Data-Driven Design of HPDC Aluminum Alloys Using Machine Learning and Inverse Design

Abstract

1. Introduction

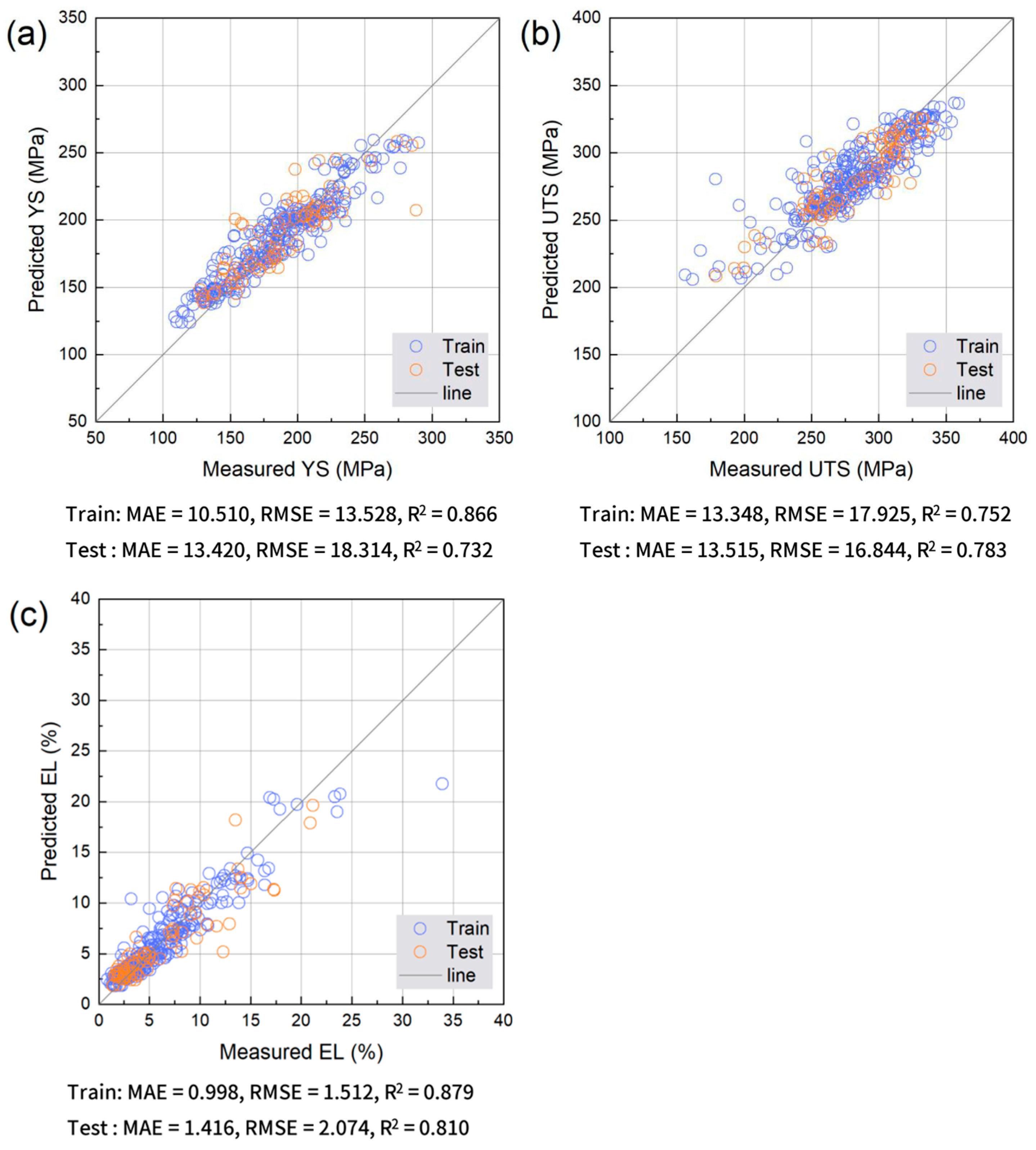

2. Experimental Data and Machine Learning Methodology

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Liu, B.; Shu, D.; Yang, Q.; Hu, T. Vehicle giga-casting Al alloys technologies, applications, and beyond. J. Alloys Compd. 2025, 1013, 178552. [Google Scholar] [CrossRef]

