Abstract

The fine description of multi-process operation behavior in steelmaking-continuous casting process is an important foundation for the improvement of production scheduling in steel plants. With sufficient consideration on non-collision movements among cranes, a dynamic simulation model is established by Plant Simulation software to describe the operation behavior of multi-process in the steelmaking-continuous casting process of lacking refining span. The design and implement of simulation are illustrated based on a typical workshop layout of “one converter-one refining furnace-one caster”. The method to avoid the collisions between adjacent cranes is represented in detail. To validate the availability of this model, an actual steel plant without refining span is studied, and simulation experiments are conducted by introducing actual production plans as simulation instances. The simulated findings agree well with the actual results of interest, including the total completed times of simulation instances, the turnover number of ladles, and the transfer times of heats among different processes. Hence, the proposed model can reliably simulate the multi-process operation behavior in steelmaking-continuous casting process.

1. Introduction

As a critical section in steel manufacturing, the steelmaking-continuous casting process (SMCC) involves the transformation of matter state, the control of matter properties and the control of mass flow (mainly denoted as molten steel, casting blank and carbon-based gases in SMCC), along with continuously receiving molten iron from ironmaking process and feeding qualified casting blank for rolling process [1]. The operations of single-process and multi-process in SMCC directly affect the product’s quality, production efficiency and waste emission [1,2]. Thereinto the single-process operation indicates the daily running of a certain process (facility), such as converters or casters. For multi-process operation, the main details refer to the implement of production scheduling with the requirement of coordination on operation pace among multiple processes. In recent years, a great progress has been made in single-process operation with the swift development of automation and information technologies [3,4]. In fact, it is still an important work to control and optimize the multi-process operation in SMCC with production requirements of order, coordination and quasi-continuation [5]. Indeed, the poor operation of multi-process could lead to the failure of single-process operation.

Currently, plenty of research has been carried out on the operation control of multi-process in SMCC, most focusing on the development of scheduling models as well as the operation optimization of ladles and cranes. In the literatures, the mainstream approaches used to study multi-process operation include: mathematical programming methods [6,7], heuristic algorithms [8,9], intelligent optimization algorithms [10,11,12] and simulation optimization methods [13,14]. Owing to the low calculating cost for large scale instances, the heuristic algorithms are still more popular in practice. Wang et al. [15] developed a scheduling system embedded with heuristic algorithm based on “furnace-caster matching”, and it has been applied in a special steel plant of long products in China. The maximum of heat number in each cast for special steel and common steel respectively increase 2 heats and 4 heats. Although many relevant models and algorithms are proposed, few achievements have been successfully applied online in actual production, and most of them still play the roles of offline reference. The bottlenecks for actual application are mainly summarized as follows: 1) The documented researches are mostly only limited to one aspect of production scheduling, ladle turnover or crane operation, and thus, the operation behavior of multi-process in SMCC couldn’t be revealed clearly yet; 2) Different from the general mixed flow workshop, SMCC presents the characteristics of high-temperature (>1600 °C), multi-process, quasi-continuation along with various complex physical and chemical reactions among gas-liquid-solid multiphase, and some technological factors are easily neglected in modeling. In particular, the first one could be paid more attention at present owing to the development of various advanced methods that could be used to study the multi-process operation concerning the constraints of cranes and ladles. Actually, the performance of ladle turnover mainly relies on crane operation. Hence, the consideration of crane constraint is the most crucial issue for studying the multi-process operation behavior in SMCC.

Compared with mathematical programming, heuristic and intelligent optimization, the approach based on simulation has a prominent advantage in studying complex practical problems [13]. As a logistics simulation software of object-oriented modeling, Plant Simulation (formerly named eM-Plant) has been widely utilized in multiple manufacturing domains since it was developed [16,17,18], and some works are also performed to study the operation dynamics in SMCC. For instance, Xiao et al. [19] established a ladle turnover model via Plant Simulation, which fully considered various constraints of equipment and process in actual production. He et al. [20] used Plant Simulation to study the influences of layout changes, process parameters on production efficiency in steel plant. Deng et al. [21] applied Plant Simulation to study the influence of converter duplex production proportion on steel plant capacity and equipment efficiency. From the above research reports, Plant Simulation could be regarded as the right candidate to study the multi-process operation behavior in SMCC.

Due to the limit of refining technologies and the larger need of common steel in the last century, most early steel plants are built without the consideration of refining facilities as well as refining span. Currently, multiple refining facilities are gradually introduced in these plants owing to the demand of high quality steel and the development of refining technologies. In general, the refining facilities added are located in tapping (casting) span because of the lack of refining span in SMCC. Obviously, the addition of refining facilities would cause the limited cranes in tapping (casting) span undertake more transportation loads among different processes, and the frequent conflicts among cranes are unavoidable, which is bad for the efficient scheduling. At present, this class of steel plants without refining span is still ubiquitous, and their reconstructions are high-cost and low-valuable. Hence, it is meaningful to study the multi-process operation in such a complex SMCC, which is the important foundation to optimize production scheduling. On the basis of the operation characteristic of mass flow in such a SMCC, a dynamic simulation model is established via Plant Simulation with consideration of the crane non-collision constraint. Aiming at an actual steel plant in China, the simulation experiments are carried out to verify this model by comparison with the actual scheduling. To the best of our knowledge, such a detailed simulation to describe the multi-process operation behavior with crane non-collision constraint is rarely reported in literatures. The remainder of this paper is organized as follows. Section 2 introduces the development of the simulation model; Section 3 presents simulation experiments and result discussion; Finally, conclusions are summarized in Section 4.

