Abstract

This study demonstrates the potential of the use of Ni/Al nanolayers for joining dissimilar titanium alloys. For this purpose, a detailed microstructural characterization of the diffusion bonding interfaces of TiAl to Ti6Al4V, TiAl to TiNi and TiNi to Ti6Al4V was carried out. The nanolayers (alternated aluminum and nickel (Ni-7V wt.%) layers) were deposited onto the base material surfaces. Diffusion bonding was performed at 700 and 800 °C under pressures ranging from 5 to 40 MPa and at dwell times between 60 and 180 min. Microstructural characterization was performed using high resolution transmission and scanning electron microscopies. The results revealed that dissimilar titanium joints (TiAl to Ti6Al4V, TiAl to TiNi and TiNi to Ti6Al4V) assisted by Ni/Al nanolayers can be obtained successfully at 800 °C for 60 min using a pressure of 20 MPa. The bond interfaces are thin (less than 10 µm) and mainly composed of NiAl grains with a few nanometric grains of Al8V5. Thin layers of Al-Ni-Ti intermetallic compounds were formed adjacent to the base materials due to their reaction with the nanolayers.

1. Introduction

Titanium alloys combine good mechanical properties, such as high specific strength, with low density and good resistance to corrosion, making them a good option for numerous applications. A significant proportion of the scientific community’s studies on titanium alloys has focused on the Ti6Al4V, TiNi and TiAl alloys, the latter more recently and due to their high temperature properties [1,2,3].

The aerospace industry’s continuous focus on reducing weight for increased fuel economy and operating efficiency requires the development of weight-saving structural materials for high service temperatures [1,2,3,4]. Conventional titanium alloys are continuously challenged by the operation at temperatures higher than 550 °C due to poor high-temperature oxidation resistance and creep properties, and undesirable grain growth in single phase titanium alloys, with consequent degradation of mechanical properties [2]. The possibility of using Ti6Al4V, TiNi and TiAl alloys in various applications has been increased by the development of production processes tailored to obtain the microstructures and mechanical properties adjusted to the needs of the market. The joining of these alloys facilitates the production of more complex components with a unique combination of properties and characteristics [5,6]. For instance, the joining of TiNi and Ti6Al4V alloys is vital for the development of a shape memory alloy (SMA) adaptive serrated nozzle to aid noise reduction in next-generation gas turbine engines and the blade SMA actuator to enable inflight rotor tracking in commercial and military helicopters [7,8].

However, the development of suitable joining techniques is crucial to further increase the applications of these alloys or even replace conventional alloys with combinations of high performance titanium alloys. In fact, it is known that these alloys are reactive, and thus it is difficult to obtain high quality joints by conventional processes, such as welding.

In recent years, several unconventional bonding techniques and even novel approaches have been intensively investigated [9,10,11,12,13,14,15,16,17,18]. These new approaches have been pointed out as being the best solution for dissimilar bonding of titanium alloys to other materials.

Processes which do not involve the melting of the base material, such as diffusion bonding or brazing, have proved to be the most advantageous in the production of sound joints with appreciable mechanical properties. These two bonding processes present competitive advantages over the fusion welding processes. Among the many advantages to be underlined is the possibility of bonding materials with very different mechanical and physical properties, whereby joints can be obtained with mechanical properties similar to those of the base materials, not only maintaining the mechanical performance of the component, but also reducing or eliminating residual stresses and distortions. However, the processing conditions normally involved in these processes make them less attractive economically. Considerable effort has been made in the development of new brazing alloys or interlayers that make brazing and diffusion bonding processes more suitable for industrial implementation.

Reactive multilayer thin films are an alternative interlayer for reducing the temperature and/or the pressure needed for diffusion bonding. These multilayers can improve the diffusivity, due to their nanocrystalline nature and high density of defects, and simultaneously act as a local heat source, as the result of the heat released by the exothermic reaction of the multilayers to form intermetallic compounds [15,16,17,18,19,20]. Previous studies [15,16,17] have shown that Ni/Al multilayers are effective in the diffusion bonding of TiAl to themselves [15], to steel [16] and to Ni-based superalloys [17]. The use of reactive nanolayers in the diffusion bonding process enables the reduction of the joining conditions or the obtaining of better mechanical properties when compared with the joints processed by conventional diffusion bonding processes.

Other multilayer systems can also be of use in assisting the diffusion bonding of similar and dissimilar titanium alloys joints. For instance, Ni/Ti nanolayers aided the production of sound joints with appreciable mechanical properties under less demanding processing conditions [18,19,20]. However, the interfaces formed are more complex than those obtained with reactive Ni/Al multilayers. The interface is formed from a mixture of TiNi and TiNi2 grains. In some cases, the formation of aligned nanometric grains that do not promote a uniformity of mechanical properties through the interface was observed.

