Abstract

This article presents the results of an examination of the properties of arc-sprayed aluminum on alloyed armor-grade steel. Thermal arc spraying was conducted with a EuTronic Arc Spray 4 wire arc sprayer. Aluminum wire 1.6 mm in diameter was used to produce dense, abrasion- and erosion-resistant coatings approx. 1.0 mm thick with and without nickel/5% aluminum-buffered subcoating. Aluminum coatings were characterized in accordance with ASTM G 65-00 abrasion resistance test, ASTM G 76-95 erosion resistance tests, ASTM C 633-01 adhesion strength, HV0.1 hardness tests and metallographic analyses. Results demonstrate properties of arc-sprayed aluminum and aluminum-nickel material coatings that are especially promising in industrial applications where erosion-, abrasion- and corrosion-resistant coating properties are required.

1. Introduction

Methods of surface engineering such as thermal spraying have undergone many changes and developments in recent years, thanks in part to advances made in heat-source technology and newly developed coating materials [1,2,3,4,5,6,7,8]. Currently, around 70% of industrial applications involving thermal spraying are used to produce new machinery parts or devices, which require a high finish and surface finish quality. The use of thermally sprayed coatings has not only increased the longevity of the protection features of steel assemblies against the effects of environmentally induced corrosion, but has also contributed to prolonging the service time of parts used in textile machinery, pump and mixer components, plastic injection molding machines, and to improving the reliability and durability of boiler components. Aluminum coatings are applied to structural components and devices made of steel, cast steel or cast iron, which are exposed to potentially corrosive environments in water, and atmospheres including exhaust gases regularly reaching 900 °C and periodically up to 1100 °C. Steel alloys coated by this method show an increased temperature and hostile environment resistance, especially with respect to sulfur. Aluminum coatings are most commonly used in constructions with corrosivity categories of C4 and higher and at pH 4 to 8, providing significant life improvement over conventional barrier coatings. It can serve for a variety of marine, atmospheric and high-temperature applications [4,5,6,7].

2. Experimental

2.1. Research Objectives

The goal of this research was to develop the technical conditions of aluminum arc spraying using a TAFA 01T grade solid aluminum thermal spray wire deposited directly onto the surface of Armox 500 T armor-grade alloy steel and, in addition, on a buffered subcoating (composed of 95% Ni + 5% Al, solid thermal spray wire TAFA 75B BondArc grade). Technical assumption validity was confirmed by macroscopic and microscopic metallographic studies, erosion resistance, adhesion, hardness and coating testing.

2.2. Materials and Equipment

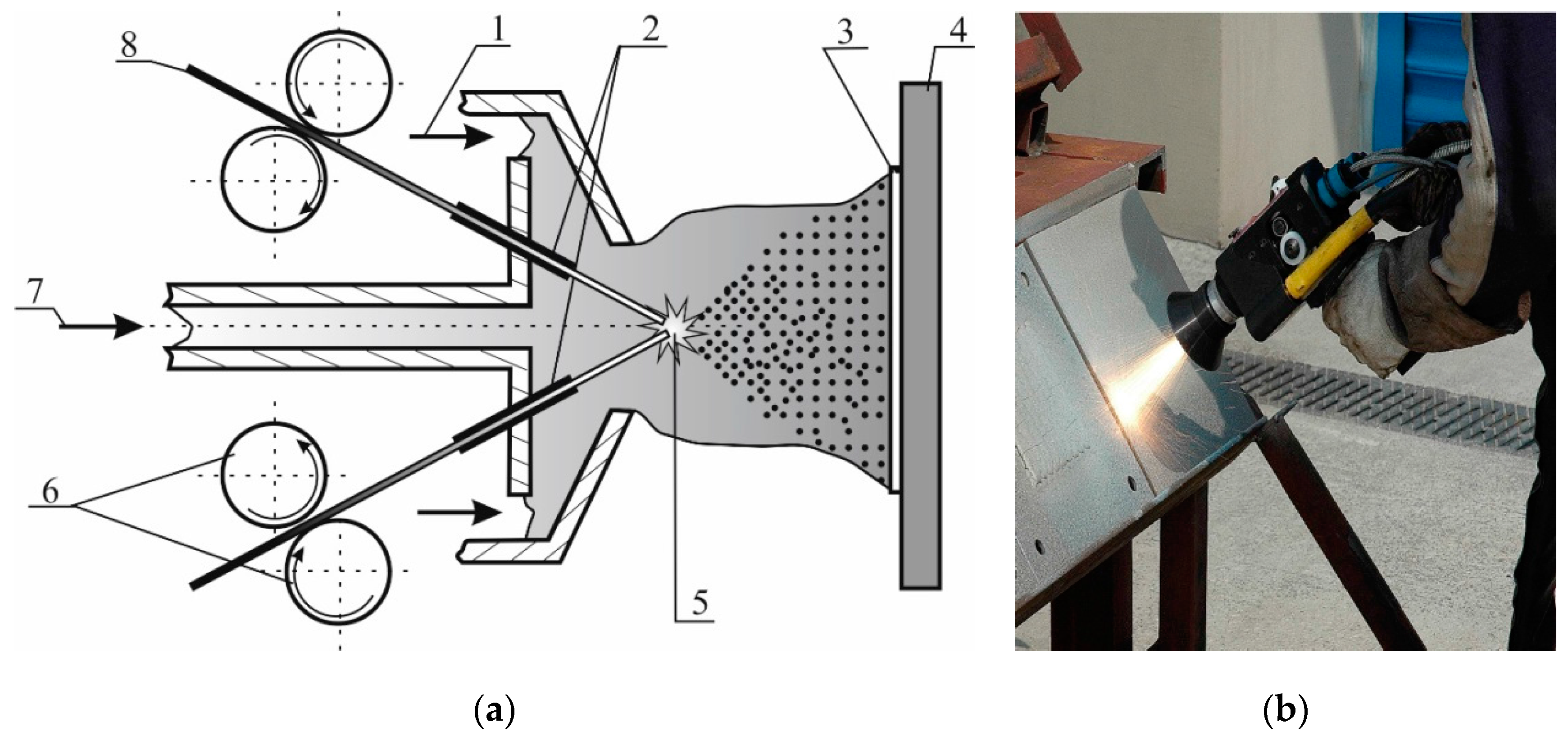

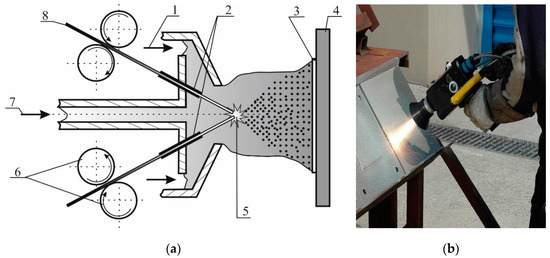

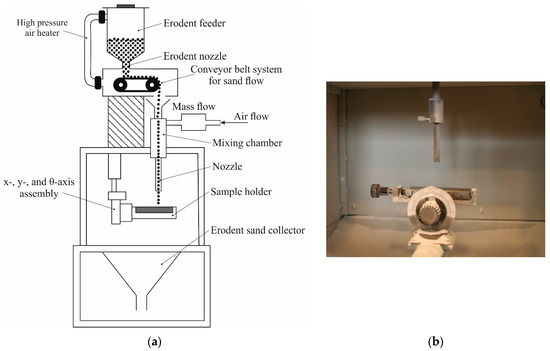

The arc spraying process was carried out in an upright position with a EuTronic Arc Spray 4 power source and a Gun 4 manual spray gun, Figure 1.