2. Description of the Simulation Model

Using Plant Simulation to establish the simulation models mainly includes two steps. Step 1: build a static model based on workshop layout and facility configuration. Step 2: write control programs (algorithms) for the static model with SimTalk language. The key for the achievement of simulation in SMCC is to design the efficient algorithms for the dynamic coordinated operation among molten steel, ladles and cranes.

2.1. Overview of Plant Simulation

Owing to the characteristics of flexible, independent and easy to use, Plant Simulation has been widely used to simulate multi-process operation in multiple industrial fields, and the implement of simulation mainly relies on SimTalk programming language internally installed in it [22]. Furthermore, Plant Simulation also provides a set of graphical function modules for modeling and allows users to create simulation models quickly. In Plant Simulation, the function modules are mainly divided into five parts: logistics module, resource module, information flow module, user interface module and some data analysis tools [22]. First two modules are mainly tailored for building the model frameworks based on the studied cases. The information flow module is used to achieve the dynamic operation of models through the control programs (algorithms) written in it, which is the emphasis and difficulty in modeling. The last two modules are used for the output and analysis of simulation results.

2.2. Characteristics of the Simulation Model

Different from the traditional discrete manufacturing processes, the multi-process operation in SMCC is restricted by strict requirements on temperature and composition of molten steel, waiting times of heats before (after) processing, etc. Continuous casting process is regarded as the center section to organize production [1]. For the scheduling problems in SMCC, the common solving idea by heuristic algorithms is first to assign continuous casting machines (CCM) for each cast with the given starting/completion times, and then select refining facilities such as ladle refining furnaces (LF) or vacuum refining furnaces (RH) and converters (BOF) for each heat in casts according to the reversed process route from CCM to BOF [23]. Indeed, the strategy of process route reversed could be applied in the simulation of SMCC to meet the constraint of continuously casting. The idea to reverse process route in simulation also has been reported in Reference [19].

In actual production, a completed cast plan contains the following details: the expected starting (completion) time in CCM, the number of heats, the steel grades, the target CCM, etc. Since the process route is reversed in simulation, it is also necessary to reverse the scheduling of heats in each cast. Assuming a batch of production plan used to simulate contains n casts, the expected completion times of each cast in CCM are defined as t1, t2, ..., ti, ..., tn (t1 < t2 < ... <ti ...< tn). The expected completion time of the last cast, tn, is treated as its expected starting time in simulation, and then the expected completion times of the rest casts are also transformed as individual expected starting times in simulation based on tn. The achievement for transforming depends on Equation (1), and the expected starting cast times of each heat in simulation are calculated by Equation (2). The expected starting (completion) times of each heat in other processes could be calculated inversely in terms of the transportation times between adjacent processes.

where represents the expected starting time of cast i in simulation; indicates the expected starting cast time of heat j in cast i; T presents the casting cycles of heats, and Ωi is the heat number in cast i.

Before establishing the model, the following rules and assumptions are made:

- (a)

- The scheduling schemes of production plans for simulation are obtained by the artificial or scheduling models in advance, which mainly contains the expected starting (completion) times of casts in CCM and the facility assignments of heats in each process;

- (b)

- The processing times of heats in each process are determined by analyzing the statistical results of actual production, and the data of processing times with serious delays is removed without considering in simulation;

- (c)

- Since the trucks mainly play the roles of buffer stations for ladles waiting before (after) processing, and their short-distance transportations between spans could be neglected;

- (d)

- The case of ladles offline wouldn’t be considered in current simulation due to their long lifetimes between successive overhauls;

- (e)

- The running of empty ladles, where the maintenance station is named as HOTR, is also considered in simulation to precisely describe the turnover process of ladles.

