Abstract

We explored the effects of different solution treatment temperatures on the microstructure, mechanical properties and wear resistance of alloyed high-manganese steel, as well as the correlations among the three parameters. The results indicated that the average grain size of high-manganese steel first decreases and then gradually increases with an increasing solution temperature. After solution treatment, the surface hardness of the high-manganese steel is lower than that of untreated steel. At a solution treatment temperature of 1050 °C, the surface hardness value is lowest, at 253.1 HV. In addition, the optimal combination of tensile strength, yield strength and work hardening rate is observed at a solution treatment temperature of 950 °C. The friction performance test results revealed that the average friction coefficient on the surface of the high-manganese steel first decreased and then increased with the increase in solution treatment temperature. After solution treatment at 950 °C, it reached a minimum value 0.273 due to oxidation friction. Meanwhile, the hardness of the steel after friction increased rapidly because of its excellent work hardening ability, so the wear rate was relatively low, approximately 0.223 × 10−13 m2/N, demonstrating optimal wear resistance. After solution treatment, the average grain size of high-manganese steel changed, and there was a transformation of the wear mechanism; the friction and wear mechanism shifted from a combination of particle wear and fatigue wear to adhesive wear, with particle wear as the auxiliary.

1. Introduction

As a traditional wear-resistant material, high-manganese steel has been widely utilized in high-wear industrial fields, including for mining equipment, railway crossings, and crusher liners [1,2,3,4]. However, evolving industrial demands have imposed increasingly complex service conditions—such as multi-axis impact loads and high-stress erosive environments—which necessitate enhanced comprehensive properties in high-manganese steel, particularly in terms of strain-hardening capacity, impact toughness, and wear resistance under extreme stress [5]. To address these challenges, researchers have employed diverse strategies to optimize the mechanical properties and wear resistance of high-manganese steel, including microalloying or re-alloying [6,7,8,9], pre-hardening treatments [10,11,12,13], and heat treatment [5,14,15,16,17,18].

Feng et al. [9] investigated the microstructural evolution and impact wear behavior of Al-alloyed high-manganese steel and reported that the addition of aluminum improved the stacking fault energy of high-manganese steel, changed the strain hardening and deformation mechanism of the metal, and thus improved the wear resistance of the austenite matrix. Wang et al. [13] studied the effects of surface impact parameters on the performance of pre-hardened high-manganese steel samples. The results revealed that impact hardening increased the hardness of the top surface and within a certain depth. In addition, the tested steel exhibited good wear resistance after surface impact hardening. However, excess impact induced microcracking along the top surface, resulting in deteriorated wear resistance. Li et al. [5] adopted the progressive solution treatment method to perform heat treatment on high-manganese steel. The results showed that, compared with those produced by the traditional solution treatment method, the number of precipitates produced by the progressive solid solution decreased, the tensile strength and impact toughness of the steel significantly increased, and the wear resistance increased by nearly 23%. Zhou et al. [15] studied the influence of two novel heat-treatment processes on the enhancement of yield strength and hardness by Ti-V-Nb alloying in high-manganese austenitic steel. The results revealed that the yield strength and impact toughness of steel after the segmented heat preservation process were obviously greater than those after the continuous heating process. Gao et al. [18] compared the friction morphology under different temperatures and reported that the microstructure was optimized after heat treatment and that the degree of bonding between the two phases increased, thereby inhibiting the detachment of particulate matter and reducing the occurrence of abrasive particles. Although these previous studies to improve the mechanical properties and wear resistance of high-manganese steels provide insights into the effects of the solution temperature on the yield strength, tensile strength, and wear resistance, the influence of the solution temperature was different for different alloy systems of high-manganese steels.

In this study, the effects of solution temperatures on microstructure, mechanical properties and wear resistance of alloyed high-manganese steel were systematically investigated. Moreover, this study provides a theoretical basis for optimizing the heat treatment process parameters of high-manganese steel and new ideas for improving the performance of new high-manganese austenite steel.