- Zhang, M.; Tian, Y.; Zheng, X.; Zhang, Y.; Chen, L.; Wang, J. Research progress on multi-component alloying and heat treatment of high strength and toughness Al–Si–Cu–Mg cast aluminum alloys. Materials 2023, 16, 1065. [Google Scholar] [CrossRef]

- Son, H.W.; Lee, J.Y.; Cho, Y.H.; Jang, J.I.; Kim, S.B.; Lee, J.M. Enhanced mechanical properties and homogeneous T5 age-hardening behavior of Al-Si-Cu-Mg casting alloys. J. Alloys Compd. 2023, 960, 170982. [Google Scholar] [CrossRef]

- Ji, S.; Yang, W.; Gao, F.; Watson, D.; Fan, Z. Effect of iron on the microstructure and mechanical property of Al–Mg–Si–Mn and Al–Mg–Si diecast alloys. Mater. Sci. Eng. A 2013, 564, 130–139. [Google Scholar] [CrossRef]

- Makhlouf, M.M.; Guthy, H.V. The aluminum–silicon eutectic reaction: Mechanisms and crystallography. J. Light Met. 2001, 1, 199–218. [Google Scholar] [CrossRef]

- Kaufman, J.G.; Rooy, E.L. Aluminum Alloy Castings: Properties, Processes, and Applications; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

- Peng, J.; Yuan, S.; Wang, W.; Gan, P.; Ji, J.; Zeng, J. Effect of short solution and artificial ageing on microstructure and mechanical properties of Al-Si-Mg-La-Ce alloy formed by high pressure die casting. J. Alloys Compd. 2025, 1020, 179436. [Google Scholar] [CrossRef]

- Lee, K.; Kwon, Y.N.; Lee, S. Effects of eutectic silicon particles on tensile properties and fracture toughness of A356 aluminum alloys fabricated by low-pressure-casting, casting-forging, and squeeze-casting processes. J. Alloys Compd. 2008, 461, 532–541. [Google Scholar] [CrossRef]

- Zhang, Y.; Lordan, E.; Dou, K.; Wang, S.; Fan, Z. Influence of porosity characteristics on the variability in mechanical properties of high pressure die casting (HPDC) AlSi7MgMn alloys. J. Manuf. Process. 2020, 56, 500–509. [Google Scholar] [CrossRef]

- Ramprasad, R.; Batra, R.; Pilania, G.; Mannodi-Kanakkithodi, A.; Kim, C. Machine learning in materials informatics: Recent applications and prospects. npj Comput. Mater. 2017, 3, 54. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Ji, X.; Li, M.; Lu, W. Small data machine learning in materials science. npj Comput. Mater. 2023, 9, 42. [Google Scholar] [CrossRef]

- Jeon, J.; Seo, N.; Son, S.B.; Lee, S.J.; Jung, M. Application of machine learning algorithms and SHAP for prediction and feature analysis of tempered martensite hardness in low-alloy steels. Metals 2021, 11, 1159. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Chen, Y. Inverse design of materials by machine learning. Materials 2022, 15, 1811. [Google Scholar] [CrossRef] [PubMed]

- Ren, F.; Ward, L.; Williams, T.; Laws, K.J.; Wolverton, C.; Hattrick-Simpers, J.; Mehta, A. Accelerated discovery of metallic glasses through iteration of machine learning and high-throughput experiments. Sci. Adv. 2018, 4, eaaq1566. [Google Scholar] [CrossRef] [PubMed]

- Hoerl, A.E.; Kennard, R.W. Ridge regression: Applications to nonorthogonal problems. Technometrics 1970, 12, 69–82. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System; Cornell University: Ithaca, NY, USA, 2016. [Google Scholar]

- Hornik, K. Approximation capabilities of multilayer feedforward networks. Neural Netw. 1991, 4, 251–257. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Shinomiya, Y.; Yamamoto, J.; Kato, K.; Ono, H.; Yamaguchi, K.; Komori, K. Thermodynamics of formation of Al3Fe inter-metallic compound for Fe removal from molten Al–Mg alloy. Mater. Trans. 2023, 64, 385–391. [Google Scholar] [CrossRef]

- Crepeau, P.N. Effect of iron in Al-Si casting alloys: A critical review (95–110). AFS Trans. 1995, 103, 361–366. [Google Scholar]

- Rheinfelden. Primary Aluminium Casting Alloys, Datasheet L 2.06/3-KH. Available online: https://www.foundry-planet.com/fileadmin/redakteur/Material/08-03-10-Leporello_engl.pdf (accessed on 13 January 2026).

