Two-Phase Numerical Modeling of Grade Intermixing in a Steelmaking Tundish

Abstract

1. Introduction

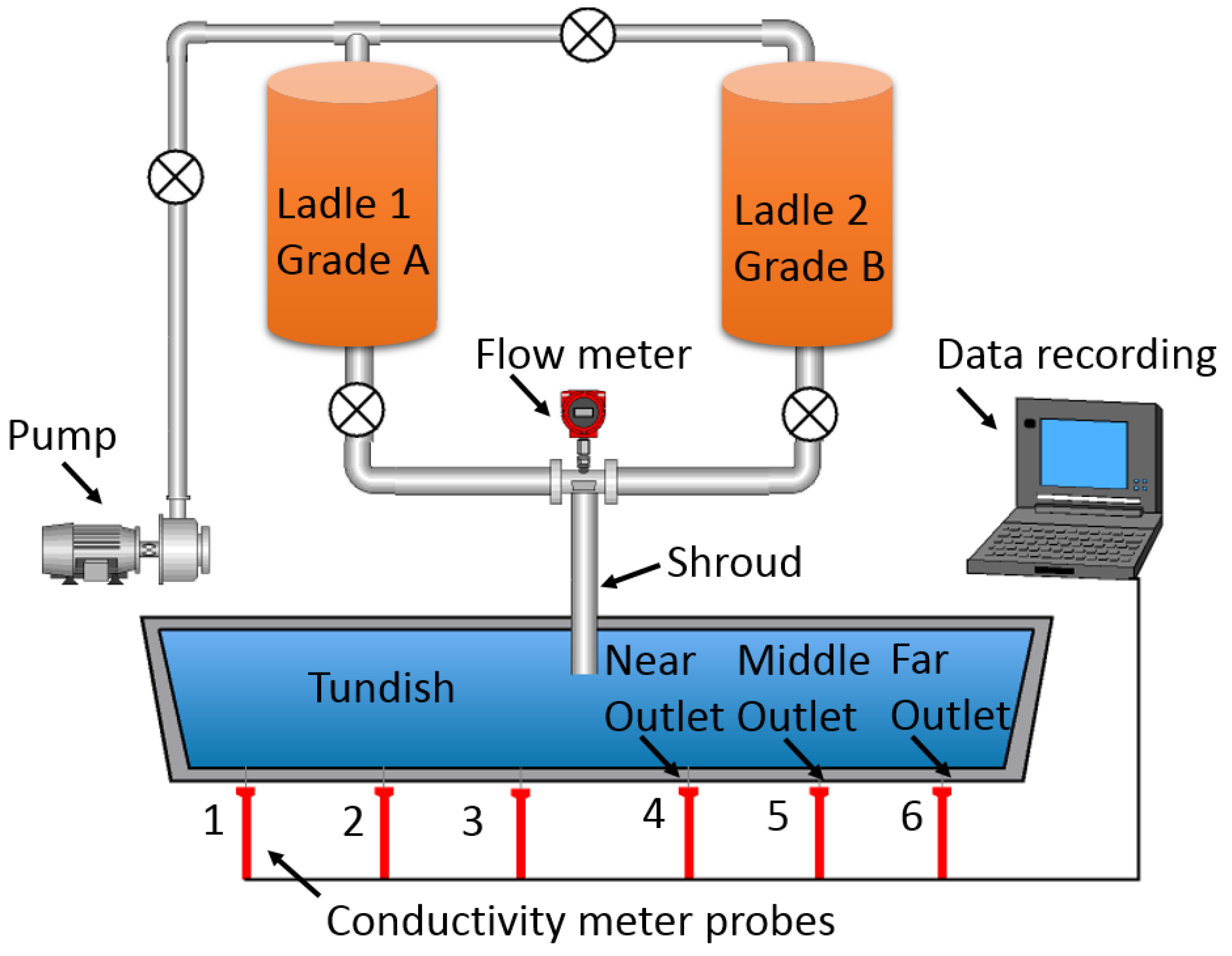

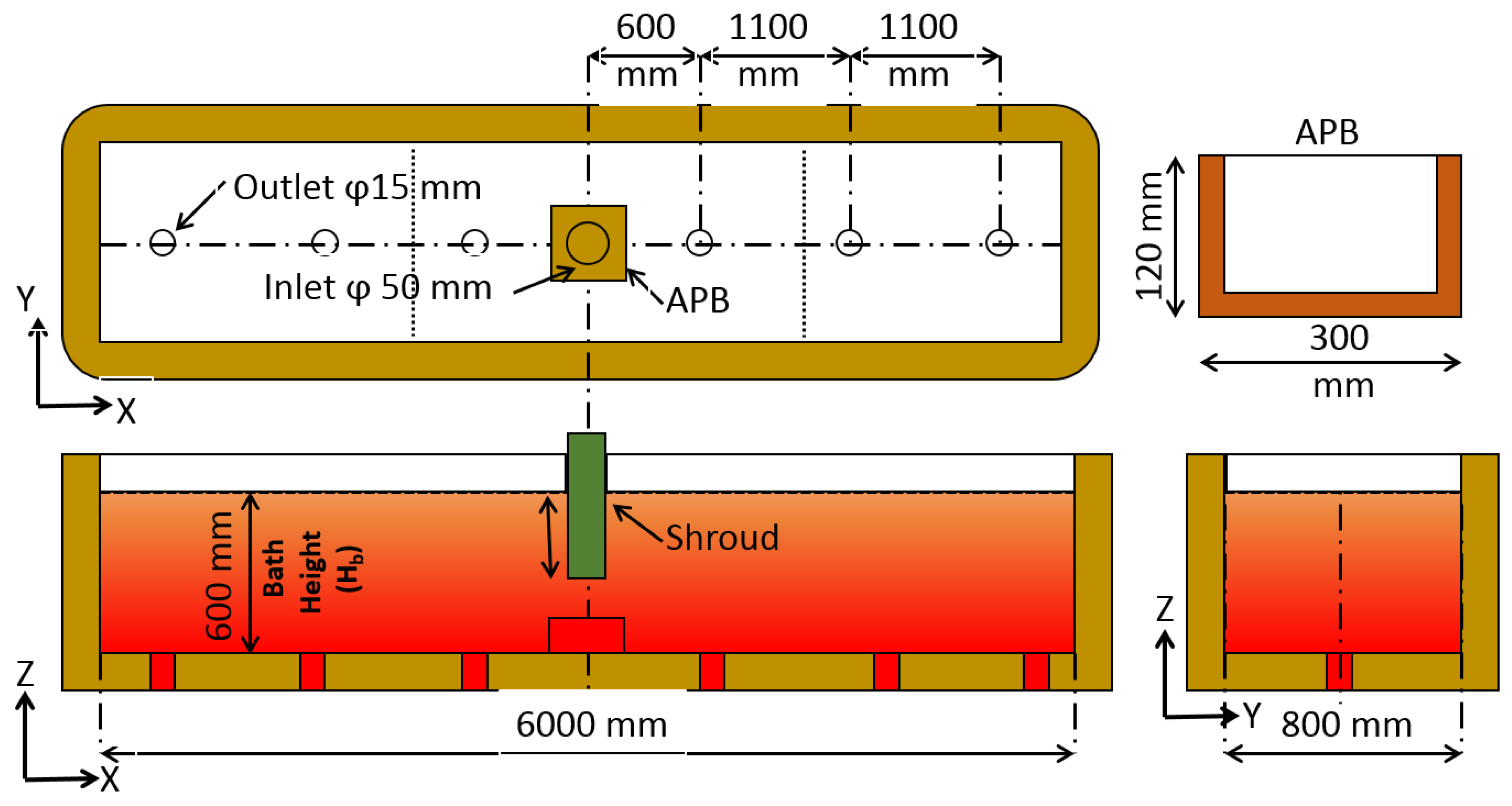

2. Experimental Studies

3. Mathematical Modeling

3.1. Governing Equations

3.2. Boundary Conditions

3.3. Two-Phase Model

4. Results and Discussion

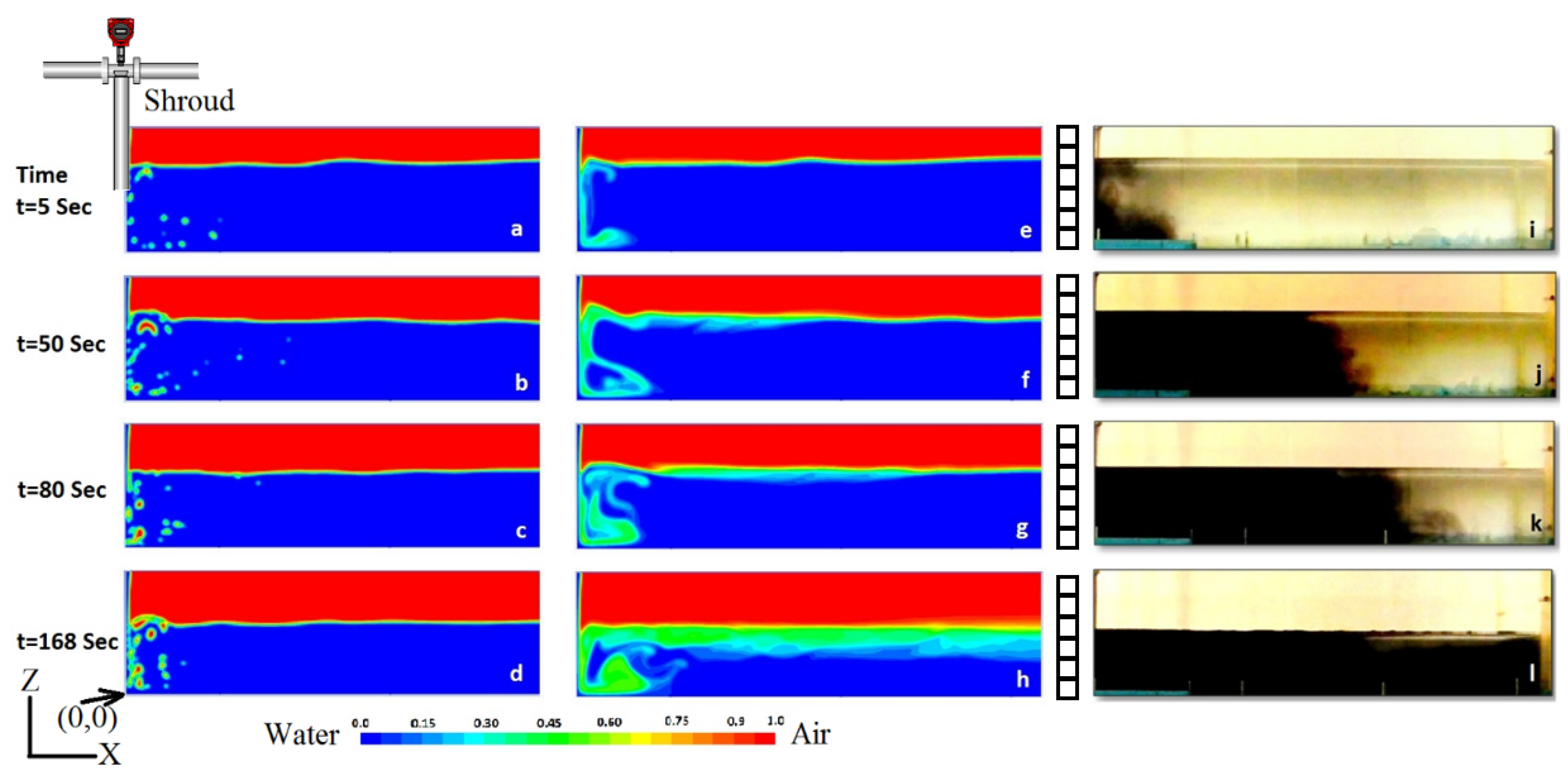

4.1. Comparison of Interface Schemes

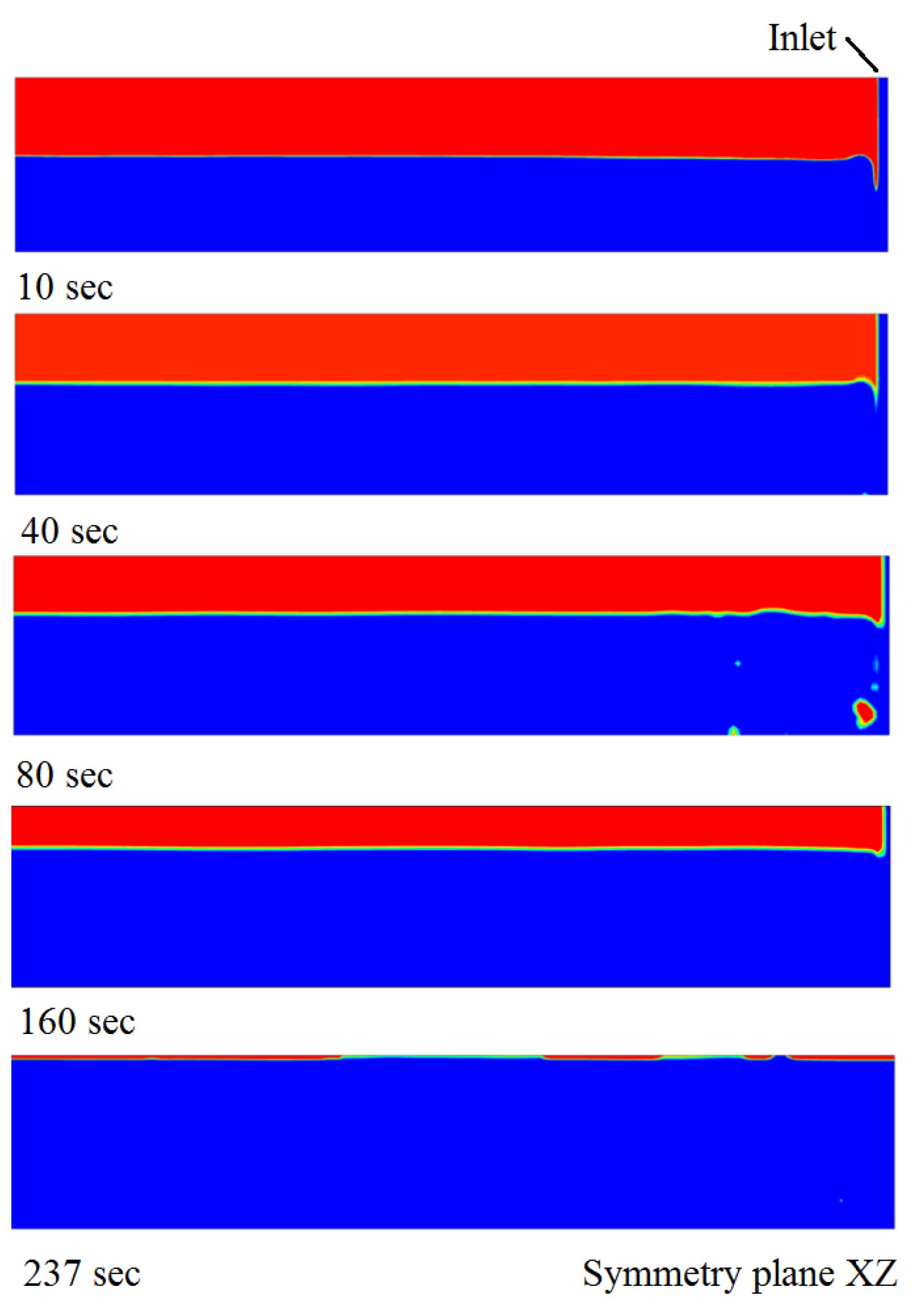

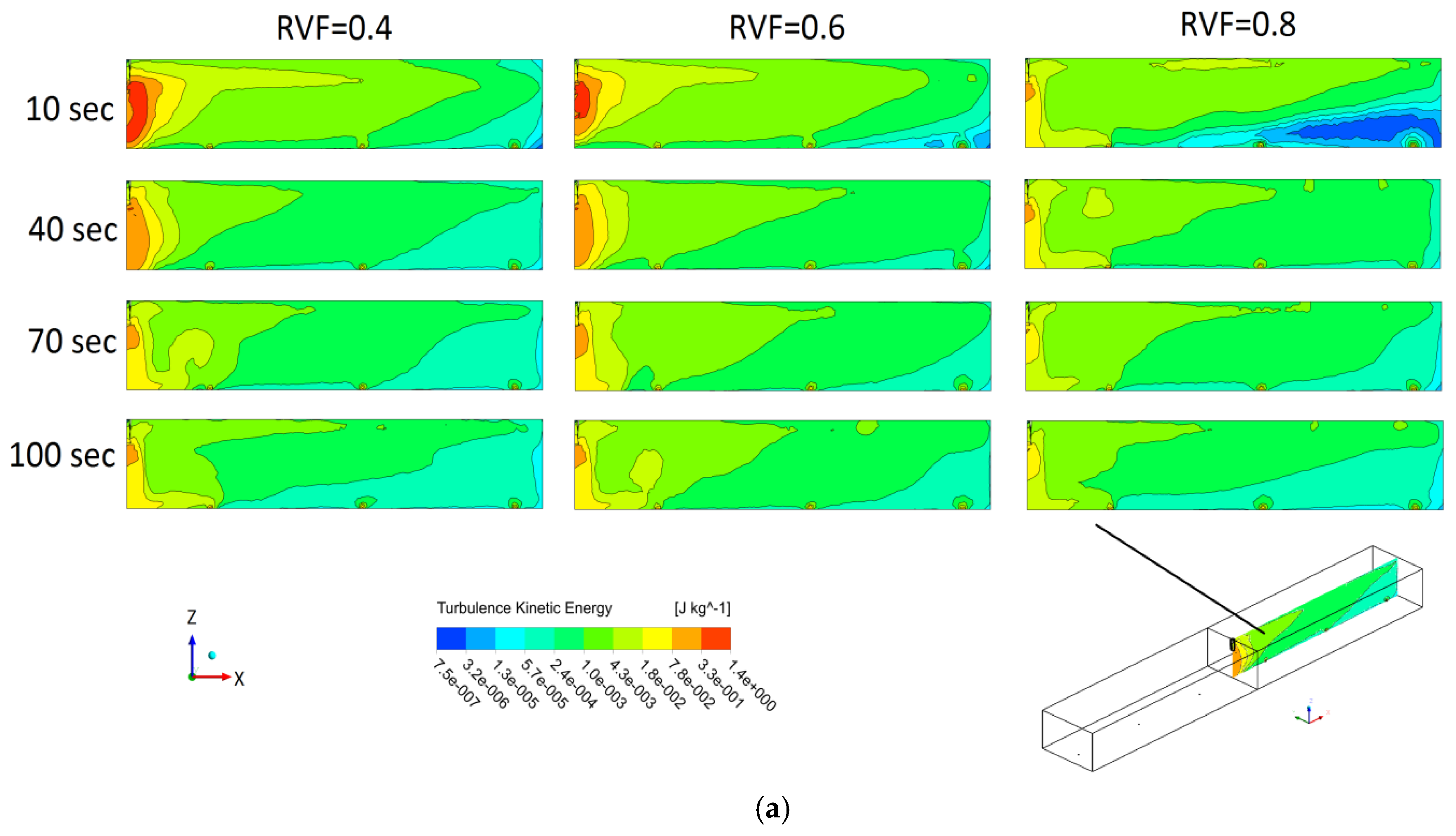

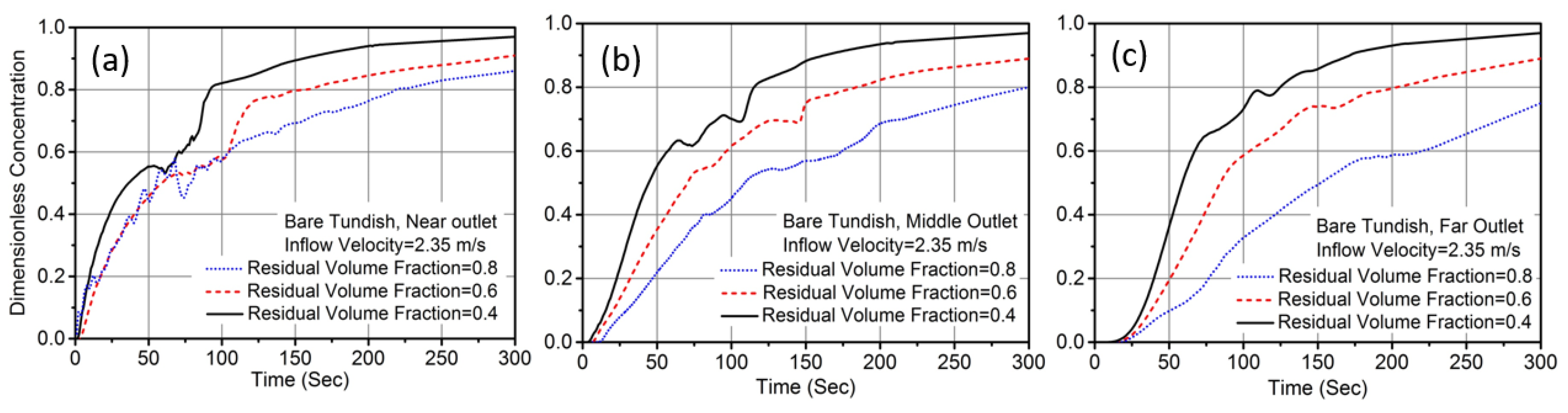