In this context, the main objective of this study is the diffusion bonding of dissimilar titanium alloys assisted by Ni/Al nanolayers. The present study centers on the microstructural characterization of the interface of these joints. Interface characterization was performed by scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS), electron backscatter diffraction (EBSD), transmission electron microscopy (TEM), and selected area electron diffraction (SAED), high resolution TEM (HRTEM) and Fast Fourier transform (FFT). Microstructural characterization of the joints is essential for evaluating the effectiveness of using the Ni/Al nanolayers. Defect-free interfaces are crucial for the processing of joints with desired mechanical behavior.

2. Materials and Methods

2.1. Materials

The base materials used were TiAl (Ti-45Al-5Nb [at. %]), Ti6Al4V (Ti-12Al-3V [at. %]), and TiNi (Ti-52Ni [at. %]) alloys.

The base materials were cut and polished down to a 1-μm diamond suspension. Nickel and aluminum nanolayers were deposited alternately onto the polished surfaces of the base materials by direct current magnetron sputtering using targets of aluminum (99.99% pure) and nickel (Ni-7V wt.%). The reactive nanolayers were designed to have ~25 nm of modulation period (bilayer thickness), an equiatomic chemical composition and a total thickness of ~2.5 µm.

2.2. Diffusion Bonding Experiments

Dissimilar joining experiments were conducted in a vertical furnace at a vacuum level better than 10−2 Pa, at 700 and 800 °C, with pressures ranging from 5 to 40 MPa, bonding times from 60 to 180 min and heating and cooling rates of 10 °C /min. A description of the diffusion bonding apparatus can be found in a previous study [18] that consist in an infrared tubular furnace with an attached vacuum system mounted on a tensile test machine.

2.3. Microstructural Characterization

In order to perform microstructural and chemical characterization of the interfaces, cross sections of the joints were prepared using standard metallographic techniques. The interfaces were observed by scanning electron microscopy (SEM), and were analyzed by energy dispersive X-ray spectroscopy (EDS) using a high-resolution FEI QUANTA 400 FEG SEM (FEI Company, Hillsboro, OR, USA). The EDS measurements were made at an accelerating voltage of 15 keV by the standardless quantification method. The results obtained by this method provide a fast quantification with an automatic background subtraction, matrix correction and normalization to 100% for all the elements in the peak identification list.

Microstructural characterization of the interfaces was also performed by transmission electron microscopy (TEM, FEI Tecnai G2, FEI Company, Hillsboro, OR, USA) and selected area electron diffraction (SAED) (FEI Tecnai G2, FEI Company, Hillsboro, OR, USA), operating at 200 kV), high resolution TEM (HRTEM, JEOL JEM 2010F, JEOL Ltd., Tokyo, Japan), scanning transmission electron microscopy (STEM, JEOL JEM 2010F, JEOL Ltd., Tokyo, Japan) and EDS (Oxford Instruments, Oxfordshire, UK). Focused ion beam (FIB) (FEI FIB200, FEI FIB200, FEI Company, Hillsboro, OR, USA), at 5-30 keV using the lift-out technique, was used to prepare the TEM cross-section specimens.

Electron backscattered diffraction (EBSD) was performed on cross sections of the joints using a SEM FEI 400 FEG QUANTA (FEI Company, Hillsboro, OR, USA). The EBSD Kikuchi patterns were indexed using the database ICDD PDF-2 (PDF-2, ICDD-International Centre for Diffraction Data, Newtown Square, PA, USA, 2006) to identify the crystal structure of the phases at the interface. EBSD is a very useful technique to identify phases at very thin interfaces, since the interaction volume for this technique is reduced. A careful preparation of the surfaces is the key factor in achieving good quality EBSD patterns; the joint interfaces were submitted to a final chemo-mechanical polishing stage, using colloidal silica to remove the damage and deformation of the surfaces. This technique can also be used to obtain grain or crystallographic orientation maps of different phases that constitute the interfaces, enabling a better understanding of the distribution of the phases through them.

3. Results and Discussion

The effectiveness of using Ni/Al nanolayers to bond dissimilar titanium alloys was assessed through the microstructural characterization of the interfaces by different techniques of characterization.