- Riestra, M. High Performing Cast Aluminium-Silicon Alloys. Ph.D. Dissertation, School of Engineering, Jönköping University, Jönköping, Sweden, 2017. [Google Scholar]

- Liang, Z.; Chang, C.S.T.; Wanderka, N.; Banhart, J.; Hirsch, J. The Effect of Fe, Mn and Trace Elements on Precipitation in Al-Mg-Si Alloy. In Proceedings of the 12th International Conference on Aluminium Alloys, Yokohama, Japan, 5–9 September 2010; pp. 492–497. [Google Scholar]

- Zhao, Y.; Zhang, W.; Yang, C.; Zhang, D.; Wang, Z. Effect of Si on Fe-rich intermetallic formation and mechanical properties of heat-treated Al–Cu–Mn–Fe alloys. J. Mater. Res. 2018, 33, 898–911. [Google Scholar] [CrossRef]

- Gupta, M.; Ling, S. Microstructure and mechanical properties of hypo/hyper-eutectic Al–Si alloys synthesized using a near-net shape forming technique. J. Alloys Compd. 1999, 287, 284–294. [Google Scholar] [CrossRef]

- Dang, B.; Zhang, X.; Chen, Y.Z.; Chen, C.X.; Wang, H.T.; Liu, F. Breaking through the strength-ductility trade-off dilemma in an Al-Si-based casting alloy. Sci. Rep. 2016, 6, 30874. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Yu, F.; Zhao, D. Aging Behavior and Precipitates Analysis of Wrought Al-Si-Mg Alloy. Materials 2022, 15, 8194. [Google Scholar] [CrossRef]

- Hajkowski, M.; Bernat, Ł.; Hajkowski, J. Mechanical properties of Al-Si-Mg alloy castings as a function of structure refinement and porosity fraction. Arch. Foundry Eng. 2012, 12, 57–64. [Google Scholar] [CrossRef]

- Liu, R.; Zheng, J.; Godlewski, L.; Zindel, J.; Li, M.; Li, W.; Huang, S. Influence of pore characteristics and eutectic particles on the tensile properties of Al–Si–Mn–Mg high pressure die casting alloy. Mater. Sci. Eng. A 2020, 783, 139280. [Google Scholar] [CrossRef]

- Kim, S.B.; Lee, J.M.; Koo, T.M.; Lee, S.U.; Lee, J.Y.; Son, K.S.; Cho, Y.H. Influence of cooling condition after solidification on T5 heat treatment response of hypoeutectic Al-7Si-0.4 Mg casting alloy. J. Alloys Compd. 2022, 906, 164339. [Google Scholar] [CrossRef]

- Peivaste, I.; Jossou, E.; Tiamiyu, A.A. Data-driven analysis and prediction of stable phases for high-entropy alloy design. Sci. Rep. 2023, 13, 22556. [Google Scholar] [CrossRef]

- Choudhury, A.; Konnur, T.; Chattopadhyay, P.P.; Pal, S. Structure prediction of multi-principal element alloys using ensemble learning. Eng. Comput. 2020, 37, 1003–1022. [Google Scholar] [CrossRef]

- Liu, Y.T.; Lin, J.X.; Wu, X.P.; Niu, L.Y.; Li, G.Y. The Effect of Sr Modification on the Microstructure and Properties of Mg2Si Reinforced Near-Eutectic Al-Si Alloy. Adv. Mater. Res. 2013, 750, 638–641. [Google Scholar]

