Abstract

Austenitic stainless steels suffer from intergranular corrosion and stress corrosion cracking when exposed to elevated temperature (500–800 °C). Under these environments, Cr-carbides and Cr-carbontrides precipitate at the grain boundaries, which results in the formation of Cr-depleted zone. In practice, alloying elements could be added into austenitic stainless steels to modify the precipitation processes. Besides the precipitation processes, the elastic properties of the iron matrix would be influenced. Using the exact muffin-tin orbitals (EMTO) method, the solute effects on the elastic properties of FeCr20Ni8 austenitic stainless steels were studied. Based on the simulated shear modulus (G) and bulk modulus (B), we proposed a design map for FeCr20Ni8 based alloys, aiming to provide a basis for the design of high-performance austenitic stainless steels.

1. Introduction

Austenitic stainless steels are widely used in the nuclear, oil and chemical industries, owing to their excellent mechanical properties, weldability and corrosion-resistance properties [1,2,3,4]. However, when exposed to elevated temperature (500–800 °C), these alloys become susceptible to intergranular corrosion and stress-corrosion cracking. Under these environments, Cr-carbides and Cr-carbontrides precipitate at the grain boundaries, which results in the formation of the Cr-depleted zone [5,6,7]. To overcome this drawback, strong carbide-forming elements are added to reduce the concentration of C, aiming to suppress the Cr-carbides and Cr-carbontrides and avoid the formation of Cr-depleted zone [3,8,9]. It should be noted the addition of carbide-forming elements not only influences the precipitation processes, but also changes the elastic properties of the iron matrix.

Using ab initio simulations, Vitos et al. investigated the elastic properties of the Fe100−(c+n)CrcNin alloys (13.5 < c < 25.5 and 8 < n < 24) [10,11] (here and throughout the paper, the concentrations are expressed in the atomic percentage, at.%). In that work, shear modulus (G) and bulk modulus (B) fall into the range of 74–81 GPa and 161–178 GPa, respectively. These authors revealed a very interesting trend that relatively high values of G correspond to relatively low values of B, and vice versa. For example, FeCr20Ni8 (corresponding approximately to alloy steel AISI 304) has an intermediate value of G (77.3 GPa) but a low value of B (165.2 GPa) [10].

It should be noted that a lower value of B means the atomic bond is weaker. Consequently, materials with a low value of B exhibit relatively poor resistance to various forms of localized corrosion (such as intergranular corrosion, pitting corrosion and stress-corrosion cracking) [10,12,13,14]. Furthermore, Clerc et al. have demonstrated the hardness of the annealed metal is proportional to G [15]. It is commonly known that high a value of the B/G ratio (>1.75) often results in ductility, while a low value of the B/G ratio (<1.75) often results in brittleness [10,11,14,16,17,18].

Potentially, alloying elements (such as Mo, Nb, Ta, Ti, V, W and Zr) might be added into austenitic stainless steels to suppress the Cr-carbides and Cr-carbontrides. In addition to the precipitation processes, the elastic properties of the iron matrix would also be influenced. In this work, we simulated the solute effects on the elastic properties of FeCr20Ni8 austenitic stainless steels. We also calculated the difference (EBCC-EFCC) between body-centered cubic (BCC) and face-centered cubic (FCC) structure. The solute concentrations considered in this work are 1 at.% and 2 at.%.

2. Computational Methods

In this work, all calculations were calculated at 0 Kelvin. We performed first principle simulations based on the exact muffin-tin orbitals (EMTO) method [19,20]. The coherent potential approximation (CPA) was used to describe the random alloys [21,22]. A 29 × 29 × 29 k-point grid was used to sample the Brillouin zone. In self-consistent calculations, the total energy converged within 10−7 Ry per atom. Frozen core approximation, disordered local magnetic moment (DLM) [23], and the local density approximation (LDA) [24] were adopted to calculate the charge density. Then, the total energy was evaluated with the full charge density technique (FCD) approach [25]. In the FCD calculation, the exchange–correlation interactions were described by the generalized gradient approximation (GGA) in the Perdew–Burke–Ernzerhof (PBE) form [26]. This combination of approximations has been used to calculate the equation of state of Fe–Cr–Ni alloys successfully [10,16]. Using EMTO package 5.8, provided by Professor Levente Vitos (Royal Institute of Technology, Stockholm, Sweden) [20], we calculated the total energies of various distorted unit cells. The bulk modulus B is obtained by fitting the total energies as a function of the unit cell volume [27,28].

where E(V) is the energy for individual V; E(V0) is the energy at the equilibrium unit cell volume V0; B0, and B′0 are the bulk modulus and its pressure derivative at V0.