Figure 1.

Spraying process: (a) scheme of wire arc spraying apparatus: 1—compressed air; 2—wire electric contact; 3—sprayed layer; 4—base metal; 5—electric arc; 6—wire feeder; 7—compressed air; 8—welding wire; (b) photo of manual arc spray trial run.

The processed Armox 500T armor-grade alloy steel from SSAB was certified according to EN 10 204-3.1B, Table 1. Final surface preparation was done by abrasive blasting sheets prior to spraying with sharp-edged cast iron of 0.5–1.5 mm shot grain size in accordance with standard PN-EN ISO 2063-1:2017. Final surface roughness of the steel substrate after abrasive blasting was: Ra = 12 μm, Rz = 85 μm. The 300 × 300 × 8 mm3 steel plates were shot with pre-heated gas just before spraying and heated to about 40 °C. During arc spraying, two types of Praxair TAFA solid wires were used; for the 0.1 mm-thick buffered subcoating, a nickel/aluminum 75B BondArc grade with a diameter of 1.6 mm and, for the outer coating, a 0.8 mm-thick 01T grade aluminum wire with a diameter of 1.6 mm.

Table 1.

Chemical composition of Armox 500 T armor-grade alloy.

2.3. Arc Spraying Parameters

Arc spraying samples were prepared in accordance with ISO 14923:2003 [9]. Optimal processing parameters are shown in Table 2. One trial sheet was made with and without binding nickel aluminate, from which the samples were subsequently cut. Testing in each case used 3 samples.

Table 2.

Arc spraying parameters for buffered subcoating NiAl 95/5 and aluminum outer coating applied to Armox 500 T.

2.4. Metallographic Analysis of Coatings

Microscopic and macroscopic studies were carried out in the cross-sectional plane and on the surface of samples (sample without buffered substrate and with nickel-aluminum buffered subcoating). Microscopic and macroscopic studies were conducted with an Olympus GX 71 light microscope. Surface analyses were carried out on an LEO 435 VP electron scanning microscope.

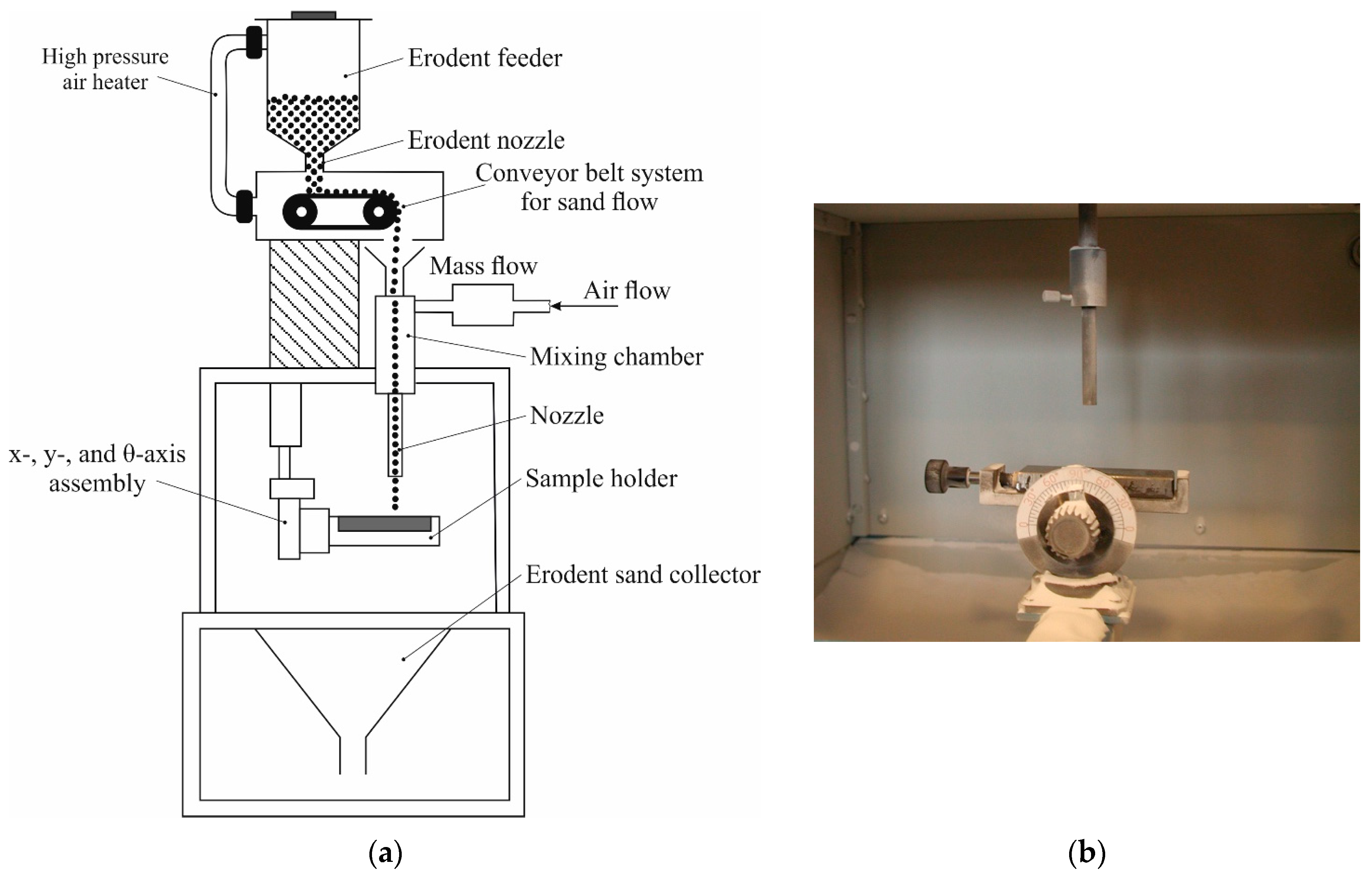

2.5. Analysis of Coating Erosion Resistance

The erosion resistance of aluminum arc sprayed coating were tested in accordance with ASTM G76-13 [10], as shown in Figure 2. Alumina (Al2O3) powder was used as the erodent material with a particle diameter of 71 μm. The erodent particle velocity was 70 ± 2 m/s, with efficiency of the erodent application set at 2.0 ± 0.5 g/min with a nozzle outlet distance from the test surface set 10 mm. Erosion resistance tests were performed at attack angles of 90°, 60° and 30°.

