Profile Map of Weld Beads and Its Formation Mechanism in Gas Metal Arc Welding

Abstract

1. Introduction

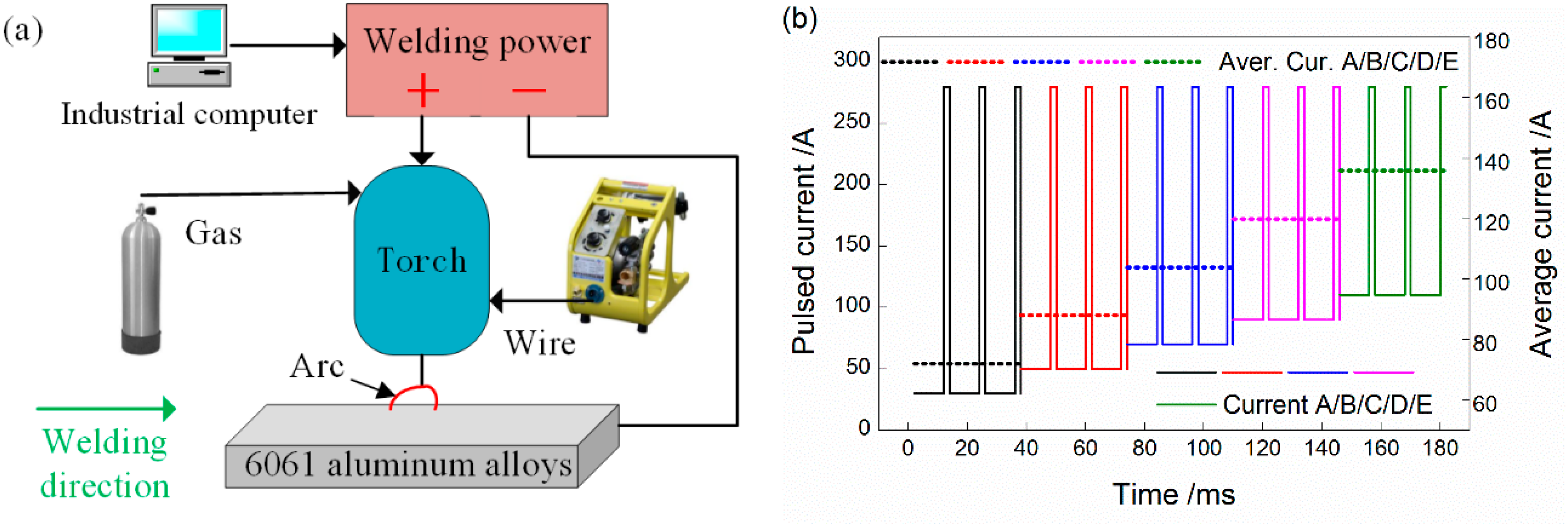

2. Materials and Methods

3. Results and Discussion

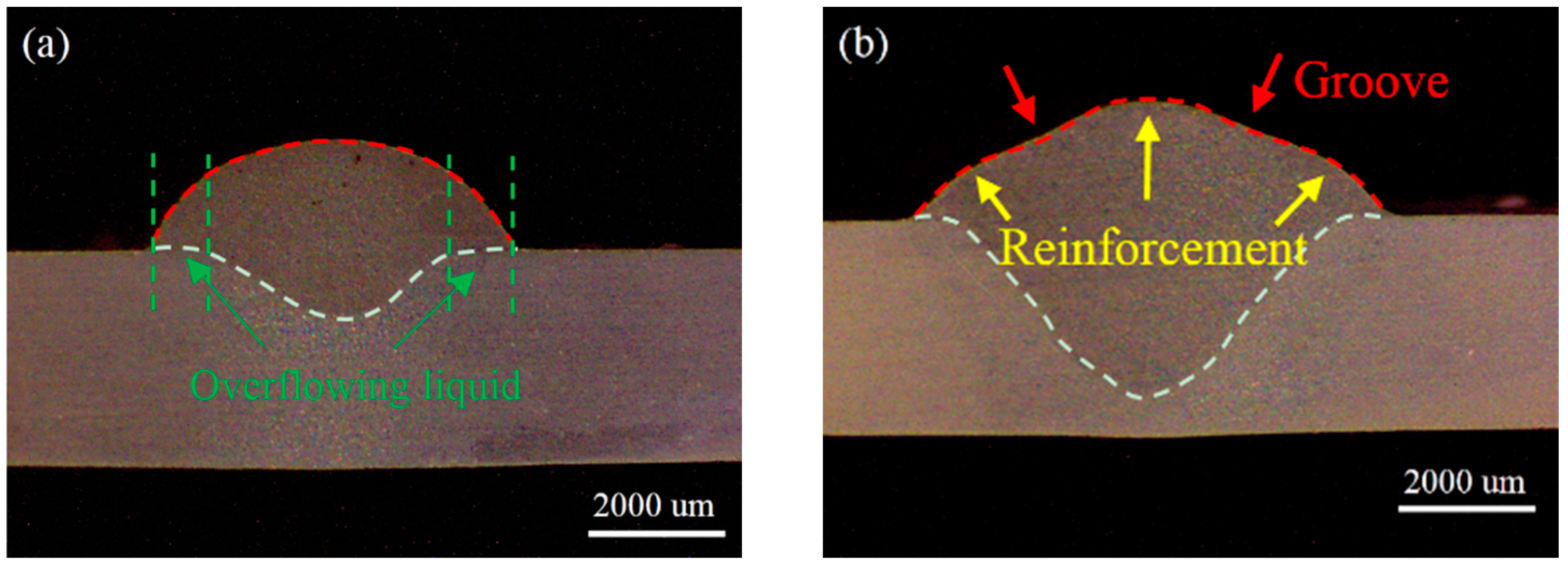

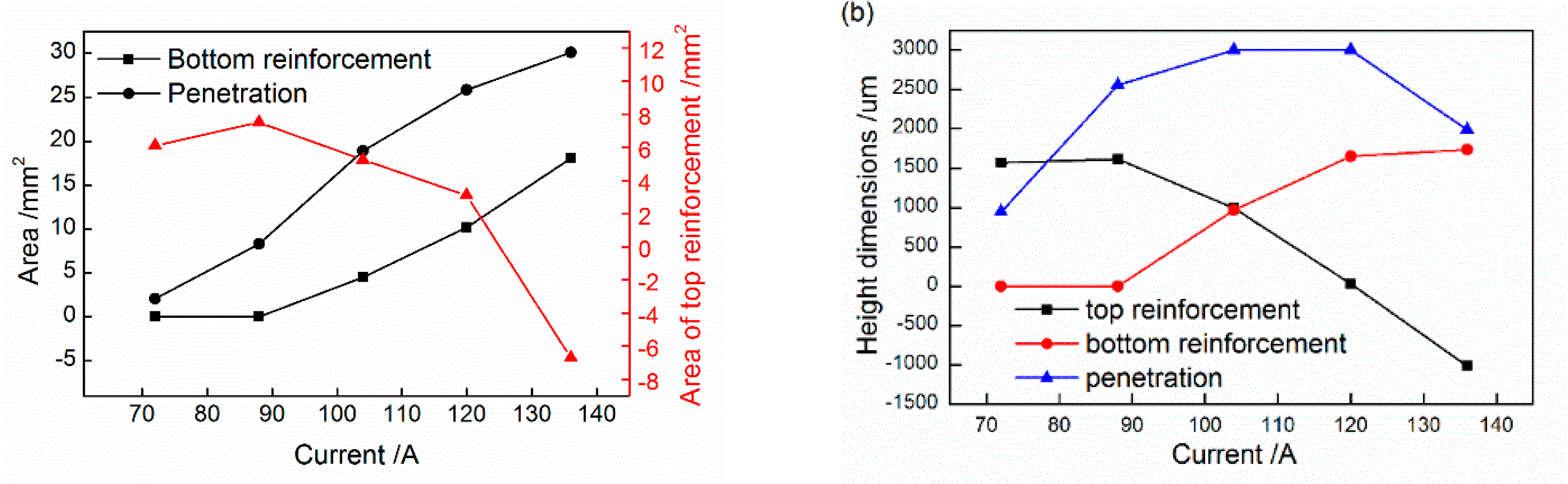

3.1. Profile Map and Stages of Weld Beads

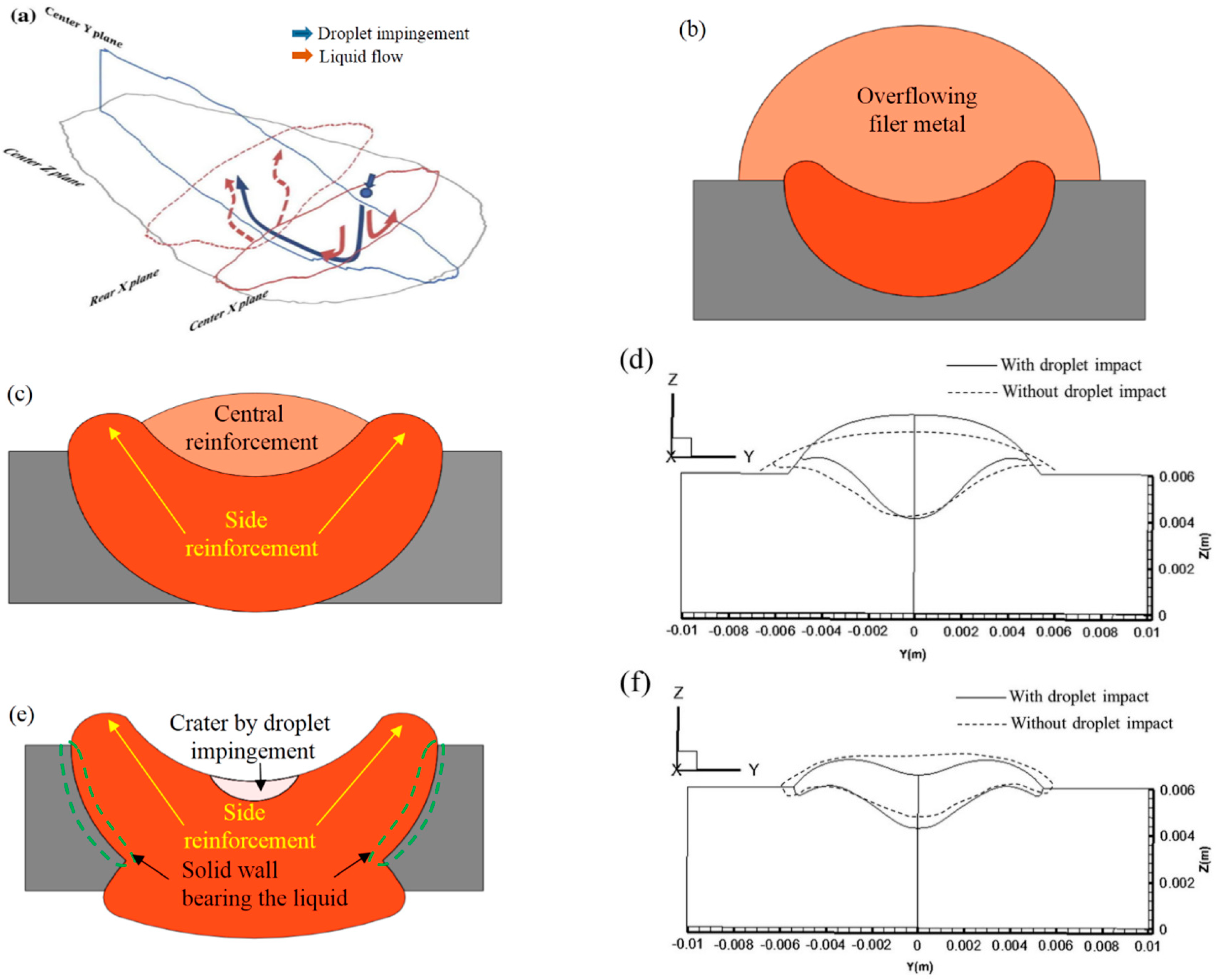

3.2. Formation Mechanism of Reinforcement

3.2.1. W-Shaped Reinforcement

3.2.2. V-Shaped Reinforcement

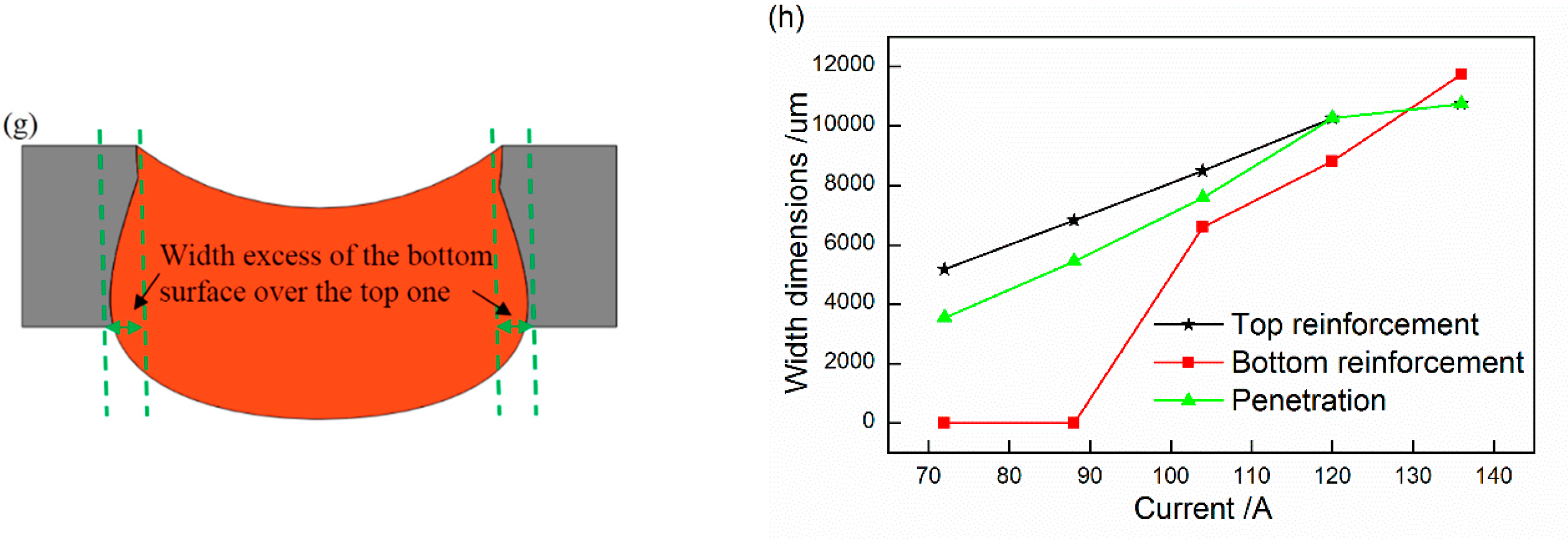

3.2.3. U-Shaped Reinforcement

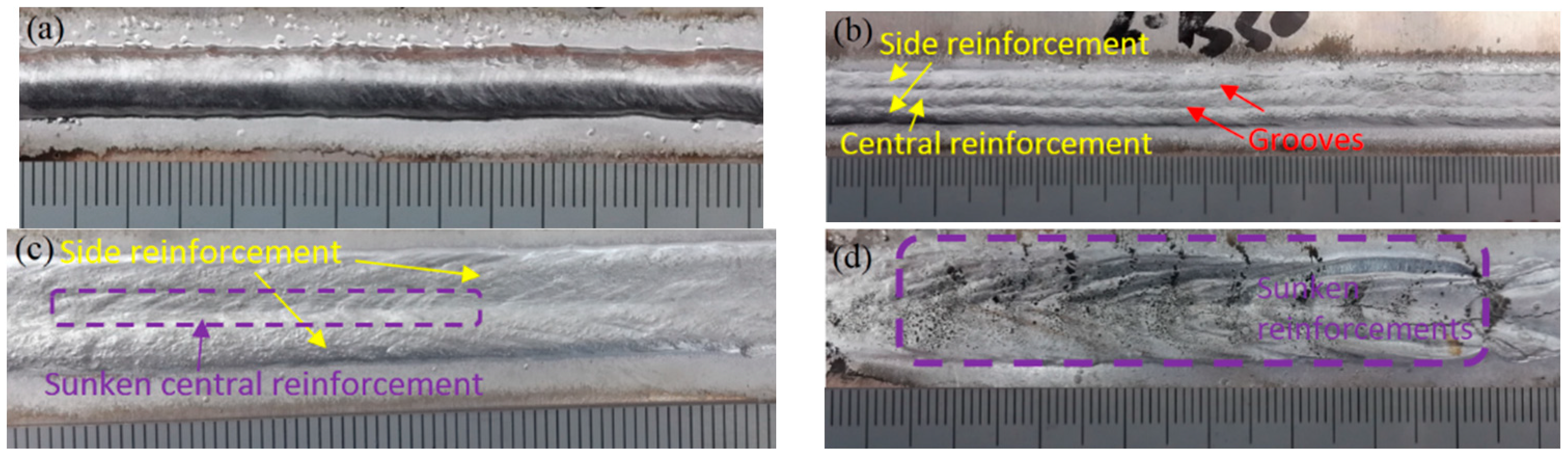

3.2.4. Four Stages of the Top Surface

4. Conclusions

- (1).