To calculate the tetragonal shear modulus C′, an orthorhombic distortion is applied to the unit cell.

Then the tetragonal shear modulus C′ is fitted as the following:

To calculate the C44, a monoclinic distortion is applied to the unit cell.

Then the C44 is fitted as the following:

For cubic lattices, there are only three independent elastic constants C44, C11 and C22. C11 and C22 can be derived as the following:

The polycrystalline elastic moduli were derived from the single elastic constants with averaging methods. Based on the Hill averaging method [29,30], the shear modulus is derived as the following:

where GV and GR are the upper and lower bounds based on the Voigt [31] and Reuss [32] method, respectively.

Using the derived bulk modulus B and shear modulus G, the polycrystalline Young’s modulus E and Poisson ratio ν can be derived as the following:

3. Results and Discussions

3.1. Elastic Properties of FeCr20Ni8

As listed in Table 1, the calculated bulk modulus (B) and shear modulus (G) for FeCr20Ni8 are 161.8 and 77.3 GPa, respectively. These values coincide with the EMTO data published by Vitos et al. [16]. Experimental measurements of bulk modulus (B) and shear modulus (G) require dedicated techniques, so the available experimental data are very limited. As listed in Table 1, the experimentally measured bulk modulus (B) and shear modulus (G) for FeCr19.7Ni8.9 are 158.2 and 77.4 GPa, respectively. Furthermore, the calculated equilibrium V0 is 11.75 Å3, coinciding well with the EMTO data (11.75 Å3) [16] and experimental data (11.83 Å3) [33].

Table 1.

Calculated equilibrium unit cell volume (V) in Å3; the energy difference between body-centered cubic (BCC) and face-centered cubic (FCC) structure (EBCC-EFCC) in mJ; C11, C12, C44, bulk modulus B, shear modulus G and Young’s modulus (E) in GPa; B/G ratio and Poisson ratio ν are listed.

