Abstract

In this study, an insert mold casting was fabricated by inserting 2024 Al extruded rods into a 2024 Al melt. The molds were kept at a 2024 Al melt for different times. The 2024 Al extruded rods were used to refine the 2024 Al alloy grains because the advantage of this method is that it is contamination free compared with other grain refiners. Moreover, we investigated the macro and microstructure of the ingots. Further, we analyzed the refinement mechanism of the 2024 Al rod on the 2024 Al alloy. Our result showed that when the immersion time of the 2024 Al insert was 0 s, a metallurgical bonding was partly formed between the 2024 Al insert and the 2024 Al alloy mold cast. When the immersion time of the 2024 Al insert increased to 5 s, the 2024 solid insert was dissolved in the liquid; the coarse dendritic grains were replaced by fine equiaxed grains. The refinement mechanism for the insertion of a 2024 Al rod on the 2024 Al alloy was to melt the 2024 Al insert and have it decrease the degree of the liquid superheat, which thus increased the cooling rate and provided a large number of small particles that acted as the nucleus of heterogeneous nucleation. However, these particles were melted gradually in the high-temperature liquid after an increase of immersion time. Thus, the refinement effect of 2024 Al insert on the solidified structure was weakened.

1. Introduction

Achieving a fine, uniform, and equiaxed grain structure is one of the most important tasks of the solidification process because a fine grain size can reduce hot cracking, porosity, and segregation. Moreover, it can enhance microstructural homogeneity and improve the mechanical properties of as-cast aluminum alloys [1,2,3,4]. Usually, adding grain refiners and/or applying physical stirring can be used to refine grains. Physical means mainly include electromagnetic stirring [5,6,7], ultrasonic stirring [8,9,10], mechanical stirring [11], and gas bubbles [12]. Various electromagnetic stirring technologies such as casting, refining, electromagnetic (CREM), low-frequency electromagnetic casting (LFEC), and annular electromagnetic stirring (A-EMS) have been applied in the solidification process. Nevertheless, still inhomogeneous microstructures are occurring especially in the large-size billets because of the skin effect. For ultrasonic stirring, Kotadia et al. [8] explored grain refinement under ultrasonication. Li et al. [9,10] researched the application of single and multiple ultrasonic treatments during semi-continuous casting. These methods have been used successfully in achieving grain-refined structures, but it is not easy to apply these into the Al casting process due to the requirement of the specific equipment when compared with adding grain refiners.

Various grain refiners have been developed to refine the as-cast structures of aluminum alloys, such as Al-Ti-B alloys, an Al-Ti-C master alloy, a nano-grain refiner, and Zr and Sc elements. It is well known that the Al-5Ti-B master alloy is an effective grain refiner for Al alloys with many advantages, such as having a high utilization ratio of Ti and B, fine refinement effect, and easy automation [13]. However, there are a few issues about this method, such as the poisoning effect [14], agglomeration of nucleating particles [15], and the fading effect [16]. Limmaneevichitr et al. [16] found that the difference in density of both TiAl3 and TiB2 particles was the major factors affecting the fading mechanism, and also confirmed the need to agitate melt before pouring especially in a large crucible of melt. Zhang et al. [17,18] reported that a kind of Al-Ti-B nano-grain refiner prepared using an in-situ reaction synthesis process can solve the problem of agglomeration of nucleating particles. For Zr and Sc elements, the primary Al3Zr or Al3Sc particles formed during solidification can act as nucleation sites to refine grains [19,20]. However, certain agglomeration Al3Zr phases that were combined with complex morphology were formed in the Al-0.2 wt.% Zr alloy [19]. With so many grain refiners, some absent elements in the aluminum alloy melt and the alloy may be contaminated. In addition, applying stirring or adding grain refiners cannot effectively decrease the temperature difference between the central and periphery parts of the melt during solidification. That is because the heat is removed mainly through outside cooling, including mold cooling and water spraying cooling.

Recently, some papers reported the study on Mg/Mg and Al/Al bimetal composites where the solid and the liquid have the same composition. Zhao et al. [21] reported the fabrication of Mg/Mg metal composites via the insert molding method, Liu et al. [22] studied the microstructure and mechanical properties of 6101 wrought Al alloy that were prepared with squeeze castings. Although excellent metallurgical bonding was formed in these studies, the effect of the melting degree of the solid insert on the cooling of the central melt and the solidification structures was not investigated. In this paper, the insert mold casting was fabricated by inserting 2024 Al extrusion rods into a 2024 Al melt and kept at a 2024 melt for different time. The effect of 2024 Al inserts on solidification structures and the refinement mechanism is herein discussed.

