A Study on the Machining Characteristics of Curved Workpiece Using Laser-Assisted Milling with Different Tool Paths in Inconel 718

Abstract

:1. Introduction

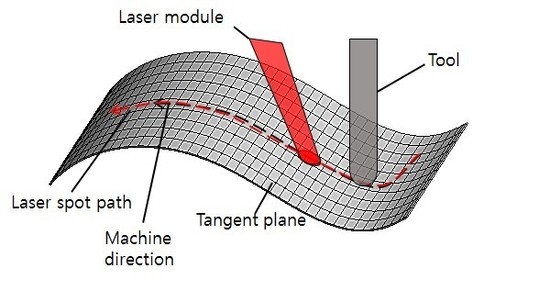

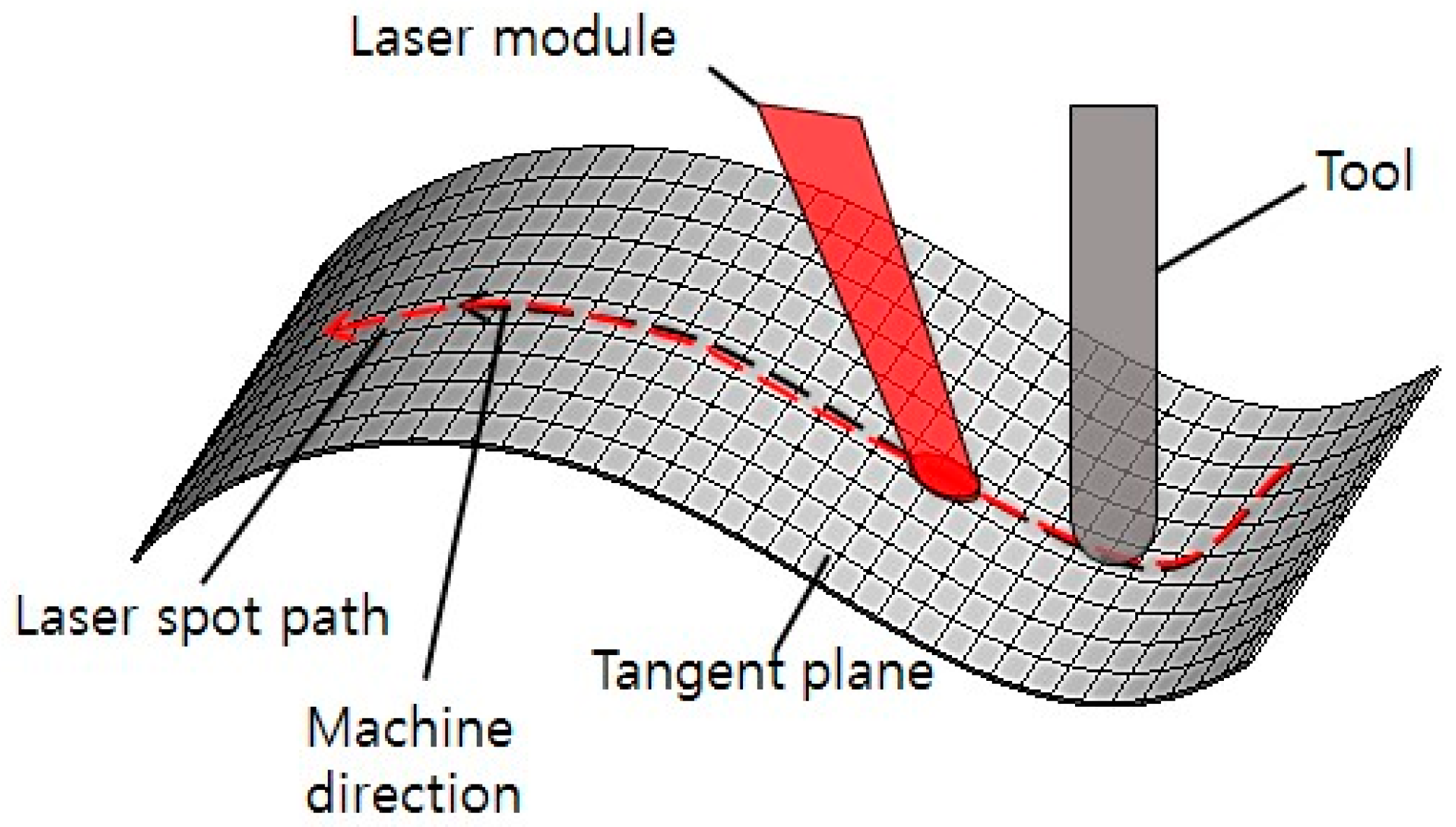

