Effect of Tempering Temperature on Microstructures and Wear Behavior of a 500 HB Grade Wear-Resistant Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Heat Treatment

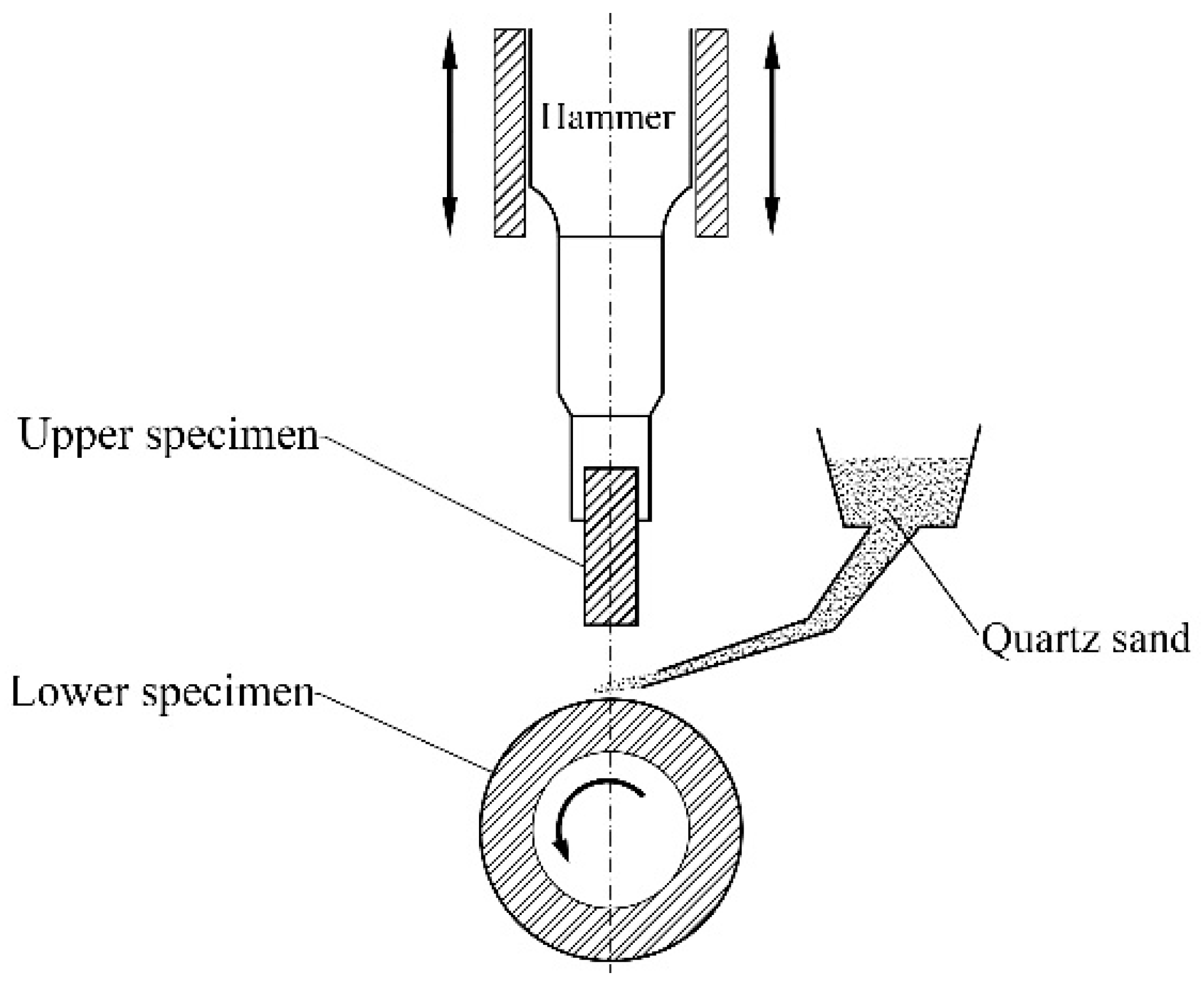

2.2. Mechanical Properties and Impact Wear Resistance Tests

2.3. Microstructure, Fracture, and Wear Morphology Observation

3. Results

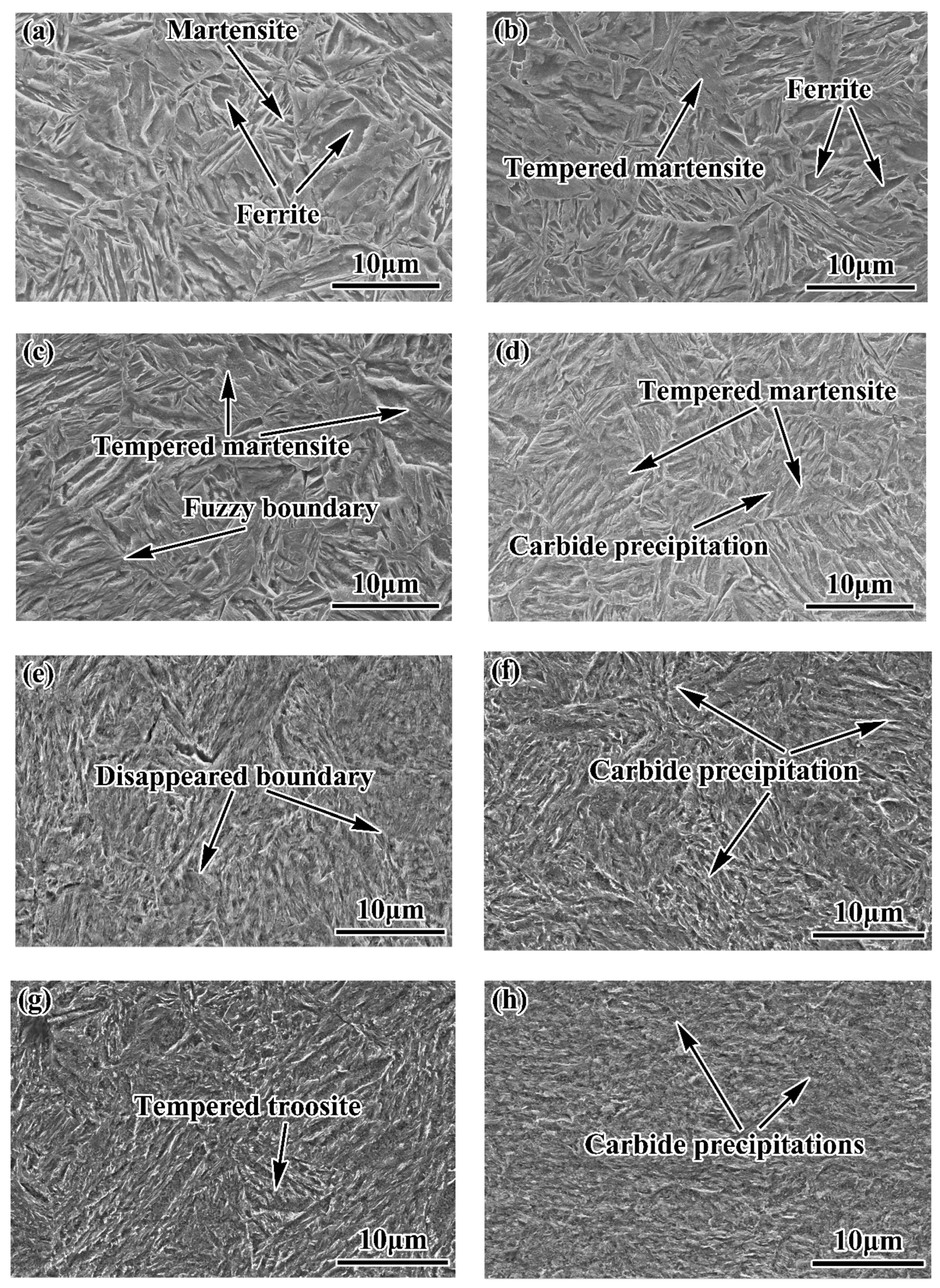

