Abstract

Using feedstock containing discrete dual or multi powders leads to segregation in the powder bed of additive manufacturing processes. In the present study, a new impregnated hybrid binder with properties closer to those of the base powder is developed to mitigate powder segregation in the inkjet 3D printing of titanium components.

1. Introduction

As per ASTM standards (ISO/ASTM 52900-15, 2015), additive manufacturing (AM) or 3D printing is defined as the process of joining materials layer upon layer to fabricate parts directly from the 3D model data available in the Standard Tessellation Language (*.STL) file format. Most AM processes for metals consist of a powder bed where fine metal powders are spread over a descending platform layer by layer and bonded or fused together as per the part cross-section. Powder bed AM processes include [1]: (a) fusion-based processes such as Selective Laser Melting, Electron Beam Melting and Selective Laser Sintering, where thermal energy (laser or electron beam) selectively fuses regions of the powder bed; and (b) non-fusion-based processes, such as inkjet and binder jet 3D printing, where a binding agent (solid or liquid) is used to join the metal powders [2]. The binding agent can either be an adhesive ink (liquid binder) jetted through the print head or a solid binder that is mixed with the part material and activated through deposition of solvent. Post 3D printing, the binder materials are burnt off and subsequently sintered to achieve high density.

Currently, most commercialized inkjet 3D printers are based on jetting of binders or binder solutions on pure metal powder [3,4,5]. However, there are some advantages with incorporating solid binders within the feedstock. By controlling the size and morphology of solid binders, various pore sizes and porosity levels can be achieved in the final part and the property of the part can be tailored to the specific application requirements. Moreover, jetting of solvents, rather than binders, is much easier and faster and requires less sophisticated printheads. On the other hand, the parts made from solid binders that are mixed with feedstock are weaker since the polymeric network does not have sufficient continuity. Solid binders that are commonly used for metals include maltodextrin, sugar, cornstarch, polyvinyl alcohol, etc. [6,7].

One of the major mitigating factor that affects the final properties of parts fabricated in powder bed AM processes is the material inhomogeneity arising due to powder segregation effects throughout the powder bed [8]. Powder spreading in the form of thin layers is a unique way of powder transfer in AM processes that are based on the powder bed, and poses a huge challenge with more predominant segregation effects in the composite feedstock, which contains two or more powder types in discrete form. The differences in powder characteristics such as density and powder granulometry (particle size and morphology) between the two or multiple phases (base material, reinforcements or binder) significantly affect their flow characteristics, mobility and thereby affect the packing of powders and spatial homogeneity [8,9]. There are only limited studies on the segregation effects in the case of powder bed processes [10,11]. The study on segregation effects in the inkjet 3D printing with dual powder feedstock could be helpful in effectively consolidating homogenous porous parts, and could be further extended to fabricate complex composite parts utilizing multi powder feedstock in the fusion and non-fusion-type powder bed processes.

In the present study, a novel hybrid binder with properties closer to the base material is proposed to mitigate feed powder segregation in the powder bed of ink jet 3D printing of Titanium parts. The effect of the new hybrid binder on the segregation of the metal/binder system was studied through thermal gravimetric analysis and density measurements along the powder spreading direction.

2. Materials and Methods

The feedstock for inkjet 3D printing was prepared with the powder materials listed in Table 1. Two types of feedstock powders were prepared in this study named as “original” and “modified” feedstock. Original feedstock was prepared by mechanical blending of Ti45 and PVA (7.5 wt %) using a tumbler mixer (Inversina, Bioengineering, Switzerland). By utilizing an inkjet 3D printer (310 Plus, Z Corporation, Rock Hill, SC, USA), 30 Titanium cubes of size 4 × 4 × 4 mm3 were fabricated in three rows (10 samples per row) along the powder spreading direction within a distance range of 10 to 100 mm from the printer wall with internal spacing of 10 mm in the X and Y directions.

Table 1.

Materials utilized in the present study.

