Abstract

Copper (Cu) is widely used in electrical, electronic, and tribological systems owing to its excellent electrical and thermal conductivity. However, its relatively low hardness and poor wear resistance limit its use in demanding engineering applications. In this study, Cu-based hybrid metal matrix composites (MMCs) reinforced with hexagonal boron nitride (h-BN) and boron carbide (B4C) were fabricated via spark plasma sintering (SPS) to improve their mechanical and tribological performance. The h-BN content was fixed at 1 wt.% to ensure solid lubrication, while the B4C content was varied (0.25, 0.5, 0.75, and 1 wt.%) to examine its influence on the microstructural, mechanical, electrical, and wear properties of the composites. Microstructural analyses confirmed a homogeneous distribution of h-BN and B4C particles in the Cu matrix at low and moderate reinforcement levels, whereas excessive B4C resulted in partial agglomeration and reduced densification. All composites achieved relative densities above 95%, demonstrating the high densification efficiency of the SPS process. Hardness increased markedly with B4C addition due to dispersion strengthening and grain refinement, while electrical conductivity decreased slightly because of the insulating nature of the reinforcements. Tribological tests showed that the composite containing 0.75 wt.% B4C exhibited the best performance, with the lowest wear rate and stable friction behavior. Overall, the results indicate that co-reinforcing Cu with h-BN and B4C through SPS is a promising strategy for developing multifunctional materials suitable for electrical contact and sliding applications.

1. Introduction

Copper (Cu) is considered one of the most widely utilized engineering materials, primarily because of its excellent electrical and thermal conductivity, high ductility, and superior corrosion resistance [,]. These attributes make Cu indispensable in a wide range of industrial applications, including electrical and electronic systems, construction materials, automotive components, and thermal management devices. However, despite these advantages, the relatively low hardness, strength, and wear resistance of pure copper limit its direct use in environments involving mechanical stress, friction, or abrasive contact [,]. Consequently, improving the mechanical performance of Cu without substantially compromising its electrical and thermal properties has become an important research focus. Previous studies have investigated Cu composites reinforced either with B4C or h-BN individually, but the combined influence of these two phases under identical conditions has not been clearly established. To overcome these limitations, researchers have increasingly explored the development of metal matrix composites (MMCs), in which hard or functional reinforcements are incorporated into a metallic matrix to achieve a synergistic improvement in properties [,,,,,,]. The addition of ceramic or carbon-based reinforcements to Cu matrices has been shown to significantly enhance hardness, wear resistance, and load-bearing capability through mechanisms such as dispersion strengthening and grain boundary pinning [,]. The overall performance of such composites depends on several factors, including the reinforcement type, particle morphology, content, distribution, and the fabrication technique used. Among various fabrication methods—such as powder metallurgy, stir casting, and friction stir processing—spark plasma sintering (SPS) has emerged as one of the most effective techniques for producing Cu-based composites [,,,]. SPS employs pulsed direct current and uniaxial pressure, enabling rapid heating and densification at relatively low temperatures and short sintering durations. This process minimizes grain growth and interfacial reactions, thereby producing microstructures with fine grains and clean interfaces, which are critical for achieving optimal mechanical, tribological, and electrical behavior []. Selecting appropriate reinforcement phases is essential for tailoring the multifunctional performance of Cu-based MMCs [,]. Among ceramic reinforcements, boron carbide (B4C) is especially attractive due to its exceptionally high hardness (~30 GPa), low density, high elastic modulus, and superior wear resistance [,,]. Incorporation of B4C particles into Cu matrices has been demonstrated to enhance hardness and wear resistance, making these composites suitable for applications such as sliding electrical contacts, electrodes, and thermal management components []. However, because of the high hardness and poor wettability of B4C, achieving a uniform distribution and strong interfacial bonding within the Cu matrix can be challenging. Excessive B4C content may result in particle agglomeration and interfacial defects, which negatively affect electrical conductivity and toughness [,,]. In addition to hard ceramic reinforcements, the integration of solid lubricants such as hexagonal boron nitride (h-BN) has been shown to significantly improve tribological performance under dry or boundary-lubrication conditions [,,]. h-BN has a layered crystal structure similar to graphite, which provides excellent lubricity and thermal stability. Its presence facilitates the formation of a protective lubricating film on sliding surfaces, reducing friction, adhesive wear, and temperature rise. When combined with a hard phase such as B4C, the dual-reinforcement system can simultaneously deliver high hardness and low friction—an ideal combination for components such as pantograph contact strips, electrical brushes, and bearings [,,]. Although recent studies on Cu-based MMCs have attempted to improve both strength and lubrication, most have relied on single-phase reinforcements and therefore do not fully clarify the interactions between a hard phase and a solid lubricant within the same microstructure. Despite the individual advantages of B4C and h-BN, limited research has examined their synergistic effects in Cu matrices, especially when processed via SPS. Most existing studies have focused on single-reinforced systems (Cu/B4C or Cu/h-BN) produced by conventional powder metallurgy or casting techniques [,]. As a result, there remains a significant gap in understanding how combined B4C/h-BN additions influence the microstructural, mechanical, electrical, and tribological behavior of Cu-based composites consolidated through SPS. Given that SPS provides precise control over densification and microstructural evolution, it represents an ideal processing route for investigating the balance between strengthening and lubrication in such hybrid systems. Therefore, this study aims to address this knowledge gap by examining how B4C and h-BN jointly influence load-bearing capability, electrical behavior, and lubricating film stability when incorporated together into an SPS-processed Cu matrix. In this work, Cu/h-BN/B4C hybrid MMCs were fabricated using SPS. The h-BN content was fixed at 1 wt.% to ensure consistent lubrication, while the B4C content was varied (0.25, 0.5, 0.75, and 1 wt.%) to evaluate its effects on densification, microstructure, hardness, electrical conductivity, and wear performance. The objectives of this study are twofold: (i) to clarify how varying B4C concentrations influence the structure–property relationships of Cu/h-BN/B4C composites, and (ii) to identify the optimal reinforcement ratio that provides the best compromise between mechanical strength, electrical conductivity, and wear resistance. By accomplishing these goals, this study contributes valuable insights toward the design of multifunctional Cu-based composites for high-performance electrical and tribological applications.

2. Materials and Methods

2.1. Materials and Fabrication Process

In this study, Cu powder (99.99% purity, d50: 50 µm, supplied by Nanografi, Ankara, Türkiye) was used as the matrix material, while h-BN (d50: 50 nm, Nanografi, Ankara, Türkiye) and B4C (d50: 2 µm, Nanografi, Ankara, Türkiye) were selected as the reinforcement phases. The h-BN content was fixed at 1 wt.% for all samples, whereas B4C was incorporated at 0.25, 0.5, 0.75, and 1 wt.% to investigate its effect on the composite properties. The hybrid samples were designated as S1, S2, S3, and S4, and their corresponding milling parameters are provided in Table 1. The sample reinforced only with B4C was coded as S0. To ensure homogeneous mixing of the powders, mechanical alloying was conducted using a Retsch PM100 planetary ball mill (Verder company, Düsseldorf, Germany). The milling parameters were set to 2 h milling time, 400 rpm rotational speed, a ball-to-powder ratio of 10:1, and 2 wt.% methanol as a process control agent. These conditions were selected based on preliminary trials, which showed that lower milling intensity resulted in insufficient dispersion of the reinforcements, whereas higher intensity caused excessive cold welding and adhesion of the powders to the milling vial. The mechanically alloyed hybrid composite powders were consolidated using a 160V spark plasma sintering system (Çelmak SPS, Elazığ, Türkiye). The SPS parameters were as follows: a heating rate of 150 °C/min, a pulse on/off ratio of 12:2, a sintering temperature of 800 °C with a 4 min holding time, and an applied pressure of 35 MPa. The sintering process was carried out under a combined vacuum and nitrogen atmosphere. The selected SPS schedule was optimized based on preliminary experiments, which revealed that lower temperatures or shorter holding times led to incomplete densification, whereas higher temperatures promoted grain coarsening and local defect formation. Similarly, the fixed content of 1 wt.% h-BN and the selected range of 0.25–1 wt.% B4C were determined through initial trials to achieve a clear response in strengthening and lubrication while maintaining acceptable electrical conductivity and densification behavior.

Table 1.

The sample codes and milling parameters.