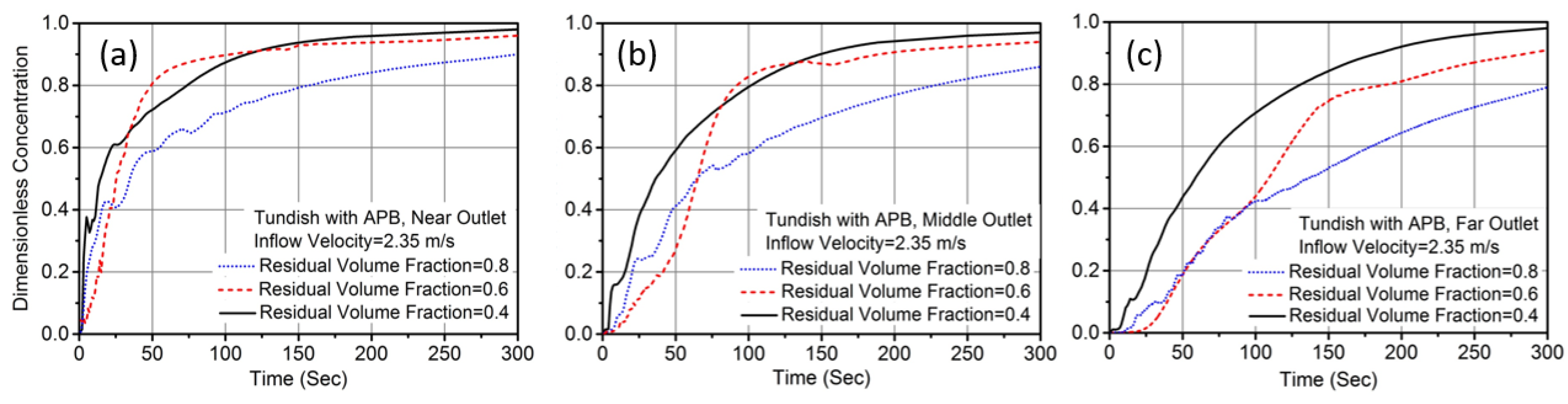

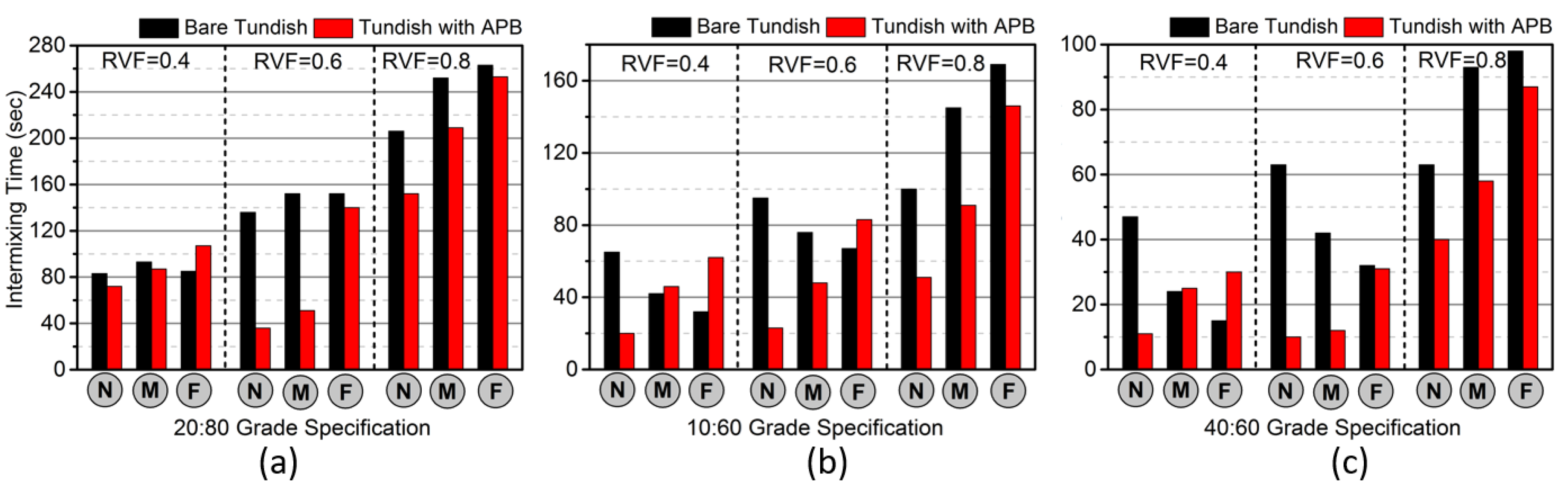

4.2. Effect of Residual Volume

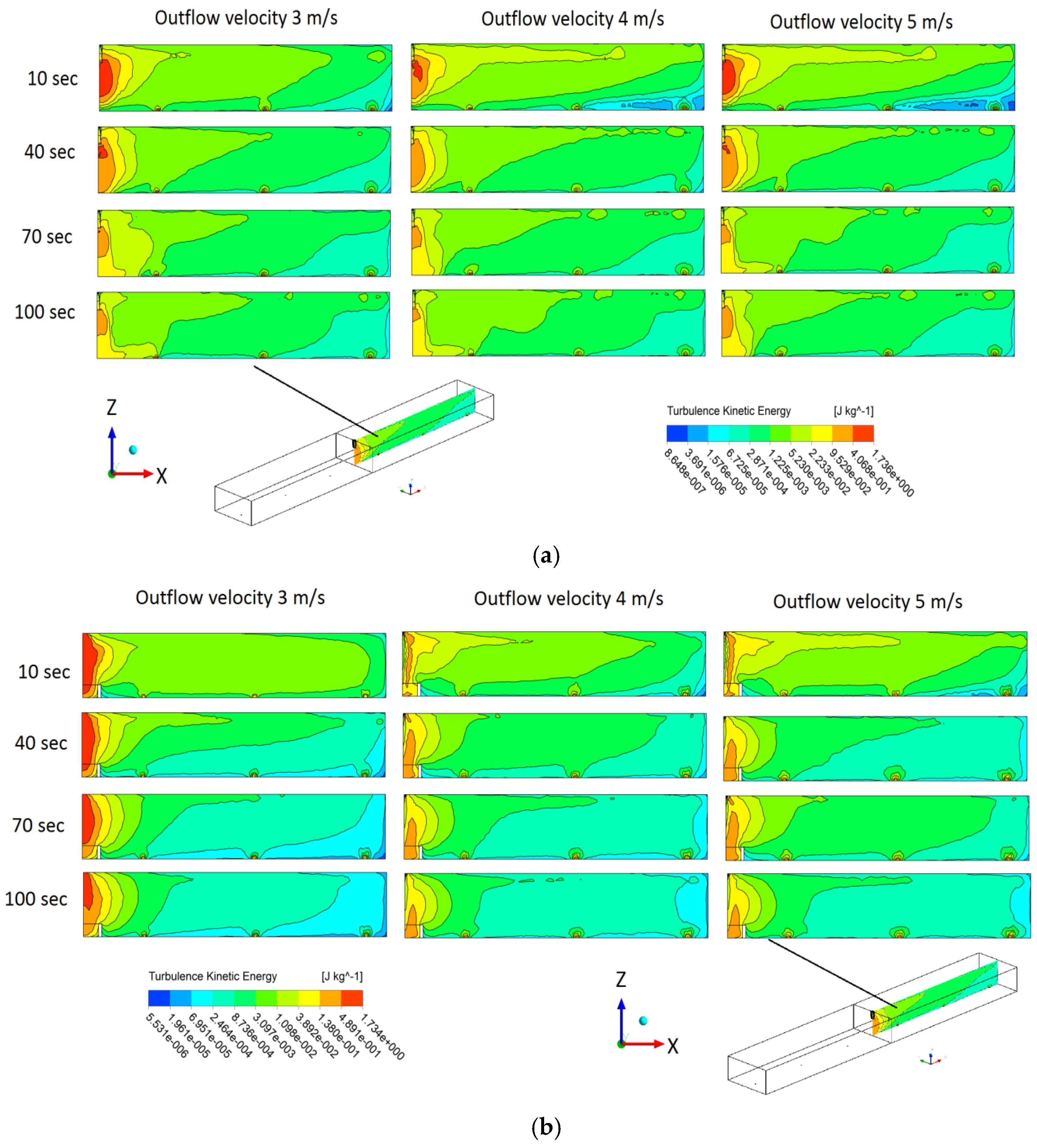

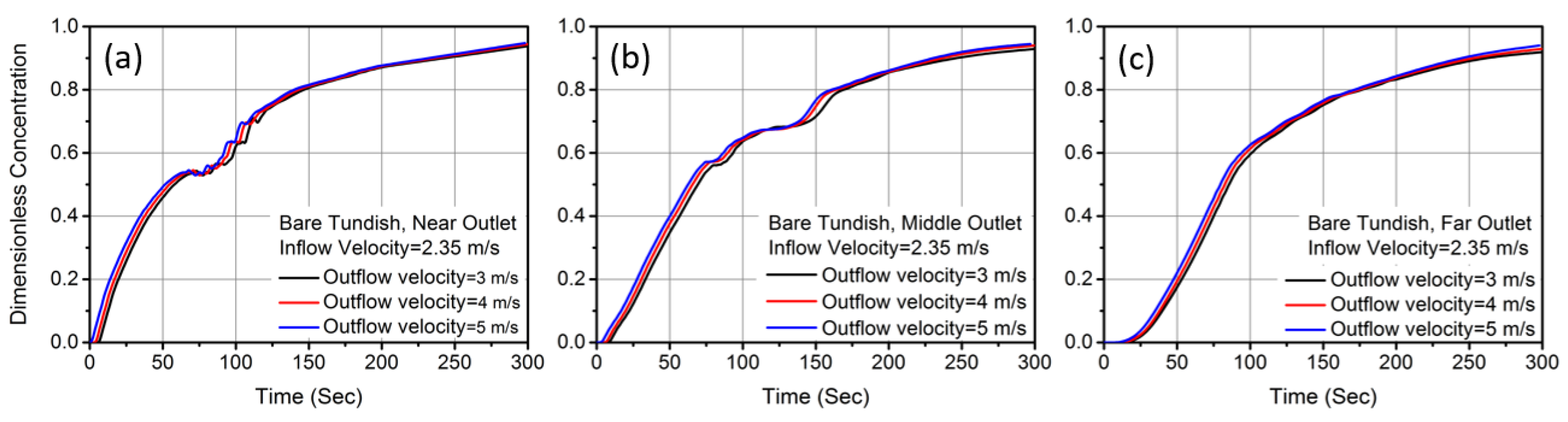

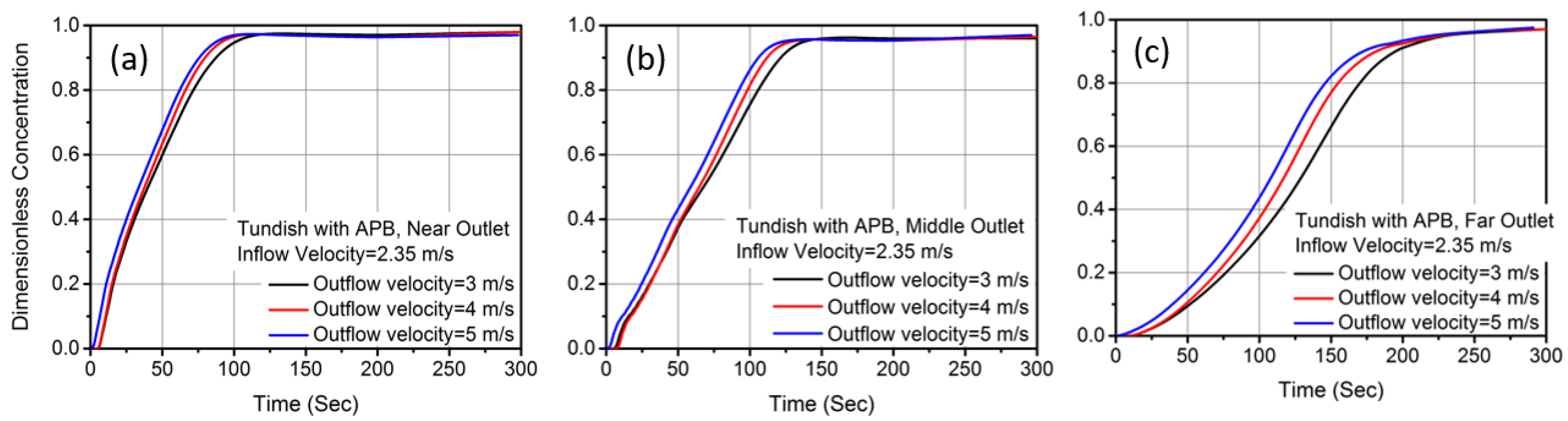

4.3. Effect of Outflow Rate

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mazumdar, D.; Singh, O.P.; Dutta, J.; Ghosh, S.; Satish, D.; Chakraborty, S. Reduction of Tundish Skull and Yield Improvement in Steel Plants Through Physical Modeling of Steelmaking Tundish Systems. Trans. Indian Inst. Met. 2011, 64, 593–605. [Google Scholar] [CrossRef]