2. Experimental Method

2.1. Material Preparation

In this study, we used commercial 2024 aluminum alloy ingots and 2024 aluminum alloy rods 10 mm in diameter and 125 mm in height as materials and inserts, respectively. Their chemical compositions were analyzed through optical emission spectroscopy (FOUNDRY-MASTER Pro, Oxford, UK). Their liquidus temperature and solidus temperature were 638 °C and 507 °C, respectively. The surface of 2024 rods were first polished with 400 grit silicon carbide papers and then treated by alkaline cleaning, acid pickling, and rinsing with alcohol before the experiments.

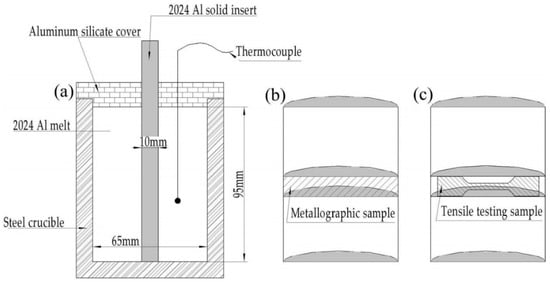

The 2024 aluminum alloys were cut into pieces, then melted in a steel crucible located in an electrical resistance furnace, followed by degassing, stirring, and slagging. When the temperature of the 2024 Al melt was stabilized at 690 °C, the 2024 Al rods (room temperature) were inserted into 2024 Al melt (Figure 1a) and kept at liquid for 0, 5, 20, and 40 s, respectively. The processing parameters of the samples are shown in Table 1. After that the steel crucible was taken out of the furnace and cooled to room temperature in a water tank. In addition, a cast ingot treated without insert was produced for comparison. During the experiments, the temperature data was measured with K-type thermocouples and recorded using a multiple-path temperature measurement instrument (HIOKI LR8402-21, Ueda, Japan). It should be noted that a customized aluminum silicate cover was set on the top of the crucible to keep the 2024 Al insert vertical and centered.

Figure 1.

Schematic diagram of the insert mold casting (a) and the sampling position for metallographic observation (b) and tensile testing (c).

Table 1.

Processing parameters of 2024 Al alloy samples.

2.2. Material Characterizations

The ingots were cut along the center plane and metallographic samples were cut from the middle part of the ingots along the cross section with a thickness of 10 mm, as shown in Figure 1b. Samples for examination macrostructures were etched in 12 wt.% NaOH water solution, pickled in 25 vol.% HNO3 water solution, and observed with a digital camera (Sony A6000, Tokyo, Japan). Samples for examination microstructures were polished using diamond suspensions and anodized at 20 V DC in 5 wt.% HBF4 water solution. The microstructures of the specimens were examined using an OLYMPUS-DX23 (Olympus DX23, Tokyo, Japan) optical microscope (OM) and a ZEISS ULTRA PLUS (Zeiss Ultra Plus, Heidenheim, Germany) scanning electron microscope (SEM) equipped with an energy dispersive spectroscope (EDS). The average grain size was measured according to the standard ASTM E112-96, linear intercept method. Figure 1c shows the sampling position for tensile testing. Tensile specimens were cut into rectangular tensile specimens according to the GBT228-2002 standard. Tensile testing was carried out on a material test machine (MTS CMT5105, Shanghai, China) at a strain rate of 10−3 s−1 and at ambient temperature.

