Hot Deformation Process Analysis and Modelling of X153CrMoV12 Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

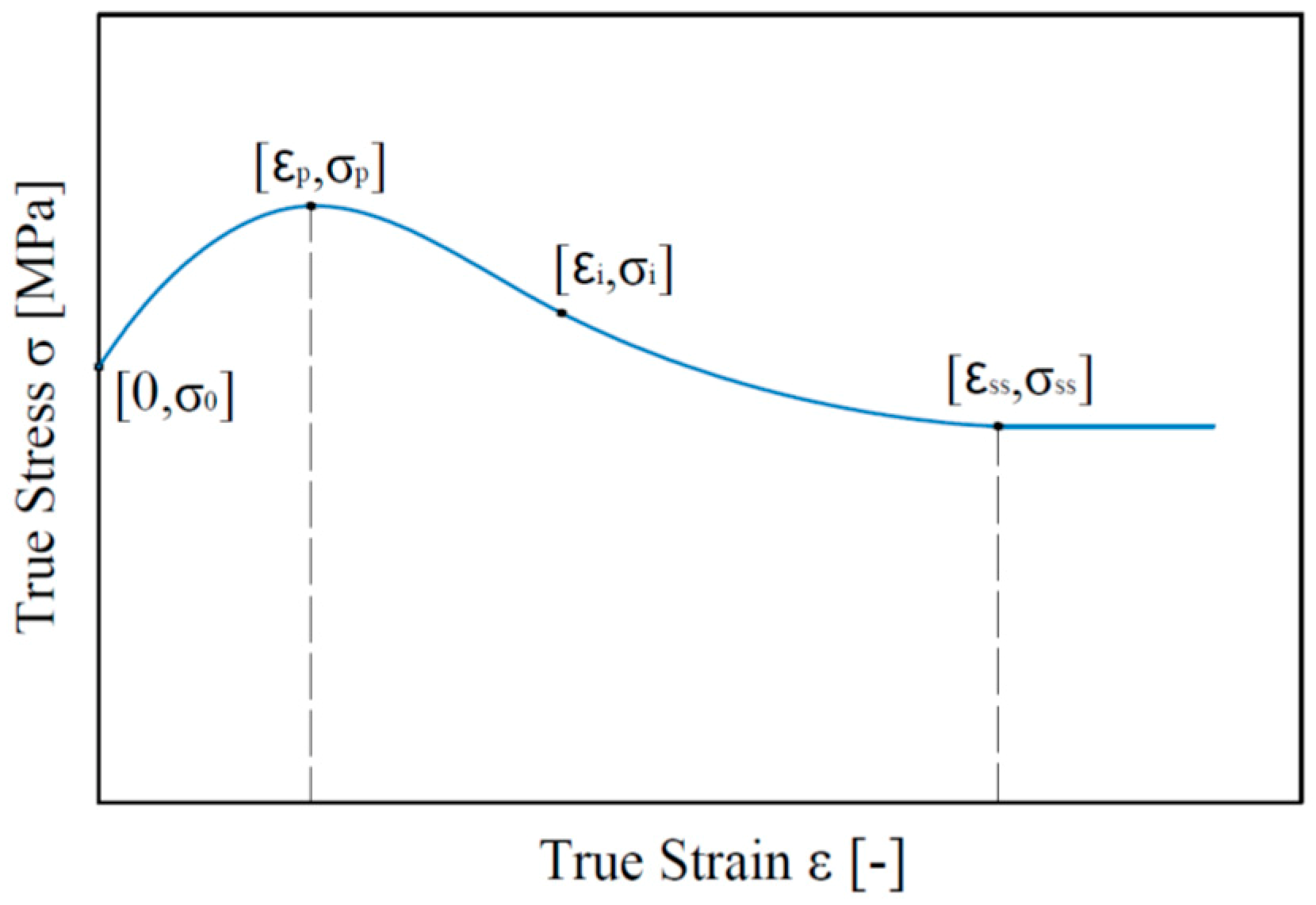

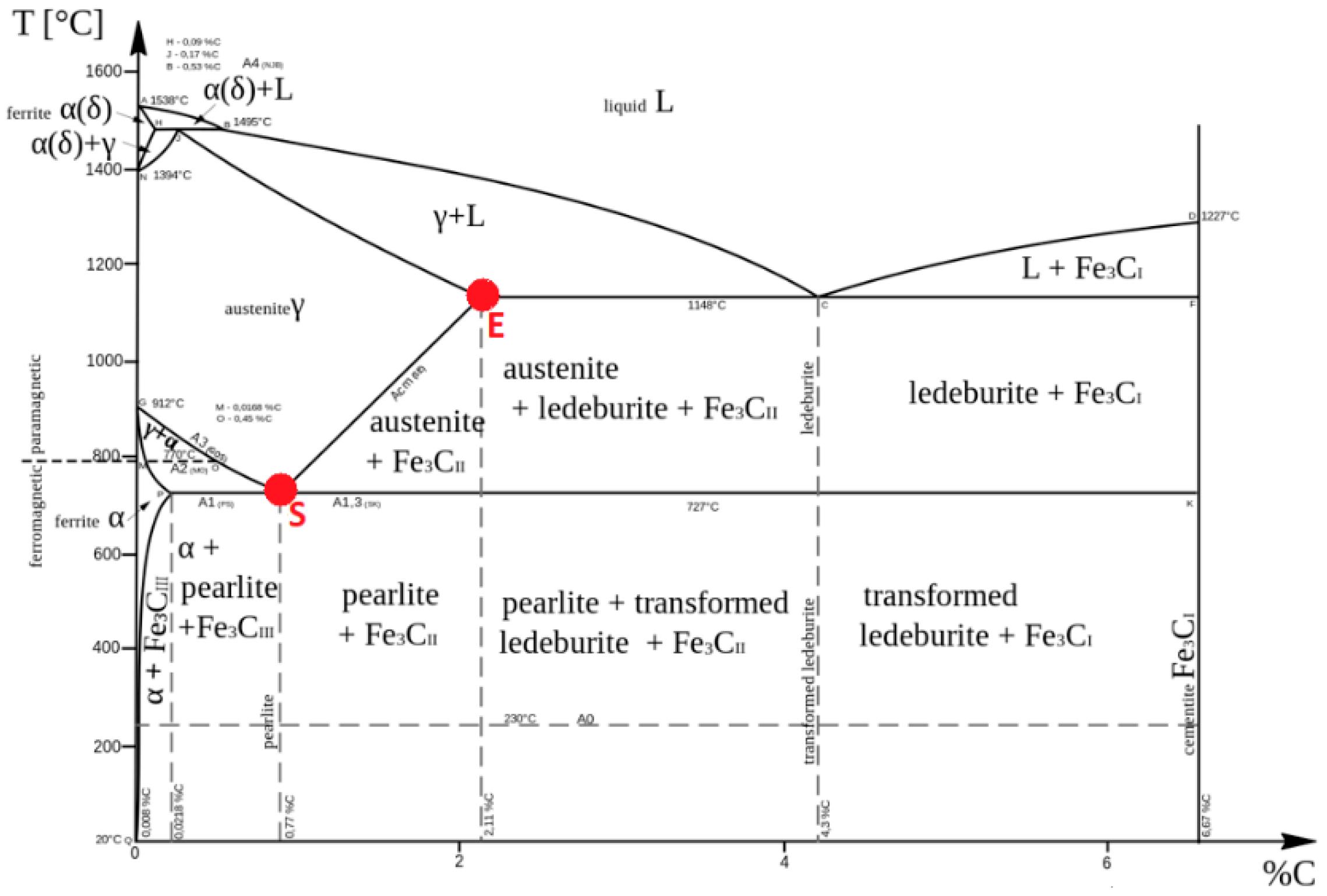