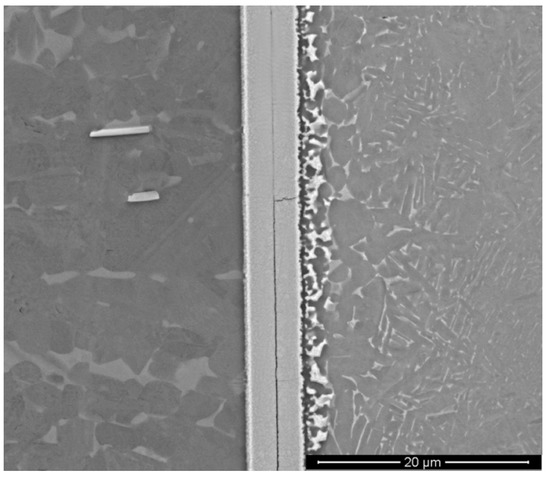

Microstructural characterization reveals that interfaces with apparent soundness were produced during solid-state diffusion bonding of dissimilar titanium alloys using Ni/Al nanolayers. The TiAl to Ti6Al4V, TiAl to TiNi and TiNi to Ti6Al4V bonds were successful at 800 °C under a pressure of 20 MPa for 60 min. A lower bonding temperature (700 °C) or reduced pressure (10 MPa) promotes the formation of interfaces with pores and cracks in the central region, showing that it is not possible to further reduce the processing conditions. Figure 1 shows the SEM image of the TiAl/Ti6Al4V interface produced at 700 °C under a pressure of 20 MPa using Ni/Al nanolayers where the presence of cracks and unbonded areas is evident. Increasing dwell time to 180 min results in a better bond but also induces a strong plastic deformation of Ti6Al4V due to the reduced creep strength of this alloy at 800 °C.

Figure 1.

Scanning electron microscopy (SEM) image of a TiAl/Ti6Al4V interface produced at 700 °C under a pressure of 20 MPa using Ni/Al nanolayers.

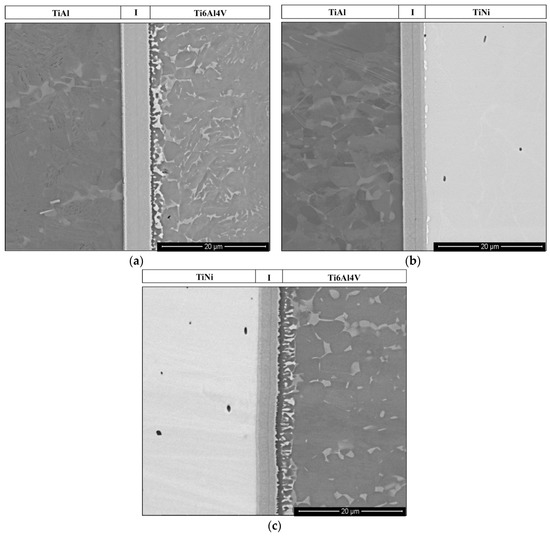

The interfaces are very thin (thickness from 3.8 to 5.4 μm). Figure 2 shows the SEM images of the interfaces obtained for the dissimilar titanium alloys joints. The microstructure of the central zone of the interfaces is very similar for all the joints and does not depend on the base materials. This zone is composed of equiaxial grains and corresponds to the larger area of the interface. This microstructure is typical of the diffusion bonding joints assisted by Ni/Al nanolayers and corresponds to the reaction of the multilayers as observed in previous researches [15,16,17].

Figure 2.

SEM images of the (a) TiAl/Ti6Al4V, (b) TiAl/TiNi and (c) TiNi/Ti6Al4V interfaces, I, produced at 800 °C under a pressure of 20 MPa using Ni/Al nanolayers.

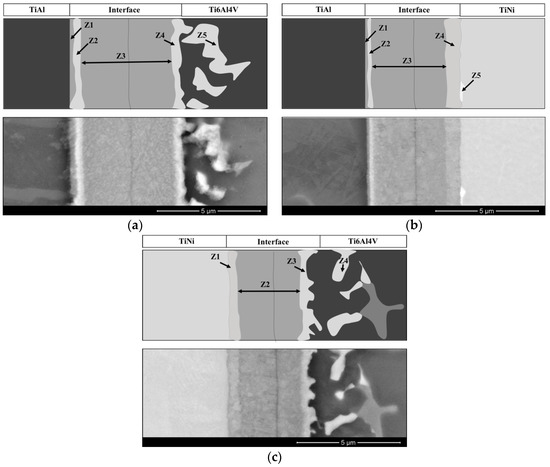

The main differences between the interfaces are the thin layers formed by the reaction of the multilayers with the base materials and the extent of diffusion during the bonding process. Higher magnifications of the SEM images and microstructure schemes of the interfaces can be observed in Figure 3.

Figure 3.

SEM images and schematic draw of the interfaces of the (a) TiAl/Ti6Al4V, (b) TiAl/TiNi and (c) TiNi/Ti6Al4V joints produced at 800 °C under a pressure of 20 MPa using Ni/Al nanolayers.

