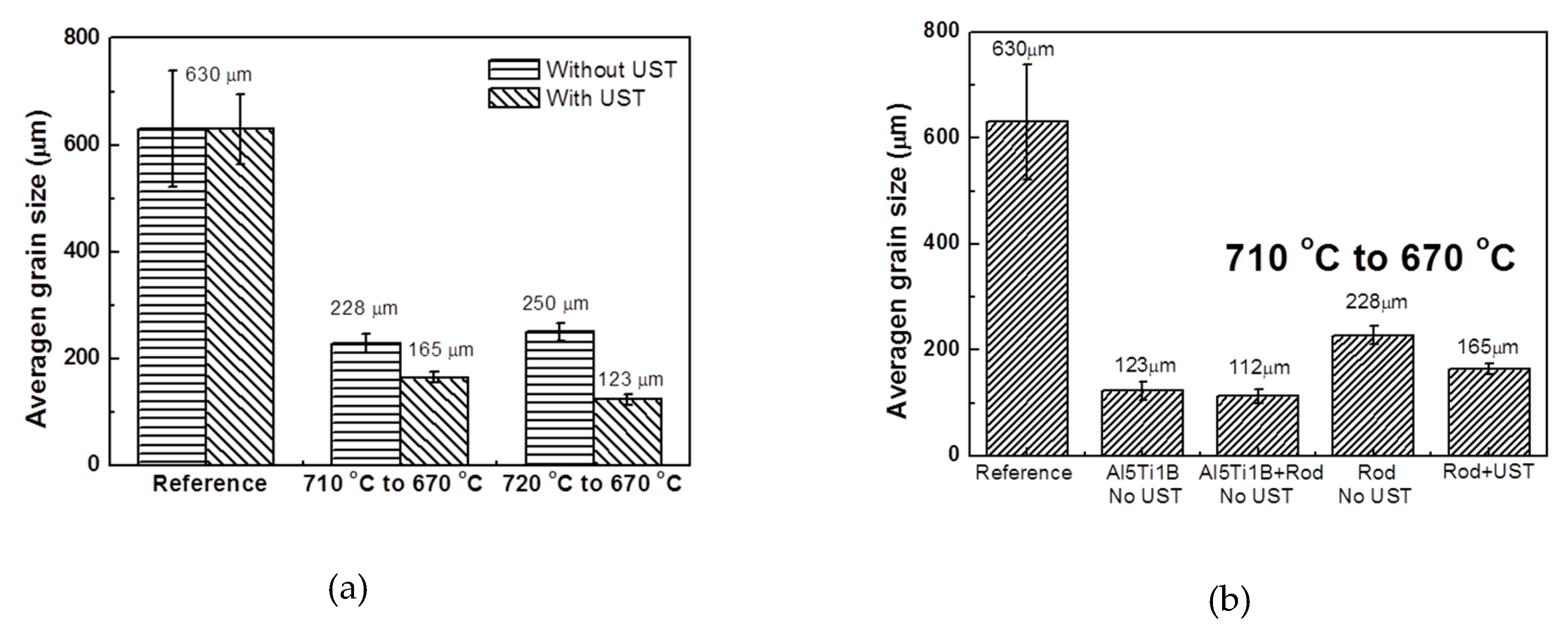

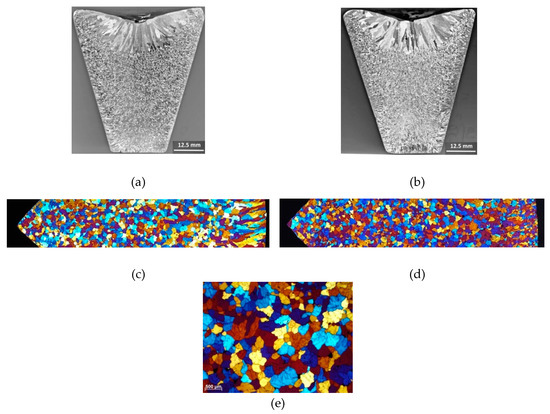

Ultrasonic oscillations applied to the rod further refined the grain structure as illustrated in Figure 4. This might be due to the better distribution of crystal fragments in the melt as well as to the additional activation of insoluble inclusions by ultrasonic cavitation [13,17]. At the same time the grain size obtained upon rod introduction with ultrasonic oscillations in a wider temperature range was finer than in a narrower temperature range, i.e., 123 µm and 165 µm, respectively. As ultrasonic oscillations, in addition to accelerated rod dissolution, may facilitate additional mechanisms of grain refinement such as activation of inclusions and fragmentation of solid crystals with their effect being time-dependent, therefore, the longer the ultrasonic cavitation and vibration works, the better the result [13]. Hence, a slight increase in the rod introduction time provided by using a wider temperature range is beneficial for the grain refinement.

Figure 4.

Effect of rod introduction with ultrasonic vibrations into the melt in the temperature range 720 to 670 °C (a,c) and 710 to 670 °C (b–e) on the grain structure of the alloy cast in a TP1 mould.

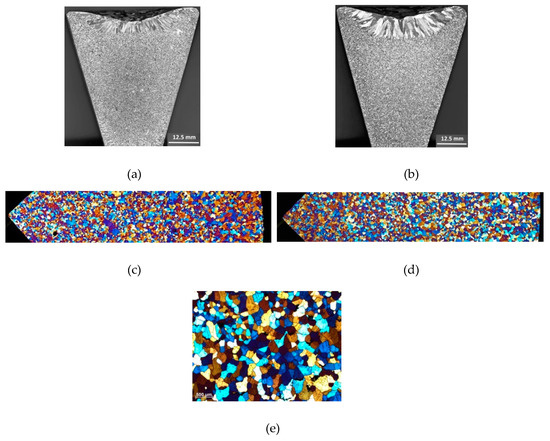

The standard procedure of grain refinement of aluminium alloys is the addition of an AlTiB master alloy. In order to compare the grain refining effects that we have achieved with the same-alloy rod introduction, we did additional experiments with the standard Al5Ti1B grain refining master alloy addition (0.2% of master alloy). Two experiments were performed, i.e., addition of the grain refiner to the base alloy and same-alloy rod introduction into the grain refined master alloy. The obtained grain sizes were rather small (112–123 µm), Figure 5, and comparable with those obtained upon same-alloy rod introduction with ultrasonic oscillations, Figure 4. Although the addition of a rod to the grain refined alloy gave a slight additional decrease in the grain size (112 µm vs 123 µm), it was not statistically