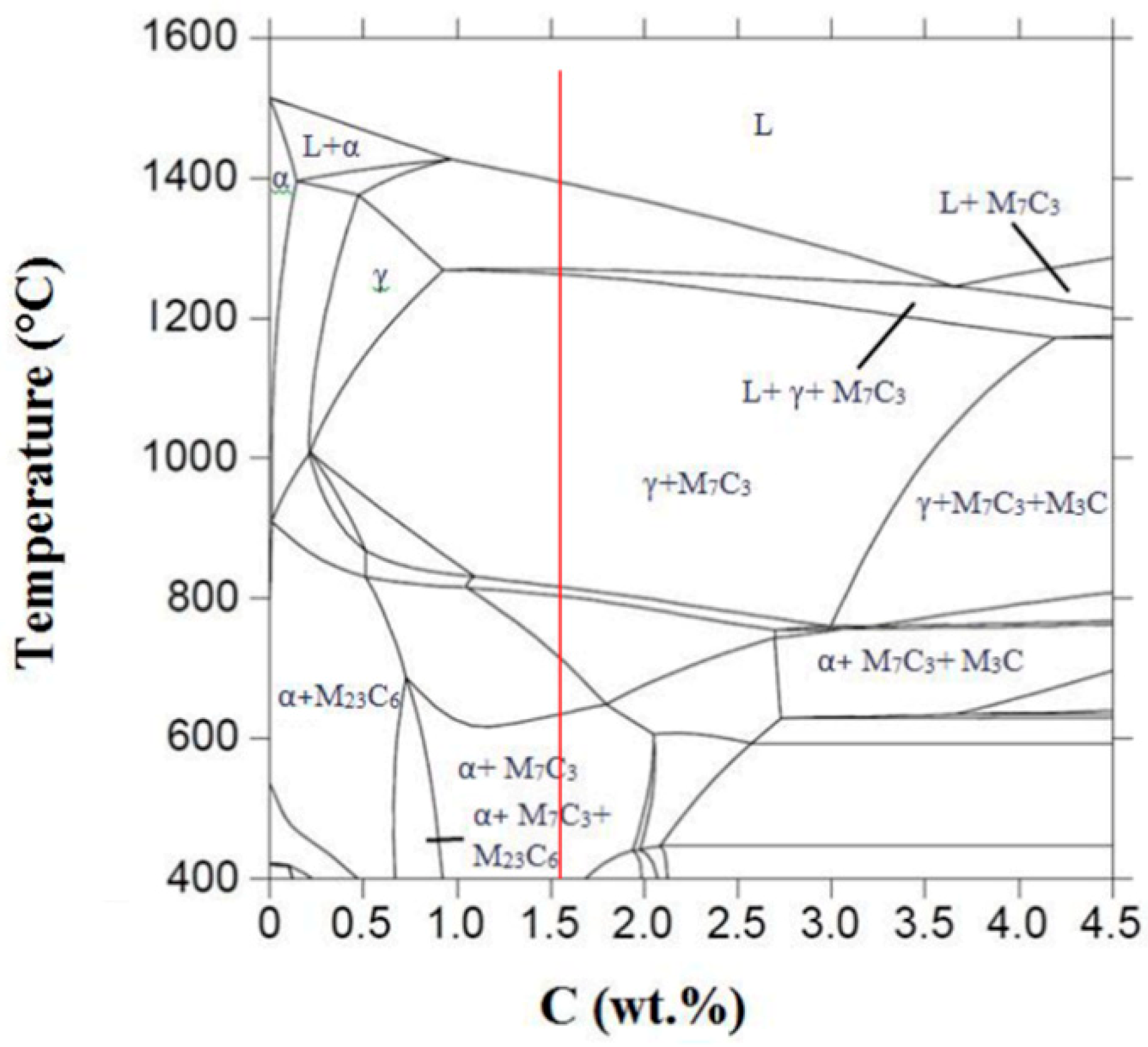

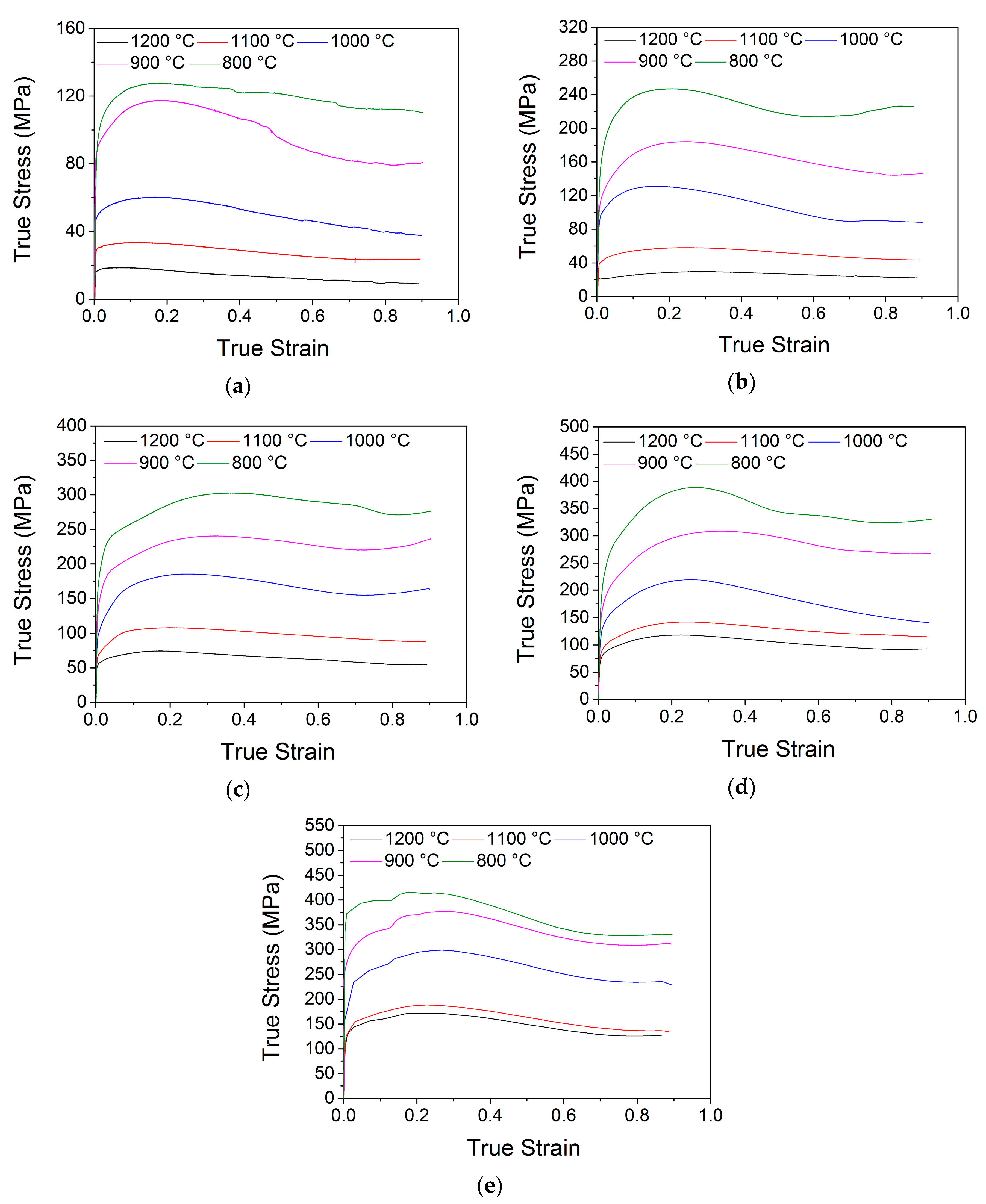

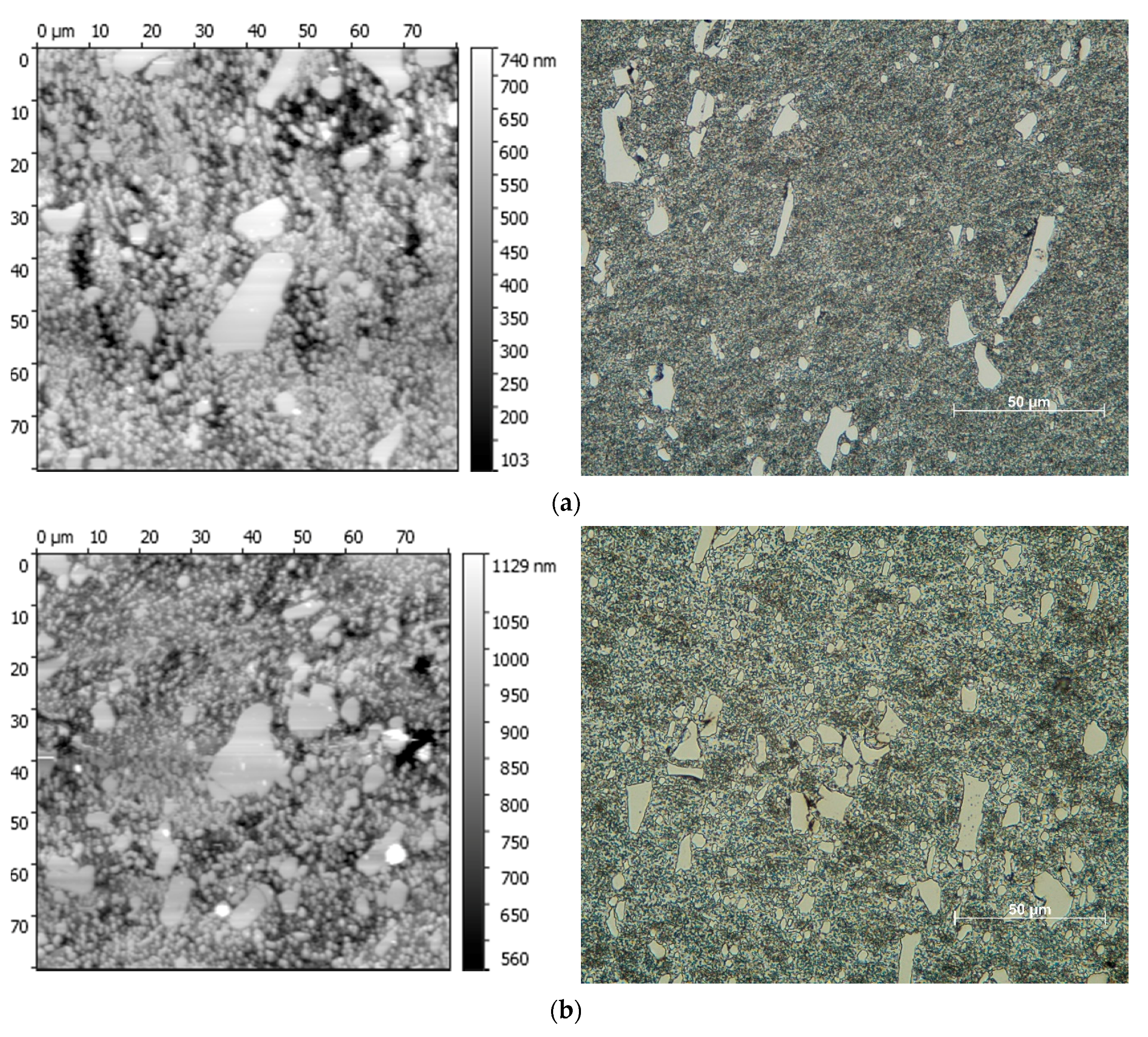

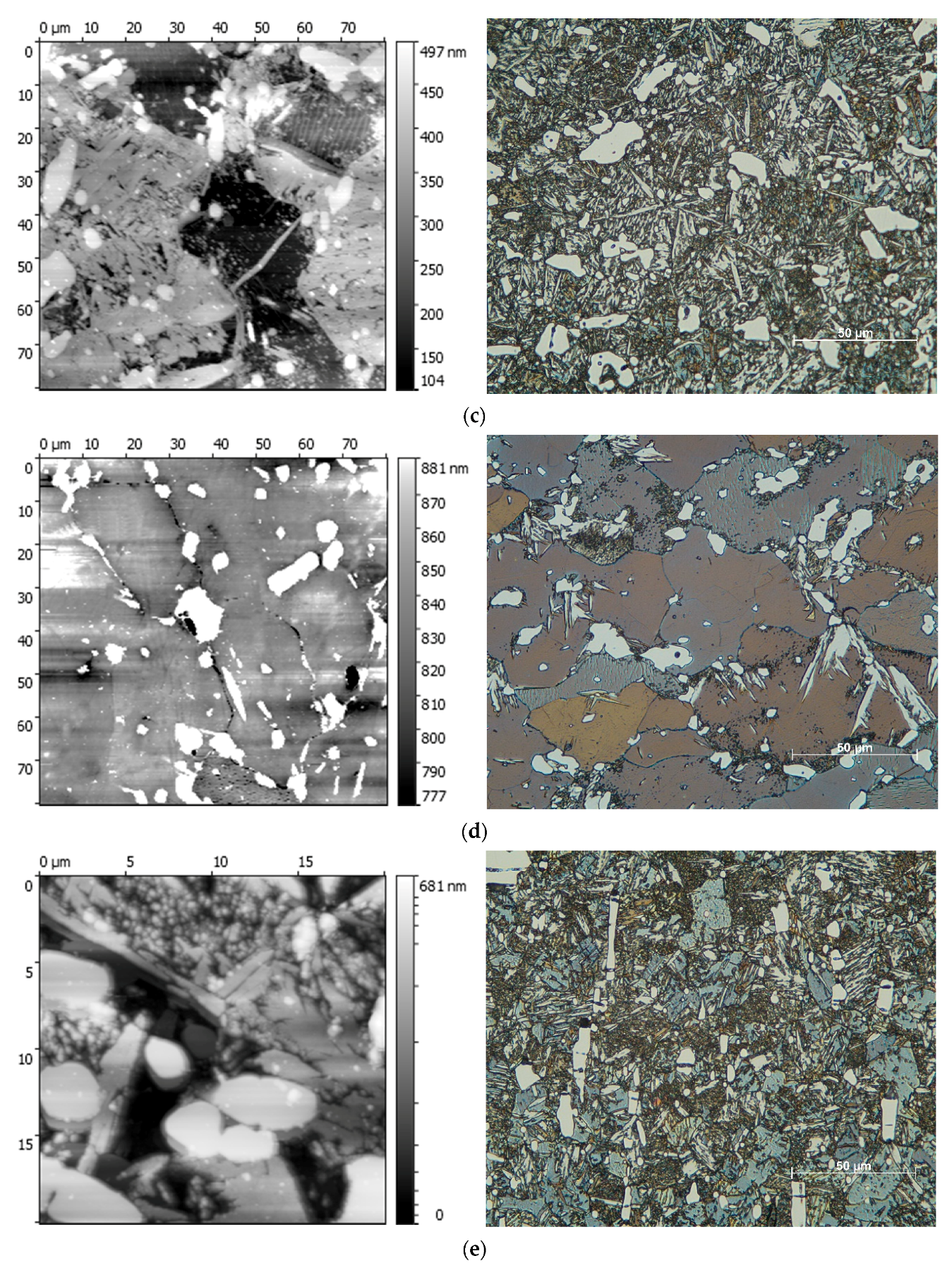

