Abstract

The current research trends of production engineering are based on optimizing the machining process concerning human and environmental factors. High-performance materials, such as hardened steels, nickel-based alloys, fiber-reinforced polymer (FRP) composites, and titanium alloys, are classified as hard-to-cut due to their ability to maintain strength at high operating temperatures. Due to these characteristics, such materials are employed in applications such as aerospace, marine, energy generation, and structural. The purpose of this article is to investigate the machinability of these alloys under various cutting conditions. The purpose of this article is to compare cryogenic cooling and cryogenic processing from the perspective of machinability and sustainability in the manufacturing process. Compared to conventional machining, hybrid techniques, which mix cryogenic and minimal quantity lubricant, led to significantly reduced cutting forces of 40–50%, cutting temperatures and surface finishes by approximately 20–30% and more than 40%, respectively. A carbon footprint is determined by several factors including power consumption, energy requirements, and carbon dioxide emissions. As a result of the cryogenic technology, the energy consumption, power consumption, and CO2 emissions were reduced by 40%, 28%, and 35%.

1. Introduction

Recent advancements in machining processing promotes the aerospace industry’s use in daily life [1]. In the aerospace industry, high-performance materials like titanium and Inconel are commonly used but are difficult to machine due to their complex geometries and strength at high temperatures. Various cooling techniques are applied during machining; however, excessive coolant use poses environmental risks despite enhancing productivity. Key machining parameters include cutting temperature, surface roughness, tool wear, cutting forces, power consumption, and CO2 emissions. This article explores cryogenic cooling as an emerging technique to effectively dissipate heat from the workpiece while promoting sustainable machining [2]. Bagherzadeh et al. [3] examined key factors affecting the machining process—including cutting forces, tool wear, surface roughness, chip morphology, and cutting temperature—using a combination of cryogenic cooling and minimum quantity lubrication (MQL). A modified nozzle was employed to assess its impact, resulting in surface finish improvements of approximately 60% for titanium and 30% for Inconel. Additionally, the Cryogenic Minimum Quantity Lubrication (CMQL) technique enhanced tool life by up to 16%. Shah et al. [4] evaluated tool life, surface finish, power consumption, and chip formation using three cooling methods: dry, flooded, and cryogenic. Among the cryogenic coolants tested, liquid nitrogen demonstrated superior performance, enhancing drilling efficiency by up to 93%. Additionally, liquid nitrogen contributed to improvements in other machining parameters while minimizing the environmental impact compared to conventional coolants. Strano et al. [5] investigated the machining of the Ti6Al4V alloy under cryogenic cutting and compared its performance with that of conventional cutting. The study revealed that cryogenic cooling significantly reduced the coefficient of friction.

Venugopal et al. [6] investigated the impact of cryogenic cooling on machining titanium alloys, specifically analyzing tool wear under dry, wet, and cryogenic conditions. Results showed that at cutting speeds below 100 m/min, cryogenic cooling significantly outperformed the other methods, increasing tool life by up to 70% at lower speeds. In addition, Stampfer et al. [7] had used Ti6Al4V to carry out cryogenic machining procedures, and the tool wear and forces generated during the machining had been used to analyze the machining performance. At higher cutting speeds, the effectiveness of the cryogenic technique declined, likely due to insufficient coolant penetration at the critical contact zones. Suhaimi et al. [8] performed experiments on titanium alloy to evaluate its performance under cryogenic conditions. The morphology of chips, tool wear, and secondary shear forces was studied by machining titanium alloy. Cryogenic machining achieved better results than oil-based machining [9,10]. Damir et al. [11] aimed to identify the optimal method for lowering cutting tool temperatures without compromising lubrication. Using computational and finite element analysis, they optimized machining conditions by combining minimum quantity lubrication (MQL) with cryogenic fluids. The hybrid approach, involving liquid nitrogen and MQL, delivered superior results in terms of surface finish and reduced tool wear when compared to high-pressure, flooded, and dry machining. This combination was specifically tested on titanium alloy (Ti6Al4V), demonstrating clear advantages over traditional flood cooling methods. Dhananchezian et al. [12] observed that the hybrid cooling technique significantly reduced the cutting forces at the rake face and minimized tool wear along the cutting edge radius. This method was employed to assess its impact on machining performance [13]. Ravi et al. [14] conducted milling on AISI P20 steel and turning on AISI 1060 under cryogenic conditions, comparing the results with both dry and flooded cooling. The experiments were carried out at varying cutting speeds while keeping the feed rate and depth of cut constant. The use of cryogenic cooling notably improved tool life and enhanced surface finish across both operations [15]. While the use of liquid nitrogen or CO2 with minimal lubricants has demonstrated a great improvement in surface finish and tool life in Cryogenic Minimum Quantity Lubrication (CMQL), there is also an innovative technique known as Minimum Quantity Cooling Lubrication (MQCL). Unlike CMQL, MQCL does not use cryogenic fluids; instead, it uses chilled emulsions or cooled air–oil mists. Without requiring extremely high temperatures, it improves the cooling capabilities of MQL systems. This is especially helpful when cutting hard materials requires improved heat removal, and complete cryogenic technology is either unavailable or too expensive.

