Abstract

Herein, ZrO2 and Si + ZrO2 composite coatings on AZ91D alloys are deposited at a constant voltage of 8 kV and 1 Å/s deposition rate using the electron beam physical vapor deposition (EBPVD) method. Further, the samples are examined for surface morphology, phase analysis, adhesion, corrosion, and antibacterial properties, as per ASTM standards. The adhesion strength of the composite (Si + ZrO2) coating nominally dropped (9%) compared to the ZrO2 coating even when the coating thickness increased by 18%. However, the composite (Si + ZrO2) coating improved wettability because silanol promotes hydrogen bonding with water molecules, which elevates the surface energy of the silica and increases its hydrophilic nature. Further, increased wettability and surface roughness have the potential to improve cell adhesion and proliferation. The corrosion potential (Ecorr) values of the coated samples exhibited a positive shift in the potentiodynamic polarization curve, indicating a substantial increase in their corrosion resistance in the artificial blood plasma (ABP) electrolyte. Similarly, SEM images of both coated corroded samples are less affected in the ABP solution, indicating that the coating mitigated heavy cracks and micropores, protecting them from corrosion. The Si + ZrO2 coatings exhibited exceptional performance in preventing bacterial infiltration by Staphylococcus aureus, thus inhibiting the subsequent formation of biofilms. In addition, these coatings demonstrate improved vitality among fibroblast cells, enabling better cellular spreading and proliferation.

1. Introduction

Magnesium (Mg) alloys are suitable for temporary implant applications owing to their biodegradable and non-toxic properties. In addition, magnesium is an obligatory nutrient for the human body, which plays a decisive role in various physiological functions [1,2]. Further, Mg alloys are distinct from many other metals used in orthopedic applications due to their similar and compatible mechanical characteristics with human bone and also prevent the stress shielding effect [3]. Correspondingly, self-corrosion can induce the degradation of magnesium implants, resulting in the production of beneficial Mg ions that enhance the formation of bone tissue [4,5]. This makes them a potentially promising choice for orthopedic implants, thereby providing more balanced load distribution and potentially reducing the risk of bone loss around the implant site. However, the negative electrode potential of magnesium (E = −2.37 V) renders it susceptible to rapid degradation in the presence of bodily fluids. Furthermore, the accelerated evolution of H2 gas leads to an elevation in the local pH and disrupts the healing process. Thus, the implant necessitates an adequate time for the appropriate bone regeneration process [6]. Moreover, the development of implant materials must deal with the challenging factors of bacterial invasion, cytocompatibility, and bio decomposition. Clinically related infections are often present in hospitals, specifically surgical suites, raising the possibility of pathogen transmission to individuals and healthcare equipment [7,8]. In addition, bacterial biofilm development, arising from bacterial adhesion and colonization, is the primary cause of peri-implantitis, a condition that leads to the loss of dental implants. Nevertheless, once a bacterial biofilm has developed, the immune system will encounter significant challenges in eliminating it. To prevent peri-implantitis, it is essential to accumulate magnesium with sufficient antibacterial capabilities to inhibit the development of biofilm [9,10]. Hence, surface modification is essential for magnesium to control rapid degradation, avoid harmful bacteria adhesion, and improve biocompatibility. Surface coating with antibacterial chemicals is a very efficient method for achieving good antibacterial properties [11].

Recently, zirconia bioceramics has gained significant popularity in the field of biomedical applications, including dental implants and femoral heads in total hip replacements, owing to its excellent aesthetic properties, substantial mechanical strength, high wear resistance, superior biocompatibility, corrosion protection, hemocompatibility, and ability to suppress bacterial invasion [12,13,14]. Zirconia ball heads have shown superior mechanical strength, with an ultimate compressive load around 2.5 times higher than that of Al2O3 heads, a property that contributes to the durability of hip replacement components [15]. Zirconia is very attractive in prosthetic dentistry due to its improved osteoconductivity, ability to promote bone growth and integration, and capability to inhibit bacterial colonization [16]. Yue’e Gao reported that in the simulated body fluid environment, an AZ31B magnesium alloy treated with a ZrO2 coating exhibited superior corrosion resistance compared to an untreated AZ31B alloy [17]. Despite these benefits, zirconia-based dental implant systems have shown cumulative failure rates of 1.8% to 28.7% after 12 months compared with titanium implants. This implies that zirconia may be sensitive to oral factors, causing dental implant system failure despite its benefits [18]. In addition, the hydrothermal aging of zirconia can transform the crystal structure from a more stable tetragonal phase to a less stable monoclinic phase [19]. This phase transformation can cause surface roughening, micro-cracking, and overall degradation, potentially leading to implant failure [20]. These structural changes due to hydrothermal aging compromise the mechanical integrity of zirconia-based implants, affecting their performance [21,22]. Likewise, the low-temperature degradation nature of zirconia may enhance the restoration of surface roughness, thus promoting biofilm development. Biofilms on dental implant restorations may cause oral health complications and shorten their lifespan [23,24]. Researchers and manufacturers often explore different strategies to mitigate this issue, such as stabilizing the zirconia structure, altering material compositions, or developing protective coatings to enhance the material’s resistance to hydrothermal aging [25]. Moreover, Nikoomanzari et al. evaluated various concentrations of ZrO2 and reported that the ZrO2-coated titanium showed improved wettability and corrosion resistance; however, the antibacterial activity diminished as the amounts of ZrO2 increased [26]. This finding highlights a tradeoff between enhanced material properties and antibacterial characteristics based on ZrO2 concentration. Hence, it is important to realize that beyond the tolerance limitations of the additional elements in the human body, there might be detrimental consequences.

Recent studies have discussed the optimal use of silica to stabilize the tetragonal phase. This approach may be better than using other additives since it does not change the structure of the zirconia or cause new flaws. Furthermore, when employed as a coating, silica has excellent adherence to the base and strong corrosion resistance as well as antibacterial qualities [27,28]. Additionally, silicon has been found to have positive effects on bone and cartilage, and it is known for providing inertness to biological tissues, making it a desirable material for medical applications [29]. The bioactivity of SiO2 coatings promotes the formation of an apatite layer at the interface between the coated implants and surrounding tissues. This formation is desirable because it can enhance the integration of the implant with the surrounding bone, a process known as osseointegration [30,31]. Furthermore, a variety of surface coating techniques have been used to deposit these ceramic materials on magnesium alloys to improve the bioactivity and corrosion resistance as well as to control the dissolution and degradation of the material. Among the various approaches, electron beam evaporation stands out for its ease of use, environmental friendliness, and deposition accuracy [32,33].

There is a lack of research on the corrosion behavior and antibacterial properties exhibited by a nanocomposite coating (Si + ZrO2) on AZ91D magnesium alloys through EBPVD deposition in the existing literature, indicating an interesting and potentially unexplored area of research. Therefore, this research focuses on the application of ZrO2 (zirconia) and a composite coating containing silica (Si) and ZrO2 onto AZ91D substrate using the EBPVD technique. Subsequently, the coating’s surface characteristics, wettability, cell viability, and antibacterial properties were analyzed by comparing it with an uncoated AZ91D substrate. Furthermore, the electrochemical characteristics of the samples were examined when exposed to artificial blood plasma as an electrolyte solution.

