Abstract

In this study, the copper-graphene oxide composites were prepared using low sintering temperature to investigate the effect of various mesh sizes of GO on Cu-GO composites. Scanning electron microscopy (SEM), X-ray diffraction (XRD) and Raman were conducted to elaborate the microstructure, diffraction pattern and disorder in the powders as well as bulk composites. Transmission electron microscopy (TEM) analysis was also carried out to further study the microstructural analysis of composites at the nano-scale level. By changing the mesh sizes of GO from lower to higher level, the tensile strength and hardness of Cu-GO composites were significantly enhanced due to better mixing of GO with higher mesh size. A fractograph analysis was also examined in detail to investigate the effect of various mesh sizes of GO on Cu-GO.

1. Introduction

Copper matrix composites are largely used in many industrial applications such as aerospace, vehicles, electronic and thermal packaging industries [1]. Among the different metals, copper (Cu) is one of the most significant due to its higher thermal properties and cost-effectiveness [2]. However, its low mechanical properties limit its use in larger application areas. To improve the mechanical properties, in recent years, most researchers have used various fillers such as carbon nanotubes (CNTs), graphene oxide (GO) and graphene (Gr) due to their excellent mechanical properties [3,4,5,6,7,8,9]. Major problems have occurred during the mixing process of Cu and fillers, which has led to the deterioration of the overall properties of final composites. Many researchers utilized various processing methods to overcome this challenge, including electroless plating, layer-by-layer self-assembly, in situ chemical vapor deposition, and flake powder metallurgy [10,11,12,13]. Many researchers in the past fabricated the Cu-GO composites using different fabrication techniques and by varying the percentage of filler. However, the fabrication of Cu-GO composites at low sintering temperature and by varying mesh sizes has seldom been studied to date. Mostly, the hot press/vacuum/spark plasma sintering technique has been used for the fabrication of pellets, and the temperature used for that ranges between 800–1000 °C, which is very high; this is performed under some protective environment [14,15,16,17,18,19]. However, in our current work, we used a simple oven at a low temperature of 750 °C for the fabrication of Cu-GO composites, which is an easy and cost-effective process. Jan Dutkiewicz et al. [20] fabricated copper-graphene nanoplates (Cu-GNP) composites using two different kinds of GNP, coarse and fine. They used 1 and 2 wt.% of both coarse and fine thickness of GNP 10–20 nm and 4–6 nm at a temperature of 550 °C under a pressure of 35 MPa. The maximum hardness values for coarse GNP at 1 and 2 wt.% GNP were 50.8 and 40 HV, whereas for fine GNP, the values were 61 HV, respectively. Hongyan yue fabricated Cu-Gr composites at a temperature of 850 °C using a vacuum sintering technique by varying the percentage of Gr [21]. At 0.5 wt.%, the value of hardness for Cu-Gr composite was reported to be 55 HV, and this further decreased with increasing percentage of filler. C. Ayyappadas et al. [17] also fabricated Cu-Gr composites by varying the Gr amount, and they also measured the effect of two different sintering techniques: microwave and conventional sintering process. In both cases, the sintering temperature was set to 900 °C, which was a very high temperature. They found that, at 0.9 vol.% Gr, the hardness values of Cu-Gr composites were 47.7 and 42.8 HV for conventional and microwave sintering, respectively. The values of hardness were very low at 0.9 vol.% Gr in both of the cases due to the poor dispersion of Gr in Cu matrix composites. Xin gao et al. synthesized [16] Cu-GO composites using a hot press sintering technique at 900 °C and 25 MPa pressure by varying GO content, including 0.1, 0.3 and 0.5 wt.%. At 0.5 wt.%, they observed the maximum hardness value for Cu-GO composites, which was 45 HV, and the ultimate tensile strength (UTS) value was 196 MPa. These values of hardness and UTS are not much higher at a high temperature of sintering. From the above discussion, it can be found that most of the researchers used very high temperature for the fabrication of Cu-GO composites and adopted different sintering techniques. However, the effect of different mesh size/grain size of GO on the mechanical properties of Cu-GO composites have seldom been studied. In this study, we determine the effect of various GO mesh sizes on Cu-GO composites using a low sintering temperature at 0.5 wt.% of GO.