2. Experimental Materials and Procedures

2.1. Experimental Materials

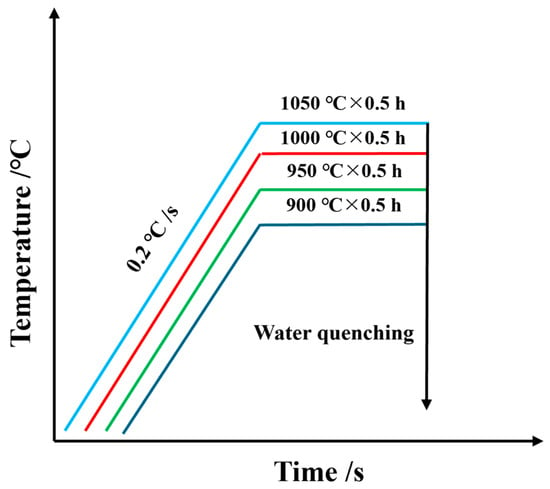

The alloy composition of existing high-manganese steel was optimized, and a new type of Fe-25Mn-0.37C-3.69Cr high-manganese steel was designed and prototyped, which was melted by a vacuum high-frequency induction furnace. The smelting steps are as follows: charging → vacuuming → filling with argon → smelting → heat preservation for 30 min → after complete melting → stirring → homogenizing at above 1200 °C for 2 h → pouring → air cooling. The chemical compositions of the investigated high-manganese steel are given in Table 1. The five test specimens with dimensions of 150 mm × 22 mm × 40 mm were prepared via the wire cutting mechanism. Specimens were solution-treated at 900 °C, 950 °C, 1000 °C and 1050 °C for 0.5 h, respectively, and then water-quenched. Figure 1 shows the solution treatment diagram of high-manganese steel.

Table 1.

Chemical compositions of the investigated high-manganese steels.

Figure 1.

Solution treatment diagram of the high-manganese steel.

2.2. Mechanical Properties

The surface hardness of the steel before and after the friction test was tested via a micro-Vickers hardness meter (HV-1000, Jinan Liling Testing Machine Co., Ltd., Jinan, China). The Vickers hardness load was 9.8 N and a total of ten samples were tested. Each sample was randomly selected to measure the hardness at 5 points, and the average value was taken as the final hardness value. Tensile tests were carried out in accordance with the GB/T 228.1-2021 standard [19] on an electronic universal testing machine (CMT-5205, Shandong Shenglin Precision Machinery Equipment Co., Ltd., Jinan, China). The test temperature was 23 °C, and the tensile speed was 2 mm/min. All tensile test samples were cut along the same direction of the plate. To ensure the accuracy of the test results, each group of tests was repeated at least 3 times, and the results were averaged.

2.3. Friction Wear Test

The friction wear test was carried out using a Bruker multifunction reciprocating friction wear tester (UMT TriboLab, Bruker Corporation, Karlsruhe, Germany). A total of five samples with dimensions of 20 mm × 20 mm × 4 mm were tested. The friction pair selected for the test was a GCr15 steel ball with a diameter of 8 mm. Spherical contact friction was used, the reciprocating movement distance was 10 mm, the frequency was 200 mm/min, the load was 20 N, and the test period was 30 min.

2.4. Microstructure Observation

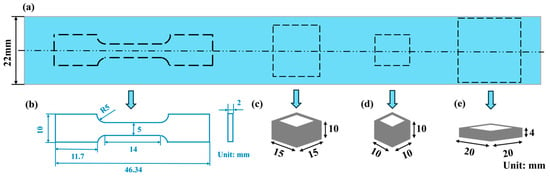

A total of five steel samples were mechanically polished and then electro-polished in a mixed solution of 10% perchloric acid (HClO4) and 90% glacial acetic acid (CH3COOH). The microstructures of high-manganese steel at various solution temperatures were observed using a field emission scanning electron microscope (FE-SEM, ZEISS Sigma 560, Oberkochen, Germany) equipped with an EBSD probe (Oxford Instruments, NordlysMax2, Abingdon, UK). Phase identification was performed via X-ray diffraction (XRD, D8 ADVANCE, Bruker Corporation, Karlsruhe, Germany) with a Cu-Kα target. A total of five samples were tested. The scanning rate and range of XRD analysis were 2 °/min and 20~100°, respectively. The microstructure of the wear marks was characterized by a field emission scanning electron microscope (FE-SEM). The wear marks were analyzed by an energy spectrometer (EDS). The sizes of the test samples are shown in Figure 2 (units: mm).

Figure 2.

(a) Sampling locations for mechanical testing and microstructural observation; (b–e) dimensions of tensile samples, microstructural observation samples, surface hardness samples, and friction wear test samples.