2. Materials and Methods

Commercially available AZ91D magnesium alloy (Al-8.3%; Mn-0.26%; Zn-0.45%; Si-0.1%; Cu-0.03%; and the remaining magnesium) was procured from NUTFIT Piping Solutions, Mumbai, India. Wire EDM was used to make a 20 mm × 10 mm × 2 mm substrate; then, it was polished with 600, 800, 1000, 2000, and 5000 grit silicon carbide (SiC) sheets to achieve a smooth surface. To eliminate surface residues, the polishing was followed by ultrasonic cleaning with acetone and distilled water for 15 min. After cleaning, the samples were sterilized (steam pressure for 15 min at 121 °C) and dried. Simultaneously, ZrO2 and Si-ZrO2 pellets were compressed using a 10 KN load and sintered at 950 °C for 5 h in a muffle furnace (Chennai Metco, Chennai, India). A base pressure of 3 × 10−6 mbar was used to develop ZrO2 and Si + ZrO2 coatings onto polished AZ91D substrates using Electron Beam Physical Vapor Deposition utilizing the MEB600 equipment provided by Plassys, Marolles-en-Hurepoix, France. The coating process parameters were maintained at a 300 °C substrate temperature, 8 kV voltage, and 1 Å/s deposition rate for all coatings. A quartz crystal-based digital thickness monitor, INFICON IC6 (Bad Ragaz, Switzerland) was used to measure coating thickness. A nano-scratch indenter (CSM Instruments, Peseux, Switzerland) was used to measure adhesive strength at the coating–substrate interface. The coated surface was loaded with a diamond indentor tip in reciprocal motion. Adhesion strength was investigated by determining the critical load at which the coating delaminated. In the experiment, detachment and crack formation in ZrO2 and Si + ZrO2 coatings were analyzed and observed by applying 1 N to 10 N loads using a diamond indenter (SMT 5000 scratch tester, San Jose, CA, USA).

Subsequently, sample morphology was inspected using a scanning electron microscope (ZEISS SUPRA 55, Carl Zeiss, Oberkochen, Germany), and the material’s presence was confirmed via quantitative elemental analysis in accordance with ASTM D4541. Phase analysis was carried out by utilizing X-ray diffraction (XRD- Bruker D8 Discover, Massachusetts, USA composed with a Cu Kβ radiation (λ = 1.5418 Å) source at 40 kV and 30 mA) employing a standard Bragg–Brentano focusing geometry from a 2θ range of 10° to 80° at a scanning speed of 10°/min. Surface roughness analysis of the coatings was performed using an NTEGRA PRIMA NTMTD Atomic Force Microscope (AFM), Amsterdam, The Netherlands. Concurrently, contact angle measurements were performed using a drop shape analysis system (DSA 10Mk2, KRÜSS, Germany) in water and serum solution to assess hydrophilicity. At ambient temperature, 2 μL of DI water and serum was carefully used on each sample surface. The liquid–sample interaction was determined by measuring the droplets’ contact angle using DSA software V1.9 after an immersion period of 30 s. Further, artificial blood plasma (ABP) electrolyte solution was used to study the electrochemical behavior (GAMRY INSTRUMENTS, Warminster, PA, USA) of coated and uncoated samples at ambient temperatures. ABP solution included NaCl (6.8 g/L), CaCl2 (0.200 g/L), KCl (0.4 g/L), MgSO4 (0.1 g/L), NaHCO3 (2.2 g/L), Na2HPO4 (0.126 g/L), and NaH2PO4 (0.026 g/L). Standard 3-electrode cell systems with 1 cm2 exposed areas were used for electrochemical tests. Three sets of each sample were immersed in the solution for 60 min to obtain a steady state and to determine the open-circuit potential (OCP). After stabilization, electrochemical impedance spectroscopy (EIS) was performed from 100 kHz to 10 mHz at 10 mV/s. After the EIS analysis, potentiodynamic polarization (PDP) tests were conducted at a scan rate of 10 mVs−1 in a potential range of ±250 mV. Tafel plot analysis revealed corrosion potential (Ecorr), current density (Icorr), and corrosion rate. Additionally, SEM, EDS and XRD analyses were performed on the corroded samples to comprehend the underlying corrosion mechanism.

Additionally, the antibacterial behavior of the samples was analyzed using Staphylococcus aureus. Initially, these bacteria were incubated overnight and then diluted in 0.9 wt% NaCl solution to reach a concentration of 1.5 × 108 bacteria. Then, the samples were tested for bactericidal activity by applying 50 μL of diluted bacterial solution to the test samples and incubating at 37 °C for 1 h in a shaking incubator. Incubated samples were differentiated into live/dead cells. For 3 min at room temperature, 20 μL of acridine orange (AO) was added to the incubated samples. The samples were examined with an Epifluorescence microscope (Nikon Eclipse, E600, Thermo Fisher Scientific, Waltham, MA, USA) after excess AO was eliminated. Additionally, human dermal fibroblast cells were grown in MEM (Minimum Essential Medium) with 10% FBS, 200 mM Glutamine, 2 mg mL−1 sodium bicarbonate and 1x antibiotic–antimycotic solution. After 15 min of UV irradiation, the sterilized samples were placed on 12-well plates for the MTT test to measure cell growth. Dermatological fibroblast cells were seeded at 0.5 × 106 per well in MEM with 10% FBS and incubated at 37 °C in 5% CO2 for 24 h. MTT solution was added to serum-free medium and incubated at 37 °C for 4 h. A spectrophotometer (ULTRA SPEC 2100 pro, Amersham Life Sciences, Buckinghamshire, UK) evaluated formazan crystals dissolved in DMSO at 570 nm. After incubation, the cells were fixed with 20% paraformaldehyde and stained with AO for 5 min. The cells were observed under an Epifluorescence microscope (Nikon Eclipse, E600). The experimental conditions were replicated three times to ensure consistency.