2.2. Characterization

After completion of the SPS process, the hybrid composite samples were metallographically prepared for microstructural and phase analyses. Detailed microstructural characterization of the bulk materials was conducted using a Thermo Scientific Apreo 2S field-emission scanning electron microscope (FE-SEM, ThermoFisher Scientific, Eindhoven, The Netherlands) equipped with a Thermo Scientific UltraDry energy-dispersive spectroscopy (EDS) detector (ThermoFisher Scientific, Eindhoven, The Netherlands). The wear scars and surface deformations generated during the wear tests were also examined using SEM to better understand the wear behavior and underlying mechanisms. Phase analyses were performed by X-ray diffraction (XRD) using a PANalytical X’Pert3 Pro diffractometer (Bruker, Westbrough, MA, USA) equipped with a Cu Kα radiation source (λ = 1.541874 Å). Measurements were carried out within the 2θ range of 30–90°, with a step size of 0.01° and a dwell time of one second per step. The theoretical densities of the hybrid composites were calculated using the rule of mixtures. Experimental density measurements were obtained using both the geometric method and a pycnometer. Based on these measurements, the relative density of each sample was determined according to the following equation:

where ρt: Theoretical density of composite materials, (%W)n: Percentage by weight in the mixture for each reinforcing material, and ρn: Density of each reinforcement material.

where ρd: Experimental density.

ρt = [(%W)1 × ρ1] + [(%W)2 × ρ2] + ⋯ + [(%W)n × ρn]

Relative density = [(ρt − ρd)/ρt] × 100

The electrical conductivity values of the hybrid composite samples were measured using a portable SIGMASCOPE® SMP10 device (Fischer Instrumentation Ltd, Hampshire, England). Three separate measurements were taken for each specimen, and the average value was recorded in %IACS (International Annealed Copper Standard). Hardness tests were performed using the Brinell method with a digital hardness tester (Innovatest–Nemesis 9000, Maastricht, Netherland) under a load of 31.25 kg, and the average of three indentations per sample was reported. The tribological behavior of the composites was examined at room temperature using a UTS linear reciprocating ball-on-disk wear tester (UTS design, Trabzon, Türkiye) operating. 100Cr6 steel balls with a diameter of 6 mm and a hardness of approximately 840 HV served as the counter surfaces in the wear experiments. In the literature, the target load range for copper-based metal matrix composites is typically within the light to moderate regime, and previous studies assessing the influence of load on Cu/h-BN/B4C hybrid systems have generally used loads between 5 and 20 N, treating 5 N as the lower limit and 20 N as the upper limit []. However, preliminary trials in this study showed that testing at 20 N caused severe surface damage, preventing accurate characterization. Therefore, to obtain meaningful results, the wear tests were conducted under loads of 5, 10, and 15 N. The total sliding distance for the friction tests was set to 100 m, a value widely adopted in the literature for short- and medium-range wear assessments in Cu-based systems. The test protocol and reporting procedure adhered to the ASTM G133 standard. The sliding speed was maintained at 40 mm/s, and the oscillation frequency was fixed at 1 Hz throughout the experiments. Each test was repeated three times using a new steel ball to ensure reproducibility. Post-test mass loss was measured with an analytical balance having a precision of ±0.0001 g, and the specific wear rate (SWR) was calculated using Equation (3). All tribological tests were performed under controlled laboratory conditions at stable room temperature, without intentional humidity regulation, corresponding to standard dry sliding conditions. Although h-BN is known to be sensitive to humidity variations, the consistent environmental conditions ensured that moisture effects did not influence the comparative wear behavior of the composites.

3. Results

3.1. Microstructure and EDS Analysis

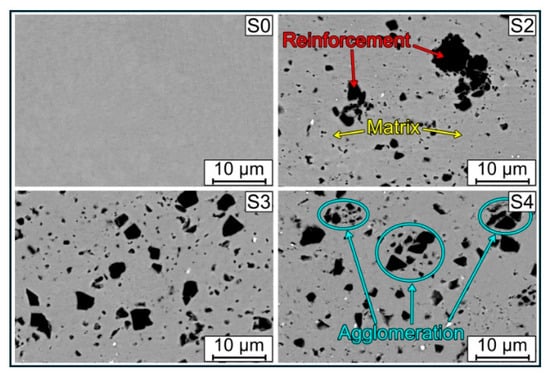

FE-SEM microstructural examinations of the hybrid composite samples containing h-BN and B4C reinforcements within the Cu matrix, as shown in Figure 1, reveal significant variations depending on the reinforcement content. Sample S0 exhibits a highly homogeneous microstructure. The fine h-BN particles are uniformly dispersed throughout the Cu matrix and do not form distinct clusters. Although the h-BN phase is present, its low volume fraction and plate-like morphology make it difficult to distinguish clearly in FE-SEM images []. Overall, the microstructure of S0 displays a uniform appearance with no observable second-phase agglomerations. In the B4C-reinforced samples (S2, S3, and S4), the microstructure gradually becomes more heterogeneous as the ceramic reinforcement content increases. With the addition of B4C, the reinforcement phases appear as darker dispersed particles within the Cu matrix and become more prominent in FE-SEM images. B4C particles are identified as black grains embedded in the matrix. In samples S2 and S3, these B4C particles—although present in limited amounts—are broadly distributed, and both h-BN and B4C demonstrate generally uniform dispersion throughout the microstructure. Sample S3 (containing 0.75 wt.% B4C) exhibits the most homogeneous distribution of reinforcement particles among the examined composites, a finding supported by complementary characterization results. Similar observations have been reported in Cu–B4C composites fabricated by techniques such as vacuum SPS, where B4C additions up to 5 wt.% resulted in a uniform particle distribution []. As the overall reinforcement content increases, a higher number of second-phase regions becomes visible within the matrix; however, even at B4C concentrations of 0.5–1 wt.%, the reinforcement phases remain evenly distributed, and no pronounced segregation zones are detected []. In sample S4, which contains the highest B4C content, some agglomerated regions become noticeable. These appear as larger clusters formed by partial joining of the reinforcement particles, with the aggregated B4C regions appearing distinctly darker in FE-SEM images. This suggests that increasing the total reinforcement content enhances the likelihood of localized agglomeration. Although agglomeration is not typically expected at B4C concentrations as low as 1 wt.%, the simultaneous presence of two ceramic phases, combined with the milling and sintering conditions, may promote localized clustering. The agglomerates observed in S4 may stem from synergistic interactions between the coexisting ceramic phases or from particle groups that were not fully separated during milling. Thus, as the reinforcement content increases, locally enriched second-phase regions become more evident in the microstructure [].

Figure 1.

FE-SEM microstructure images of Cu/h-BN/B4C hybrid composites produced by SPS method.

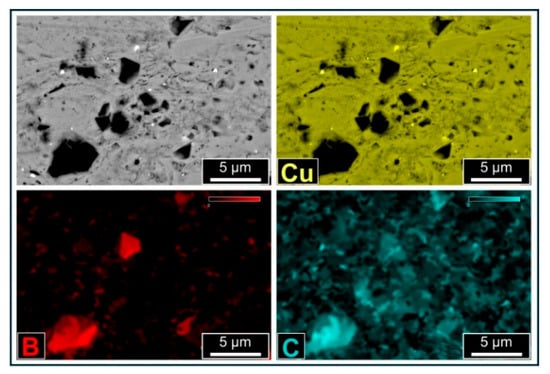

The FE-SEM–EDS mapping of the Cu/h-BN/B4C hybrid composite containing 1 wt.% h-BN and 1 wt.% B4C (Figure 2) shows that copper forms the continuous matrix phase, while the B4C and h-BN particles are dispersed as discrete reinforcements. Because the Cu matrix constitutes the majority of the sample, the copper signal (yellow) appears uniformly throughout the EDS maps. In the elemental maps, Cu is represented in yellow, B in red, N in green, and C in blue, enabling clear distinction between the Cu matrix and the B4C/h-BN reinforcement phases. This uniform distribution reflects the rapid and efficient densification achieved by the spark plasma sintering (SPS) process. Owing to its relatively low sintering temperature and short dwell time, SPS is known to minimize grain growth and interfacial reactions while producing materials with densities close to theoretical values. Similar SPS-processed Cu composites reported in the literature also show uniform copper distribution and homogeneous reinforcement dispersion []. The EDS elemental maps indicate that boron (red) and carbon (blue) are concentrated at the reinforcement particle locations, confirming that B4C and h-BN remain as stable discrete phases after sintering. Although boron carbide can react with many metals to form metal borides or release free carbon, Cu is one of the few metals that does not react with B4C. Consequently, the B4C particles preserve their chemical identity, appearing as dark, hard grains within the Cu matrix. Likewise, the chemically inert h-BN phase retains its original structure during SPS and remains uniformly dispersed in the matrix, consistent with findings from previous Cu/BN composite studies []. In the examined maps, regions of high B signal correspond to both h-BN and B4C, while areas enriched in C coincide specifically with B4C locations. These observations provide direct evidence that both reinforcement phases persist independently within the matrix without undergoing chemical transformation. The EDS maps also show a relatively widespread carbon signal throughout the matrix. This may result from limited carbon dissolution in Cu at elevated SPS temperatures or from the dispersion of extremely fine carbon-containing fragments derived from partial B4C dissociation. Although the solubility of carbon in Cu is negligible at room temperature, SPS involves high temperature and pressure, conditions under which nanoscale carbon fragments can form or diffuse to grain boundaries. Previous studies have shown that carbon nanoparticles can become uniformly distributed in Cu matrices processed by mechanical alloying and SPS; even at contents as low as 0.5 wt.%, EDS maps reveal widespread C distribution, despite the absence of detectable carbon peaks in XRD. This demonstrates that nanoscale carbon dispersed throughout the matrix can yield a homogeneous EDS signal without forming a crystallographically detectable phase. A similar mechanism is likely in the present hybrid composite, where some carbon originating from B4C becomes finely distributed or accumulates at Cu grain boundaries. Thus, the diffuse blue signal observed in the carbon map can be attributed to nanoscale carbon dispersion rather than true solubility in the Cu matrix [].