When the base material is the TiAl alloy, for any combination, the formation of two very thin reaction layers is observed (Z1 and Z2 in Figure 3a,b) corresponding to the reaction between the multilayers and TiAl. There is no change in the microstructure of TiAl adjacent to the interface, which is an indication of the limited diffusion. Regarding TiNi and Ti6Al4V alloys, different results are observed. For Ti6Al4V, only one reaction layer is observed, Z4 in Figure 3a and Z3 in Figure 3c, but the diffusion extends towards the Ti6Al4V and some bright particles are observed at approximatively 3 μm from the interface, Z5 in Figure 3a and Z4 in Figure 3c. For TiNi only one reaction layer is formed, Z4 in Figure 3b and Z1 in Figure 3c. In the TiNi/TiAl bond interface, small bright particles, Z5 in Figure 3b, are observed adjacent to this reaction layer. These particles are detected in localized areas.

Another important aspect to note for all bonds is the fact that the bond line is visible. A higher bonding temperature is required so that this line becomes no longer visible, as observed in a previous study. In similar TiAl diffusion bonds assisted by Ni/Al nanolayers, the bond line begins to disappear at temperatures above 900 °C [15]. However, these temperatures are too high, especially for Ti6Al4V, due to its low creep strength. The identification of the phases present at the interfaces was carried out through the combination of different characterization techniques such as EDS in SEM and TEM, EBSD, SAED and FFT. The need to use these techniques is related to the dimensions of the particles and layers formed during bonding, ranging from a few micrometers to nanometers. For example, the interaction volume of EDS in SEM is greater than the thickness of the two layers close to the TiAl base material or the thickness of the reaction layer of the Ti6Al4V and the multilayers. High resolution techniques and techniques with small interaction volume are therefore essential for the microstructural characterization of these interfaces, composed of thin layers and nanometric phases.

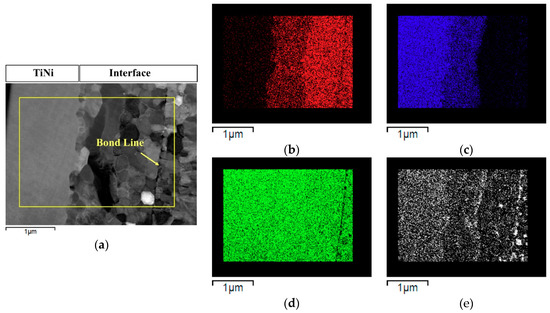

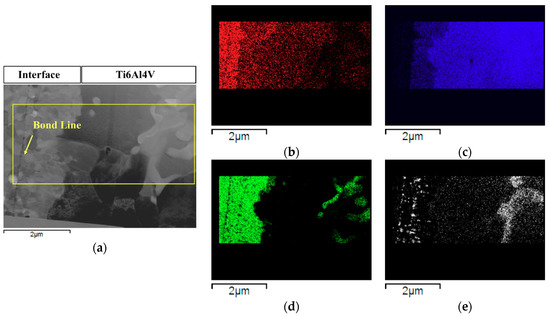

The evaluation of the elemental distribution through EDS in TEM (Figure 4 and Figure 5) confirms that at the center interface of all dissimilar joints, a larger layer of equiaxed grains composed essentially of Ni and Al is observed. The formation of these equiaxed grains is the result of the reaction of Ni and Al nanolayers during the bonding process. This multilayer reaction is essential for ensuring the bond and is well documented for TiAl alloys in previous studies [15,16,17]. However, for the bonding to be successfully achieved, the reaction and adhesion between the base materials and the multilayers is also essential. A good adhesion/bond without the formation of very brittle phases is crucial for obtaining interfaces with good mechanical behavior.

Figure 4.

(a) Scanning transmission electron microscopy (STEM) image of the TiNi/Ti6Al4V interface close to the TiNi alloy and EDS elemental maps of (b) Al, (c) Ti, (d) Ni and (e) V.

Figure 5.

(a) STEM image of the TiNi/Ti6Al4V interface close to the Ti6Al4V alloy and EDS elemental maps of (b) Al, (c) Ti, (d) Ni and (e) V.

EDS analysis in TEM clearly shows that the center of the interface consists mainly of Ni and Al. However, the V map reveals some bright points. These particles or grains enriched in V are mainly observed along the bond central line but also dispersed in the central NiAl layer. EDS and EBSD analyses in SEM did not detect the presence of these grains, probably due to their size being smaller than the interaction volume of these techniques.

