Abstract

316L austenitic stainless steel is an ideal candidate for high-temperature applications. However, the relatively low strength and poor wear resistance at high temperatures significantly limit its application in high-temperature environments. In this study, we address this challenge by tracing TiB2 microalloying austenitic steel via L-PBF (laser powder bed fusion), a micro-melting pool metallurgy method. The results show that adding 2.5 wt.% TiB2 significantly refines the austenite grain size from ~19 μm to ~1 μm. The austenite grain size characterizes thermal stability at 300 °C and 600 °C. The fabricated TiB2-reinforced steel shows extraordinarily high-temperature tensile strength, achieving 740 MPa and 636 MPa at 300 °C and 600 °C, respectively. The high tensile strength under high temperature is attributed to the TiB2 phase strengthening and ultrafine austenite grain sizes. Regarding the high-temperature wear friction coefficient of 0.69 at 300 °C and 0.47 at 600 °C, the predominant wear mechanism is abrasive wear, accompanied by adhesive and oxidative wear mechanisms. The present study provides new insight for the development of L-PBF austenitic steels that combine high-temperature strength with superior wear resistance.

1. Introduction

316L austenitic stainless steel is an ideal candidate for high-temperature pressure vessels and pipelines due to its corrosion resistance, weldability, and cost-effectiveness [1]. However, its tensile strength and wear resistance remain inferior, particularly at high temperatures, significantly limiting its applications in extreme environments [2,3], and thereby restricting austenitic stainless steel’s deployment in such extreme service environments. Consequently, enhancing the high-temperature mechanical properties of 316L has drawn significant attention.

Introducing hard ceramic particles into the austenitic steel is a common strategy to improve both wear resistance and the strength of the steel [4]. Tjong et al. [5] demonstrated that TiB2 ceramic particles exhibit excellent thermal stability, not only providing second-phase strengthening but also refining the austenite grain size, leading to a significant increase in both strength and wear performance. Conventional fabrication methods such as casting, powder metallurgy and hot rolling have been employed to produce such composites [6,7]. However, powder metallurgy suffers from persistent densification control issues [8], while solidification routes frequently result in particle segregation at interdendritic regions and gravity-driven agglomeration in hypereutectic systems [9,10]; subsequent rolling introduces additional defects [11]. The L-PBF (laser powder bed fusion) additive manufacturing technology, which enables in situ alloying and rapid solidification, provides a novel route for fabricating ceramic-reinforced metal matrix composites [12]. The technique has been widely applied to aluminum matrix composites [13], where it has been shown to promote the columnar to equiaxed transition (CET) [14], resulting in fine grain sizes and a significant increase in tensile strength.

Previous studies have reported that the L-PBF-fabricated particle-reinforced austenitic stainless steels exhibits significant refinement of austenite grain size and enhanced compressive yield strengths at both room- and high-temperature conditions [15]. Zhai et al. [16] systematically studied the various contents of TiC nanoparticles addition in 316L, demonstrating that increasing TiC from 1 wt.% to 3 wt.% raises the room temperature yield strength from 694 MPa to 773 MPa. Zhai [17] furtherly annealed 3 wt.% TiC reinforced 316L at 700 °C for 1 h, and showed a further increase in yield strength from 832 MPa to 959 MPa. AlMangour et al. [18] fabricated TiB2 particle-reinforced austenitic steel (with 5 vol.% and 10 vol.% TiB2) via L-PBF, showing that the L-PBF TiB2-reinforced 316L was characterized by good printability and refined austenite microstructure, confirming that TiB2 particle-reinforced 316L exhibits excellent high-temperature compressive strength (498.2 MPa and 833.8 MPa with 5 vol.% and 10 vol.% TiB2 addition at 600 °C).

To date, investigations on the wear performance of L-PBF-fabricated ceramics and particle-reinforced austenitic steels have concentrated on room-temperature wear properties. It is generally accepted that ceramic particles improve wear resistance, yet the underlying mechanisms and their influence on mechanical performance remain unclear. AlMangour et al. [19] added 2.5–15 vol.% TiC and observed higher wear resistance, but the wear mechanisms remain unclear. Gain et al.’s [20] studies showed that 3 wt.% nano-TiB2 markedly reduced the wear rate of 316L steel by suppressing material removal and plastic deformation under a high load. Karan et al. [21] found that WC + TiN co-reinforced 316L steel exhibited the lowest coefficient of friction (0.51) and wear rate (0.31 × 10−6 mm3/N). The ceramic particles (WC + TiN) refined the microstructure, acted as solid lubricants, decreased adhesive interaction, and stabilized the tribo-layer, finally leading to smoother worn surfaces and less material loss.