2. Experimental Procedure

2.1. Materials

Copper powder (purity > 99.9%, size 6–8 µm) and various graphite (GF) mesh sizes (400, 800 and 1600) µm were purchased from Shanghai Sheeny Metal Materials Co., Ltd. (shanghai, China). GO powder was synthesized using the modified Hammer’s method by varying graphite mesh size. Details of GO synthesis have been reported in our previous work [1].

2.2. Fabrication of Cu-GO Composites

The GO powder was ultra-sonicated in an ethanol solution for 1 h for the better mixing of the GO solution. The GO solution was added into the Cu powder and ball-milled using a ball-to-powder ratio of 20:1 and speed 450 rpm for 4.5 h in the presence of an ethyl alcohol solution. After the milling process, the mixed powder was dried in an oven at 100 °C for 48 h. The dried powder was green compacted using 100 MPa pressure, and after that, the pellets were sintered in an oven at a low sintering temperature of 750 °C. Moreover, the sintered samples were annealed at 400 °C under a mixture of Ar and N2 gas for 1 h, and the sample dimensions were diameter 25 mm and height 10 mm.

2.3. Characterizations

The microstructure of powders and fracture behavior of bulk composites were observed with the help of scanning electron microscopy (SEM, Hitachi S-4800, Hitachi, Ltd., Tokyo, Japan). Further microscopic investigation for bulk composites was carried out through transmission electron microscopy (TEM) with point mapping using a Tecnai G2 F20 microscope (Hitachi, Ltd., Tokyo, Japan). A phase investigation was performed using an X-ray diffraction technique (XRD, X’Pert PRO MPD, Panalytial Inc., Almelo, The Netherlands) with Cu Kα radiation (λ = 1.5418 Å). The Vickers hardness of each sample was assessed using an AHVD-1000 (songshan materials laboratory, Dongguan, China) by applying 100 g force for 15 seconds and making seven indentations. An (Instron universal material machine, Tokyo, Japan) with a crosshead speed of 0.5 mm/min was used to perform the tensile test, using a tensile test sample of a dog-bone shape. Three samples were conducted for each composite to obtain reliable results.

3. Results and Discussions

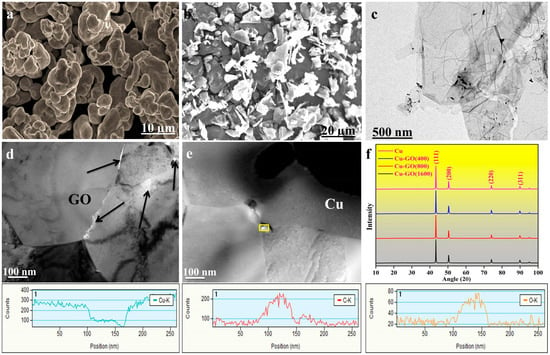

The structure of as-received Cu and GF powders are oval and flake-like, which are shown in Figure 1a,b, respectively. GO was synthesized by Hammer’s method and sheet-like structure and curl from the edges, which are shown in Figure 1c. TEM analysis of Cu-GO(1600) shows that the GO mixed well with the Cu matrix, and there are no obvious voids is showing on the interface. The white region in Figure 1d shows the presence of GO, whereas the black region is the Cu matrix. For further verification of the presence of GO, we performed point mapping (Figure 1f) of the yellow region shown in Figure 1e. The point maps data analysis showed that the white region is GO where the carbon is present in huge amounts; however, there can also be seen a small peak for oxygen, and the interface bonding is also good. The XRD analysis of bulk composite only showed four peaks for Cu, whereas there is no peak of GO, as can be seen in Figure 1f. This is due to the very low amount of 0.5 wt.% of GO, which means is impossible to detect GO through XRD. Similar kinds of results are frequent in the literature.

Figure 1.

SEM of (a) Cu and (b) GF, (c) TEM of GO and (d) Cu-GO (1600 µm), (e) TEM with point analysis, and (f) XRD of Cu and Cu-GO composites.