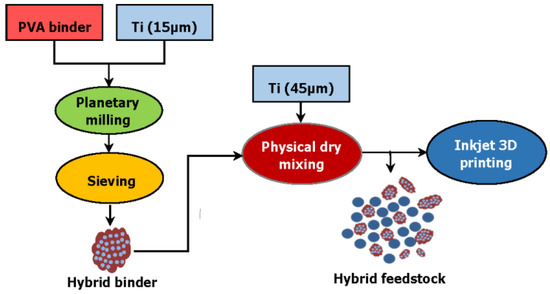

A hybrid modified binder system was synthesized by mechanical milling of an equal volumetric amount of PVA with fine Ti15 powder (as shown in Figure 1) using a planetary ball milling machine PM-400 RETSCH, Germany. The ball to powder ratio was kept at 3:1 and milled at 200 rpm for 3 h. No process control agent was utilized during powder milling. The powders were fully dried in a vacuum oven at 110 °C overnight and later sieved through a mesh with 80 µm opening size. The hybrid binder was then dry mixed with Ti45 powder to prepare the modified feedstock. The total binder content in both the original and modified feedstock was set to 7.5 wt %.

Figure 1.

Flowchart—preparation of hybrid binder.

The morphologies of the two feedstocks (Ti45 and Ti15) were observed using a Zeiss Sigma Field Emission Scanning Electron Microscope (FESEM, Oberkochen, Germany). Tap density of the powders was measured by mechanically tapping a graduated measuring cylinder containing the powder samples. Powders were accurately weighed and poured into the graduated cylinder. After measuring the initial volume of the powders, the cylinder was mechanically tapped by raising the cylinder and allowing it to drop under its own weight, and volume readings were taken after a definite volume change was observed. Tap count was gradually increased to 1000 at a constant tapping frequency of 300 tap min−1 until the powder drop height due to tapping becomes stable. Tapped density was determined from the ratio between the weight of the powders filled within the graduated cylinder and the final tapped volume.

To evaluate the binder content and measure the binder segregation in Ti parts, a Thermal Gravimetric Analysis (TGA) was performed using (TGA, Q-500TA Instruments, New Castle, DE, USA). The green parts printed along the powder spreading direction (x = 10 to 100 mm) were heated from 30 °C to 600 °C at a heating rate of 5 °C/min under a constant flow of pure argon (20 mL/min). The debinding and sintering were performed at a temperature of 600 °C and 1350 °C for 1 h, respectively within a tube furnace under streaming flow of Argon gas. The brown and the sintered density values of the Ti parts were measured by using Archimedes method.

3. Results and Discussion

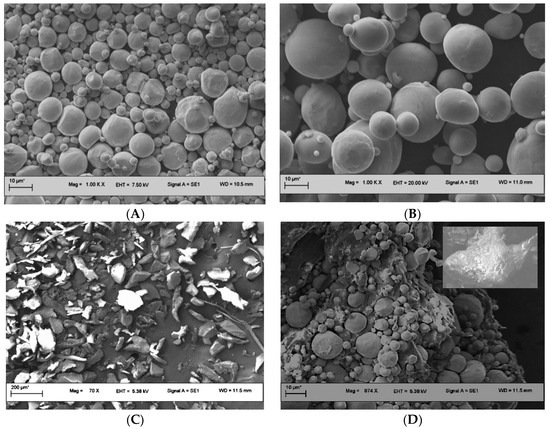

Microstructural characterization studies (Figure 2) indicate that Ti45 and Ti15 powders are spherical in shape. PVA powders are of size ~80 µm and have irregular morphology. Figure 2D shows the SEM images of the modified binder. Because of the high centrifugal forces generated within the planetary ball mill, the steel balls effectively mill the powders and embed Ti15 into the soft polymer matrix (PVA) and thereby making a hybrid binder system.

Figure 2.

SEM images of (A) Pure Ti powder (D90 = 15 µm) (B) Pure Ti powder (D90 = 45 µm) (C) polyvinyl alcohol (PVA powder of size < 80 µm) and (D) hybrid modified binder system—PVA impregnated with fine Ti powder (15 µm).