3.2. Solutes Effects on the Elastic Properties of FeCr20Ni8

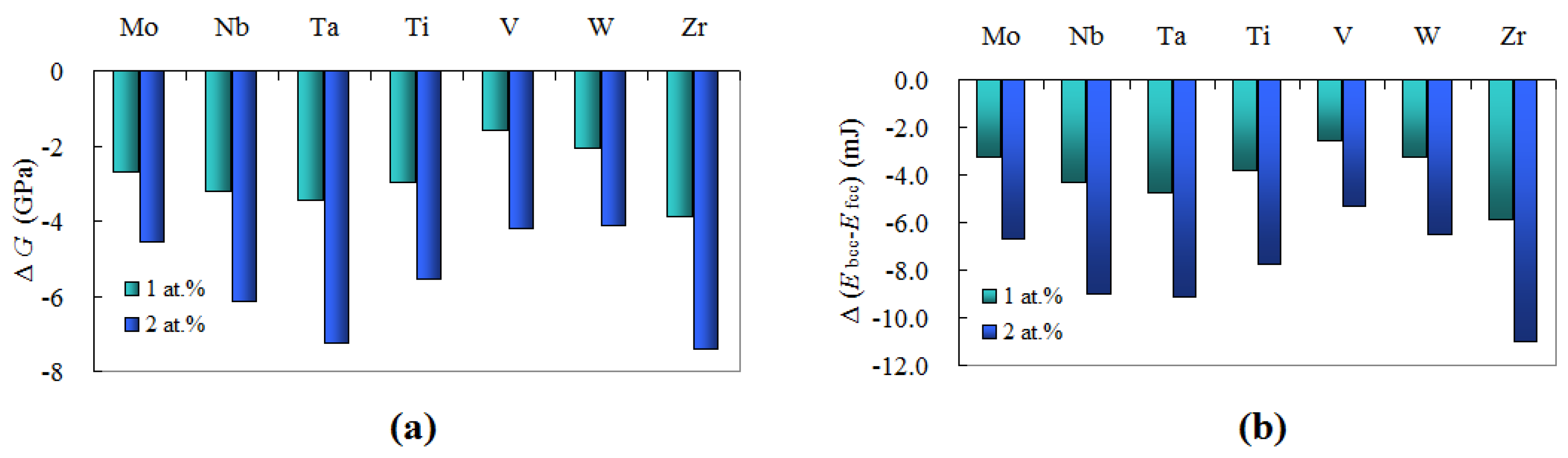

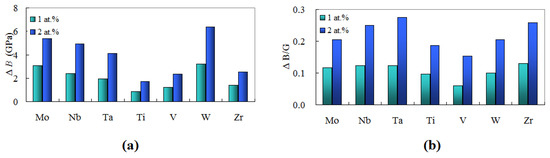

As shown in Figure 1a, all the alloying elements considered here decrease the shear modulus (G) of FeCr20Ni8. For FeCr20Ni8, the shear modulus (G) is 77.3 GPa. The addition of 1 at.% X (X = Mo, Nb, Ta, Ti, V, W and Zr) decrease the shear modulus (G) by 2.7, 3.2, 3.4, 3.0, 1.6, 2.1 and 3.9 GPa, respectively. Increasing the solute concentration to 2 at.% further decreases the shear modulus (G) by 1.9, 2.9, 3.8, 2.6, 2.6, 2.0 and 3.5 GPa, respectively. Experimentally, adding 1.2 at.% Mo into commercial steel grades (SAE 310, 316) decreases the shear modulus (G) [35]. Furthermore, EMTO results also revealed that the shear modulus (G) of FeCr18Ni24 would be decreased by the addition of Mo, Nb and V [10].

Figure 1.

(a) Solute effects on the shear modulus (G). (b) Solute effects on the energy difference between the body-centered cubic (BCC) and the face-centered cubic (FCC), (EBCC-EFCC).

It is believed that the shear modulus (G) of a face-centered cubic (FCC) metal is related to the energy difference between the body-centered cubic (BBC) and the face-centered cubic (FCC) structure, EBCC-EFCC [16,36]. Δ(EBCC-EFCC) is defined as the following:

Based on this definition, a lower value of Δ(EBCC-EFCC) means lower stability of the austenitic phase. As shown in Figure 1b, all the alloying elements considered here decrease the stability of the austenitic phase. This coincides with the fact that Mo, Ta, Ti, Nb, V and W are ferrite-promoting elements [37]. The addition of 1 at.% X (X = Mo, Nb, Ta, Ti, V, W and Zr) decrease the Δ(EBCC-EFCC) from 0 to −3.3, −4.3, −4.8, −3.8, −2.6, −3.3 and −5.9 eV, respectively. Increasing the solute concentration to 2 at.% further decreases the Δ(EBCC-EFCC) to −6.7, −9.0, −9.1, −7.8, −5.3, −6.5 and −11.0 eV, respectively.