2.3. Design of the Simulation Model

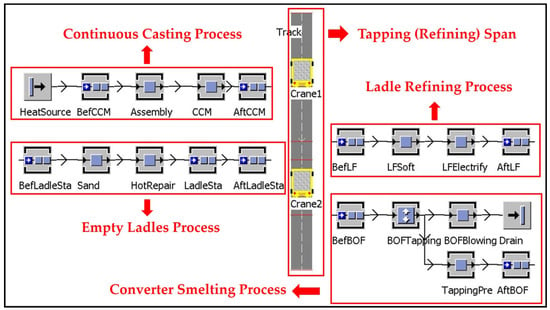

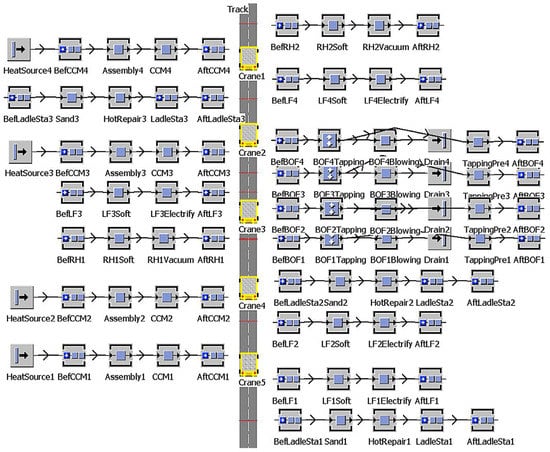

In Figure 1, a static model is firstly established based on a typical workshop layout that involves one set of BOF, one set of LF and one set of CCM. The red lines across the “Track” indicate the corresponding positions of each process and are also used to sense the real-time positions of cranes in simulation. The indications and functions of main facility objects in the static model are listed in Table 1. Due to the changeover of process routes, the operation sequence of heats in simulation is opposite to that in actual scheduling. For LF process, the soft blowing operation of molten steel in simulation is prior to electrified heating operation. Moreover, some working stations in simulation may not represent their original schemes. For instance, the tapping operation of BOF in simulation means the separation of molten steel from ladle, and so the BOF process in simulation is split into two stations of blowing and tapping in order to correctly describe the behavior of separating from each other.

Figure 1.

Static model based on a typical workshop layout.

Table 1.

Main facility objects in model and their corresponding indication and function.

After establishing the static model based on workshop layout, the next step is to design the control programs (algorithms) for each facility object to achieve the dynamic operation of simulation model. It is, indeed, a critical work to design the efficient algorithms for the coordinated operation among molten steel, ladles and cranes since they play the vital roles on describing the operation behavior of multi-process in SMCC. Here, the detailed procedure is given as follows to primarily illustrate the coordinated operation among molten steel, cranes and ladles in the process from ladle preparation to casting completion, where the indications of variables reference to Equations (1) and (2).

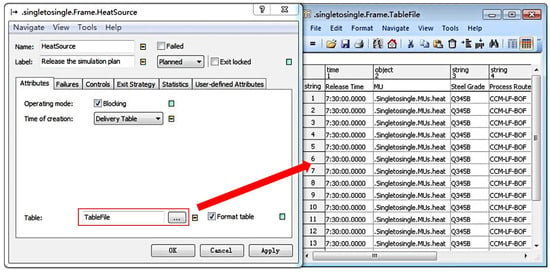

Step 1: Before simulating, the simulation instance containing n casts is prepared as the form of table file and inputted to “HeatSource”. The presentation of simulation instance imported is shown in Figure 2. The partial scheduling details of heats in simulation are given, including their release times from “HeatSource”, casting cycles, steel grades and process routes. In particular, the release times of heats in any one cast are the same and set as the time of (i = 1, 2, …, n).

Figure 2.

Presentation of simulation instance.

Step 2: Start simulating, all heats in cast i are simultaneously released to “BefCCM” at the time of and wait for ladle preparation in sequence. For heat j (j = 1, 2, …, Ωi), if j is Ωi, heat j releases the demand of ladle preparation once it arrives at “BefCCM”; otherwise, heat j releases the demand of ladle preparation at the time of ( + T − THORT-CCM). In particular, THORT-CCM represents the mean transfer time of ladles from HORT to CCM, which is determined in terms of the statistics of actual transfer times.

Step 3: Receive the demand of ladle preparation, “LadleSta” would create a new ladle if there is no ladles in it; otherwise, the ladle with the longest waiting time in “LadleSta” would be chosen as the candidate.

Step 4: When the actuated crane arrives at the corresponding position of “LadleSta” on “Track”, the chosen ladle would be loaded to the crane, and then the crane moves to the corresponding position of “Assembly” on “Track”.

Step 5: After reaching the position, the crane releases the ladle to “Assembly”, and then heat j at the font of “BefCCM” would be loaded into the ladle to form a completed heat j, which indicates the completion of ladle preparation.

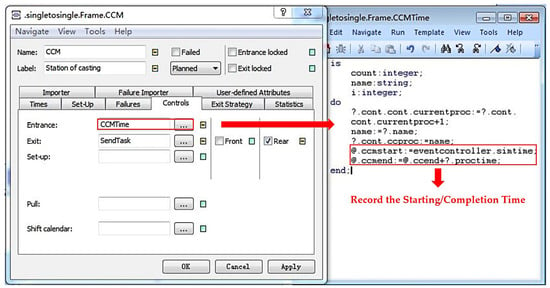

Step 6: The completed heat j moves to “CCM” once “CCM” is available without other heats, and simultaneously record the time of arrival at “CCM” as . The program for recording the starting (completion) times of heats in CCM is exhibited in Figure 3. Indeed, the obtained in simulation is larger than that calculated in Equation (2) due to the time consuming for ladle preparation.

Figure 3.

Record on the staring (completion) times of heats in CCM.

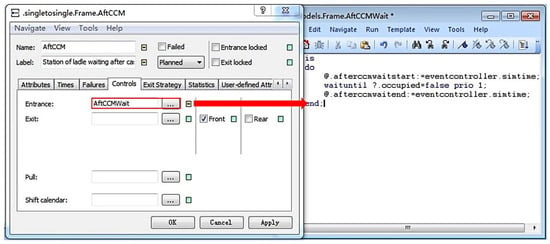

Step 7: After finishing casting in “CCM”, heat j would move to “AftCCM” along with releasing the demand of crane loading. The detailed program for recording the waiting times of heats in “AftCCM” is shown in Figure 4, whose values directly depend on the organization of crane operation.

Figure 4.

Record on the waiting times of heats after casting.