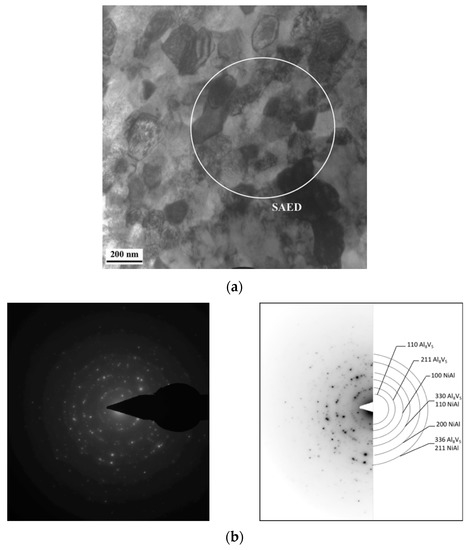

In Figure 6 it is possible to observe the TEM image of the larger central zone of the interface. The SAED pattern from this region reveals spots that were indexed as the NiAl phase, but some were indexed as the Al8V5 phase. The presence of this phase has been reported by Maj et al. [21,22] as a reaction product of Ni(V)/Al reactive multilayers. In multilayers without the addition of vanadium to the nickel target this phase is not observed, but they exhibit several defects and the deposition rate is low, since pure nickel is a ferromagnetic material [23].

Figure 6.

(a) Transmission electron microscopy (TEM) image of the grains that composed the center of the TiNi/Ti6Al4V interface and (b) Selected area electron diffraction (SAED) of the selected area indicated in (a) and the indexing scheme of the diffraction pattern.

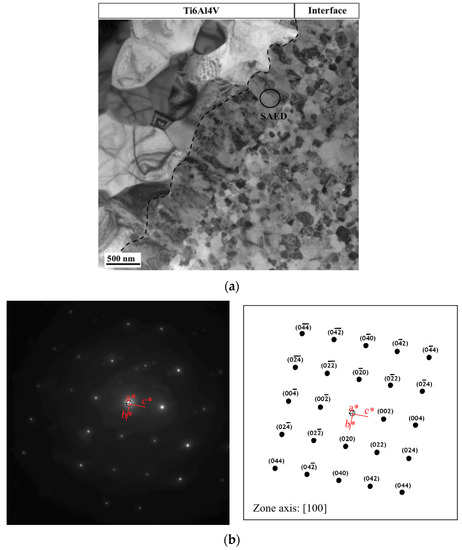

On the Ti6Al4V side, the elemental EDS maps obtained in TEM (Figure 5) clearly show that the reaction layer is constituted by Al, Ni and Ti. The TEM image and SAED pattern in Figure 7 identified the AlNi2Ti phase in this layer.

Figure 7.

(a) TEM image of the TiNi/Ti6Al4V joint and (b) SAED of the selected area indicated in (a) and the indexing scheme of the AlNi2Ti phase.

The EDS maps of Figure 5 also show the distribution of Ti, Al and V on the Ti6Al4V alloy. On the V map it is possible to observe not only the bright Al8V5 particles in the central AlNi layer, but also larger bright areas in the base material that must correspond to the grains of the β-Ti phase. Observing the Ni map, it is possible to detect Ni diffusion from the center of the interface towards the Ti6Al4V alloy, accumulating in regions adjacent to β-Ti grains. Ni diffusion is more intense on this side of the interface, extending for distances as long as 3 μm.