- The profile of weld beads obtained over a wide range of welding current in GMAW can be divided into three stages: (i) the filler metal overflowing the weld pool; (ii) the filler metal matching the weld pool; and (iii) the filler metal inadequate for the weld pool.

- (2).

- Both the flow pattern in the weld pool and the profile of a weld bead are determined by the combined effect of driving forces and the significant role played by the weld pool wall, such as bearing, constraining, and redirecting the liquid. The essence of the bottom wall’s role is redirecting and redistributing the molten metal.

- (3).

- The top surface of the reinforcement goes through stages of inversed-U, W, V, and U shapes, which consists of two parts: the central plate and the side plate. The side reinforcement is covered by the central one when the current is at a low level and emerges gradually with increasing current.

Author Contributions

Funding

Conflicts of Interest

References

- Pal, K.; Pal, S.K. Effect of Pulse Parameters on Weld Quality in Pulsed Gas Metal Arc Welding: A Review. J. Mater. Eng. Perform. 2010, 20, 918–931. [Google Scholar] [CrossRef]

- Rao, Z.H.; Zhou, J.; Liao, S.M.; Tsai, H.L. Three-dimensional modeling of transport phenomena and their effect on the formation of ripples in gas metal arc welding. J. Appl. Phys. 2010, 107, 054905. [Google Scholar] [CrossRef]

