Abstract

In the present study, the influence of the Zn content (0.0, 0.5, 1.0, and 2.0 wt.%) on the microstructure, texture, tensile mechanical properties and formability of Mg-1.0Sn-0.5Ca-based alloys after extrusion were investigated via extrusion of Mg sheets and analysis of the extruded materials. Adding Zn improved the microstructure uniformity and accelerated the formation of more CaMgSn and the Ca2Mg6Zn3 phase. In addition, after the addition of Zn, the texture evolved from the initial extrusion direction tilted bimodal texture to a weakened and symmetrical texture. Compared with the Mg-1.0Sn-0.5Ca alloy, the average tensile yield strength and elongation values were simultaneously improved after 0.5 wt.% Zn addition due to the synergistic effect of the solid solution of elemental Zn, the decreased amount of coarse unrecrystallized grains, and the existence of an additional tilted direction texture component. The formability first increased and then decreased with increasing Zn content. In contrast, the deterioration of formability after the further addition of Zn was closely associated with the increased volume fractions of the coarse CaMgSn and Ca2Mg6Zn3 phases.

1. Introduction

Magnesium (Mg) alloys, due to their low density, high specific strength, high electromagnetic shielding performance, high elastic modulus, and relative friendliness to the environment, have been widely employed in the aerospace, electronics, and automobile industries, as well as other fields [1,2,3,4,5]. However, shortcomings such as insufficient strength, poor plasticity, and formability of magnesium alloys seriously hinder their further extensive application and marketing promotion [6,7,8]. Appropriate alloying is a simple and effective method that can greatly improve the mechanical properties of Mg alloys by refining grains, strengthening precipitates, and modifying texture [9,10]. Among many Mg alloy systems, Mg-Sn-based alloys stand out and have received continuous attention due to their cost advantage [9], excellent creep resistance [11], and undemanding extrusion conditions [12,13].

With an acceptable price, Ca is widely used in magnesium alloys to refine grains and reduce texture [6,14]. Adding Ca into magnesium alloys can improve the metallurgical quality and creep resistance and reduce the flammability of alloys by forming a CaO protective film. In particular, Pan et al. [11,15] indicated that Mg-2 wt.% Sn alloy with the addition of 2 wt.% Ca finally has an extremely high tensile yield strength (440 MPa), which they mainly attributed to the submicron grain size (which is related to the segregation of solid solution Ca elements and the precipitation of nanometer Mg2Ca). According to the Mg-Ca binary phase diagram, the solid phase solubility of Ca in Mg is small, and the maximum solid solubility is only 1.34 wt.% at 516.5 K. Hence, in the Mg-Sn binary alloy, the Sn/Ca ratio seriously affects the composition of the ultimate second phase. Generally, the CaMgSn phase is preferentially formed, followed by the formation of the Mg2Ca phase. At present, Mg-Sn-Ca alloys are recently attracting more and more attention due to their low cost, excellent creep properties, and high temperature property. However, The Mg-Sn-Ca alloy has some problems, such as non-uniform microstructures and poor forming performance after extrusion, that cannot meet requirements for structural components. Zn is a common and effective additive element in Mg alloys, and the compound addition of Zn and Ca has recently become a research focus. According to the Mg-Zn phase diagram, the solid solubility of Zn in pure Mg at 503 K is approximately 2.5 wt.%. The addition of Zn in Mg-Sn alloys is considered to be likely to improve plastic behavior. In addition, the Mg2Sn phase will be refined and distributed more evenly, thus enhancing the precipitation strengthening effect [15]. For example, Sasaki et al. reported that the addition of 0.5 wt.% Zn can significantly increase the peak hardness of Mg-2.2Sn alloy [16]. However, the effects of Zn content on the microstructure, texture, tensile properties, and formability of the Mg-Sn-Ca alloys have not been studied in detail.

Therefore, this study investigated the effect of the Zn content on the second phase formation, dynamic recrystallization, and texture evolution of Mg-Sn-Ca alloys during extrusion. In addition, the tensile mechanical properties and formability of extruded Mg-1.0Sn-0.5Ca-xZn (x = 0.0, 0.5, 1.0, 2.0 wt.%) alloys were preliminarily studied. The effect of Zn addition on the microstructure is studied systematically, and the internal relationship among the elements, structure, and properties are expounded. The research results provide an important basis for improving the mechanical properties of Mg-Sn-Ca alloys, which may promote their practical applications.

2. Materials and Methods

Mg-1.0Sn-0.5Ca-based alloys with various Zn contents (denoted as TX10, TXZ100, TXZ101 and TXZ102, respectively) were prepared by melting commercial pure Mg (99.85 wt.%), pure Sn (99.90 wt.%), pure Zn (99.90 wt.%), and Mg-25 Ca (wt.%) master alloys under the protection of a CO2 + 0.5% SF6 (volume fraction) mixture gas. The actual chemical compositions of these four alloys were determined by an XRF-1800CCDE X-ray fluorescence spectrometer (Shimadzu, Kyoto, Japan), and the relative results are shown in Table 1. After homogenization treatment (400 °C for 12 h and then air-cooled), the ingots were hot extruded at 380 °C with a ram speed of 3 mm/s−1 and an extrusion ratio of 32 to obtain rods with a final diameter of 14 mm.

Table 1.

Chemical compositions of the as-cast Mg-1.0Sn-0.5Ca-xZn (x = 0.0, 0.5, 1.0, 2.0 wt.%) alloys.

X-ray diffraction (XRD, Empyrean) with Cu Ka radiation was employed to detect the category of the phase component. The microstructure, including grain size and distribution of secondary phases, was analyzed using optical microscopy (OM, XploRA PLUS, HORIBA, Paris, France) and scanning electron microscopy (SEM, ZEISS SIGMA300, ZEISS, O ‘Bochen, Germany) equipped with an energy dispersive X-ray spectroscopy (EDS, O ‘Bochen, Germany). The average grain size was measured using the linear intercept method. The samples were ground, polished, and etched (5.0 g picric acid + 5 mL acetic acid + 10 mL water + 100 mL ethanol). Furthermore, the texture details could be effectively collected and evaluated using electron back-scattered diffraction (EBSD, Oxford, Oxford, UK) and the accompanying orientation imaging microscopy (OIM, HKL-channel 5, Oxford, Oxford, UK) analysis software.

The tensile mechanical properties were measured using a CMT6305-300 kN testing machine (Liangong, Jinan, China) at a strain rate of 1 × 10−3 s−1 along the extrusion direction (ED), 45° direction and transverse direction (TD) at room temperature. The tensile samples were processed into standard samples with a diameter of 5 mm and a length of 69 mm. The n-value was derived from the uniform plastic deformation region of the tensile stress–strain curve. εw and εt are the width-direction and thickness-direction strains, respectively, determined by adopting the specimens deformed to 10% nominal strain. The formability of the as-extruded Mg-Sn-Ca-based alloy with added Zn was measured by an Erichsen tester at room temperature with a 20 mm diameter hemispherical punch at 3 mm/min. The measurements of each sample were carried out at least three times to avoid accidental errors.