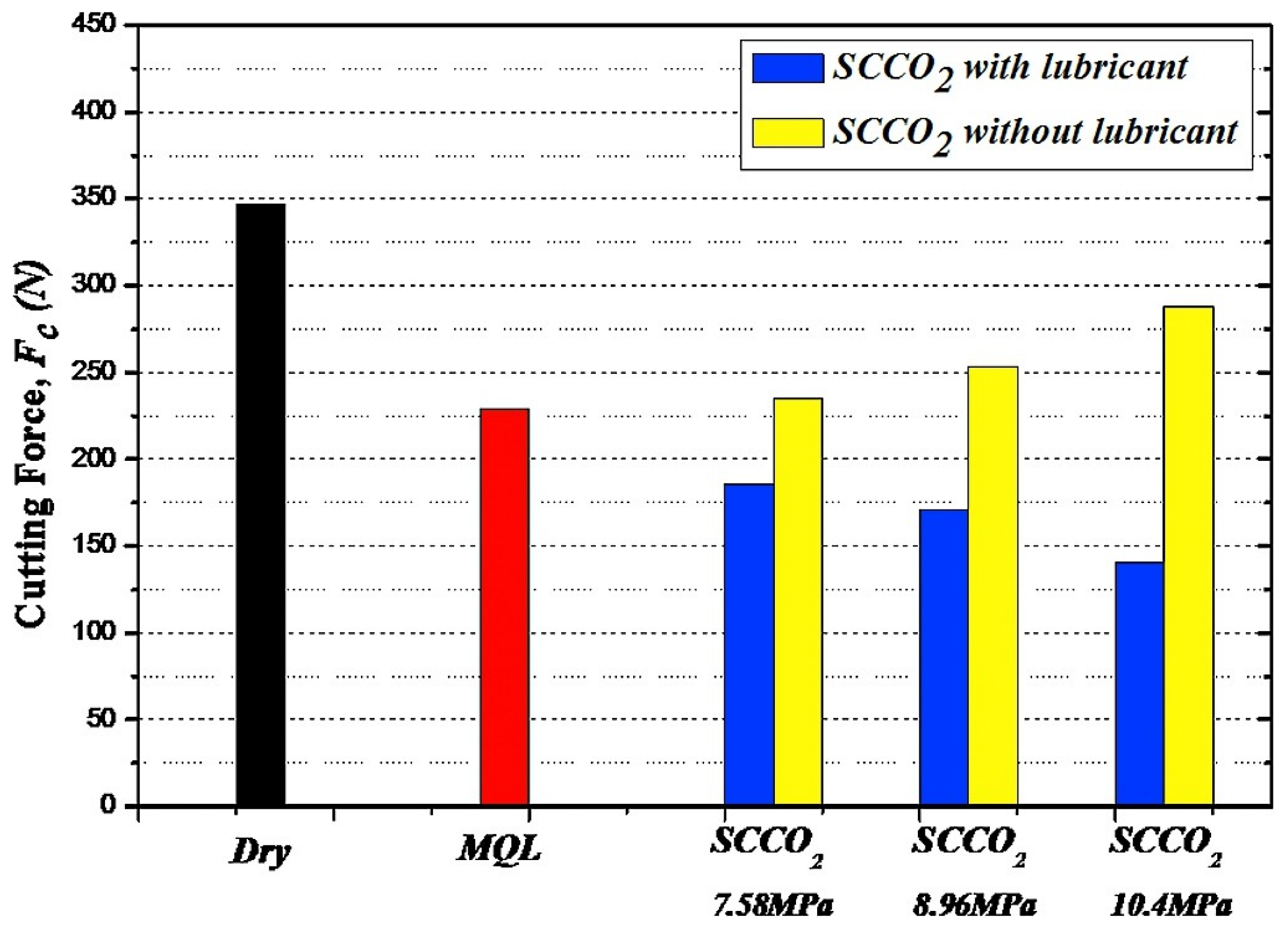

Machining processes have been applied to polymers to meet strict dimensional accuracy requirements. In such applications, achieving a high-quality surface finish and improved material hardness is essential. One study compared the performance of Polyamide 6 under cryogenic cooling and traditional flooded cooling, highlighting the advantages of cryogenic conditions in enhancing surface integrity. Bertolini et al. [16] observed that the optimal temperature range for the material lies between −20 °C and 20 °C within which it exhibited improved surface finish and minimal defects. Ultra-high-strength steel, commonly used in automotive components for enhanced performance, is produced through a process of preheating followed by quenching to achieve greater hardness and rigidity. Since supercritical carbon dioxide (SCCO2) is less hazardous to the environment, it is considered an alternative to liquid nitrogen. A comparison was made between the SCCO2 cutting process using lubricants and the SCCO2 cutting process without lubricants. Using hybrid cooling (MQL, liquid nitrogen, and carbon dioxide) to turn Ti6Al4V is an essential alternative to conventional techniques to reduce the tool wear, and build-up edges [17]. A study examined titanium alloy’s performance under various cooling conditions, and it was found that hybrid cooling techniques were effective [18]. Several researchers, including Mulyana et al. [19], identified adhesion as the primary contributor to tool wear during the machining of high-performance alloys. Incorporating supercritical CO2 (SCCO2) with lubrication significantly enhanced machining performance by reducing cutting temperature and forces by approximately 60% and 55%, respectively. Additionally, tool life under dry conditions improved by nearly 150% when SCCO2 with lubricant was applied. A supercritical condition was found to be optimal with the use of carbon dioxide, extending tool life remarkably and enabling sustainable production [20]. Several trials have been conducted to study the impact of different cooling strategies in milling titanium alloys, such as cryogenic cooling with CO2, emulsion cooling, MQL, dry cutting, or cryogenic combined with air or MQL. It was noted that the best results were obtained when CO2 and MQL were combined during cryogenic cooling [21]. Busch et al. [22] investigated the cooling strategies for the Inconel and Ti-6Al-4V, and found that the hybrid showed the optimized results for machining parameters.