3. Results and Discussion

3.1. Effect of Solution Treatment on Microstructures of High-Manganese Steel

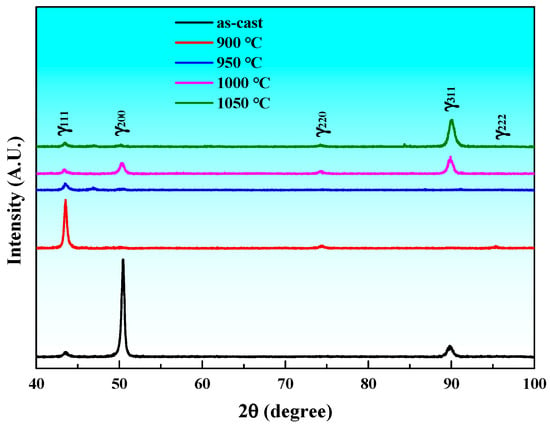

The XRD patterns of the initial microstructures of the samples at different solution treatment temperatures are given in Figure 3 From the XRD results, only the characteristic diffraction peaks of austenite appeared in the specimens under different solution treatment temperatures. In addition, it was also found that the diffraction peak intensities of specimens were different. This may be related to the preferred grain orientation and texture of steels after solution treatment processes [15].

Figure 3.

XRD patterns of the microstructures of high-manganese steel at various solution temperatures.

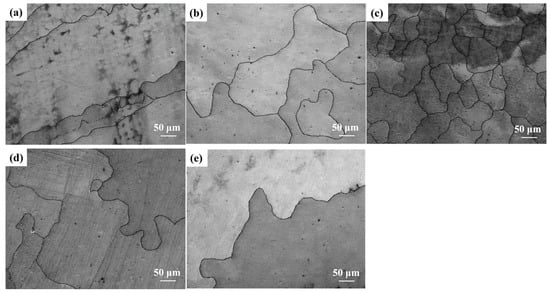

The microstructures of high-manganese steel at various solution temperatures are given in Figure 4. When the solution treatment temperature increased, part of the carbides precipitated and then dissolved, and the average grain size of high-manganese steel first decreased and then gradually increased, which was consistent with some research findings [20,21]. As shown in Figure 4a, some carbides remained in the original form at the grain boundary of the untreated steel, and the austenite grains were relatively coarse. The average grain size was approximately 100.08 μm. After 900 °C solution treatment (Figure 4b), part of the recrystallization produced equiaxed grains accompanied by residual carbides, and the average grain size was approximately 109.17 μm. As can be seen from Figure 4c, high-manganese steel undergoes optimal grain refinement at 950 °C, and the average grain size is approximately 48.21 μm. At this time, complete recrystallization produces uniform grains and annealing twins. When the solution temperature continues to rise to 1000 °C and 1050 °C, the carbides at the grain boundary dissolve into the matrix, and the austenite grain size increases significantly (Figure 4d,e). The average grain size is approximately 115.35 μm and 242.81 μm, respectively.

Figure 4.

Microstructures of high-manganese steel at various solution temperatures: (a) untreated steel, (b) 900 °C, (c) 950 °C, (d) 1000 °C, (e) 1050 °C.

3.2. Effects of Solution Treatment on the Mechanical Properties of High-Manganese Steel

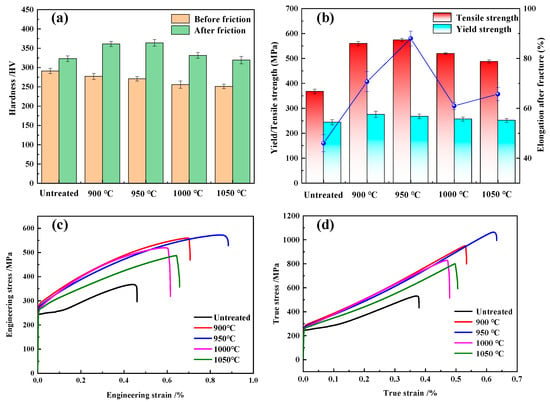

The hardness test results before and after friction for the high-manganese steel at different solution treatment temperatures are given in Figure 5a. Before the friction test, it can be observed that the hardness of the original steel sample was 291.2 HV. With the increase in the solution temperature, the hardness showed a tendency to fall. This result was consistent with the results of Xu et al.’s study [22]. With a solution temperature of 900 °C, carbides at the grain boundaries had not yet completely dissolved, which significantly improved the surface hardness of the steel. When the solution temperature increased to 1050 °C, the carbides gradually dissolved completely [23,24], resulting in the hardness of the steel sample decreasing with increasing heat treatment temperature. The steel after the 1050 °C solution treatment had the lowest hardness, approximately 251.3 HV, which can be attributed to the dissolution of carbides [22]. High-manganese steel undergoes work hardening to varying degrees after friction, resulting in a greater increase in hardness after friction than before friction. In particular, with solution temperature at 950 °C, the surface hardness is 271.1 HV to 364.2 HV, and the surface hardness of the steel is 34.3% greater than that before friction.

Figure 5.

High-manganese steels subjected to different solution treatment temperatures: (a) surface hardness of high-manganese steel before and after friction, (b) engineering stress–strain curve, (c) true stress–strain curve, (d) tensile test results.