3. Results

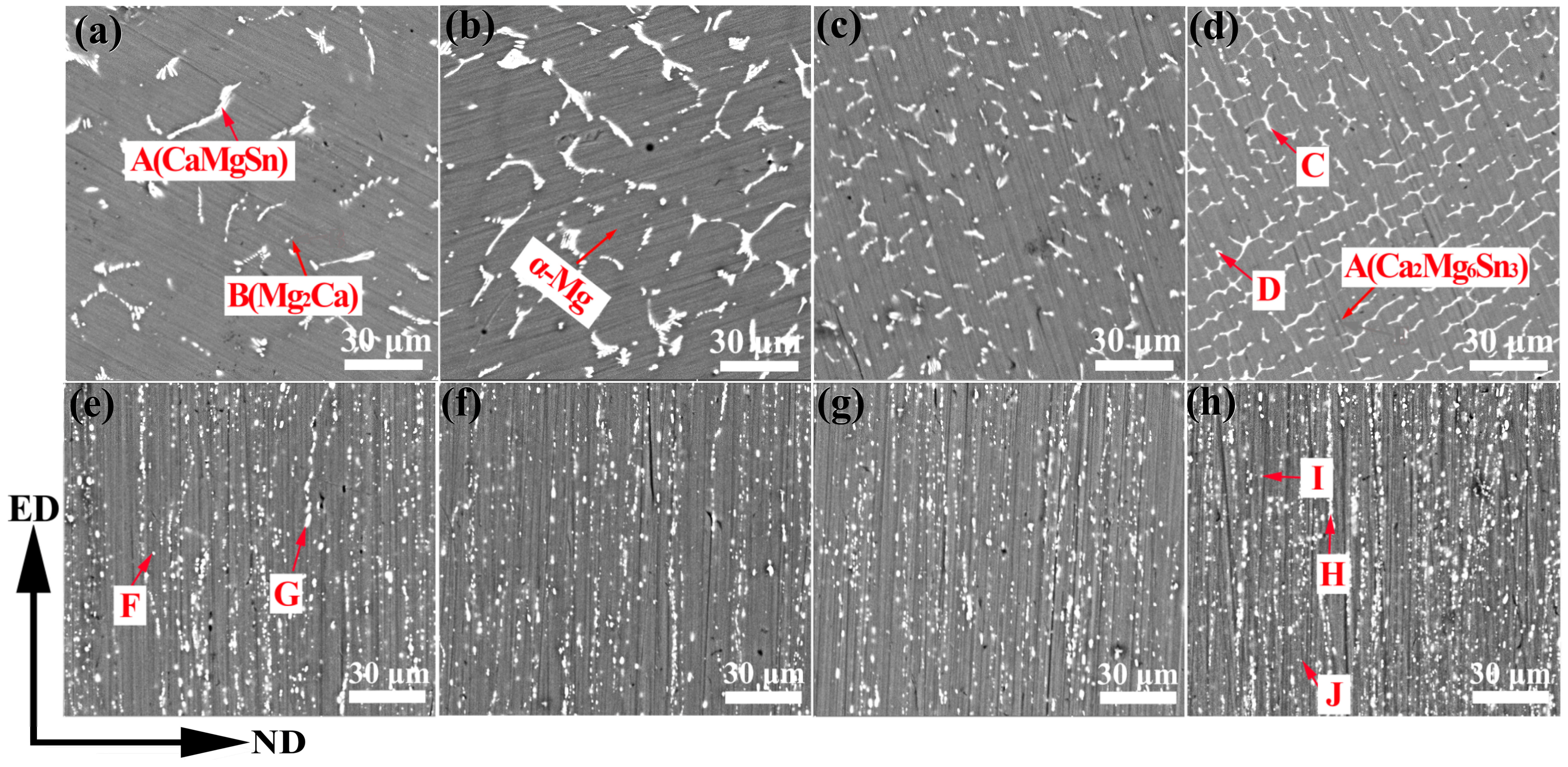

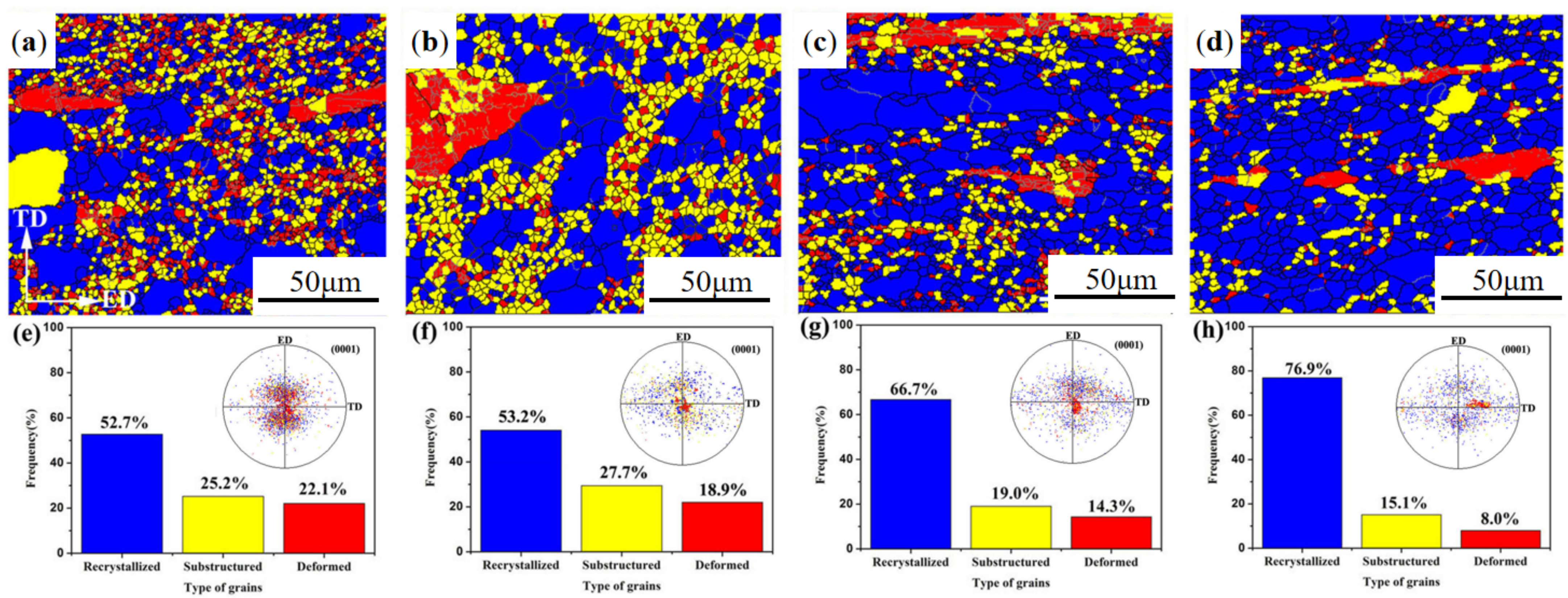

Figure 1 presents the SEM images of the as-homogenized and as-extruded Mg-1.0Sn-0.5Ca-xZn alloys, and the relative EDS results are shown in Table 2. Figure 2 displays the XRD patterns of the as-homogenized Mg-1.0Sn-0.5Ca-xZn series alloys. In the case of the as-homogenized samples, it is evident that the addition of Zn considerably accelerated the formation and refinement of the second phase. In addition, these main second phases can be roughly divided into two categories: (1) coarse strips distributed at grain boundaries and (2) tiny spheres randomly distributed within the grain. For the as-homogenized samples, with increasing Zn content, the second phase size decreases from 36.4 ± 8 μm to 26.2 ± 6 μm, 10.7 ± 3 μm, and 12.1 ± 5 μm, and its volume fraction increases from 5.6% to 8.8%, 9.6%, and 11.8%. The second phase after hot extrusion was significantly refined and presented a chain distribution along the ED.

Figure 1.

SEM images of the as-homogenized (a–d) and as-extruded (e–h) Mg-1.0Sn-0.5Ca-xZn alloys: (a,e) TX10 alloy; (b,f) TXZ100 alloy; (c,g) TXZ101 alloy; (d,h) TXZ102 alloy.

Table 2.

EDS results of the Mg-1.0Sn-0.5Ca-xZn alloys in Figure 1 (wt.%).

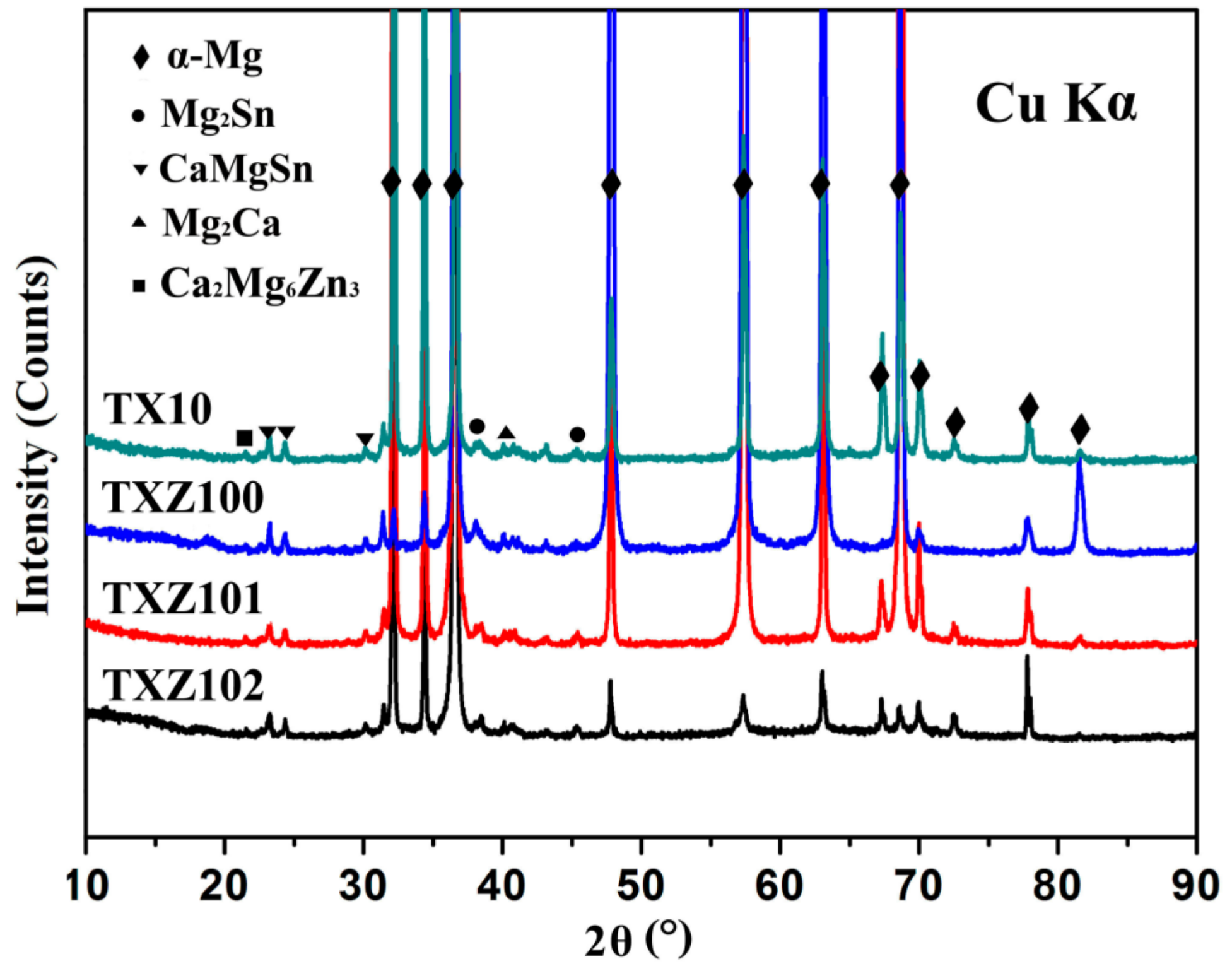

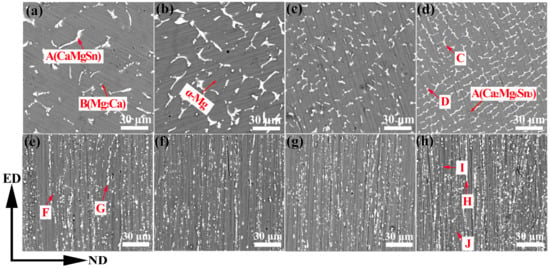

Figure 2.