significant. These results demonstrate that under given cooling conditions (TP1 mould) the addition of 0.2% grain refiner as well as the addition of the same-alloy rod gives the maximum number of solidification sites that can be realised and produce grains. Therefore the achieved grain size 112–123 µm is the smallest possible and does not depend on the way how the active solidification sites are introduced.

Figure 5.

Effect of Al5Ti1B grain refiner addition and same-alloy rod introduction into the melt in the temperature range 710 to 670 °C on the grain structure of the alloy cast in a TP1 mould: (a), macrostructure; (b,c) microstructure.

Figure 6 summarises the results of grain size measurements for all studied cases.

Figure 6.

Grain sizes achieved in experiments: (a) the effects of the same-rod introduction, ultrasonic oscillations and the temperature range of introduction and (b) comparison of the same-alloy rod introduction with the standard grain refinement by master alloy addition.

This work has a limited scope of demonstrating the grain refining effect of the introduction of a same-alloy solid material into the melt facilitated by ultrasonic vibration of this rod. We based our discussion on the known mechanisms of suspension casting that include the introduction of active substrates and rapid undercooling of the melt [2,3,4,5] and known mechanisms of ultrasonic melt processing that include (in relation to the observed effects) accelerated dissolution and mixing [14] facilitated by fragmentation of solid suspended particles [13]. The combination of these effects produced a remarkable grain refinement effect, comparable with the standard procedure of grain refinement. The following research should focus on the further optimisation of the procedure with respect to the temperature range, processing time, amount of the introduced solid material and further cooling conditions during solidification. The effect of ultrasonic vibrations on the melt degassing on the one hand and on the introduction of potential oxides with the solid material on the other hand, should be further explored.