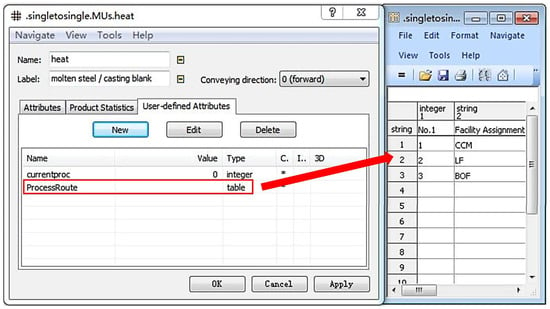

Step 8: Hoisted by crane, heat j would be delivered to refining process, and the process route is identified according to its steel grade as shown in Figure 2. In simulation, the collections of facility assignments of heats in each process are set as their attributes, which is displayed in Figure 5.

Figure 5.

Collection of facility assignments of heats in each process.

Since the operation behaviors of molten steel, ladles and cranes in other processes are similar to the details stated in Steps 1–8, this paper does not give the redundant illustration.

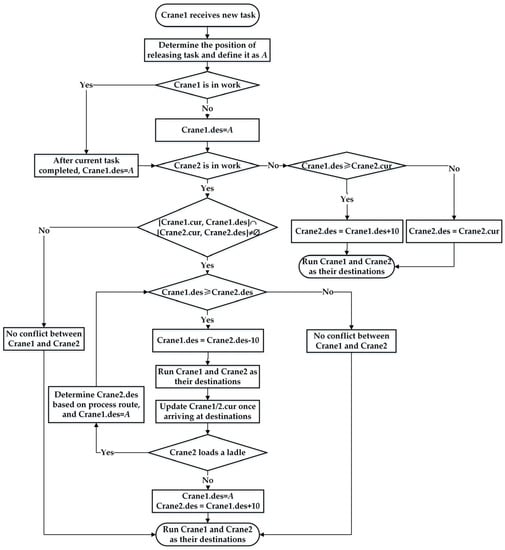

Due to the complex workshop layout or the poor control on crane running in actual production, the frequent conflicts among cranes are unavoidable. In Figure 1, “Crane1” is arranged to undertake the relevant transportation tasks along with the process of HOTR–CCM–LF, and “Crane2” is in charge of the transportation tasks along with the process of LF–BOF–HOTR. Therefore, it is obvious that the conflicts between them could happen in the overlap region from HOTR to LF. Aiming at avoiding the collisions, the proposed strategy is illustrated as shown in Figure 6 where “Crane1.cur” and “Crane1.des” respectively stand for the current position and the destination position of “Crane1”. Moreover, “Crane1.des +(−) 10” indicates “Crane1” marching downward (upward) another 10 m along with “Track” in Figure 1 based on “Crane1.des”, and the gap of 10 m is the minimum tolerance interval between adjacent cranes. The passive crane without any transportation task currently stops moving until arriving at the designated position. When the active crane, that is in state of working, completes the current task of unloading a ladle, the subordination between adjacent cranes will be re-determined according to the arrangement of the next transportation task. In fact, after receiving the transportation task, the passive crane also could implement it if there is no conflicts with the active crane during the process of performing the task. Similarly, the coordinated operation among multiple cranes without collisions in the same span can be realized as well based on this strategy for conflict elimination.

Figure 6.

Conflict elimination strategy for adjacent cranes.

Owing to heats running in simulation as the reversed process routes, the simulated results of scheduling also should be reversed to keep consistent with the actual ones. The specific means for scheduling transformed symmetrically are similar to the ones in Equations (1) and (2). After reversing scheduling, the outputted results can be used to evaluate the performance of multi-process operation in SMCC.

3. Simulation Experiment and Result Analysis

3.1. Studied Case

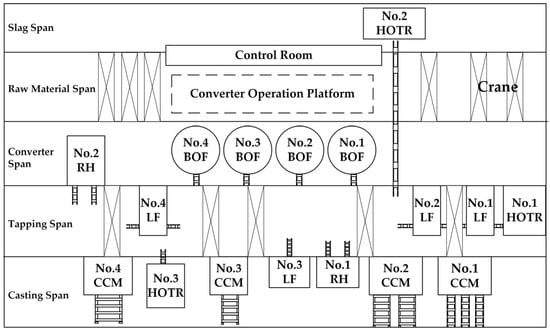

In order to validate the availability of the proposed model for describing the multi-process operation behavior in SMCC, a representative steel plant with lack of refining span is selected as the research object. The workshop layout diagram of SMCC in the studied plant is drawn in Figure 7, with the characteristics of multi-process and multi-facility in tapping (casting) span. The details about process configuration in SMCC are given in Table 2, where the standard casting cycles of heats under each specification section are given, and the ones shown as bold fonts are frequently applied in actual production. The static model based on the layout of tapping (casting) span is built and shown as Figure 8, in which the intervals among processes and the speed of crane moving are identified as the actual scene of the studied plant. In addition, the allocations of transportation tasks for five sets of cranes in tapping span are provided by the studied plant and listed in Table 3. It is easily found that the idea of assigning transportation tasks is to avoid conflicts among cranes as much as possible. The algorithms used to assign transportation tasks for each crane are designed in terms of the details in Table 3, and the movements of cranes in simulation are in strict accordance with the defined algorithms. Since some production disturbances occur occasionally, the adjustment of task allocations for each crane is also unavoidable in practice to ensure production stable. In general, the execution degree of cranes scheduling reaches approximately 90% in accordance with the provisions in Table 3.