XRD patterns of the as-homogenized Mg-1.0Sn-0.5Ca-xZn series alloys.

Meanwhile, increasing Zn content gradually increased the density of these chain-distributed second phases. In conjunction with the EDS results (Table 1) and the XRD patterns (Figure 2), the impact of Zn addition on the evolution of the phase composition in the Mg-1.0Sn-0.5Ca alloy could be seen. In the as-extruded TX10 alloy, the second phase was mainly composed of CaMgSn (the coarse bulk) and Mg2Ca (tiny spheres). In contrast, after the addition of Zn, not only was a small amount of Zn dissolved in the original second phase, but also a Ca2Mg6Zn3 phase was formed.

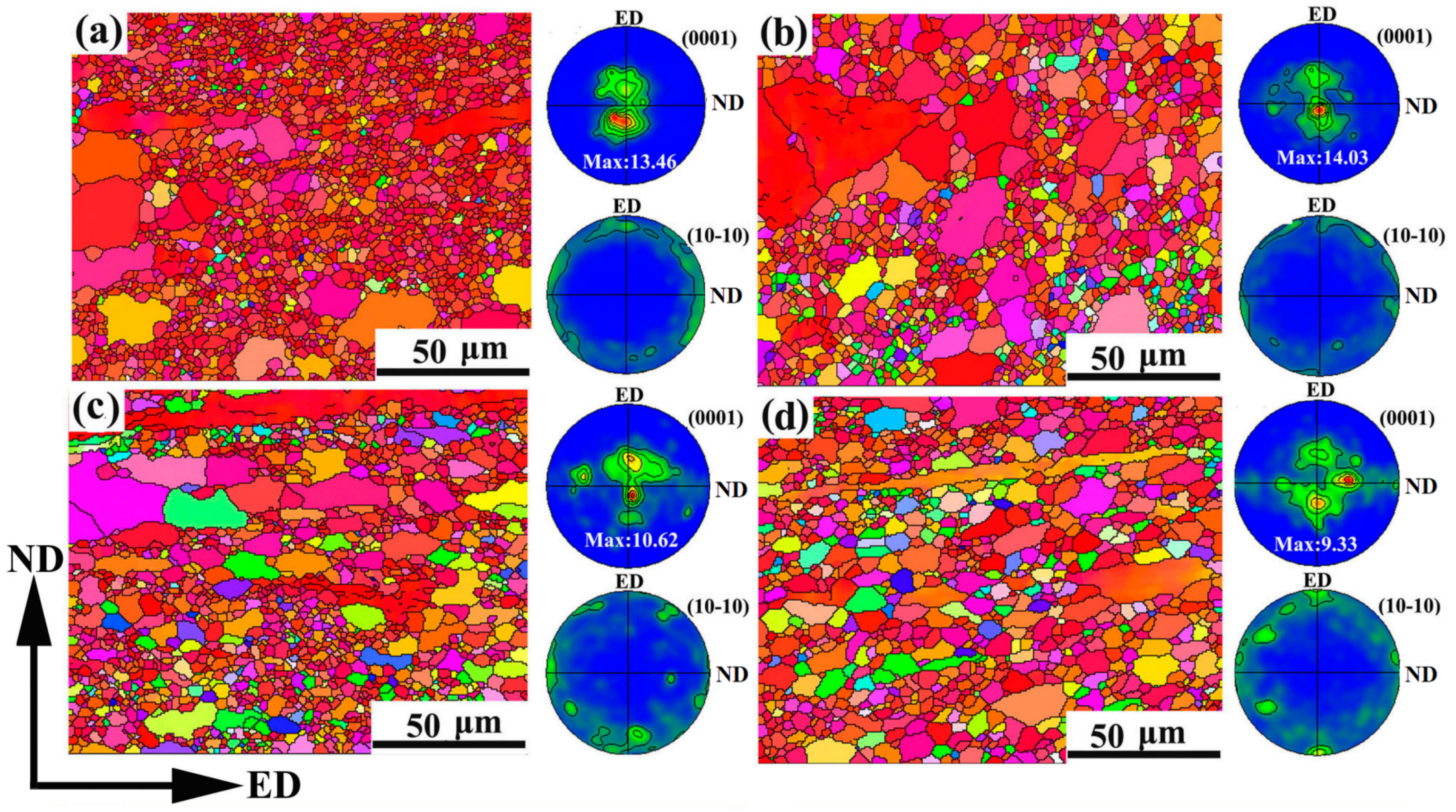

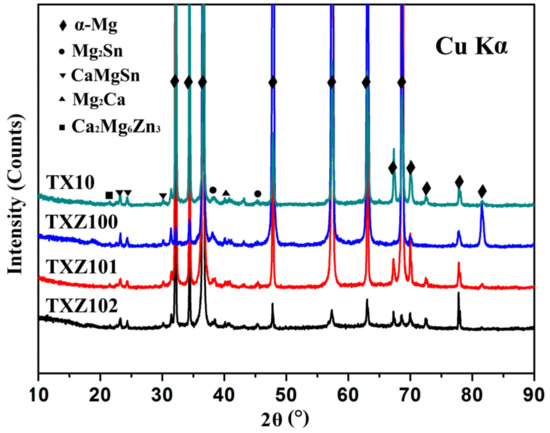

Figure 3 presents the EBSD inverse pole figure maps and (0001) and (10-10) pole figures from the ED–ND plane of the as-extruded Mg-1.0Sn-0.5Ca-xZn alloys along with the functional relationship between the texture intensity in the (0001) plane and the tilted direction (ED or ND). The microstructure of the initial as-extruded Mg-Sn-Ca-based alloy was inhomogeneous. Many fine recrystallized grains (only approximately 1.7 μm) were embedded near the coarse unrecrystallized grains (approximately 25.1 μm). With increasing Zn content, the volume fraction of unrecrystallized grains decreased, the proportion of dynamically recrystallized grains increased, and their size grew to a certain extent. For example, when the Zn content reached 2 wt.%, the microstructure is mainly composed of equiaxed grains, indicating that complete dynamic recrystallization has occurred. These phenomena imply that the dynamic recrystallization degree and microstructure uniformity of Mg-1.0Sn-0.5Ca alloys can be improved by adding Zn. According to the analysis of the texture characteristics, the initial as-extruded TX10 alloy had a bimodal texture typical of a Ca-containing alloy (the maximum poles tilts from the ND to the ED), and the maximum texture intensity was 13.46 mrd. With increasing Zn content, texture distribution became more dispersed. The volume fraction of grains with the ND texture component increased gradually along with the decreasing maximum polar density intensity (TXZ100: 14.03 mrd; TXZ101: 10.62 mrd; TXZ102: 9.33 mrd). In other words, adding Zn in the as-extruded Mg-Sn-Ca-based alloy will enhance the ND texture component and be conducive to the texture distribution, becoming more dispersed and symmetrical.

Figure 3.

EBSD inverse pole figure maps and (0001) and (10-10) pole figures from the ED–ND plane of the as-extruded Mg-1.0Sn-0.5Ca-xZn alloys: (a) TX10 alloy; (b) TXZ100 alloy; (c) TXZ101 alloy; (d) TXZ102 alloy.