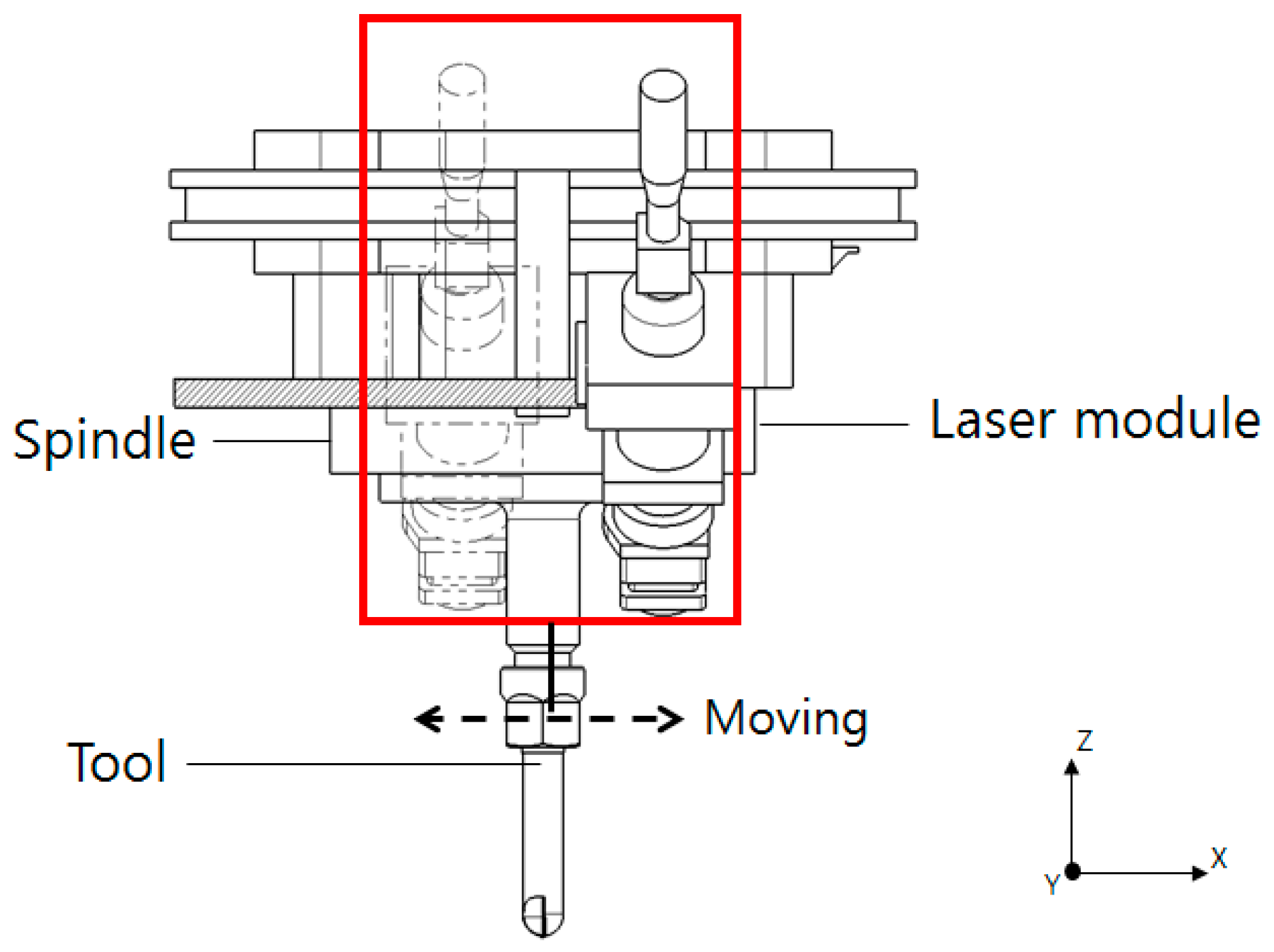

2. Machining Methods

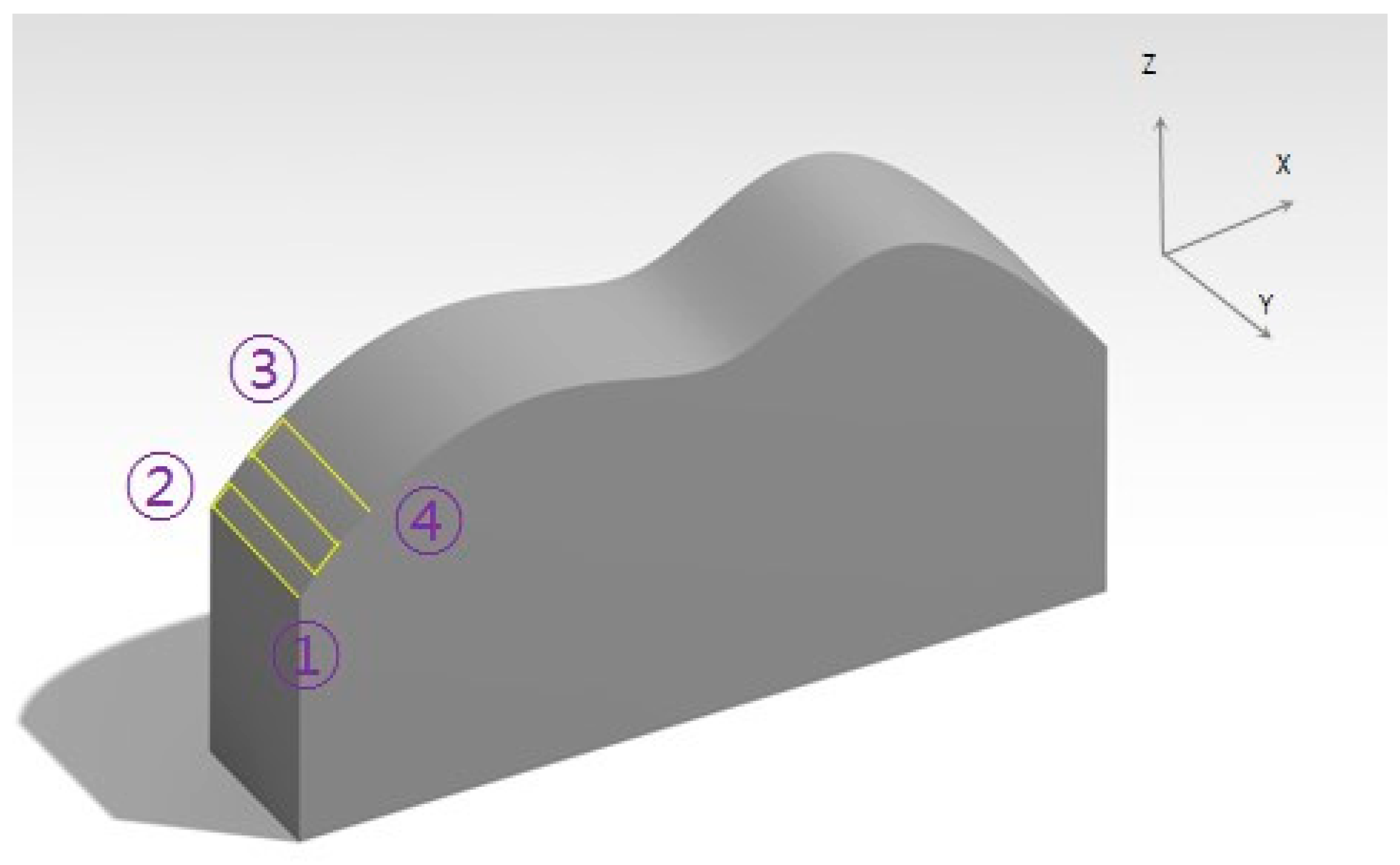

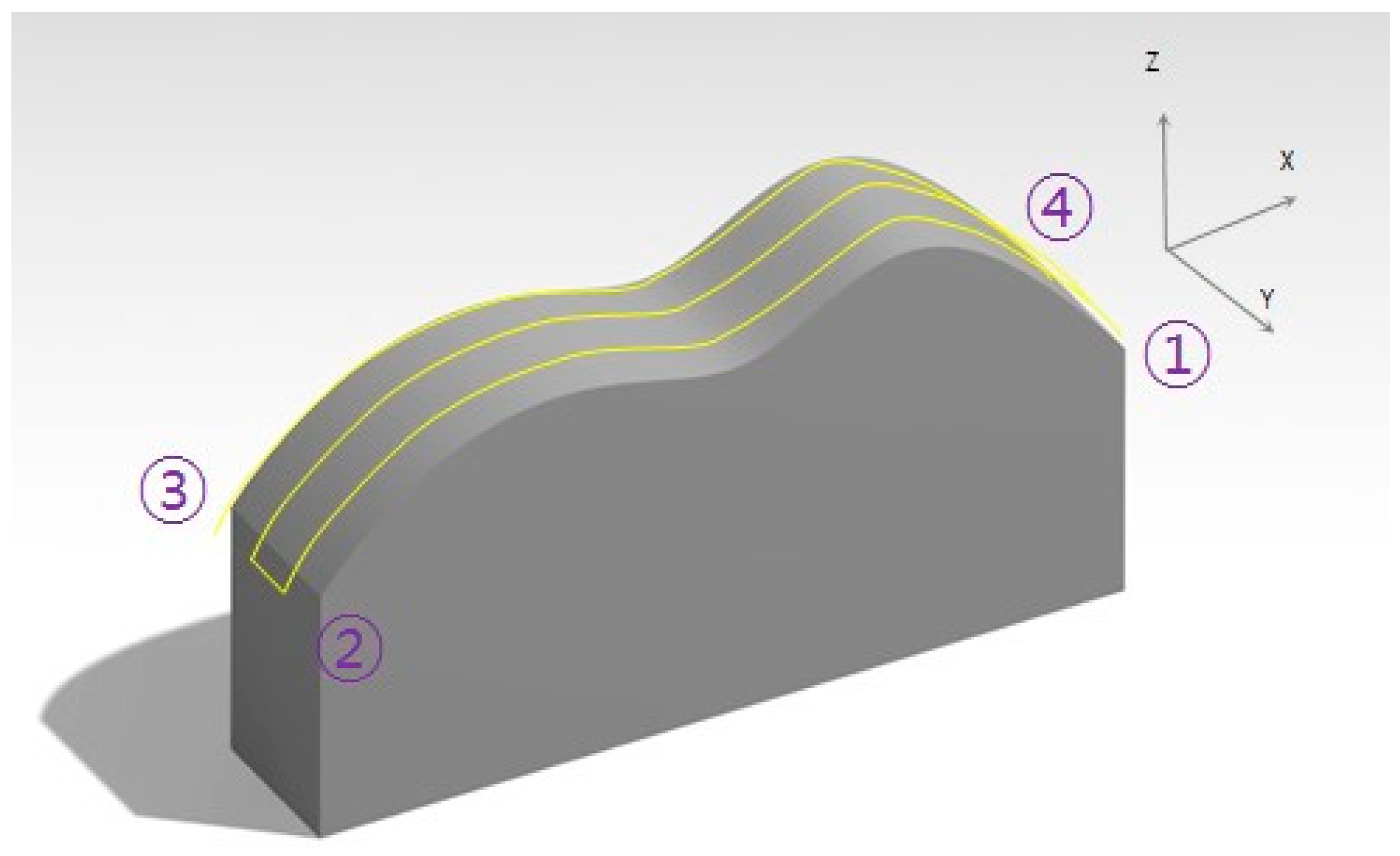

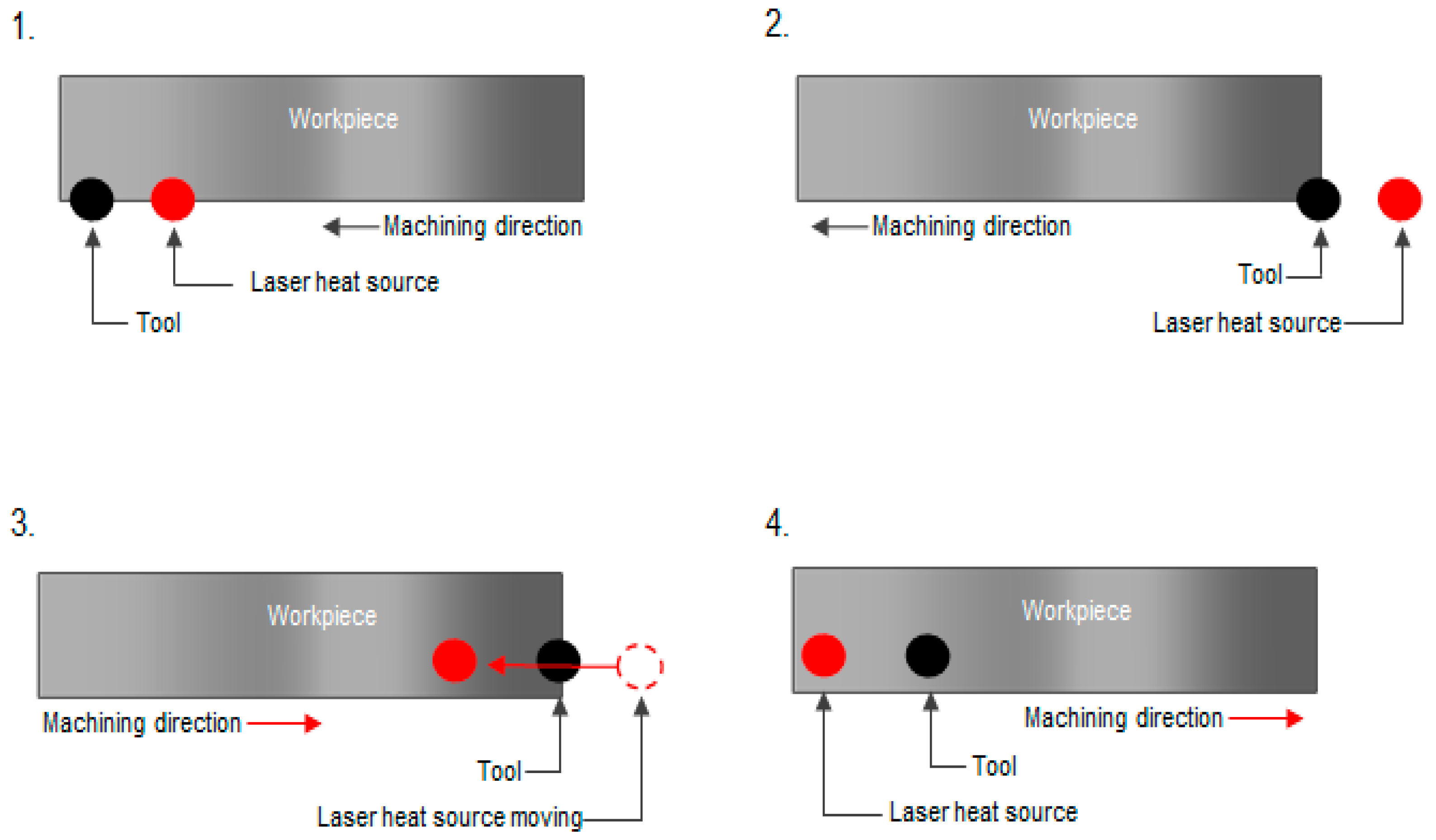