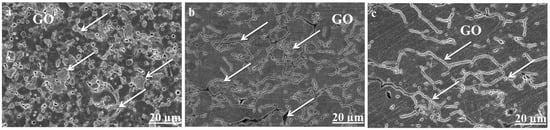

We conducted a SEM analysis of different Cu-GO composites after the sintering process, which is shown in Figure 2 below. We can see that the GO is well-dispersed in the Cu matrix at a mesh size 1600 µm, whereas the other two composites have some voids, and GO is agglomerated little bit in the Cu matrix.

Figure 2.

Cross-sectional SEM analysis of Cu-GO composites (a) Cu-GO(400), (b) Cu-GO(800), and (c) Cu-GO(1600).

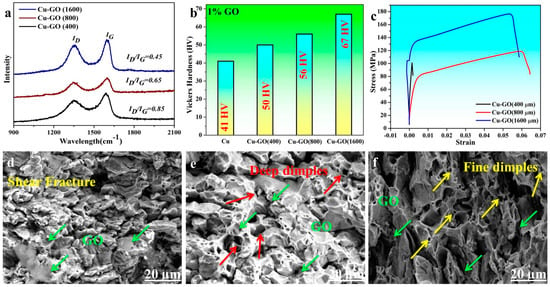

Figure 3a shows the Raman analysis of different Cu-GO composites by varying the mesh size of GO. With the increasing trend in mesh size, the ID to IG ratio of Cu-GO composites significantly reduced which means the number of oxide layers reduced significantly. The ratio of the intensity of the D-Raman peak to the G-Raman peak (ID/IG) is frequently used to characterize graphite-based carbon materials such as to estimate the number and size of sp2 clusters present in the carbon structures. The highest ratio of ID/IG is 0.85 for Cu-GO(400), whereas for Cu-GO(1600), the ratio is 0.45. The Vickers hardness of Cu and Cu-GO composites are also shown in Figure 3b. By increasing the mesh size of GO, the hardness values for Cu-GO composites enhanced significantly, which is in good agreement with the hall petch effect. By decreasing the particle size of filler, it acts well on the interface boundary and restrains the sliding of atoms on the interface, which is the basic principle for the pinning effect. Another important factor is the interface between Cu and GO, which is strong for the 1600 mesh size compared to the other two mesh sizes, which leads to the higher values of hardness and strength of the Cu-GO(1600) composite. Similar results are also observed for the stress–strain curves for Cu-GO, which can be seen in Figure 3c. Moreover, with a very low percentage of 0.5 wt% of GO, the yield strength (YS), 106 MPa, and ultimate tensile strength (UTS), 177 MPa, were observed for Cu-GO(1600) composite with the agreement of ductility. For Cu-GO(400), the YS and UTS are 98 and 100 MPa, which are very low due to shear fracture, which can be seen in Figure 3d. The Cu-GO(800) composites have a high ductility value due to deep dimples, but the YS and UTS are still low at 82 and 118 MPa compared to Cu-GO(1600) composites. In Table 1 below, we compared the strength and hardness values of different Cu-based matrix composites with our Cu-GO composite. Most of the composites listed below are prepared at high temperatures using hot-press or spark plasma sintering (SPS) machines (shanghai, China), but the hardness values are still low compared with our Cu-GO(1600) composites prepared at a low sintering temperature.

Figure 3.

(a) Raman analysis of Cu-GO composites; (b) Vickers hardness of Cu and Cu-GO composites; (c) stress–strain analysis of Cu-GO composites; (d–f) fractographs of Cu-GO composites, (d) 400 µm, (e) 800 µm, and (f) 1600 µm.

Table 1.

Ultimate tensile strength (UTS), Vickers hardness (HV) of various Cu matrix composites with Cu-GO composites.

The fracture behavior of the Cu-GO(1600) composite shows the presence of fine dimples, which cause good ductility, and the bonding of GO is better with the Cu matrix, which results in increases in the YS and UTS. The presence of GO in all the Cu-GO composites can be seen in the fractograph, which is denoted by blue arrows. In the Cu-GO(1600) composite, the GO acts as a bridge between the Cu matrix, which is very beneficial to increase the strength and the ductility of the composite.