Previous studies have confirmed the technical feasibility of producing TiB2 particle-reinforced austenitic steels via L-PBF, and have indicated their potential for high-temperature applications. However, there is limited understanding of the high-temperature tensile and wear properties, as well as the failure mechanisms, of L-PBF-processed TiB2 particle-reinforced 316L steel. This study not only quantifies the high-temperature tensile and wear performance but also provides an in-depth analysis of the failure mechanisms. Our findings demonstrate the steel’s potential for use in demanding applications within the aerospace and power-generation industries, thereby advancing the field with new insights and practical applications.

2. Materials and Methods

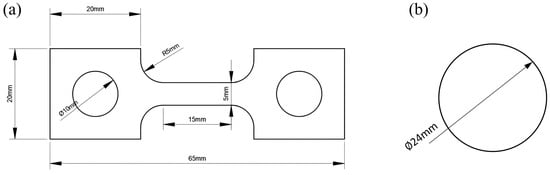

In the present study, a Y-type powder mixer was utilized for the mechanical mixing of commercial 316L powder (produced by LiaoNing Guanda Co., Anshan, China; particle size ranges from 15 to 53 μm) and TiB2 particles (acquired from Zhongye New Materials Co., Ltd., Beijing, China; median size ~1 μm). The XRD patterns and SEM morphologies of the two powders are shown in Supplementary Figures S1 and S2. The mixing process was carried out at a speed of 10 r/min for 12 h to prepare the TiB2-reinforced feedstock powder with a composition of 97.5 wt.% 316L + 2.5 wt.% TiB2. A specific image of the Y-type powder mixer used in this study is provided in Supplementary Figure S2a. JHL-100E+ (Jihua Laboratory, Foshan, China) conducted the L-PBF build process without heating the substrate; the detailed parameters were as follows: a laser power of 145 W, 30 μm in layer thickness, 900 mm/s in scanning speed and 60 μm in hatch spacing. The as-fabricated samples are shown in Supplementary Figure S3. The density of the samples was obtained using a densitometer, and the results showed that the samples had a density of over 99.5%. The high-temperature tensile tests have been carried out by a universal testing machine (Shimadzu AG-X, Shimadzu Corporation, Kyoto, Japan) with a heating furnace at a constant strain rate of 1 × 10−4 s−1, following the ASTM E21-20 standard [22]. The detailed tensile test sample dimensions are presented in Figure 1a. In this study, the high-temperature wear experiment was conducted using a ball-on-disc reciprocating tribometer at two temperatures, 300 °C and 600 °C. A ZD-WPM-20 reciprocating friction and wear tester was used for the experiments, following the ASTM G99-23 standard [23]. The tester has a loading force range of 0–20 N with a linearity of 0.5%, a reciprocating frequency of 0.1–20 Hz, an amplitude of 0–16 mm and an X-axis travel distance of 6 mm. The wear test specimen was a 24 mm diameter disc (Figure 1b), and the counter-body was a 9.525 mm diameter silicon nitride (Si3N4) ball. The test parameters were a reciprocating frequency of 5 Hz, an applied load of 5 N and a reciprocating distance of 10 mm. The microstructure was characterized by SEM (scanning electron microscopy, FEI-Scios 2 Hivac, FEI American Company, Waltham, MA, USA) with EBSD (electron backscattered diffraction, C-nano+, Oxford Instruments, High Wycombe, UK) and EDS (energy dispersive spectroscopy, X-Max 80, Oxford Instruments, High Wycombe, UK). EBSD samples are electro-polished in a solution composed of 10% HClO4 and 90% alcohol at 22 V for 20 s.

Figure 1.

Schematic diagram of test specimens. (a) Schematic diagram of tensile specimens, (b) schematic diagram of wear specimens.

3. Results and Discussion

3.1. Composite Powder and L-PBF-Fabricated Samples Characterization

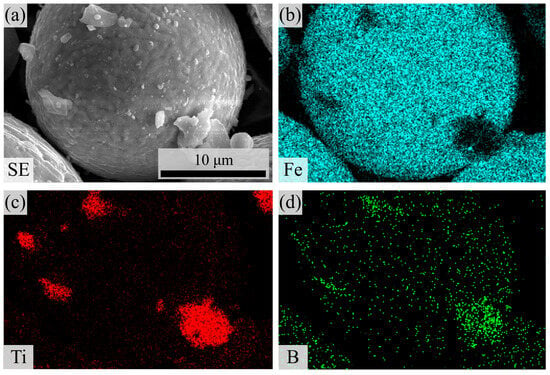

The 97.5 wt.% 316L + 2.5 wt.% TiB2 powder after mechanical mixing was characterized, with the results shown in Figure 2. Figure 2a displays the morphology of the mixed powder, while Figure 2b–d present the elemental distributions of Fe, Ti and B, respectively. It can be observed that irregular TiB2 particles adhere to the surface of the 316L spherical particles after mechanical mixing. This ensures the uniform composition of the L-PBF materials. Furthermore, the element distribution maps (Supplementary Figure S5) of as-fabricated TiB2 particle-reinforced austenitic steels also show the uniform chemical composition distribution.