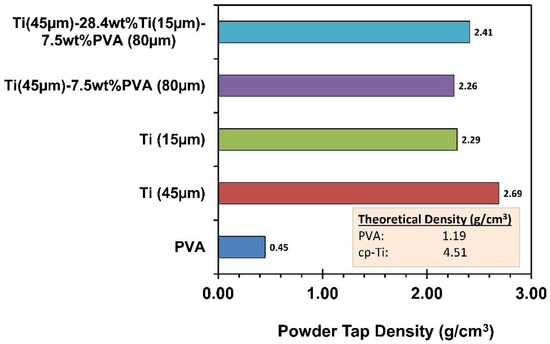

To evaluate the friction among the powder particles and powder packing using the hybrid binder system, the tap density of the powders was determined, and the results are shown in Figure 3. The feedstock containing modified binder exhibited a higher tap density of ~2.41 g/cm3 when compared to that of feedstock with PVA (~2.26 g/cm3). The results indicate that, although the tap density of Ti15 powder is less than that of Ti45, it gives a better packing when hybridized with PVA. Ti15 increases the density of individual binder particles compared to PVA and the rearrangement of particles in the modified binder during tapping is much easier.

Figure 3.

Tap density of Ti, PVA and two feedstock materials.

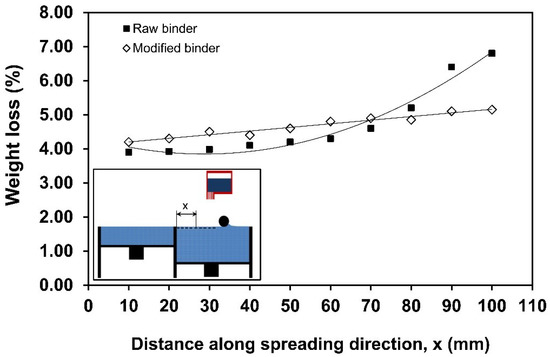

The results of thermal gravimetric analysis (TGA) conducted on the green parts fabricated by utilizing PVA and hybrid binders are shown in Figure 4. In the case of PVA, along the powder spreading distance at x = 10–100 mm, the weight loss due to burning of PVA increases (up to T = 600 °C) and found to be the maximum at x = 100 mm (~6.8%) with a binder gradient of ~2.5 wt %. These results indicate increase in the amount of binder content (PVA) along the powder spreading direction, thereby revealing segregation effects in the powder bed, which may be due to the combined effects of: (a) difference in the density values between the binder (PVA, 1.19 g/cm3) and metal powder material (Ti, 4.51 g/cm3) [9], and (b) difference in the powder morphology between the binder (PVA, irregular) and base powder (Ti, spherical) [8], as shown in Figure 2. The TGA results of the hybrid binder indicate a significant reduction in the binder gradient (~1 wt % at x = 100 mm) along the powder spreading direction indicating the possibilities for obtaining more homogenous properties on the powder bed of inkjet 3D printing.

Figure 4.

Thermal gravimetric analysis (TGA) results of printed parts along the powder spreading direction utilizing PVA and hybrid binder system.

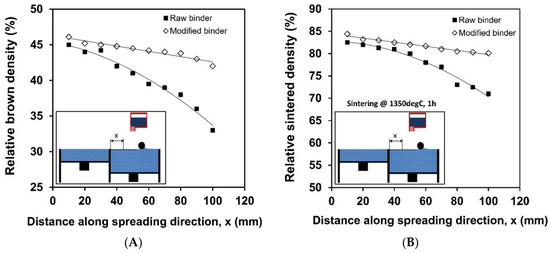

The results of brown and sintered density measurements of the Ti parts 3D printed using the PVA and hybrid modified binders are discussed in Figure 5A,B, respectively. Ti parts 3D printed with the modified binder is found to exhibit higher density values than those of the parts 3D printed with PVA. Along the powder spreading direction of distance x = 0–100 mm, the parts 3D printed using the PVA binder exhibited density difference of 27% and 13% for brown and sintered density, respectively, whereas this density difference reduced to 5% and 7% in the case of hybrid modified binder exhibiting possible homogeneous properties along the powder spreading direction. The significant change in the density of Ti parts observed with PVA and modified binder is due to the segregation effects and is found to be minimal with the hybrid binder and this is due to the combined effects of: (a) improved density of the binder with Ti15 impregnation (2.26 g/cm3 to 2.41 g/cm3) and (b) improved powder packing with possible free Ti15 powders in the hybrid binder occupying the interstitial spaces contributing to the densification of the powder bed.

Figure 5.

(A) Relative brown density, and (B) Relative sintered density of printed parts along the powder spreading direction utilizing PVA and hybrid binder system.