4. Conclusions

In short, different mesh size Cu-GO composites were successfully fabricated at low sintering temperatures. Their microstructure showed that the higher-mesh-size GO mixed well with the Cu matrix and led to significantly enhanced mechanical properties of Cu-GO(1600) composites. The TEM analysis of Cu-GO(1600) composite also verifies the strong interfacial bonding between Cu and GO, and the presence of GO can be seen. The Cu-GO(1600) composite had higher hardness, YS, UTS and ductility values compared to other composites and to pure Cu. The higher mechanical values of the Cu matrix are significantly important for their use at the industrial level.

Author Contributions

F.N.: Investigation, Formal analysis, Data curation, Visualization, Writing—original draft. H.W.: Supervision, Conceptualization, Writing—review & editing, Funding acquisition. A.M.: Visualization, Conceptualization, Writing—review & editing. X.M.: Writing—review & editing. C.L.: Writing—review & editing. J.L.: Writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by National Key Research and Development Program of China (No. 2019YFE0124100).

Data Availability Statement

Not applicable.

Conflicts of Interest

There are no competing interests in this present work.

References

- Nazeer, F.; Ma, Z.; Gao, L.; Wang, F.; Khan, M.A.; Malik, A. Thermal and mechanical properties of copper-graphite and copper-reduced graphene oxide composites. Compos. Part B Eng. 2019, 163, 77–85. [Google Scholar] [CrossRef]

- Nazeer, F.; Ma, Z.; Gao, L.; Abubaker Khan, M.; Malik, A.; Wang, F.; Li, H. Effect of particle size on mechanical and anisotropic thermal conductivity of copper-reduced graphene oxide composites. Results Phys. 2019, 14, 102432. [Google Scholar] [CrossRef]

- Li, C.; Malik, A.; Nazeer, F.; Abrar, S.; Long, J.; Yang, Z.; Ma, Z.; Gao, L. Hardness and thermal conductivity of Cu-carbon composites by using different carbon-based fillers. Results Phys. 2021, 105157. [Google Scholar] [CrossRef]

- Naik, R.B.; Reddy, K.V.; Reddy, G.M.; Arockia Kumar, R. Development of high strength and high electrical conductivity Cu/Gr composites through friction stir processing. Mater. Lett. 2020, 265, 127437. [Google Scholar] [CrossRef]

- Yang, J.; He, Y.; Zhang, X.; Yang, W.; Li, Y.; Li, X.; Chen, Q.; Chen, X.; Du, K.; Yan, Y. Improving the electrical conductivity of copper/graphene composites by reducing the interfacial impurities using spark plasma sintering diffusion bonding. J. Mater. Res. Technol. 2021, 15, 3005–3015. [Google Scholar] [CrossRef]

- Han, X.; Huang, Y.; Gao, Q.; Fan, R.; Peng, X. Effects of nanotube content on thermal and mechanical properties of NT@Cu/Ag@GF/Al composites. J. Alloys Compd. 2018, 766, 594–600. [Google Scholar] [CrossRef]

- Nazeer, F.; Ma, Z.; Gao, L.; Malik, A.; Abubaker Khan, M.; Wang, F.; Li, H. Excellent mechanical properties of copper-graphite composites with the addition of tantalum alloying element. Vacuum 2019, 169, 108913. [Google Scholar] [CrossRef]

- Dong, D.; Duan, L.; Cui, J.; Li, G.; Jiang, H.; Pan, H. Influence of compaction temperature on the mechanical properties and micro morphology of Cu/CNTs composites prepared by electromagnetic impacting. Powder Technol. 2022, 396, 433–443. [Google Scholar] [CrossRef]

- Wei, C.; Ye, N.; Xia, W.; Jie, M.; Yao, J.; Tang, J. An electroless deposition strategy for preparing ultrathin CNTs/Cu composite foils with excellent mechanical properties. Diam. Relat. Mater. 2022, 121, 108785. [Google Scholar] [CrossRef]