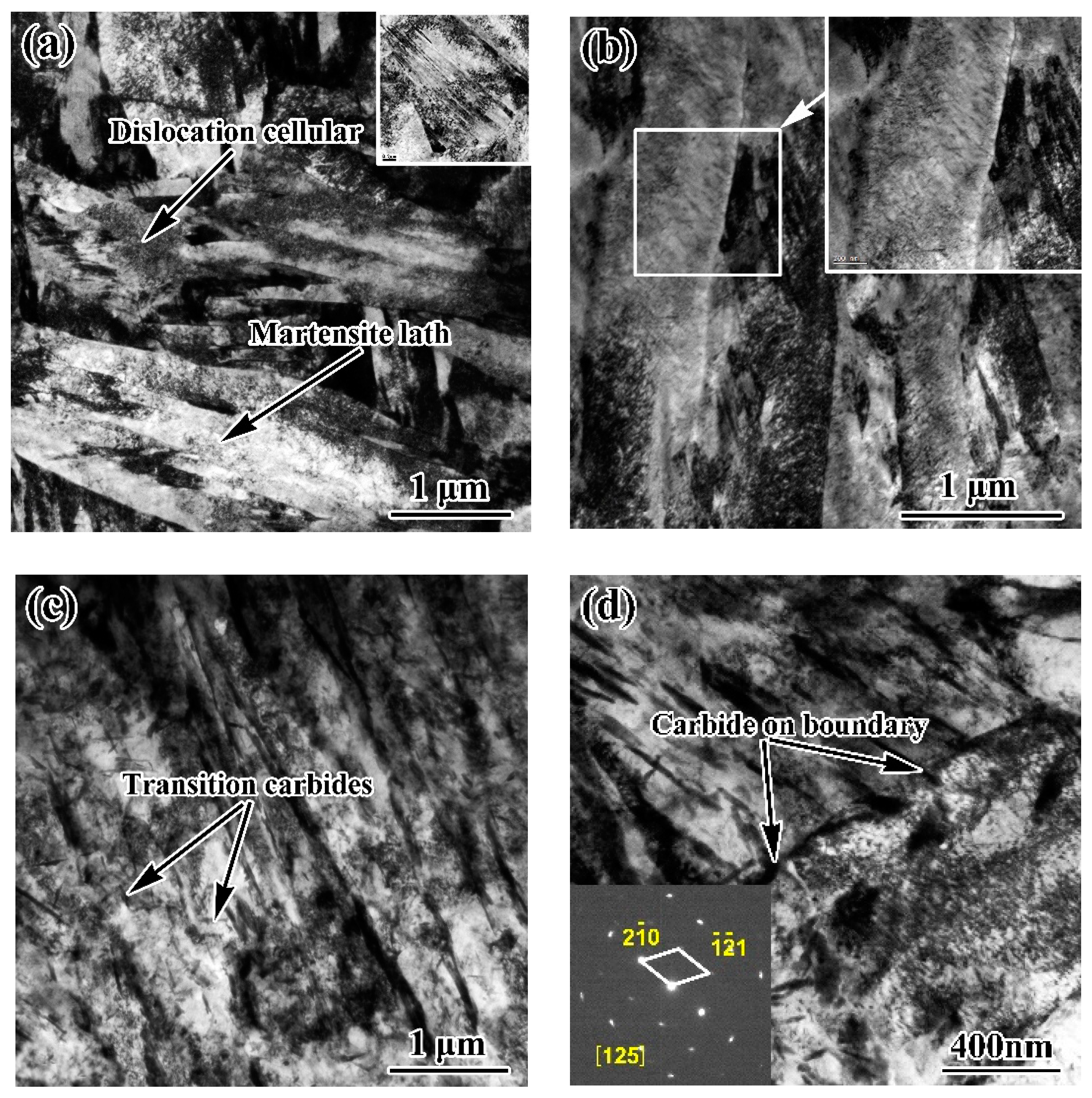

3.1. Microstructure Morphologies

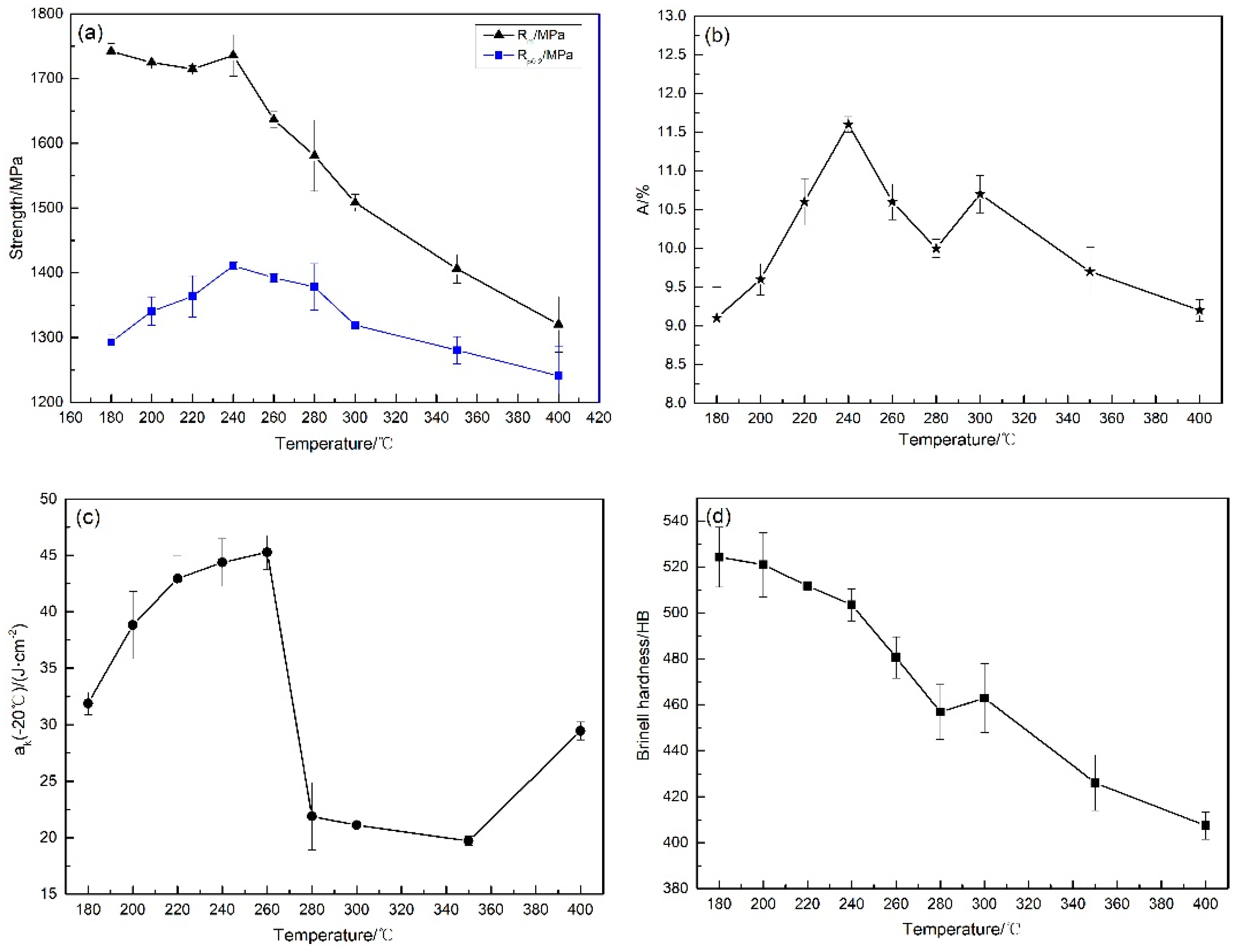

3.2. Mechanical Properties

3.3. Wear Resistance

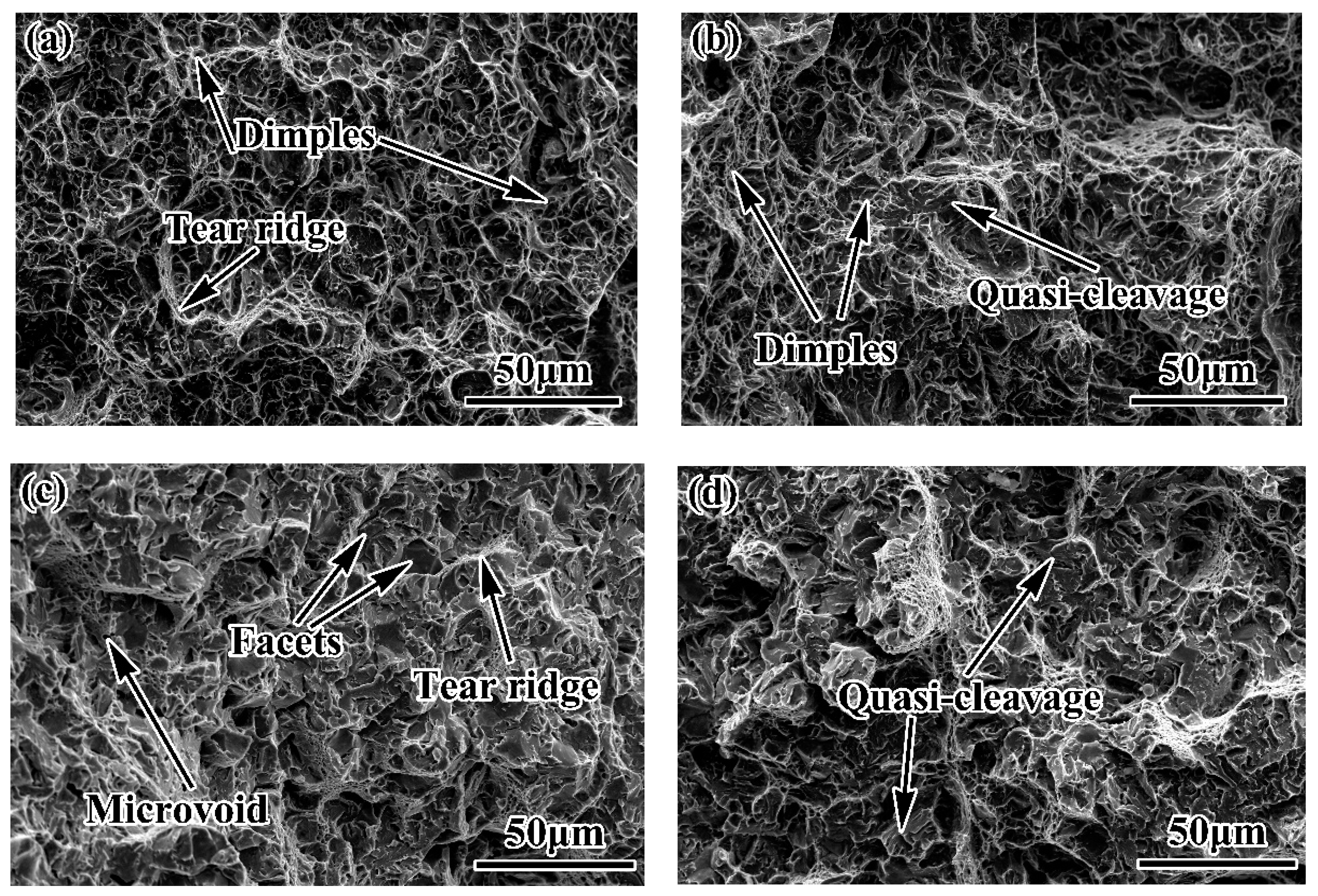

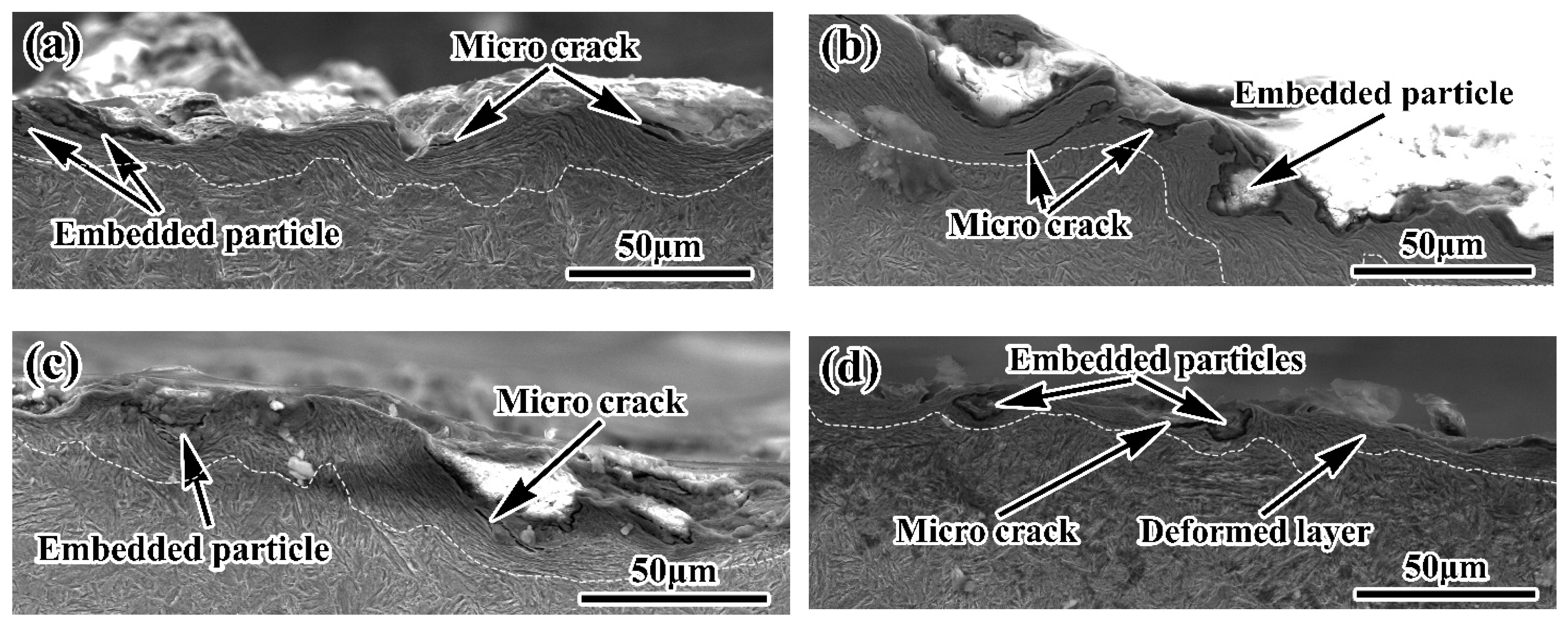

3.4. Wear Surfaces

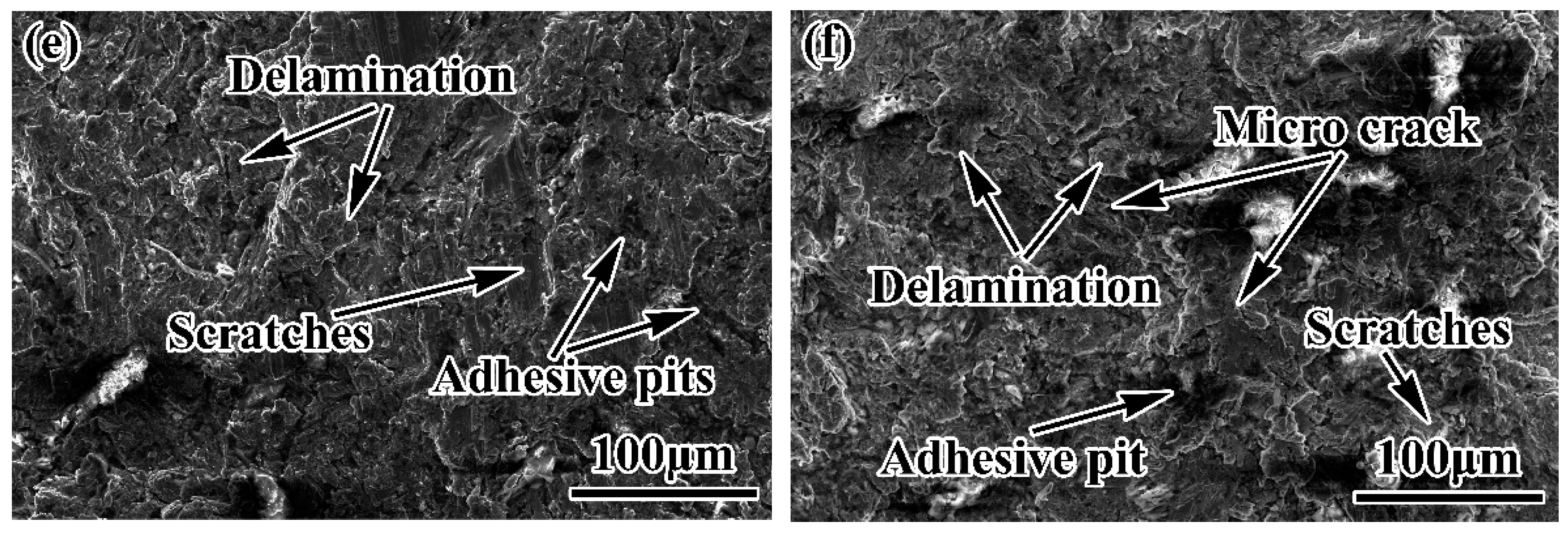

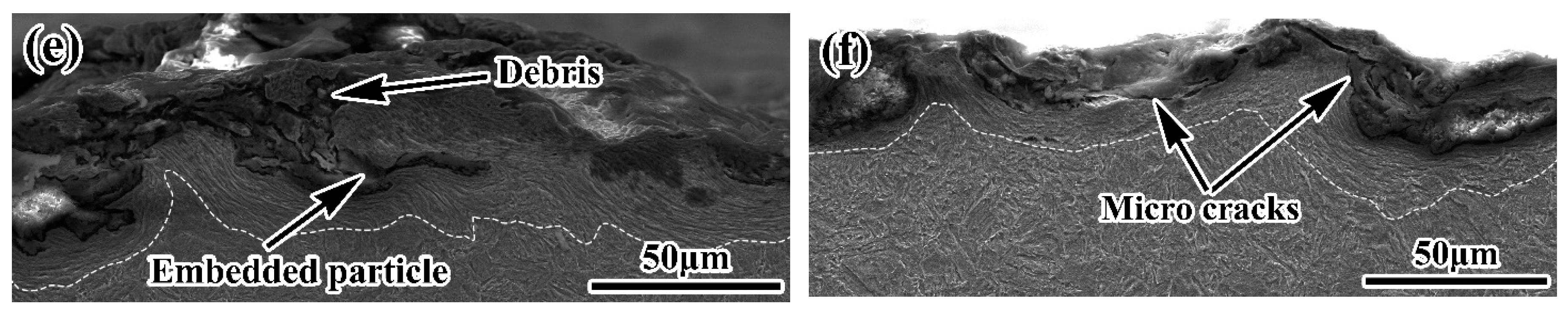

3.5. Wear Subsurface Layers

4. Discussion