Figure 2.

Erosion resistance test rig according to ASTM G 76-2: (a) a schematic view, (b) the interior view of the erosion measuring chamber.

2.6. Coating Hardness Measurements

The hardness test of the aluminum shell and arc sub-cushion was done with a Vickers HV0.1 (Aluminum and Nickel Alloy Buffer Substrate) and HV1 (Substrate—Armox 500 T) on a Micro-Hardness Tester 401MVD™. The test was carried out in accordance with ISO 6507-1.

2.7. Analysis of Coating Adhesion Strength

An attempt to determine the adhesion of the aluminum coating arc-sprayed to the steel substrate was carried out in accordance with ASTM C 633-01. For Armox 500 T steel plates subjected to arc-sprayed aluminum without buffering subcoating and with nickel-aluminum buffered subcoating, 40 mm-diameter discs were cut. The sprayed samples were bound together using Henkel Loctite® Hysol® 3478 A & B Superior Metal Adhesive. Static testing was performed on a Zwick Z100 tensile test machine.

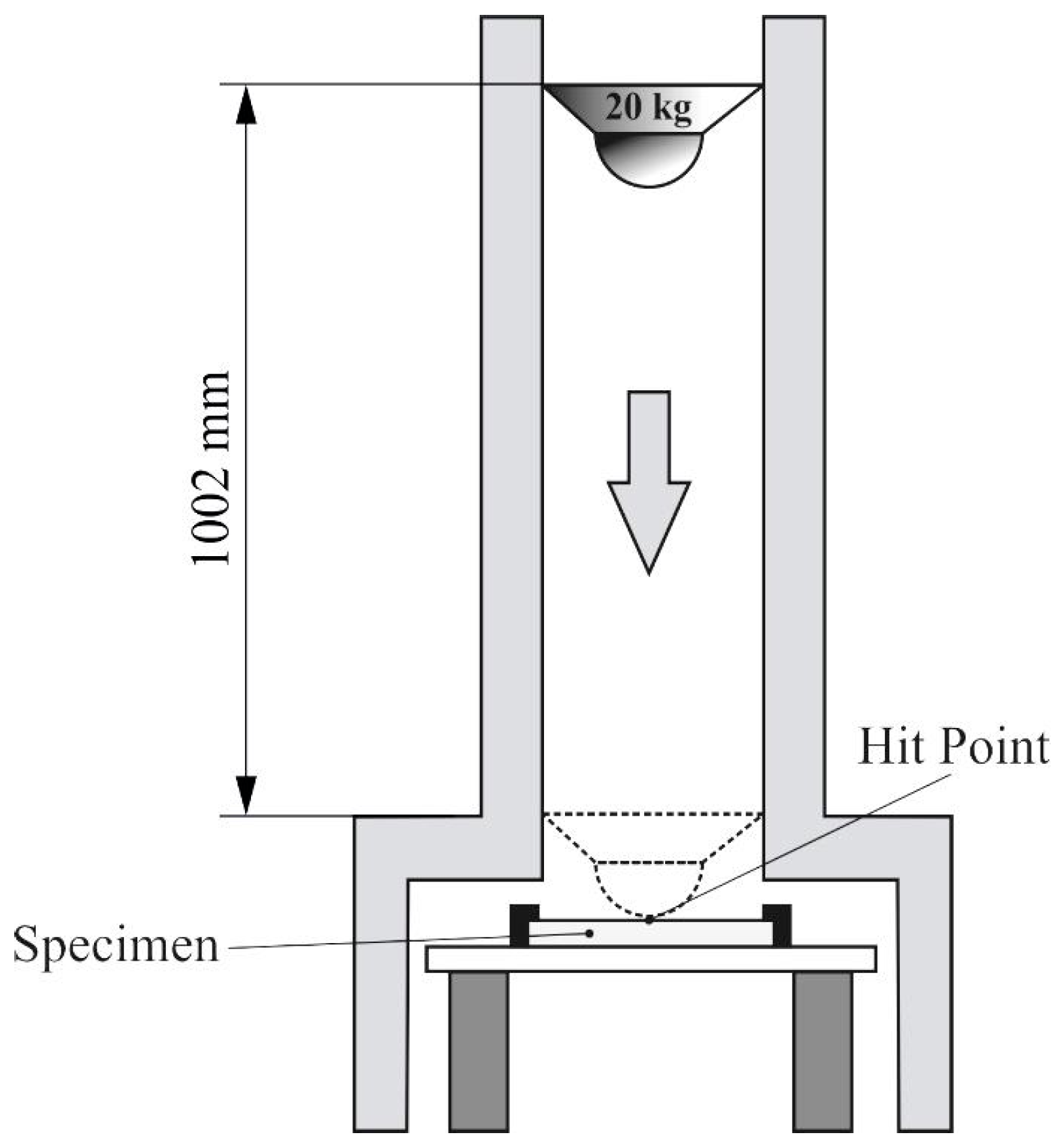

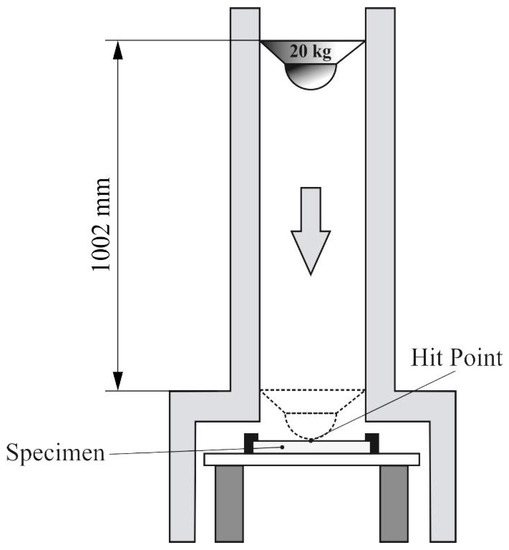

2.8. Analysis of Coating Shock Resistance

The impact resistance testing of aluminum arc-coated coatings on a steel substrate were carried out on a specially constructed test stand, patented PL 200880, Figure 3. The spray coating resistance criterion was the number of cracks and shattered shell fragments produced by repeated impact on the sprayed surface with a 20.0 kg carbon steel spatula tool freely released from a height of 1.02 m (impact energy 200 J). The surface quality of the sprayed coating was evaluated on the basis of visual analysis at 50, 100, 150 and 200 impacts.