4. Conclusions

Inkjet 3D printing of metals using premixed feedstock that contain various powders with different physical and morphological properties promotes powder segregation and has detrimental effect on the compositional uniformity during of the final part. The primary conclusions of the present study are summarized below:

- In the inkjet 3D printing of metal parts, segregation is remarkable when using low density polymeric binder mixed with metal powder.

- The feedstock containing hybrid modified binder exhibited higher tap density of ~2.41 g/cm3 when compared to feedstock with PVA (~2.26 g/cm3).

- By using hybrid modified binder, the brown and sintered density values of the printed part were found to substantially increase, exhibiting low segregation with density differences as low as ~5% and ~7% measured at a distance x = 0 and 100 mm from the printer wall, respectively. Whereas, density differences of ~27% (brown) and ~13% (sintered) were measured in the case of feedstock with PVA (Original binder).

- Reduction in the powder segregation effects with the hybrid modified binder can also be confirmed from the results of thermal gravimetric analysis conducted on the feedstock collected from the powder bed at a distance x = 0–100 mm from the printer wall indicating only ~1 wt % reduction in the binder gradient for the hybrid modified binder which is significantly low when compared to PVA (~2.5 wt %).

In summary, a hybrid binder that consists of fine powders embedded inside polymeric binder proved to be a solution for mitigating the risk of powder segregation during the printing process. The hybrid binder reduces the density mismatch between the metal powder and binder and can also influence final density of the parts.

Author Contributions

W.J. contributed in development of concept, S.M. and G.K.M. designed the experiments and prepared the feedstock and did 3D printing, also contributed in writing the report, S.L. and M.S. analyzed the data.

Acknowledgments

This research was supported in part by A*STAR’s Science and Engineering Research Council in Singapore (Grant ID: 142 68 00088).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bhavar, V.; Kattire, P.; Patil, V.; Khot, S.; Gujar, K.; Singh, R. A review on powder bed fusion technology of metal additive manufacturing. In Proceedings of the 4th International Conference and Exhibition on Additive Manufacturing Technologies-AM-2014, Bangalore, India, 1–2 September 2014; pp. 1–2. [Google Scholar]

- Salehi, M.; Gupta, M.; Maleksaeedi, S.; Sharon, N.M.L. Inkjet Based 3D Additive Manufacturing of Metals; Materials Research Forum LLC: Millersville, PA, USA, 2018. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Binder jetting. In Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; pp. 205–218. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Bai, Y.; Williams, C.B. Binder jetting additive manufacturing with a particle-free metal ink as a binder precursor. Mater. Des. 2018, 147, 146–156. [Google Scholar] [CrossRef]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; Osman, N.A.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef] [PubMed]

- El-Hajje, A.; Kolos, E.C.; Wang, J.K.; Maleksaeedi, S.; He, Z.; Wiria, F.E.; Choong, C.; Ruys, A.J. Physical and mechanical characterisation of 3D-printed porous titanium for biomedical applications. J. Mater. Sci. Mater. Med. 2014, 25, 2471–2480. [Google Scholar] [CrossRef] [PubMed]

- Gürtler, F.; Karg, M.; Dobler, M.; Kohl, S.; Tzivilsky, I.; Schmidt, M. Influence of powder distribution on process stability in laser beam melting: Analysis of melt pool dynamics by numerical simulations. In Solid Freeform Fabrication Symposium; SFF: Austin, TX, USA, 2014; pp. 1099–1117. [Google Scholar]

- Jacob, G.; Donmez, A.; Slotwinski, J.; Moylan, S. Measurement of powder bed density in powder bed fusion additive manufacturing processes. Measur. Sci. Technol. 2016, 27, 115601. [Google Scholar] [CrossRef]

- Haeri, S.; Wang, Y.; Ghita, O.; Sun, J. Discrete element simulation and experimental study of powder spreading process in additive manufacturing. Powder Technol. 2017, 306, 45–54. [Google Scholar] [CrossRef]

- Bae, C.-J.; Ramachandran, A.; Halloran, J.W. Quantifying Particle Segregation in Sequential Layers fabricated by Additive Manufacturing. J. Eur. Ceram. Soc. 2018, in press. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).