Figure 7.

Workshop layout of SMCC in the studied steel plant.

Table 2.

Process configuration of SMCC in the studied steel plant.

Figure 8.

Static model based on the layout of tapping (casting) span in SMCC.

Table 3.

Task allocations for cranes in tapping span.

3.2. Simulation Experiment

Based on the details of processing cycles in Table 2, the production capacity of four sets of BOFs is less than that of four sets of CCMs. Therefore, the production mode of “four sets of BOFs to three sets of CCMs” is reasonable, and now has been widely adopted to organize production in the studied plant. With the objective of maximization on steel output, the popular mode is of four sets of BOFs supplying molten steel for three sets of CCM1, CCM2 and CCM4 because of the lowest casting speed in CCM3. Once one of three sets of CCMs completes the casting for a certain cast, it will be downtime and CCM3 starts working to keep the simultaneous operation of three sets of CCMs. Since the production mode of “four sets of BOFs to three sets of CCMs” accounts for more than 80 percent of all production modes in the studied plant, four following representative production plans are singled out as simulation instances and presented in Table 4. Each instance contains three casts, and the corresponding CCMs for each cast are listed in the second column of Table 4. For the common steel grades, such as Q235B steel, Q345B steel and SPHC steel, their process routes are the same, namely the process of BOF → LF → CCM. While for the special steel grades casted only in CCM4, such as Q550D steel, NVA36 steel and etc., the process route for them is the process of BOF → LF → RH → CCM. In the process of simulation, the schemes of facility assignments for each heat, including BOF, LF, RH and HOTR, are determined in advance according to the artificial or scheduling models. The starting cast time in Table 4 indicates the expected starting times of each cast in CCMs.

Table 4.

Simulation instances for model validation.

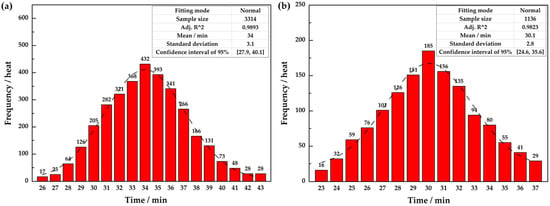

Through field survey in the studied plant, it is found that the processing times of heats in BOF change frequently, which is mainly resulted from the fluctuation on chemical composition of molten iron, such as the elements of P and C. Indeed, the obvious fluctuation on processing times in BOF is found in the smelting process before tapping. Moreover, the unstable tapping temperatures of heats also lead to the real-time adjustment on heating times in LF. The distributions on processing times of heats in BOF before tapping and heating times of heats in LF in recent months are both drawn as displayed in Figure 9, and the normal distribution modes are confirmed by Origin 2018 with the higher confidence level against other distribution ones. According to the statistic results, the processing times of heats in BOF before tapping and heating times of heats in LF are respectively set in the objects of “BOF(x)Blowing” and “LF(x)Electrify”, which are shown in Figure 8. Owing to the relative constant weight of molten steel for tapping, the tapping times in BOF change with a tiny variation of ±0.7 min around the standard time of 5 min. Hence, the tapping times of heats in simulation are fixed as 5 min in the object of “BOF(x)Tapping”. The processing times of heats in “LF(x)Soft” are also fixed as a constant of 12 min that is the shortest required time for soft blowing, and the additional time for soft blowing is regarded as a part of the transfer time from LF to CCM. With respect to the processing times of heats in CCM, they are just determined in dependence on section specification of CCM due to the relatively stable weight of molten steel for casting. Therefore, the casting cycles in Table 4 are applied in simulation. In addition, the processing times of empty ladles in HOTR basically keep constant gathered from the strict regulations for ladle maintenance and sand filling, whose values are set as 25 min and 3 min in the objects of “HotRepair(x)” and “Sand(x)”.

Figure 9.

Distributions on processing times: (a) Processing times of heats in BOF before tapping; (b) Heating times of heats in LF.

3.3. Result Analysis

In this section, three indices of interest are picked out to evaluate the simulation performances and listed as follows.

- (a)

- The total completed times of each simulation instance, which indicates, in each instance, the time elapsed from the start of the first heat in BOF till the end of the last heat in CCM;

- (b)

- The turnover number of ladles, which presents the required number of ladles in the whole process of simulation;

- (c)

- The transfer times of heats among different processes, which includes the waiting times of heats before (after) processing and the requisite transportation times between adjacent processes; The transfer times of heats from BOF (LF/RH) to LF (CCM) are recorded in this section.

Besides the simulation experiments based on variable processing times in terms of fidelity of the duplication of actual scheduling (named as Sim.1), the ones under the condition of standard operation are also performed (named as Sim.2), where the processing times of heats are fixed as standard values in Table 2.

The simulation results of performance indices are obtained as shown in Table 5, where the actual scheduling results of simulation instances are also given to make comparisons with the simulation ones. In particular, the strategy of ladle exchange [24], meaning a certain ladle could be used in succession for different production lines, is not applied in the studied plant due to the difference in chemical composition of steel grades produced by different CCMs. Thus, it is correct to calculate the turnover number of ladles through counting the number of ladles passing through each CCM.

Table 5.

Comparisons on performance indices between the simulated and the actual scheduling.