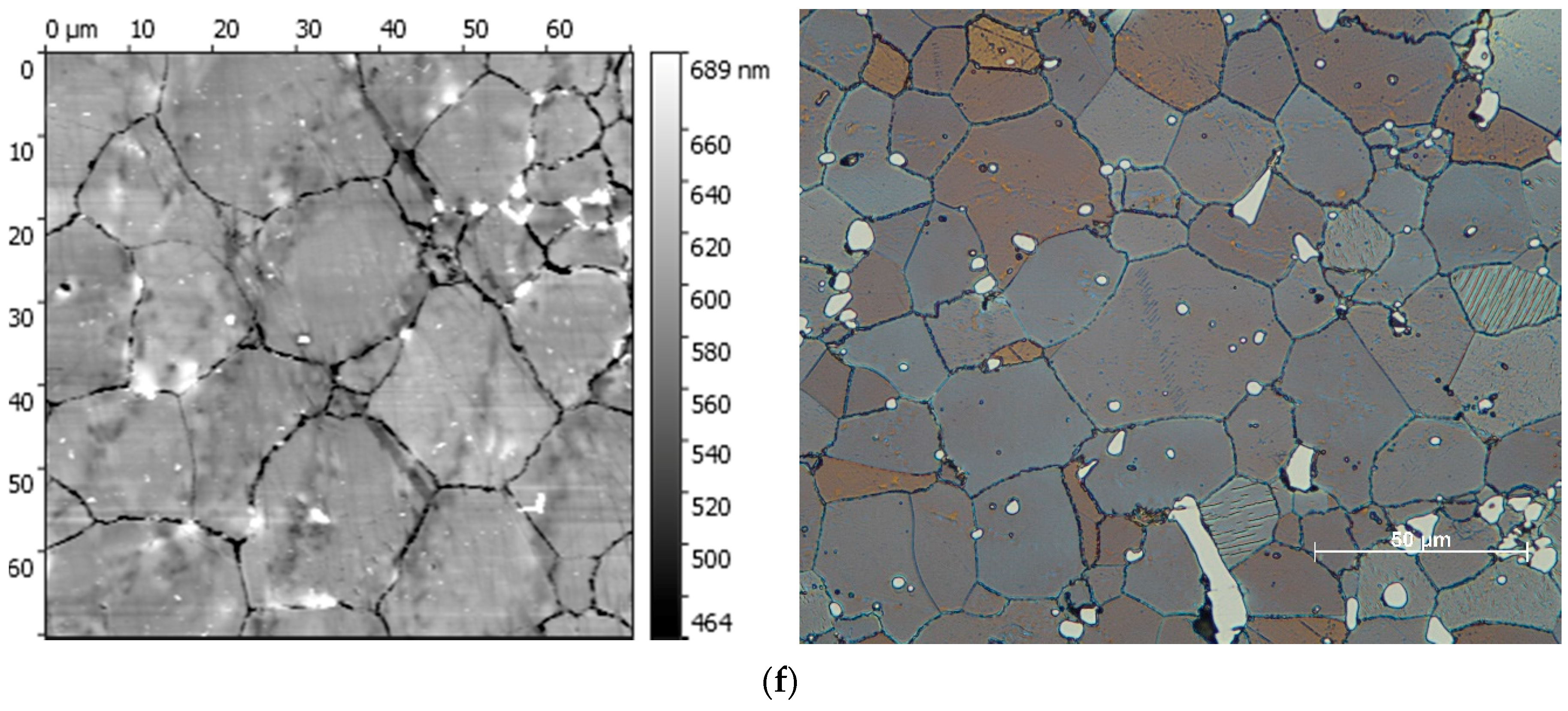

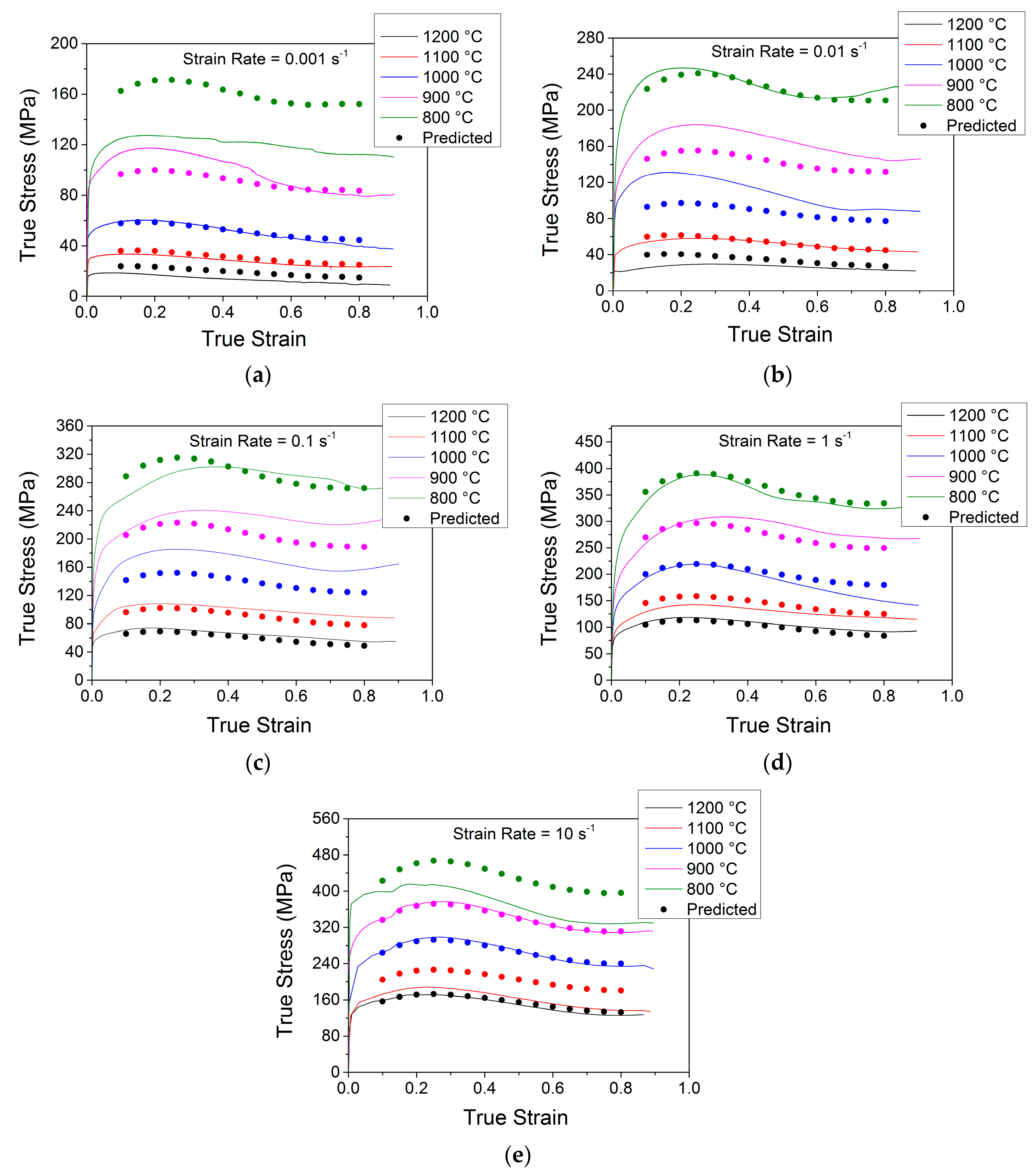

3.1. True Stress–Strain Behavior and Microstructure of X153CrMoV12 Steel

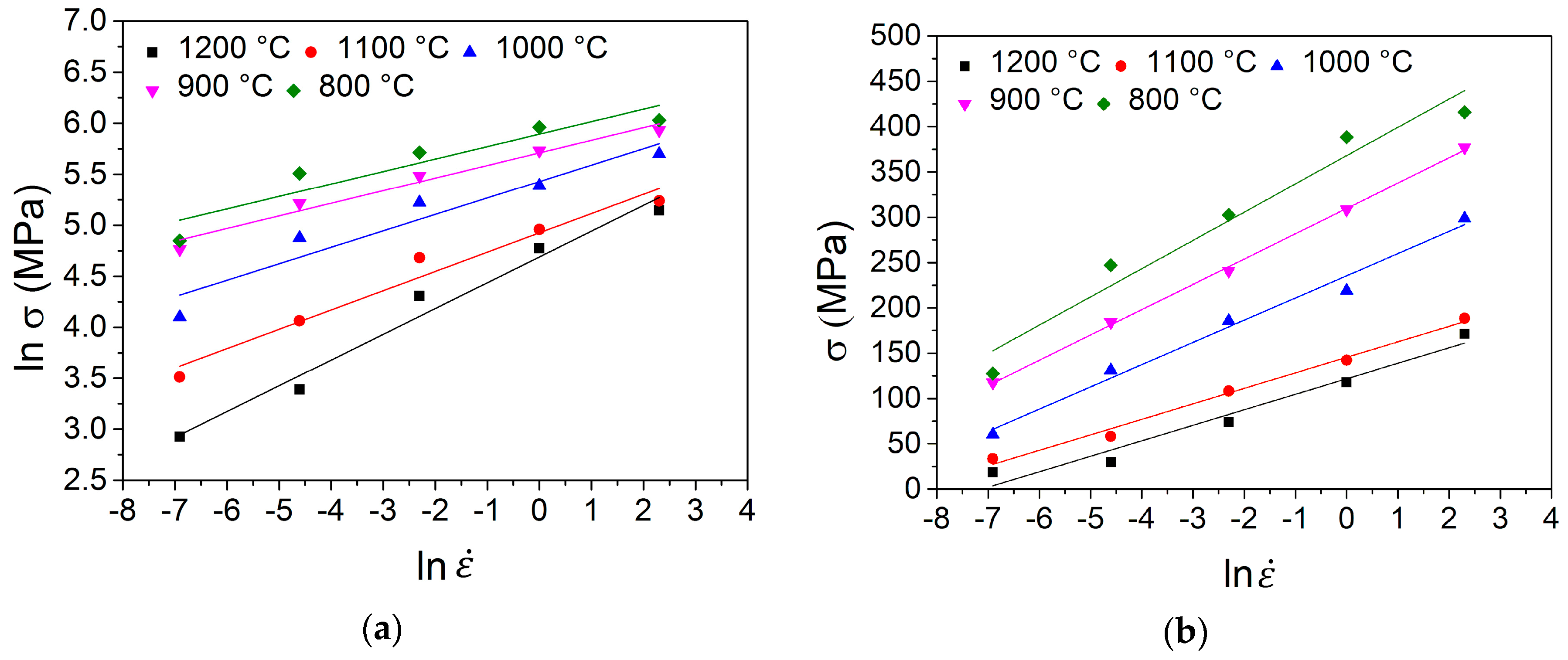