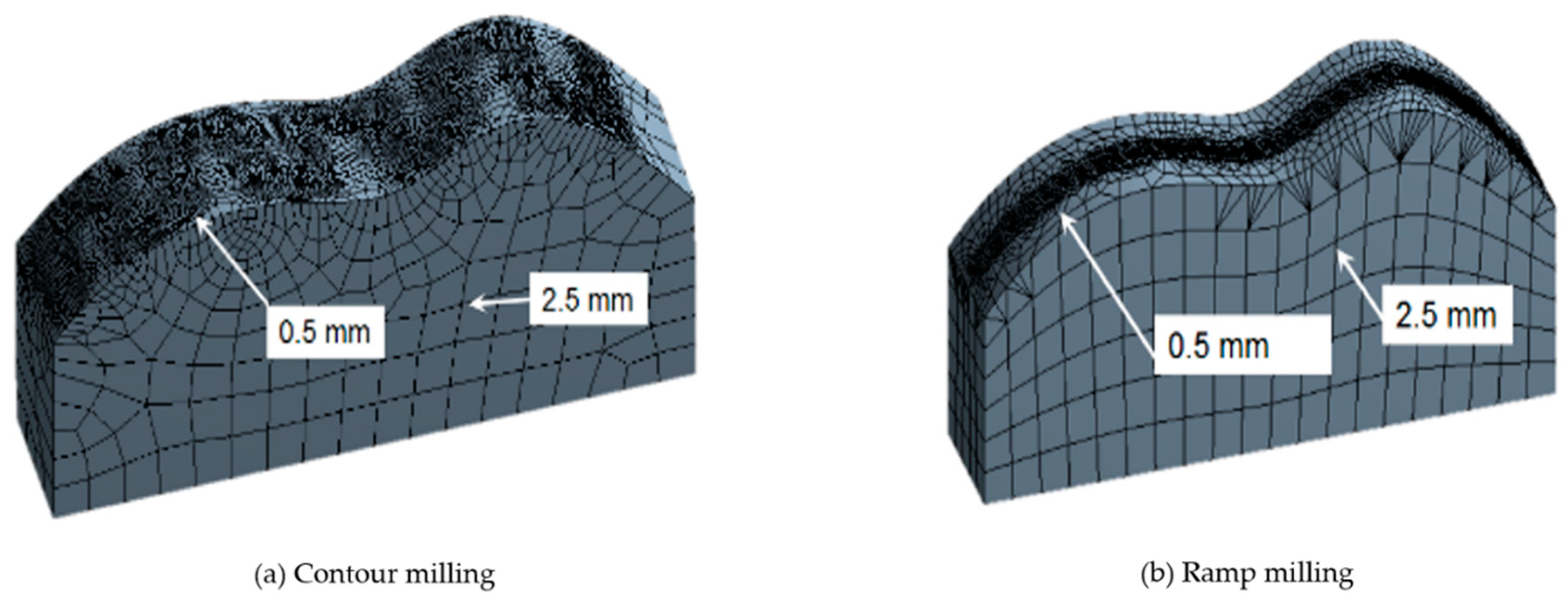

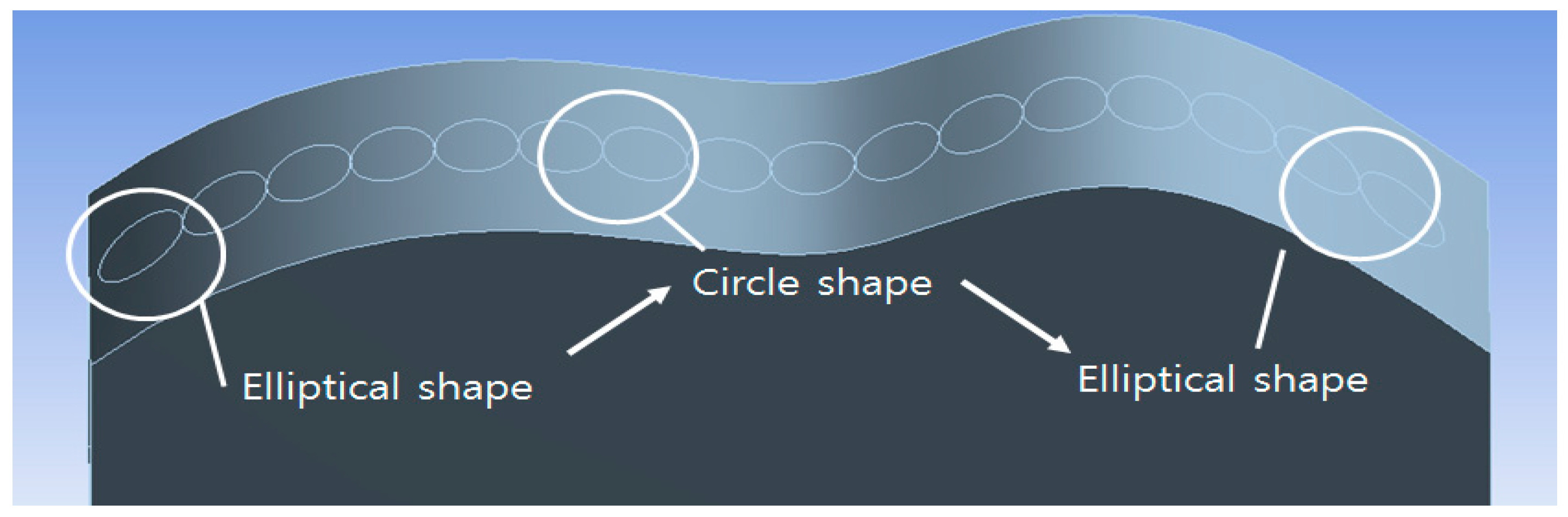

2.1. Contour Milling

2.2. Ramp Milling

2.3. Mechanical Model

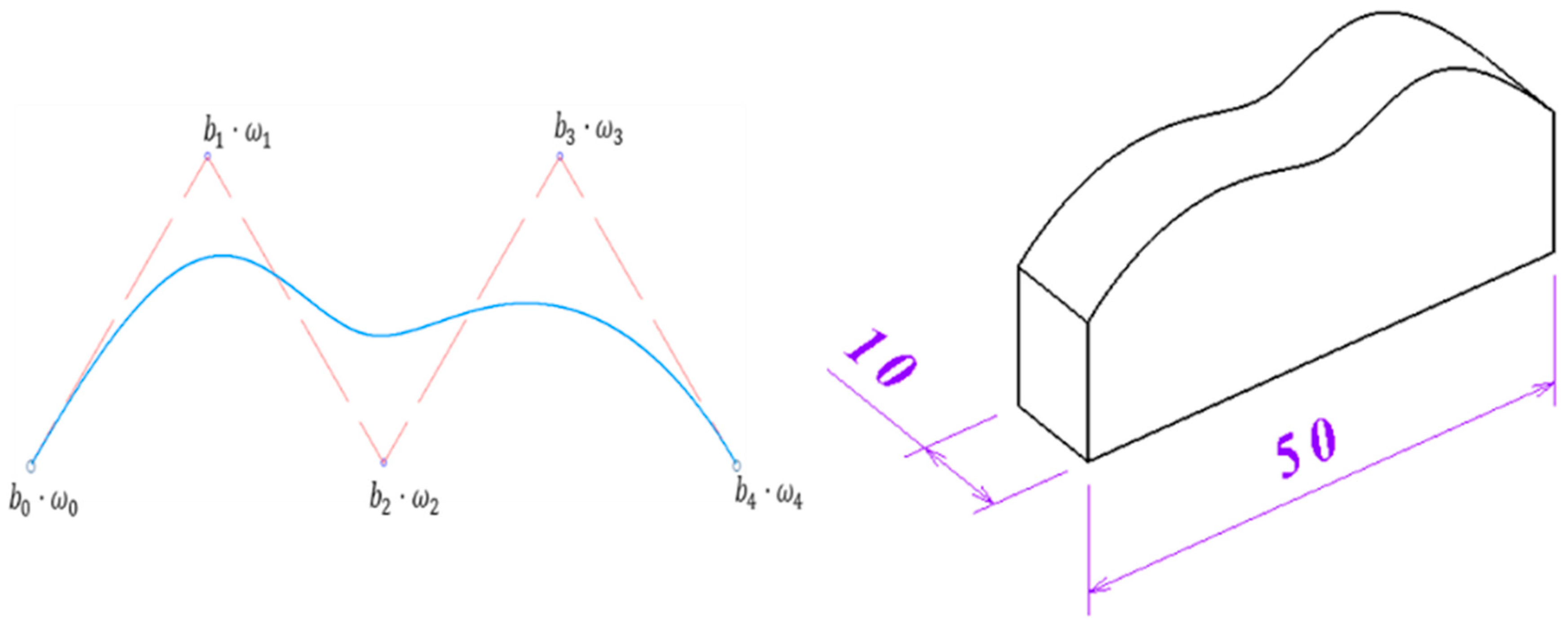

3. Finite Element Analysis