Tensile test results are given in Figure 5b and Table 2. A comparison of the tensile results revealed that the high-manganese steel after solution treatment had excellent yield strength and tensile strength compared to the original steel. In addition, the high-manganese steel after solution treatment further improved the elongation of the steel. The high-manganese steel has a relatively high yield/tensile strength and elongation due to the dissolution of inclusion precipitates at the grain boundaries [15]. After solution treatment at 950 °C, the steel possesses good mechanical properties, exhibiting a good combination of high yield strength (268 MPa), high tensile strength (574 MPa) and high total elongation (88.0%). Figure 5c,d showed the engineering and true stress–strain curves of high-manganese steels subjected to different solution treatment temperatures. All the samples exhibited continuous yielding behavior. The true stress–strain curve of the steel after solution treatment at 950 °C showed that the steel possesses good mechanical properties, exhibiting high true stress (1100 MPa) and large true strain (0.6).

Table 2.

Tensile test results under different heat treatment temperatures.

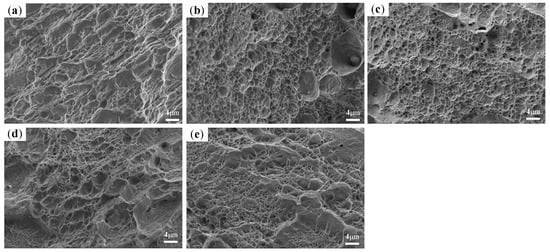

Figure 6 shows the room temperature tensile specimen fracture morphologies of high-manganese steels subjected to different solution treatment temperatures. As can be seen from Figure 6a, the fracture surface exhibited typical ductile fracture characteristics. The fracture surface of as-cast steel was covered with a large distribution of dimples, of varying depths and significant size differences, indicating significant plastic deformation during the stretching process [19]. The tensile fracture morphology of high-manganese steel after solution treatment also involved typical ductile fractures. In Figure 6b,c, after solution treatment at 900 °C and 950 °C, high-manganese steel had more small and deep dimples at the fracture. However, compared with 900 °C solution treatment, the size of precipitates in high-manganese steel with 950 °C solution treatment was smaller, and the dimples were more evenly distributed. With an increase in solution treatment temperatures of up to 1000 °C and 1050 °C, there were more large and shallow dimples at the fracture, and the dimples were not evenly distributed (Figure 6d,e). Some studies showed that the larger size precipitates in high-manganese steel tend to become stress concentration points during the tensile process, which accelerates the fracture of the specimen, resulting in a decrease in tensile strength and elongation of steel [19,25,26]. This is consistent with the results of tensile tests in this work.

Figure 6.

Room-temperature tensile fracture morphologies of high-manganese steels subjected to different solution treatment temperatures: (a) untreated steel, (b) 900 °C, (c) 950 °C, (d) 1000 °C, (e) 1050 °C.

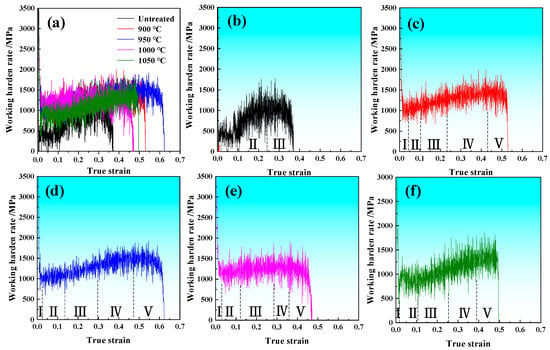

Figure 7 provides the work hardening rate curves of high-manganese steels subjected to different solution treatment temperatures. The work hardening rate is generally associated with grain size, dislocation density, and deformation in high-manganese steel [27,28,29,30]. As shown in Figure 7b–f, the work hardening rate of high-manganese steel involves five stages (I, II, III, Ⅳ and Ⅴ) [27,28]. The work hardening rate appears in stages II and III. During stages II and III, deformation twins continue to form, resulting in continuous work hardening. By comparing the work hardening rates at different stages, it is found that the work hardening rates at 900 °C and 950 °C are slightly higher than those of high-manganese steel at other solution treatment temperatures, indicating that the work hardening rate is higher and is most sensitive to work hardening [31].

Figure 7.

(a) Work hardening rate curves of high-manganese steels subjected to different solution treatment temperatures: (b) untreated, (c) 900 °C, (d) 950 °C, (e) 1000 °C, (f) 1050 °C.