Figure 2.

SEM and EDS images of the mixed powder. (a) SE image, (b) element Fe distribution map, (c) element Ti distribution map, and (d) element B distribution map.

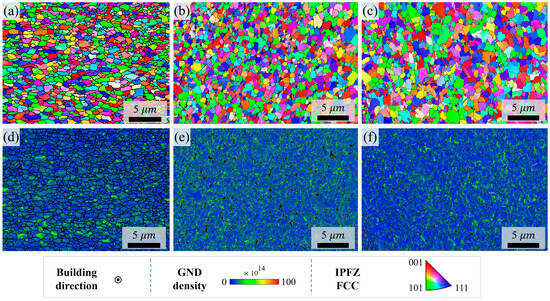

Figure 3 characterizes the microstructural evolution of TiB2-reinforced austenitic steel produced by L-PBF. Inverse pole figure Z (IPF Z) maps (Figure 3a–c) show the as-printed condition and the condition after isothermal exposure at 300 °C and 600 °C for 30 min each. Compared with the L-PBF 316L microstructure (Figure S6), adding 2.5 wt.% TiB2 significantly refines the austenite grains, reducing the average size from 18.95 μm to 0.9 μm. This refinement is attributed to TiB2 particles that act as potent heterogeneous nucleation sites during solidification, thus effectively refining the grain size of the 316L stainless steel matrix, which is in agreement with previous studies [24]. Phase mapping (Figure S7) reveals only austenite; the absence of a detectable TiB2 signal is attributed to the nanoscale particle size (~50 nm) [18,24], which lies below the spatial resolution of conventional EBSD. After isothermal annealing, the austenite grain size remains essentially constant (0.89 μm at 300 °C and 1.1 μm at 600 °C), indicating pronounced thermal stability. This stability arises from the pinning effect, whereby TiB2 particles restrict grain-boundary and dislocation migration [25]. Moreover, the EDS distribution maps after isothermal treatment (Figure S5) indicate that the elements remain homogeneously distributed, with no particle coarsening or agglomeration. Geometrically necessary dislocation (GND) density maps (Figure 3d–f) show a progressive reduction from 12.5 × 1014 m−2 in the as-printed state to 10.5 × 1014 m−2 after exposure at 600 °C, consistent with the thermally activated recovery processes. Compared with L-PBF-manufactured 316L, the higher GND density in TiB2-reinforced 316L was attributed to the local lattice distortion introduced in specific regions after TiB2 addition, as reported in Gain et al.’s work [24].

Figure 3.

Microstructure characterization of TiB2-reinforced austenitic steel. (a–c) IPF Z map of TiB2-reinforced austenitic steel at as-print state, 300 °C isothermal 30 min, and 600 °C isothermal 30 min; (d–f) GND map of TiB2-reinforced austenitic steel at as-print state, 300 °C isothermal 30 min, and 600 °C isothermal 30 min.