4.1. Microstructure and Mechanical Properties

4.2. Relationship between Mechanical Properties and Wear Resistance

4.3. Wear Mechanism

- (1)

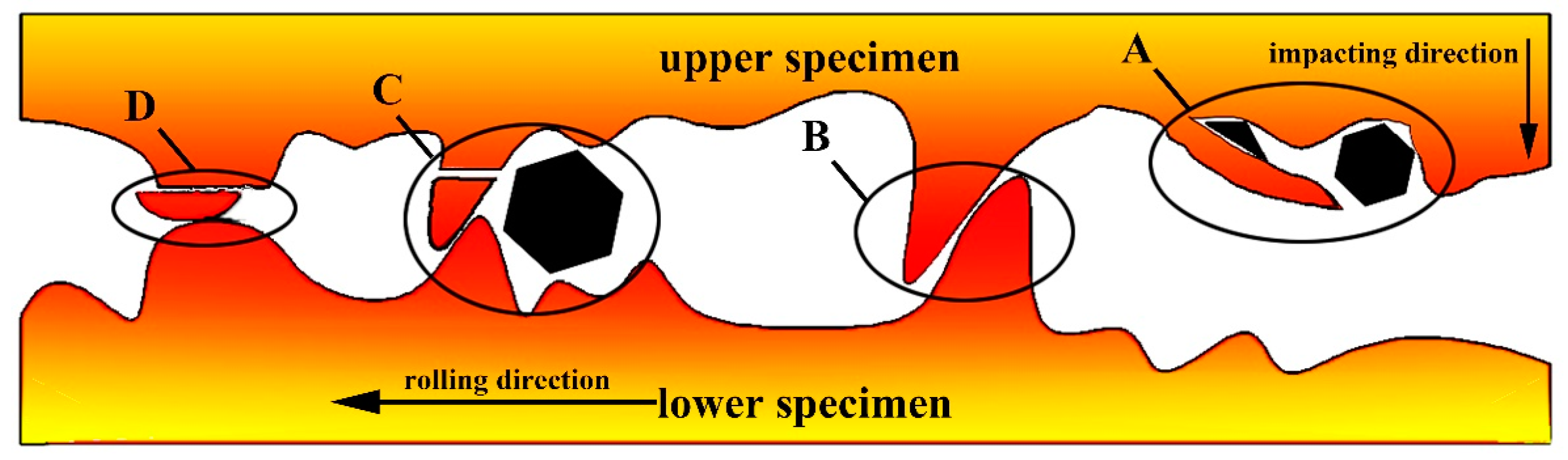

- As shown in Figure 9 (part A) and (part C), some flowing quartz sand particles would embed in the matrix or be crushed because of the intense and localized stress. With the rolling of the lower specimen, some particles on the surface would slide along the rolling direction and leave scratches behind. Meanwhile, the embedded particles would cut down part of the matrix and the cracks formed because of the movement of the crushed particles. During this stage, the surface hardness of the matrix was considered to be the dominant factor which could hinder the embedding of the quartz sand particles and the ploughing of the particles on the surface [4,25].

- (2)

- With the periodical impact of the upper specimen, the surface of the steel was deformed. Delamination formed because of the contact of upper and lower specimens shown in Figure 9 (part B). Meanwhile, shallow deformation layers were obtained because of the high surface hardness and low impact toughness of the matrix, which could be observed in Figure 8. As the wear test continued, the dislocation piled up, resulting in the improvement of the surface hardness. Otherwise, the deformation layers would lead to a detrimental loss of toughness on the matrix surface, which might cause brittleness and be cut away, as shown in Figure 7e [26]. However, the cut-down burs would act as new abrasive particles which would mix with the crushed quartz sand particles and cause further wear.