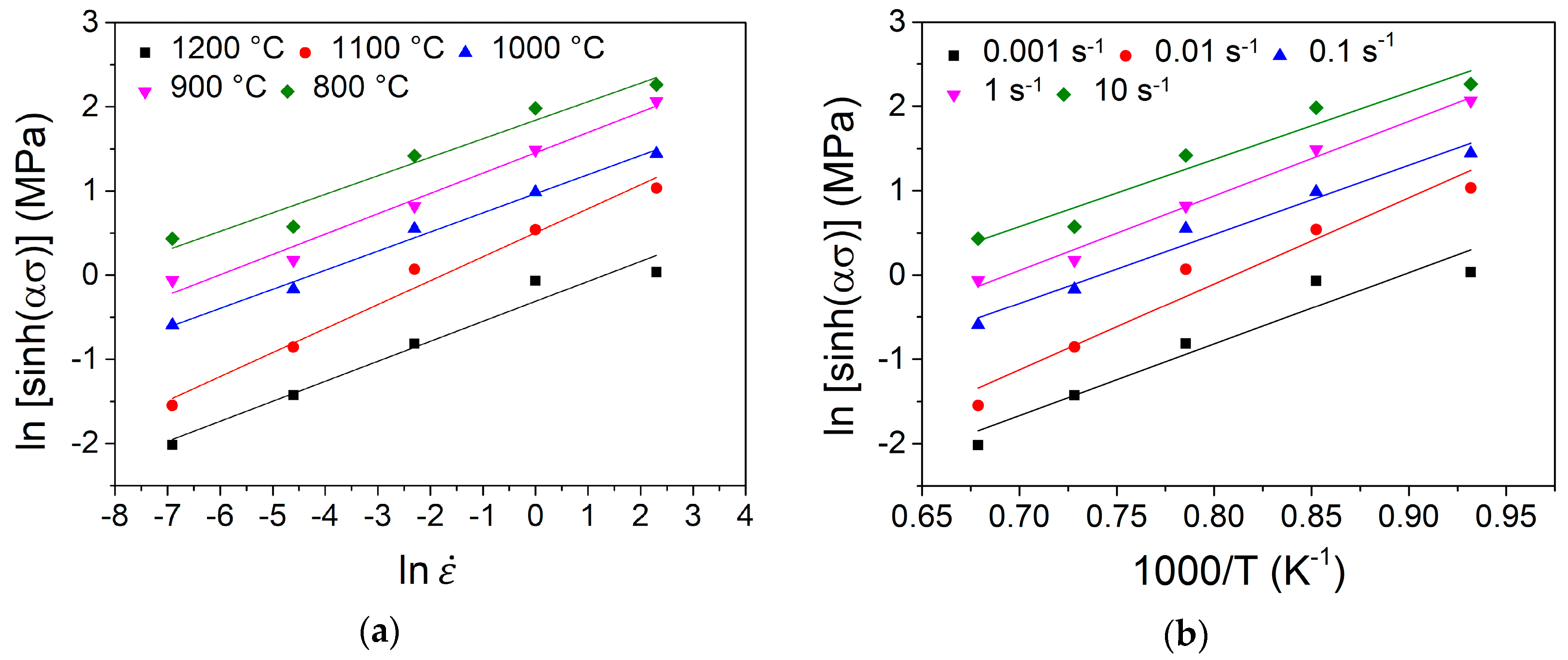

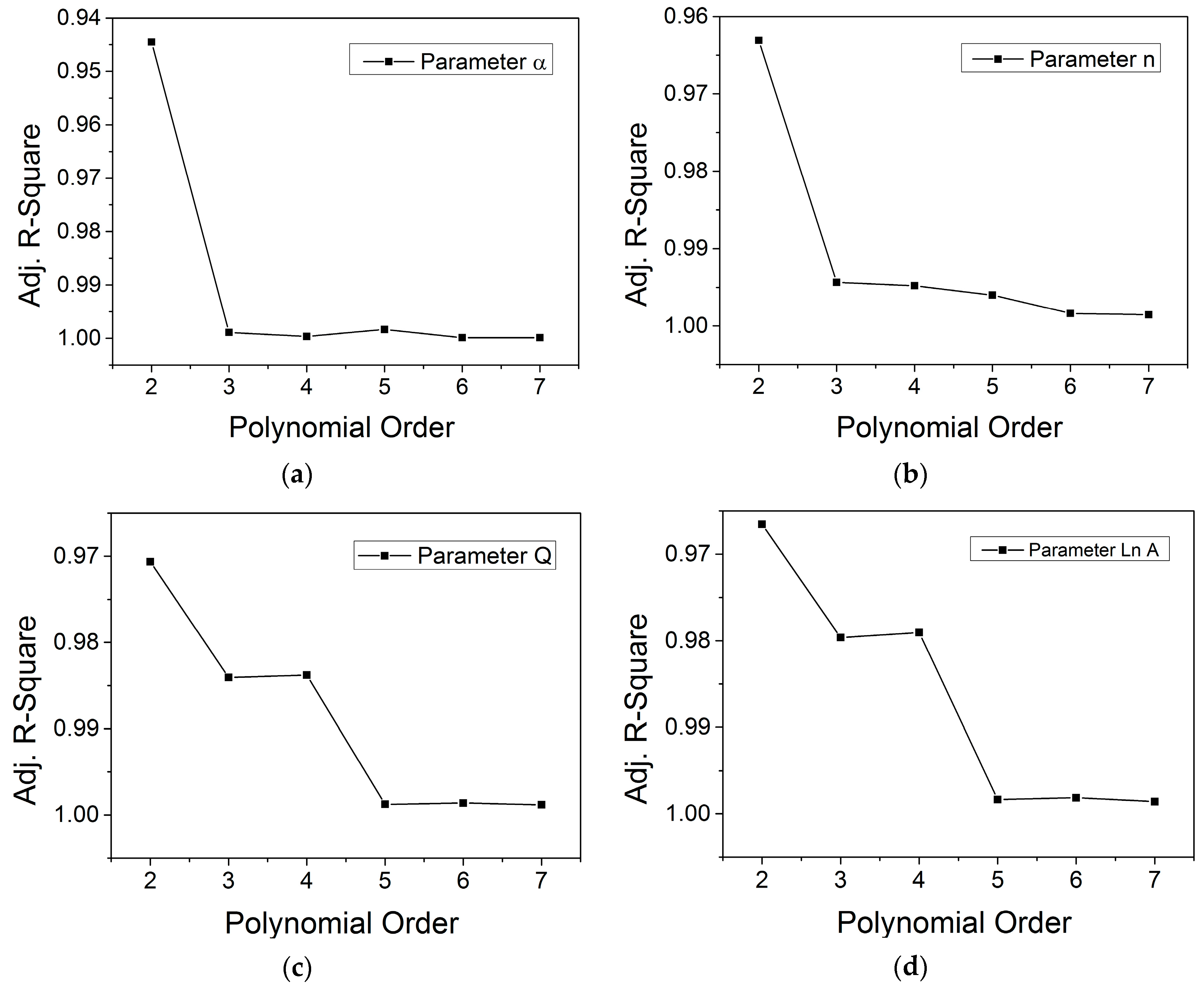

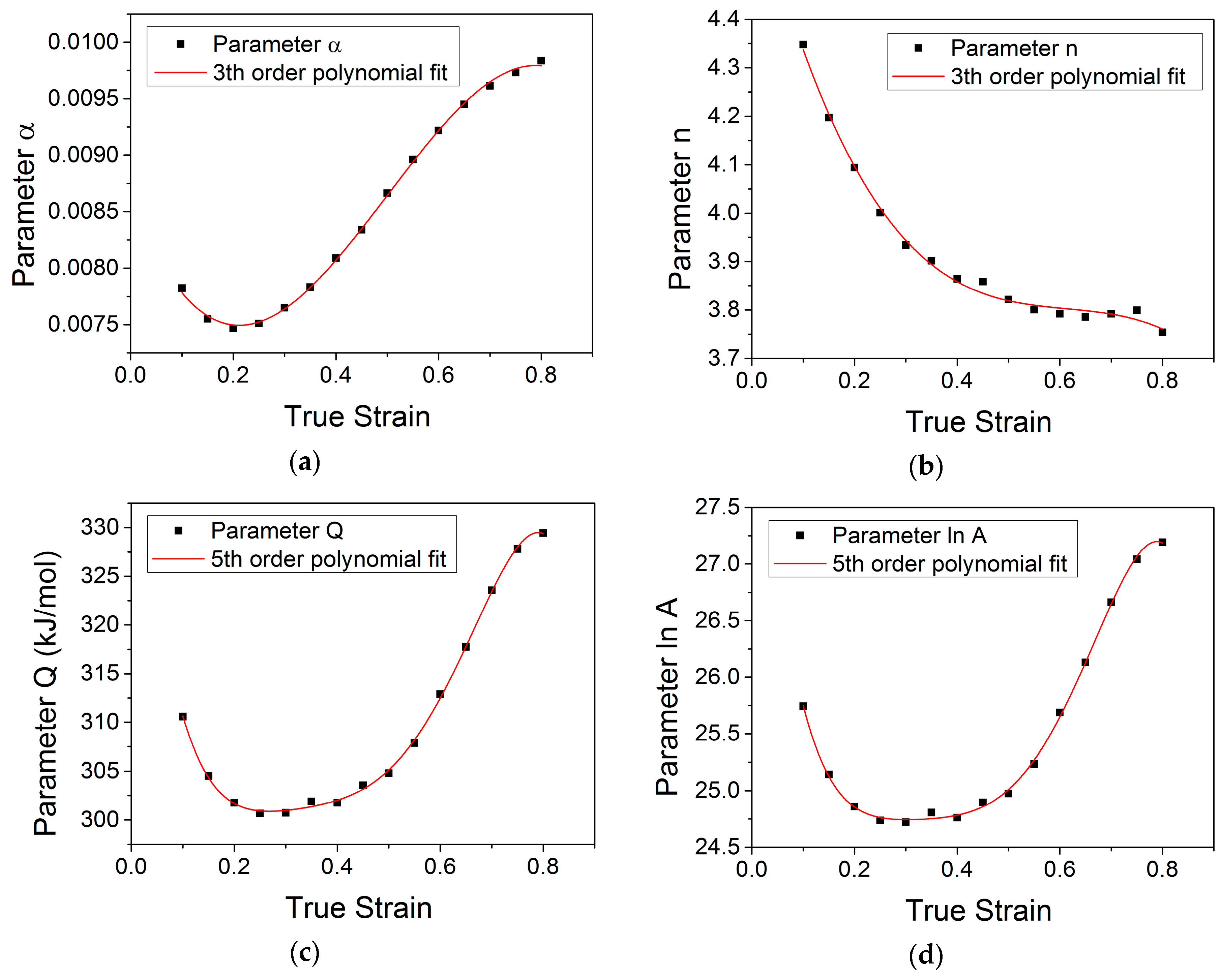

3.2. Constitutive Modelling

4. Discussion