3.2. High-Temperature Tensile Properties and Fracture Behaviour of TiB2-Reinforced 316L Austenitic Steel

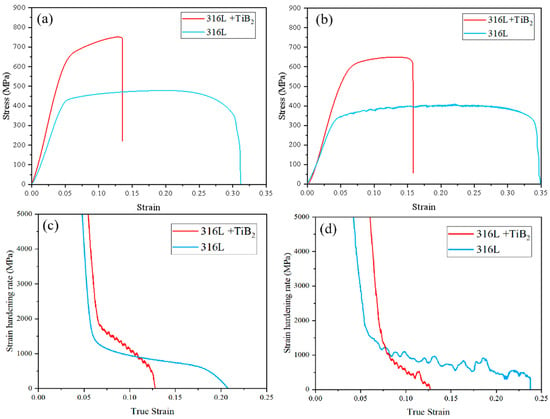

Figure 4a,b present the tensile behaviour of 316L and TiB2-reinforced 316L austenitic steel after isothermal annealing for 30 min at 300 °C and 600 °C. At 300 °C, the TiB2-reinforced 316L steel exhibits an ultimate tensile strength of 740 ± 11 MPa, with a total elongation of 13.5% (Figure 4a). When the temperature is raised to 600 °C, the ultimate tensile strength decreases to 636 ± 7 MPa, whereas the total elongation increases to 15.8% (Figure 4b). Compared to the high-temperature tensile mechanical properties of L-PBF 316L steel, the UTS of the TiB2-reinforced steel increases by ~60% at 300 °C and ~58% at 600 °C, respectively. Similarly to previous studies on the tensile properties of ceramic-particle-reinforced austenitic steels, the addition of ceramic particles effectively promotes the high-temperature strength. And, from the elastic segment slope in Figure 4a,b, it can be observed that the Young’s modulus of TiB2-reinforced 316L is higher than that of 316L without TiB2 particles at both 300 °C and 600 °C, which is consistent with prior studies of TiB2 particle-reinforced high-Young’s modulus steel [26]. Figure 4c,d show the strain-hardening behaviour at different temperatures; the TiB2-reinforced austenitic steel still exhibits pronounced strain hardening (dσ/dε > 0), indicating that dislocation multiplication remains active [27]. Consistent with the conclusions of AlMangour et al. [18], the strain-hardening stage of the TiB2-reinforced steel is more prolonged at 300 °C than at 600 °C, which can be attributed to the stronger particle-pinning effect on dislocations at the lower temperature [28]. Moreover, at 300 °C, the TiB2-reinforced steel displays stronger strain-hardening behaviour than 316L, whereas at 600 °C, its strain-hardening in the late deformation stage is slightly lower than that of 316L. The improved high-temperature tensile performance of the TiB2-reinforced steel at 300 °C therefore results from the synergistic effect of its high yield strength and excellent strain hardening, while the enhancement at 600 °C is due to its higher yield strength.

Figure 4.

Tensile properties of 316L and TiB2-reinforced 316L steel. (a) Engineering stress–engineering strain curve under 300 °C; (b) engineering stress–engineering strain curve under 600 °C; (c) true strain vs. strain-hardening curve under 300 °C, and (d) true strain vs. strain-hardening curve under 600 °C.

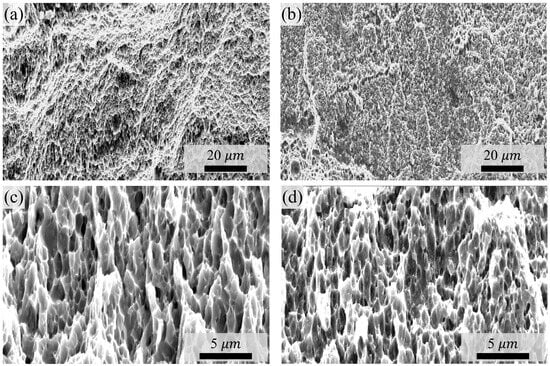

Figure 5 shows the fracture morphology of TiB2-reinforced 316L austenitic steel tensile tested at different temperatures. Figure 5a,b present the macroscopic fracture surfaces of TiB2-reinforced 316L austenitic steel tensile-tested at 300 °C and 600 °C, respectively. The fracture surface appears relatively smooth and is populated with numerous small dimples interspersed with a limited number of large dimples, indicating a predominantly ductile fracture mode. At higher magnification, consistent with the favourable ductility, the fracture surfaces (Figure 5c,d) are densely covered with equiaxed dimples; the dimple size closely matches the initial austenite grain size. The results show that the addition of a 2.5 wt.% fraction of TiB2 particles does not change the failure mode of 316L austenitic steel. However, it markedly refines the dimple size compared to the fracture morphology of 316L steel, as studied by Huang et al. [29].

Figure 5.

Tensile fracture of TiB2-reinforced 316L austenitic steel at 300 °C and 600 °C, respectively. (a,c) Fracture of TiB2-reinforced 316L austenitic steel under 300 °C; (b,d) fracture of TiB2-reinforced 316L austenitic steel under 600 °C.