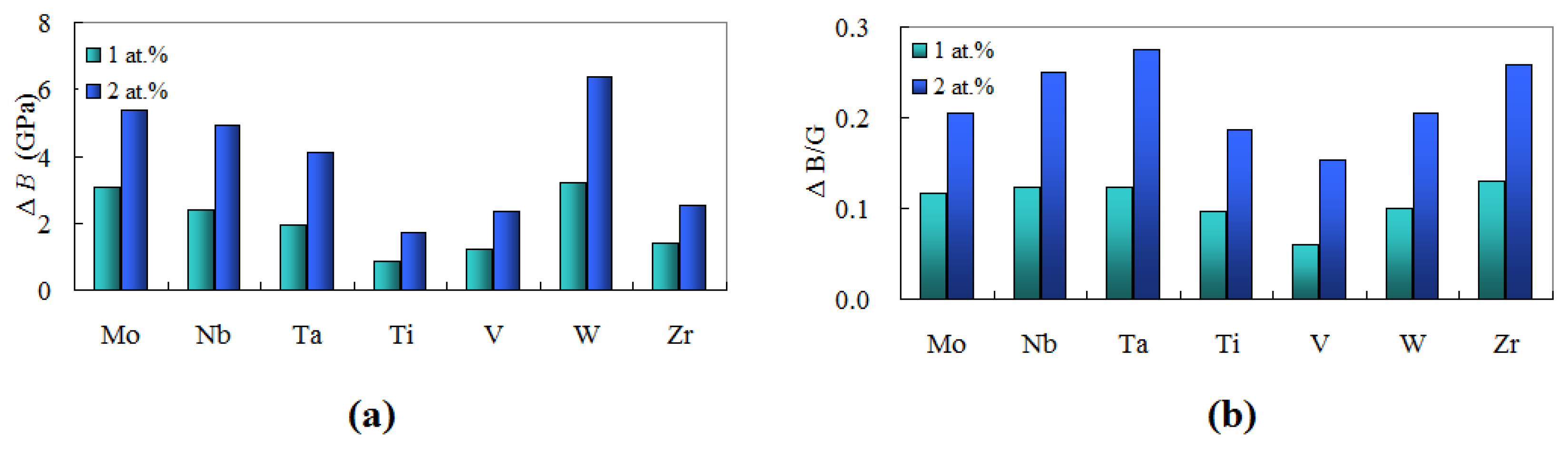

Let us shift the focus onto bulk modulus (B). As shown in Figure 2a, all the alloying elements considered here increase the bulk modulus (B) of FeCr20Ni8. For FeCr20Ni8, the bulk modulus (B) is 161.8 GPa. The addition of 1 at.% X (X = Mo, Nb, Ta, Ti, V, W and Zr) increase the bulk modulus (B) by 3.1, 2.4, 1.9, 0.9, 1.2, 3.2 and 1.4 GPa, respectively. Increasing the solute concentration to 2 at.% further increases the bulk modulus (B) by 5.4, 4.9, 4.1, 1.7, 2.4, 6.4 and 2.5 GPa, respectively. Experimentally, adding 1.2 at.% Mo into commercial steel grades (AISI 310, 316) increases the bulk modulus (B) [35]. Furthermore, EMTO results also revealed that the bulk modulus (B) of FeCr18Ni24 would be increased by the addition of Mo, Nb and V [10].

Figure 2.

(a) Solute effects on the bulk modulus (B). (b) Solute effects on the B/G ratios.

Solutes effects on the B/G ratios are shown in Figure 2b. All the alloying elements considered in this study increase bulk modulus (B) and decrease the shear modulus (G). Consequently, these alloying elements should increase the values of B/G ratio. For FeCr20Ni8, the B/G ratio is 2.09. The addition of 1 at.% X (X = Mo, Nb, Ta, Ti, V, W and Zr) increase the B/G ratio by 0.117, 0.123, 0.123, 0.096, 0.061, 0.100 and 0.130, respectively. Increasing the solute concentration to 2 at.% further increases the B/G ratio by 0.206, 0.249, 0.275, 0.186, 0.153, 0.205 and 0.259, respectively.

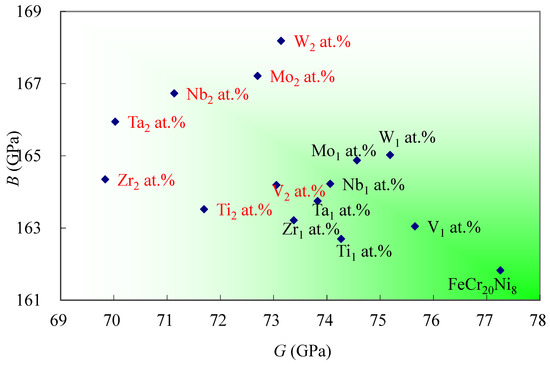

3.3. Design Map of FeCr20Ni8 Based Alloys

AISI 304 stainless steel is the most common stainless steel. However, it suffered from intergranular corrosion and stress corrosion cracking when exposed to elevated temperature (500–800 °C) [5,6,7]. Under these environments, Cr-carbides and Cr-carbontrides precipitate at the grain boundaries, which results in the formation of a Cr-depleted zone. Potentially, alloying elements (such as Mo, Nb, Ta, Ti, V, W and Zr) might be added into austenitic stainless steels to modify the precipitate processes. Taking Ti and V as examples, the formation energies of Ti23C6, V23C6 and Cr23C6 are −268, −292 and −105 meV/atom, respectively [38]. This means the addition of Ti and V will suppress the Cr-carbides and Cr-carbontrides [5,39].