5. Conclusion

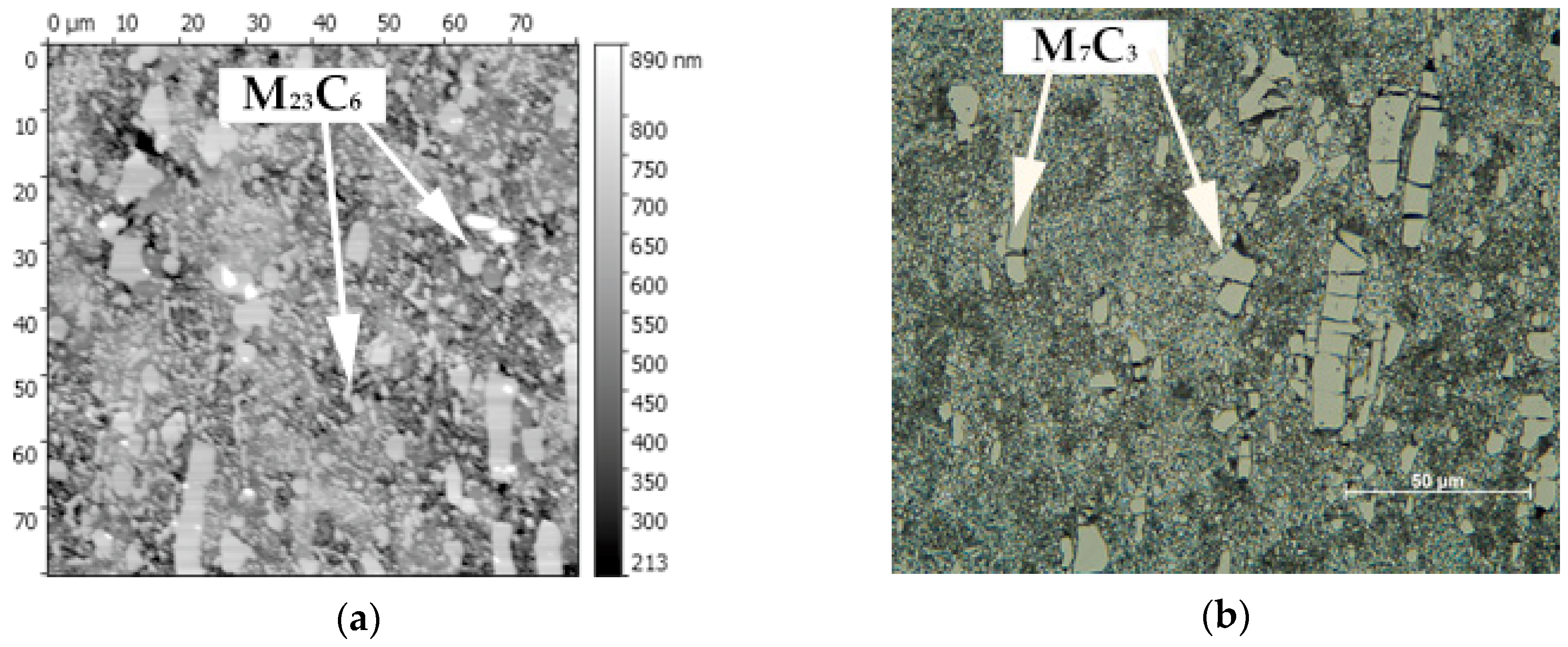

- The microstructure of X153CrMoV12 steel in normalized condition consists of a mixture of coarse M7C3 and fine M23C6 carbides embedded in a ferritic matrix. This microstructure also persisted at low deformation temperatures (T = 800 °C) due to annealing and deformation below critical transformation temperatures.