- Mazumdar, D. Tundish Metallurgy: Towards Increased Productivity and Clean Steel. Trans. Indian Inst. Met. 2013, 66, 597–610. [Google Scholar] [CrossRef]

- Jha, P.K.; Ranjan, R.; Mondal, S.S.; Dash, S.K. Mixing in a tundish and a choice of turbulence model for its prediction. Int. J. Numer. Methods Heat Fluid Flow 2003, 13, 964–996. [Google Scholar] [CrossRef]

- Huang, X.; Thomas, B.G. Intermixing model of continuous casting during a grade transition. Metall. Mater. Trans. B 1996, 27, 617–632. [Google Scholar] [CrossRef]

- Thomas, B.G. Modeling study of intermixing in tundish and strand during a continuous-casting grade transition. Iron Steelmak. ISS Trans. 1997, 24, 83–96. [Google Scholar]

- Ni, P.; Ersson, M.; Jonsson, L.T.I.; Zhang, T.; Jönsson, P.G. Numerical Study on the Influence of a Swirling Flow Tundish on Multiphase Flow and Heat Transfer in Mold. Metals 2018, 8, 368. [Google Scholar] [CrossRef]

- Buľko, B.; Priesol, I.; Demeter, P.; Gašparovič, P.; Baricová, D.; Hrubovčáková, M. Geometric Modification of the Tundish Impact Point. Metals 2018, 8, 944. [Google Scholar] [CrossRef]