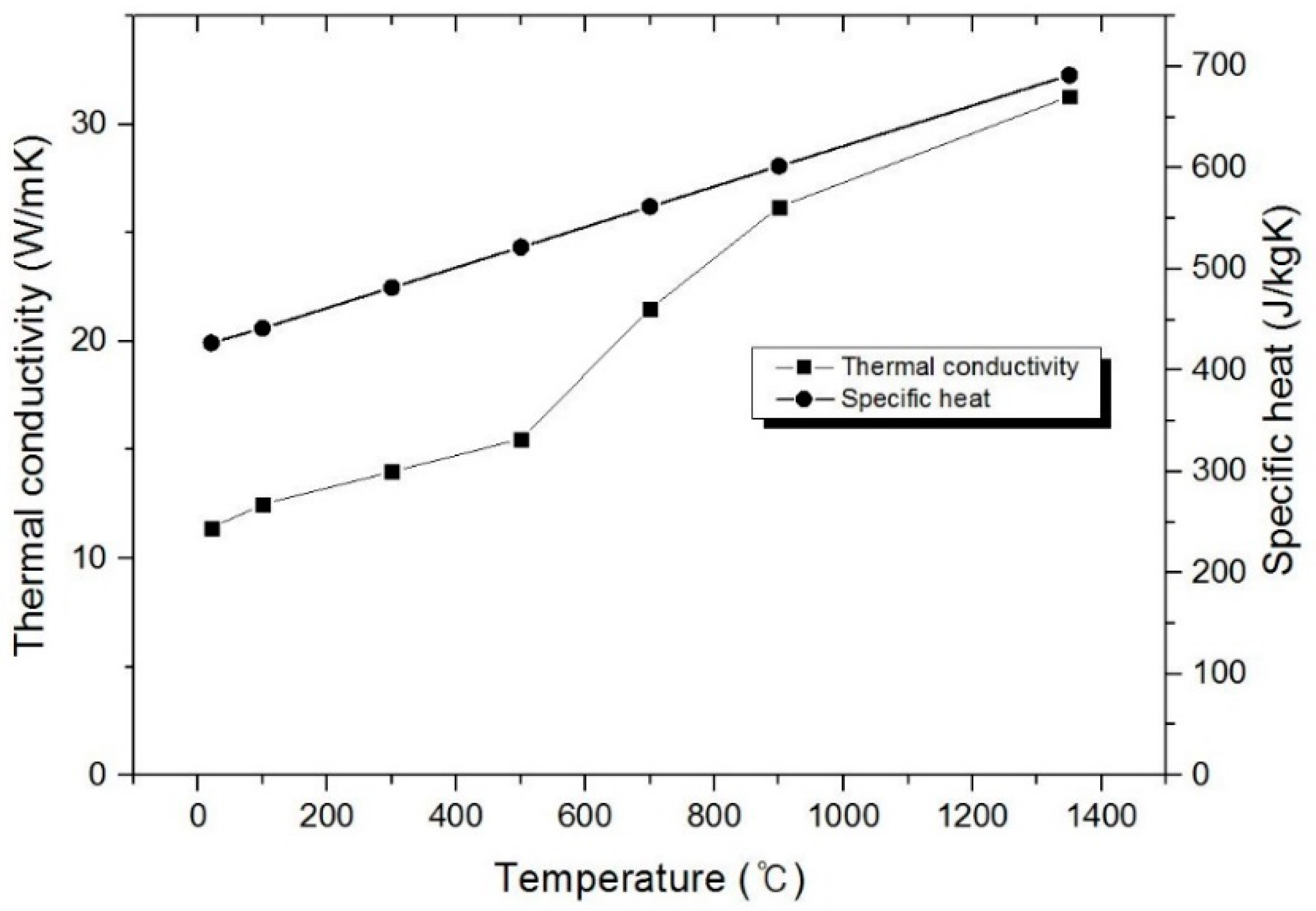

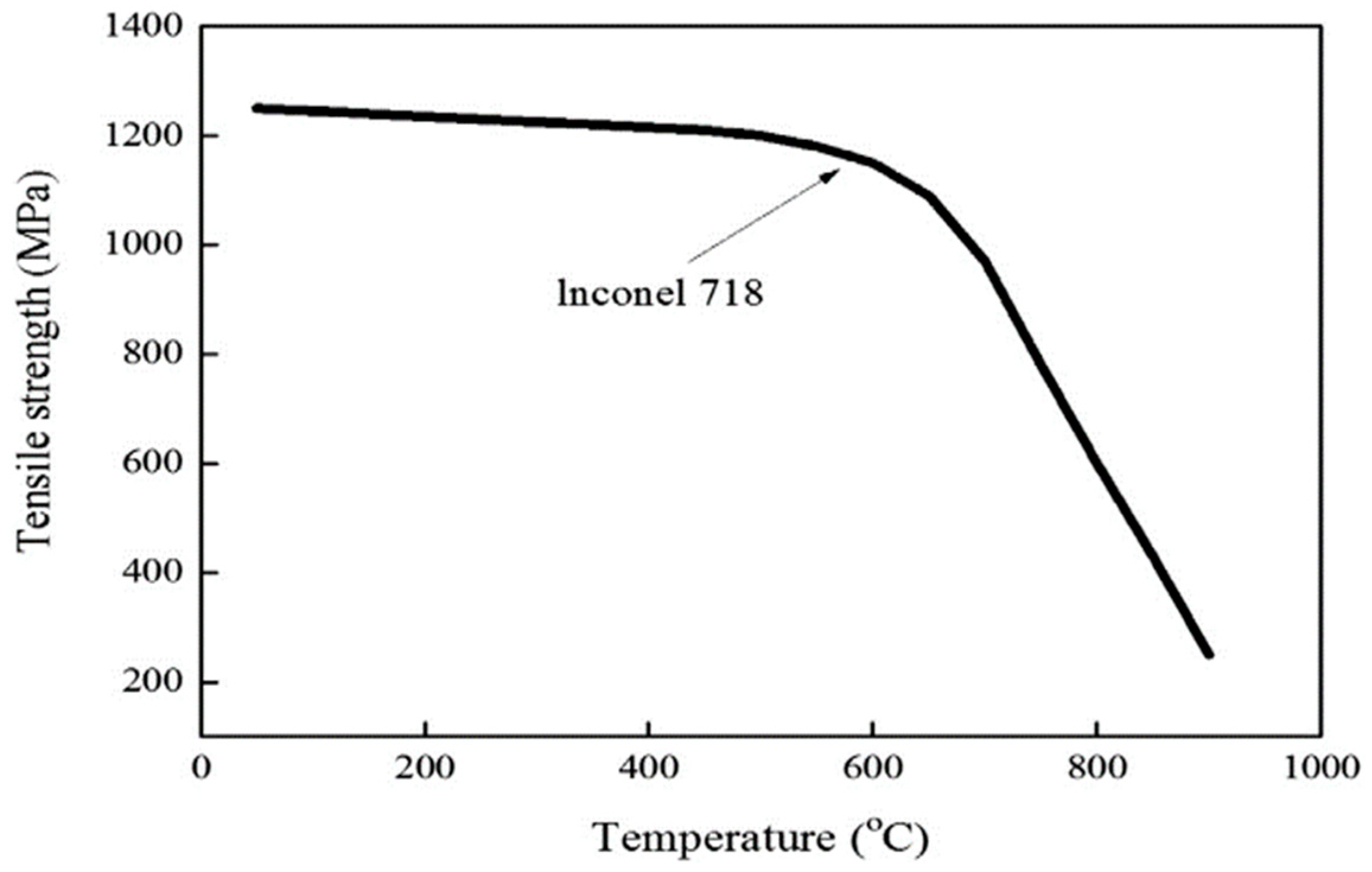

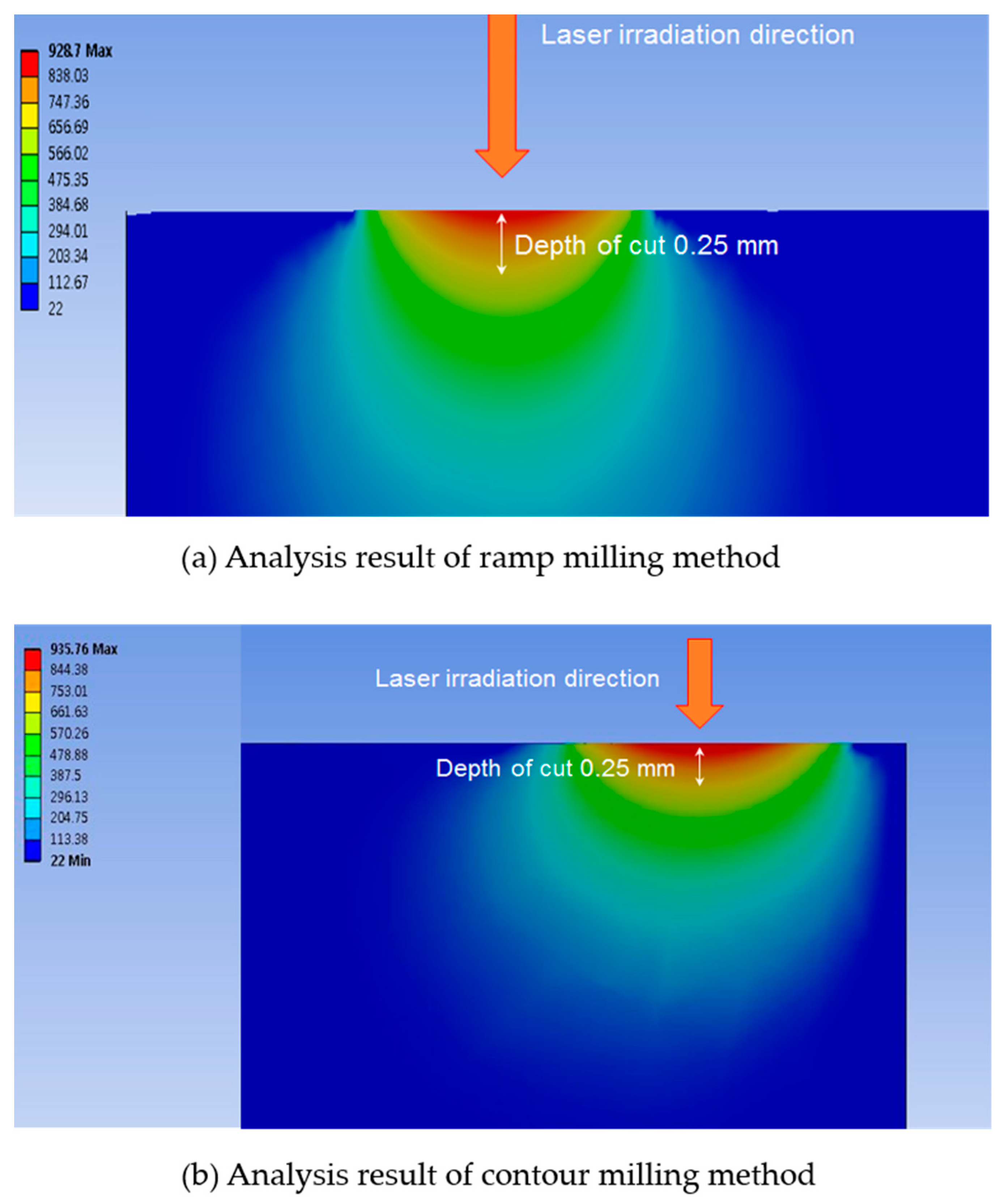

3.1. Thermal Analysis

3.2. Thermal Analysis Results

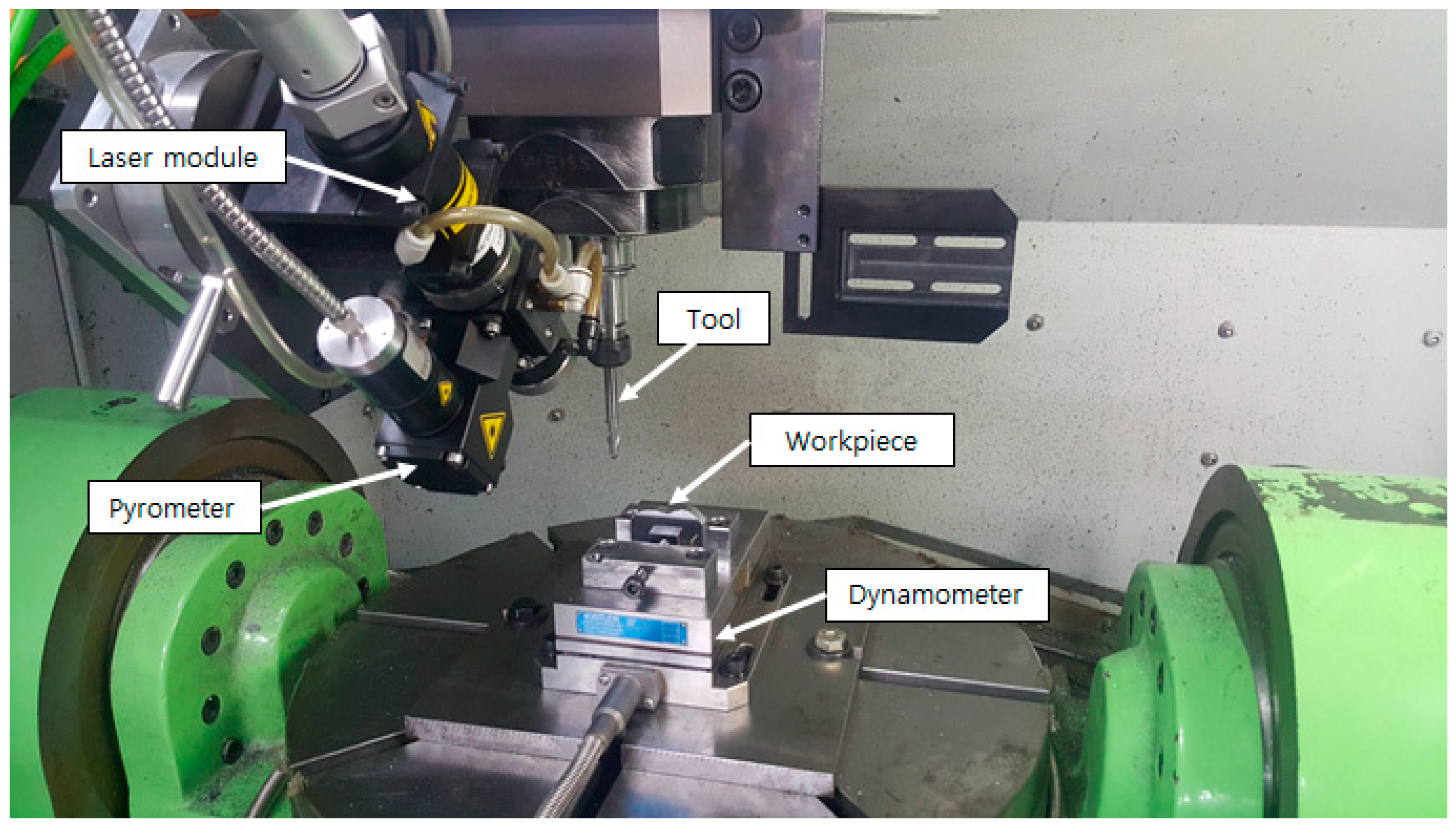

4. Experimental Set-Up