- Liu, F.; Chen, S.; Dong, Q.; Qin, J.; Li, Z.; Zhang, B.; Nagaumi, H. Tailoring microstructure and mechanical properties of Al-Mg-Si-Cu alloy with varying Mn and/or Cr additions. Mater. Sci. Eng. A 2024, 892, 146053. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, S.J.; Kim, D.U.; Kim, M.S. Experimental investigation on tensile properties and yield strength modeling of T5 heat-treated counter pressure cast A356 aluminum alloys. Metals 2021, 11, 1192. [Google Scholar] [CrossRef]

- Zhang, J.; Cinkilic, E.; Huang, X.; Wang, G.G.; Liu, Y.C.; Weiler, J.P.; Luo, A.A. Optimization of T5 heat treatment in high pressure die casting of Al–Si–Mg–Mn alloys by using an improved Kampmann-Wagner numerical (KWN) model. Mater. Sci. Eng. A 2023, 865, 144604. [Google Scholar] [CrossRef]

- Zhu, X.; Blake, P.; Dou, K.; Ji, S. Strengthening die-cast Al-Mg and Al-Mg-Mn alloys with Fe as a beneficial element. Mater. Sci. Eng. A 2018, 732, 240–250. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. In NIPS’17: Proceedings of the 31st International Conference on Neural Information Processing Systems; Curran Associates Inc.: Red Hook, NY, USA, 2017; pp. 4768–4777. [Google Scholar]

- Kim, H.Y.; Park, T.Y.; Han, S.W.; Lee, H.M. Effects of Mn on the crystal structure of α-Al (Mn, Fe) Si particles in A356 alloys. J. Cryst. Growth 2006, 291, 207–211. [Google Scholar] [CrossRef]

- Djurdjevic, M.; Manasijević, S.; Patarić, A.; Stopić, S.; Mihailović, M. Impact of Mg on the Feeding Ability of Cast Al–Si7–Mg (0_0.2_0.4_0.6) Alloys. Crystals 2024, 14, 816. [Google Scholar] [CrossRef]

- Lordan, E.; Zhang, Y.; Dou, K.; Jacot, A.; Tzileroglou, C.; Wang, S.; Wang, Y.; Patel, J.; Lazaro-Nebreda, J.; Zhou, X.; et al. High-pressure die casting: A review of progress from the EPSRC future lime hub. Metals 2022, 12, 1575. [Google Scholar] [CrossRef]

- Hwang, J.Y.; Doty, H.W.; Kaufman, M.J. The effects of Mn additions on the microstructure and mechanical properties of Al–Si–Cu casting alloys. Mater. Sci. Eng. A 2008, 488, 496–504. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Liu, K.; Rometsch, P.; Parson, N.; Chen, X.G. Effects of Al(MnFe)Si dispersoids with different sizes and number densities on microstructure and ambient/elevated-temperature mechanical properties of extruded Al–Mg–Si AA6082 alloys with varying Mn content. J. Alloys Compd. 2021, 861, 157937. [Google Scholar] [CrossRef]

- Lee, C. Effects of Damage Evolution of Eutectic Si Particle and Microporosity to Tensile Property of Al-xSi Alloys. J. Korea Foundry Soc. 2021, 41, 434–444. [Google Scholar]

- Jeong, C.Y.; Kim, Y.S.; Ryu, J.H.; Kim, H.J. Mechanical and Die Soldering Properties of Al-Si-Mg Alloys with Vacuum HPDC Process. In Proceedings of the 12th International Conference on Aluminium Alloys, Yokohama, Japan, 5–9 September 2010; pp. 1768–1773. [Google Scholar]

- Dons, A.L.; Heiberg, G.; Voje, J.; Mæland, J.S.; Løland, J.O.; Prestmo, A. On the effect of additions of Cu and Mg on the ductility of AlSi foundry alloys cast with a cooling rate of approximately 3 K/s. Mater. Sci. Eng. A 2005, 413, 561–566. [Google Scholar] [CrossRef]