- Meng, X.; Qin, G.; Zou, Z. Characterization of molten pool behavior and humping formation tendency in high-speed gas tungsten arc welding. Int. J. Heat Mass Transf. 2018, 117, 508–516. [Google Scholar] [CrossRef]

- Wang, L.; Chen, J.; Wu, C.; Gao, J. Backward flowing molten metal in weld pool and its influence on humping bead in high-speed GMAW. J. Mater. Process. Technol. 2016, 237, 342–350. [Google Scholar] [CrossRef]

- Liu, Z.; Fang, Y.; Qiu, J.; Feng, M.; Luo, Z.; Yuan, J. Stabilization of weld pool through jet flow argon gas backing in C-Mn steel keyhole TIG welding. J. Mater. Process. Technol. 2017, 250, 132–143. [Google Scholar] [CrossRef]

- Chai, X.; Yang, Y.K.; Carlson, B.E.; Kou, S. Gas Metal Arc Welding of Magnesium Alloys: Oxide Films, High Crowns, and Fingers. Weld. J. 2015, 94, 16S–33S. [Google Scholar]

- Pang, J.; Hu, S.; Shen, J.; Wang, P.; Liang, Y. Arc characteristics and metal transfer behavior of CMT + P welding process. J. Mater. Process. Technol. 2016, 238, 212–217. [Google Scholar] [CrossRef]

- Fan, H.G.; Kovacevic, R. A unified model of transport phenomena in gas metal arc welding including electrode, arc plasma and molten pool. J. Phys. D Appl. Phys. 2004, 37, 2531–2544. [Google Scholar] [CrossRef]