Figure 3.

Stand for impact resistance tests on impact coatings reserved by Patent PL 200880.

3. Results and Discussion

As reported by the American Welding Society, pure aluminum and aluminum alloys are normally used in arc-spray processes, as they are the most outstanding coating materials in aggressive environments such as marine environments, under thermal insulation conditions, or for hot surfaces [11,12]. The advantages of aluminum coating originate from their passive film formation ability and, thus, their lower corrosion rate [13,14]. In this research, we additionally explored the potential of thermal arc-sprayed coatings without buffered subcoating and NiAl-buffered subcoating on Armox 500 T alloy steel with respect to erosion and impact loads.

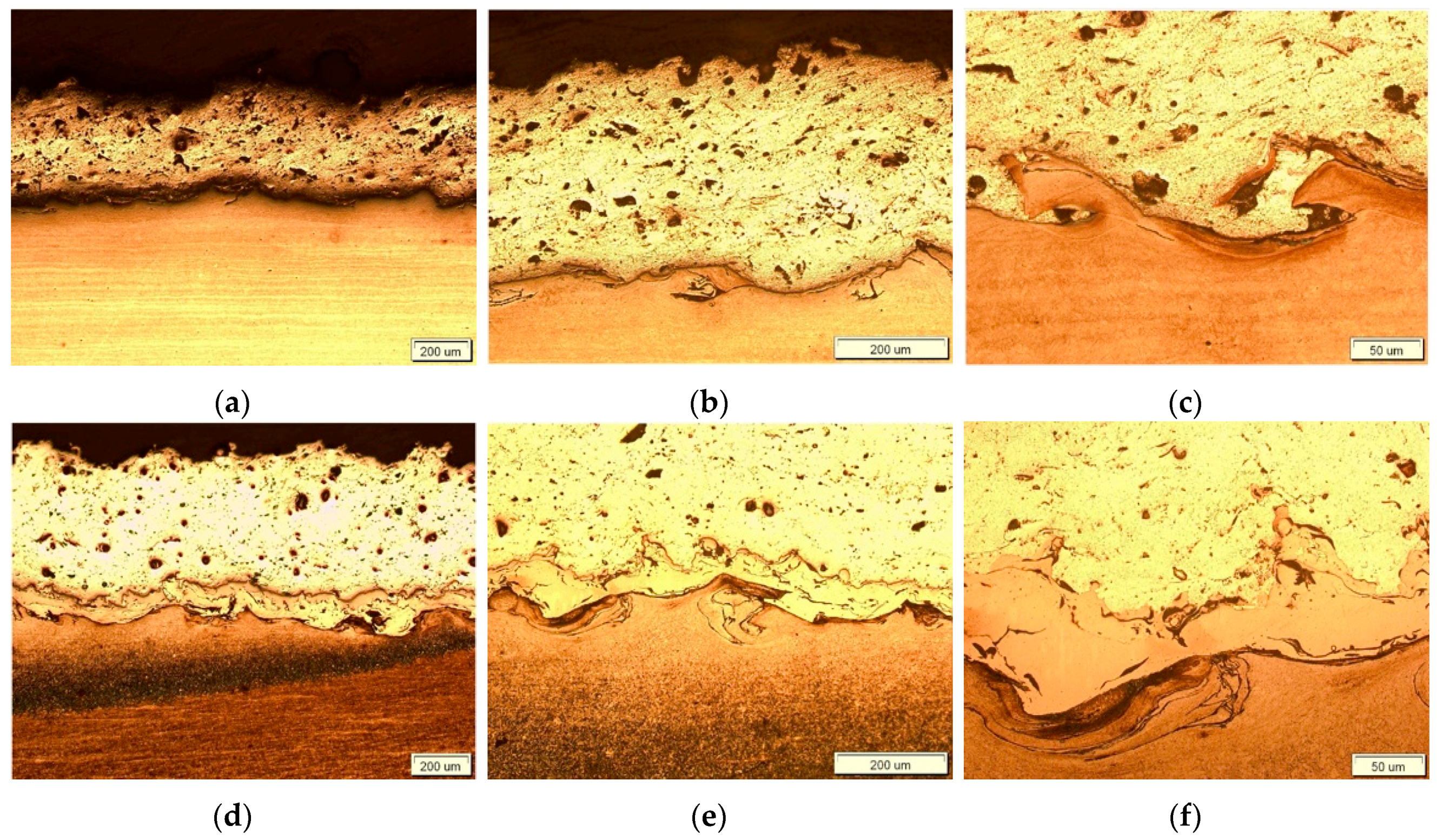

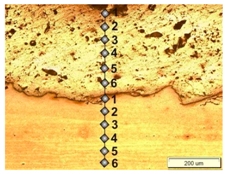

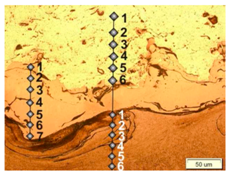

3.1. Metallographic and Roughness Test Results of Coatings

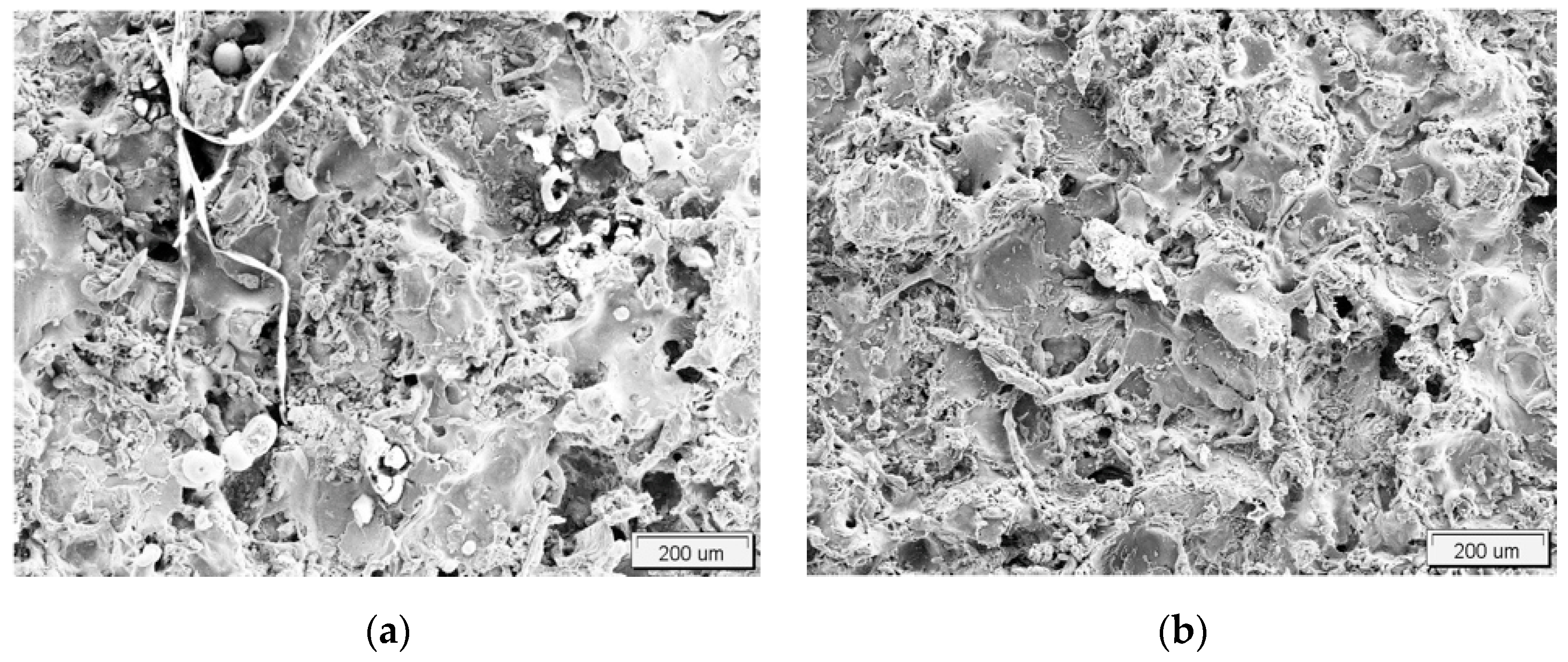

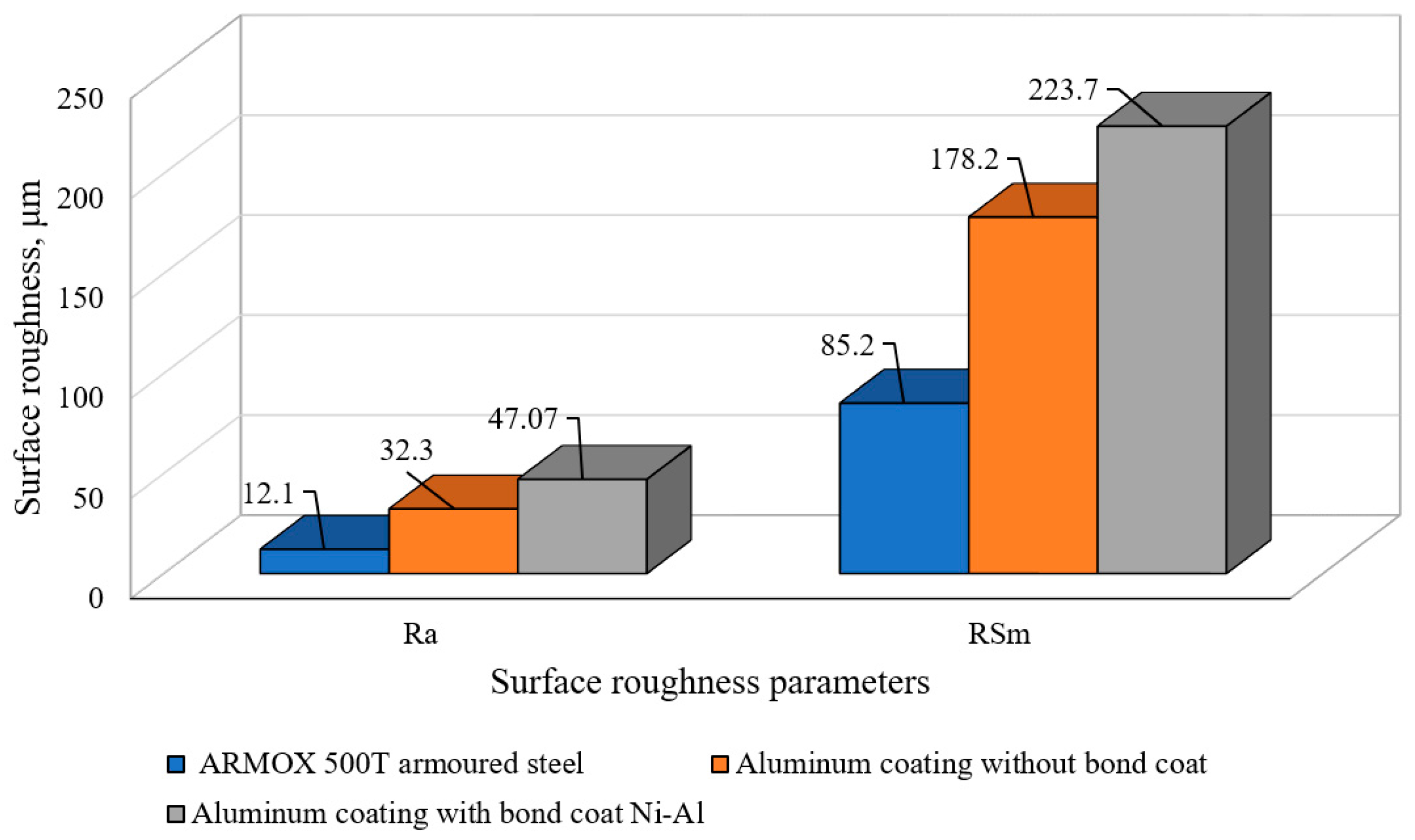

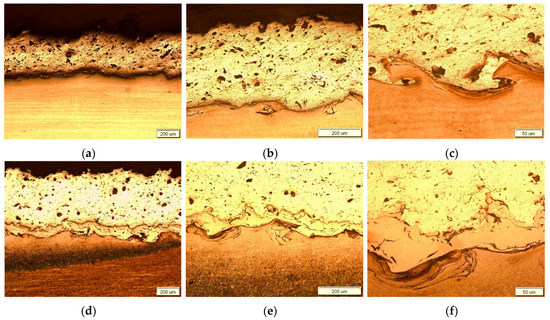

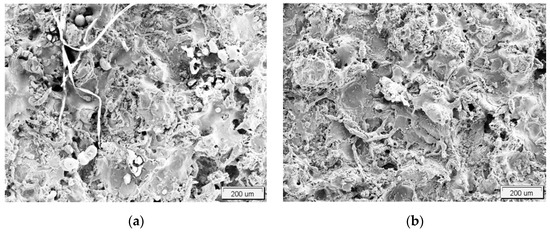

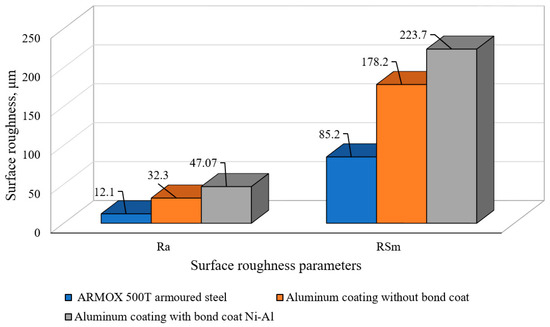

The images of sprayed coatings’ cross-sections are shown in Figure 4. The surface images are shown in Figure 5. Based on surface roughness testing, it was determined that the individual values for surface roughness of the aluminum coating without the binding subcoating were lower than those for the aluminum coating with nickel-aluminum subcoating (roughness difference of Ra = 15 μm), Figure 6. Metallurgical microscopic and macroscopic analyses on the cross-sections and surfaces of the arc-sprayed samples with and without subcoating