- Battaglia, V.; De Santis, M.; Volponi, V.; Zanforlin, M. Steel Thermo-Fluid-Dynamics at Tundish Drainage and Quality Features. Steel Res. Int. 2013, 84, 237–245. [Google Scholar] [CrossRef]

- Siddiqui, M.I.H.; Jha, P.K. Numerical simulation of flow-induced wall shear stresses in three different shapes of multi-strand steelmaking tundishes. Steel Res. Int. 2015, 86, 799–807. [Google Scholar] [CrossRef]

- Siddiqui, M.I.H.; Kim, M.-H. Optimization of flow control devices to minimize the grade mixing in steelmaking tundish. J. Mech. Sci. Technol. 2018, 32, 3213–3221. [Google Scholar] [CrossRef]

- Muralikrishna, A.; Bagui, S.; Mazumdar, D. Modeling and Measurements of Intermixing Time in a Water Model of a Four Strand Steelmaking Tundish System. Trans. Indian Inst. Met. 2013, 66, 281–295. [Google Scholar] [CrossRef]

- Siddiqui, M.I.H.; Jha, P.K. Assessment of Turbulence Models for Prediction of Intermixed Amount with Free Surface Variation Using Coupled Level-Set Volume of Fluid Method. ISIJ Int. 2014, 54, 2578–2587. [Google Scholar] [CrossRef]

- Odenthal, H.-J.; Boiling, R.; Pfeifer, H. Numerical and physical simulation of tundish fluid flow phenomena. Steel Res. Int. 2000, 74, 44. [Google Scholar] [CrossRef]

- Tripathi, A. Mathematical modelling of flow control in a tundish using electro-magnetic forces. Appl. Math. Model. 2011, 35, 5075–5090. [Google Scholar] [CrossRef]

- Raghavendra, K.; Sarkar, S.; Ajmani, S.K.K.; Denys, M.B.; Singh, M.K. Mathematical modelling of single and multi-strand tundish for inclusion analysis. Appl. Math. Model. 2013, 37, 1–17. [Google Scholar] [CrossRef]