3. Results and Discussion

3.1. Structural and Morphological Analysis

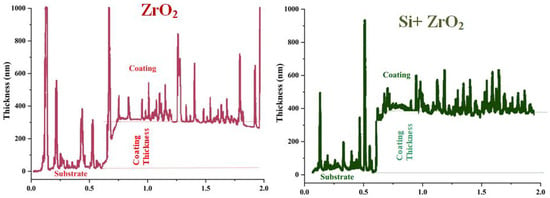

A quartz crystal-based digital thickness monitor was used to measure the frequency change of a quartz crystal as the coating was applied. The frequency change is proportional to coating thickness. By measuring the frequency shift, coating thickness can be accurately measured. The measurements indicated that the ZrO2 coating on the AZ91D substrate had an average thickness of 330 nm, whereas the Si + ZrO2 coating showed an average thickness of 390 nm. The observations suggest that both coatings were evenly spread over the entire surface of the substrate, as depicted in Figure 1. The even distribution of the coatings indicates a uniform deposition process, which is essential for ensuring the reliability and efficacy of the coatings in real-world applications. X-ray diffraction patterns of AZ91D (base material), ZrO2, and Si + ZrO2-coated samples are presented in Figure 2, and all the peaks were validated with standard JCPDS files. The AZ91D alloy consists of α-Mg (JCPDS file no. 35-0821) and β-phases (Mg17Al12, JCPDS file no. 01-1128), the diffraction peaks of 2 theta (crystallographic Miller indices) appear at 32.2 (100), 34.4 (002), 36.6 (101), 47.8 (102), 63.1 (103), 68.6 (112), 72.5 (004) and 81.5 (104), respectively [34]. Zhu et al. reported the diffraction peaks of Mg and Mg17Al12 and suggested that the surface of AZ91D magnesium alloy could be covered by magnesium hydroxide (Mg(OH)2, JCPDS file no. 76-0667) (before heating, 8.8° (110), 51° (012), 38° (011) and 18.6° (001)) and MgO (after heating, 73.2° (004), 70.9° (201), 69.4° (112), 68.1° (200), 63.7° (103), 58° (110), 48.3° (102), 37° (101), 34.7° (002) and 32.5° (100)) [35]. From the result, it is observed that the intensity of the diffraction peaks regarding AZ91D are lowered compared with ZrO2 and Si + ZrO2 coated samples.

Figure 1.

Coating thickness comparison between ZrO2 (Pink) and Si + ZrO2 (Green).

Figure 2.

XRD patterns representing the AZ91D substrate, ZrO2 coating, and Si + ZrO2 coating samples.

In specific, the silica-coated substrate (Si + ZrO2 coating) possessed the highest peak intensities at the position of 15–23°, confirming the inclusion of silica, which has a crystal orientation [36]. Figure 2 shows the highest intensity peaks at 2θ of 69.4° (100) and 75°, indicating the presence of a high concentration of silica [37,38]. Moreover, the diffraction peaks of silica were not found in other samples. The diffraction peaks of zirconia oxides were found to be at 34.9° (002), 35.85° (101), 57.7° (−311), and 58.1° (221), respectively [39]. The results imply that the peak intensity of AZ91D at 34–37° degrees increased, which might be due to the inclusion of zirconia. In addition, zirconia has sharp, high-intensity peaks, signifying its crystalline structure, whereas silica is amorphous, having broader peaks within a certain angle range. In both coatings, tetragonal zirconia is the main phase, while amorphous silica is secondary. Additionally, increased voltage causes the total decomposition of molten particles of ZrO2 and SiO2. The decomposition results in the formation of Zr and Si, which combine to form zirconium disilicate. Since Mg and Al peaks are observed in the coating due to deep X-ray penetration, which amplifies substrate peaks. Additionally, detecting reidite in the ZrO2 coating may imply anomalous circumstances or high pressure, resembling impact environments, perhaps suggesting significant alterations in the zirconia structure caused by the aging process. However, Si has stabilized zirconia over hydrothermal aging, inhibiting reidite production and favoring the development of magnesium zirconium disilicate.