showed that the joining method of the coating to the substrate in the case of the arc-sprayed samples with and without binding subcoating expressed characteristic mechanical interlocking adhesion between the substrate and coating. Metallographic pictures show the deformed surface of the substrate by shot blasting, which makes the mechanical interlocking adhesion of the arc-sprayed coating possible. It was observed that the alumino-nickel subcoating shared a much more intricate bond with the aluminum substrate after shot blasting than with the steel substrate. Recess depth, projection height and feature widths are more favorable for coating adhesion on the surface of the nickel-aluminum subcoating than on the steel, and are denser by area, creating a more intricate mechanical interlocking adhesion surface. Metallographic analysis showed that the aluminum coating exhibited a porosity of 6–9%. Cross sectional analysis of the structure showed that aluminum arc spraying, with and without binding nickel-aluminum subcoated surfaces, increased the occurrence of deposited molten drops of aluminum wire and spatter, and favored dynamic solidification of the aluminum coating.

Figure 4.

Images of the 01T grade wire arc-coated aluminum: (a–c) without buffering subcoating; (d–f) with wire-coated subcoating with 75B BondArc grade, Ni/Al alloy.

Figure 5.

Images of the surface structure of wire 01T grade arc-sprayed aluminum: (a) without buffering subcoating; (b) buffered subcoating with 75B BondArc grade wire.

Figure 6.

Surface roughness changes for Armox 500 T steel, 01T grade wire arc-sprayed aluminum without buffering subcoating, and buffered subcoating with 75B BondArc grade wire.