| Min | Max | Mean | Avg | SD | |

|---|---|---|---|---|---|

| Si (wt.%) | 0 | 11.49 | 4.33 | 5.73 | 4.31 |

| Mg (wt.%) | 0.01 | 6.5 | 0.67 | 1.78 | 2.06 |

| Mn (wt.%) | 0 | 0.61 | 0.37 | 0.3 | 0.26 |

| Zn (wt.%) | 0 | 9.4 | 0 | 0.76 | 2.14 |

| Nb (wt.%) | 0.11 | 0.11 | 0.11 | 0.11 | 0 |

| Cu (wt.%) | 0 | 4.7 | 0 | 0.25 | 0.76 |

| Ti (wt.%) | 0.01 | 0.18 | 0.06 | 0.08 | 0.05 |

| Sr (wt.%) | 0.01 | 0.06 | 0.01 | 0.02 | 0.02 |

| Fe (wt.%) | 0.12 | 1.1 | 0.18 | 0.44 | 0.41 |

| Cr (wt.%) | 0.04 | 0.04 | 0.04 | 0.04 | 0 |

| Ni (wt.%) | 0.06 | 0.06 | 0.06 | 0.06 | 0 |

| Zr (wt.%) | 0.1 | 0.1 | 0.1 | 0.1 | 0 |

| Temp (°C) | 100 | 350 | 180 | 194 | 53 |

| Time (min) | 30 | 2880 | 120 | 383 | 551 |

| YS (MPa) | 23.2 | 290 | 185.8 | 185.8 | 37.6 |

| UTS (MPa) | 33.2 | 359.4 | 280.9 | 280.7 | 38.2 |

| EL (%) | 0.9 | 34 | 4.5 | 6 | 4.4 |

| #1 | #2 | #3 | #4 | #5 | |

|---|---|---|---|---|---|

| Si (wt.%) | 2.54 | 2.66 | 1.43 | 2.54 | 2.87 |

| Mg (wt.%) | 0.20 | 0.22 | 0.11 | 0.14 | 0.07 |

| Mn (wt.%) | 0.58 | 0.53 | 0.59 | 0.55 | 0.54 |

| Zn (wt.%) | 7.04 | 1.66 | 5.18 | 2.28 | 1.12 |

| Nb (wt.%) | 0.11 | 0.11 | 0.11 | 0.11 | 0.11 |

| Cu (wt.%) | 1.02 | 1.70 | 3.81 | 2.96 | 3.50 |

| Ti (wt.%) | 0.13 | 0.10 | 0.15 | 0.14 | 0.10 |

| Sr (wt.%) | 0.01 | 0.03 | 0.02 | 0.03 | 0.02 |

| Fe (wt.%) | 0.78 | 0.74 | 0.97 | 1.04 | 0.85 |

| Cr (wt.%) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Ni (wt.%) | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| Zr (wt.%) | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Temp (°C) | 154 | 186 | 169 | 191 | 143 |

| Time (min) | 209 | 600 | 1618 | 1371 | 1085 |

| YS (MPa) | 210.9 | 203.9 | 211.8 | 219.2 | 201.2 |

| UTS (MPa) | 307.9 | 314.4 | 310.6 | 313.9 | 310.8 |

| EL (%) | 8.3 | 8.0 | 8.7 | 8.1 | 10.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Choi, S.; Kim, S.; Lee, J.; Choi, J.; Lee, M.; Kim, J.; Jung, J.-G.; Lee, S.-J. Data-Driven Design of HPDC Aluminum Alloys Using Machine Learning and Inverse Design. Metals 2026, 16, 99. https://doi.org/10.3390/met16010099

Choi S, Kim S, Lee J, Choi J, Lee M, Kim J, Jung J-G, Lee S-J. Data-Driven Design of HPDC Aluminum Alloys Using Machine Learning and Inverse Design. Metals. 2026; 16(1):99. https://doi.org/10.3390/met16010099

Chicago/Turabian StyleChoi, Seunghyeok, Sungjin Kim, Junho Lee, Jeonghoo Choi, MiYoung Lee, JaeHwang Kim, Jae-Gil Jung, and Seok-Jae Lee. 2026. "Data-Driven Design of HPDC Aluminum Alloys Using Machine Learning and Inverse Design" Metals 16, no. 1: 99. https://doi.org/10.3390/met16010099

APA StyleChoi, S., Kim, S., Lee, J., Choi, J., Lee, M., Kim, J., Jung, J.-G., & Lee, S.-J. (2026). Data-Driven Design of HPDC Aluminum Alloys Using Machine Learning and Inverse Design. Metals, 16(1), 99. https://doi.org/10.3390/met16010099