O. Pereria et al. [23] investigated the environmental impact of cryogenic and minimum quantity lubrication techniques, specifically focusing on liquid nitrogen and carbon dioxide. Both methods demonstrated a significant reduction in power consumption [24]. O. Pereira et al. [25] used liquid nitrogen (LN2) in the study and demonstrated a lower environmental impact by producing approximately 17% less benzene compared to carbon dioxide (CO2). However, the consumption rate of LN2 was significantly higher, about 43% more than that of CO2. Additionally, the use of CO2 necessitated a controlled environment to maintain a sustainable manufacturing process. This research focused on machining duplex stainless steel using a TiAlN-coated insert under cryogenic cooling conditions. Shokrani et al. [23] examined chip morphology, cutting temperature, surface roughness, cutting forces, and tool wear while maintaining a constant feed rate and depth of cut, varying only the cutting speed and cooling conditions to evaluate the effectiveness of different cooling methods [25,26]. Dhananchezian et al. [27] found that cutting temperature, cutting forces, and surface roughness improved by approximately 55%, 35%, and 20%, respectively. Ranjith et al. [28] focused on optimizing the machining of aluminum alloys under cryogenic conditions. The key parameters analyzed were material removal rate and surface roughness, which were evaluated by varying depth of cut, spindle speed, and feed rate. Among these, the depth of cut was identified as the most significant factor, substantially reducing both material removal rate and surface roughness. The optimal machining settings determined were a spindle speed of 1400 RPM, a feed rate of 120 mm/min, and a depth of cut of 0.4 mm. Additionally, the study on 7075 aluminum alloy under cryogenic cooling investigated the effects of cutting speed, feed rate, and other input variables. According to [29], cryogenic liquid nitrogen (LN2) reduced temperature and cutting forces and improved surface finish.