3.2. Coating Erosion Resistance Results

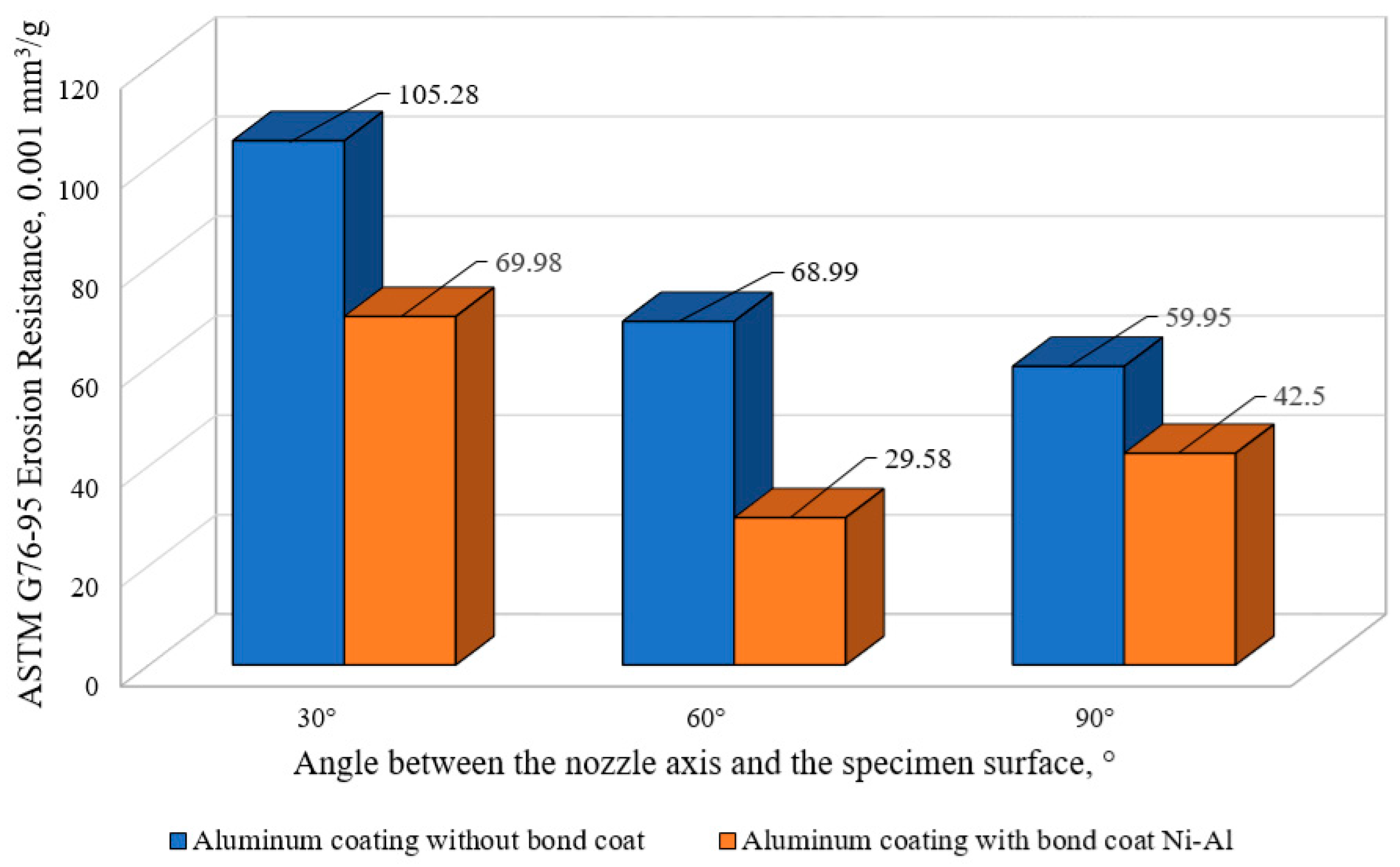

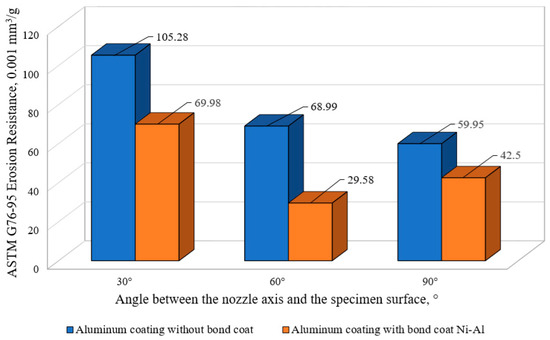

The results of the erosion-resistant aluminum coating without buffered subcoating (PE1) and with the buffered aluminum sub-coating (PE2) are shown in Table 3 and Table 4 and Figure 7. The 01T grade solid wire-based aluminum arc coating with nickel-aluminum 75B BondArc grade arc spray subcoating was observed to be most resistant to erosion with a particle angle of attack set to 60°. In this case, resistance to erosion was ~55% lower than the aluminum arc-sprayed with 01T grade solid wire without a binding subcoating. At a particle impact angle of 90°, the sample with the nickel-aluminum subcoating was observed to be 30% higher than ones without a binding subcoating; a similar outcome was observed for the 30° attack angle—a higher resistance to erosion (about 35%) than samples without nickel-aluminum binding subcoatings. The least resistant sample was observed to be the 01T aluminum-sprayed sample without subcoating at a 90° attack angle; erosion resistance for this coating at maximum angle was 70% of the value for the nickel-aluminum subcoated aluminum samples.

Table 3.

Summary of results obtained during the erosion test.

Table 4.

PE1 and PE2 samples after erosion test, comparison of erodent effect on the sample surfaces for each of the angles studied.

Figure 7.

Results of erosion resistance tests for investigated materials and different erodent impact angles.

3.3. Coating Hardness Testing Results

Hardness measurements were made on the cross-section of sprayed coatings according to the scheme outlined in Table 5. Coating hardness test results indicated an increase in the hardness of the aluminum layer with Ni/Al subcoating. The increase in hardness was approx. 14%, and was associated with a decrease in porosity and an increase in the density of the coating. In addition, the formation of the intermediate layer influenced the state of stress in the arc-sprayed aluminum layer.

Table 5.

Results of hardness measurements measured on cross-section of arc-coated aluminum coatings on Armox 500 T alloy steel.

3.4. Coating–Subcoating Adhesion Results

The results of adhesion testing of aluminum without buffering subcoating (PE1) and aluminum coating with nickel-aluminum buffered subcoating (PE2) are presented in Table 6. As demonstrated in the study, the use of an intermediate layer causes an expected increase in adhesion of the coating to the substrate material. The increased adhesion of the coating is caused by the reduction of residual stresses in the sprayed layer and the increase in the integrity of the Ni/Al sublayer with a steel substrate. In addition, a greater degree of surface development improves the conditions for joining the Al coating with the sublayer. The use of an intermediate layer results in a 15% increase in the adhesion of the coatings produced.

Table 6.

Summary of results obtained during the static tensile test of arc sprayed coatings.