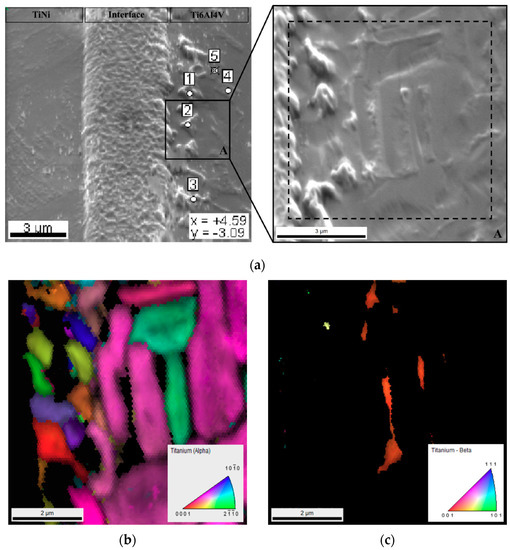

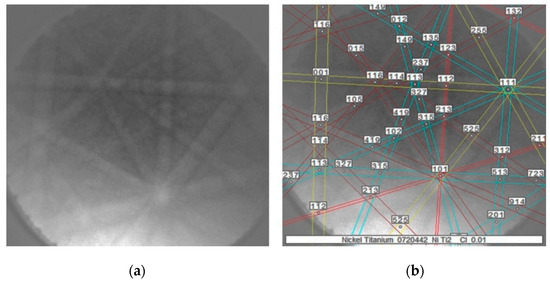

The diffusion of Ni to Ti6Al4V was analyzed in more detail by EBSD. Crystallographic orientation maps of Figure 8 were used to characterize the distribution of α-Ti and β-Ti phases of Ti6Al4V close to the interface. These maps show some dark unidentified areas due to the relief of the surface, visible in Figure 8a. This relief prevents the detection of the diffraction patterns of the saliences, hindering the identification of the phases in these regions. The areas that are composed of Ni rich grains were identified as Ti2Ni by indexing Kikuchi patterns by point analysis, as shown in Figure 9.

Figure 8.

(a) SEM image of the TiNi/Ti6Al4V joint and orientation imaging microscopy (OIM) maps of (b) α-Ti and (c) β-Ti phases.

Figure 9.

Kikuchi patterns of the point 2 indicated on Figure 8a indexed as Ti2Ni phase (a) Kikuchi pattern and (b) indexation of the pattern presented in (a).

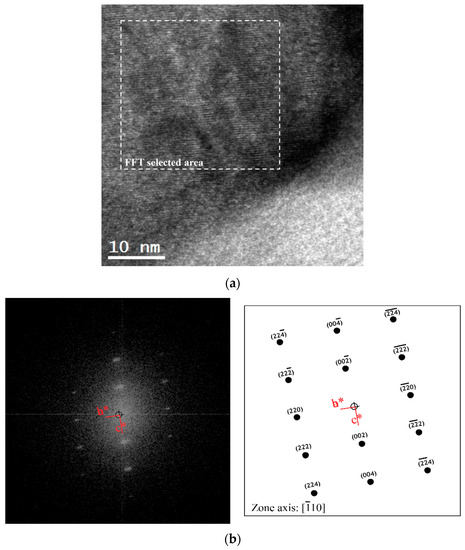

The same microstructural characterization sequence was performed for the other dissimilar bonds between the titanium alloys. Table 1 presents the possible phases, the techniques used for the identification of the different zones that constitute the interfaces and the thickness of each layer. It is important to point out that the combination of different characterization techniques was fundamental for the complete microstructural characterization of the interface. The identification of the reaction layer close to the TiNi base material was based on the indexation of the FFT of the area represented in the HRTEM image of Figure 10. From the analysis of these results it was possible to conclude that this zone consists of the AlNi2Ti phase.

Table 1.

Phase identification of the zones indicated in Figure 3 that comprised the interfaces of the titanium alloys dissimilar joints produced at 800 °C under a pressure of 20 MPa.

Figure 10.

(a) High resolution TEM (HRTEM) image of the reaction layer close to the TiNi of the TiNi/Ti6Al4V joint and (b) Fast Fourier transform (FFT) of the selected area indicated in (a) and the indexing scheme of the AlNi2Ti phase.

To sum up, the dissimilar diffusion bonding of titanium alloys assisted by nanolayers is achieved by the reaction of the multilayers, which provides good quality defect-free interfaces, and by the interdiffusion and reaction of the nanolayers with the base materials.

The larger central zone of the interfaces is composed mainly of nanometric NiAl grains, formed by the exothermic reaction of the multilayer. Grains of the Al8V5 phase are observed along the central bond line but also dispersed in this NiAl layer. These grains are formed by the reaction of Al with the V incorporated in the Ni nanolayers during sputtering.

If the base material is the TiAl alloy, two fine reaction layers consisting of AlNiTi and AlNi2Ti are formed due to the reaction between this alloy and the multilayers. These layers ensure the adhesion between the base material and the multilayers. When the base materials are Ti6Al4V and TiNi alloys, the bond is ensured by the formation of the AlNi2Ti layer.

For Ti6Al4V joints to TiAl and to TiNi, an intense diffusion of Ni is observed from the interface towards the Ti6Al4V, extending up to 3 μm from the AlNi2Ti reaction layer. Ni accumulates adjacent to the β-Ti phase in the form of Ti2Ni grains.

For the TiAl to TiNi joint a new phase, TiNi3, is observed on the TiNi side of the interface, adjacent to the AlNi2Ti reaction layer and only in localized areas.

The formation of two reaction layers composed of Al-Ni-Ti phases close to TiAl is not observed at the interface of TiAl similar joints [15]. However, these layers were observed at the interface of dissimilar joints of TiAl to steels or superalloys [16,17].