Figure 2.

EDS analysis of S4-coded Cu/h-BN/B4C hybrid composite sample.

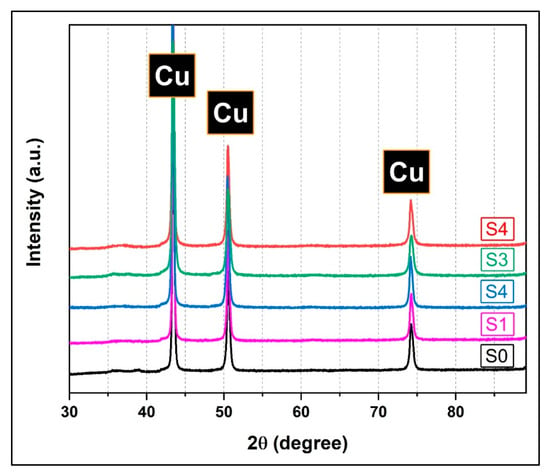

3.2. XRD Analysis

In Figure 3, the comparative XRD patterns of the Cu/h-BN/B4C hybrid composites are presented. Samples S0, S1, S2, S3, and S4 were examined individually according to increasing B4C contents, and their structural differences were evaluated. Three dominant peaks appear in the XRD patterns for all samples at 2θ values of 43.4°, 50.5°, and 74.2°, corresponding to the (111), (200), and (220) planes of Cu, respectively. These reflections, consistent with JCPDS card no. 003-10182, confirm the face-centered cubic crystal structure of Cu. A general examination shows that the XRD patterns of all samples closely resemble one another, indicating no significant changes in the major phase composition. Despite the addition of small amounts of h-BN and B4C, Cu remains the dominant crystalline phase, and no new major phases are detected. The absence of distinct diffraction peaks from the reinforcement phases is primarily attributed to their low concentrations (≤1 wt.%). XRD can typically detect only phases present above a few weight percent; therefore, diffraction from low-content ceramic reinforcements may be masked by the intense Cu peaks or fall below the detection limit of the instrument. Additionally, if the dopants are extremely finely dispersed or partially amorphous, their characteristic reflections may be further diminished. In some cases, the characteristic peaks of the reinforcing ceramics may also overlap with those of Cu. For instance, the strong Cu (111) reflection at 43.4° lies very close to the h-BN (100) peak at approximately 42°, making it difficult to distinguish the h-BN signal at low concentrations. Similar overlap may occur between B4C peaks and Cu reflections. These phenomena have been widely reported in Cu-based composites with low ceramic reinforcement levels [,].

Figure 3.

XRD graph of Cu/h-BN/B4C hybrid composites.

A more detailed evaluation of the XRD patterns reveals slight shifts in peak positions and noticeable peak broadening across all samples. Such changes are indicative of microstructural effects, including crystallite size reduction and increased internal microstrain. During mechanical milling, repeated collisions between powder particles lead to the fragmentation of crystallites and the introduction of lattice defects such as dislocations []. These microstructural alterations manifest in the XRD patterns as peak broadening and minor peak shifts. The observed broadening also suggests a reduction in crystallite size, as quantified by the Scherrer equation. These milling-induced structural modifications may influence the mechanical performance of the composites. In particular, finer crystallite sizes and a homogeneous distribution of reinforcements are known to enhance properties such as hardness and wear resistance [,].

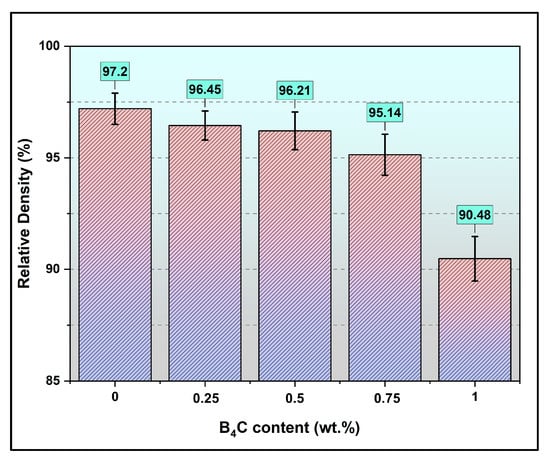

3.3. Relative Density

The relative density values of the Cu/h-BN/B4C composites are presented in Figure 4, showing a slight but consistent decrease with increasing amounts of B4C reinforcement. The highest relative density was observed in the unreinforced sample (S0), while the lowest relative density was recorded in the sample containing 1 wt.% B4C (S4). Specifically, the measured relative densities were 97.20% for S0, 96.45% for S1, 96.21% for S2, 95.14% for S3, and 90.48% for S4, confirming the gradual reduction illustrated in Figure 4. This decrease in density with increasing ceramic content is primarily attributed to the intrinsic characteristics of B4C, such as its high hardness and low ductility, which reduce the compressibility of the powder mixture during sintering. Furthermore, ceramic reinforcements often act as diffusion barriers during the sintering process, thereby impeding mass transport and densification at the matrix–reinforcement interfaces. Nevertheless, the use of spark plasma sintering (SPS) was found to be remarkably effective in achieving substantial densification across all specimens. SPS has been shown to promote rapid sintering kinetics due to the combined effects of pulsed electric current and mechanical pressure [,]. This process also minimizes porosity, even in systems containing refractory ceramic phases. The relative densities of all samples exceeding 95% confirm the efficiency of SPS in fabricating dense copper-based composites, even when incorporating hard and poorly sinterable reinforcements such as B4C. Additionally, the constant presence of 1 wt.% h-BN may have positively influenced powder compaction by acting as a solid lubricant during pressing, partially offsetting the densification hindrance caused by B4C. A marginal decline in density is evident with higher B4C additions; however, the final densification levels remain satisfactory for ensuring the desired mechanical and functional properties of the composites. Similar Cu–ceramic composite systems produced by SPS typically exhibit relative densities in the 92–97% range, and the values obtained in this study fall well within this interval, indicating comparable densification efficiency.

Figure 4.

Relative density values changing with B4C content.

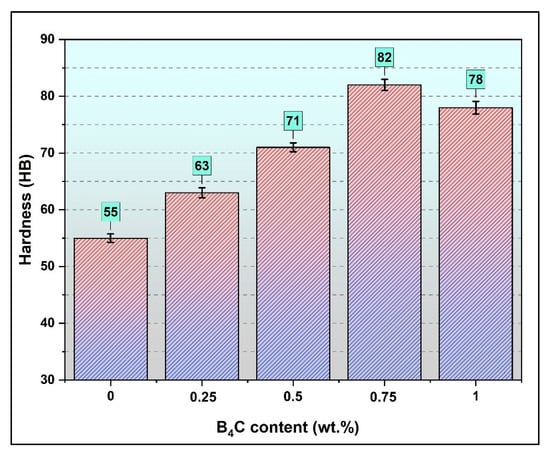

3.4. Hardness

The hardness behavior of the Cu/h-BN/B4C hybrid composites as a function of B4C content is illustrated in Figure 5. A progressive increase in Brinell hardness was observed with the incremental addition of B4C, with the unreinforced S0 sample exhibiting the lowest hardness and the 1 wt.% B4C-reinforced S4 sample displaying the highest. This phenomenon can be primarily attributed to the dispersion of ultra-hard B4C particles within the copper matrix, which act as effective barriers against dislocation motion during plastic deformation. As the B4C content increases, the number of these reinforcing barriers becomes more pronounced, thereby enhancing the composite’s resistance to indentation and surface wear. Furthermore, the microstructural refinement achieved via the SPS process plays a pivotal role in the development of hardness. The rapid heating and short sintering times inherent to SPS limit grain growth, resulting in a finer grain structure. According to the Hall-Petch relationship, this microstructural refinement enhances hardness by increasing grain boundary density, which acts as an additional barrier to dislocation motion. It is also hypothesized that the constant 1 wt.% h-BN content contributes to microstructural uniformity and particle dispersion due to its layered morphology and solid-lubricating properties, although its direct effect on hardness is less significant compared to B4C. The enhanced particle–matrix bonding and reduced porosity resulting from SPS further improve the mechanical integrity of the composite structure. The combined strengthening effects of dispersion hardening, grain boundary pinning, and improved interfacial bonding collectively underpin the substantial improvement in hardness, demonstrating the effectiveness of the dual-phase (h-BN/B4C) reinforcement strategy in addressing the mechanical limitations of pure copper [,]. Comparable studies on Cu/B4C systems report hardness increases of about 20–35% for similar reinforcement levels, and the present work shows values in the upper range of these reports. This agreement supports the dominant role of grain refinement and particle strengthening observed here. For instance, Cu/1 wt.% B4C composites reported in the literature typically reach 75–95 HB, closely matching the hardness improvement trend observed in the S1–S4 samples of this study. Quantitatively, the S3 specimen (0.75 wt.% B4C) exhibits about a 30% increase in hardness compared with the unreinforced S0 sample, supporting its designation as the optimal composition in this series.