3.3. Effect of Solution Treatment on the Wear Characteristics of High-Manganese Steel

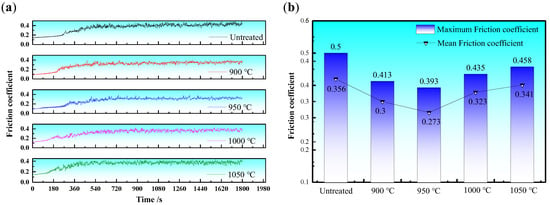

The change curves of the friction coefficient of high-manganese steel at different solution temperatures with friction time are shown in Figure 8a. It can be seen that the friction coefficient of the high-manganese steel gradually increased and finally stabilized between 0.30 and 0.50. In general, adhesive wear happens when two friction surfaces slide or rub against each other under pressure, causing them to stick together and then tear apart; fatigue wear is a type of wear generated due to the repeated application of cyclic loads on a material [32]. At first, many particles fall off the surface due to adhesion wear, and adhesion wear gradually becomes abrasive contact wear. Moreover, due to fatigue wear, the friction contact surface forms local protrusions, leading to an increase in the roughness of the friction surface, so the friction coefficient fluctuates within a certain range [33].

Figure 8.

Different solution treatment temperatures: (a) friction coefficient curves and (b) maximum and mean friction coefficient.

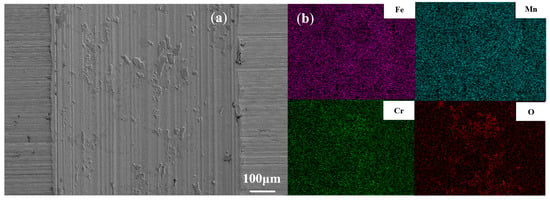

Figure 8b shows the changes in the average and maximum friction coefficients with the increase in solution treatment temperature. With the increase in solution temperature, the maximum friction coefficient and the average friction coefficient first decrease and then increase. When the solution temperature was 950 °C, the mean friction coefficient reached a minimum value of 0.273. To explore the reason for the decrease in the friction coefficient at 950 °C, EDS energy spectrum analysis was performed on the wear surface, and the results are shown in Figure 9. The energy spectrum revealed that the oxidation reaction occurred during the friction process in places with deep wear marks. Owing to the combined action of friction and friction heat, each element undergoes an oxidation reaction on the friction surface, forming an oxide layer [34], increasing the surface hardness, and oxidizing the high-manganese steel, so the average friction coefficient decreases.

Figure 9.

Wear surface morphology at 950 °C: (a) SEM micrograph and (b) EDS spectrum.

3.4. Effect of Solution Treatment on the Wear Mechanism of High-Manganese Steel

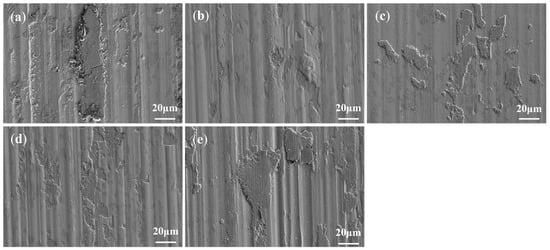

Figure 10 presents the wear surface of high-manganese steel subjected to different solution temperatures. It can be seen from Figure 10a that there was more wear debris and larger adhesive metals on the surface of the original steel wear marks, which reflects obvious abrasive wear characteristics. As shown in Figure 10b, when the solution temperature was 900 °C, the amount of surface wear debris was obviously lower, but pitting, spalling layer, and a small number of furrows remained, indicating that the wear mechanism of this high-manganese steel is mainly abrasive wear. Figure 10c shows that when the solution temperature was 950 °C, the wear surface was smoother, and small amounts of pitting, wear debris, and adhesion metals were present and evenly distributed. The wear mechanism is currently a combination of fatigue wear and adhesion wear [32,35]. When the solution temperature increased to 1000 °C, the shallow furrows and a small number of adhesion metals appeared (Figure 10d), so the wear mechanism was based on adhesive wear. When the solution temperature increased up to 1050 °C, as shown in Figure 10e, more furrows and larger adhesive metals appeared on the surface of the wear marks, the furrows were deeper, and the wear surface was rough, indicating that the degree of particle wear was very high.

Figure 10.

SEM micrographs of wear marks under different solution treatment temperatures: (a) untreated steel, (b) 900 °C, (c) 950 °C, (d) 1000 °C, (e) 1050 °C.