In Table 5, the simulation results of Sim.1 and Sim.2 on total completed times of each instance all can agree well the actual ones. In four instances, the largest difference between the total completed times in Sim.1 (Sim.2) and the ones in Actual is 5.2 (7.5) min, which are both found in Instance 3. In fact, the deviation of total completed time is unavoidable to simulate large scale instances, and the difference of 5.2 (7.5) min could be acceptable with the deviation ratio of 0.41% (0.54%). For the turnover number of ladles, the simulation results of Sim.1 and Sim.2 for each instance are all the same as the actual ones, where the need of more ladles for CCM2 and CCM4 is originated from their shorter casting cycles. With respect to the mean transfer times of heats among different processes, the desired matchings are also obtained between the simulated scheduling and the actual one. For the processes of BOF–LF, LF–CCM and RH–CCM, the largest differences of the mean transfer times in Sim.1 against the ones in Actual are respectively 0.5 min, 0.4 min and 0.4 min, in which the ones in the process of BOF–LF and LF–CCM are also found from Instance 3. While for the largest differences between the mean transfer times in Sim.2 and the ones in Actual, the values of them are respectively 0.6 min, 0.6 min and 0.2 min corresponding to the processes of BOF–LF, LF–CCM and RH–CCM. In particular, the mean transfer times of heats among different processes in Instance 1 and Instance 3 are obviously larger than those in two other instances. When CCM2 and CCM4 operate simultaneously, such as in Instance 1 and Instance 3, more than two sets of BOFs alternately supply molten steel for them due to their shorter casting times. Indeed, the frequent cross supply of molten steel could induce more conflicts among cranes, which causes the longer transfer times of heats.