5. Results

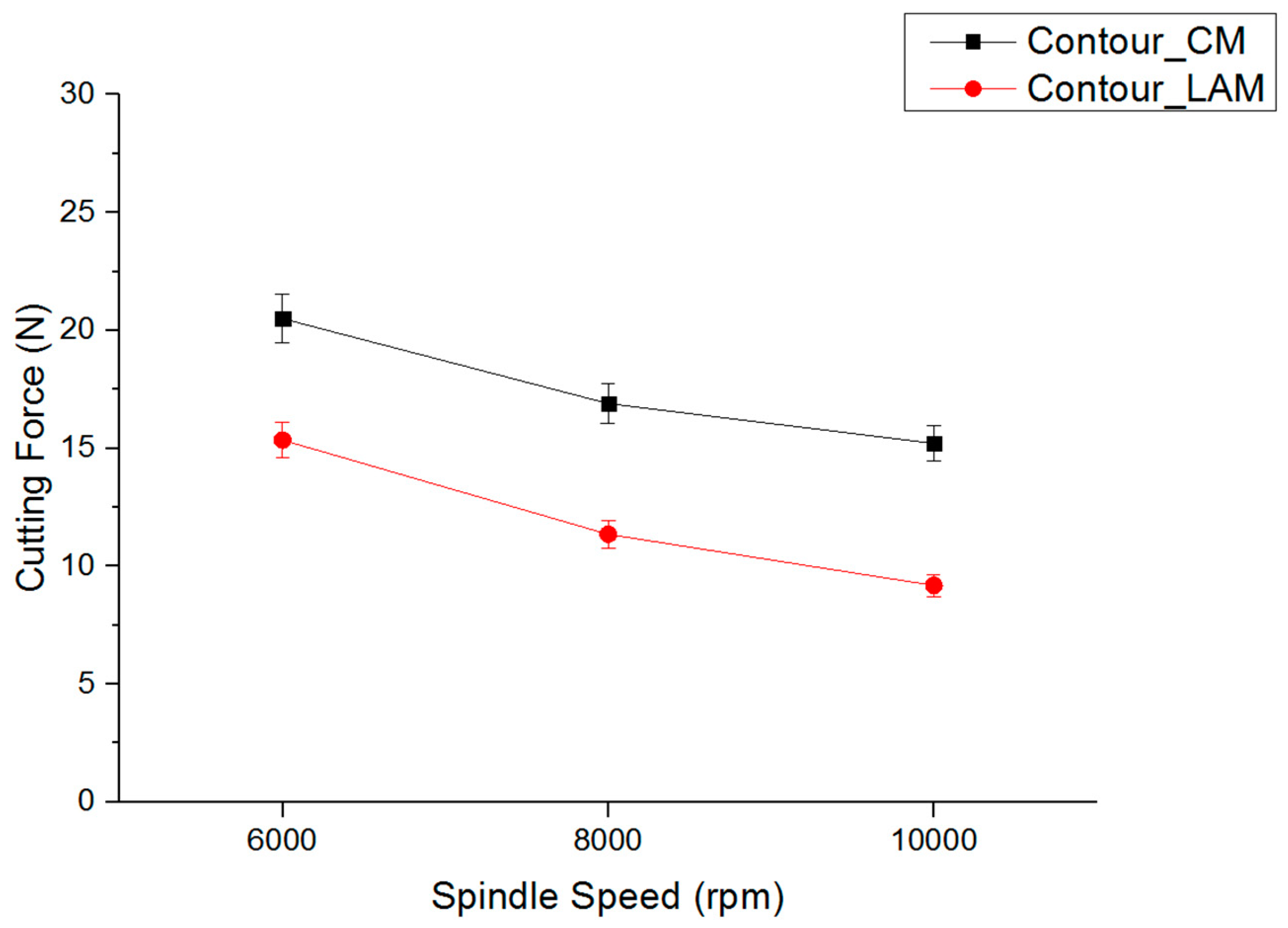

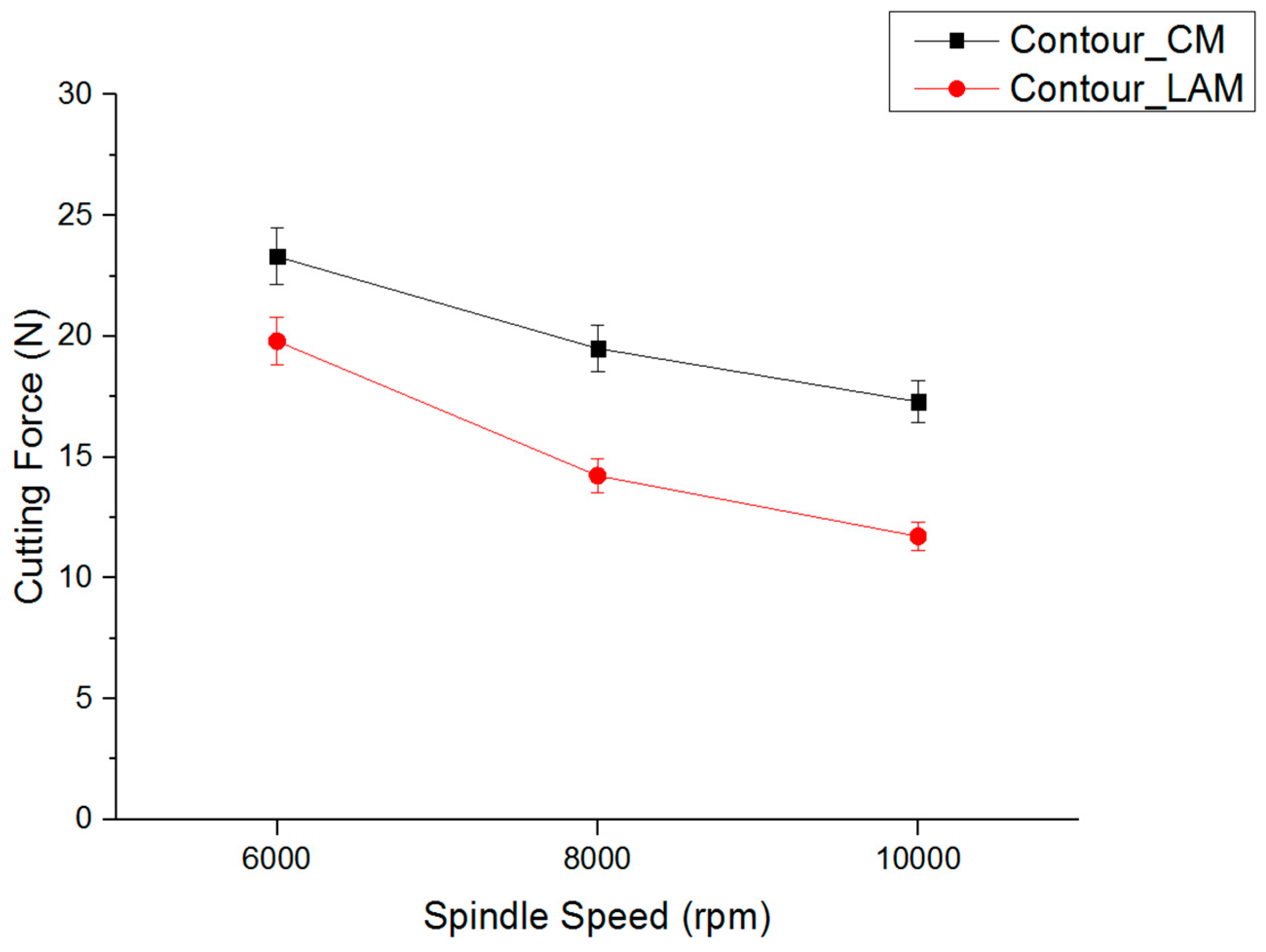

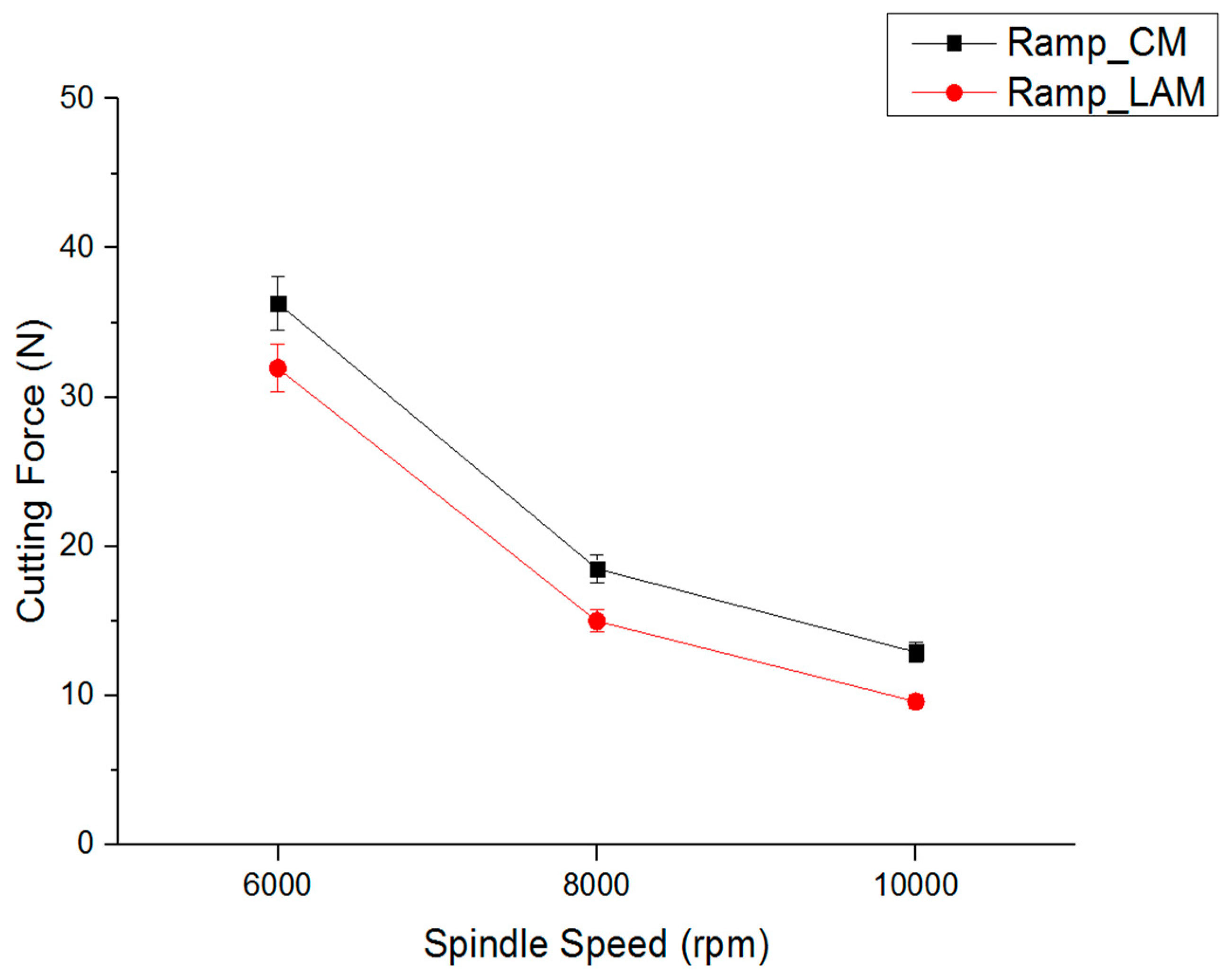

5.1. Cutting Force

5.1.1. Contour Milling Method

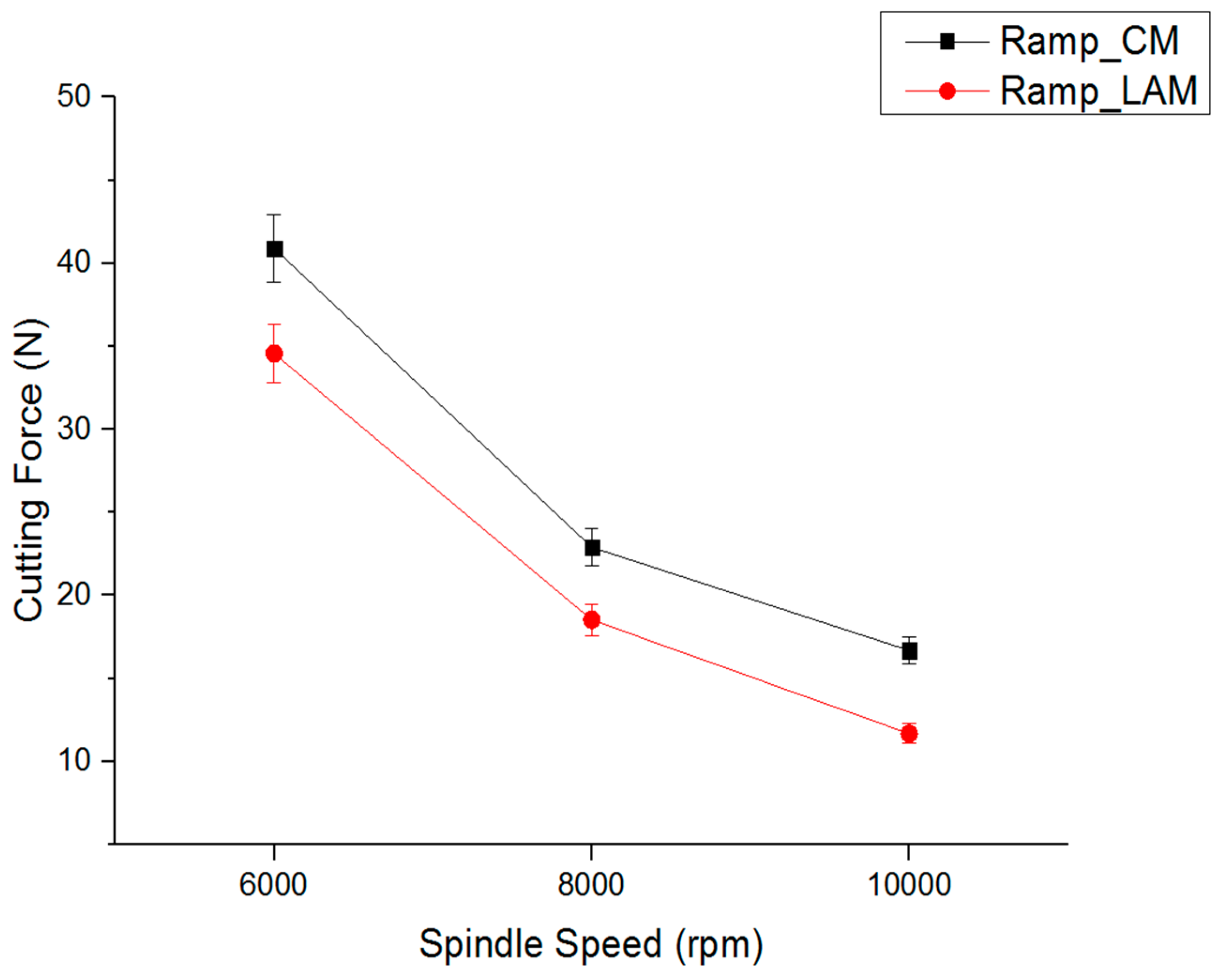