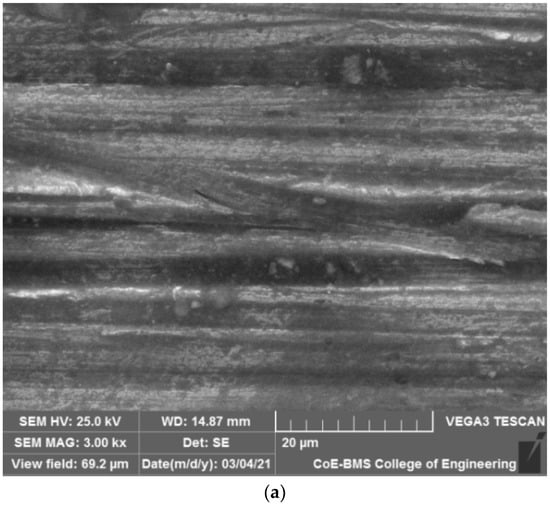

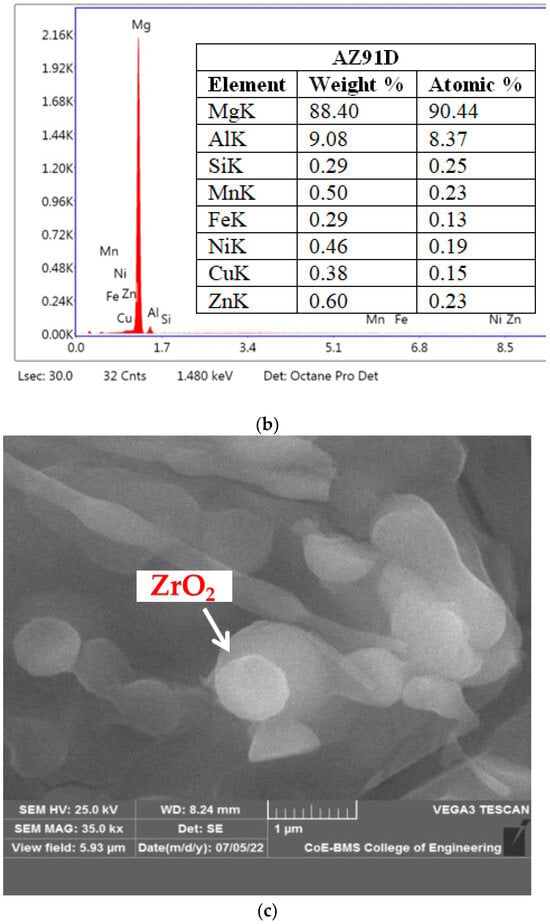

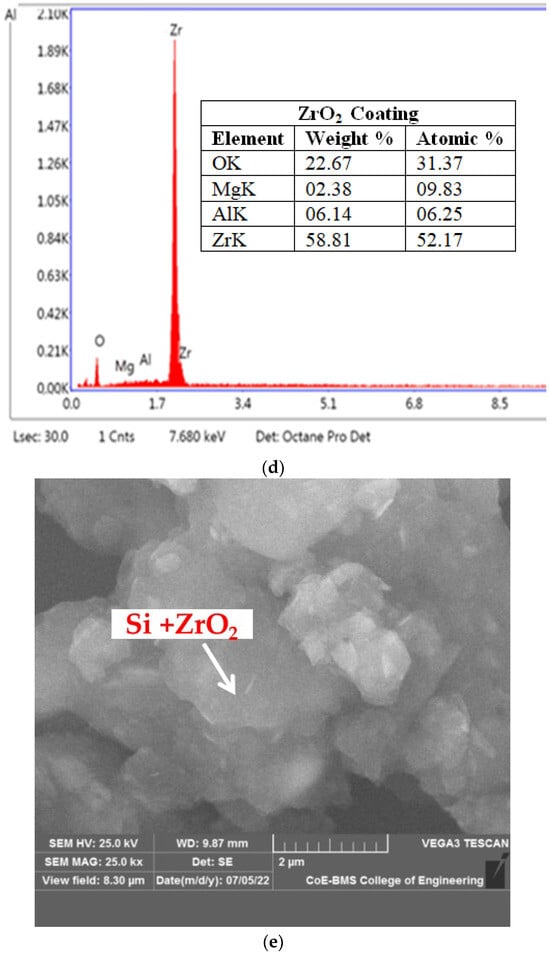

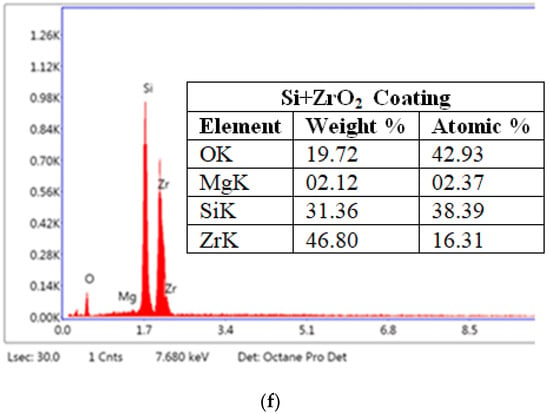

Top view morphologies of coated and uncoated AZ91D are shown in Figure 3a–c. The topographic view of ZrO2 and Si + ZrO2 coating exhibited a uniform homogeneous distribution of particles, and no voids were observed. On increasing beam current, a greater deposition of bioceramic particles on the substrate was detected. Figure 3c shows the deposition of spherical-like particles of ZrO2 on the surface, whilst Figure 3e shows the agglomeration of SiO2 + ZrO2 particles, which is consistent with the XRD results. The purity of the obtained AZ91D sample was confirmed through the utilization of EDS elemental values (Figure 3b).

Figure 3.

SEM images of the uncoated sample (a) AZ91D, (c) ZrO2-coated sample, and (e) Si + ZrO2-coated sample and EDS images of (b) AZ91D and (d) ZrO2-coated sample and (f) Si + ZrO2 coated sample.

Likewise, both the coated samples (Figure 3d,f) exhibited the characteristic peaks corresponding to Zr, Si, and O. Mg and Al peaks are observed in the coating due to deep X-ray penetration, which amplifies substrate peaks.

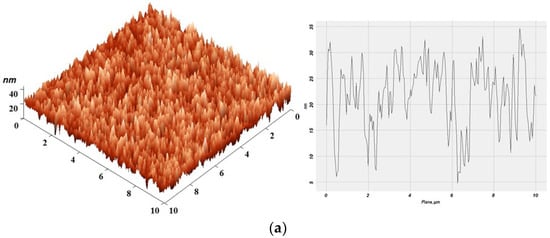

The topographical characteristics of coated and uncoated samples were analyzed using the AFM images, as shown in Figure 4. There was a 20–30% increase in surface roughness of the coated samples compared to uncoated samples, as determined by the average surface roughness of AZ91D, ZrO2, and Si + ZrO2 samples, which were 5.21 nm, 6.35 nm, and 6.85 nm, respectively. The visibility of micropores in the coating is a result of the implosions of gas bubbles. A rougher surface is produced when SiO2 forms on the substrate due to the increase in the oxide layer’s electrical resistance, which in turn requires more discharge energy [40]. However, the entire coated sample’s average surface roughness values were controlled to less than 10 nm through optimized coating process parameters and the purity of the coating materials.

Figure 4.

AFM images of the uncoated sample and (a) AZ91D, (b) ZrO2-coated sample, and (c) Si + ZrO2-coated sample.

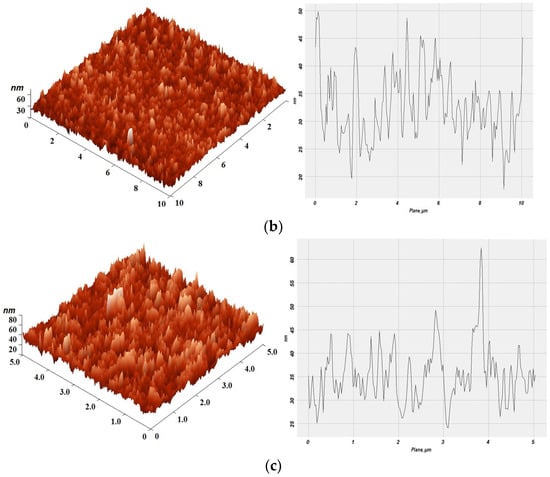

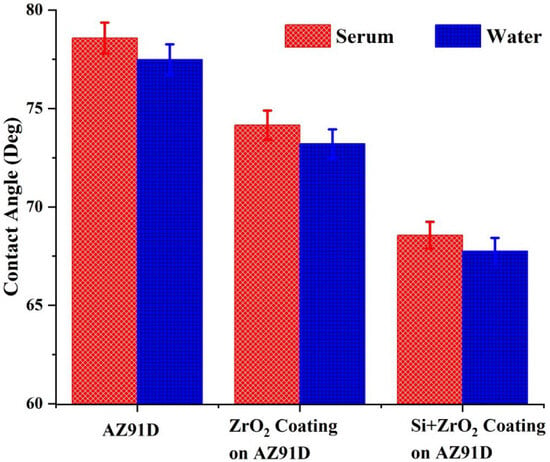

In biological applications, the hydrophilicity of an implant’s surface is an essential surface property because it encourages cell attachment and proliferation. The water and serum contact angles of the coated and uncoated samples are plotted in Figure 5. The AZ91D, ZrO2, and Si + ZrO2 sample surfaces exhibited average water contact angles of 78.58°, 74.14°, and 68.56°, respectively. Likewise, The AZ91D, ZrO2, Si + ZrO2 sample surfaces exhibited average serum contact angles of 77.48°, 73.21°, and 67.75°, respectively. The results indicate that the addition of silica greatly enhanced the wettability in both water and serum solutions as compared to the zirconia coating. Indeed, the presence of silanol groups on the surface of silica facilitates hydrogen bonding with water molecules. These polar interactions lead to an increase in the surface energy of silica, enhancing its attraction towards water and making it hydrophilic. Altogether, enhanced surface hydrophilicity of the implant facilitates the process of osseointegration, protein adhesion, and bone interaction [41].

Figure 5.

Contact angle of the samples in serum and water medium.

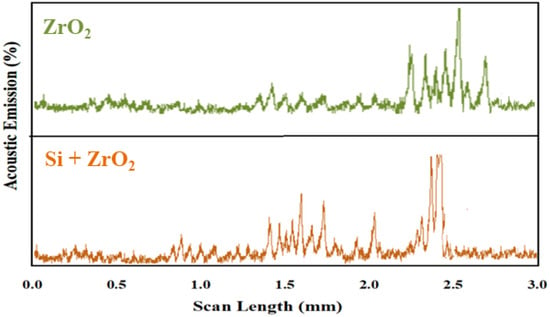

Figure 6 shows how acoustic signals indicate coating adhesion behavior under mechanical stress. Acoustic signals indicating coating deformation began at different load points for each coating. The ZrO2 coating exhibited these signals at 7.1 N, whereas the Si + ZrO2 coating showed similar signals at 6.5 N. The subtle differences in load threshold could be associated with a slight variation in coating thickness (~60 nm), influencing the adhesion properties, although the impact might be marginal. Further investigations correlating these acoustic signals with adhesion strength would provide additional insights into the influence of composition on coating performance.

Figure 6.