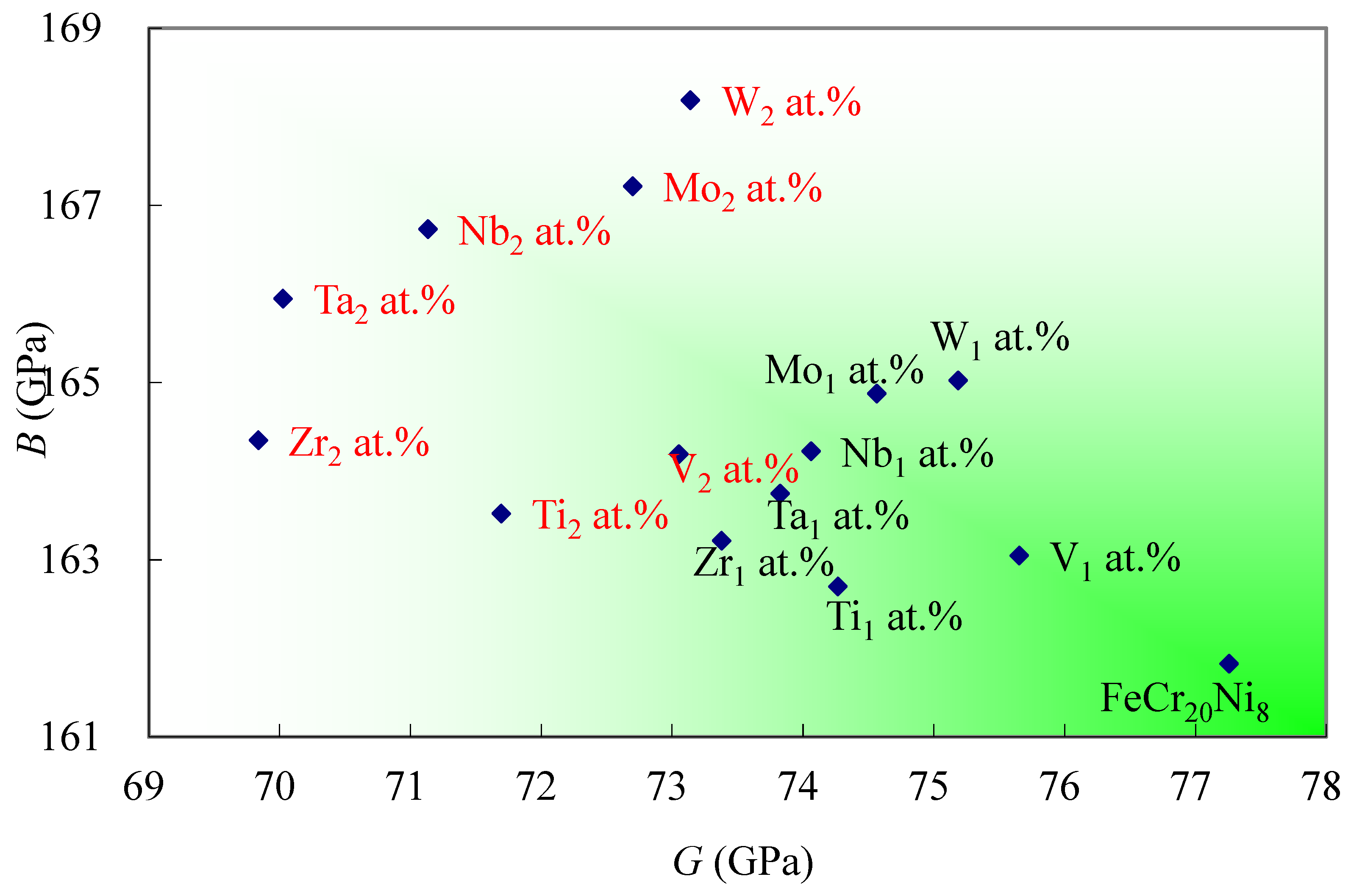

On the one hand, the addition of Mo, Nb, Ta, Ti, V, W and Zr increase the bulk modulus (B). Higher values of bulk modulus (B) correspond to stronger atomic bonds, which results in better resistance to various forms of localized corrosion, such as intergranular corrosion, pitting corrosion and stress-corrosion cracking [10,12,13,14]. On the other hand, these alloy elements might decrease the shear modulus (G). Based on the simulated shear modulus (G) and bulk modulus (B), we proposed a design map of FeCr20Ni8 based alloys. As shown in Figure 3, from left to right, the hardness of annealed alloys could be increased. While, from bottom to top, the resistance to various forms of localized corrosion could be enhanced. Experimentally, Mo, Ti, V and W were used to increase the resistance to intergranular stress-corrosion in various austenitic stainless steels [40,41,42]. This design map could provide a basis for the design of high-performance austenitic stainless steels. All alloying elements considered in this work increase the corrosion resistance and ductility of the FeCr20Ni8 matrix. When using this design map, we should keep in mind the reaction between the selected alloying element and the master alloy must be taken into account. Moreover, the dosage of the alloying element should be dedicatedly controlled to avoid the formation of brittle participates [1].

Figure 3.

Design map of FeCr20Ni8 based alloys. From left to right, the hardness of annealed alloys could be increased. From bottom to top, the resistance to various forms of localized corrosion could be enhanced.

4. Conclusions

Using the exact muffin-tin orbitals (EMTO) method, we studied the elastic properties of FeCr20Ni8Xn (X = Mo, Nb, Ta, Ti, V, W and Zr) austenitic stainless steels. The solute concentrations considered in this work were 1 at.% and 2 at.%. All the alloying elements considered in this study increase bulk modulus (B) but decrease the shear modulus (G). As a consequence, these alloying elements should increase the values of B/G ratio. Based on the simulated shear modulus (G) and bulk modulus (B), we proposed a design map for FeCr20Ni8-based alloys, aiming to provide a basis for the design of high-performance austenitic stainless steels.