Since the world is moving towards the sustainability of the environment [30], the Minimum Quantity Cooling Lubrication (MQCL) has drawn a great interest recently as a more environmentally friendly substitute for conventional cooling techniques. In contrast to cryogenic or flooded cooling methods, which demand large amounts of resources, MQCL lowers cutting temperature and tool wear by using a small quantity of lubricants in conjunction with cooled air or mist. Under a variety of machining situations, MQCL has been shown by researchers to dramatically lower energy usage, limit environmental effect, and prolong tool life. MQCL is a useful option for environmentally conscious manufacturing since it provides a workable balance between sustainability and performance when compared to completely cryogenic systems.

Recent research has focused on machining methods that investigate coolants that are easy to recycle and have minimal effects on the environment. Yildirim et al. [31] investigated the properties of a nickel-based alloy using minimum quantity lubrication (MQL), cryogenic cooling, and a hybrid cryo-MQL technique. Experimental tests were conducted at cutting speeds ranging from 10 to 50 m/min, while maintaining a constant feed rate and depth of cut. The most significant improvements were achieved with the cryo-MQL method, which reduced surface roughness by approximately 25% and decreased tool wear by 80%. Recent research on cooling methods highlighted their effectiveness in minimizing adhesion without compromising the material’s inherent properties. Cryogenic cooling and ethanol-based minimum quantity lubrication (MQL) were evaluated in Machining Removal Fluid (MRF) to assess their effects on both the material and the environment. Titanium alloy was machined using uncoated carbide tools. Cryogenic cooling effectively reduced cutting temperature, forces, and rough surface, although it led to a decrease in the material’s fracture energy. In contrast, the use of ethanol in MQL resulted in a 65% reduction in cutting force and adhesion with the same tooling. This technique did not affect the fracture strength and significantly increased the material removal rate, which was attributed to the reactive hydroxyl (OH) groups in ethanol [32].

Kesavan et al. [33] investigated the effects of cryogenic cooling on Hastelloy machining. Using LN2 cryogenic cooling, the cutting temperature, surface roughness, and machining parameters significantly improved. Akıncıoğlu et al. [34] used the cryo-treated cutting tool to perform an experiment on Hastelloy; surface roughness improved by 28% and 73% in shallow and deep cryogenic conditions, respectively. Statistical analysis was conducted. Feed rate was found to be the most influential factor in machining. The machinability of Hastelloy was investigated using TiAlN-coated cutting tools with multilayer PVD coatings. The study was conducted under cryogenic conditions using liquid nitrogen, maintaining a constant feed rate and depth of cut while varying the cutting speeds. Results showed that cryogenic cooling reduced cutting temperature, cutting forces, and surface roughness by approximately 60%, 15%, and 15%, respectively. Titanium alloys, commonly used in biomedical and aerospace industries, are known for their machining challenges due to their hardness and strength [35]. Venugopal et al. [36] evaluated tool wear behavior during the machining of titanium alloys under cryogenic conditions. Using uncoated carbide tools, experiments were conducted at cutting speeds ranging from 70 to 100 m/min to assess the impact of liquid nitrogen cooling on tool wear. The optimal reduction in tool wear was achieved at a cutting speed of 70 m/min.

Sustainability has become a crucial priority in the 21st century. Aramcharoen et al. [37] and Pušavece et al. [38] investigated sustainable machining approaches for Inconel 718 by applying various cooling techniques. Their analysis focused on multiple factors such as cutting forces, power consumption, surface roughness, tool wear, and residual stress. A reduction in these factors was used to demonstrate the sustainability benefits of cryogenic machining.