The TiNi to Ti6Al4V joints with Ni/Al nanolayers promote the formation of an interface with a more uniform microstructure than that obtained under the same processing conditions but with Ni/Ti nanolayers [18]. With the Ni/Al multilayers it is possible to avoid the formation of TiNi and Ti2Ni in alternated layers observed in joints with Ni/Ti nanolayers, which may have a beneficial effect on the mechanical properties of the joints, representing an advantage in the use of this multilayered system.

The use of multilayers is effective for the dissimilar bonding of titanium alloys. For example, in the dissimilar bond between TiAl and Ti6Al4V, published studies report temperatures of 915–1000 °C and pressures of 20 to 80 MPa for the diffusion bond [11,12]. With the multilayers it is possible to reduce these conditions to 800 °C and 20 MPa. This decrease is particularly important for the Ti6Al4V alloys and for the new generation of TiAl alloys, since these processing conditions avoid macroscopic plastic deformation, thus maintaining the dimensional stability of the base materials.

Regarding the TiNi to Ti6Al4V joints, the use of nanolayers does not significantly reduce the bonding conditions compared to those used in infrared brazing using an Ag-based braze alloy [13]. However, the use of the nanolayers has a clear advantage when it is applied to this dissimilar joint, since it avoids the formation of low melting temperature Ag-rich phases, thus not compromising the service temperature of the joints. When compared with diffusion braze joints using TiNi and TiCuNi braze alloys, then the use of the nanolayers enables the reduction of the bonding temperature from 970 to 800 °C [14], which is a significant reduction.

4. Conclusions

The use of Ni/Al nanolayers is effective in obtaining defect-free interfaces in dissimilar diffusion bonding of titanium alloys. The joining of TiAl to Ti6Al4V, TiAl to TiNi and TiNi to Ti6Al4V, assisted by Ni/Al nanolayers, can be successfully processed at 800 °C, for 60 min and under a pressure of 20 MPa. The dissimilar joining of titanium alloys assisted by nanolayers is achieved by the reaction of the multilayers, which provides good quality defect-free interfaces, and by the interdiffusion and reaction of the nanolayers with the base materials.

The wider layer was observed in the central zone of all interfaces, which is composed of a mixture of NiAl and Al8V5 nanometric grains, formed by the exothermic reaction of the multilayer.

For the TiAl to Ti6Al4V joints, two thin reaction layers, consisting of AlNiTi and AlNi2Ti, are formed close to the TiAl and one AlNi2Ti layer formed close to Ti6Al4V. Dispersed Ti2Ni particles were detected in the Ti6Al4V alloy.

For the TiAl to TiNi joints, intermetallic layers similar to those formed at the TiAl/Ti6Al4V bond were observed at the interface, whereas TiNi3 dispersed particles were observed in the TiNi alloy.

When the base materials are Ti6Al4V and TiNi alloys, the bond has fewer intermetallic layers, AlNi2Ti layers being detected close to both base materials. The dispersed particles observed in the Ti6Al4V alloy are composed by Ti2Ni.

Compared with the diffusion bonding of these alloys without the use of multilayers, a significant decrease in bonding temperature and processing pressure is achieved. This decrease is very important, taking into consideration the mechanical response of the Ti6Al4V alloy and the new TiAl alloys at higher temperatures and higher pressures.

The application of these multilayers also presents a clear advantage in relation to brazing as a process of joining these dissimilar alloys. In fact, although being possible to obtain brazed joints at temperatures similar to those observed in this study, especially in bonding TiNi to Ti6Al4V, brazing at these temperatures is only possible with the use of Ag-based alloys, consequently limiting the application of components to low service temperatures. Thus, by replacing the brazing process with the multilayer-assisted diffusion bonding process, similar bonding conditions can be obtained without compromising the mechanical properties at high temperatures.

Author Contributions

S.S. implemented and conducted the diffusion bonding experiments; A.S.R. and M.T.V. produced and characterized the multilayers; S.S., F.V. and M.F.V. characterized the interfaces and analyzed and discussed the results; all the authors participated in the design of the experiments and cooperated in writing this paper.

Funding

This work was financially supported by: Project-POCI-01-0145-FEDER-031579- funded by FEDER funds through COMPETE2020—Programa Operacional Competitividade e Internacionalização (POCI) and by national funds (PIDDAC) through FCT/MCTES and by the grant SFRH/BPD/109788/2015.