3.3. Microstructure Evolution Under High-Temperature Tensile Test

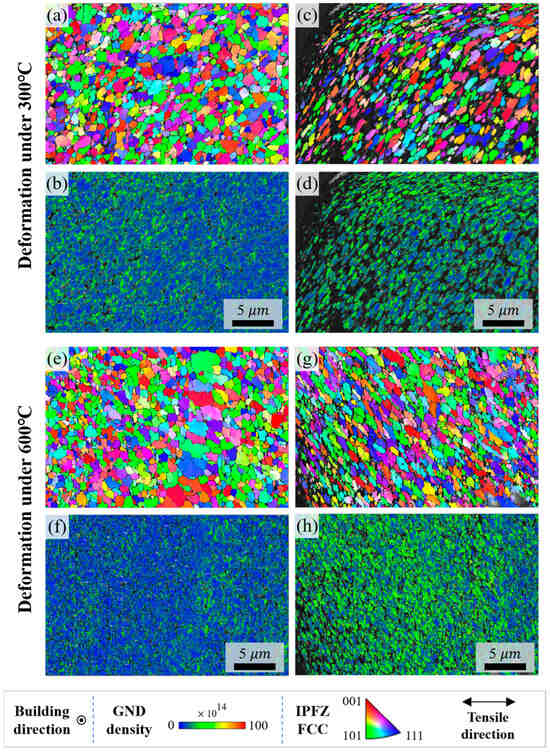

To investigate the microstructure evolution at different temperatures, EBSD characterization was performed on steels deformed to 5% strain and at fracture strain, as shown in Figure 6. When comparing the microstructure of deformation at 300 °C and 600 °C, the IPF Z maps reveal that no deformation twinning forms during high-temperature deformation. However, the significant elongation of austenite grains is attributed to the increase in stacking fault with temperature, and the high SFE at high temperature suppresses the formation of deformation twins [30]. The deformation mechanism is predominantly accommodated by dislocation slips. Allain et al. [31] systematically demonstrated in Fe–22Mn–0.6C austenitic steel that, when SFE exceeds ~18 mJ m−2, twinning is completely inhibited, consistent with the present observations.

Figure 6.

Microstructure evolution of TiB2-reinforced 316L steel at different temperatures. (a,b) IPF Z maps for the 5% and fracture strain at 300 °C; (c,d) IPF Z maps for the 5% and fracture strain at 600 °C; (e,f) GND maps for the 5% and fracture strain at 300 °C; (g,h) GND maps for the 5% and fracture strain at 600 °C. Note: in EBSD maps, black regions represent unindexed points in the EBSD map.

In addition, the temperature dependence of the geometrically necessary dislocation (GND) density supports this interpretation. At 5% strain, the average GND density decreases from 14.3 × 1014 m−2 to 12.3 × 1014 m−2 when the temperature rises to 600 °C, with GNDs predominantly accumulating at grain boundaries. This reduction in GND density with increasing temperature suggests that thermally activated processes, such as climb and cross-slip, are active and help to relieve dislocation pile-ups. Li et al. [32] reported a similar trend in 316L steel, when the test temperature was raised from 173 K to 297 K, the volume fraction of deformation twins dropped sharply and GNDs migrated from grain interiors to grain boundaries. This is in good agreement with the grain-boundary GND accumulation observed in the present study. Consequently, the high temperature promotes the transition from TWIP to a slip-dominated deformation regime by increasing SFE and enhancing dislocation mobility.

3.4. Wear Properties and Morphology

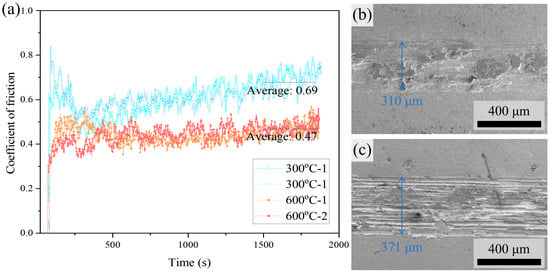

Figure 7a shows the variation in COF (coefficient of friction) versus time curves for a sample test under different temperatures. As depicted in the figure, at all test temperatures, the COF rapidly reaches a steady-state regime following quite stable COF values throughout the remainder of the tests. At 300 °C, the friction coefficient first reaches ~0.8, drops rapidly to ~0.5 and then stabilizes at 0.6–0.7. Notably, during the interval from 1500 to 1800 s, the average COF is 0.69. At 600 °C, the coefficient rises sharply to ~0.5 within the first 200 s because of the rougher contact interface, and then enters a steady-state regime. Within the same time window of 1500 to 1800 s, the average COF at this temperature is measured at 0.47. As reported previously [33], higher test temperature increases the friction coefficient and thus degrades tribological performance [34].

Figure 7.

Wear behaviour of TiB2-reinforced 316L steel under high temperature. (a) Friction coefficient vs. time curves for sample tests under various temperatures, (b) scratch morphology at 300 °C and (c) scratch morphology at 600 °C.

Figure 7b,c demonstrate the macroscopic morphologies of wear sample surfaces at 300 °C and 600 °C, respectively. The wear resistance is inversely proportional to the width/volume of wear traces [35]. It was determined that the wear scar width was 310 μm under 300 °C, while the wear trace width reached 371 μm at 600 °C, indicating a larger cross-sectional area. The width of the wear trace indicates that higher environmental temperatures worsen the wear performance. Simultaneously, it can be observed that groove-like morphologies within the wear tracks are more pronounced at high temperatures, further demonstrating that increased temperatures pronounced the wear failure behaviour.