- Li, C.; Zhang, M.; Ruan, M.; Wang, J.; Liang, J.; Zhang, D. A nanograins-attached and ultrathin Cu flake powder fabricated by high energy mechanical milling and dealloying. Mater. Lett. 2020, 265, 127432. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Yin, Y.; Li, C.; Xu, M.; Li, R.; Chen, Q. Preparation and properties of lead-free copper matrix composites by electroless plating and mechanical alloying. Wear 2022, 488–489, 204164. [Google Scholar] [CrossRef]

- Nazeer, F.; Ma, Z.; Xie, Y.; Gao, L.; Malik, A.; Khan, M.A.; Wang, F.; Li, H. A novel fabrication method of copper–reduced graphene oxide composites with highly aligned reduced graphene oxide and highly anisotropic thermal conductivity. RSC Adv. 2019, 9, 17967–17974. [Google Scholar] [CrossRef] [Green Version]

- Fang, L.; Yuan, W.; Wang, B.; Xiong, Y. Growth of graphene on Cu foils by microwave plasma chemical vapor deposition: The effect of in-situ hydrogen plasma post-treatment. Appl. Surf. Sci. 2016, 383, 28–32. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Liu, E.; He, C.; Han, Y.; Li, Q.; Nash, P.; Zhao, N. Fabrication of three-dimensional graphene/Cu composite by in-situ CVD and its strengthening mechanism. J. Alloys Compd. 2016, 688, 69–76. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.; Wang, Y.; Du, S.; Liu, Z.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Gao, X.; Yue, H.; Guo, E.; Zhang, H.; Lin, X.; Yao, L.; Wang, B. Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites. Powder Technol. 2016, 301, 601–607. [Google Scholar] [CrossRef]

- Ayyappadas, C.; Muthuchamy, A.; Raja Annamalai, A.; Agrawal, D.K. An investigation on the effect of sintering mode on various properties of copper-graphene metal matrix composite. Adv. Powder Technol. 2017, 28, 1760–1768. [Google Scholar] [CrossRef]

- Adams, P.M.; Katzman, H.A.; Rellick, G.S.; Stupian, G.W. Characterization of high thermal conductivity carbon fibers and a self-reinforced graphite panel. Carbon 1998, 36, 233–245. [Google Scholar] [CrossRef]

- Nazeer, F.; Ma, Z.; Gao, L.; Malik, A.; Abrar, S.; Wang, F.; Li, H. Effect of graphite mesh sizes on thermo-mechanical properties of Cu-GF composites. Vacuum 2021, 185, 109989. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Ozga, P.; Maziarz, W.; Pstruś, J.; Kania, B.; Bobrowski, P.; Stolarska, J. Microstructure and properties of bulk copper matrix composites strengthened with various kinds of graphene nanoplatelets. Mater. Sci. Eng. A 2015, 628, 124–134. [Google Scholar] [CrossRef]

- Yue, H.; Yao, L.; Gao, X.; Zhang, S.; Guo, E.; Zhang, H.; Lin, X.; Wang, B. Effect of ball-milling and graphene contents on the mechanical properties and fracture mechanisms of graphene nanosheets reinforced copper matrix composites. J. Alloys Compd. 2017, 691, 755–762. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A. Microstructure, electrical conductivity and hardness of multilayer graphene/Copper nanocomposites synthesized by flake powder metallurgy. Met. Mater. Int. 2015, 21, 704–712. [Google Scholar] [CrossRef]

- Xiong, D.-B.; Cao, M.; Guo, Q.; Tan, Z.; Fan, G.; Li, Z.; Zhang, D. High content reduced graphene oxide reinforced copper with a bioinspired nano-laminated structure and large recoverable deformation ability. Sci. Rep. 2016, 6, 33801. [Google Scholar] [CrossRef] [Green Version]

- Li, J.-F.; Zhang, L.; Xiao, J.-K.; Zhou, K.-C. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite. Trans. Nonferrous Met. Soc. China 2015, 25, 3354–3362. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Approach to Enhance the Mechanical Strength and Electrical and Thermal Conductivity of Cu-GNP Nanocomposites. Metall. Mater. Trans. A 2018, 49, 333–345. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).