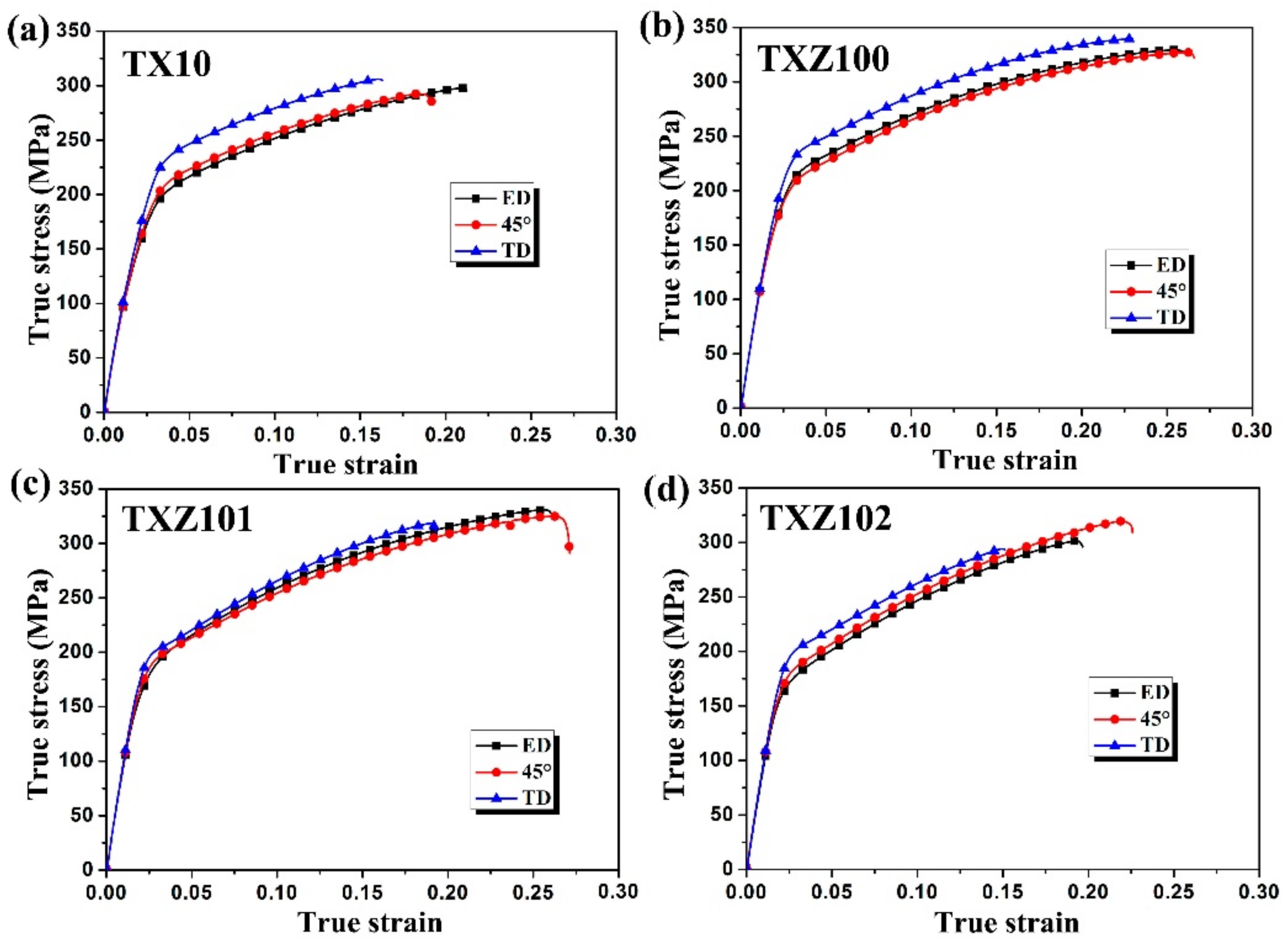

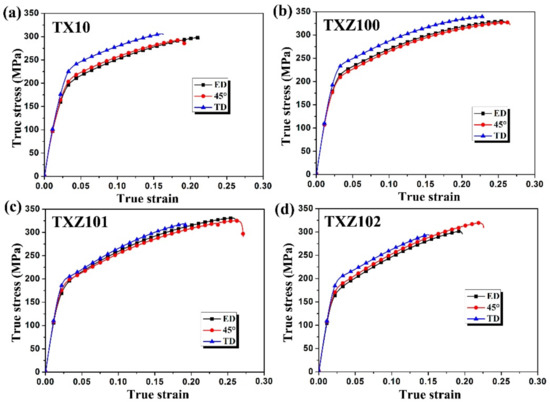

Figure 4 presents the true tensile stress–strain curves of the four as-extruded Mg-1.0Sn-0.5Ca-based alloys with different Zn contents when the tension was along the ED, 45°, and TD. The ultimate relevant mechanical parameters are summarized in Table 3. First, due to the existence of an initial bimodal texture (the maximum poles tilting from the ND to the ED), the tensile yield strength (TYS) of the as-extruded TX10 alloy had obvious anisotropy in the three directions. Specifically, the TYS increased with increasing angles between the tensile and extrusion directions (ED: 192.3 MPa; 45°: 201.5 MPa; TD: 222.7 MPa). After Zn addition, the above anisotropic behavior of the TYS was improved. For example, the TYS of TXZ101 alloy stretched along ED, 45°, and TD are 184.2 MPa, 188.5 MPa, and 193.2 MPa, respectively. The above phenomenon shows that the differences in the TYS among the three directions decreased after adding Zn. By comparing the average TYS values of the four alloys, it can be seen that with increasing Zn content, a trend of first increasing and then decreasing occurred. Specifically, the TYS of the TX10 alloy was 205.5 MPa. When the content of Zn was 0.5 wt.%, the TYS of the alloy reached its highest value, approximately 211.1 MPa. However, with the further addition of Zn (1.0 and 2.0 wt.%), the TYS values of the alloy decreased to 181.6 MPa and 178.1 MPa, respectively. With the increase in Zn content, the average EL value of the alloy also tended to increase first and then decrease.

Figure 4.

The true tensile stress–strain curves of the as-extruded Mg-1.0Sn-0.5Ca-xZn alloys: (a) TX10 alloy; (b) TXZ100 alloy; (c) TXZ101 alloy; (d) TXZ102 alloy.

Table 3.

Summary of the tensile properties at room temperature consisting of the YS, UTS, EL, n-value, and rave values of the four as-extruded Mg-1.0Sn-0.5Ca-xZn series alloys.

Meanwhile, its maximum EL value was 21.9% when the additive amount of Zn was 0.5 wt.%. The variations of El were largely related to the microstructure (homogeneity of the microstructure, texture, and secondary phase). It will be further discussed in the Discussion section. With increasing Zn content, the average values of YS/UTS in the as-extruded Mg-1.0Sn-0.5Ca-based alloys decreased successively from 0.69 to 0.63, 0.58, and 0.57. In contrast, the average values of n increased gradually from 0.22 to 0.24, 0.28, and 0.30 for the TX10, TXZ100, TXZ101, and TXZ102 alloys, respectively.

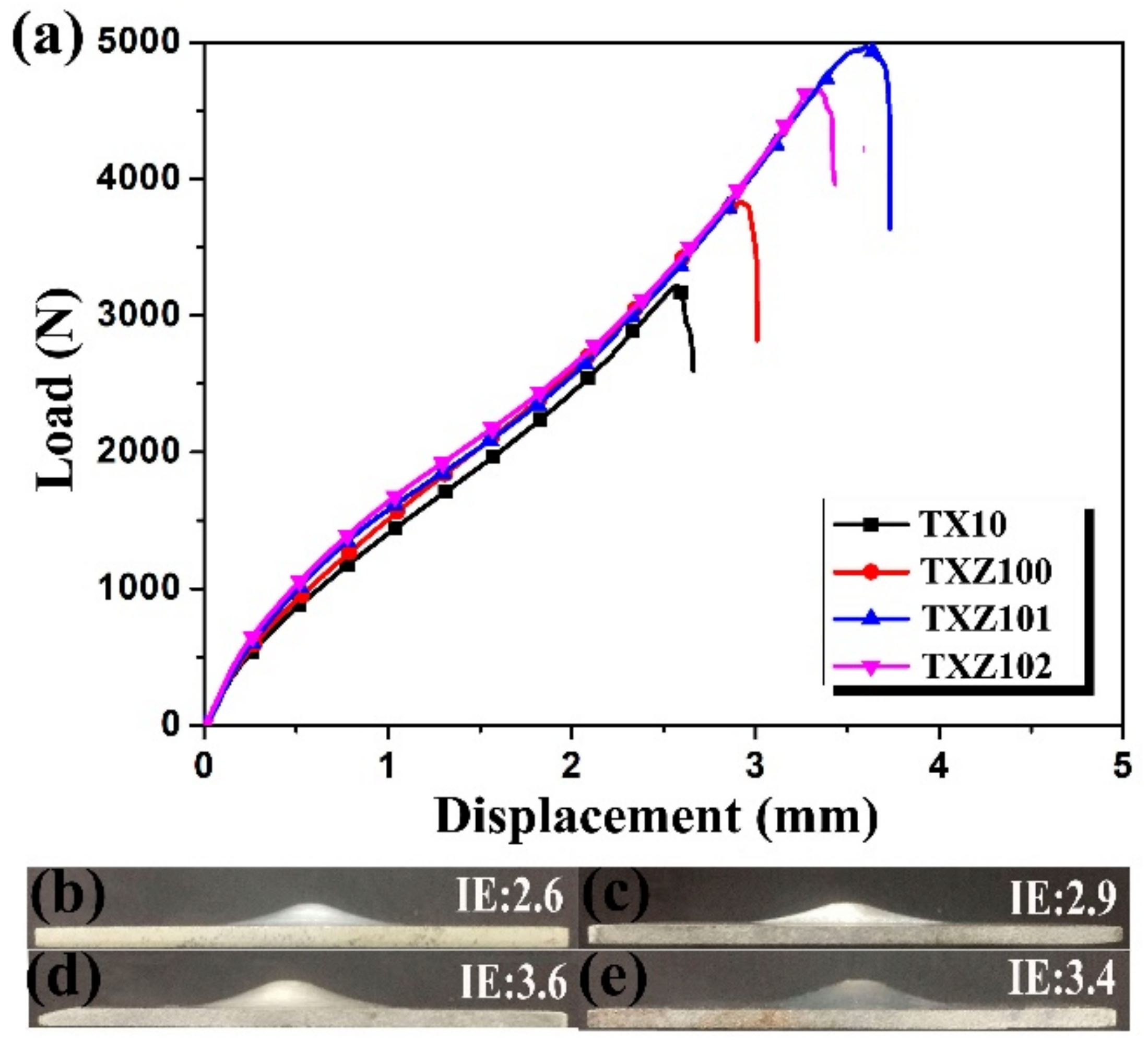

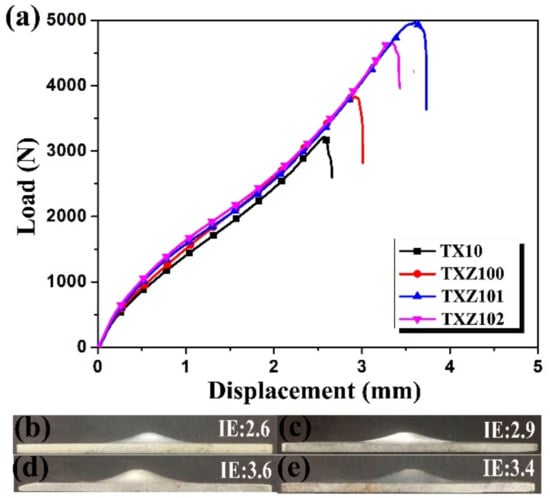

Figure 5 depicts the results of the Erichsen test at room temperature of the four as-extruded Mg-1.0Sn-0.5Ca-based alloys. With the increase in Zn content, the cupping test values (IE) of the Mg-1.0Sn-0.5Ca-based alloys (2.6 ± 0.1) increased gradually, which were 2.9 ± 0.1, 3.6 ± 0.2, and 3.4 ± 0.2 mm, increasing by 11.5%, 38.5%, and 30.8%, respectively. It means that Zn addition can improve formability, microstructure uniformity, and weakened and symmetrical texture.