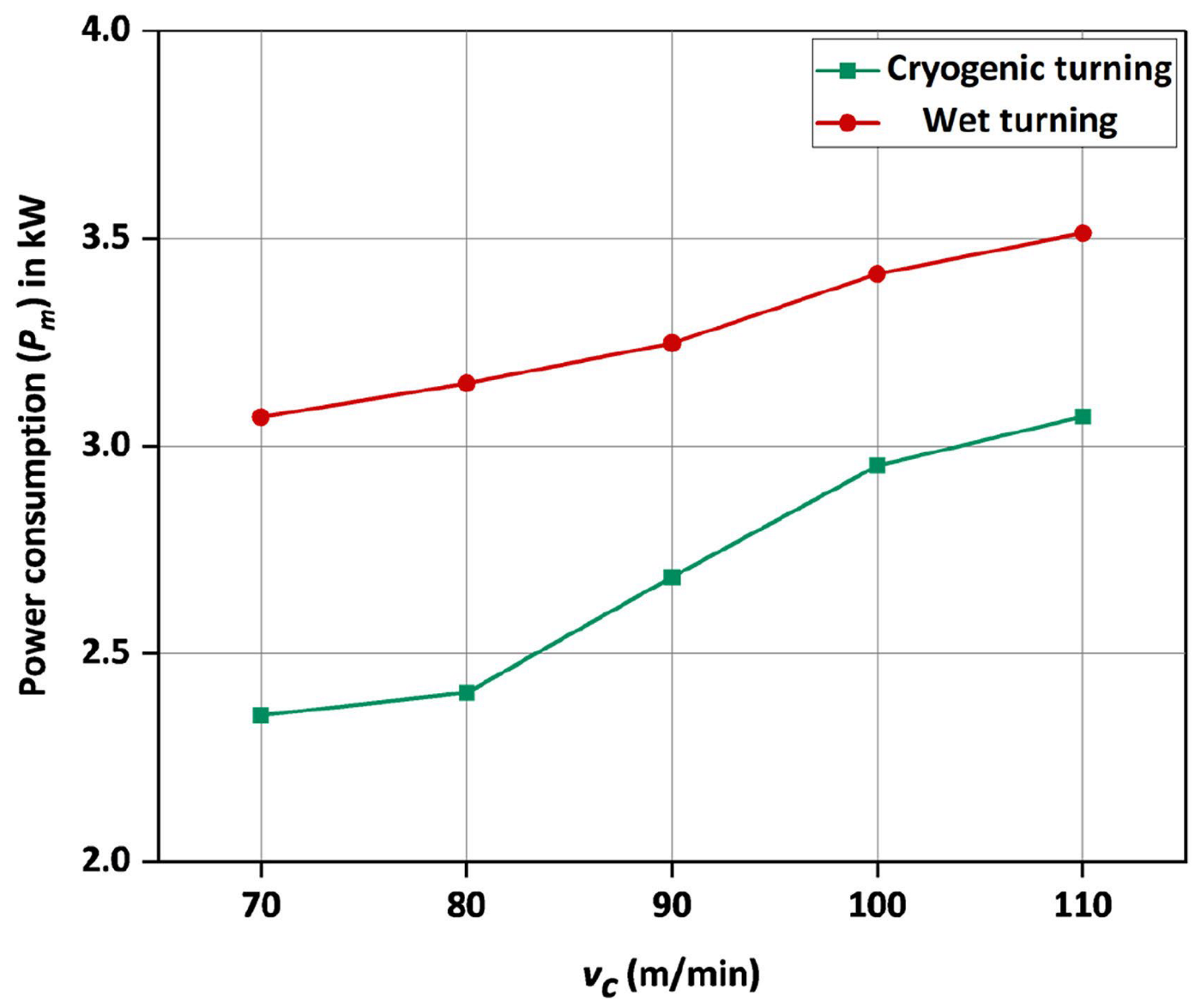

Shah et al. [39] found that liquid carbon dioxide (LCO2) outperformed liquid nitrogen (LN2) in machining Inconel 718. Power consumption was reduced by 19% with LNCO2, while the drilling capacity increased by up to 300%. However, according to the life cycle assessment (LCA) results, LN2 is favored due to its lower environmental impact. Following the EN ISO 14044 standard [40], the researchers evaluated the energy consumption during milling, taking into account the cutting energy, the pumping energy for flood cooling, and the energy needed for recycling CO2. Gross et al. [41] detected that employing the CMQL technique reduced the overall energy consumption by 39% compared to conventional flood cooling. Experiments were carried out across varying material removal rates to evaluate and compare the effectiveness of different cooling scenarios. Agrawal et al. [42] investigated various parameters affecting the machining process, including power consumption, tool life, and surface roughness. Additionally, machining costs and carbon emissions were examined to assess the operation from a sustainability standpoint. On the Ti-6Al-4V, an experiment was performed using the cryogenic technique, while wet machining was used as a comparison. Cryogenic machining significantly enhances tool life, more than doubling it at higher cutting speeds. Additionally, surface roughness and power consumption were reduced by 22% and 23.4%, respectively. The use of cryogenic cooling also lowered machining costs by 27% and decreased carbon emissions by up to 22%.