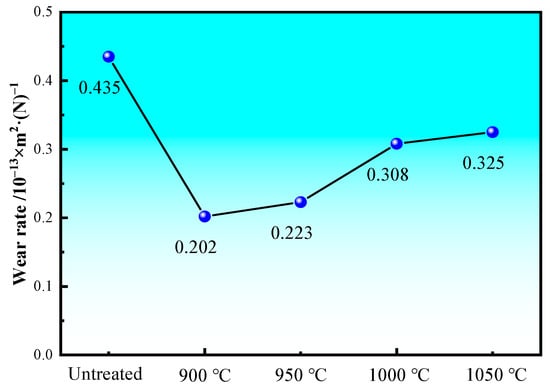

Wear resistance is typically associated with the hardness of materials. In addition, wear resistance is also closely related to the work hardening behavior [36,37,38]. The wear rates of the original steel and high-manganese steel at different solution temperatures are shown in Figure 11. As can be seen from Figure 11, there is a large difference between the wear rate of the original steel and the high-manganese steel at different solution temperatures, which was attributed to the work hardening effect. The surface hardness of high-manganese steel decreases after solution temperature at 950 °C, but the surface work hardening effect is improved in the friction test, the hardness is greater, and the wear resistance is excellent. The wear rate reached a minimum (0.202 × 10−13 m2/N) when the solution temperature was 900 °C, which was consistent with the wear scar morphology results. Studies have shown that if the wear rate is faster than the strain hardening rate, a sample will deteriorate rapidly. The wear resistance of materials is closely related to the strength and hardening ability of the matrix [39]. The hardness of the high-manganese steel at a solution treatment temperature of 1000 °C and 1050 °C continued to decrease; although surface work hardening occurred during the friction process, the work hardening rate was lower than that at the solution treatment temperature of 900 °C and 950 °C, so the wear resistance was constantly reduced.

Figure 11.

Wear rate under different solution treatment temperatures.

4. Conclusions

(1) With the increase in solution treatment temperature, part of the carbides precipitated and then dissolved, and the average grain size of high-manganese steel first decreased and then gradually increased. After solution treatment, the surface hardness of high-manganese steel gradually decreased. Compared with before friction, the surface hardness of high-manganese steel greatly increased after friction, especially after 950 °C solution temperature, and the surface hardness of the steel reached 364.2 HV, an increase of 34.3%. This is because high-manganese steel undergoes varying degrees of work hardening after friction. By comparing the work hardening rate of high-manganese steel, the work hardening rate is slightly higher at solution temperatures of 900 °C and 950 °C, and the hardness after friction is relatively higher.

(2) All the samples exhibited continuous yielding behavior. A comparison of the tensile results revealed that the high-manganese steel after solution treatment had excellent yield strength, tensile strength and elongation compared to the original steel. After solution temperature at 950 °C, the steel possesses good mechanical properties and wear resistance, exhibiting a good combination of high yield strength (268 MPa), high tensile strength (574 MPa) and optimal wear resistance.

(3) The friction mechanism of steel without solution treatment is mainly abrasive wear. When the solution temperature is 900–1000 °C, there is less wear debris and fewer peeling pits and grooves on the worn surface of the high-manganese steel, and the wear mechanism is mainly combined with fatigue wear and adhesive wear. When the solution temperature rises to 1050 °C, the worn surface becomes rougher, plowing grooves become more pronounced, particle wear becomes severe, and the wear resistance of the steel is reduced.

Author Contributions

X.Q.: Writing—original draft, Validation, Software, Investigation, Formal analysis, Data curation. B.L.: Writing—review and editing, Software, Formal analysis, Data curation. X.H.: Writing—review and editing, Supervision, Resources, Project administration, Methodology, Funding acquisition, Formal analysis, Conceptualization. X.Z.: Resources, Methodology, Formal analysis, Conceptualization. X.Y.: Methodology, Investigation, Data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Joint Fund Project of State Key Laboratory of Metal Material for Marine Equipment and Application (HGSKL-USTLN (2021) 10).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank team partners from the Key Laboratory of Green Low-Carbon and Intelligent Metallurgy of Liaoning Province for their valuable contribution to this work and the preparation of this paper.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Weeks, J.D. Hadfield’s manganese steel. Science 1888, 12, 284–286. [Google Scholar] [CrossRef]

- Wen, Y.H.; Peng, H.B.; Si, H.T.; Xiong, R.L.; Raabe, D. A novel high manganese austenitic steel with higher work hardening capacity and much lower impact deformation than Hadfield manganese steel. Mater. Des. 2014, 55, 798–804. [Google Scholar] [CrossRef]

- Efstathiou, C.; Sehitoglu, H. Strain hardening and heterogeneous deformation during twinning in Hadfield steel. Acta Mater. 2010, 58, 1479–1488. [Google Scholar] [CrossRef]