Figure 5.

(a) Load–displacement curves of the four as-extruded Mg-1.0Sn-0.5Ca-xZn series alloys; (b–e) images of the sheet samples after the Erichsen test of the TX10, TXZ100, TXZ101, and TXZ102 alloys.

4. Discussion

4.1. Microstructural Evolution

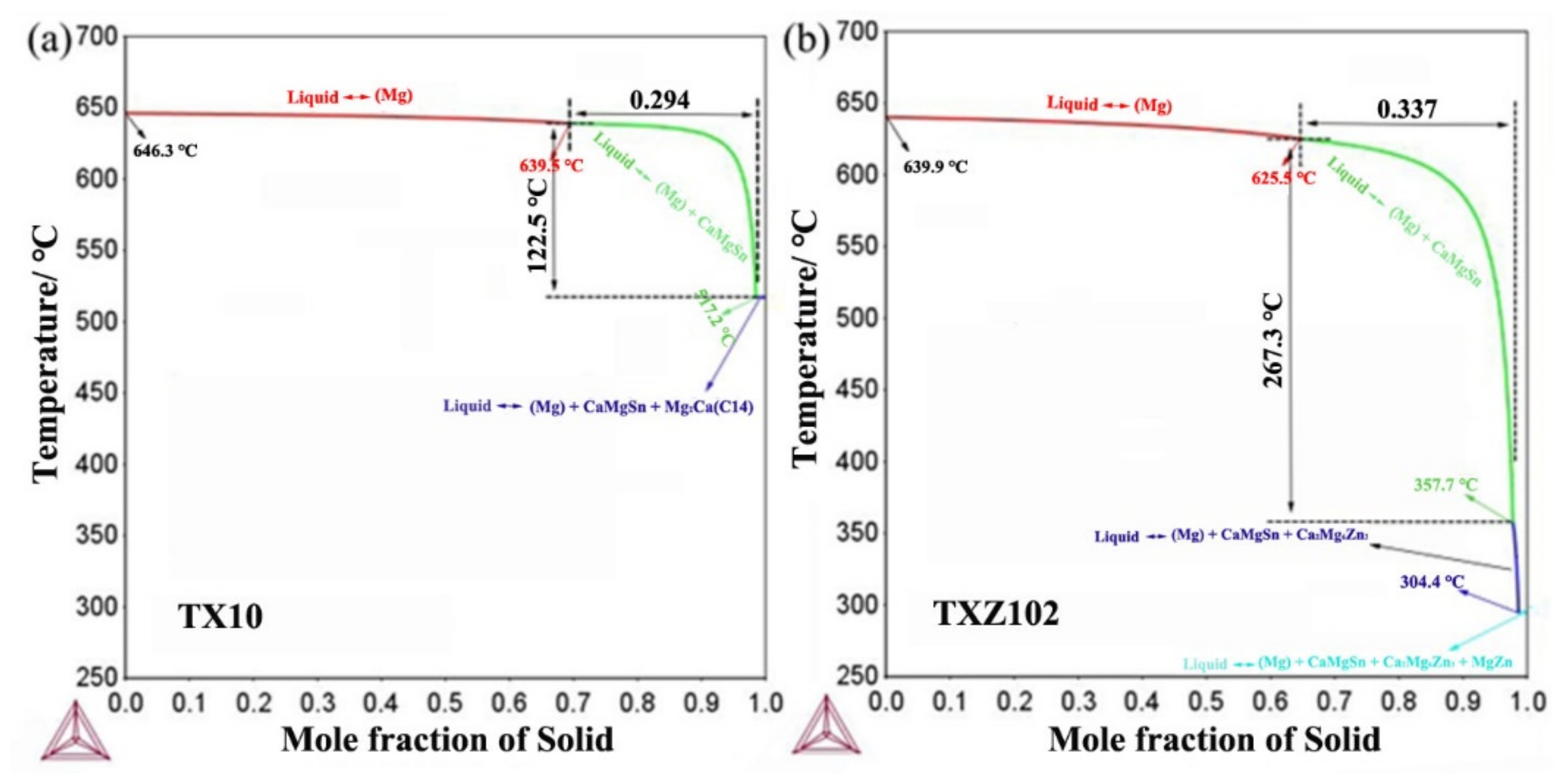

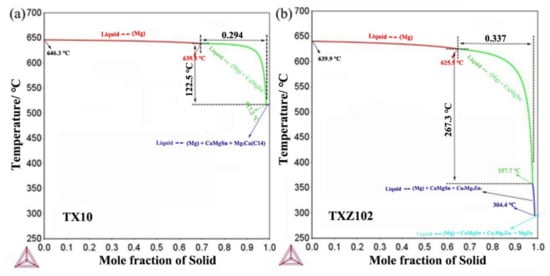

In order to further explain the effect of Zn on the formation of the second phase during nonequilibrium solidification of Mg-Sn-Ca-based alloys, especially the formation of CaMgSn and Ca2Mg6Zn3 phases, the Scheil Gulliver solidification simulation is required. Based on reliable CALPHAD (phase diagram calculation method) and thermodynamic databases [17,18], the nonequilibrium solidification curve of a given alloy composition (a function of volume fraction and temperature) during casting can be calculated by Scheil Gulliver solidification simulation. In the study presented in this paper, the ThermoCalc2016a database was adopted to simulate the nonequilibrium solidification of the TX10 and TXZ102 alloys, and the relevant results are shown in Figure 6. In the TX10 alloy, the Mg matrix is first formed at 646.3 °C, and then the eutectic reaction at 639.5 °C formed the Mg matrix and CaMgSn phase. Finally, the remaining liquid phase formed the Mg matrix and CaMgSn phase and Mg2Ca (C14) phase at 517.2 °C during the cooling process. In contrast, in the TXE102 alloy, the Mg matrix is first formed, and then a large amount of Mg matrix and CaMgSn phase were generated by the eutectic reaction, while a small amount of liquid phase was generated in the Mg matrix, the CaMgSn phase, and the Ca2Mg6Zn3 phase. The formation temperatures of the Mg matrix, the CaMgSn phase, the Ca2Mg6Zn3 phase, and the MgZn phase were 639.9, 625.5, 357.7, and 304.4 °C, respectively. In addition, by comparing the solidification process of the CaMgSn phase before and after adding Zn, it was found that the addition of Zn in the Mg-Sn-Ca-based alloy not only increased the solidification interval from 122.5 °C to 267.3 °C but also increased the volume fraction of CaMgSn. The above phenomenon intuitively indicates that the addition of Zn can promote the formation of the CaMgSn phase. In the case of grain size variations induced by the Zn addition, except for the second phase, they may also be closely related to the growth restriction factor (GRF) and dendrite coherency potential (DCP). The GRF value can be defined by the following formula:

where mL is the slope of the liquid phase, k is the diffusion coefficient of solid solution elements, and C0 is the content of solid solution elements. The DCP value reflects the possibility of branch tips colliding with each other and eventually forming a continuous network structure during the entire casting process, which is also associated with the content of solid solution elements, and then significantly impacts the grain size. Coincidently, Li et al. [19] also declared that by influencing the values of GRF and DCP, the grain size decreases gradually with increasing Zn content from 0 to 4 wt.%.

GRF = mL × (k − 1)C0

Figure 6.

Simulated solidification path of Mg-1.0Sn-0.5Ca-based alloys with and without 2.0 wt.% Zn under Scheil–Gulliver conditions: (a) TX10 alloy; (b) TXZ102 alloy.