3. Results

3.1. Macro and Micro structure Characterization

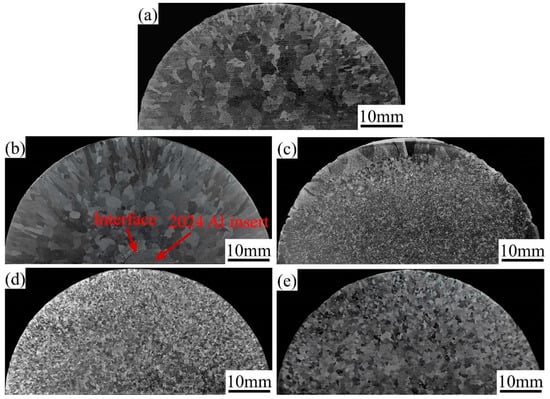

The 2024 Al alloy ingots and the 2024 Al rods have the same composition, which is shown in Table 2. Figure 2 exhibits the macrostructure of the cross section of the ingot without and with a 2024 Al insert. Coarse grains and relatively fine grains can be observed at the inner layer and the periphery of the ingot without 2024 Al insert (Figure 2a), respectively. From Figure 2b, the 2024 Al solid insert was not dissolved in the melt and partly metallurgical bonding was formed between the 2024 solid insert and the mold cast 2024 Al alloy. As shown in Figure 2c, the 2024 solid insert was dissolved in the melt after keeping at 2024 Al melt for 5 s, finer grains were noticed in the central region of the ingot, and the grains were clearly larger at the periphery of the ingot. When the immersion time increased to 20 s (Figure 2d), the solidified structure consisted of fine and uniform grains. However, the grains size of the ingot was increased remarkably while the immersion time of 2024 Al insert increased to 40 s, as shown in Figure 2e.

Table 2.

Chemical compositions of 2024 Al alloys used in this study (wt.%).

Figure 2.

The macrostructure of the cross section of 2024 Al alloy: (a) without 2024 Al insert; (b) with 2024 Al insert and for 0 s immersion; (c) with 2024 Al insert and for 5 s immersion; (d) with 2024 Al insert and for 20 s immersion; (e) with 2024 Al insert and for 40 s immersion.

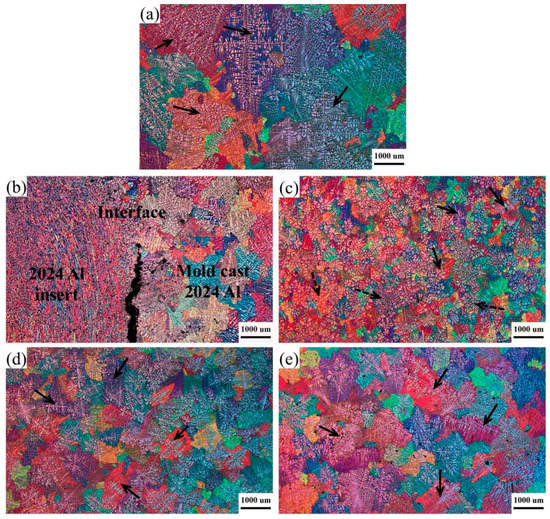

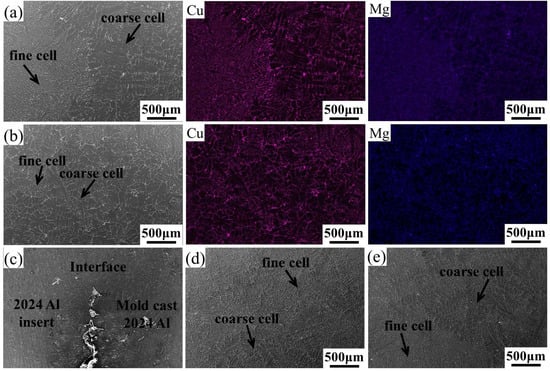

Figure 3 displays the microstructure at the center area of the ingot prepared with and without the 2024 Al insert. Figure 3a presents a duplex structure of grains (as signed by the solid black arrows) with coarse core and fine periphery from the microstructure without the 2024 Al insert, the average grain size was 2815 ± 194 μm. As shown in Figure 3b, partly metallurgical bonding was found between the 2024 solid insert and the mold cast 2024 Al alloys (also shown in Figure 2b and Figure 4b). From Figure 3c, when the immersion time was 5 s, a mixture of coarse-cell grains (as signed by the dashed black arrows) and duplex structured grains (as signed by the solid black arrows) can be observed, and these grains are considerably smaller than those observed in the conventional casting ingot with an average size of 489 ± 31 μm. However, the refinement effect of 2024 Al insert on the solidified structure was weakened for the immersion time above 5 s. The measured average grain size of the ingots increased from 875 ± 58 μm to 1251 ± 109 μm when the immersion time increased from 20 to 40 s, the grains of the ingots also have a duplex structure (as signed by the solid black arrows in Figure 3d,e). Figure 4 shows the SEM images of the samples with and without 2024 Al insert. The duplex structures can also be observed in Figure 4a,b and Figure 4d,e. In order to identify the differences in distributions and contents of alloying elements between the coarse-cell and fine-cell structures, the samples with and without 2024 Al insert were analyzed using EDS through point scan spectrum (Table 3) and area scan spectrum (Figure 4). As shown in Table 2 and Figure 4, the content of Cu and Mg in fine-cell structures was higher than these elements in coarse-cell structures. Thus, the coarse-cell structures cause an inhomogeneous structure and composition, as well as a decrease of the solute content of Cu and Mg in different samples.