- High deformation temperature (T = 1200 °C) triggered microstructural changes due to the preceding phase transformations and DRX. As a result, the final microstructure had a polygonal ferritic matrix with the carbides deposited at the grain boundaries. In addition, an increase of deformation rate resulted in the obvious grain refinement as an aftermath of proceeding DRX.

- X153CrMoV12 steel exhibits DRX with a single peak stress in the entire range of temperatures and deformation rates. When peak stress is reached, softening mechanisms start to prevail, which at higher deformation temperatures, balanced with the hardening mechanisms. Finally, the steady state stress stabilizes the flow stress. In case of lower temperatures, where the peak stress is also significant, there is also a significant DRX process in play. Therefore, a significantly refined structure could be observed using both the AFM as well as the LOM technique.

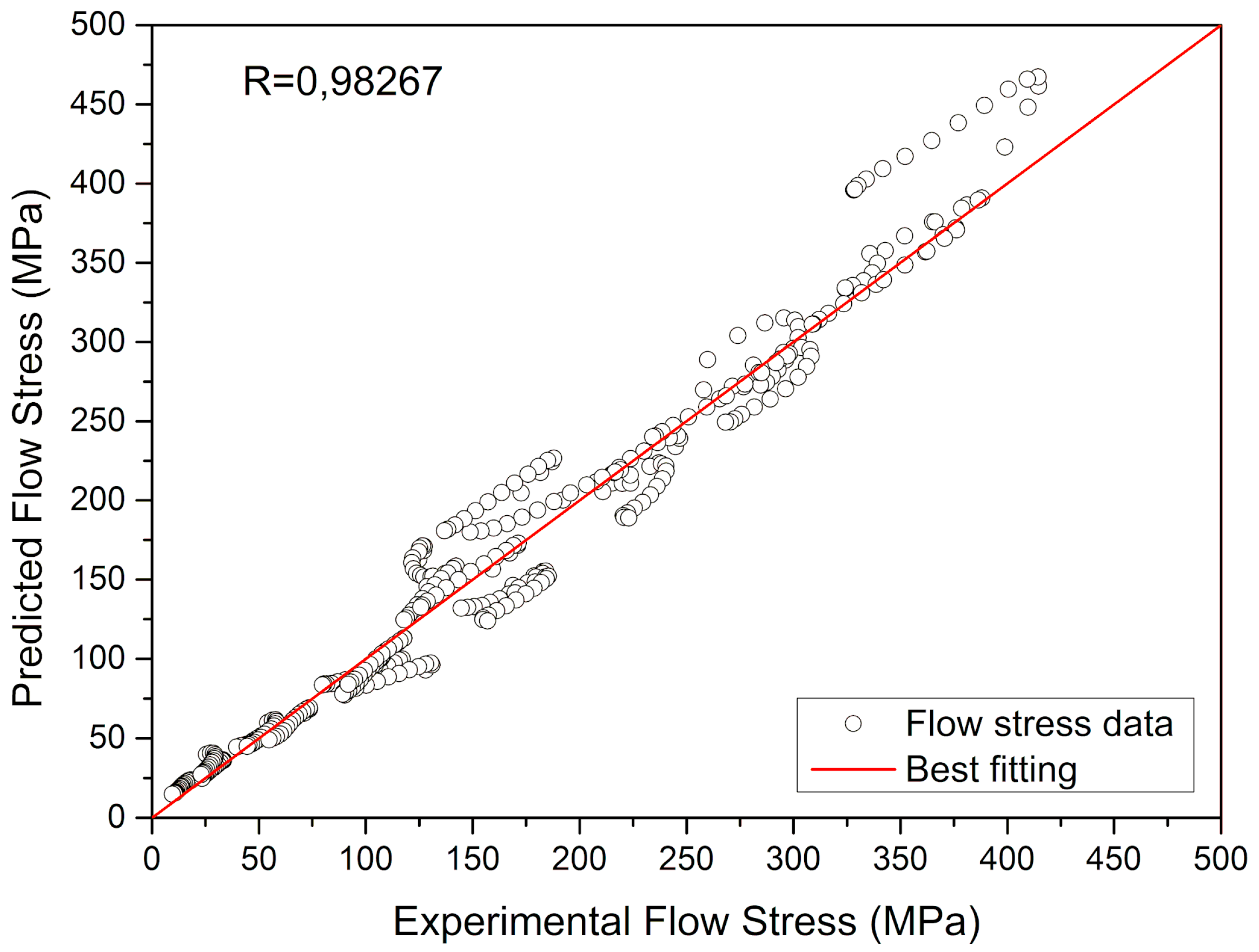

- With constitutive model and flow curves it is possible to obtain material parameters and thus predict true stress and strain behavior in a wide range of temperatures and deformation rates. Material parameters can be obtained by polynomial fitting of the third and fifth order, respectively, which also preserves a certain physical meaning of the parameters while maintaining relative mathematical simplicity.

- The flow stress prediction using the above procedure is in relatively good agreement with the experimental flow stress patterns obtained with the correlation coefficient of R = 0.98267. Such a result, along with a graphical comparison of predicted and measured flow stress patterns, allows the use of a constitutive model for predicting the flow curves during hot deformation for these types of high-strength steels.

Author Contributions

Funding

Conflicts of Interest

References

- Pernis, R.; Kasala, J.; Bořuta, J. High temperature plastic deformation of CuZn30 brass-calculation of the activation energy. Kov. Mater. 2010, 48, 41–46. [Google Scholar] [CrossRef]

- Garofalo, P. An Empirical Relationship Defining the Stress Dependence of Minimum Creep Rate in Metals. Trans. Metall. Soc. AIME 1963, 227, 351–355. [Google Scholar]

- Sellars, C.M.; Tegart, W.J. Hot Workability. Int. Metall. Rev. 1972, 17, 1–24. [Google Scholar] [CrossRef]

- Lenard, J.G. Modelling Hot Deformation of Steels: An Approach to Understanding and Behaviour, 1st ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1989; pp. 1–33. [Google Scholar]

- Bai, D.Q.; Yue, S.; Sun, W.P.; Jonas, J.J. Effect of deformation parameters on the no-recrystallization temperature in Nb-bearing steels. Metall. Trans. A 1993, 24A, 2151–2159. [Google Scholar] [CrossRef]

- Maccagno, T.M.; Jonas, J.J.; Yue, S.; McCrady, B.J.; Slobodian, R.; Deeks, D. Determination of Recrystallization Stop Temperature from Rolling Mill Logs and Coparison with Laboratory Simulation Results. ISIJ Int. 1994, 34, 917–922. [Google Scholar] [CrossRef]

- Spigarelli, S.; Cabibbo, M.; Evangelista, E.; Bidulská, J. A study of the hot formability of an Al-Cu-Mg-Zr alloy. J. Mater. Sci. 2003, 38, 81–88. [Google Scholar] [CrossRef]

- Solhjoo, S. Analysis of flow stres sup to the peak at hot deformation. Mater. Des. 2009, 30, 3036–3040. [Google Scholar] [CrossRef]

- Ptačinová, J.; Sedlická, V.; Hudáková, M.; Dlouhý, I.; Jurči, P. Microstructure—Toughness relationship in sub-zero treated and tempered Vanadis 6 steel compared to conventional treatment. Mater. Sci. Eng. A 2017, 702, 241–258. [Google Scholar] [CrossRef]

- Yang, J.; Cao, B.; Wu, Y.; Gao, Z.; Hu, R. Continuous cooling transformation (CCT) behavior of a high Nb-containing TiAl alloy. Materialia 2019, 5, 100169. [Google Scholar] [CrossRef]