Due to the increase in demand for reducing carbon footprints, Lu et al. [43] experimented on metric-based sustainability under cryogenic conditions. To study machining processes under different conditions, the process sustainability index (ProcSI) technique was used. Using high cutting speed, the machining performance was more efficient. When the cutting speed is 500 m/min, the CO2 emissions score is 7.0. Kumar et al. [44] studied the sustainability aspect by machining the Ti-6Al-4V using the analytic hierarchy process (AHP) combined with a technique for order preference based on an ideal solution (TOPSIS). A hybrid of MQL and liquid nitrogen, as well as dry experiments, was conducted on it. Using a hybrid system of LN2 combined with MQL resulted in a 16% reduction in energy consumption and a 66% decrease in machining costs. Furthermore, the overall life cycle performance improved by up to 34% compared to dry machining. Rotella et al. [45] examined cryogenic cooling from a sustainability perspective and subsequently compared its performance to conventional oil-based and dry machining methods. Coolant consumption is reduced in machining when using near-dry machining, and sustainability indicators showed an improved result. Cutting temperatures, power consumption, and forces decreased due to cryogenic cooling [46]. A series of experiments was conducted using a combination of cryogenic cooling and minimum quantity lubrication (MQL) at varying pressures. The study evaluated sustainability factors including tool life, chip morphology, cost analysis, and risk assessment. The optimal results were achieved by integrating cryogenic and MQL techniques, resulting in more than a 100% increase in tool life and a 44% reduction in operating costs compared to traditional flooded cooling [47].

Cryogenic processing is an advanced technique used to enhance the performance and efficiency of machining operations [48]. Singh et al. [49] investigated the friction stir processing of AZ91 magnesium alloy, with samples prepared using deep cryogenic treatment (DCT) and sodium chloride (NaCl) to assess corrosion behavior. The application of DCT enhanced the mechanical properties, attributed to the scattering effect, and promoted a more refined and orderly solid microstructure. Kumar et al. [50] aimed to optimize the specific wear rate of AZ91D magnesium alloy by analyzing the effects of three key parameters: applied load, sliding distance, and sliding speed. According to their analysis, the optimal values identified were 44.71 N, 521.12 m, and 1.77 m/s, respectively. Satyanarayana et al. [51] developed a model for the good grain structure requirement demand. The aluminum 6061 alloys are processed using cryogenic friction stir. Elongation was enhanced through this process as a result of more uniform stress distribution across the bulk stir zone. Additionally, the formation of fine equiaxed grains within the stir zone contributed to a significant increase in hardness. The mill feeding system and liquid nitrogen (LN) jets from the mill nozzles were analyzed using computational fluid dynamics (CFD) simulations [52]. In this experiment, nozzle geometry, coolant pressure, and efficiency of coolant delivery were varied. The Ansys Fluent software simulated the system at various nozzle locations, observing how the phase of the liquid nitrogen changed as the simulation progressed, as demonstrated by Kim et al. [53]. For example, several issues, such as optimizing the number, position, and orientation of the cryogenic jets, and considering the alternative configuration setups, were examined [54].

To improve productivity in titanium alloy (Ti-6Al-4V), cutting speeds and feeds must increase, causing higher cutting temperatures that adversely affect the tool life. Cryogenic machining was conducted using ABAQUS to investigate the cutting temperature behavior by varying nozzle position with tool–chip interface using simulation techniques [55]. FEA and CFD models are used to study the optimization of the nozzle in cryogenic conditions using carbon dioxide for titanium alloys. During machining, the distance between the nozzles played a significant role, leading to a reduction of approximately 45% in both surface roughness and cutting temperature [56].