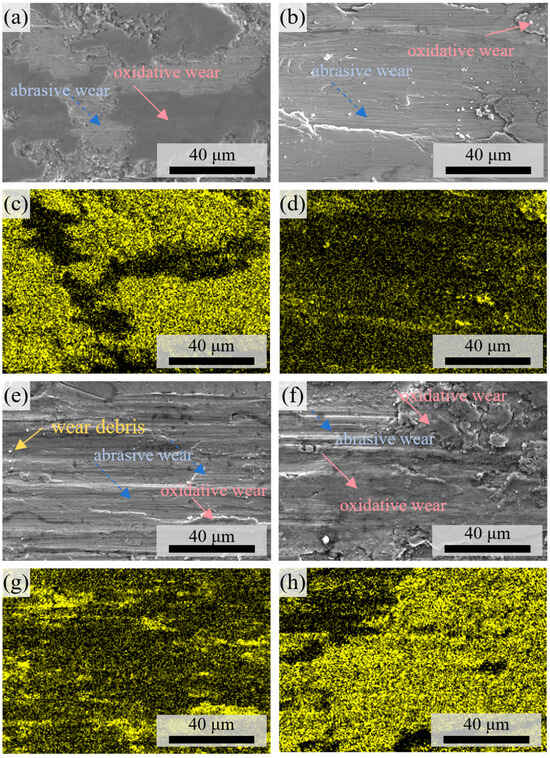

Figure 8 shows the wear track surface morphology and elemental distribution at 300 °C (a–d) and 600 °C (e–h). At each temperature, the (a, b, e and f) figures show the surface micrographs, while the corresponding oxygen maps (c, d, g and h) were acquired by EDS. All specimen surfaces exhibit sliding grooves parallel to the direction of sliding. Due to thermal softening, the long, thin, uneven and rough features become more pronounced at higher temperature (600 °C). Regarding wear mechanisms, the wear surfaces of TiB2-reinforced 316L steel tested at both temperatures show plastic deformation produced by adhesive wear and grooves aligned along the sliding direction, generated by abrasive wear (as indicated by blue arrows). There is also oxidative wear (as indicated by pink arrows) behaviour evidenced by a dark blocky area within the wear traces, whose oxygen content is confirmed by EDS (Figure 8c,d,g,h), while adhesive wear induced by the counter-body (Si3N4 ball) appears as blocky layers on the wear surface. But the parallel grooves, scratches and debris (as indicated by yellow arrows) characteristics demonstrate that severe abrasive wear is the predominant wear mechanism.

Figure 8.

Scratch morphology of TiB2-reinforced 316L steel under high temperature. (a,b) Microstructure of the scratch region at 300 °C, (c,d) EDS map of the scratch region at 300 °C, (e,f) microstructure of the scratch region at 600 °C and (g,h) EDS map of the scratch region at 600 °C.

4. Conclusions

In this work, TiB2-reinforced 316L austenitic steel was successfully produced by L-PBF. The microstructure, high-temperature tensile behaviour and wear performance of the steel were systematically evaluated. The results demonstrate that trace TiB2 doping (2.5 wt.%) integrated into a standard L-PBF 316L feedstock simultaneously enhances the high-temperature strength and wear resistance of austenitic stainless steels.

(1) The addition of 2.5 wt.% TiB2 particles significantly refined the grain size of L-PBF 316L austenitic steel from ~19 μm to ~1 μm and imparted thermal stability to the austenitic grains at 300 °C and 600 °C.

(2) The TiB2-reinforced austenitic steel demonstrated excellent tensile strength at both 300 °C, reaching 740 MPa, and 600 °C, with a strength of 636 MPa. Compared to the L-PBF 316L steel, the UTS of the TiB2-reinforced steel increases by ~60% at 300 °C and ~58% at 600 °C, respectively.

(3) In terms of high-temperature wear performance, the material exhibited a friction coefficient of 0.69 at 300 °C and 0.47 at 600 °C. The parallel grooves, scratches and debris characteristics show that abrasive wear is the predominant wear mechanism.

(4) Limitations: It should be acknowledged that there are certain limitations to the current study. Specifically, the build-size scalability of the fabricated components has not yet been verified for dimensions exceeding 100 mm3, which is crucial for industrial applications requiring larger-scale components. Additionally, the long-term oxidation behaviour of the material remains untested beyond 1000 h, which is essential for assessing the material’s durability and stability in high-temperature environments over extended periods.

(5) Future work: Comprehensive creep-fatigue tests will be conducted under cyclic thermal-mechanical loads. This is critical for evaluating the material’s performance and structural integrity in service conditions.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/met15111233/s1, Figure S1: XRD patterns of the two powders. Figure S2: SEM images of the two powders. (a) SEM images of the 316L steel powder, (b) SEM images of the TiB2 powder. Figure S3: Photos of the experimental equipment. Figure S4: Schematic diagram of tensile and wear specimens. Figure S5: SEM and EDS images of the TiB2 samples under various treatments. (a1–a3) SE map, element Cr distribution map, and element Ti distribution map of the as-built sample, respectively. (b1–b3) SE map, element Cr distribution map, and element Ti distribution map of the 300 °C@30 min sample, respectively. (c1–c3) SE map, element Cr distribution map, and element Ti distribution map of the 600 °C@30 min sample, respectively. Figure S6: Microstructure characterization of L-PBF 316L austenitic steel. Figure S7: Phase map of fabricated TiB2-reinforced 316L steel.