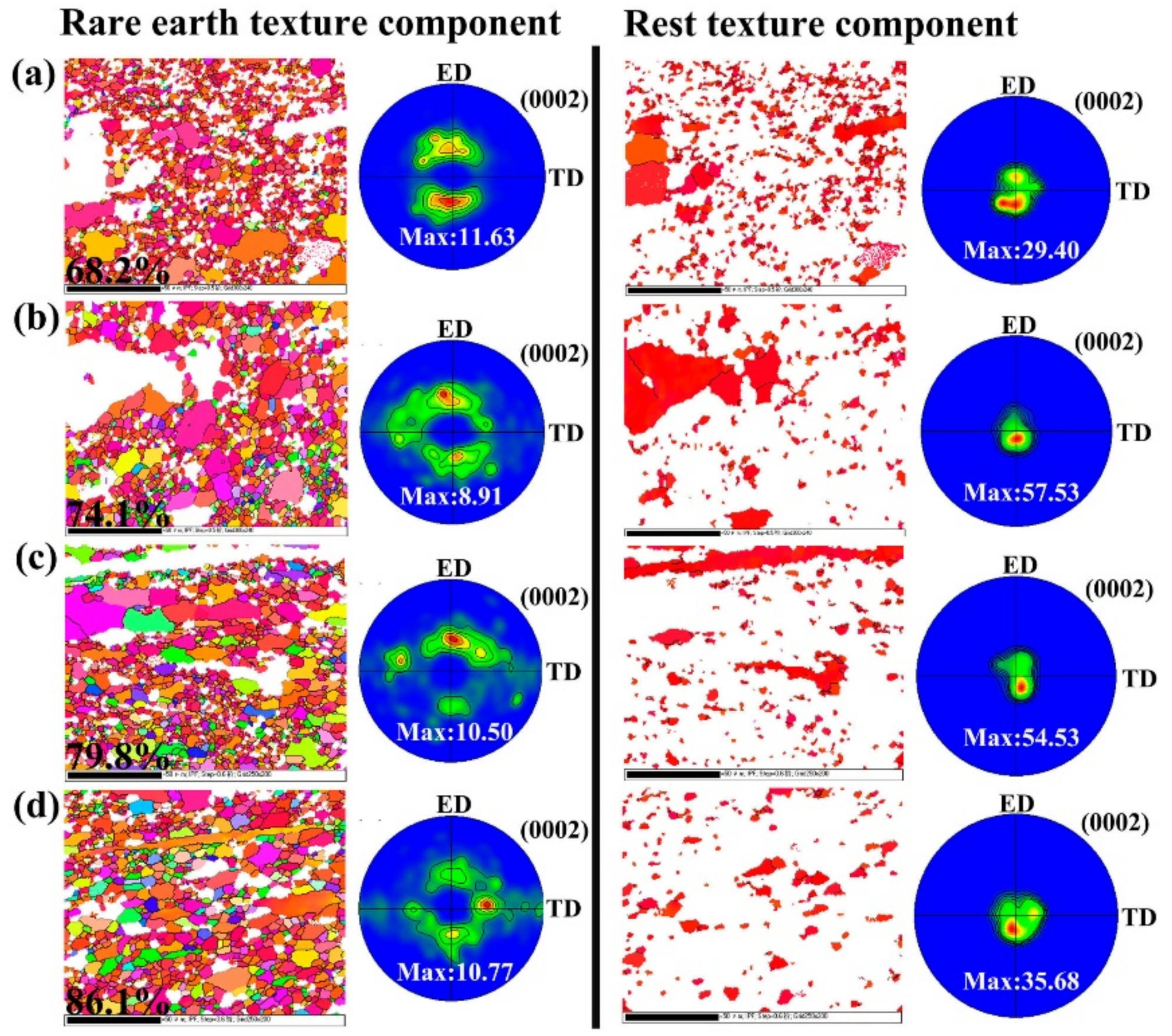

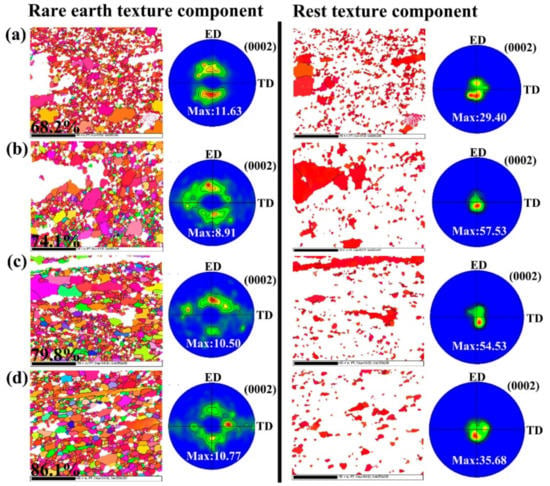

In order to reveal the texture changes caused by zinc addition, Figure 7 presents the rare earth texture component of the four as-extruded Mg-1.0Sn-0.5Ca-xZn alloys, while the separation of the rare earth texture and the rest of the texture component is based on the boundary of a 30° deflection angle from the ND [20]. The colors were more diverse for the rare earth texture component, and the main part was composed of newly recrystallized grains. In contrast, the residual texture component was mainly red and mostly consisted of coarse unrecrystallized grains with typical strong basal texture characteristics. In addition, it can be seen from the comparison between the rare earth and other texture components that the intensity of the rare earth texture is relatively weak. The maximum polarity density is 8.91–11.63 mrd. In contrast, the intensity of the rest of the texture components is relatively high, within the range of 29.40–57.53 mrd. Finally, in the Mg-Sn-Ca-based alloys, with increasing Zn content, the proportions of rare earth texture gradually increased from 68.2% to 74.1%, 79.8%, and 86.1%. According to the texture distribution characteristics, Zn addition induced a significant texture evolution from the initial bimodal texture (its maximum poles tilting from the ND to the ED) to a more dispersed and symmetrical texture (appearance and enhancement of additional TD texture components).

Figure 7.

Rare earth texture components of the four as-extruded alloys: (a) TX10 alloy. (b) TXZ100 alloy. (c) TXZ101 alloy. (d) TXZ102 alloy.