Scratch resistance curve comparison between ZrO2 (green) and Si + ZrO2 (Brown) coating.

3.2. In Vitro Corrosion Behavior

Figure 7 exhibits potentiodynamic polarization curves, while Table 1 gives the electrochemical parameters derived from these curves. To ensure the accuracy of the results, the polarisation test was repeated three times for each sample under identical conditions. Each repetition achieved consistent and satisfactory results. The results indicate that the use of a composite coating applied by the EBPVD process significantly improves the corrosion resistance of the AZ91D substrate. The corrosion current density (Icorr) values observed for AZ91D, ZrO2, and Si + ZrO2 were 379.31, 0.940, and 0.10 μA cm−2, respectively. The corrosion potential (Ecorr) values for AZ91D, ZrO2, and Si + ZrO2 were determined to be −1.47, −1.25, and −1.15 V, respectively. The Si + ZrO2 sample had a significant increase in Ecorr and a decrease in Icorr in its potentiodynamic polarization curve, suggesting enhanced resistance to corrosion compared to the other samples. The corrosion rate of the samples mentioned in Table 1 clearly indicated that both coatings have offered substrate protection of 99% and above. Moreover, higher amounts of βa (349 mV) in the composite coating sample suggest superior corrosion resistance due to the growth of an additional resistant layer on the underlying material. In addition, the porosity of the coating layer calculated from potentiodynamic polarization and Equation (1) suggested a substantial decrease in the Si + ZrO2 composite (0.25%) as compared to the ZrO2 sample (0.65%), indicating a decrease in the coating layer’s surface defects [30].

Figure 7.

Tafel plot of the samples in ABP solution.

Table 1.

Corrosion response of coated and uncoated samples.

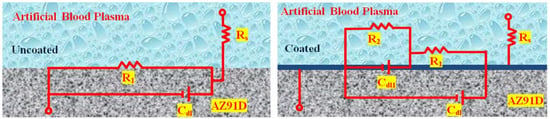

Further, the corrosion resistance of the samples was assessed using electrochemical impedance spectroscopy (EIS) with Nyquist plots, as shown Figure 8. The use of the EBPVD coating significantly enhanced the corrosion resistance of the composite coating, as shown by the considerable increase in the Rct values (Table 1). More precisely, the Rct values increased from 151 Ω (AZ91D) to 4.3 KΩ (ZrO2) and 5.2 KΩ (Si + ZrO2), indicating a substantial improvement in the coating’s corrosion resistance. Furthermore, the exceptional performance of resistance, exceeding 96% in both coatings, confirms the excellent resistance efficacy of the coatings, showing the effective sealing of surfaces, with fewer pores, strong adherence to the substrate, and uniform dispersion across the whole surface area. The coatings possess these qualities, which together enable them to effectively prevent the penetration of corrosive substances, thereby strengthening the corrosion barrier. The EIS plots revealed the equivalent circuit for both coated and uncoated samples, which is shown in Figure 9. This circuit consists of Rs, R1(Cdl), and R2(Cdl1), representing the solution resistance along with two resistances and capacitors connected in series. The circuit schematic indicates the existence of R1 and Cdl, which represents the resistance and double-layer capacitance of the uncoated AZ91D substrate. Rs denotes the electrolyte resistance of ABP, which is equivalent to the ohmic resistance. R2 and Cdl1 denote the electrical resistance and the capacitance of the double layer for coatings made of ZrO2 and Si + ZrO2.

Figure 8.

Nyquist plot of the samples in ABP solution.

Figure 9.

Equivalent circuits of uncoated and coated samples.

Furthermore, the scanning electron microscope (SEM) images of corroded AZ91D samples (as shown in Figure 10a) reveal many interlinked cracks on the surface of the substrate, indicating severe corrosion. The exfoliation should be induced by the infiltration of the solution via cracks. Furthermore, the metal surface has experienced corrosion all over, with the presence of surface pitting observed at various locations. After contacting an aqueous solution, magnesium undergoes a chemical reaction resulting in the formation of magnesium hydroxide and/or chloride on its surface. Nevertheless, the porous nature of this layer makes it incapable of shielding the alloy from corrosion when exposed to a corrosive solution containing Cl−. Figure 10c indicates that the weight percentage of chlorine content in the composite coating is 4.02%, which is almost 50% compared with AZ91D (8.93%) and zirconia coating (8.02%). SEM images of both coated samples were less impacted in the ABP solution (Figure 10b,c), indicating that the coating effectively mitigated heavy cracks and micropores, performing as a protective barrier against corrosion and resulting in a more stable surface.

Figure 10.

SEM and EDS images of the uncoated sample and (a) AZ91D, (b) ZrO2-coated sample, and (c) Si + ZrO2 coated sample.

Likewise, coating a metal alloy suppresses the anodic dissolution process of magnesium/OH− ions (due to an increase in pH above 9) and inhibits the robust release of metal ions into the environment, indicating coating prevents primary corrosion. Figure 11 shows the diffraction pattern of zirconia-coated magnesium alloy after corrosion evaluation. The peak intensity of Si and ZrO2 increased compared to the peak intensity of AZ91D and the synergistic effect of the composite-coated sample showed excellent corrosion resistance. In addition, the strong intensified peak at 2θ = 38° increased compared to silica and zirconia peak intensity. This might be due to the formation of Mg(OH)2 crystallites found at 2θ of 38° (JCPDS card no. 00-007-0239), which is in accordance with Saoud et al. [42].

Figure 11.

XRD patterns representing the corrosion effects on AZ91D, ZrO2 coating, and Si + ZrO2 coating samples.

In immersed samples, there is a chance of calcium phosphate precipitation on the surface of the implant, indicating that the zirconia and silica coating slightly increased the deposition of hydroxyapatite on the surface. Kazemi et al. anticipated that the amorphous nature of zirconia leads to an increase in porosity and bioactivity in the physiological environment [43]. The XRD results confirmed the presence of silica + zirconia on the magnesium alloy substrate after the corrosion test.

4. Bacterial Activity

The bacterial adhesion of coated and uncoated samples was investigated using Staphylococcus aureus bacteria. Figure 12 shows epifluorescence micrographs of Staphylococcus aureus bacterial adhesion on uncoated bare AZ91D and composite-coated specimens, where the live and dead cells were determined by orange (when AO binds with RNA indicating live cells)/green emission (when AO intercalates with DNA indicating dead cells) from cells. After 24 h of incubation (Figure 12), the ZrO2-coated sample showed green color fluorescence, indicating antibacterial efficiency (i.e., higher density of bacterial death cells). The coated and uncoated AZ91D substrates display green fluorescence when exposed to Gram-positive Staphylococcus aureus. In contrast, Si + ZrO2 composite-coated AZ91D exhibits both green and orange fluorescence in the presence of Gram-positive bacteria. The Si + ZrO2 sample showed more greenish marks, indicating more death of bacterial colonies, resulting in higher antibacterial efficacy against pathogens.

Figure 12.

Antibacterial activity of uncoated and coated AZ91D samples.