Acknowledgments

A.S. Ramos would like to thank FCT for the grant SFRH/BPD/109788/2015. The authors are grateful to CEMUP-Centro de Materiais da Universidade do Porto for expert assistance with SEM.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; WILEY-VCH: Weinheim, Germany, 2003; pp. 89–145. ISBN 9783527305346. [Google Scholar]

- Dai, J.; Zhu, J.; Chem, C.; Weng, F. High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides: A review. J. Alloys Compd. 2016, 685, 784–798. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Weimer, M.; Kelly, T.; Suzuki, A.; Subramanian, P.R. The science, technology and implementation of TiAl alloys in commercial aircraft engines. MRS Symp. Proc. 2013, 1516, 49–58. [Google Scholar] [CrossRef]

- Dimiduk, D.M. Gamma titanium aluminide alloys—An assessment within the competition of aerospace structural materials. Mater. Sci. Eng. A 1999, 263, 281–288. [Google Scholar] [CrossRef]

- Cao, J.; Qi, J.; Song, X.; Feng, J. Welding and joining of titanium aluminides. Materials 2014, 7, 4930–4962. [Google Scholar] [CrossRef] [PubMed]

- Akselsen, O.M. Joining of Shape Memory Alloys. In Shape Memory Alloys; Cismasiu, B., Ed.; IntechOpen: London, UK, 2010; ISBN 978-953-307-106-0. [Google Scholar]

- Chau, E.T.F.; Friend, C.M.; Allen, D.M.; Hora, J.; Webster, J.R. A technical and economic appraisal of shape memory alloys for aerospace applications. Mater. Sci. Eng. A 2006, 438–440, 589–592. [Google Scholar] [CrossRef]

- Calkins, F.T.; Mabe, J.H. Shape memory alloy based morphing aerostructures. J. Mech. Des. 2010, 132, 111012. [Google Scholar] [CrossRef]

- Cao, R.; Sun, J.H.; Chen, J.H. Mechanisms of joining aluminium A6061-T6 and titanium Ti–6Al–4V alloys by cold metal transfer technology. Sci. Technol. Weld Join. 2013, 18, 425–433. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P. Metallurgical strategies for the joining of titanium alloys with steels. Adv. Eng. Mater. 2018, 20, 1700764. [Google Scholar] [CrossRef]

- Glatz, W.; Clemens, H. Diffusion bonding of intermetallic Ti-47Al-2Cr-0.2Si sheet material and mechanical properties of joints at room temperature and elevated temperatures. Intermetallics 1997, 5, 415–423. [Google Scholar] [CrossRef]

- Xue, Z.; Yang, Q.; Gu, L.; Hao, X.; Ren, Y.; Geng, Y. Diffusion bonding of TiAl based alloy to Ti-Al-4V alloy using amorphous interlayer. Mater. Sci. Eng. Technol. 2015, 46, 40–46. [Google Scholar] [CrossRef]

- Shiue, R.H.; Wu, S.K. Infrared brazing Ti50Ni50 and Ti-6Al-4V using the BAg-8 braze alloy. Mater. Trans. 2005, 46, 2057–2066. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, Y.T.; Shiue, C.Y. Infrared brazing of Ti50Al50 and Ti6Al4V using two Ti-based filler metals. Intermetallics 2008, 16, 1083–1089. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. TEM and HRTEM characterization of TiAl diffusion bonds using Ni/Al nanolayers. Microsc. Microanal. 2015, 21, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Reaction-assisted diffusion bonding of TiAl alloy to steel. Mater. Chem. Phys. 2016, 171, 73–82. [Google Scholar] [CrossRef]

- Ramos, A.S.; Vieira, M.T.; Simões, S.; Viana, F.; Vieira, M.F. Reaction-assisted diffusion bonding of advanced materials. Defect Diffus. Forum. 2010, 297–301, 972–977. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Reaction zone formed during diffusion bonding of TiNi to Ti6Al4V using Ni/Ti nanolayers. J. Mater. Sci. 2013, 58, 7718–7727. [Google Scholar] [CrossRef]

- Simões, S.; Ramos, A.S.; Viana, F.; Vieira, M.T.; Vieira, M.F. Joining of TiAl to steel by diffusion bonding with Ni/Ti reactive multilayers. Metals 2016, 6, 96. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Microstructural characterization of diffusion bonds assisted by Ni/Ti nanolayers. J. Mater. Eng. Perfom. 2016, 25, 3245–3251. [Google Scholar] [CrossRef]

- Maj, L.; Morgiel, J. In-situ transmission electron microscopy observations of nucleation and growth of intermetallic phases during reaction of Ni(V)/Al multilayers. Thin Solid Films 2017, 621, 165–170. [Google Scholar] [CrossRef]

- Maj, L.; Morgiel, J.; Szlezynger, M.; Bala, P.; Cios, G. Effect of low and high heating rates on reaction path of Ni(V)/Al multilayer. Mater. Chem. Phys. 2017, 193, 244–252. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. TEM characterization of as-deposited and annealed Ni/Al multilayer thin film. Microsc. Microanal. 2010, 16, 662–669. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).