Author Contributions

conceptualization, Y.D., H.L. and J.Z.; methodology, Y.D., H.L. and J.Z.; software, Y.D.; validation, Y.D., formal analysis, Y.D., investigation, Y.D., H.L. and J.Z.; resources, Y.D.; data curation, Y.D.; writing—original draft preparation, Y.D.; writing—review and editing, Y.D. and J.Z.; visualization, Y.D.; supervision, H.L. and J.Z.; project administration, Y.D.; funding acquisition, Y.D.

Funding

This research was funded by the Material Corrosion and Protection Key Laboratory of Sichuan province, grant number 2017CL05 and he Research Foundation for the introduction of talent of Sichuan University of Science and Engineering, China, grant number 2015RC57. The APC was funded by 2015RC57.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Wen, D.H.; Wang, Q.; Jiang, B.B.; Zhang, C.; Li, X.N.; Chen, G.Q.; Tang, R.; Zhang, R.Q.; Dong, C.; Liaw, P.K. Developing Fuel Cladding Fe-25cr-22ni Stainless Steels with High Microstructural Stabilities Via Mo/Nb/Ti/Ta/W Alloying. Mater. Sci. Eng. A 2018, 719, 27–42. [Google Scholar] [CrossRef]

- Morris, W.Y.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively Manufactured Hierarchical Stainless Steels with High Strength and Ductility. Nat. Mater. 2017, 17, 63–71. [Google Scholar]

- Donghui, W.; Jiang, B.; Wang, Q.; Yu, F.; Li, X.; Tang, R.; Zhang, R.; Chen, G.; Dong, C. Influences of Mo/Zr Minor-Alloying on the Phase Precipitation Behavior in Modified 310s Austenitic Stainless Steels at High Temperatures. Mater. Des. 2017, 128, 34–46. [Google Scholar]

- Hojná, A. Overview of Intergranular Fracture of Neutron Irradiated Austenitic Stainless Steels. Metals 2017, 7, 392. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Carboneras, M.; Arrabal, R. Influence of Ti, C and N Concentration on the Intergranular Corrosion Behaviour of Aisi 316ti and 321 Stainless Steels. Acta Mater. 2007, 55, 2239–2251. [Google Scholar] [CrossRef]