Figure 3.

The microstructure at the center area of 2024 Al alloy: (a) without 2024 Al insert; (b) with 2024 Al insert and for 0 s immersion; (c) with 2024 Al insert and for 5 s immersion; (d) with 2024 Al insert and for 20 s immersion; (e) with 2024 Al insert and for 40 s immersion.

Figure 4.

SEM images and area scan spectrum maps of the samples: (a) without 2024 Al insert; (b) with 2024 Al insert and for 5 s immersion; (c) with 2024 Al insert and for 0 s immersion; (d) with 2024 Al insert and for 20 s immersion; (e) with 2024 Al insert and for 40 s immersion.

Table 3.

Point scan spectrum results taken from different positions as denoted by arrows in Figure 4.

3.2. Tensile Tests

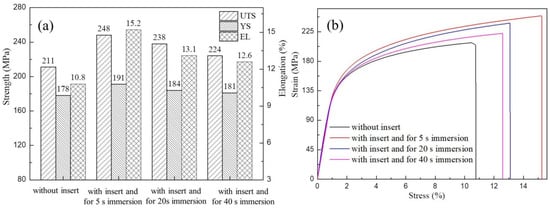

Figure 5 shows the mechanical properties and engineering stress-strain curves of the samples with and without the 2024 Al insert. It can be seen that the mechanical properties of the samples with 2024 Al insert are higher than the sample without 2024 Al insert. In addition, when the immersion time of the 2024 Al insert increased from 5 to 40 s, the ultimate tensile stress (UTS), yield stress (YS), and elongation (EL) decreased from 248 MPa, 191 MPa, 15.2% to 224 MPa, 181 MPa, 12.6%, respectively. This can be explained by the grain size, the homogeneity of structure and composition, and solute levels of Cu and Mg in different samples.

Figure 5.

Tensile properties (a) and engineering stress-strain curves (b) of 2024 Al alloys with and without 2024 Al insert.

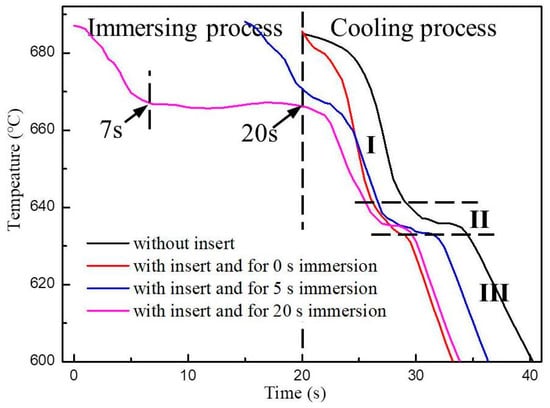

3.3. Thermal Analysis

The time-temperature curves measured during 2024 Al alloy mold casting with and without the 2024 Al insert are presented in Figure 6. The insert mold casting includes the melting of the 2024 Al alloy pieces, the immersing process of the insert, and the cooling process of the melt. The time-temperature curve without 2024 Al insert was taken from the beginning of the cooling process to the melt cooling of 600 °C. Then, the time-temperature curves with the 2024 Al insert were taken from the beginning of the immersion of the 2024 Al insert to the melt cooling of 600 °C. During the immersion process of the insert, the melt temperature decreased gradually until the temperature of the melt and the 2024 Al insert achieved unity. The purple curve in Figure 6 shows that the 2024 Al melt temperature remained unchanged and higher than 638 °C when the immersion time of the 2024 Al insert was above 7 s. This means that the 2024 Al insert have been melted after immersing 7 s in the melt. Thus, the different immersion time of 2024 Al insert has an important effect on the melt temperature and the melting degree of the 2024 Al insert. The melt temperature reflected the superheat degree of the melt. The melting degree of the 2024 Al insert affected the subsequent cooling process. For the conventional 2024 alloy casting, the degree of superheat and the cooling rate of stage I (between the casting temperature and liquidus temperature) were 47.1 °C and 4.6 °C·s−1, respectively. When the cooling process accompanies the insertion of 2024 rod, the cooling rate of 7.1 °C·s−1 was significantly higher than 4.6 °C·s−1 of conventional casting. When the immersion time increased to 5 s, the superheat degree of the melt was less than 45.1 °C and the cooling rate of 4.9 °C·s−1 was still higher than 4.6 °C·s−1. When the immersion time exceeded 7 s, the melt superheat degree was kept at about 28 °C and the cooling rate of the melt was same with the conventional casting. Different temperature curves also reflected that the cooling rate at stage II (near the liquidus temperature) was much less than the cooling rate at stage III (the liquid-solid phase region).