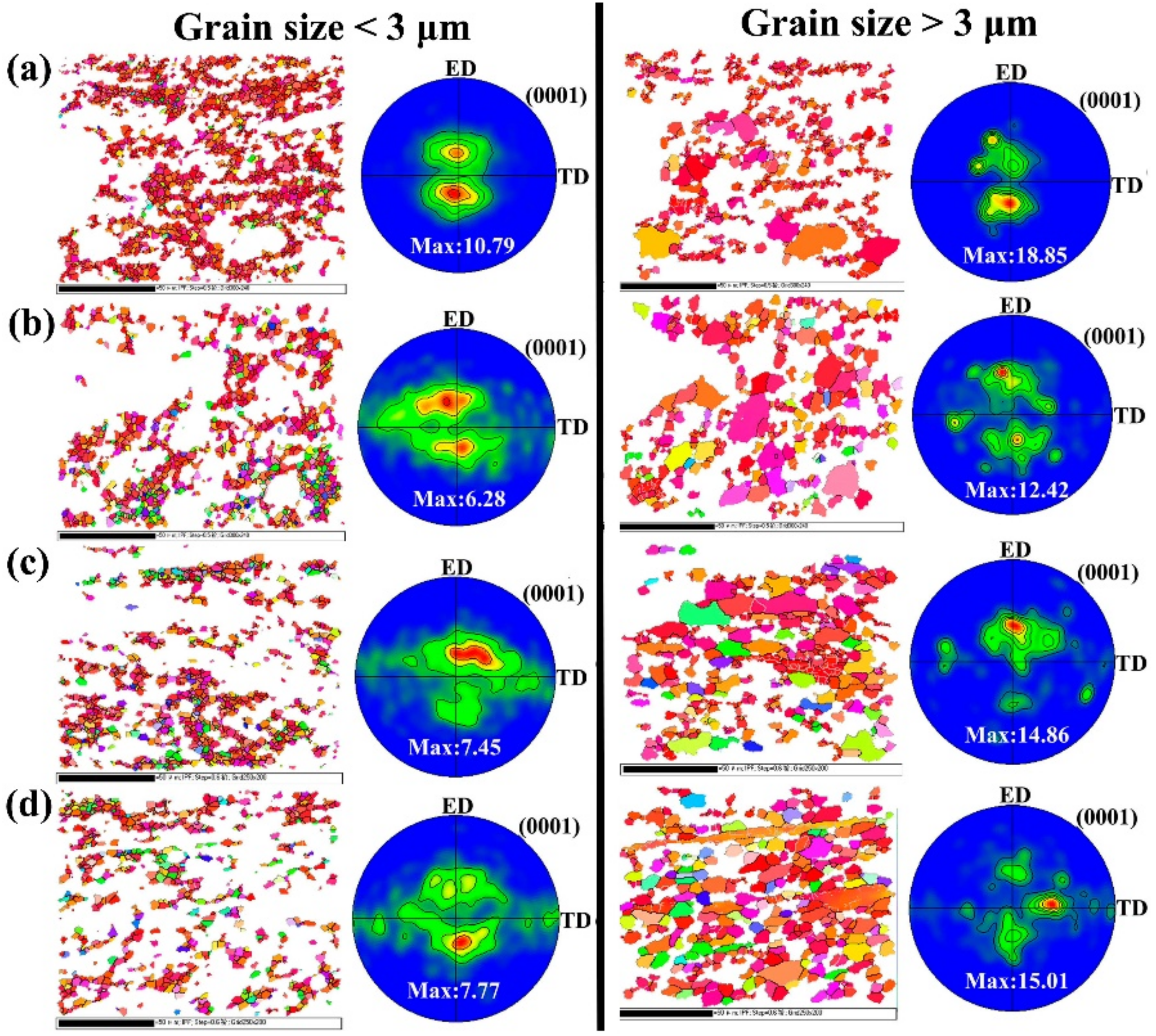

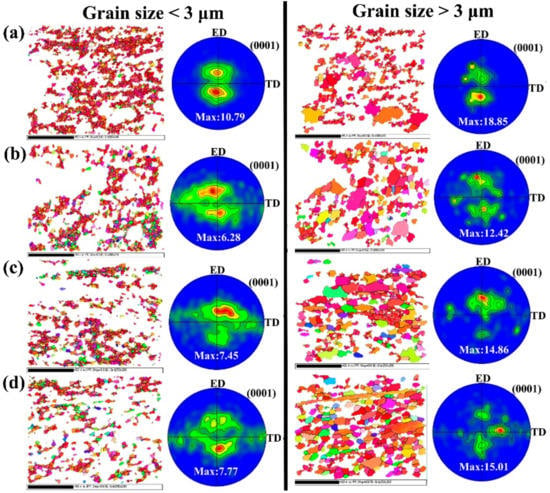

Figure 8 presents EBSD IPF maps in the ED-ND plane and {0001} pole figures of the four as-extruded Mg-1.0Sn-0.5Ca-xZn alloys corresponding to grains with sizes <3 μm and >3 μm. The component with grain size <3 μm was generally regarded as a new recrystallized grain. At the initial stage, the texture type was bimodal (its maximum pole inclined from the ND to the ED). After Zn addition, the TD texture gradually strengthened. For the component with grain size >3 μm, the coarse unrecrystallized grains occupied a large part. The texture characteristics of the first three alloys were typically bimodal, while the TD texture component appeared only when the addition of Zn reached 2.0 wt.%. Compared with the coarse grains (>3 μm), the new recrystallized grains (<3 μm) had a smaller maximum polar density, and the degrees of texture dispersion and symmetry (the appearance of an additional TD texture component) caused by the addition of Zn was more evident.

Figure 8.

EBSD IPF maps in the ED-ND plane and {0001} pole figures of the four as-extruded Mg-1.0Sn-0.5Ca-xZn alloys corresponding to grains with sizes <3 μm and >3 μm, respectively: (a) TX10 alloy; (b) TXZ100 alloy; (c) TXZ101 alloy; (d) TXZ102 alloy.

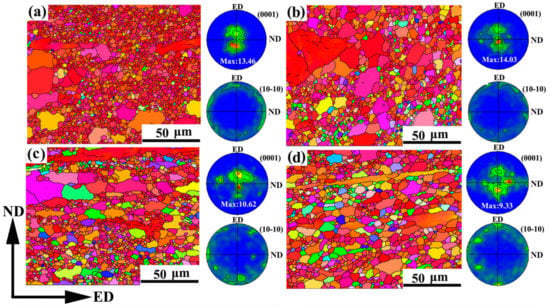

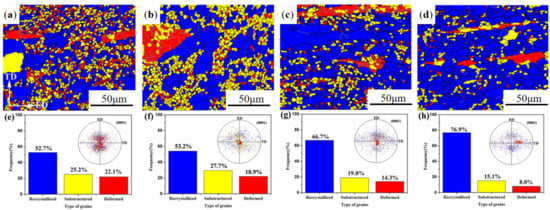

By reviewing Figure 9, it can be concluded that, in the newly recrystallized grains, the effects of Zn addition on texture weakening, dispersion, and symmetry were more significant than those of coarse grains. In other words, compared with the grain growth stage, the texture changes caused by Zn addition were focused on the grain nucleation stage. Therefore, Figure 9 shows the influence of dynamic recrystallization, including the blue—recrystallized grains, yellow—substructure grains, and red—deformed grains of the four as-extruded Mg-1.0Sn-0.5Ca-xZn alloys after hot extrusion. In the extruded Mg-Sn-Ca-based alloy, with increasing Zn content, the proportions of deformed grains (the red color) decreased from 22.1% to 18.9%, 14.3%, and 8.0%, which corresponds to the increase in the volume fraction of the recrystallized grains (the blue color) from 52.7% to 53.2%, 66.7%, and 76.9%, respectively. In addition, the (0001) pole diagram indicates that the deformed grains (red) mainly had basal texture, while the newly recrystallized grains were more dispersed. As shown in Figure 1 and Figure 7, adding Zn into Mg-Sn-Ca-based alloys can promote the formation of bulk second phases (CaMgSn and Ca2Mg6Zn3) with sizes greater than 1 μm. Therefore, the bulk of the CaMgSn and Ca2Mg6Zn phases can be used as nucleating positions of recrystallized grains through the particle nucleation effect (PSN). Subsequently, these new recrystallized grains formed by the PSN mechanism generally had relatively dispersed, disordered, and weakened texture orientation, while these texture characteristics could still be effectively retained in the subsequent growth process [21]. The results show that the increase in recrystallized grain volume fraction during hot extrusion leads to the weakening and dispersion of texture. The essence is related to more bulk CaMgSn and Ca2Mg6Zn3 formation caused by the Zn addition.

Figure 9.

Different types of grains in the as-extruded (a) TX10 alloy; (b) TXZ100 alloy; (c) TXZ101 alloy; (d) TXZ102 alloy: blue—recrystallized, yellow—substructure, red—deformed; (e–h) frequency and corresponding (0001) pole figures of the different types of grains shown in (a), (b), (c), and (d), respectively. (In this figure, R is recrystallized, S is substructured, and D is deformed.).

4.2. Variation in Mechanical Properties

As shown in Figure 5 and Table 3, with increasing Zn content, the average values of the TYS showed trends of first increasing and then decreasing, from 205.5 to 211.1, 118.6, and 178.1 MPa, for the TX10, TXZ100, TXZ101, and TXZ102 alloys, respectively. Generally, the main factors affecting the strength of the alloys were as follows: (1) Solid solution strengthening originates from the interactions between solute atoms and dislocations. Labusch et al. [22] demonstrated that the solid solution strengthening effects of different solid solution atoms were largely due to the size mismatch and modulus mismatch. (2) Grain boundary strengthening: Grain boundaries can act as a barrier to dislocation movement and thus have a strengthening effect. (3) Texture strengthening: {0001} <11–20> basal slip is the main operative slip system of Mg alloy at room temperature. Hence, due to the weakening and dispersion of the texture caused by the addition of Zn, the Schmidt factor (SF) of the basal slip of the as-extruded Mg-Sn-Ca alloys with different Zn contents must be different. (4) Precipitation strengthening: For the Orowan precipitation strengthening rule, the precipitation interphase gap should be less than several hundred nanometers, and the smaller the particle size is, the more obvious the strengthening effect.

Based on the above four strengthening effects, it can be inferred that the increase in TYS caused by the initial addition of 0.5 wt.% Zn is attributable to the strengthening effect caused by grain refinement, solid solution strengthening, and second phase strengthening, which is more significant than the weakening effect originating from texture weakening and dispersion. However, with a further increase in Zn content, the TYS decreased instead, which is attributed to the weakening effect (coarsening of recrystallized grains and weakening of the texture) being much more significant than the strengthening effect (solid solution and second phase strengthening).

From the average EL values of the alloys, it can be seen that with increasing Zn content, the EL showed a trend of first increasing and then decreasing. The maximum EL value was 21.9% when 0.5 wt.% Zn was added. The increase in EL could be attributed to the weakening and dispersion of the texture (especially in the presence of additional TD texture components), which contributed to the activity of more basal slip and the improvement of strain coordination in the thickness direction during subsequent tensile deformation. On the other hand, the volume fraction of unrecrystallized grains in the as-extruded Mg-Sn-Ca-based alloys decreased with increasing Zn content. However, with the subsequent addition of Zn, the EL had a decreasing trend, largely related to the corresponding increased coarse CaMgSn and Ca2Mg6Zn3 phases. It is generally accepted that second phase precipitation can be used as the main initiation source of microcracks in the corresponding materials. When an external force is applied to the material, obvious stress concentration and the formation of microscopic pores will occur near the second phase particles. The stress (SVF) required to form a microscopic cavity near the second phase particles can be roughly estimated by the following formula [23]:

where q is the average stress concentration factor near the second phase particles, γs refers to the surface energy of the matrix material, E is the elastic modulus of the matrix material, YS is the yield strength of the matrix material, V describes the volume fraction of the second phase particles, and V refers specifically to the volume fraction of the plastic deformation zone in the matrix material near the second phase particles. The above formula indicates that the applied stress depends largely on the size of the second phase particles. Similarly, Park et al. [24,25,26] showed that the presence of coarse second phase particles significantly deteriorates the plasticity of the sheet, especially when the particle size of the second phase exceeds 10 μm. In addition, it is worth mentioning that the weakening, more dispersed, and symmetrical texture characteristics caused by Zn addition were the main reasons for the variations in the average values of YS/UTS and n.

5. Conclusions

The addition of Zn into the as-cast Mg-Sn-Ca-based alloy will promote the formation of the CaMgSn phase (the main second phases) and the Ca2Mg6Zn3 phase (newly emerging phase in the Zn-added alloys). The addition of Zn to alloy can increase the solidification interval temperature from 122.5 °C to 267.3 °C, resulting in an increase in the volume fraction from 5.6% to 11.8% and a decrease in size from 36.4 μm to 12.1 μm of the second phase of the alloy.

The EL and IE values of TXZ101 and TXZ100 alloys increased by 38.5% and 21.9% over the original alloy. The increase in EL is caused by the weakening and dispersion of the texture, which contributed to the activity of more basal slip and the improvement of strain coordination in the thickness direction during subsequent tensile deformation, suggesting that the addition of zinc could improve formability.

With the increase in Zn content, the TYS values increased first and then decreased. When the content of Zn was 0.5 wt.%, the TYS of the alloy reached the highest values, approximately 211.1 MPa. The increase in TYS is attributable to the strengthening effect caused by grain refinement, solid solution strengthening, and second phase strengthening, which is more significant than the weakening effect originating from texture weakening and dispersion.