The inclusion of silica increased the antibacterial effect compared to ZrO2. The silicate group could electrostatically interact with bacterial cell walls and migrate and destroy the bacterial cell system. Moreover, Kaliaraj et al. reported that positively charged zirconia ions decrease cell adhesion and antibacterial efficacy compared with the inclusion of silica due to strong repulsion between zirconia and Gram-positive bacteria [32]. Kalaiyarasan et al. anticipated that bacterial colonies on the bare Mg decrease (i.e., dissolution of Mg2+) and increase local pH during the corrosion process, which increases the antibacterial effect [6]. Vishwakarma et al. reported that the functional groups of AO could electrostatically bind with phosphate domains of RNA of bacteria; it emits orange fluorescence [44]. In contrast, green fluorescence is emitted when AO intercalates with DNA phosphates. This outcome signifies that the inclusion of silica enhanced the antibacterial activity against Gram-positive bacteria in comparison to both bare AZ91D and ZrO2-coated samples.

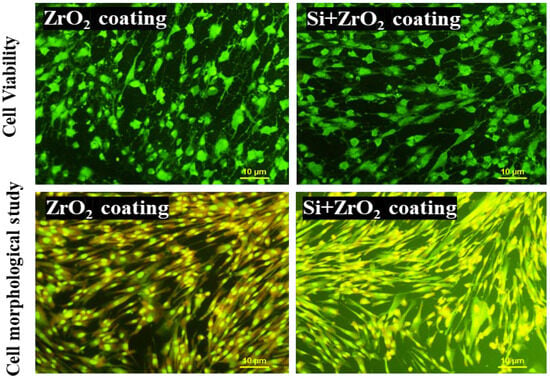

5. Cell Morphology and In Vitro Biocompatibility Evaluation

The biocompatibility of the coated and uncoated AZ91D alloy was evaluated via cytotoxicity assay, summarized in Figure 13, and the cell morphology of the fibroblast cells is exemplified in Figure 14. The coated metal alloys were subjected to fibroblast cells and assessed using the MTT assay after 24 h, 48 h and 72 h of culture, respectively. Figure 14 reveals that most fibroblast cells adhere to the surface of the substrate, exhibiting a spindle-shaped morphology. The cell viability was found to be nearly 75–90%, indicating that all the samples are biocompatible, which is coincident with the inferred biocompatibility. The obtained results showed a significant statistical difference of AZ91D (p = 0.0024), ZrO2, (p = 0.0009), Si + ZrO2 (p = 0.0001), at 28 h, 72 h, 196 h of incubation. In the initial stage, there was no notable distinction in either cell viability or OD values. After 48 h of immersion, the absorbance of Si + ZrO2-coated AZ91D was higher than that of other coated samples, and the inclusion of silica with ZrO2 coated on alloy increased L929 cell proliferation. Shi et al. revealed that local alkalization of Mg2+ ions could exert a negative impact on cells [45]. As discussed in the section (antibacterial), the dissolution of Mg2+ ions could increase the pH over a prolonged incubation period. Peron et al. had anticipated that too high pH can affect the fibroblast cell viability (i.e., pH greater than 9), which, in turn, increases the amount of hydroxide ions during the corrosion process, and the study suggested that coated magnesium alloy could mechanistically prevent corrosion and increase viability [46].

Figure 13.

Cell viability (% of control sample) of L929 fibroblast cells incubated on bare and coated AZ91D alloy for 24 h, 48 h and 72 h, respectively. The (*) displays the difference is statistically significant at p < 0.05 (Data represent the Mean ± Standard deviation of AZ91D, ZrO2, Si + ZrO2).

Figure 14.

Epifluorescence images of fibroblast cell morphological and viability study on ZrO2 and Si + ZrO2-coated AZ91D alloy.

Furthermore, Rodrigues et al. clarified that the reduction in H2 evolution during the dissolution of magnesium and formation of Mg(OH)2 (as discussed in XRD) may lead to the formation of subcutaneous bubbles, consequently impeding cell adhesion [47]. Moreover, the surface coating of silica and zirconia oxide on magnesium alloy could control the dissolution of the alloy and maintain higher O.D. values. Hence, the cytocompatibility was found to be favorable in Si + ZrO2-coated Mg alloys compared with other samples.

6. Conclusions

In this article, the effect of biocompatible silica and zirconia coatings on magnesium alloy (AZ91D) using the electron beam physical vapor deposition method was investigated. The bioceramic coatings improved the functionality of substrates due to multiple compositions and electrostatic interactions with biological systems, which promote compatibility. Moreover, the biocompatible coating also contributed to the weak adhesion of pathogens and minimized adverse reactions. Controversially, coating using electric energy (i.e., physical vapor deposition) provides a uniform coating with optimum thickness and good adhesion of film on the magnesium substrate. The following results were obtained,

- ✓ The cell adhesion and viability of fibroblast cells were found to be higher on the surface of Si + ZrO2 composite coating, which might be due to the increased hydrophilicity in the addition of silica particles or ZrO2 surface alone exhibits low surface interaction with hydroxyl groups (OH).

- ✓ Moreover, the inclusion of silica with ZrO2 increased the antibacterial efficacy of AZ91D. The results of corrosion (almost 96% excellent resistance efficacy) and antibacterial efficacy of the coated magnesium alloy substrate were strongly influenced by the silica/zirconia oxide coatings and played a conclusive role in corrosion behavior by suppressing the anodic dissolution process of magnesium/OH- ions.

- ✓ Overall, the application of vapor deposition coatings on AZ91D magnesium alloy resulted in an improvement of biological characteristics and enhanced corrosion resistance.

7. Future Work

In the future, a comprehensive investigation of the long-term biocompatibility and mechanical stability of the coated substrates under physiological conditions will be carried out. Further, investigating the impact of various coating compositions and thicknesses on the overall performance of the magnesium alloy will also be a priority. This will aid in cultivating a thorough understanding of the optimal utilization of biocompatible coatings for medical implant applications.

Author Contributions

Conceptualization, M.G. and A.T.; methodology, M.G. and A.T.; software, R.M.; validation, A.T. and R.M.; formal analysis, A.T.; investigation, A.T.; resources, M.G.; data curation, R.M.; writing—original draft preparation, A.T. and R.M.; writing—review and editing, M.G.; visualization, R.M.; supervision, M.G.; project administration, M.G.; funding acquisition, M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work is partially funded by Center for Additive Manufacturing, Chennai Institute of Technology, India vide funding number CIT/CAM/2024/RP/009.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The work of one of the authors gratefully acknowledges the kind support rendered by the Centre for Additive Manufacturing, Chennai Institute of Technology, India and the Department of Mechanical Engineering, National University of Singapore, Singapore.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Azzeddine, H.; Hanna, A.; Dakhouche, A.; Luthringer-Feyerabend, B. Corrosion behaviour and cytocompatibility of selected binary magnesium-rare earth alloys. J. Magnes. Alloys 2021, 9, 581–591. [Google Scholar] [CrossRef]

- Bairagi, D.; Mandal, S. A comprehensive review on biocompatible Mg-based alloys as temporary orthopaedic implants: Current status, challenges, and future prospects. J. Magnes. Alloys 2022, 10, 627–669. [Google Scholar] [CrossRef]