Figure 5.

Hardness values changing with B4C content.

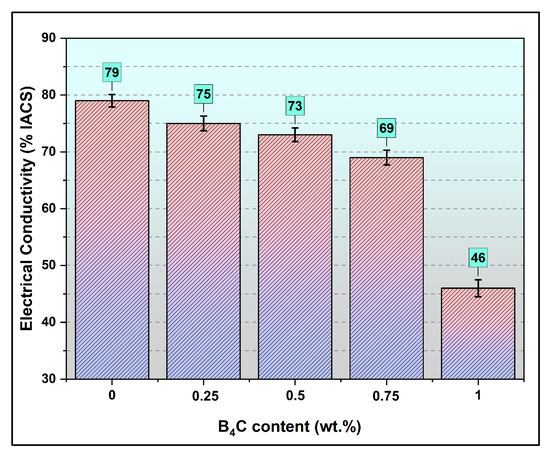

3.5. Electrical Conductivity

The electrical conductivity values of the fabricated Cu/h-BN/B4C composites are shown in Figure 6. A clear decreasing trend in conductivity was observed with increasing B4C content, with the maximum value in the unreinforced sample (S0) and the minimum in the S4 sample, which contains the highest B4C content (1 wt.%). The inverse relationship between conductivity and reinforcement content can be explained by the insulating nature of both B4C and h-BN particles []. The incorporation of non-conductive ceramic phases within the continuous copper matrix disrupts the electron flow path, thereby increasing the electrical resistivity of the composite. As the volume fraction of these phases increases, the number of copper–copper contact points decreases, reducing the effective cross-sectional area available for electron transport [,,]. Furthermore, electron scattering at the ceramic–metal interfaces, along with potential microstructural inhomogeneities—particularly at higher reinforcement loadings—further contributes to the reduction in conductivity. Quantitatively, this decrease is consistent with simple effective medium models, in which composite resistivity increases approximately in proportion to the ceramic volume fraction, even at levels far below the percolation threshold, thus providing a predictable reduction as the insulating phase content rises. Nevertheless, the SPS technique effectively promotes metallurgical bonding and minimizes interface defects, helping to preserve reasonable levels of conductivity even in the presence of non-metallic phases. Despite the reduction, the electrical conductivity values of all reinforced samples remain within acceptable ranges for engineering applications involving moderate current loads []. It is important to note that the mechanical performance gains, particularly in terms of hardness and wear resistance, present a trade-off that may be acceptable or even advantageous in multifunctional applications. Composites with 0.5–0.75 wt.% B4C content appear to offer a favorable balance between mechanical strength and electrical performance, making them promising candidates for use in sliding contacts, electrical brushes, and pantograph components, where both wear resistance and electrical transmission are required.

Figure 6.

Electrical conductivity changing with B4C content.

Similar copper-based composites reinforced with ceramic particles show conductivity reductions of 8–20%, depending on particle fraction, and the values in this study fall within this well-established range. This correspondence suggests that electron scattering at interfaces is the primary mechanism governing the conductivity drop. Reported Cu/B4C and Cu/h-BN composites with ~1 wt.% ceramic content generally retain 80–92% IACS conductivity, closely aligning with the values measured for S1–S4, confirming similar levels of electronic transport degradation.

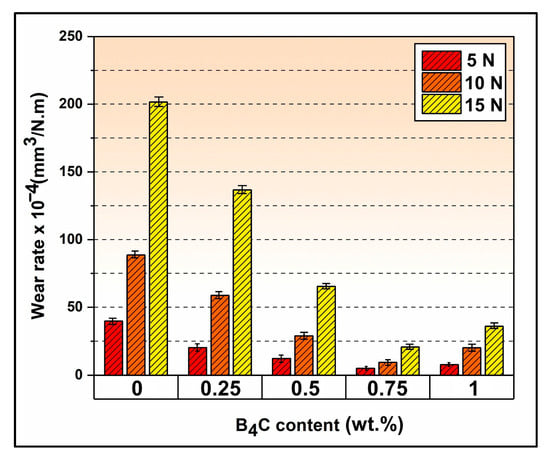

3.6. Tribological Properties

Figure 7 presents the wear rates of the Cu matrix composites under normal loads of 5 N, 10 N, and 15 N. As evident, wear rates increase with load for all specimens. This behavior arises from the enlargement of the real contact area with increasing normal load in Cu-based composites, the facilitation of plastic plowing and micro-cutting due to the relatively low yield strength of the Cu matrix, the accelerated degradation of thin tribo-oxide/transfer films as the interfacial temperature rises, and the greater contribution of third-body abrasion by detached wear debris [,]. At a given load, the S0 specimen containing only 1 wt.% h-BN develops a low-shear transfer film owing to the layered structure of h-BN, mitigating adhesive wear; however, in the absence of a hard reinforcing phase, plastic deformation of the Cu matrix dominates, resulting in the highest wear. Although this explanation aligns with the observed wear behavior, it should be regarded as an interpretation rather than direct experimental evidence of film chemistry or structure. Upon the addition of B4C, increasing hardness and load-bearing capacity stabilize the h-BN-derived film [] and progressively reduce wear. Relative to S0, the wear decreases are approximately 49%, 69%, 87%, and 81% at 5 N for S1, S2, S3, and S4, respectively; about 33%, 67%, 89%, and 77% at 10 N; and 32%, 68%, 90%, and 82% at 15 N. This downward trend is primarily attributed to: (i) the high hardness and elastic modulus of B4C, which reduce the real contact area and plowing depth; (ii) strengthening of the matrix via Orowan bypass and Zener pinning, which elevate yield strength and microhardness; and (iii) the resulting preservation of a continuous lamellar transfer film from h-BN, limiting frictional heating and film rupture [,]. These mechanisms are therefore discussed as plausible contributors, supported indirectly by wear and friction trends. Specimen-wise, S1 (0.25 wt.% B4C) shows noticeable improvement at low load, but the reduction remains modest at higher loads because the B4C content is insufficient to fully support film continuity and load-bearing. In S2 (0.5 wt.% B4C), hardness and load-support approach an effective threshold, leading to clear wear reductions at all loads. The lowest wear is observed for S3 (0.75 wt.% B4C), indicating a composite architecture in which the balance between hard and lubricating phases allows the h-BN film to operate without disruption, while SPS processing yields high densification (low porosity) and robust interfaces. Quantitatively, this optimal S3 composition provides about an 89% reduction in wear rate at 10 N compared with S0, with comparable reductions (approximately 87–90%) also observed at 5 and 15 N. In S4 (1 wt.% B4C), by contrast, wear increases relative to S3 by approximately 53% at 5 N, 113% at 10 N, and 74% at 15 N. This regression is attributed to agglomeration of B4C and locally reduced densification (increased porosity) beyond the S3 composition under SPS conditions, which compromises interfacial integrity. The resulting particle pull-out generates abrasive third-body fragments that partially negate the stabilization provided by h-BN, thereby increasing the wear rate from the S3 minimum to the higher values observed in S4. Wear reductions of 60–90% have been reported for Cu composites with similar fractions of hard ceramic phases, which aligns closely with the reductions found in S2 and S3. This agreement confirms that improved load-bearing and stable film formation are the dominant mechanisms at these reinforcement levels. In this study, the specific wear rate was evaluated from mass loss measurements in accordance with Equation (3).

Figure 7.

The wear rates of fabricated samples according to loads.