5.1.2. Ramp Milling Method

5.2. Specific Cutting Energy

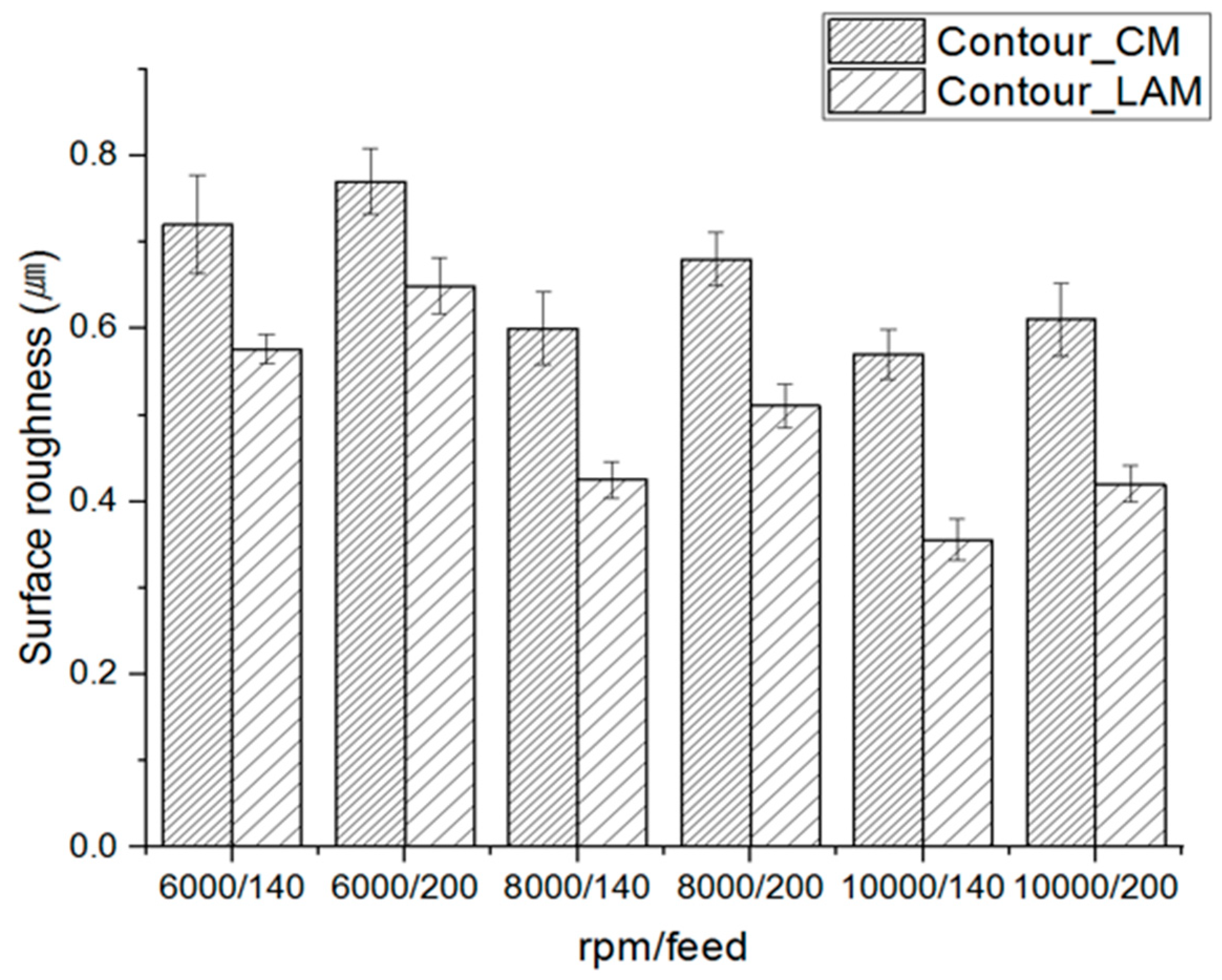

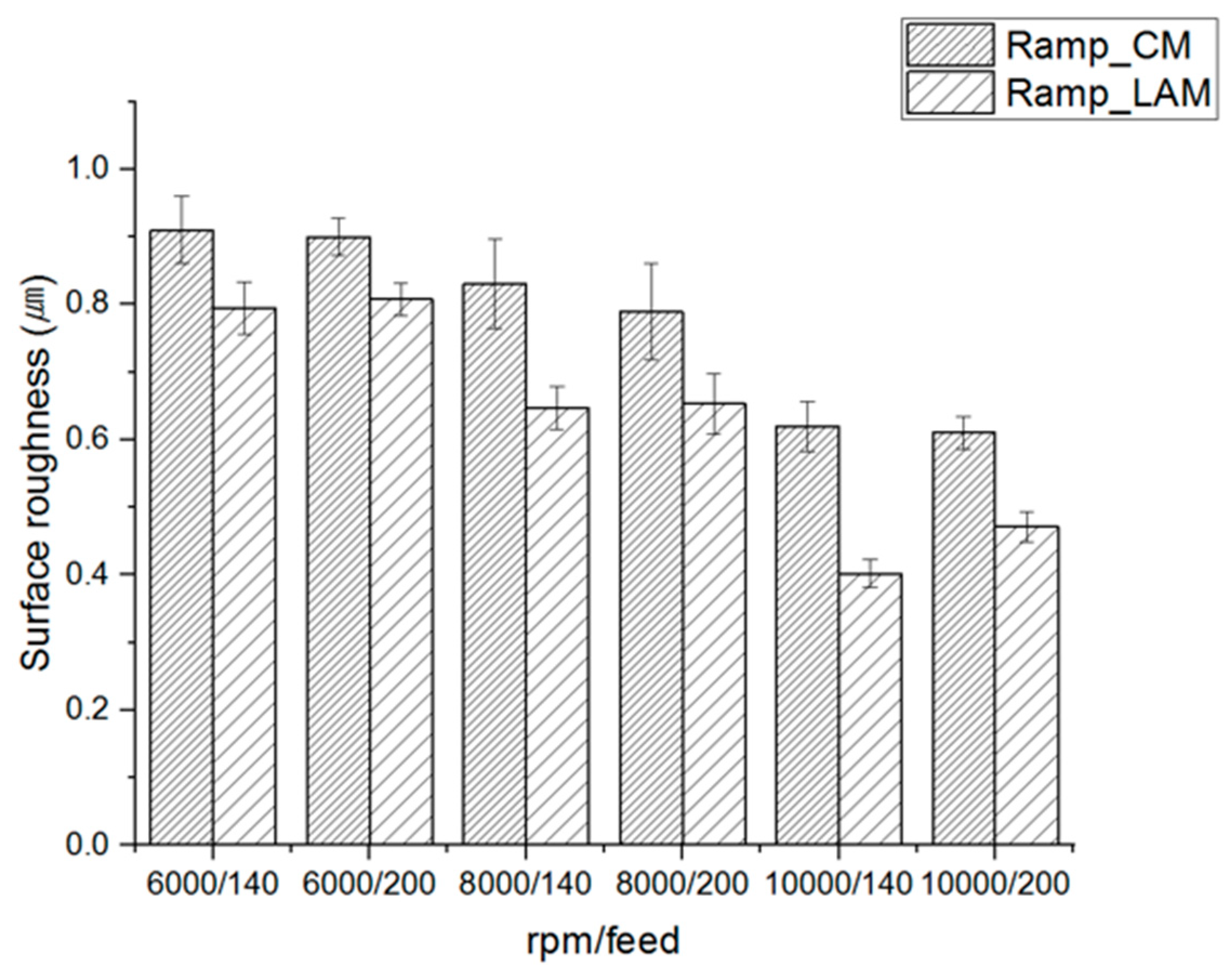

5.3. Surface Roughness

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, D.H.; Lee, C.M. A study of cutting force and preheating-temperature prediction for laser-assisted milling of Inconel 718 and AISI 1045 steel. Int. J. Heat Mass Transf. 2014, 71, 264–274. [Google Scholar] [CrossRef]