2. Research Aims and Motivation

Many previous studies have explored aspects of cryogenic machining, but most of them have focused solely on machinability performance or environmental sustainability. This article provides an integrated perspective by addressing sustainability and machinability using a unified structure. Furthermore, unlike other studies, this one makes use of recent advancements in computer modeling, such as CFD and FEA, to examine nozzle design and coolant delivery efficiency. By combining practical use and business developments, it also emphasizes the industrial significance of cryogenic hybrid systems. On the other hand, governmental bodies have put intense pressure on the metal cutting industry to reduce the environmental impact of its operations. The metal cutting community has been introduced to sustainable manufacturing as a means of refuting the negative aspects of manufacturing. Sustainable manufacturing is based on the following fundamental principles:

- Reducing the consumption of input resources, such as energy, water, and materials.

- Minimizing the use of hazardous and non-biodegradable materials.

- Improving the efficiency of the production process by reducing waste streams.

In terms of metal cutting, the research community has been focused on implementing the above recommendations in the context of cutting fluid strategies. Nevertheless, the state-of-the-art in cutting fluid cooling and lubrication strategies needs to be summarized to highlight the research gap.

- Could a green alternative based on cryogenic cooling be used instead of the conventional flood cooling method?

This study aims to provide a significant, comprehensive, and critical overview of various aspects of cryogenic machining of superalloys, with a particular emphasis on titanium alloy, nickel alloy, and steel materials. The research will focus on the following:

- Being familiar with cryogenic cooling systems and processing methods for machining superalloys.

- Different methods of cooling and processing examined and their impact on other output parameters during the machining of a difficult-to-cut material.

In addition to this, the study,

- Presents an overview of various peer-reviewed publications that have been published in the same field.

- By identifying current research gaps in the state-of-the-art and recommending appropriate solutions, this article makes a valuable contribution to the field.

3. Research Methodology

A literature review, typically focusing on specific areas, provides a structure that can serve as a basis for identifying and evaluating relevant research. It helps to assess previous research work to determine and fill gaps in the field. It helps to understand how previous researchers have approached the same topic area by assessing the challenges they have faced.

This study examines the state-of-the-art for machining different hard materials under cryogenic cooling or cryogenic processing and how it impacts sustainability. Study objectives include determining “general recommendations for optimal process parameters,” describing “challenges with machine-hard materials,” and discussing the effect of these processes on sustainability. According to previous studies, the machinability of superalloys under different conditions was not thoroughly explored. A scheme for evaluation development, as proposed by [57], has been used. According to the referred evaluation development scheme, the research methodology was broken down into three steps.

3.1. First Phase: Review Planning

- Determining the research questions and objectives for the review is a significant part of the planning process.

3.2. Second Phase: Reviewing the Development Phase

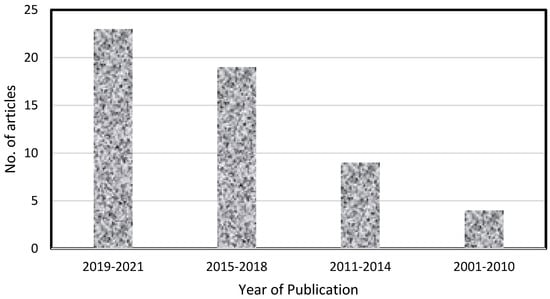

- The method through which the systematic review was performed should also be mentioned. In search of original research articles, journal articles, and conference proceedings of Elsevier, Emerald, Springer, and Google, the authors gathered information on the machining of hard materials under cryogenic cooling or cryogenic processing, and the sustainable aspects of such machining. Some keywords were machinability, tool wear, superalloys, cutting temperatures, cutting forces, surface roughness, cryogenic cooling, cryogenic processing, sustainability, FEA, and CFD simulation. Researchers analyzed studies from the last two decades, especially those from the previous ten years, from 2021 to 2011. An extensive selection of experimental and numerical studies was the basis for the systematic review. Different material studies were conducted to determine how different cooling techniques were performed on hard materials. These publications were selected for the study according to Figure 1 below.

3.3. Third Phase: Results Dissemination and Communication

- Following confirmation of the selected articles in the previous phase (Phase 2), the related metadata from these articles was uploaded to Microsoft Excel for use in creating the query. In the descriptive analysis, different cooling strategies were used to machine difficult-to-cut materials, analyzed and described based on their machinability (tool and workpiece materials), sustainability (water, coolant, and energy), and type of operation (turning, milling, and drilling).