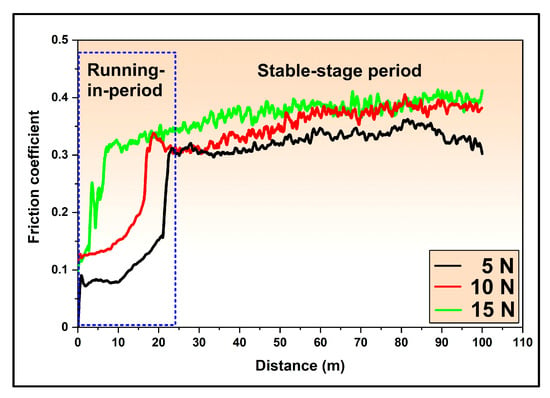

Figure 8 shows the friction coefficient–sliding distance curves of the S3 specimen under different normal loads. As observed, the “running-in” stage shortens progressively with increasing load. This behavior arises from the concurrent acceleration of contact-mechanics accommodation and third-body (transfer-film) tribology. At the onset of sliding, the counterfaces interact via asperity–asperity contacts; a higher normal load increases the real contact pressure, thereby promoting rapid plastic flattening of asperities and enabling a swift transition to a more conformal contact geometry []. Consequently, surface roughness is reduced, the real contact area grows over a shorter distance, effective contact stiffness increases, fluctuations in the friction coefficient are damped, and the system reaches a steady state earlier. The composition and microstructure of S3 facilitate this acceleration. The high hardness of B4C enhances load-bearing capacity and restrains plowing, so that the initial debris is not crushed into abrasive fragments but instead beds in and is incorporated into the developing film. The layered h-BN promotes lamellar alignment under higher pressure, establishing a low-shear sliding plane []. These descriptions of lamellar alignment and early-stage film evolution should be interpreted as reasonable mechanistic hypotheses rather than direct observations obtained through in situ tribological film analysis. In addition, the SPS-derived high densification and low porosity, optimized in S3, homogenize subsurface plasticity, mitigate interfacial decohesion, and strengthen film–substrate adhesion. As a result, with increasing load, topographic conformity, tribochemical/tribophysical film formation, and subsurface work hardening are completed over much shorter sliding distances. Hence, the running-in period contracts, and the stable stage is reached earlier in S3. While excessively high loads could, in principle, increase the risk of film rupture or particle pull-out, within the load range examined, the balanced synergy between the hard phase (B4C) and the lubricating phase (h-BN) effectively manages these risks and enables early stabilization.

Figure 8.

Friction coefficient–distance curves of the S3 specimen under different normal loads.

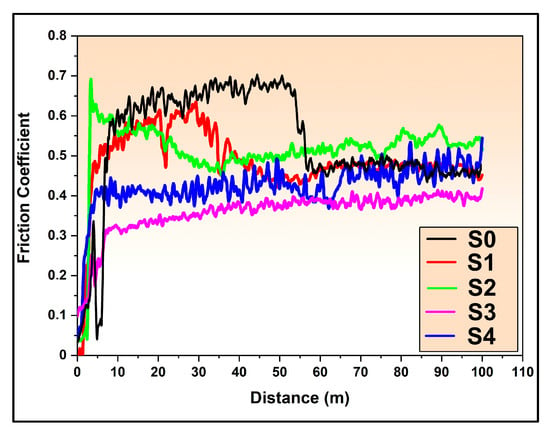

Figure 9 presents the friction coefficient–sliding distance curves of the specimens under a 15 N load. The S0 (Cu/1 wt.% h-BN) curve exhibits a distinctly zigzag trajectory: after the running-in stage, the friction coefficient rises rapidly and proceeds with large-amplitude fluctuations. This behavior occurs because, in the absence of a hard reinforcing phase, the Cu matrix remains susceptible to plowing and micro-cutting, while the wear debris generated (Cu/oxide/h-BN fragments) circulates as a third body. With increasing sliding distance, portions of this debris intermittently adhere to and compact on the surface, forming a sticky transfer layer. Once this debris flow becomes bedded-in and begins to shear steadily, the fluctuations are damped, and the curve approaches a more stable plateau at intermediate to long distances. With the addition of B4C, the load-bearing capacity and matrix hardness increase, the real contact area is effectively reduced, and both groove depth and the instantaneous debris generation rate decline. Consequently, the lamellar h-BN transfer film develops more rapidly and continuously; instead of being crushed into sharp abrasive fragments, the initial debris is incorporated into the film and aligned with the sliding plane. The friction fluctuations therefore diminish markedly, and the curves become progressively more stable []. This effect is most pronounced in S3 (0.75 wt.% B4C), where a low-shear sliding regime is established, and the friction coefficient is maintained at a lower, narrowly scattered plateau. The high densification, low porosity, and robust interfaces achieved via SPS in the S3 composition strengthen film–substrate adhesion and sustain this stable behavior. In S4 (1 wt.% B4C), the friction increases again, and the fluctuations reappear relative to S3. This regression is linked to B4C agglomeration during SPS and locally reduced densification (micro-porosity). The resulting heterogeneity promotes stress concentrations and particle pull-out; the detached hard fragments act as abrasive third bodies, enhancing plowing and disrupting the transfer film. As a result, the S4 curve shifts to a higher friction level with somewhat reduced stability—although it still maintains a more controlled frictional response than S0, which lacks B4C altogether.

Figure 9.

Friction coefficient–distance curves of the specimens under a 15 N load.

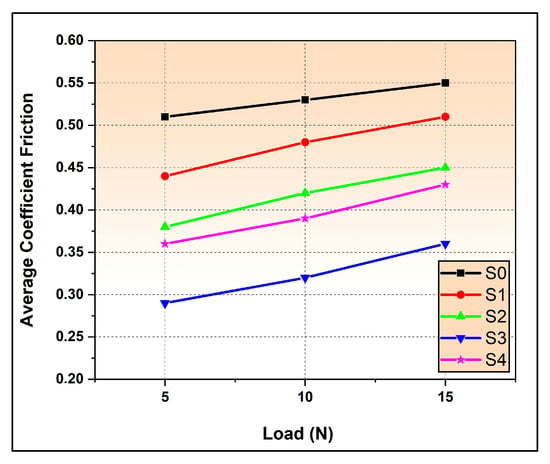

Figure 10 illustrates the relationship between average friction coefficient and load, showing that friction increases with load for all specimens; however, the absolute level of this increase is markedly suppressed by the addition of B4C. The S0 specimen, containing only 1 wt.% h-BN, exhibits the highest coefficients at every load (0.51–0.55), due to the Cu matrix’s susceptibility to plowing and micro-cutting. With B4C incorporation, enhanced hardness and load-bearing capacity—together with a more continuous h-BN-derived transfer film—lead to a gradual reduction in friction. This trend indicates that the S3 composition (0.75 wt.% B4C) achieves the most favorable balance between the hard and lubricating phases, establishing a low-shear sliding regime and yielding the minimum average friction across all three loads. When the B4C content is increased to 1 wt.% (S4), the friction rises again relative to S3 (0.36–0.43), which can be attributed to B4C agglomeration during SPS and localized densification losses (micro-porosity) that promote third-body abrasion and partial film disruption. Nevertheless, S4 still exhibits substantially lower friction than S0.

Figure 10.

Mean values of friction coefficient.