- Siefen, S.; Höck, M. Development of magnesium implants by application of conjoint-based quality function deployment. J. Biomed. Mater. Res. Part A 2019, 107, 2814–2834. [Google Scholar] [CrossRef] [PubMed]

- Ling, C.; Li, Q.; Zhang, Z.; Yang, Y.; Zhou, W.; Chen, W.; Dong, Z.; Pan, C.; Shuai, C. Influence of heat treatment on microstructure, mechanical and corrosion behavior of WE43 alloy fabricated by laser-beam powder bed fusion. Int. J. Extrem. Manuf. 2023, 6, 015001. [Google Scholar] [CrossRef]

- Liu, W.; Guo, S.; Tang, Z.; Wei, X.; Gao, P.; Wang, N.; Li, X.; Guo, Z. Magnesium promotes bone formation and angiogenesis by enhancing MC3T3-E1 secretion of PDGF-BB. Biochem. Biophys. Res. Commun. 2020, 528, 664–670. [Google Scholar] [CrossRef] [PubMed]

- Kalaiyarasan, M.; Pugalmani, S.; Rajendran, N. Fabrication of chitosan/silica hybrid coating on AZ31 Mg alloy for orthopaedic applications. J. Magnes. Alloys 2023, 11, 614–628. [Google Scholar] [CrossRef]

- Zhang, E.; Zhao, X.; Hu, J.; Wang, R.; Fu, S.; Qin, G. Antibacterial metals and alloys for potential biomedical implants. Bioact. Mater. 2021, 6, 2569–2612. [Google Scholar] [CrossRef] [PubMed]

- Ferraris, S.; Spriano, S. Antibacterial titanium surfaces for medical implants. Mater. Sci. Eng. C 2016, 61, 965–978. [Google Scholar] [CrossRef] [PubMed]

- Nobles, K.P.; Janorkar, A.V.; Williamson, R.S. Surface modifications to enhance osseointegration–Resulting material properties and biological responses. J. Biomed. Mater. Res. Part B Appl. Biomater. 2021, 109, 1909–1923. [Google Scholar] [CrossRef]

- Subramani, K.; Jung, R.E.; Molenberg, A.; Hämmerle, C.H.F. Biofilm on dental implants: A review of the literature. Int. J. Oral Maxillof. Implant. 2009, 24, 616–626. [Google Scholar]

- Wang, C.; Yi, Z.; Sheng, Y.; Tian, L.; Qin, L.; Ngai, T.; Lin, W. Development of a novel biodegradable and anti-bacterial polyurethane coating for biomedical magnesium rods. Mater. Sci. Eng. C 2019, 99, 344–356. [Google Scholar] [CrossRef] [PubMed]

- Berni, M.; Lopomo, N.; Marchiori, G.; Gambardella, A.; Boi, M.; Bianchi, M.; Visani, A.; Pavan, P.; Russo, A.; Marcacci, M. Tribological characterization of zirconia coatings deposited on Ti6Al4V components for orthopedic applications. Mater. Sci. Eng. C 2016, 62, 643–655. [Google Scholar] [CrossRef] [PubMed]

- Aati, S.; Akram, Z.; Ngo, H.; Fawzy, A.S. Development of 3D printed resin reinforced with modified ZrO2 nanoparticles for long-term provisional dental restorations. Dent. Mater. 2021, 37, e360–e374. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, H.; Zhang, J.; Zhao, W.; Shen, J.; Jiang, D. In vitro evaluation of an yttria-stabilized zirconia reinforced nano-hydroxyapatite/polyamide 66 ternary biomaterial: Biomechanics, biocompatibility and bioactivity. RSC Adv. 2016, 6, 114086–114095. [Google Scholar] [CrossRef]

- Sollazzo, V.; Pezzetti, F.; Scarano, A.; Piattelli, A.; Bignozzi, C.; Massari, L.; Brunelli, G.; Carinci, F. Zirconium oxide coating improves implant osseointegration in vivo. Dent. Mater. 2008, 24, 357–361. [Google Scholar] [CrossRef] [PubMed]

- Das, I.; Chattopadhyay, S.; Mahato, A.; Kundu, B.; De, G. Fabrication of a cubic zirconia nanocoating on a titanium dental implant with excellent adhesion, hardness and biocompatibility. RSC Adv. 2016, 6, 59030–59038. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, L.; Yao, X.; Hang, R.; Zhang, X.; Tang, B. Corrosion behavior of porous ZrO2 ceramic coating on AZ31B magnesium alloy. Surf. Coat. Technol. 2018, 349, 434–441. [Google Scholar] [CrossRef]

- Siddiqui, D.A.; Jacob, J.J.; Fidai, A.B.; Rodrigues, D.C. Biological characterization of surface-treated dental implant materials in contact with mammalian host and bacterial cells: Titanium versus zirconia. RSC Adv. 2019, 9, 32097–32109. [Google Scholar] [CrossRef]

- de Araújo-Júnior, E.N.; Bergamo, E.T.; Campos, T.M.; Jalkh, E.B.B.; Lopes, A.C.; Monteiro, K.N.; Cesar, P.F.; Tognolo, F.C.; Tanaka, R.; Bonfante, E.A. Hydrothermal degradation methods affect the properties and phase transformation depth of translucent zirconia. J. Mech. Behav. Biomed. Mater. 2020, 112, 104021. [Google Scholar] [CrossRef]

- Ahmed, S.; Zou, L.; Yan, H. Stability of 3Y-TZP nano zirconia powder after hydrothermal ageing treatment. Adv. Appl. Ceram. 2022, 121, 159–165. [Google Scholar] [CrossRef]

- Kohal, R.-J.; Trinkner, A.; Burkhardt, F.; Patzelt, S.B.M.; Vach, K.; Kušter, M.; Abram, A.; Kocjan, A.; Nold, J. Long-Term Stability of Hydrothermally Aged and/or Dynamically Loaded One-Piece Diameter Reduced Zirconia Oral Implants. J. Funct. Biomater. 2023, 14, 123. [Google Scholar] [CrossRef] [PubMed]

- Amarante, J.E.V.; Pereira, M.V.S.; De Souza, G.M.; Alves, M.F.R.P.; Simba, B.G.; dos Santos, C. Effect of hydrothermal aging on the properties of zirconia with different levels of translucency. J. Mech. Behav. Biomed. Mater. 2020, 109, 103847. [Google Scholar] [CrossRef] [PubMed]

- Deville, S.; Chevalier, J. Martensitic Relief Observation by Atomic Force Microscopy in Yttria-Stabilized Zirconia. J. Am. Ceram. Soc. 2003, 86, 2225–2227. [Google Scholar] [CrossRef]

- Al-Radha, A.S.D.; Dymock, D.; Younes, C.; O’Sullivan, D. Surface properties of titanium and zirconia dental implant materials and their effect on bacterial adhesion. J. Dent. 2012, 40, 146–153. [Google Scholar] [CrossRef]

- Soon, G.; Pingguan-Murphy, B.; Lai, K.W.; Akbar, S.A. Review of zirconia-based bioceramic: Surface modification and cellular response. Ceram. Int. 2016, 42, 12543–12555. [Google Scholar] [CrossRef]