- El Fawkhry, M.K. Feasibility of new ladle-treated Hadfield steel for mining purposes. Int. J. Miner. Metall. Mater. 2018, 25, 300–309. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; Zhao, Y.; Wu, L.; Zhang, F.; Shan, Q. Effect of progressive solid-solution treatment on microstructures, mechanical properties and impact abrasive wear behavior of alloyed high manganese steel. Mater. Res. Express 2022, 9, 036512. [Google Scholar] [CrossRef]

- Barbangelo, A. Influence of alloying elements and heat treatment on impact toughness of chromium steel surface deposits. J. Mater. Sci. 1990, 25, 2975–2984. [Google Scholar] [CrossRef]

- Reyes-Calderón, F.; Mejía, I.; Boulaajaj, A.; Cabrera, J.M. Effect of microalloying elements (Nb, V and Ti) on the hot flow behavior of high-Mn austenitic twinning induced plasticity (TWIP) steel. Mater. Sci. Eng. A 2013, 560, 552–560. [Google Scholar] [CrossRef]

- Scott, C.; Remy, B.; Collet, J.-L.; Cael, A.; Bao, C.; Danoix, F.; Malard, B.; Curfs, C. Precipitation strengthening in high manganese austenitic TWIP steels. Int. J. Mater. Res. 2011, 102, 538–549. [Google Scholar] [CrossRef]

- Feng, X.Y.; Zhang, F.C.; Yang, Z.N.; Zhang, M. Wear behaviour of nanocrystallised Hadfield steel. Wear 2013, 305, 299–304. [Google Scholar] [CrossRef]

- Beheshti, M.; Zabihiazadboni, M.; Ismail, M.C.; Kakooei, S.; Shahrestani, S. Investigation on simultaneous effects of shot peen and austenitizing time and temperature on grain size and microstructure of austenitic manganese steel (Hadfield). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 328, p. 012006. [Google Scholar]

- Meng, S.; Cui, C.Y.; Chen, K.; Zhao, K. Microstructure and mechanical properties of laser-shock-peened high-manganese steel. Electroplat. Finish 2020, 39, 760–765. [Google Scholar]

- Hu, X.; Shen, Z.; Liu, Y.; Liu, T.; Wang, F. Influence of explosive density on mechanical properties of high manganese steel explosion hardened. J. Appl. Phys. 2013, 114, 213507. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Chen, C.; Li, Y.; Yang, Z.; Lv, B.; Zhang, F. Effect of surface impacting parameters on wear resistance of high manganese steel. Coatings 2023, 13, 539. [Google Scholar] [CrossRef]

- Grajcar, A.; Borek, W. Thermo-mechanical processing of high-manganese austenitic TWIP-type steels. Arch. Civ. Mech. Eng. 2008, 8, 29–38. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Shan, Q.; Li, Z.; Jiang, Y.; Ge, R. Influence of heat-treatment on enhancement of yield strength and hardness by Ti-V-Nb alloying in high-manganese austenitic steel. Metals 2019, 9, 299. [Google Scholar] [CrossRef]

- Feng, Y.; Song, R.; Peng, S.; Pei, Z.; Song, R. Microstructures and impact wear behavior of Al-alloyed high-Mn austenitic cast steel after aging treatment. J. Mater. Eng. Perform. 2019, 28, 4845–4855. [Google Scholar] [CrossRef]

- Pu, J.; Li, Z.; Hu, Q.; Wang, Y. Effect of heat treatment on microstructure and wear resistance of high manganese steel surfacing layer. Int. J. Mod. Phys. B 2019, 33, 1940035. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, W.Z.; Yi, G.W.; Shi, P.; Fen, X.; Sun, H. Influences of annealing on microstructures and tribological properties of Ni/Ti2AlC composites. Tribology 2022, 42, 242–253. [Google Scholar]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

- Yang, Y.; Liu, R.X.; Yang, H.K.; Long, J.; Han, P.; Zheng, Z. Effect of solution temperature on microstructure and properties of lightweight high manganese steel. Heat Treat. Met. 2023, 48, 113–118. [Google Scholar]

- Sun, J.; Li, Z.; Xia, M.L.; Luo, L.; Li, J.; Huang, Z. Effect of solution treatment on microstructure and properties of Fe30Mn10Al1C low density steel. Trans. Mater. Heat Treat. 2024, 45, 121–131. [Google Scholar]

- Xu, T.; Fu, B.; Jiang, Y.; Wang, J.; Li, G. Machine learning and experimental study on a novel Cr–Mo–V–Ti high manganese steel: Microstructure, mechanical properties and abrasive wear behavior. J. Mater. Res. Technol. 2024, 31, 1270–1281. [Google Scholar] [CrossRef]