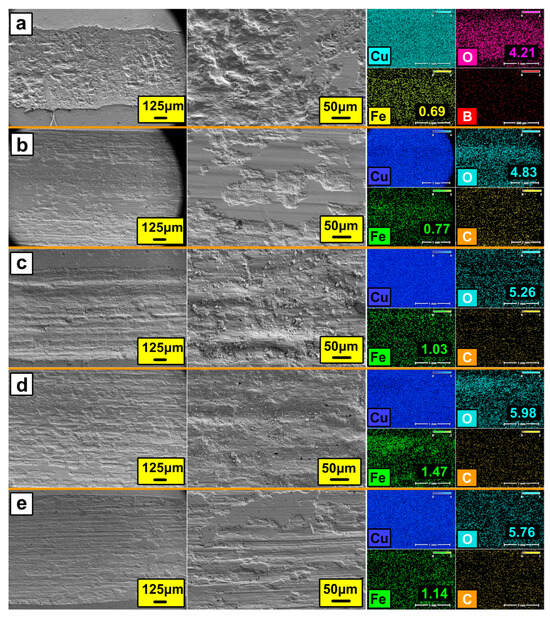

Figure 11 presents SEM micrographs and EDS analyses of the wear tracks obtained under a 5 N load. In Figure 11a, the S0 surface shows a deep but narrow groove, attributable to the absence of the hard B4C phase and the low hardness of the Cu matrix, which concentrates the load on a few micro-contacts. Without a hard phase to distribute the load, sliding proceeds within a confined channel, producing a narrow track width but large penetration depth. The observed smearing, delamination, and pull-out are consistent with a soft matrix lacking hard reinforcement: subsurface shear promotes directed plastic flow and surface smearing; repeated sliding nucleates and advances micro-cracks parallel to the surface, causing thin-layer delamination; cohesion locally degrades around trapped h-BN lamellae and small oxide/contamination islands, enabling particle pull-out and third-body formation. The low EDS signals of O (≈4.21%) and Fe (≈0.69%) further support this mechanism: plastic dissipation at localized contacts limits sustained flash temperatures, hindering the development of a thick, continuous tribo-oxide; continual resurfacing removes nascent oxides; and the low-shear, anti-adhesive character of h-BN restricts chemical/adhesive interaction with the steel counterface, minimizing Fe transfer. As seen in Figure 11b, adding 0.25 wt.% B4C increases microhardness and load-bearing capacity, distributing the real contact more uniformly and reducing local stress concentrations. Accordingly, large pull-out events diminish, and the wear track widens as the load is carried over a broader area. Nevertheless, subsurface shear accumulation and locally weaker interface/densification zones still drive layered delamination, indicating that the wear mechanism remains predominantly adhesive with transfer-layer formation–removal cycles. At 0.5 wt.% B4C (Figure 11c), the stiffening skeleton effect of B4C and improved SPS densification further homogenize subsurface plasticity and strengthen interfacial locking, so delamination decreases markedly. Under these conditions, the load is shared by multiple micro-contacts, plowing depth drops, and the surface exhibits well-defined abrasive grooves (stable micro-cutting) alongside smooth regions where a persistent h-BN-assisted transfer film supports low-shear sliding. This morphology evidences a transition from an adhesion-dominated regime toward abrasive wear with stabilized third-body flow. At 0.75 wt.% B4C (Figure 11d), higher densification (low porosity) and a more homogeneous B4C distribution substantially enhance load-bearing, suppress subsurface plastic flow, and strengthen interface integrity. The h-BN–derived transfer film remains continuous and stable, topography becomes rapidly conformal, delamination traces vanish, and smooth-surface areas prevail—signaling a predominantly abrasive (polishing/micro-cutting) regime. In this state, the highest O and Fe levels in EDS reflect (i) the formation and retention of a stable Cu2O/CuO tribo-oxide film and (ii) selective micro-cutting of the steel counterface that yields limited Fe transfer, consistent with a hard, well-supported surface and steady low-shear sliding. Because the analyses rely on post-test SEM/EDS rather than real-time surface chemistry measurements, these interpretations are presented as informed but indirect indications of tribo-film formation. When the B4C content is raised to 1 wt.% (S4), agglomeration and localized porosity emerge during SPS, lowering effective hardness and interfacial integrity and heterogenizing contact stresses. The resulting worn surface combines deep/fine abrasive striations, delamination steps, and frequent abrasive scratches, with intermittent third-body instability. Although abrasive features persist locally, adhesive components reappear due to film rupture and cohesive weakening—directly indicating that the balanced “hard phase + lubricating film” synergy achieved at S3 cannot be fully sustained in S4 because of microstructural heterogeneity.

Figure 11.

The SEM images and EDS mapping analysis of worn surface after the wear test under the 5 N of samples: (a) S0, (b) S1, (c) S2, (d) S3 and (e) S4.

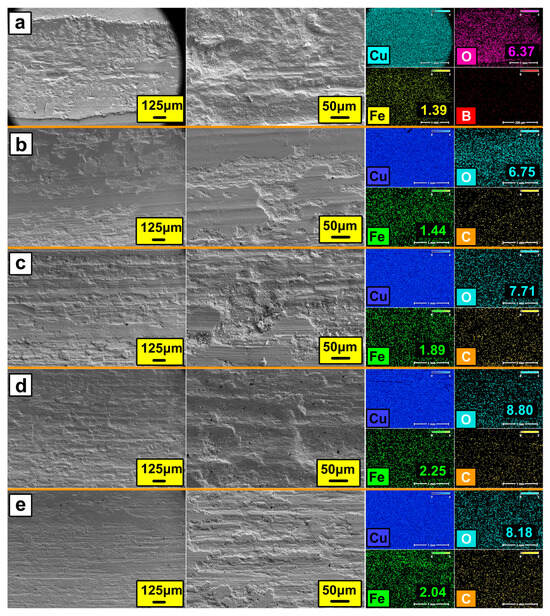

Figure 12 presents SEM micrographs and EDS analyses of the wear tracks obtained under a 15 N load. At this higher load, the worn-surface morphology and chemistry evolve markedly compared with 5 N. Across all specimens, the O and Fe signals increase, indicating (i) higher flash temperatures that promote a more effective Cu2O/CuO tribo-oxide film and (ii) slightly greater counterface micro-wear/transfer under the increased contact pressure. For S0 (Cu/1 wt.% h-BN), the wear track becomes wider and displays isolated deep furrows with a reduction in extended delamination bands. This is consistent with work hardening of the near-surface Cu, which suppresses large-scale layer detachment while plowing remains active (Figure 12a). In S1 (0.25 wt.% B4C), delamination further diminishes, and smooth patches begin to appear, reflecting improved load sharing and a more persistent h-BN-assisted transfer film (Figure 12b). For S2 and S3 (0.5–0.75 wt.% B4C), occasional pits are observed, but the surface is increasingly dominated by smooth regions interspersed with shallow, regular grooves, evidencing a transition to a micro-abrasive/polishing regime sustained by higher hardness, better interfacial locking, and stabilized third-body flow (Figure 12c,d). In S4 (1 wt.% B4C), compared with 5 N, the track shows suppressed delamination and a larger fraction of smooth-surface areas, consistent with compaction/closure of near-surface porosity and consolidation of the transfer layer under the higher load. Nevertheless, fine abrasive striations persist due to B4C agglomeration and heterogeneity. While S4 exhibits improved wear resistance relative to its 5 N state, its friction and stability remain inferior to S3, in line with the overall trends reported in this work (Figure 12e).

Figure 12.

The SEM images and EDS mapping analysis of worn surface after the wear test under the 15 N of samples: (a) S0, (b) S1, (c) S2, (d) S3 and (e) S4.

4. Conclusions

In this study, Cu/h-BN/B4C hybrid metal matrix composites were successfully fabricated via the spark plasma sintering (SPS) method, and the effects of varying B4C content on the microstructural, mechanical, electrical, and tribological properties were systematically investigated. The experimental results confirmed that the SPS process enabled near-full densification of the composite samples, producing refined microstructures and clean interfaces between the copper matrix and the reinforcement phases. A slight decrease in relative density was observed with increasing B4C content; however, all specimens achieved densities exceeding 95% of the theoretical value, demonstrating the effectiveness of SPS for fabricating dense Cu-based composites containing refractory ceramic reinforcements. Microstructural analyses revealed a homogeneous distribution of the h-BN and B4C reinforcement phases within the copper matrix at low and moderate B4C contents. The composite containing 0.75 wt.% B4C exhibited optimal microstructural uniformity, with dispersed and interfacially bonded hard and lubricating phases, and no visible agglomeration. At the highest reinforcement level (1 wt.% B4C), however, partial particle clustering and localized porosity were detected, indicating that excessive ceramic addition can hinder powder densification and promote inhomogeneities during sintering. Mechanical characterization showed that hardness increased progressively with B4C content, confirming that the incorporation of the hard B4C phase effectively impedes dislocation motion and enhances load-bearing capability. The combined effects of dispersion strengthening, grain refinement, and improved interfacial bonding under SPS conditions resulted in significant strengthening of the composites. The highest recorded hardness was observed at 1 wt.% B4C, although the accompanying rise in porosity suggests that mechanical reinforcement reaches a practical limit, beyond which further additions may negatively impact other properties. Electrical conductivity measurements exhibited a decreasing trend with increasing B4C content, primarily due to the insulating nature of both h-BN and B4C phases and increased scattering of conduction electrons at ceramic–metal interfaces. Nevertheless, all composites maintained sufficient conductivity levels for functional use in electrical contact and tribological components, particularly in applications requiring moderate current transmission combined with high wear resistance.

Tribological tests demonstrated that wear resistance improved significantly with increasing B4C content up to 0.75 wt.%, after which a marginal deterioration occurred. The composite containing 0.75 wt.% B4C showed the most favorable combination of low wear rate and stable friction behavior across all tested loads. This enhancement was attributed to the synergistic effect of the hard B4C phase, which imparted elevated surface strength and load support, and the h-BN phase, which facilitated formation of a continuous low-shear lubricating film on the sliding surface. At higher reinforcement levels, however, B4C agglomeration and localized porosity led to third-body abrasion and transfer-film instability, increasing the wear rate. The outcomes of this study demonstrate that the hybrid reinforcement strategy combining B4C and h-BN within a copper matrix can effectively overcome the inherent limitations of pure Cu by achieving a balanced enhancement in mechanical and tribological performance while maintaining acceptable electrical conductivity. Among the compositions investigated, the Cu/1 wt.% h-BN/0.75 wt.% B4C composite offered the optimal balance of properties, making it a promising candidate for sliding electrical contacts, pantograph strips, and other multifunctional components requiring simultaneous electrical conductivity, hardness, and wear resistance. Subsequent studies may focus on optimizing sintering parameters, exploring nanoscale reinforcements, and evaluating performance under actual current-carrying and high-temperature operating conditions to further advance the applicability of these hybrid Cu-based composites.