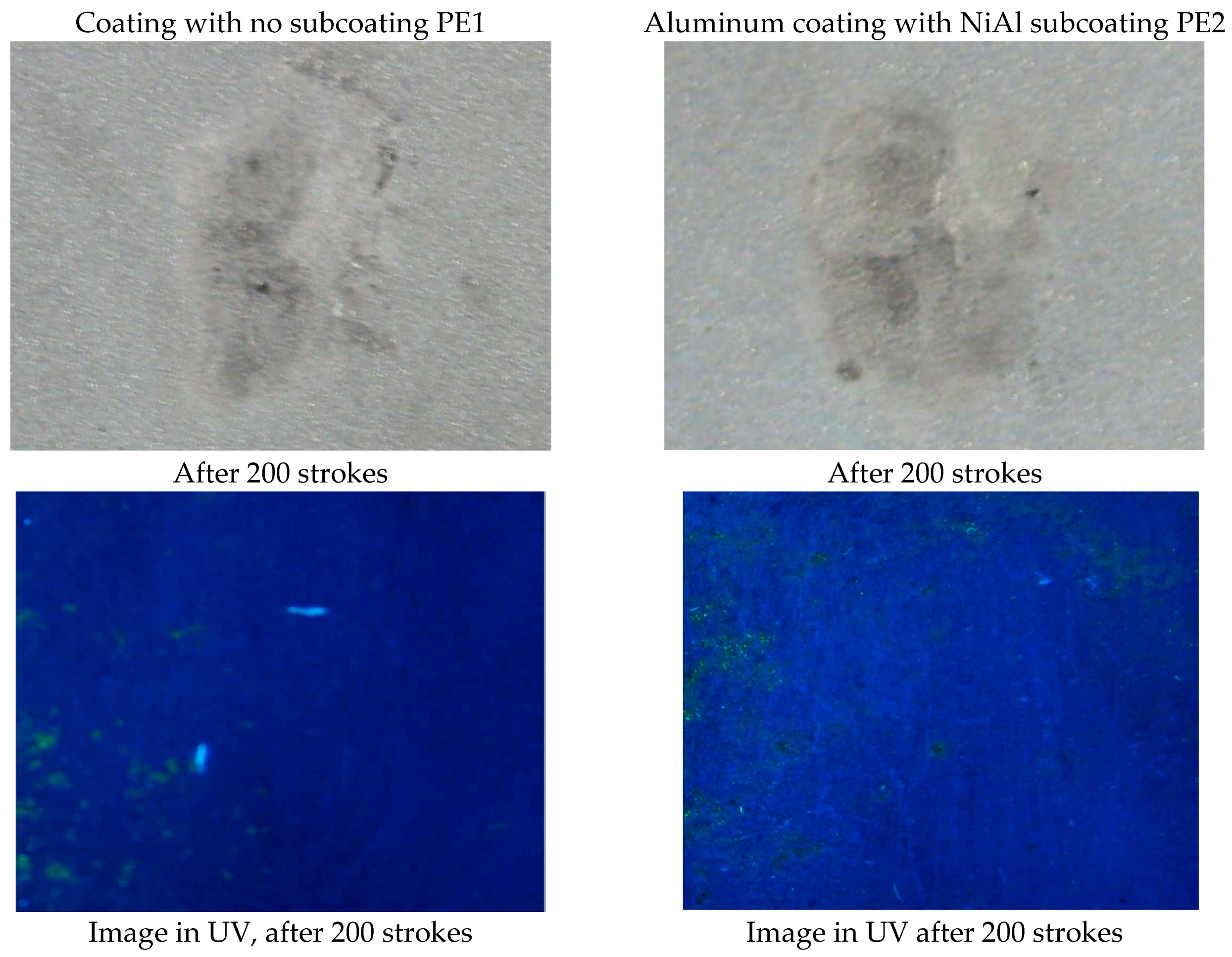

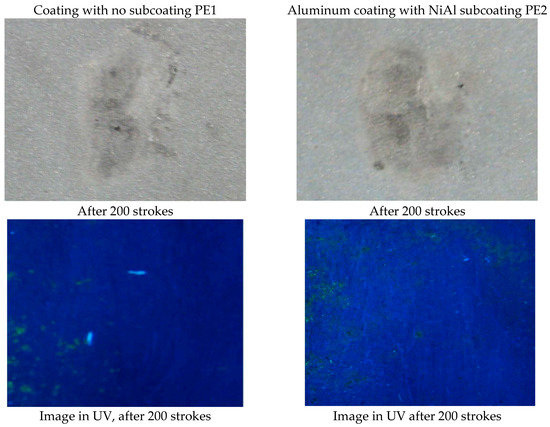

3.5. Coating Shock Load Testing Results

The results of resistance tests of the aluminum coating without buffered subcoating (PE1) and alumina-coated aluminum (PE2) coating on impact loads are shown in Figure 8. The impact load resistance analysis of aluminum coatings arc-sprayed on Armox 500 T grade steel did not reveal delamination or cracks in the coatings. The penetration impact testing conducted using ultraviolet light indicated that both the coating without the intermediate layer and with the Ni/Al layer showed no crack network formation. In addition, macroscopic observations showed only plastic deformation of the coatings, with no clear difference due to the presence of the undercoat layer. The obtained results indicate good adhesion of the coatings to the substrate material, as well as their ability to undergo plastic deformation.

Figure 8.

View of aluminum arc-sprayed coatings on Armox 500 T steel after impact resistance tests (impact energy 200 J).

4. Conclusions

Analysis of the results of the investigations into the development of the technical conditions of aluminum coatings with thicknesses of about 1.0 mm, arc-sprayed from a TAFA 01T grade solid wire, both with no buffering subcoating and with a buffered aluminum coating sprayed with solid subcoating wire 75B BondArc grade, onto the Armox 500 T alloy steel has shown:

- Arc-sprayed coatings without buffered subcoating and NiAl-buffered subcoating on Armox 500 T alloy steel provide high-quality spray coatings with a thickness of approximately 1.0 mm.

- The use of Nickel Alloy Buffer (NiAl 95/5) increases the adhesion of the aluminum coating by more than 4 MPa as compared to aluminum sprayed directly onto the Armox 500 T steel substrate.

- Much higher erosion wear resistance (about 55% at 60° attack angle, and about 30% at erodent attack angles of 90° and 30°) was exhibited by arc-coated aluminum on Armox 500 T alloy steel substrate using Nickel Alumina (NiAl 95/5)-buffered subcoating.

- Metallographic studies of spray coatings showed the mechanically interlocked mode of adhesion of the joint between the arc-sprayed coatings and the Armox 500 T alloy steel substrate.

- Arc-sprayed aluminum coatings without buffering subcoating and with subcoating of nickel alumina have a mean hardness of 36.4 HV0.1 and 42.4 HV0.1, respectively. The mean hardness of the buffered nickel alumina coating was 364 HV1.6. The impact load resistance analysis of aluminum coatings arc-sprayed on Armox 500 T grade steel did not reveal delamination or cracks in the coatings for both of analyzed coatings type.

Author Contributions