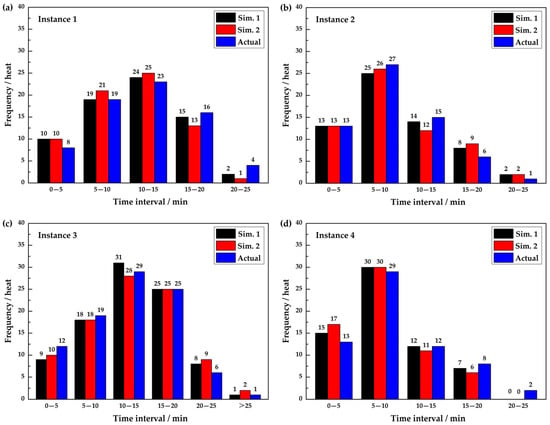

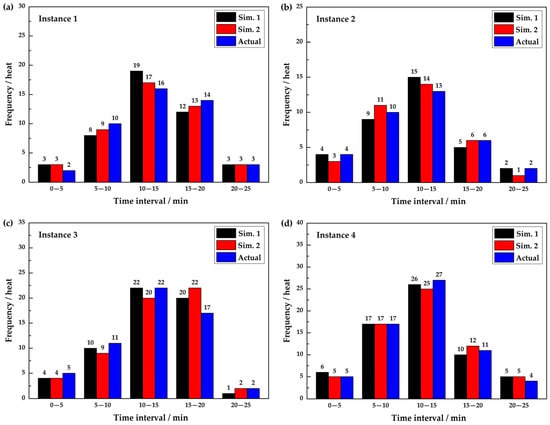

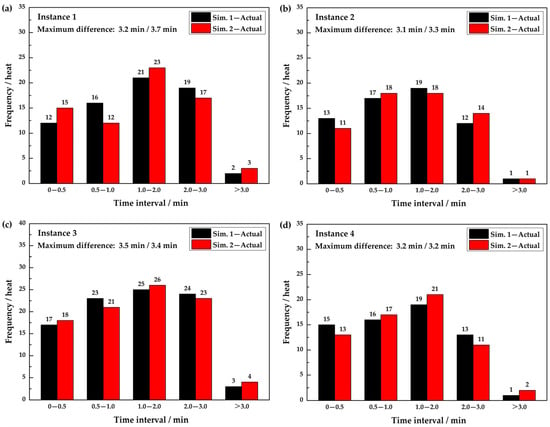

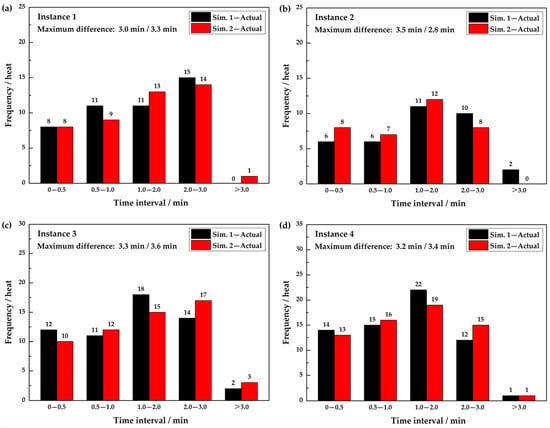

As shown in Figure 10, Figure 11, Figure 12 and Figure 13, two sorts of distributions, including the transfer times of heats from BOF (LF) to LF (CCM) and the corresponding differences between the simulated and the actual transfer times, are drawn to further compare the simulated scheduling with the actual one. In Figure 10 and Figure 11, the distributions on transfer times of heats for either BOF–LF process or LF–CCM process in simulated scheduling can match well with the ones in actual scheduling even though there are some deviations of heat number in individual time intervals. For all heats in each instance, the maximum differences between the simulated and the actual transfer times are revealed as “X/Y” in Figure 12 and Figure 13, where “X (Y)” indicates the ones between Sim.1 (Sim.2) and Actual. Seen from the results in Figure 12 and Figure 13, the differences of transfer times of most heats are within 3 min. The reason of generating deviations is mostly deduced from the unexpected differences between the simulated and the actual processing times. It is certain that the less deviations of transfer times could be expected when simulating the more stable actual operation where the alternative of processing times is limited for simulation, and the better matching could be gotten between the simulated and the actual processing times. In summary, the matching of evaluation indices between Sim.1 and Actual is slightly better than that between Sim.2 and Actual, which means that it is correct for simulation experiments to generate processing times based on the statistics in Figure 9. In some instances, the larger values of indices in Sim.2 against the ones in Sim.1 (Actual) indicate the standard operations should be properly adjusted under some actual cases to keep the coordination on processing pace among processes.

Figure 10.

Distributions on the transfer times of heats from BOF to LF.

Figure 11.

Distributions on the transfer times of heats from LF to CCM.

Figure 12.

Distributions on the differences between the simulated and the actual transfer times from BOF to LF.

Figure 13.

Distributions on the differences between the simulated and the actual transfer times from LF to CCM.

Based on expert knowledge, the upper limit of the transfer times of heats between adjacent processes is commonly ruled as 25 min. For the actual results in Figure 10c, there is one heat whose transfer time from BOF to LF exceeds the upper limit. This indication as well as the results including the turnover number of ladles and the mean transfer times in Table 5 indicate the difficulty of production scheduling when three sets casters of CCM1, CCM2 and CCM4 operate simultaneously. Thus, the operation control of multi-process in the studied steel plant should be improved through stabilizing the single-process operation rhythm as well as optimizing the production organization modes.

Broadly speaking, the proposed simulation model can reliably describe the operation behavior of multi-process in SMCC even if the attention to details is not perfect. For example, the simulation of crane operation may not be in complete agreement with actual scenario on account of the high flexibility of crane operation in actual scheduling. The most highlighted meaning of this study is to verify the feasibility of alternative scheduling schemes by simulation with crane non-collision constraint and single out the optimal one for actual production. In addition, the bottleneck process for output raising is also identified in terms of the comparisons on transfer times of heats among different processes and other related factors. These details will be discussed in our next works. Currently, a scheduling system is being developed for the studied steel plant, where the proposed simulation model is treated as the core component.

4. Conclusions

Owing to the advantages of high efficiency and low cost to study the complex production problems by simulation, a dynamic simulation model with crane non-collision constraint is developed via Plant Simulation software to describe the multi-process operation behavior in steelmaking-continuous casting process. The simulation experiments on an actual steel plant lacking refining span are carried out to verify the proposed model in comparison with actual scheduling. The experimental results on practical plans indicate the effectiveness of the proposed model along with the acceptable consistencies between the simulated and the actual scheduling on the total completed times of simulation instances, the turnover number of ladles and the transfer times of heats among different processes. Indeed, the proposed simulation model is the appropriate candidate to study the multi-process operation behavior in steelmaking-continuous casting process.

Furthermore, the proposed modeling methods could also be applied to study the multi-process operation in other types of steel plants as a result of the flexible modeling of Plant Simulation. In brief, the proposed simulation model is valuable for the research on complex process system. In our future work, the effect of variable production factors on the operation efficiency of multi-process in SMCC will be discussed, such as the consideration of the matching relations among different processes and the task allocation schemes for cranes.

Author Contributions

Formal analysis, J.Y. and J.Z.; Methodology, J.Y.; Project administration, M.G. and Q.L.; Resources, S.G. and W.G.; Validation, Y.H.; Writing—original draft, J.Y.; Writing—review & editing, J.Z. and Q.L.

Funding

This research was funded by the Innovative & Entrepreneurial Talent Project in Jiangsu province, China (Grant No. 2016A426) and the Fundamental Research Funds for Central Universities (Grant No. FRF-BR-17-029A).

Acknowledgments

This research was supported by the Innovative & Entrepreneurial Talent Project in Jiangsu province, China (Grant No. 2016A426) and the Fundamental Research Funds for Central Universities (Grant No. FRF-BR-17-029A). The authors also would like to give their thanks to Senior Steelmaking Expert Dong-sheng Liao (ArcelorMittal Dofasco Inc.), Ming-tian Shao (Shandong Iron & Steel Group CO., LTD) for their inspiring contribution to this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yin, R.Y. Theory and Methods of Metallurgical Process Integration, 1st ed.; Metallurgical Industry Press: Beijing, China, 2016; pp. 87–88. [Google Scholar]

- Birat, J.P. Steel cleanliness and environmental metallurgy. Metall. Res. Technol. 2016, 113, 1–24. [Google Scholar] [CrossRef]

- Liao, D.S.; Sun, S.; Waterfall, S.; Boylan, K.; Pyke, N.; Holdridge, D. Integrated KOBM steelmaking process control. In Proceedings of the 6th International Congress on the Science and Technology of Steelmaking, Beijing, China, 12–14 May 2015; Chinese Society for Metals: Beijing, China, 2015; pp. 107–112. [Google Scholar]