- Sobotova, J.; Jurci, P.; Dlouhy, I. The effect of subzero treatment on microstructure, fracture toughness, and wear resistance of Vanadis 6 tool steel. Mater. Sci. Eng. A 2016, 652, 192–204. [Google Scholar] [CrossRef]

- Jurči, P.; Dománková, M.; Hudáková, M.; Ptačinová, J.; Pašák, M.; Palček, P. Characterization of microstructure and tempering response of conventionally quenched, short- and long-time sub-zero treated PM Vanadis 6 ledeburitic tool steel. Mater. Charact. 2017, 134, 398–415. [Google Scholar] [CrossRef]

- Fischmeister, H.F.; Riedl, R.; Karagöz, S. Solidification of high-speed tool steels. Metall. Trans. A 1980, 20, 2133–2148. [Google Scholar] [CrossRef]

- Hetyner, D.W. Refining carbide size distributions in M1 high speed steel by processing and alloying. Mater. Charact. 2001, 46, 175–182. [Google Scholar] [CrossRef]

- Kheirandish, S. Effect of Ti and Nb on the formation of carbides and the mechanical properties in As-cast AISI-M7 high-speed steels. ISIJ Int. 2001, 41, 1502–1509. [Google Scholar] [CrossRef]

- Pirtovšek, T.V.; Kugler, G.; Godec, M.; Terčelj, M. Microstructural characteritation during the hot deformation of 1.17C-11.3Cr-1.48V-2.24W-1.35Mo ledeburitic tool steel. Mater. Charact. 2011, 62, 189–197. [Google Scholar] [CrossRef]

- Valloton, J.; Herlach, D.; Henein, H. Effect of convection on the dendride groeth kinetics in undercooled melts of D2 tool steels. IPO Conf. Ser. Mater. Sci. Eng. 2016, 117, 012058. [Google Scholar] [CrossRef]

- Hunkel, M.; Surm, H.; Steinbacher, M. Dilatometry. In Handbook of Thermal Analysis and Calorimetry; Vazovkin, S., Koga, N., Schick, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 6, pp. 103–129. [Google Scholar]

- Berkowski, L. The influence of warm plastic deformation on the structure and on the applicable properties of high speed steel. J. Mater. Process. Technol. 1996, 60, 637–641. [Google Scholar] [CrossRef]

- Lan, L.; Zhou, W.; Misra, R.D.K. Effect of hot deformation parameters on flow stress and microstructure in a low carbon microalloyed steel. Mater. Sci. Eng. A 2019, 756, 18–26. [Google Scholar] [CrossRef]

- Jha, J.S.; Toppo, S.P.; Singh, R.; Tewari, A.; Mishra, S.K. Flow stress constitutive relationship between lamellar and equiaxed microstructure during hot deformation of Ti-6Al4V. J. Mater. Process. Technol. 2019, 270, 216–227. [Google Scholar] [CrossRef]

- McQueen, H.J.; Yue, S.; Ryan, N.D.; Fry, E. Hot working characteristic of steels in austenitic state. J. Mater. Process. Technol. 1995, 53, 293–310. [Google Scholar] [CrossRef]

- Solhjoo, S.; Vakis, A.I.; Pei, Y.T. Two phenomenological models to predict the single peak flow stress curves up to the peak during hot deformation. Mech. Mater. 2017, 105, 61–66. [Google Scholar] [CrossRef]

- Jiang, L.; Fuguo, L.; Jun, C. Constitutive Model Prediction and Flow Behavior Considering Strain Response in the Thermal Processing for the TA15 Titanium Alloy. Materials 2018, 11, 1985. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr-1Mo steel. Comput. Mater. Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Shang, X.; Cui, Y.; Fu, M.W. A ductile fracture model considering stress state and Zener-Hollomon parameter for hot deformation of metallic materials. Int. J. Mech. Sci. 2018, 144, 800–812. [Google Scholar] [CrossRef]

- Choudhary, B.K. Activation energy for serrated flow in type 316L(N) austenitic stainless steel. Mater. Sci. Eng. A 2014, 603, 160–168. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, C.; Lu, X.; Wang, C.; Zhao, G. Constitutive Equations and Flow Behavior of an As-Extruded AZ31 Magnesium Alloy Under Large Strain Condition. J. Mater. Eng. Perform. 2016, 25, 2267–2281. [Google Scholar] [CrossRef]

- Wei, G.; Peng, X.; Hadadzedeh, A.; Mahmoodkhani, Y.; Xie, W.; Yang, Y.; Wells, M.A. Constitutive modelling of Mg-9Li-3Al-2Sr-2Y at elevated temperatures. Mech. Mater. 2015, 89, 241–253. [Google Scholar] [CrossRef]

- Li, J.; Gao, B.; Tang, S.; Liu, B.; Liu, Y.; Wang, Y.; Wang, J. High temperature deformation behavior of carbon-containing FeCoCrNiMn high entropz alloy. J. Alloys Compd. 2018, 747, 571–579. [Google Scholar] [CrossRef]

- Ammouri, A.H.; Kridli, G.; Ayoub, G.; Hamade, R.F. Relating grain size to the Zener-Hollomon parameter for twin-roll-cast AZ31B alloy refined by friction stir processing. J. Mater. Process. Technol. 2015, 222, 301–306. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Liu, B.; Wang, Y.; Cao, Y.; Li, T.; Zhou, R. Flow behavior and microstructures of powder metallurgical CrFeCoNiMo0.2 high entropy alloy during high temperature deformation. Mater. Sci. Eng. A 2017, 689, 233–242. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

| ISO 4967 | C | Mn | Si | Cr | Mo | V |

|---|---|---|---|---|---|---|

| Min. | 1.45 | 0.20 | 0.10 | 11.00 | 0.70 | 0.70 |

| Max. | 1.60 | 0.60 | 0.40 | 13.00 | 1.00 | 1.00 |

| Spectral analysis | 1.53 | 0.40 | 0.35 | 12.00 | 1.00 | 1.00 |

| Mechanical and Physical Properties | Tensile Strength Rm [MPa] | Young’s Modulus E [GPa] | Thermal Conductivity [W·m−1·°C] | Hardness * [HV] | Specific Heat [J·kg−1·°C] |

|---|---|---|---|---|---|

| Value | 2180 | 210 | 20 | 790 | 460 |

| Parameter α F1(ε) | Parameter n F2(ε) | Parameter Q F3(ε) | Parameter lnA F4(ε) |

|---|---|---|---|

| D0 = 0.00865 | E0 = 4.68845 | F0 = 345.97489 | G0 = 29.20644 |

| D1 = −0.01197 | E1 = −4.13312 | F1 = −584.199 | G1 = −56.96311 |

| D2 = 0.03589 | E2 = 6.57538 | F2 = 2959.985 | G2 = 288.41427 |

| D3 = −0.02392 | E3 = −3.57347 | F3 = −7346.774 | G3 = −719.18308 |

| - | - | F4 = 8897.969 | G4 = 871.30332 |

| - | - | F5 = −4048.710 | G5 = −395.7832 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krbaťa, M.; Eckert, M.; Križan, D.; Barényi, I.; Mikušová, I. Hot Deformation Process Analysis and Modelling of X153CrMoV12 Steel. Metals 2019, 9, 1125. https://doi.org/10.3390/met9101125

Krbaťa M, Eckert M, Križan D, Barényi I, Mikušová I. Hot Deformation Process Analysis and Modelling of X153CrMoV12 Steel. Metals. 2019; 9(10):1125. https://doi.org/10.3390/met9101125

Chicago/Turabian StyleKrbaťa, Michal, Maroš Eckert, Daniel Križan, Igor Barényi, and Ivana Mikušová. 2019. "Hot Deformation Process Analysis and Modelling of X153CrMoV12 Steel" Metals 9, no. 10: 1125. https://doi.org/10.3390/met9101125

APA StyleKrbaťa, M., Eckert, M., Križan, D., Barényi, I., & Mikušová, I. (2019). Hot Deformation Process Analysis and Modelling of X153CrMoV12 Steel. Metals, 9(10), 1125. https://doi.org/10.3390/met9101125