Author Contributions

Conceptualization, S.W. and Y.C.; methodology, S.W.; validation, S.W., L.Y. and L.L.; formal analysis, S.W. and Y.Z.; resources, Y.C. and B.J.; data curation, L.Y.; writing—original draft preparation, S.W.; writing—review and editing, Y.C. and B.J.; visualization, Y.H.; supervision, B.J.; project administration, B.J.; funding acquisition, S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Shandong Province (ZR202111270002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, [Y.C.], upon reasonable request.

Acknowledgments

Throughout the writing of this dissertation I have received a great deal of support and assistance. I would first like to thank Yanfu Chai, whose expertise was invaluable in formulating the research questions and methodology. Your insightful feedback pushed me to sharpen my thinking and brought my work to a higher level. I would particularly like to acknowledge team members, for their wonderful collaboration and patient support. I would also like to thank Yanfu Chai, for their valuable guidance. You provided me with the tools that I needed to choose the right direction and successfully complete my dissertation. Finally, I would like to thank my parents for their wise counsel and sympathetic ear. You are always there for me.

Conflicts of Interest

The authors declared that they have no conflict of interest to this work. We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

References

- Laser, T.; Hartig, C.; Nürnberg, M.R.; Letzig, D.; Bormann, R. The influence of calcium and cerium mischmetal on the microstructural evolution of Mg-3Al-1Zn during extrusion and resulting mechanical properties. Acta Mater. 2008, 56, 2791–2798. [Google Scholar] [CrossRef]

- Xu, J.; Song, J.F.; Jiang, B.; He, J.J.; Wang, Q.H.; Liu, B.; Huang, G.S.; Pan, F.S. Effect of effective strain gradient on texture and mechanical properties of Mg-3Al-1Zn alloy sheets produced by asymmetric extrusion. Mater. Sci. Eng. A 2017, 706, 172–180. [Google Scholar] [CrossRef]

- Wang, Q.H.; Jiang, B.; Tang, A.T.; Ma, S.X.; Jiang, Z.T.; Chai, Y.F.; Liu, B.; Pan, F.S. Ameliorating the mechanical properties of magnesium alloy: Role of texture. Mater. Sci. Eng. A 2017, 689, 395–403. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.F.; Jiang, B.; Zeng, Y.; Wang, Q.H.; Jiang, Z.T.; Liu, B.; Huang, G.S.; Pan, F.S. Effect of Al content on microstructure and mechanical properties of as-cast Mg-5Nd alloys. J. Alloys Compd. 2018, 737, 263–270. [Google Scholar] [CrossRef]

- Xin, T.Z.; Tang, S.; Ji, F.; Cui, L. Michael Ferry Phase transformations in an ultralight BCC Mg alloy during anisothermal aging. Acta Mater. 2022, 239, 118248. [Google Scholar] [CrossRef]

- Chai, Y.F.; Jiang, B.; Song, J.F.; Wang, Q.H.; He, J.J.; Zhao, J.; Huang, G.S.; Jiang, Z.T.; Pan, F.S. Role of Al content on the microstructure, texture and mechanical properties of Mg-3.5Ca based alloys. Mater. Sci. Eng. A 2018, 730, 303–316. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, B.; Song, J.F.; He, J.J.; Gao, P.; Liu, W.J.; Yang, T.H.; Huang, G.S.; Pan, F.S. Unusual texture formation in Mg–3Al–1Zn alloy sheets processed by slope extrusion. Mater. Sci. Eng. A 2018, 732, 1–5. [Google Scholar] [CrossRef]

- Lv, B.J.; Wang, S.; Xu, T.W.; Guo, F. Effects of minor Nd and Er additions on the precipitation evolution and dynamic recrystallization behavior of Mg–6.0Zn–0.5Mn alloy. J. Magnes. Alloy 2021, 9, 840–852. [Google Scholar] [CrossRef]

- Xia, D.B.; Huang, G.S.; Deng, Q.Y.; Jiang, B.; Liu, S.S.; Pan, F.S. Influence of stress state on microstructure evolution of AZ31 Mg alloy rolled sheet during deformation at room temperature. Mater. Sci. Eng. A 2018, 715, 379–388. [Google Scholar] [CrossRef]

- Xia, D.B.; Chen, X.; Huang, G.S.; Jiang, B.; Tang, A.T.; Yang, H.; Gavras, S.; Huang, Y.D.; Hort, N.; Pan, F.S. Calculation of Schmid factor in Mg alloys: Influence of stress state. Scr. Mater. 2019, 171, 31–35. [Google Scholar] [CrossRef]

- Sun, Z.Q.; Li, Y.J.; Zhang, K.; Li, X.G.; Ma, M.L.; Shi, G.L.; Yuan, J.W. Effect of Al content on the microstructure and mechanical properties of Mg-5wt%Sn-xAl as-cast alloys. IOP Conf. Ser. Mater. Sci. Eng. 2019, 770, 12–15. [Google Scholar] [CrossRef]

- Yarkadaş, G.; Kumruoğlu, L.C.; Şevik, H. The effect of Cerium addition on microstructure and mechanical properties of high pressure die cast Mg-5Sn alloy. Mater. Charact. 2018, 136, 152–156. [Google Scholar] [CrossRef]

- Zhang, A.Y.; Kang, R.; Wu, L.; Pan, H.C.; Xie, H.B.; Huang, Q.Y.; Liu, Y.J.; Ai, Z.R.; Ma, L.F.; Ren, Y.P.; et al. A new rare-earth-free Mg-Sn-Ca-Mn wrought alloy with ultra-high strength and good ductility. Mater. Sci. Eng. A 2019, 754, 269–274. [Google Scholar] [CrossRef]

- Yang, M.B.; Zhu, Y.; Liang, X.F.; Pan, F.S. Effects of Gd addition on as-cast microstructure and mechanical properties of Mg-3Sn-2Ca magnesium alloy. Mater. Sci. Eng. A 2011, 528, 1721–1726. [Google Scholar] [CrossRef]

- Jiang, Z.T.; Jiang, B.; Yang, H.; Wang, Q.H.; Dai, J.H.; Pan, F.S. Influence of the Al2Ca phase on microstructure and mechanical properties of Mg–Al–Ca alloys. J. Alloys Compd. 2015, 647, 357–363. [Google Scholar] [CrossRef]

- Pan, H.C.; Qin, G.W.; Huang, Y.; Ren, Y.P.; Sha, X.C.; Han, X.D.; Liu, Z.Q.; Li, C.F.; Wu, X.L.; Chen, H.W.; et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Si, H.J.; Jiang, Y.X.; Tang, Y.; Zhang, L.J. Stable and metastable phase equilibria in binary Mg-Gd system: A comprehensive understanding aided by CALPHAD modeling. J. Magnes. Alloy 2019, 7, 501–513. [Google Scholar] [CrossRef]

- Huang, L.; Liu, S.H.; Du, Y.; Zhang, C. Thermal conductivity of the Mg–Al–Zn alloys: Experimental measurement and CALPHAD modeling. Calphad 2018, 62, 99–108. [Google Scholar] [CrossRef]

- Li, P.; Hou, D.H.; Han, E.-H.; Chen, R.S.; Shan, Z.W. Solidification of Mg–Zn–Zr Alloys: Grain Growth Restriction, Dendrite Coherency and Grain Size. Acta Metall. Sinica 2020, 33, 1477–1486. [Google Scholar] [CrossRef]

- Wang, G.G.; Huang, G.S.; Chen, X.; Deng, Q.Y.; Tang, A.T.; Jiang, B.; Pan, F.S. Effects of Zn addition on the mechanical properties and texture of extruded Mg-Zn-Ca-Ce magnesium alloy sheets. Mater. Sci. Eng. A 2017, 705, 46–54. [Google Scholar] [CrossRef]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle effects on recrystallization in magnesium–manganese alloys: Particle-stimulated nucleation. Acta Mater. 2009, 57, 2739–2747. [Google Scholar] [CrossRef]

- Gao, L.; Chen, R.S.; Han, E.H. Solid solution strengthening behaviors in binary Mg–Y single phase alloys. J. Alloys Compd. 2009, 472, 234–240. [Google Scholar] [CrossRef]

- Peng, Q.Z.; Zhou, H.T.; Zhong, F.H.; Ding, H.B.; Zhou, X.; Liu, R.R.; Xie, T.; Peng, Y. Effects of homogenization treatment on the microstructure and mechanical properties of Mg-8Li-3Al-Y alloy. Mater. Design 2015, 66, 566–574. [Google Scholar] [CrossRef]

- Park, S.H.; Jung, J.-G.; Yoon, J.; You, B.S. Influence of Sn addition on the microstructure and mechanical properties of extruded Mg-8Al-2Zn alloy. Mater. Sci. Eng. A 2015, 626, 128–135. [Google Scholar] [CrossRef]

- Deng, H.B.; Chen, Y.H.; Jia, Y.l.; Pang, Y.; Zhang, T.M.; Wang, S.I.; Yin, L.M. Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. J. Manuf. Process 2021, 64, 379–391. [Google Scholar] [CrossRef]

- Xie, J.l.; Chen, Y.H.; Yin, L.M.; Zhang, T.M.; Wang, S.I.; Wang, L.T. Microstructure and mechanical properties of ultrasonic spot welding TiNi/Ti6Al4V dissimilar materials using pure Al coating. J. Manuf. Process 2021, 64, 473–480. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).