- Cho, M.; Kim, I. Simple tundish mixing model of continuous casting during a grade transition. ISIJ Int. 2006, 46, 1416–1420. [Google Scholar] [CrossRef]

- Cho, M.J.; Kim, S.J. A Practical Model for Predicting Intermixed Zone During Grade Transition. ISIJ Int. 2010, 50, 1175–1179. [Google Scholar] [CrossRef]

- Alizadeh, M.; Edris, H.; Pishevar, A. Behavior of mixed grade during the grade transition for different conditions in the slab continuous casting. ISIJ Int. 2008, 48, 28–37. [Google Scholar] [CrossRef]

- Pieprzyca, J. Cast strand’s structure quality research in respect to method of the liquid steel flow through cc device’s tundish. Metalurgija 2013, 52, 157–160. [Google Scholar]

- Siddiqui, M.I.H.; Jha, P.K. Effect of Inflow Rate Variation on Intermixing in a Steelmaking Tundish During Ladle Change-Over. Steel Res. Int. 2016, 87, 733–744. [Google Scholar] [CrossRef]

- Cwudzinski, A. Influence of Hydrodynamic Structure on Mixing Time of Alloy Additions with Liquid Steel in One Strand Tundish. Arch. Metall. Mater. 2016, 61, 295–300. [Google Scholar] [CrossRef]

- Al-Harbi, M.N.; Pillai, S.; Al-Shammary, A.; Hamjad, B.; Tewari, N.; Tayeb, M.A. Mathematical modeling approach toward the optimization of the tundish mix grades process. In Proceedings of the 5th International Conference on ThermoMechanical Processing, Milan, Italy, 26–28 October 2016. [Google Scholar]

- Chatterjee, S.; Asad, A.; Kratzsch, C.; Schwarze, R.; Chattopadhyay, K. Mixing and Residence Time Distribution in an Inert Gas-Shrouded Tundish. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2017, 48, 17–21. [Google Scholar] [CrossRef]

- Cwudziński, A. Physical and mathematical simulation of liquid steel mixing zone in one strand continuous casting tundish. Int. J. Cast. Met. Res. 2017, 30, 50–60. [Google Scholar] [CrossRef]

- Krashnavtar; Mazumdar, D. Transient, Multiphase Simulation of Grade Intermixing in a Tundish Under Constant Casting Rate and Validation Against Physical Modeling. Jom 2018, 70, 2139–2147. [Google Scholar] [CrossRef]

- Hirt, C.; Nichols, B. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Osher, S.; Sethian, J. Fronts propagating with curvature-dependent speed: Algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 1988, 79, 234–246. [Google Scholar] [CrossRef]

- Dafermos, C.M. Polygonal approximations of solutions of the initial value problem for a conservation law. J. Math. Anal. Appl. 1972, 38, 33–41. [Google Scholar] [CrossRef]

- Harlow, F.H.; Welch, J.E. Numerical calculation of time-dependent viscous incompressible flow of fluid with a free surface. Phys. Fluids 1965, 8, 2182–2189. [Google Scholar] [CrossRef]

- Langer, J.S. Models of Pattern Formation in First-Order Phase Transitions. In Directions in Condensed Matter Physics; World Scientific: Singapore, 1986; pp. 165–186. [Google Scholar]

- Mazumdar, D.; Yamanoglu, G.; Shankarnarayanan, R.; Guthrie, R.I.L. Similarity considerations in the physical modelling of steel making tundish systems. Steel Res. 1995, 66, 14–19. [Google Scholar] [CrossRef]

- Launder, B.; Spalding, D. The Numerical Computation of Turbulent Flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Hinze, J.O. Turbulence; McGraw-Hill Publishing Co.: New York, NY, USA, 1975. [Google Scholar]

- Ansys Inc. ANSYS FLUENT 18.0 Theory Guide; ANSYS Inc.: Canonsburg, PA, USA, 2017. [Google Scholar]

| Parameters | λ = 0.25 Scale Model Tundish | Full-Scale Tundish |

|---|---|---|

| Length (mm) | 1500 | 6000 |

| Bath height (mm) | 150 | 600 |

| Inflow rate (m3/s) | 0.2 × 10−3 | 6.4 × 10−3 |

| APB height (mm) | 30 | 120 |

| SEN diameter (mm) | 3.75 | 15 |

| Shroud diameter (mm) | 12.5 | 50 |

| Viscosity (Pa.s) | 0.001 | 0.00637 |

| Density (kg/m3) | 1000 | 7030 |

| Volume (m3) | 0.045 | 2.88 |

| Theoretical residence time (s) | 234 | 934 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddiqui, M.I.H.; Kim, M.-H. Two-Phase Numerical Modeling of Grade Intermixing in a Steelmaking Tundish. Metals 2019, 9, 40. https://doi.org/10.3390/met9010040

Siddiqui MIH, Kim M-H. Two-Phase Numerical Modeling of Grade Intermixing in a Steelmaking Tundish. Metals. 2019; 9(1):40. https://doi.org/10.3390/met9010040

Chicago/Turabian StyleSiddiqui, Md Irfanul Haque, and Man-Hoe Kim. 2019. "Two-Phase Numerical Modeling of Grade Intermixing in a Steelmaking Tundish" Metals 9, no. 1: 40. https://doi.org/10.3390/met9010040

APA StyleSiddiqui, M. I. H., & Kim, M.-H. (2019). Two-Phase Numerical Modeling of Grade Intermixing in a Steelmaking Tundish. Metals, 9(1), 40. https://doi.org/10.3390/met9010040