Marcin Adamiak and Artur Czupryński conceived and designed the experiments; Artur Czupryński, Zbigniew Monica performed the experiments; Małgorzata Olender, Aleksander Gwiazda, Adam Kopyść analyzed the data; Adam Kopyść, Marcin Adamiak, Artur Czupryński wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Janicki, D. Laser cladding of Inconel 625-based composite coatings reinforced by porous chromium carbide particles. Opt. Laser Technol. 2017, 94, 6–14. [Google Scholar] [CrossRef]

- Lisiecki, A.; Piwnik, J. Tribological characteristic of titanium alloy surface layers produced by diode laser gas nitriding. Arch. Metall. Mater. 2016, 61, 543–552. [Google Scholar] [CrossRef]

- Janicki, D.; Musztyfaga, M.M. Direct diode laser cladding of Inconel 625/WC composite coatings. J. Mech. Eng. 2016, 62, 363–372. [Google Scholar] [CrossRef]

- Lisiecki, A.; Kurc-Lisiecka, A. Erosion wear resistance of titanium-matrix composite Ti/TiN produced by diode-laser gas nitriding. Mater. Technol. 2017, 51, 29–34. [Google Scholar] [CrossRef]

- Czupryński, A. Properties of Al2O3/TiO2 and ZrO2/CaO flame-sprayed coatings. Mater. Technol. 2017, 51, 205–212. [Google Scholar] [CrossRef]

- Czupryński, A.; Górka, J.; Adamiak, M. Examining properties of arc sprayed nanostructured coatings. Metalurgija 2016, 55, 173–176. [Google Scholar]

- Czupryński, A.; Górka, J.; Adamiak, M.; Tomiczek, B. Testing of flame sprayed Al2O3 matrix coatings containing TiO2. Arch. Metall. Mater. 2016, 61, 1363–1370. [Google Scholar] [CrossRef]

- Dobrzański, L.; Adamiak, M.; D’Errico, G. Relationship between erosion resistance and the phase and chemical composition of PVD coatings deposited onto high-speed steel. J. Mater. Process. Technol. 1999, 92–93, 184–189. [Google Scholar] [CrossRef]

- ISO 14923:2003. Thermal Spraying—Characterization and Testing of Thermally Sprayed Coatings; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- ASTM G76-13. Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Regina, M.H.; Pombo, R.; Paredes, R.S.C.; Wido, S.H.; Calixto, A. Comparison of aluminum coatings deposited by flame spray and by electric arc spray. Surf. Coat. Technol. 2007, 202, 172–179. [Google Scholar]

- American Welding Society. Corrosion Test of Flame Sprayed Coated Steel—19 Years Report; American Welding Society: Miami, FL, USA, 2013. [Google Scholar]

- Li, Y.; Liu, J.; Duan, J.; Hou, B. Thermally sprayed aluminium and zinc coatings for tidal zone cathodic protection of offshore platform pile leg. Mater. Perform. 2006, 45, 16–20. [Google Scholar]

- Malek, M.H.A.; Saad, N.H.; Abas, S.K.; Nik Roselina, N.R.; Shah, N.M. Performance and microstructure analysis of 99.5% aluminium coating by thermal arc spray technique. Procedia Eng. 2013, 68, 558–565. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).