- Mao, Y.S.; Du, S.M.; Fu, L.H.; Zhang, Y.; Gao, Y.; Yang, J.; Bao, X. Effect of isothermal quenching process on microstructure and friction and wear properties of GCr15SiMo steel. Tribology 2023, 43, 778–790. [Google Scholar]

- Xu, Y.R.; Zhu, T.Y.; Li, Y.J.; Wang, C.L.; Ma, T.; Hu, G.Y.; Wang, Y. Wear behavior of cobalt- based alloy brush bristles and chromium carbide coating under high line speed. Tribology 2022, 42, 1216–1225. [Google Scholar]

- Huang, Y.; Cheng, G.G.; Li, S.J.; Dai, W.X.; Xie, Y. Effect of Ti (C, N) particle on the impact toughness of B-microalloyed steel. Metals 2018, 8, 868. [Google Scholar] [CrossRef]

- Xu, H.F.; Zhao, J.; Cao, W.Q.; Shi, J.; Wang, C.Y.; Li, J.; Dong, H. Tempering effects on the stability of retained austenite and mechanical properties in a medium manganese steel. ISIJ Int. 2012, 52, 868–873. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and prediction of flow behavior in high-manganese twinning induced plasticity steels: Part I. Mechanism maps and work-hardening behavior. Metall. Mater. Trans. A 2012, 43, 1688–1704. [Google Scholar] [CrossRef]

- Barbier, D.; Gey, N.; Bozzolo, N.; Allain, S.; Humbert, M. EBSD for analysing the twinning microstructure in fine-grained TWIP steels and its influence on work hardening. J. Microsc. 2009, 235, 67–78. [Google Scholar] [CrossRef]

- Renard, K.; Jacques, P.J. On the relationship between work hardening and twinning rate in TWIP steels. Mater. Sci. Eng. A 2012, 542, 8–14. [Google Scholar] [CrossRef]

- Ding, H.; Ding, H.; Song, D.; Tang, Z.; Yang, P. Strain hardening behavior of a TRIP/TWIP steel with 18.8% Mn. Mater. Sci. Eng. A 2011, 528, 868–873. [Google Scholar] [CrossRef]

- Lee, S.I.; Lee, S.Y.; Han, J.; Hwang, B. Deformation behavior and tensile properties of an austenitic Fe-24Mn-4Cr-0.5C high-manganese steel: Effect of grain size. Mater. Sci. Eng. A 2019, 742, 334–343. [Google Scholar] [CrossRef]

- Yan, J.; Zhou, M.; Wu, H.; Liang, X.; Xing, Z.; Li, H.; Zhao, L.; Jiao, S.; Jiang, Z. A review of key factors affecting the wear performance of medium manganese steels. Metals 2023, 13, 1152. [Google Scholar] [CrossRef]

- Wang, D.S.; Wang, S.Y.; Sun, S.B.; Chang, X.-T.; Yin, Y.-S. Reciprocating friction characteristics of marine Arctic steel plate at dry state room temperature. Surf. Technol. 2017, 46, 120–127. [Google Scholar]

- Peng, Y.X.; Wang, G.F.; Zhu, Z.C.; Chang, X.D.; Lu, H.; Tang, W.; Wang, D. Friction and wear characteristics of mine hoist wire rope at low temperature. Tribology 2022, 42, 552–561. [Google Scholar]

- Harsha, B.P.; Patnaik, A.; Banerjee, M.K.; Kozeschnik, E. Physical, mechanical, and tribological assessment of high manganese-silicon steel alloys. Silicon 2023, 15, 3305–3322. [Google Scholar] [CrossRef]

- Yan, X.; Hu, J.; Wang, L.; Chai, Z.; Sun, W.; Xu, W. The coupled effect of thermal and mechanical stabilities of austenite on the wear resistance in a 0.2C–5Mn-1.6Si steel down to cryogenic temperatures. Wear 2021, 486, 204116. [Google Scholar] [CrossRef]

- Rendón, J.; Olsson, M. Abrasive wear resistance of some commercial abrasion resistant steels evaluated by laboratory test methods. Wear 2009, 267, 2055–2061. [Google Scholar] [CrossRef]

- Jost, N.; Schmidt, I. Friction-induced martensitic transformation in austenitic manganese steels. Wear 1986, 111, 377–389. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Hu, J.; Wang, G.; Xu, W. Optimum wear resistance achieved by balancing bulk hardness and work-hardening: A case study in austenitic stainless steels. Tribol. Lett. 2023, 71, 7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).