- Speer, J.G. The continuing development of modern steel products. In Proceedings of the AISTech 2018 Iron and Steel Technology Conference and Exposition, Philadelphia, PA, USA, 7–10 May 2018; Association for Iron and Steel Technology: Pittsburgh, PA, USA, 2018; pp. 1–6. [Google Scholar]

- Liu, Q.; Wang, B.; Wang, Z.; Xie, F.M.; Chang, J. Fine production in steelmaking plants. In Proceedings of the Joint 3rd UK-China Steel Research Forum & 15th CMA-UK Conference on Materials Science and Engineering, Oxford, UK, 10–11 July 2014; Elsevier: Amsterdam, The Netherlands, 2015; pp. 348–357. [Google Scholar]

- Mori, J.; Mahalec, V. Planning and scheduling of steel plates production. Part II: Scheduling of continuous casting. Comput. Chem. Eng. 2017, 101, 312–325. [Google Scholar] [CrossRef]

- Mao, K.; Pan, Q.K.; Chai, T.Y.; Luh, P.B. An Effective Subgradient Method for Scheduling a Steelmaking-Continuous Casting Process. IEEE Trans. Autom. Sci. Eng. 2015, 12, 1140–1152. [Google Scholar] [CrossRef]

- Wichmann, M.G.; Spengler, T.S. Slab scheduling at parallel continuous casters. Int. J. Prod. Econ. 2015, 170, 551–562. [Google Scholar] [CrossRef]

- Wei, Z.; Zhu, T.; He, T.Z. A Fast Heuristic Algorithm for Ladle Scheduling Based on Vehicle Routing Problem with Time Windows Model. ISIJ Int. 2014, 54, 2588–2597. [Google Scholar] [CrossRef][Green Version]

- Tang, L.X.; Zhao, Y.; Liu, J.Y. An improved differential evolution algorithm for practical dynamic scheduling in steelmaking-continuous casting production. IEEE Trans. Evol. Comput. 2014, 18, 209–225. [Google Scholar] [CrossRef]

- Jiang, S.L.; Zheng, Z.; Liu, M. A preference-inspired multi-objective soft scheduling algorithm for the practical steelmaking-continuous casting production. Comput. Ind. Eng. 2018, 115, 582–594. [Google Scholar] [CrossRef]

- Pan, Q.K. An effective co-evolutionary artificial bee colony algorithm for steelmaking-continuous casting scheduling. Eur. J. Oper. Res. 2016, 250, 702–714. [Google Scholar] [CrossRef]

- Fanti, M.P.; Iacobellis, G.; Rotunno, G.; Ukovich, W. A simulation based analysis of production scheduling in a steelmaking and continuous casting plant. In Proceedings of the 2013 IEEE International Conference on Automation Science and Engineering, Madison, WI, USA, 17–20 August 2013; IEEE Computer Society: Washington, WA, USA, 2013; pp. 150–155. [Google Scholar]

- Yu, S.P.; Lv, R.X.; Zheng, B.L.; Chai, T.Y. Simulation system for logistics in steelmaking process based on flexsim. In Proceedings of the 2009 Chinese Control and Decision Conference, Guilin, China, 17–19 June 2009; IEEE Computer Society: Washington, DC, USA, 2009; pp. 3741–3746. [Google Scholar]

- Wang, G.; Wang, B.; Wang, B.; Wang, C.; Mu, Y.Q.; Wang, B.L.; Liu, Q. Scheduling model for steelmaking-continuous casting process based on “furnace-caster matching” principle. Beijing Keji Daxue Xuebao 2013, 35, 1080–1092. [Google Scholar]

- Chen, E.J.; Lee, Y.M.; Selikson, P.L. A simulation study of logistics activities in a chemical plant. Simul. Model. Pract. Theory 2002, 10, 235–245. [Google Scholar] [CrossRef]

- Shan, H.Y.; Li, L.N.; Yuan, Y.; Wang, C. Simulation and optimization of production line in Em-plant based assembly workshop. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok, Thailand, 16–19 December 2018; IEEE Computer Society: Washington, DC, USA, 2018; pp. 1381–1385. [Google Scholar]

- Chai, S.F.; Luo, S.J.; Zhang, L.J. Study on simulation of the main shaft production line. Adv. Mater. Res. 2012, 472, 2076–2079. [Google Scholar] [CrossRef]

- Xiao, Y. Research on ladle scheduling based on UML and plant simulation in steel plant. Master’s Thesis, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- He, L.M.; Hu, Y. Logistic simulator for steel-making process. Adv. Mater. Res 2011, 154, 712–715. [Google Scholar] [CrossRef]

- Deng, S.; Xu, A.J.; Wang, H.B. Simulation study on steel plant capacity and equipment efficiency based on plant simulation. Steel Res. Int. 2019, 90, 1800507, (1–14). [Google Scholar] [CrossRef]

- Bangsow, S. Manufacturing Simulation with Plant Simulation and SimTalk, 1st ed.; Springer: Berlin, Germany, 2010. [Google Scholar]

- Yu, S.P.; Chai, T.Y. Heuristic scheduling method for steelmaking and continuous casting production process. Control Theory Appl. 2016, 33, 1413–1421. [Google Scholar]

- Huang, B.F.; Tian, N.Y.; Shi, Z.; Ma, W. Steel ladle exchange models during steelmaking and continuous casting process. J. Iron Steel Res. Int. 2017, 24, 617–624. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).