- Perron, A.; Toffolon-Masclet, C.; Ledoux, X.; Buy, F.; Guilbert, T.; Urvoy, S.; Bosonnet, S.; Marini, B.; Cortial, F.; Texier, G.; et al. Understanding Sigma-Phase Precipitation in a Stabilized Austenitic Stainless Steel (316nb) through Complementary Calphad-Based and Experimental Investigations. Acta Mater. 2014, 79, 16–29. [Google Scholar] [CrossRef]

- Kil, K.J.; Kim, Y.H.; Lee, B.H.; Kim, K.Y. New Findings on Intergranular Corrosion Mechanism of Stabilized Stainless Steels. Electrochim. Acta 2011, 56, 1701–1710. [Google Scholar]

- Yabuuchi, A.; Maekawa, M.; Kawasuso, A. Influence of Oversized Elements (Hf, Zr, Ti and Nb) on the Thermal Stability of Vacancies in Type 316l Stainless Steels. J. Nucl. Mater. 2012, 430, 190–193. [Google Scholar] [CrossRef]

- Bogdan, P. Effect of Nb and Ti Additions on Microstructure, and Identification of Precipitates in Stabilized Ni-Cr Cast Austenitic Steels. Mater. Charact. 2001, 47, 181–186. [Google Scholar]

- Vitos, L.; Korzhavyi, P.A.; Johansson, B. Elastic Property Maps of Austenitic Stainless Steels. Phys. Rev. Lett. 2002, 88, 155501. [Google Scholar] [CrossRef]

- Levente, V.; Korzhavyi, P.A.; Johansson, B. Modeling of Alloy Steels. Mater. Today 2002, 5, 14–23. [Google Scholar]

- Vijh, A.K. The Pitting Corrosion Potentials of Metals and Surface Alloys in Relation to Their Solid State Cohesion. Mater. Chem. Phys. 1988, 20, 371–380. [Google Scholar] [CrossRef]

- Gschneidner, K.A. Physical Properties and Interrelationships of Metallic and Semimetallic Elements. In Solid State Physics; Seitz, F., Turnbull, D., Eds.; Academic Press: Cambridge, MA, USA, 1964; pp. 275–426. [Google Scholar]

- Li, X.Q.; Zhao, J.J.; Xu, J.C.; Liu, X. Mechanical Properties and Defective Effects of 316ln Stainless Steel by First-Principles Simulations. J. Mater. Sci. Technol. 2011, 27, 1029–1033. [Google Scholar] [CrossRef]

- Clerc, D.G. Mechanical Hardness: Atomic-Level Calculations for Diamond-Like Materials. J. Mater. Sci. Lett. 1998, 17, 1461–1462. [Google Scholar] [CrossRef]

- Levente, V.; Korzhavyi, P.A.; Johansson, B. Stainless Steel Optimization from Quantum Mechanical Calculations. Nat. Mater. 2002, 2, 25–28. [Google Scholar]

- Reeh, S.; Music, D.; Ekholm, M.; Abrikosov, I.A.; Schneider, J.M. Elastic Properties of Fcc Fe-Mn-X (X = Cr, Co, Ni, Cu) Alloys from First-Principles Calculations. Phys. Rev. B 2013, 87, 224103. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, J.; Korzhavyi, P.; Johansson, B. Ab Initio Calculations of Elastic Properties of Fe-Cr-W Alloys. Comput. Mater. Sci. 2014, 84, 301–305. [Google Scholar] [CrossRef]

- Vitos, L. Total-Energy Method Based on the Exact Muffin-Tin Orbitals Theory. Phys. Rev. B 2001, 64, 014107. [Google Scholar] [CrossRef]

- Vitos, L. Computational Quantum Mechanics for Materials Engineers the Emto Method and Applications; Springer: London, UK, 2007. [Google Scholar]

- Vitos, L.; Abrikosov, I.A.; Johansson, B. Anisotropic Lattice Distortions in Random Alloys from First-Principles Theory. Phys. Rev. Lett. 2001, 87, 156401. [Google Scholar] [CrossRef]

- Soven, P. Coherent-Potential Model of Substitutional Disordered Alloys. Phys. Rev. 1967, 156, 809–813. [Google Scholar] [CrossRef]