Figure 6.

The results of time-temperature curves measured during 2024 Al alloy mold casting with and without 2024 Al insert.

4. Discussion

Generally, the grain size depends mainly on the heterogeneous nucleation of solid particles and subsequent growth of the nuclei during solidification. In addition, a rapid cooling and low superheat also favor the survival of nuclei and the formation of fine grains.

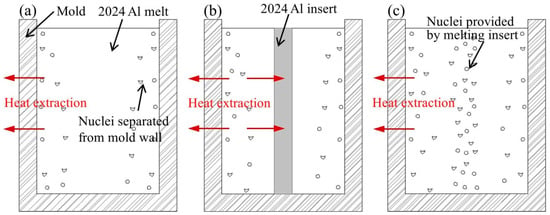

In conventional mold casting, the heat is removed through the mold wall, crystals are nucleated and separated from the mold wall [23], some of these crystals re-melt during the transition process, and the other not melted crystals become the source of equiaxed grains in the ingot, as shown in Figure 7a. In the case of mold casting with 2024 Al insert, the degree of melting for the 2024 Al insert has a significant effect on the structure formation where the melting degree of insert depends on the immersion time [21]. When the cooling process is accompanied with the insertion of 2024 Al rod, the heat is dissipated or absorbed not only through the mold wall but also by means of the latent heat of fusion during melting 2024 Al insert (Figure 7b). Thus, the cooling rate of the melt increases greatly. Due to the rapid cooling of the melt, only the surface zone of the 2024 insert is melted and then partly metallurgical bonding occurs between the two materials. When the immersion time increased to 5 s, the 2024 solid rod is heated to the solid-liquid phase during the immersion process and melt during the subsequent cooling process. Thus, the superheat degree of the melt is decreased, and the cooling rate is increased, which was caused by the latent heat of fusion of the 2024 Al insert during the immersion and cooling process. Due to the low degree of superheat and rapid cooling rate, more nuclei survive and fine grains are formed. Moreover, the melting of 2024 Al insert provides a large number of small particles (Figure 7c), which act as the nucleus of heterogeneous nucleation. Therefore, the 2024 Al insert refined grains by three key mechanisms: decreased the degree of superheat, increased the cooling rate and provided heterogeneous nuclei. When the immersion time was above 7 s, the solid insert was melted and the particles provided by the insert melted gradually in the high-temperature liquid with an increase of immersion time. This explains why the refinement effect of 2024 Al insert on the solidified structure was weakened for the immersion times above 5 s.

Figure 7.

Schematic diagrams of the solidification behavior of 2024 mold casting with and without 2024 Al insert: (a) without 2024 Al insert; (b) with 2024 Al insert - unmelted; (c) with 2024 Al insert - melted.

The relationship between secondary dendrite arm spacing (DAS) and cooling rate is given by the equation [24] d = CVc−n, where d is the secondary DAS, C is a constant depending on the alloy, Vc is the cooling rate in the solidification range, and n is the coarsening exponent, which varies between 0.2 and 0.4 for various aluminum alloys. The equation indicates that the secondary DAS is anticorrelated with the cooling rate. Figure 6 shows the low and high cooling rate at the initial and later stage of the solidification, respectively. Therefore, it can be concluded that the coarse-cell structures reflect grains growing at low cooling rate during the initial stage of solidification and fine-cell structures reflect grains growing at high cooling rate during the later stage of solidification. It should be noted that the solid particles separate from the mold wall or provided by the melting of 2024 Al insert are depleted of solute elements such as Cu and Mg. This can be explained by the distribution coefficient K of Cu and Mg that is less than unity, meaning the concentration of these elements in the solid phase is less than in the liquid phase [25]. Thus, the concentration of Cu and Mg in the early formed solid phase is less than in the latter formed solid phase. This explains why the content of Cu and Mg elements in fine-cell structures is higher than those elements in coarse-cell structures.