- Nikoomanzari, E.; Fattah-Alhosseini, A.; Alamoti, M.R.P.; Keshavarz, M.K. Effect of ZrO2 nanoparticles addition to PEO coatings on Ti-6Al-4V substrate: Microstructural analysis, corrosion behavior and antibacterial effect of coatings in Hank’s physiological solution. Ceram. Int. 2020, 46, 13114–13124. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.; Hamzah, E.; Kasiri-Asgarani, M.; Saud, S.N.; Yaghoubidoust, F.; Akbari, E. Structure, corrosion behavior, and antibacterial properties of nano-silica/graphene oxide coating on biodegradable magnesium alloy for biomedical applications. Vacuum 2016, 131, 106–110. [Google Scholar] [CrossRef]

- Li, X.; Du, S.; Ma, C.; Shi, T.; Qi, W.; Yang, H. Nano-SiO2 based anti-corrosion superhydrophobic coating on Al alloy with mechanical stability, anti-pollution and self-cleaning properties. Ceram. Int. 2024, 50, 9469–9478. [Google Scholar] [CrossRef]

- Qiu, X.; Wan, P.; Tan, L.; Fan, X.; Yang, K. Preliminary research on a novel bioactive silicon doped calcium phosphate coating on AZ31 magnesium alloy via electrodeposition. Mater. Sci. Eng. C 2014, 36, 65–76. [Google Scholar] [CrossRef]

- Ahangari, A.; Mokhtarzade, A.; Mahmoodi, M. In vitro tribological behavior and corrosion resistance of SiO2/TiO2/ZrO2 coatings formed on the tantalum substrate using plasma electrolytic oxidation for orthopedic implant applications. Mater. Chem. Phys. 2023, 308, 128210. [Google Scholar] [CrossRef]

- Srinivasan, A.; Rajendran, N. Electrochemical Corrosion and In Vitro Bioactivity of SiO2:ZrO2-Coated 316L Stainless Steel in Simulated Body Fluid. J. Mater. Eng. Perform. 2015, 24, 3056–3067. [Google Scholar] [CrossRef]

- Kaliaraj, G.S.; Vishwakarma, V.; Alagarsamy, K.; Kirubaharan, A.M.K. Biological and corrosion behavior of m-ZrO2 and t-ZrO2 coated 316L SS for potential biomedical applications. Ceram. Int. 2018, 44, 14940–14946. [Google Scholar] [CrossRef]

- Rathee, G.; Bartwal, G.; Rathee, J.; Mishra, Y.K.; Kaushik, A.; Solanki, P.R. Emerging Multimodel Zirconia Nanosystems for High-Performance Biomedical Applications. Adv. NanoBiomed Res. 2021, 1, 2100039. [Google Scholar] [CrossRef]

- Li, S.; Sun, B. Preparation of corrosion-resistant surface of magnesium alloy and its performance study. Mater. Res. Express 2023, 10, 096402. [Google Scholar] [CrossRef]

- Zhu, J.; Jia, H.; Liao, K.; Li, X. Improvement on corrosion resistance of micro-arc oxidized AZ91D magnesium alloy by a pore-sealing coating. J. Alloys Compd. 2021, 889, 161460. [Google Scholar] [CrossRef]

- Imoisili, P.E.; Ukoba, K.O.; Jen, T.-C. Synthesis and characterization of amorphous mesoporous silica from palm kernel shell ash. Boletín Soc. Española Cerámica Vidr. 2020, 59, 159–164. [Google Scholar] [CrossRef]

- Barma, M.D.; Kannan, S.D.; Indiran, M.A.; Rajeshkumar, S.; Kumar, R.P. Antibacterial Activity of Mouthwash Incorporated with Silica Nanoparticles against S. aureus, S. mutans, E. faecalis: An in-vitro Study. J. Pharm. Res. Int. 2020, 32, 25–33. [Google Scholar] [CrossRef]

- Bošković, M.V.; Šljukić, B.; Radović, D.V.; Radulović, K.; Rafajilović, M.R.; Frantlović, M.; Sarajlić, M. Full-Self-Powered Humidity Sensor Based on Electrochemical Aluminum–Water Reaction. Sensors 2021, 21, 3486. [Google Scholar] [CrossRef] [PubMed]

- Fernández-González, D.; Piñuela-Noval, J.; Ruiz-Bustinza, Í.; González-Gasca, C.; Gómez-Rodríguez, C.; Quiñonez, L.V.G.; Fernández, A.; Verdeja, L.F. Solar dissociation of zirconium silicate sand: A clean alternative to obtain zirconium dioxide. J. Clean. Prod. 2023, 420, 138371. [Google Scholar] [CrossRef]

- Zehra, T.; Kaseem, M.; Hossain, S.; Ko, Y.-G. Fabrication of a Protective Hybrid Coating Composed of TiO2, MoO2, and SiO2 by Plasma Electrolytic Oxidation of Titanium. Metals 2021, 11, 1182. [Google Scholar] [CrossRef]

- Lee, S.S.; Huber, S.; Ferguson, S.J. Comprehensive in vitro comparison of cellular and osteogenic response to alternative biomaterials for spinal implants. Brain Spine 2021, 1, 100006. [Google Scholar] [CrossRef]

- Saoud, K.M.; Ibala, I.; El Ladki, D.; Ezzeldeen, O.; Saeed, S. Microwave Assisted Preparation of Calcium Hydroxide and Barium Hydroxide Nanoparticles and Their Application for Conservation of Cultural Heritage. Lect. Notes Comput. Sci. 2014, 8740, 342–352. [Google Scholar] [CrossRef] [PubMed]

- Kazemi, S.; Ghamsarizade, R.; Yazdani, S.; Mohammadloo, H.E.; Yeganeh, H. The combined effect of hydroxyapatite and zirconia coatings on magnesium-based-implant to improve corrosion resistance and induce antibacterial activity. J. Alloys Compd. 2024, 971, 172790. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Josephine, J.; George, R.P.; Krishnan, R.; Dash, S.; Kamruddin, M.; Kalavathi, S.; Manoharan, N.; Tyagi, A.K.; Dayal, R.K. Antibacterial copper–nickel bilayers and multilayer coatings by pulsed laser deposition on titanium. Biofouling 2009, 25, 705–710. [Google Scholar] [CrossRef]

- Shi, L.; Chen, S.; Shahzad, M.B.; Wei, Z.; Leng, B. Enhanced corrosion resistance and biocompatibility of an elastic poly (butyleneadipate-co-terephthalate) composite coating for AZ31 magnesium alloy vascular stents. Prog. Org. Coat. 2022, 172, 107138. [Google Scholar] [CrossRef]

- Peron, M.; Bertolini, R.; Cogo, S. On the corrosion, stress corrosion and cytocompatibility performances of ALD TiO2 and ZrO2 coated magnesium alloys. J. Mech. Behav. Biomed. Mater. 2022, 125, 104945. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, J.d.S.; Antonini, L.M.; Bastos, A.A.d.C.; Zhou, J.; Malfatti, C.d.F. Corrosion resistance and tribological behavior of ZK30 magnesium alloy coated by plasma electrolytic oxidation. Surf. Coat. Technol. 2021, 410, 126983. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).