- Cho, M.H.; Farson, D.F. Understanding Bead Hump Formation in Gas Metal Arc Welding Using a Numerical Simulation. Metall. Mater. Trans. B 2007, 38, 305–319. [Google Scholar] [CrossRef]

- Chen, X.; Yu, G.; He, X.; Li, S.; Miao, H. Effect of droplet impact on molten pool dynamics in hybrid laser-MIG welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 96, 209–222. [Google Scholar] [CrossRef]

- Zhang, Z.; Xue, J.; Jin, L.; Wu, W. Effect of Droplet Impingement on the Weld Profile and Grain Morphology in the Welding of Aluminum Alloys. Appl. Sci. 2018, 8, 1203. [Google Scholar] [CrossRef]

- Liang, Y.; Hu, S.; Shen, J.; Zhang, H.; Wang, P. Geometrical and microstructural characteristics of the TIG-CMT hybrid welding in 6061 aluminum alloy cladding. J. Mater. Process. Technol. 2017, 239, 18–30. [Google Scholar] [CrossRef]

- Pickin, C.G.; Williams, S.W.; Lunt, M. Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Mater. Process. Technol. 2011, 211, 496–502. [Google Scholar] [CrossRef]

- Chen, S.; Xu, B.; Jiang, F. Blasting type penetrating characteristic in variable polarity plasma arc welding of aluminum alloy of type 5A06. Int. J. Heat Mass. Transf. 2018, 118, 1293–1306. [Google Scholar] [CrossRef]

- Mendez, P.F.; Eagar, T.W. Penetration and defect formation in high current arc welding. Weld. J. 2003, 82, S296–S306. [Google Scholar]

- Wang, L.L.; Lu, F.G.; Cui, H.C.; Tang, X.H. Investigation of molten pool oscillation during GMAW-P process based on a 3D model. J. Phys. D Appl. Phys. 2014, 47, 465204. [Google Scholar] [CrossRef]

- Wang, L.; Wu, C.S.; Gao, J.Q. Suppression of humping bead in high speed GMAW with external magnetic field. Sci. Technol. Weld. Join. 2016, 21, 131–139. [Google Scholar] [CrossRef]

- Cheon, J.; Kiran, D.V.; Na, S.J. CFD based visualization of the finger shaped evolution in the gas metal arc welding process. Int. J. Heat Mass Transf. 2016, 97, 1–14. [Google Scholar] [CrossRef]

- Silwal, B.; Santangelo, M. Effect of vibration and hot-wire gas tungsten arc (GTA) on the geometric shape. J. Mater. Process. Technol. 2018, 251, 138–145. [Google Scholar] [CrossRef]

| Material | Mg | Si | Fe | Cu | Mn | Cr | Al |

|---|---|---|---|---|---|---|---|

| AA6061 | 0.96 | 0.52 | 0.25 | 0.25 | 0.12 | 0.26 | Bal. |

| ER4043 | 0.05 | 5.60 | 0.80 | 0.30 | 0.05 | – | Bal. |

| Process Parameters | Value |

|---|---|

| Mean voltage (V) | 24.3 |

| Mean current (A) | A: 72 B: 88 C: 104 D: 120 E: 136 |

| Wire feeding rate (mm/s) | A: 61 B: 71 C: 82 D: 94 E: 103 |

| Wire diameter (mm) | 1.2 |

| Welding speed (mm/s) | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Xue, J. Profile Map of Weld Beads and Its Formation Mechanism in Gas Metal Arc Welding. Metals 2019, 9, 146. https://doi.org/10.3390/met9020146

Zhang Z, Xue J. Profile Map of Weld Beads and Its Formation Mechanism in Gas Metal Arc Welding. Metals. 2019; 9(2):146. https://doi.org/10.3390/met9020146

Chicago/Turabian StyleZhang, Zhanhui, and Jiaxiang Xue. 2019. "Profile Map of Weld Beads and Its Formation Mechanism in Gas Metal Arc Welding" Metals 9, no. 2: 146. https://doi.org/10.3390/met9020146

APA StyleZhang, Z., & Xue, J. (2019). Profile Map of Weld Beads and Its Formation Mechanism in Gas Metal Arc Welding. Metals, 9(2), 146. https://doi.org/10.3390/met9020146