In addition, the large-size aluminum alloy billet produced by traditional direct chill (DC) casting has an inhomogeneous structure [10], which is mainly caused by the difference of the cooling strength between the internal and external of the melt. It is believed that the method of insert Al rods with the same compositions as the melt during DC casting can solve this problem.

5. Conclusions

In this paper, the effect of 2024 Al insert on the structures and mechanical properties of 2024 ingots prepared by insert mold casting was discussed. It has been confirmed that the 2024 Al insert affect the grain size and the strength of the castings. The results show that under the condition of 2024 Al insert and for 5 s immersion, the grains size of the 2024 Al alloy reduced from 2815 ± 194 μm (without 2024 Al insert) to 489 ± 31 μm, which was about 80% size reduction. The ultimate tensile stress, yield stress, and elongation of the 2024 Al alloy increased from 211 MPa, 178 MPa, 10.8% to 248 MPa, 191 MPa, 15.2%, respectively. The 2024 Al insert refined solidified structures using three key mechanisms: decreased degree of superheat, increased cooling rate, and a large number of small particles that acted as the nucleus of heterogeneous nucleation. A duplex structure of grains with coarse core and fine periphery was observed from all samples. This structure was formed because the solid particles separated from the mold wall or were provided by the 2024 Al insert and grew at a low cooling rate during the initial stage of solidification, then grew at a high cooling rate during the latter stage of solidification.

Author Contributions

C.Z. and Z.Z. conceived and designed the experiments; S.W. performed the experiments; G.W. and Q.Z. analyzed the data; C.Z. wrote the paper.

Funding

This research was funded by National Natural Science Foundation of China (grant number 51674078), the Fundamental Research Funds for the Central Universities (grant number N170913008) and the Doctoral Start-up Fund of Liaoning Province (grant number 20170520403).

Acknowledgments

The authors would like to thank Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education for the material supply and technical support of the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Spittle, J.A. Columnar to equiaxed grain transition in as solidified alloys. Metall. Rev. 2006, 51, 247–269. [Google Scholar] [CrossRef]

- Easton, M.; Qian, M.; Prasad, A.; Stjohn, D.H. Recent advances in grain refinement of light metals and alloys. Curr. Opin. Solid State Mater. Sci. 2016, 20, 13–24. [Google Scholar] [CrossRef]

- Easton, M.; Grandfield, J.F.; Stjohn, D.H.; Rinderer, B. The Effect of Grain Refinement and Cooling Rate on the Hot Tearing of Wrought Aluminium Alloys. Mater. Sci. Forum. 2006, 519, 1675–1680. [Google Scholar] [CrossRef]

- Fang, Q.; Granger, D. Porosity formation in modified and unmodified A356 alloy castings. AFS Trans. 1989, 97, 989–1000. [Google Scholar]

- Vives, C. Electromagnetic refining of aluminum alloys by the CREM process: Part, I. Working principle and metallurgical results. Metall. Trans. B 1989, 20, 623–629. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Cui, J.Z.; Dong, J.; Zhang, B.J. Effect of low-frequency magnetic field on microstructures and macrosegregation of horizontal direct chill casting 7075 aluminum alloy. J. Mater. Process. Technol. 2007, 182, 185–190. [Google Scholar] [CrossRef]

- Gao, Z.H.; Xu, J.; Zhang, Z.F.; Tang, M.G. Effect of Annular Electromagnetic Stirring on Microstructure and Mechanical Property of 7075 Aluminium Alloy. J. Mater. Sci. Forum. 2013, 749, 75–81. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Qian, M.; Eskin, D.G.; Das, A. On the microstructural refinement in commercial purity Al and Al-10wt% Cu alloy under ultrasonication during solidification. Mater. Des. 2017, 132, 266–274. [Google Scholar] [CrossRef]

- Jiang, R.P.; Li, X.Q.; Zhang, M. Investigation on the mechanism of grain refinement in aluminum alloy solidified under ultrasonic vibration. J. Met. Mater. Int. 2015, 21, 104–108. [Google Scholar] [CrossRef]