Author Contributions

Conceptualization, S.Ö., D.M.S., A.Ç., M.Ç., A.H.K. and H.Y.; methodology, S.Ö., H.Y., A.H.K., A.Ç., E.Ç. and M.Ç.; investigation, A.H.K., A.Ç., E.Ç., S.Ö., D.M.S. and M.Ç.; writing—original draft preparation, A.H.K., E.Ç., S.Ö., M.Ç., H.Y. and D.M.S.; supervision, S.Ö., H.Y., D.M.S., E.Ç. and A.Ç. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Dursun Murat Sekban was employed by the company WMS Engineering Services Industry Trade Limited Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ho, V.; Ladani, L.; Razmi, J.; Gruber, S.; Murphy, A.B.; Chen, C.; East, D.; Lopez, E. Powder Bed Fabrication of Copper: A Comprehensive Literature Review. Metals 2025, 15, 1114. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, L.; Mi, X.; Xie, H.; Feng, X.; Ahn, J.H. Researches for Higher Electrical Conductivity Copper—Based Materials. CMat 2024, 1, e13. [Google Scholar] [CrossRef]

- Özorak, C.; Islak, S. Microstructure, Wear and Corrosion Properties of Cu–SiC/WCCo Composite Coatings on the Cu Substrate Surface by Plasma Spray Method. Mater. Chem. Phys. 2024, 314, 128903. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, Y.; Zhang, H.; Wang, Z.; Liu, D.; Cao, S.; Cui, X.; Nong, Z.; Man, T.; Liu, T. Development and Research Status of Wear-Resistant Coatings on Copper and Its Alloys: Review. Crystals 2025, 15, 204. [Google Scholar] [CrossRef]

- Hvizdoš, P.; Besterci, M.; Kulu, P.; Kvačkaj, T. Tribological Characteristics of Copper Based Composites with Al2O3 Particles at Various Temperatures. High Temp. Mater. Process. 2013, 32, 437–442. [Google Scholar] [CrossRef]

- Fathy, A.; Elkady, O.; Abu-Oqail, A. Microstructure, Mechanical and Wear Properties of Cu–ZrO2 Nanocomposites. Mater. Sci. Technol. 2017, 33, 2138–2146. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, W.; Tan, H.; Yang, J. Fabrication of Ti3AlC2/Cu Composites via Vacuum Infiltration and Their Tribological Properties. Vacuum 2025, 242, 114772. [Google Scholar] [CrossRef]

- Ahmadian, H.; Fouly, A.; Zhou, T.; Kumar, A.S.; Fathy, A.; Weijia, G. Investigating the Valence Balance of Adding Nano SiC and MWCNTs on the Improvement Properties of Copper Composite Using Mechanical Alloying and SPS Techniques. Diam. Relat. Mater. 2024, 145, 111113. [Google Scholar] [CrossRef]

- Karabacak, A.H.; Çanakçı, A.; Özkaya, S.; Tunç, S.A.; Güler, O.; Çelebi, M. Effect of AlCrCuFeNi High Entropy Alloy Reinforcements with and without B4C on Powder Characteristic, Mechanical and Wear Properties of AA5083 Metal-Metal Composites. J. Alloys Compd. 2024, 1008, 176627. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozkaya, S.; Erdemir, F. Determining the Effect of Flake Matrix Size and Al2O3 Content on Microstructure and Mechanical Properties of Al2O3 Nanoparticle Reinforced Al Matrix Composites. Part. Sci. Technol. 2018, 36, 312–323. [Google Scholar] [CrossRef]

- Canakci, A.; Erdemir, F.; Varol, T.; Ozkaya, S. Effect of Process Parameters on the Formation of Fe-Al Intermetallic Coating Fabricated by Mechanical Alloying. Indian. J. Eng. Mater. Sci. 2014, 21, 595–600. [Google Scholar]

- Huang, C.-W.; Aoh, J.-N. Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite. Materials 2018, 11, 599. [Google Scholar] [CrossRef]

- Arif, S.; Samad, A.; Hadidi, H.; Shaikh, M.B.N.; Ansari, S. Dry Sliding Wear Investigation of Graphene Reinforced Copper-Silica Sand Composite by Response Surface Methodology. Mater. Today Commun. 2022, 33, 104857. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Li, J.; Cao, H.; He, L. Effect of Sintering Process on the Microstructures and Properties of in Situ TiB2–TiC Reinforced Steel Matrix Composites Produced by Spark Plasma Sintering. J. Mater. Process Technol. 2010, 210, 91–95. [Google Scholar] [CrossRef]

- Salifu, S.; Olubambi, P.A. Microstructural and Nanoindentation Study of Spark Plasma Sintered High Entropy Alloy Reinforced Aluminium Matrix Composites. J. Alloys Compd. 2024, 999, 175021. [Google Scholar] [CrossRef]

- Singh, K.; Khanna, V.; Sonu; Singh, S.; Bansal, S.A.; Chaudhary, V.; Khosla, A. Paradigm of State-of-the-Art CNT Reinforced Copper Metal Matrix Composites: Processing, Characterizations, and Applications. J. Mater. Res. Technol. 2023, 24, 8572–8605. [Google Scholar] [CrossRef]

- Yilmaz, N.; Baltaci, E.; Baygin, O.; Tüzüner, T.; Ozkaya, S.; Canakci, A. Effect of the Usage of Er,Cr:YSGG Laser with and without Different Remineralization Agents on the Enamel Erosion of Primary Teeth. Lasers Med. Sci. 2020, 35, 1607–1620. [Google Scholar] [CrossRef]

- Stuer, M.; Bowen, P.; Zhao, Z. Spark Plasma Sintering of Ceramics: From Modeling to Practice. Ceramics 2020, 3, 476–493. [Google Scholar] [CrossRef]

- Lee, H.; Kim, K.I.; Kim, J.; Pin, M.-W.; Oh, K.H.; Kim, K.T. Electron Microscopy Characterization of the Tribolayer Formation Mechanism in Sintered Cu-Based Composites under Dry Sliding. Mater. Today Commun. 2022, 30, 103154. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Tribological Behaviour of SiC Particle-Reinforced Copper Matrix Composites. Mater. Lett. 2000, 43, 274–280. [Google Scholar] [CrossRef]

- Gajević, S.; Miladinović, S.; Güler, O.; Özkaya, S.; Stojanović, B. Optimization of Dry Sliding Wear in Hot-Pressed Al/B4C Metal Matrix Composites Using Taguchi Method and ANN. Materials 2024, 17, 4056. [Google Scholar] [CrossRef]

- Karabacak, A.H.; Çanakçı, A.; Erdemir, F.; Özkaya, S.; Çelebi, M. Corrosion and Mechanical Properties of Novel AA2024 Matrix Hybrid Nanocomposites Reinforced with B4C and SiC Particles. Silicon 2022, 14, 8567–8579. [Google Scholar] [CrossRef]

- Akkaş, M.; Islak, S. Microstructure, Wear and Corrosion Properties of NiB-TiC Composite Materials Produced by Powder Metallurgy Method. Sci. Sinter. 2019, 51, 327–338. [Google Scholar] [CrossRef]

- Yan, Y.-F.; Kou, S.-Q.; Yang, H.-Y.; Shu, S.-L.; Qiu, F.; Jiang, Q.-C.; Zhang, L.-C. Ceramic Particles Reinforced Copper Matrix Composites Manufactured by Advanced Powder Metallurgy: Preparation, Performance, and Mechanisms. Int. J. Extrem. Manuf. 2023, 5, 032006. [Google Scholar] [CrossRef]

- Shu, D.; Li, X.; Yang, Q. Effect on Microstructure and Performance of B4C Content in B4C/Cu Composite. Metals 2021, 11, 1250. [Google Scholar] [CrossRef]

- Carreño-Gallardo, C.; Mendoza-Duarte, J.M.; López-Meléndez, C.; Estrada-Guel, I.; Reyes-Ronquillo, J.L.; Uriza-Vega, E.; Martínez-Sánchez, R. Effect of B4C Particles Addition on the Microstructure and Mechanical Performance of Some Aluminum-Based Composites. Microsc. Microanal. 2016, 22, 1888–1889. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, D.; Wang, J.; Dai, S.; Xue, Y.; Zhu, L. Enhancing Interfacial Bonding in Metal Matrix Composites: Challenges, Methods, and Future Prospects. Crit. Rev. Solid State Mater. Sci. 2025, 324, 1–54. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Pan, W.; Wang, W.; Tang, C. A Review on the Preparation and Application of BN Composite Coatings. Ceram. Int. 2023, 49, 24–39. [Google Scholar] [CrossRef]