- Gyorffy, B.L.; Pindor, A.J.; Staunton, J.; Stocks, G.M.; Winter, H. A First-Principles Theory of Ferromagnetic Phase Transitions in Metals. J. Phys. F Met. Phys. 1985, 15, 1337. [Google Scholar] [CrossRef]

- Ceperley, D.M.; Alder, B.J. Ground State of the Electron Gas by a Stochastic Method. Phys. Rev. Lett. 1980, 45, 566–569. [Google Scholar] [CrossRef]

- Vitos, L.; Kollár, J.; Skriver, H.L. Full Charge-Density Scheme with a Kinetic-Energy Correction: Application to Ground-State Properties of the 4d Metals. Phys. Rev. B 1997, 55, 13521–13527. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.L.; Ho, K.M. First-Principles Calculation of the Equilibrium Ground-State Properties of Transition Metals Applications to Nb and Mo. Phys. Rev. B 1983, 28, 5480–5486. [Google Scholar] [CrossRef]

- Murnaghan, F.D. The Compressibility of Media under Extreme Pressures. Proc. Natl. Acad. Sci. USA 1944, 30, 244–247. [Google Scholar] [CrossRef] [PubMed]

- Hill, R. The Elastic Behaviour of a Crystalline Aggregate. Proc. Phys. Soc. A 1952, 65, 349–354. [Google Scholar] [CrossRef]

- Hill, R. Elastic Properties of Reinforced Solids: Some Theoretical Principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Voigt, W. Ueber Die Beziehung Zwischen Den Beiden Elasticitätsconstanten Isotroper Körper. Ann. Phys. 1889, 274, 573–587. [Google Scholar] [CrossRef]

- Reuss, A. Berechnung Der Fließgrenze Von Mischkristallen Auf Grund Der Plastizitätsbedingung Für Einkristalle. PMM J. Appl. Math. Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Ledbetter, H.M. Sound Velocities and Elastic Constants of Steels 304, 310, and 316. Met. Sci. 1980, 14, 595–596. [Google Scholar] [CrossRef]

- Geng, Y.J.; Wang, D.H.; Chen, B.Q.; Cui, F.Z. Orientation Relationships of Crn and Fe3O4 with Gamma—Phase in the High-Dose Nitrogen-Implanted 304 Stainless Steel. J. Phys. D Appl. Phys. 1995, 28, 226. [Google Scholar] [CrossRef]

- Ledbetter, H.M.; Kim, S.A. Molybdenum Effect on Fe-Cr-Ni-Alloy Elastic Constants. J. Mater. Res. 1988, 3, 40–44. [Google Scholar] [CrossRef]

- Wills, J.M.; Eriksson, O.; Söderlind, P.; Boring, A.M. Trends of the Elastic Constants of Cubic Transition Metals. Phys. Rev. Lett. 1992, 68, 2802–2805. [Google Scholar] [CrossRef] [PubMed]

- Hull, F.C. Delta Ferrite and Martensite Formation in Stainless Steels. Weld. J. 1973, 52, 193–203. [Google Scholar]

- Medvedeva, N.I.; van Aken, D.C.; Medvedeva, J.E. Stability of Binary and Ternary M23c6 Carbides from First Principles. Comput. Mater. Sci. 2015, 96, 159–164. [Google Scholar] [CrossRef]

- Moura, V.; Kina, A.Y.; Tavares, S.S.M.; Lima, L.D.; Mainier, F.B. Influence of Stabilization Heat Treatments on Microstructure, Hardness and Intergranular Corrosion Resistance of the Aisi 321 Stainless Steel. J. Mater. Sci. 2008, 43, 536–540. [Google Scholar] [CrossRef]

- Fullman, R.L. A Thermodynamic Model of the Effects of Composition on the Susceptibility of Austenitic Stainless Steels to Intergranular Stress Corrosion Cracking. Acta Metall. 1982, 7, 1407–1415. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent Developments in Stainless Steels. Mater. Sci. Eng. R 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Ha, H.-Y.; Seo, W.-G.; Park, J.Y.; Lee, T.-H.; Kim, S. Influences of Mo on Stress Corrosion Cracking Susceptibility of Newly Developed Fecrmnninc-Based Lean Austenitic Stainless Steels. Mater. Charact. 2016, 119, 200–208. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).