- Li, R.Q.; Liu, Z.L.; Dong, F.; Li, X.Q.; Chen, P.H. Grain Refinement of a Large-Scale Al Alloy Casting by Introducing the Multiple Ultrasonic Generators During Solidification. J. Metall. Mater. Trans. A 2016, 47, 3790–3796. [Google Scholar] [CrossRef]

- Zuo, Y.B.; Fan, Z.Y.; Cui, J.Z. Grain refinement of AZ91D alloy by intensive melt shearing and its persistence after remelting and isothermal holding. China Foundry 2013, 10, 39–42. [Google Scholar]

- Wannasin, J.; Martinez, R.A.; Flemings, M.C. Grain refinement of an aluminum alloy by introducing gas bubbles during solidification. Scr. Mater. 2006, 55, 115–118. [Google Scholar] [CrossRef]

- Zhu, Q.F.; Zhao, Z.H.; Cui, J.Z.; Zuo, Y.B.; Wang, X.J. Effect of combined application of electromagnetic fields on horizontal direct chill casting of 7050 aluminium alloy. Mater. Sci. Technol. 2008, 24, 560–566. [Google Scholar] [CrossRef]

- Bunn, A.M.; Schumacher, P.; Kearns, M.A.; Boothroyd, C.B.; Greer, A.L. Grain refinement by Al–Ti–B alloys in aluminium melts: A study of the mechanisms of poisoning by zirconium. Mater. Sci. Technol. 1999, 15, 1115–1123. [Google Scholar] [CrossRef]

- Gazanion, F.; Chen, X.G.; Dupuis, C. Studies on the Sedimentation and Agglomeration Behavior of Al-Ti-B and Al-Ti-C Grain Refiners. Mater. Sci. Forum. 2002, 396, 45–52. [Google Scholar] [CrossRef]

- Limmaneevichitr, C.; Eidhed, W. Fading mechanism of grain refinement of aluminum–silicon alloy with Al–Ti–B grain refiners. Mater. Sci. Eng. A 2003, 349, 197–206. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Le, Y.K.; Ma, N.H.; Wang, H.W.; Li, S.C. Effect of AlTiB Nano-Grain Refiner on Mechanical Property and Damping Capacity of ZL101 Alloy. Rare Met. Mater. Eng. 2006, 35, 476–479. [Google Scholar]

- Zhang, Y.J.; Ma, N.H.; Le, Y.K.; Li, S.C.; Wang, H.W. Mechanical properties and damping capacity after grain refinement in A356 alloy. Mater. Lett. 2005, 59, 2174–2177. [Google Scholar] [CrossRef]

- Zhu, Q.F.; Zhu, C.; Kang, Y.L.; Kong, S.P.; Zhao, Z.H.; Zuo, Y.B. Effect of Zr content on the existence form of Zr element and as-cast structure of high purity commercial aluminium. Int. J. Mater. Res. 2018, 109, 1027. [Google Scholar]

- Knipling, K.E.; Karnesky, R.A.; Lee, C.P.; Dunand, D.C.; Seidman, D.N. Precipitation evolution in Al–0.1Sc, Al–0.1Zr and Al–0.1Sc–0.1Zr (at.%) alloys during isochronal aging. Acta Mater. 2010, 58, 5184–5195. [Google Scholar] [CrossRef]

- Zhao, K.N.; Liu, J.C.; Nie, X.Y.; Li, Y.; Li, H.X.; Du, Q.; Zhuang, L.Z.; Zhang, J.S. Interface formation in magnesium–magnesium bimetal composites fabricated by insert molding method. Mater. Des. 2016, 91, 122–131. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.D.; Sun, Y.D.; Wang, Q.G. Microstructure and Mechanical Properties of Overcast 6101-6101 Wrought Al Alloy Joint by Squeeze Casting. J. Mater. Sci. Technol. 2016, 4, 298–304. [Google Scholar] [CrossRef]

- Ohno, A. Solidification of Metals; Chijin Shokan: Tokyo, Japan, 1984. [Google Scholar]

- Eskin, D.G. Physical Metallurgy of Direct Chill Casting of Aluminum Alloy; CRC Press: New York, NY, USA, 2008; pp. 22–24. [Google Scholar]

- Eskin, D.G.; Nadella, R.; Katgerman, L. Effect of different grain structures on centerline macrosegregation during direct-chill casting. Acta Mater. 2008, 56, 1358–1365. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).