- Islak, S.; Çelik, E.; Houssain, H.; Danacı, H.C. Effect of Boron on Microstructure, Thermal, and Mechanical Properties of Ni B Matrix Diamond Cutting Tools. Int. J. Refract. Met. Hard Mater. 2024, 123, 106758. [Google Scholar] [CrossRef]

- Yalçın, E.D.; Çanakçı, A.; Çuvalcı, H.; Varol, T.V.; Karabacak, A.H. The Effect of Boron Nitride (h-BN) and Silicon Carbide (SiC) on the Microstructure and Wear Behavior of ZA40/SiC/h-BN Hybrid Composites Processed by Hot Pressing. Kov. Mater.-Met. Mater. 2023, 61, 257–266. [Google Scholar] [CrossRef]

- Sathishkumar, A.; Soundararajan, R.; Ramesh, A.; Muthu Vel, T.J.; Richie Ronaldo, A.; Sai Deepesh, J. Experimental Investigations on Mechanical and Tribological Behaviour of A356 with x Wt% Boron Carbide and Fly Ash Hybrid Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 988, 012023. [Google Scholar] [CrossRef]

- Çanakçı, A.; Çelebi, M. Determination of Nano-Graphene Content for Improved Mechanical and Tribological Performance of Zn-Based Alloy Matrix Hybrid Nanocomposites. J. Alloys Compd. 2024, 1001, 175152. [Google Scholar] [CrossRef]

- Dearnley, P.A.; Bell, T. Engineering the Surface with Boron Based Materials. Surf. Eng. 1985, 1, 203–217. [Google Scholar] [CrossRef]

- Hussain, Z.; Yang, H.-W.; Choi, B.-S. Synthesis of Three-Dimensionally Interconnected Hexagonal Boron Nitride Networked Cu-Ni Composite. Korean J. Met. Mater. 2021, 59, 505–513. [Google Scholar] [CrossRef]

- Kostecki, M.; Cygan, T.; Petrus, M.; Jaroszewicz, J. Thermal Properties of Multilayer Graphene and HBN Reinforced Copper Matrix Composites. J. Therm. Anal. Calorim. 2019, 138, 3873–3883. [Google Scholar] [CrossRef]

- Djouider, F.; Alhawsawi, A.; Elmoujarkach, E.; Banoqitah, E.; Alammari, O.A.; Moustafa, E.B. The Effect of Hybrid B4C and Si3N4 Nanoparticles on the Mechanical and Physical Properties of Copper Nanocomposites. Metals 2023, 13, 1504. [Google Scholar] [CrossRef]

- Balalan, Z.; Gulan, F. Microstructure and Mechanical Properties of Cu-B4C and CuAl-B4C Composites Produced by Hot Pressing. Rare Met. 2019, 38, 1169–1177. [Google Scholar] [CrossRef]

- Kuş, H. Influence of B4C Addition on the Tribological Properties of Bronze Matrix Brake Pad Materials. Open Chem. 2025, 23, 20240126. [Google Scholar] [CrossRef]

- Pellizzari, M.; Cipolloni, G. Spark Plasma Sintering of Copper Matrix Composites Reinforced with TiB2 Particles. Materials 2020, 13, 2602. [Google Scholar] [CrossRef] [PubMed]

- El-Tantawy, A.; Daoush, W.M.; El-Nikhaily, A.E. Microstructure and Properties of BN/Ni-Cu Composites Fabricated by Powder Technology. J. Exp. Nanosci. 2018, 13, 174–187. [Google Scholar] [CrossRef]

- Bobrynina, E.; Koltsova, T.; Larionova, T. Investigation of Copper–Carbon Composite Microstructure and Properties. Metals 2023, 13, 1052. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, D.; Yang, J.; Zhang, X.; Zhu, J.; Li, W. β-Ga2O3 Thin Films via an Inorganic Sol–Gel Spin Coating: Preparation and Characterization. Nanomaterials 2025, 15, 277. [Google Scholar] [CrossRef] [PubMed]

- Vukkum, V.B.; Darwish, A.A.; Choudhari, A.; Yang, Z.; Storck, S.M.; Borkar, T.; Gupta, R.K. Effect of Nitride Addition on Microstructure, Hardness, and Wear Resistance of Additively Manufactured Stainless Steel. J. Mater. Eng. Perform. 2025, 34, 15991–16007. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozsahin, S.; Erdemir, F.; Ozkaya, S. Artificial Neural Network-Based Prediction Technique for Coating Thickness in Fe-Al Coatings Fabricated by Mechanical Milling. Part. Sci. Technol. 2018, 36, 742–750. [Google Scholar] [CrossRef]

- Digole, S.; Bohara, S.; Kothapalli, C.R.; Bajaj, B.; Borkar, T. Effect of Hexagonal Boron Nitride (HBN) Addition on Microstructure, Mechanical, and Biocompatible Properties of Spark Plasma Sintered Titanium (Ti) Matrix Composites. J. Mech. Behav. Biomed. Mater. 2025, 168, 107030. [Google Scholar] [CrossRef]

- Kumar, R.; Bakshi, S.; Joardar, J.; Parida, S.; Raja, V.; Singh Raman, R. Structural Evolution during Milling, Annealing, and Rapid Consolidation of Nanocrystalline Fe–10Cr–3Al Powder. Materials 2017, 10, 272. [Google Scholar] [CrossRef]

- Suzuki, T.S.; Uchikoshi, T.; Sakka, Y. Densification of SiC by Colloidal Processing and SPS without Sintering Additives. Adv. Appl. Ceram. 2014, 113, 85–88. [Google Scholar] [CrossRef]

- Ghafuri, F.; Ahmadian, M.; Emadi, R.; Zakeri, M. Effects of SPS Parameters on the Densification and Mechanical Properties of TiB2-SiC Composite. Ceram. Int. 2019, 45, 10550–10557. [Google Scholar] [CrossRef]

- Babu, N.; Soundararajan, R.; Santhosh, V.J.; Kamaraj, M. Effect of Processing Route on the Mechanical and Tribological Behaviour of AA8011 Hybrid Composites. J. Inst. Eng. Ser. D 2023, 104, 561–567. [Google Scholar] [CrossRef]

- Tasci, U. Microstructure, Mechanical Strength, and Tribological Behavior of B4C/WS2-Hybrid-Reinforced B319 Aluminum Matrix Composites. Lubricants 2025, 13, 247. [Google Scholar] [CrossRef]

- Somasundaram, M.; Uttamchand, N.K.; Annamalai, A.R.; Jen, C.-P. Insights on Spark Plasma Sintering of Magnesium Composites: A Review. Nanomaterials 2022, 12, 2178. [Google Scholar] [CrossRef]

- Boldin, M.S.; Popov, A.A.; Lantsev, E.A.; Nokhrin, A.V.; Chuvil’deev, V.N. Investigation of the Densification Behavior of Alumina during Spark Plasma Sintering. Materials 2022, 15, 2167. [Google Scholar] [CrossRef] [PubMed]

- Hajagos, S.; Kovács, J.G.; Suplicz, A.; Széplaki, P.; Zink, B. An Experimental and Theoretical Study on the Electrical Conductivity of Polymer Composites. J. Mater. Res. Technol. 2025, 39, 6300–6309. [Google Scholar] [CrossRef]

- Şap, S.; Uzun, M.; Usca, Ü.A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Investigation on Microstructure, Mechanical, and Tribological Performance of Cu Base Hybrid Composite Materials. J. Mater. Res. Technol. 2021, 15, 6990–7003. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N. Microstructure and Mechanical Characterization of (B4C+ h-BN)/Al Hybrid Nanocomposites Processed by Ultrasound Assisted Casting. Int. J. Mech. Sci. 2018, 144, 814–826. [Google Scholar] [CrossRef]

- Ayyanar, S.; Gnanavelbabu, A.; Rajkumar, K.; Loganathan, P. Studies on High Temperature Wear and Friction Behaviour of AA6061/B4C/HBN Hybrid Composites. Met. Mater. Int. 2021, 27, 3040–3057. [Google Scholar] [CrossRef]

- Jin, H.; Jiang, G.-Y. Synergistic Effect of B4C/h-BN Addition on the Tribological and Corrosion Behavior of Laser Prepared Ni60AA Composite Coating. Surf. Coat. Technol. 2025, 517, 132781. [Google Scholar] [CrossRef]

- Igual Munoz, A.; Espallargas, N.; Mischler, S. Tribocorrosion; Springer International Publishing: Cham, Germany, 2020; ISBN 978-3-030-48106-3. [Google Scholar]

- Yunus, M.; Alfattani, R. Assessment of Mechanical and Tribological Behavior of AA6061 Reinforced with B4C and Gr Hybrid Metal Matrix Composites. Coatings 2023, 13, 1653. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).