Author Contributions

Conceptualization, M.H.; Methodology, M.H. and Y.C.; Software, M.H.; Validation, M.H. and Y.C.; Formal analysis, M.H.; Investigation, M.H. and Y.C.; Resources, M.H.; Data curation, M.H. and Y.C.; Writing—original draft, M.H.; Writing—review & editing, M.H. and Y.C.; Visualization, M.H. and Y.C.; Supervision, M.H.; Project administration, M.H.; Funding acquisition, M.H. All authors have read and agreed to the published version of the manuscript.

Funding

The research was financially supported by the National Key R&D program of China (Grant No. 2024YFB3713301) and Zhejiang Provincial Natural Science Foundation of China (No. LQ24E040003).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mannan, M.S.; Jang, C. High temperature corrosion of wrought and wire arc additively manufactured 316L stainless steel in a simulated boiler environment. J. Mater. Res. Technol. 2024, 32, 4278–4292. [Google Scholar] [CrossRef]

- Zou, Y.; Tan, C.; Qiu, Z.; Ma, W.; Kuang, M.; Zeng, D. Additively manufactured SiC-reinforced stainless steel with excellent strength and wear resistance. Addit. Manuf. 2021, 41, 101971. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, R.; Qin, X.; Ouyang, W.; Wang, Z.; Wang, R. Investigations of the hybrid laser polishing and high-temperature tribological properties of the 316L stainless steel formed by selective laser melting. Tribol. Int. 2024, 200, 110152. [Google Scholar] [CrossRef]

- Wang, Y.; Li, T.; Gu, Z.; Yan, Z.; Di, R.; Lei, J. Effect of directional energy deposition of dual-scale WC particles on the anti-wear properties of 316L. Appl. Surf. Sci. 2025, 688, 162441. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Sliding wear of stainless steel matrix composite reinforced with TiB2 particles. Mater. Lett. 1999, 41, 153–158. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, D.; Jia, Y.; Wang, G.; Prashanth, K.G. Microstructure evolution and tensile property of high entropy alloy particle reinforced 316 L stainless steel matrix composites fabricated by laser powder bed fusion. J. Alloys Compd. 2023, 965, 171430. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, M.; Zhang, D.; Wang, E. Effect of rare-earth elements on microstructure and mechanical properties of in-situ Fe-TiB2 composites. Mater. Today Commun. 2021, 29, 102860. [Google Scholar] [CrossRef]

- Saxena, A.; Saxena, K.K.; Jain, V.K.; Rajput, S.K.; Pathak, B.N. A review of reinforcements and process parameters for powder metallurgy-processed metal matrix composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Zhang, H.; Springer, H.; Aparicio-Fernández, R.; Raabe, D. Improving the mechanical properties of Fe—TiB2 high modulus steels through controlled solidification processes. Acta Mater. 2016, 118, 187–195. [Google Scholar] [CrossRef]

- Wang, X.; Leng, H.; Han, B.; Wang, X.; Hu, B.; Luo, H. Solidified microstructures and elastic modulus of hypo-eutectic and hyper-eutectic TiB2-reinforced high-modulus steel. Acta Mater. 2019, 176, 84–95. [Google Scholar] [CrossRef]

- Wang, B.G.; Wang, G.D.; Misra, R.D.K.; Yi, H.L. Increased hot-formability and grain-refinement by dynamic recrystallization of ferrite in an in situ TiB2 reinforced steel matrix composite. Mater. Sci. Eng. A 2021, 812, 141100. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Agrawal, P. Additive manufacturing of metal matrix composites. Mater. Des. 2025, 252, 113609. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Lin, X.; Kang, N.; Wen, X.L.; Cao, Y.; Lu, J.L.; Peng, D.J.; Bai, J.; Zhou, Y.X.; El Mansori, M.; et al. Effect of laser additive manufacturing on the microstructure and mechanical properties of TiB2 reinforced Al-Cu matrix composite. Mater. Sci. Eng. A 2022, 840, 142950. [Google Scholar] [CrossRef]

- Al Mahmoud, Z.; Safaei, B.; Asmael, M.; Kenevisi, M.S.; Sahmani, S.; Karimzadeh, S.; Jen, T.-C.; Hui, D. Impact of process parameters on mechanical and microstructure properties of aluminum alloys and aluminum matrix composites processed by powder-based additive manufacturing. J. Manuf. Process. 2025, 146, 79–158. [Google Scholar] [CrossRef]