- (3)

- As the wear test continued, the contact temperature of the wear surface would increase significantly. As shown in Figure 9 (part D), the matrix softened, and part of the embedded quartz sand particles would take away the matrix directly instead of sliding in the matrix. Moreover, the adhesive wear happened because of the welding of the upper specimen and lower specimen in the high temperature condition. During this period, the adhesive wear was considered to be the dominant wear mechanism which would lead to severe wear.

5. Conclusions

- (1)

- The microstructure after tempering mainly consists of tempered martensite and ferrite. With tempering temperature increasing, the carbide precipitations separated out constantly and were recognized as Fe3C. At temperatures over 260 °C, the tempered martensite transformed to tempered troosite. With the increasing of tempering temperature, the hardness decreased constantly. The impact toughness increased firstly, and then decreased sharply when the temperature was over 280 °C. According to the fracture morphologies, the amount of dimples decreased significantly when the temperature increased from 260 °C to 280 °C, which was confirmed to be temper embrittlement. The precipitation of Fe3C carbides along the grain boundaries was the main reason for temper embrittlement.

- (2)

- The best wear resistance was obtained when steel was tempered at 200 °C. With the wear time extending, the wear resistance of all specimens decreased constantly, except for the specimen tempered at 240 °C, whose best wear resistance was obtained when tested for 60 min. In this test condition, the hardness was considered to be the dominant factor that improved the wear resistance at the initiation of the wear test. Impact toughness would not effectively improve the wear resistance of the steels without a sufficient surface hardness.

- (3)

- In the initial wear test period, the abrasive wear was considered to be the dominant wear mechanism. The embedded and crushed quartz sand particles slid and cut the burs, leaving scratches and adhesions behind. With the wear time extending, the contact temperature increased significantly, and the adhesive wear turned to be the dominant wear mechanism which would result in severe wear.

Author Contributions

Funding

Conflicts of Interest

References

- Tylczak, J.H. Friction, lubrication, and wear technology. In Metal Handbook; American Society for Metals: Metals Park, OH, USA, 1992; Volume 18, p. 400. [Google Scholar]

- Speich, G.R.; Leslie, W.C. Tempering of steel. Metall. Trans. 1972, 3, 1043–1054. [Google Scholar] [CrossRef]

- Lindroos, M.; Ratia, V.; Apostol, M.; Valtonen, K.; Laukkanen, A.; Molnar, W.; Holmberg, K.; Kuokkala, V. The effect of impact conditions on the wear and deformation behavior of wear resistant steels. Wear 2015, 328–329, 197–205. [Google Scholar] [CrossRef]

- Singh, K.; Khatirkar, R.K.; Sapate, S.G. Microstructure evolution and abrasive wear behavior of D2 steel. Wear 2015, 328–329, 206–216. [Google Scholar] [CrossRef]

- Yi, C.; Wang, Z.D.; Kang, J.; Wu, D.; Wang, G.D. Effects of tempering temperature and Mo/Ni on microstructures and properties of lath martensitic wear-resistant steels. J. Iron Steel Res. Int. 2013, 20, 70–75. [Google Scholar]

- Ojala, N.; Valtonen, K.; Heino, V.; Kallio, M.; Aaltonen, J.; Siitonen, P.; Kuokkala, V. Effects of composition and microstructure on the abrasive wear performance of quenched wear resistant steels. Wear 2014, 317, 225–232. [Google Scholar] [CrossRef]

- Rendón, J.; Olsson, M. Abrasive wear resistance of some commercial abrasion resistant steels evaluated by laboratory test methods. Wear 2009, 267, 2055–2061. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, J.; Wang, H.; Wu, X. Effect of tempering on microstructure and mechanical properties of a non-quenched bainitic steel. Mater. Sci. Eng. A-Struct. 2010, 527, 3433–3437. [Google Scholar] [CrossRef]

- Salemi, A.; Abdollah-Zadeh, A. The effect of tempering temperature on the mechanical properties and fracture morphology of a NiCrMoV steel. Mater. Charact. 2008, 59, 484–487. [Google Scholar] [CrossRef]

- Qin, B.; Wang, Z.Y.; Sun, Q.S. Effect of tempering temperature on properties of 00Cr16Ni5Mo stainless steel. Mater. Charact. 2008, 59, 1096–1100. [Google Scholar] [CrossRef]

- Hu, R.R.; Cai, Q.W.; Wu, H.B.; Tang, D. Heat treatment influence on the microstructure and mechanical properties of NM500 wear resistant steel. J. Univ. Sci. Technol. B 2013, 35, 1015–1020. [Google Scholar]

- Fu, H.; Xiao, Q.; Fu, H. Heat treatment of multi-element low alloy wear-resistant steel. Mater. Sci. Eng. A-Struct. 2005, 396, 206–212. [Google Scholar] [CrossRef]

- Shahram, K.; Hasan, S.; Jalal, H.; Mohammad, M. Effect of heat treatment on microstructure of modified cast AISI D3 cold work tool steel. J. Iron Steel Res. Int. 2010, 17, 40–45, 52. [Google Scholar]

- Grange, R.A.; Hribal, C.R.; Porter, L.F. Hardness of tempered martensite in carbon and low-alloy Steels. Metall. Trans. A 1977, 8A, 1775–1785. [Google Scholar] [CrossRef]