4. Conclusions

- The grain refining effect upon introduction of a same-alloy rod into the melt prior to casting has been confirmed.

- The temperature range of the same-alloy rod introduction should be close the casting temperature to assure that the generated solidification sites remain active.

- The application of ultrasonic vibrations to the same-alloy rod gives additional grain refining effect that is most probably related to the known effects of cavitation on the accelerated dissolution and mixing as well as on the fragmentation of solidification sites.

- The observed grain refining by the same-alloy rod introduction with the ultrasonic oscillations applied is similar to that achieved by the standard grain refining procedure.

- The results show a promising technology of using the same-alloy rod instead of the grain refining rod in continuous casting processes.

Author Contributions

D.E. provided funding acquisition, supervision, conceptualization, methodology, participated in experiments, prepared the original draft and edited the final version. F.W. contributed to methodology, performed experiments and analysis and reviewed the draft paper.

Funding

The research was funded by the UK Engineering and Physical Science Research Council (EPSRC), Ultra-Cast project, grant number EP/L019884/1.

Acknowledgments

This paper is based on the presentation at the 16th International Conference on Aluminum Alloys (ICAA16, Montreal, Canada, 17–21 June, 2018. Technical assistance of S. Venditti and P. Lloyd in conducting experiments is highly appreciated.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Danilov, V.I.; Neimark, V.E. Effects of solidification conditions on the structure of an aluminium ingot. Metallurg 1938, 10, 34–43. [Google Scholar]

- Scheil, E. Inoculation and inoculants in metal melts. Giesserei 1956, 43, 233–240. [Google Scholar]

- Madyanov, A.M. Suspension Casting; Metallurgizdat: Moscow, Russia, 1969. [Google Scholar]

- Zatulovsky, S.S. Suspension Casting; Naukova Dumka: Kiev, Russia, 1981. [Google Scholar]

- Balandin, G.F. Formation of Grain Structure in Castings; Mashinostroenie: Moscow, Russia, 1973; pp. 225–227. [Google Scholar]

- Schmidt, W. Method of Solidifying Molten Metal. U.S. Patent US3247557 (A), 26 April 1966. [Google Scholar]

- Talbot, A.M.; Soller, H.W. Method of Internal Nucleation of a Casting. U.S. Patent GB1324526 (A), 25 July 1973. [Google Scholar]

- Krupp GmbH. Foundry Mould Castings—With Solid Metal Particles Added to Molten Metal in Mould. U.S. Patent FR2201149 (A1), 26 April 1974. [Google Scholar]

- Bondarev, B.I.; Napalkov, V.I.; Tararayshkin, V.I. Modification of Aluminium Wrought Alloys; Metallurgiya: Moscow, Russia, 1979; pp. 96–98. [Google Scholar]

- Eskin, G.I. Ultrasonic Treatment of Molten Aluminium; Metallurgiya: Moscow, Russia, 1965. [Google Scholar]

- Abramov, O.V. Crystallization of Metals in Ultrasonic Field; Metallurgiya: Moscow, Russia, 1972. [Google Scholar]

- Abramov, O. High Intensity Ultrasonics. Theory and Industrial Application; Gordon and Breach: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Brodova, I.G.; Popel, P.S.; Eskin, G.I. Liquid Metal Processing. Application to Aluminum Alloy Production; Taylor and Francis: London, UK, 2002. [Google Scholar]

- Komarov, S.; Oda, K.; Ishiwata, Y.; Dezhkunov, N. Characterization of acoustic cavitation in water and molten aluminum alloy. Ultrason. Sonochem. 2012, 20, 754–761. [Google Scholar] [CrossRef] [PubMed]

- Aluminum Association. Standard Test Procedure for Aluminum Grain Refiners, TP-1; The Aluminum Association: Washington, DC, USA, 1990. [Google Scholar]

- Wang, F.; Eskin, D.; Connolley, T.; Wang, C.; Koe, B.; King, A.; Reinhard, C.; Mi, J. In-situ synchrotron X-ray radiography observation of primary Al2Cu intermetallic growth on fragments of aluminium oxide film. Mater. Lett. 2018, 213, 303–305. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).