- AlMangour, B.; Baek, M.-S.; Grzesiak, D.; Lee, K.-A. Strengthening of stainless steel by titanium carbide addition and grain refinement during selective laser melting. Mater. Sci. Eng. A 2018, 712, 812–818. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. In-situ formation of TiC nanoparticles in selective laser melting of 316L with addition of micronsized TiC particles. Mater. Sci. Eng. A 2022, 829, 142179. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Yu, Y.; Nai, S.M.L. Direct evidence of melting and decomposition of TiC particles in laser powder bed fusion processed 316L-TiC composite. J. Mater. Sci. Technol. 2024, 198, 166–175. [Google Scholar] [CrossRef]

- AlMangour, B.; Kim, Y.-K.; Grzesiak, D.; Lee, K.-A. Novel TiB2-reinforced 316 L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Jenn, M. Selective laser melting of TiC reinforced 316 L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater. Des. 2016, 104, 141–151. [Google Scholar] [CrossRef]

- Gain, A.K.; Cui, Y.; Zhang, L. Wear mechanism and subsurface structure of ultra-fine-grained stainless steel-titanium boride nanocomposites fabricated via selective laser melting. Wear 2025, 571, 205788. [Google Scholar] [CrossRef]

- Karan, B.; Tan, Q.; Moheimani, K.; Wang, F.; Bhowmik, A.; Zhang, M. Enhancement of tribological properties by reinforcing 316L stainless steel with nano ceramics fabricated by laser powder bed fusion. Wear 2025, 582–583, 206334. [Google Scholar] [CrossRef]

- ASTM E21-20; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM G99-23; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- Gain, A.K.; Cui, Y.; Zhang, L.; Li, Z. Mechanical properties of additively manufactured ultrafine grain stainless steel-titanium boride (SS–TiB2) nanocomposites. Mater. Sci. Eng. A 2024, 911, 146961. [Google Scholar] [CrossRef]

- Zhang, K.; Gao, Y.; Zhang, A.; Chen, Z.; Zhao, J.; Song, Y.; He, W.; Dong, Z.; Yang, Y.; Song, J.; et al. Excellent high temperature mechanical properties of Mg-5Y-0.6La composites reinforced by Al2Y-TiB2 particles. J. Alloys Compd. 2025, 1038, 182683. [Google Scholar] [CrossRef]

- Liu, J.K.; Li, Y.Z.; Zhuang, Q.D.; Huang, M.X.; Xu, W. Low-density and high-modulus steel achieved by hypereutectic TiB2 and high Al ferrite phase. J. Mater. Sci. Technol. 2026, 258, 83–99. [Google Scholar] [CrossRef]

- Bae, J.-S.; Lim, K.-H.; Chandra, S.; Tan, X.; Sim, G.-D. Exploring the high-temperature tensile behavior of additively manufactured 316 L stainless steel with fine equiaxed grains. J. Mater. Res. Technol. 2025, 36, 9790–9802. [Google Scholar] [CrossRef]

- Shuai, L.; Huang, T.; Yu, T.; Wu, G.; Hansen, N.; Huang, X. Segregation and precipitation stabilizing an ultrafine lamellar-structured Al-0.3%Cu alloy. Acta Mater. 2021, 206, 116595. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Yuan, S.; Wang, J.; Wang, C.; Mogucheva, A.; Xu, W. Scale-up fabrication of gradient AGS in austenitic stainless steels achieves a simultaneous increase in strength and toughness. Mater. Sci. Eng. A 2022, 853, 143763. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Wang, C.; Li, Y.; Wang, J.; Yuan, J.; Hu, J.; Huang, M.; Xu, W. Optimizing crack initiation energy in austenitic steel via controlled martensitic transformation. J. Mater. Sci. Technol. 2024, 198, 231–242. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Li, S.; Withers, P.J.; Deng, Y.; Yan, K. Deformation microstructures and martensitic transformation pathways in cryogenically deformed 316 L stainless steel. J. Mater. Sci. 2024, 59, 2134–2154. [Google Scholar] [CrossRef]

- Yetim, A.F.; Tekdir, H.; Turalioglu, K.; Taftali, M.; Yetim, T. Tribological behavior of plasma-sprayed Yttria-stabilized zirconia thermal barrier coatings on 316 L stainless steel under high-temperature conditions. Mater. Lett. 2023, 336, 133873. [Google Scholar] [CrossRef]

- Wen, S.; Hu, H.; Zhou, Y.; Chen, Z.; Wei, Q.; Shi, Y. Enhanced hardness and wear property of S136 mould steel with nano-TiB2 composites fabricated by selective laser melting method. Appl. Surf. Sci. 2018, 457, 11–20. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).