- Momeni, M.; Kheirandish, S.; Saghafian, H.; Hedjazi, J.; Momeni, M. Effects of heat treatment on mechanical properties of modified cast AISI D3 tool steel. Mater. Design. 2014, 54, 742–747. [Google Scholar] [CrossRef]

- Zhou, W.H.; Challa, V.S.A.; Guo, H.; Shang, C.J.; Misra, R.D.K. Structure–mechanical property relationship in a low carbon Nb–Cu microalloyed steel processed through a three-step heat treatment: The effect of tempering process. Mater. Sci. Eng. A-Struct. 2015, 620, 454–462. [Google Scholar] [CrossRef]

- Hernandez, S.; Leiro, A.; Ripoll, M.R.; Vuorinen, E.; Sundin, K.; Prakash, B. High temperature three-body abrasive wear of 0.25C 1.42Si steel with carbide free bainitic (CFB) and martensitic microstructures. Wear 2016, 360–361, 21–28. [Google Scholar] [CrossRef]

- Chakraborty, G.; Das, C.R.; Albert, S.K.; Bhaduri, A.K.; Paul, V.T.; Panneerselvam, G.; Dasgupta, A. Study on tempering behaviour of AISI 410 stainless steel. Mater. Charact. 2015, 100, 81–87. [Google Scholar] [CrossRef]

- Mishra, B.; Kumbhar, K.; Kumar, K.S.; Prasad, K.S.; Srinivas, M. Effect of copper addition on microstructure and mechanical properties of ultra high strength NiSiCrCoMo steel. Mater. Sci. Eng. A-Struct. 2016, 651, 177–183. [Google Scholar] [CrossRef]

- Zambrano, O.A.; Coronado, J.J.; Rodríguez, S.A. Tempering temperature effect on sliding wear at high temperatures in mottled cast iron. Tribol. Lett. 2015, 57, 1–11. [Google Scholar] [CrossRef]

- Jha, A.K.; Prasad, B.K.; Modi, O.P.; Das, S.; Yegneswaran, A.H. Correlating microstructural features and mechanical properties with abrasion resistance of a high strength low alloy steel. Wear 2003, 254, 120–128. [Google Scholar] [CrossRef]

- Kennedy, F.E.; Lu, Y.; Baker, I. Contact temperatures and their influence on wear during pin-on-disk tribotesting. Tribol. Int. 2015, 82, 534–542. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T.; Yung, D. Effect of temperature on sliding and erosive wear of fiber reinforced polyimide hybrids. Tribol. Int. 2015, 82, 525–533. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Zhang, H.X.; Li, H.; Shen, H.P. Effect of tempering temperature on the microstructure and mechanical properties in mooring chain steel. Mater. Sci. Eng. A-Struct. 2015, 636, 164–171. [Google Scholar] [CrossRef]

- Xu, X.; van der Zwaag, S.; Xu, W. Prediction of the abrasion resistance of construction steels on the basis of the subsurface deformation layer in a multi-pass dual-indenter scratch test. Wear 2015, 338–339, 47–53. [Google Scholar] [CrossRef]

- Ojala, N.; Valtonen, K.; Antikainen, A.; Kemppainen, A.; Minkkinen, J.; Oja, O.; Kuokkala, V. Wear performance of quenched wear resistant steels in abrasive slurry erosion. Wear 2016, 354–355, 21–31. [Google Scholar] [CrossRef]

| Elements | C | Mn | Si | Cr | Ni + Nb | Mo | V + Ti + B | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass fraction | 0.30 | 1.00 | 0.26 | 0.80 | ≤0.10 | 0.20 | ≤0.03 | 0.001 | 0.014 | Bal. |

| Tempering Temperature/°C | Impact Energy/J | Impact Times of Upper Specimen/(t/min) | Rotate Speed of Lower Specimen/(r/min) | Wear Time/min | Flow Rate of Quartz Sand/(kg/h) |

|---|---|---|---|---|---|

| As quenched | 2 | 200 | 200 | 30 60 90 | 40 |

| 200 | |||||

| 240 | |||||

| 260 | |||||

| 300 | |||||

| 400 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, E.; Song, R.; Xiong, W. Effect of Tempering Temperature on Microstructures and Wear Behavior of a 500 HB Grade Wear-Resistant Steel. Metals 2019, 9, 45. https://doi.org/10.3390/met9010045

Wen E, Song R, Xiong W. Effect of Tempering Temperature on Microstructures and Wear Behavior of a 500 HB Grade Wear-Resistant Steel. Metals. 2019; 9(1):45. https://doi.org/10.3390/met9010045

Chicago/Turabian StyleWen, Erding, Renbo Song, and Wenming Xiong. 2019. "Effect of Tempering Temperature on Microstructures and Wear Behavior of a 500 HB Grade Wear-Resistant Steel" Metals 9, no. 1: 45. https://doi.org/10.3390/met9010045

APA StyleWen, E., Song, R., & Xiong, W. (2019). Effect of Tempering Temperature on Microstructures and Wear Behavior of a 500 HB Grade Wear-Resistant Steel. Metals, 9(1), 45. https://doi.org/10.3390/met9010045