- Artetxe, E.; González, H.; Calleja, A.; Valdivielso, A.F.; Polvorosa, R.; Lamikiz, A.; Lacalle, L.N.L. Optimised methodology for aircraft engine IBRs five-axis machining process. Int. J. Mechatron. Manuf. Syst. 2016, 9, 385–401. [Google Scholar] [CrossRef]

- Valdivielso, A.F.; Lacalle, L.N.L.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. J. Mech. Eng. Sci. 2015, 230, 3725–3742. [Google Scholar] [CrossRef]

- Cha, N.H.; Lee, C.M. A Study on Machining Characteristics of Silicon Nitride with Spline Members in Laser-Assisted Turn-Mill. Int. J. Precis. Eng. Manuf. 2015, 16, 2691–2697. [Google Scholar] [CrossRef]

- Lee, C.M.; Kim, D.H.; Back, J.T.; Kim, E.J. Laser assisted milling device: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 199–208. [Google Scholar] [CrossRef]

- Jang, D.Y.; Jung, J.H.; Seok, J.W. Modeling and parameter optimization for cutting energy reduction in MQL milling process. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 5–12. [Google Scholar] [CrossRef]

- Ahn, J.W.; Woo, W.S.; Lee, C.M. A study on the energy efficiency of specific cutting energy in laser-assisted machining. Appl. Therm. Eng. 2016, 94, 748–753. [Google Scholar] [CrossRef]

- Kizaki, T.; Ito, Y.; Tanabe, S.; Kim, Y.J.; Sugita, N.; Misuishi, M. Laser-Assisted Machining of Zirconia Ceramics using a Diamond Bur. Procedia CIRP 2016, 42, 497–502. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Sim, W.M.; Kent, D.; Gardiner, S.; Dargusch, M.S. Tool life and wear mechanisms in laser assisted milling Ti-6Al-4V. Wear 2015, 322, 151–163. [Google Scholar] [CrossRef]

- Woo, W.S.; Lee, C.M. A study of the machining characteristics of AISI 1045 steel and Inconel 718 with a cylindrical shape in laser-assisted milling. Appl. Therm. Eng. 2015, 91, 33–42. [Google Scholar] [CrossRef]

- Bucciarelli, A.; Kulia, P.D.; Melkote, S.M.; Fortunato, A. Micro-machinability of A-286 Steel with and without Laser Assist. Procedia CIRP 2016, 46, 432–435. [Google Scholar] [CrossRef]

- Hedberg, G.K.; Shin, Y.C. Laser-assisted milling of Ti-6Al-4V with the consideration of surface integrity. Int. J. Adv. Manuf. Technol. 2015, 79, 1645–1658. [Google Scholar] [CrossRef]

- Kong, X.J.; Yang, L.J.; Zhang, H.Z.; Zhou, K.; Wang, Y. Cutting performance and coated tool wear mechanisms in laser-assisted milling K24 nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2015, 77, 2151–2163. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Schaffarzyk, P.; Palanisamy, S.; Dargusch, M.S. Laser-assisted milling strategies with different cutting tool paths. Int. J. Adv. Manuf. Technol. 2014, 74, 1487–1494. [Google Scholar] [CrossRef]

- Xi, Y.; Zhan, H.Y.; Rashid, R.A.R.; Wang, G.; Sun, S.J.; Dragusch, M. Numerical modeling of laser assisted machining of a beta titanium alloy. Comput. Mater. Sci. 2014, 92, 149–156. [Google Scholar] [CrossRef]

- Kang, D.W.; Lee, C.M. A study on the development of the laser-assisted milling process and a related constitutive equation for silicon nitride. CIRP Ann. Manuf. Technol. 2014, 63, 109–112. [Google Scholar] [CrossRef]

- Ravindra, D.; Ghantassla, M.K.; Patten, J. Ductile mode material removal and high-pressure phase transformation in silicon during micro-laser assisted machining. Precis. Eng. 2014, 36, 364–367. [Google Scholar] [CrossRef]

- Kim, I.W.; Lee, C.M. A study of the machining characteristics of specimens with spherical shape using laser-assisted milling. Appl. Therm. Eng. 2016, 100, 636–645. [Google Scholar] [CrossRef]

- Ding, H.T.; Shen, N.G.; Shin, Y.C. Thermal and mechanical modeling analysis of laser-assisted micro-milling of difficult-to-machine alloys. J. Mat. Proc. Technol. 2012, 212, 601–613. [Google Scholar] [CrossRef]

- Lehtinen, P.; Vaisanen, T.; Salmi, M. The effect of local heating by laser irradiation for aluminum, deep drawing steel and copper sheets in incremental sheet forming. Phys. Procedia 2015, 78, 312–319. [Google Scholar] [CrossRef]

- Kim, I.W.; Lee, C.M. Investigarion into the machining characteristics of AISI 1045 steel and Inconel 718 for an ellipsoidal shape using laser-assisted contouring and ramping machining. Int. J. Precis. Eng. Manuf. 2017, 18, 1231–1238. [Google Scholar] [CrossRef]

- Kim, E.J.; Lee, C.M. A Study on the preheating Method of NURBS Shaped Workpiece by Laser Assisted Machining. J. Korean Soc. Precis. Eng. 2016, 33, 101–107. [Google Scholar] [CrossRef]

- Kobayashi, T.; Simons, J.W.; Brown, C.S.; Schokey, D.A. Plastic flow behavior of Inconel 718 under dynamic shear loads. Int. J. Impact Eng. 2008, 35, 389–396. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. Thermally enhanced machining of hard-to-machine materials—A review. Int. J. Mach. Tools Manuf. 2010, 50, 663–680. [Google Scholar] [CrossRef]

| A (GPa) | B (GPa) | n | m | C | Tmelt (°C) | (kg m−3) | Cv (kg °C−1) |

|---|---|---|---|---|---|---|---|

| 0.98 | 1.37 | 0.164 | 1.03 | 0.02 | 1300 | 8190 | 435 |

| Element | Cr | Ni | Al | Nb | Ti | Co | Mo |

|---|---|---|---|---|---|---|---|

| Content (%) | 0.79 | 0.45 | 0.55 | 0.25 | 0.016 | 0.08 | 0.018 |

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HC) |

|---|---|---|---|

| 980 | 1280 | 12 | 42 |

| Laser Power (W) | Contour (°C) | Ramp (°C) |

|---|---|---|

| 80 | 814.35 | 803.93 |

| 90 | 877.06 | 869.43 |

| 100 | 938.87 | 928.70 |

| 110 | 997.60 | 986.98 |

| 120 | 1054.60 | 1044.00 |

| Instrument | Company | Specification |

|---|---|---|

| Machine | Hyundai-WIA | Hi-V560M |

| Laser optic | Laserline | LDM 1000-100 |

| Pyrometer | Dr. Mergenthaler | LPC03 |

| Dynamometer | Kistler | 9257B |

| Amplifier | Kistler | 5019 |

| Condition | Inconel 718 |

|---|---|

| Tool path | ramp, contour |

| Spindle speed (rpm) | 6000, 8000, 10,000 |

| Feed rate (mm/min) | 140, 200 |

| Depth of cut (mm) | 0.25 |

| Tool | Ø 8 Ball end mill, 2F, 100 L |

| Preheating temperature (°C) | 940 |

| Laser heat source size (mm) | 3 |

| Laser wavelength (nm) | 920–980 |

| Laser power (W) | 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, E.J.; Lee, C.M. A Study on the Machining Characteristics of Curved Workpiece Using Laser-Assisted Milling with Different Tool Paths in Inconel 718. Metals 2018, 8, 968. https://doi.org/10.3390/met8110968

Kim EJ, Lee CM. A Study on the Machining Characteristics of Curved Workpiece Using Laser-Assisted Milling with Different Tool Paths in Inconel 718. Metals. 2018; 8(11):968. https://doi.org/10.3390/met8110968

Chicago/Turabian StyleKim, Eun Jung, and Choon Man Lee. 2018. "A Study on the Machining Characteristics of Curved Workpiece Using Laser-Assisted Milling with Different Tool Paths in Inconel 718" Metals 8, no. 11: 968. https://doi.org/10.3390/met8110968

APA StyleKim, E. J., & Lee, C. M. (2018). A Study on the Machining Characteristics of Curved Workpiece Using Laser-Assisted Milling with Different Tool Paths in Inconel 718. Metals, 8(11), 968. https://doi.org/10.3390/met8110968