Figure 1.

Number of articles included in this study each year.

Figure 1.

Number of articles included in this study each year.

4. Machining Performance Indicators

4.1. Cutting Temperature

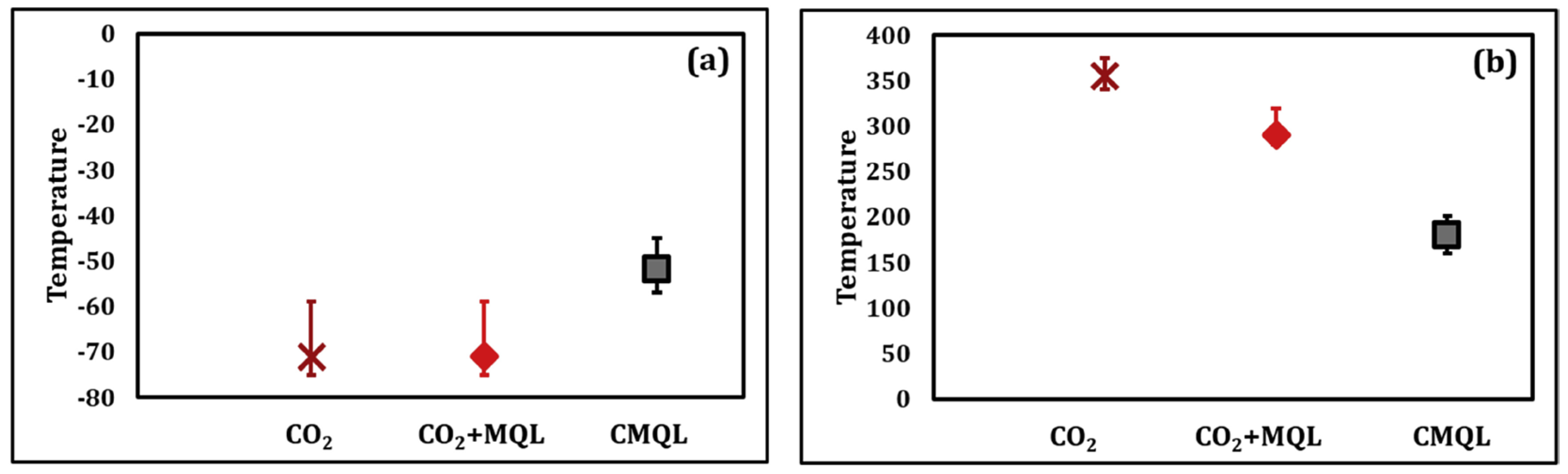

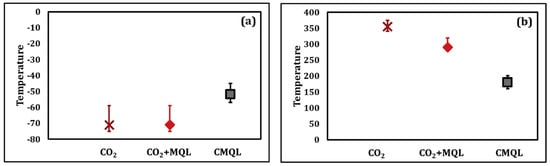

The cutting temperature is the most prominent factor in machining. Most of the researchers performed different experiments on different materials. Figure 1 investigated the cutting temperature at a feed rate of 0.2 mm/rev and a cutting speed of 150 m/min for the Ti6Al4V by using the CO2, CO2 mixed with MQL, and CMQL. Figure 2a shows the temperature of the material before it started, and Figure 2b showes the temperature while machining was performed. The temperature drop using the CMQL method is around 49% compared to the CO2 cryogenic cooling. The cutting temperature reduced from more than 350 to around 150 °C. The mixture of CO2 with MQL is also investigated in this experiment, showing enhanced results of up to 19%. Cryo-MQL turning of Inconel 686 significantly enhanced machining performance, reducing cutting temperature by 33%, surface roughness by 25%, and tool wear by 40%, compared to conventional methods [58]. Cryogenic treatment of cemented carbide enhanced wear resistance by 28% and cutting performance by 35%, due to refined microstructure and improved hardness stability [59].

Figure 2.

The cryogenic cooling effect of TiAl4V in turning at cutting speed of 150 m/min and feed rate 0.2 mm/rev (a) before cutting and (b) during cutting operation [3].

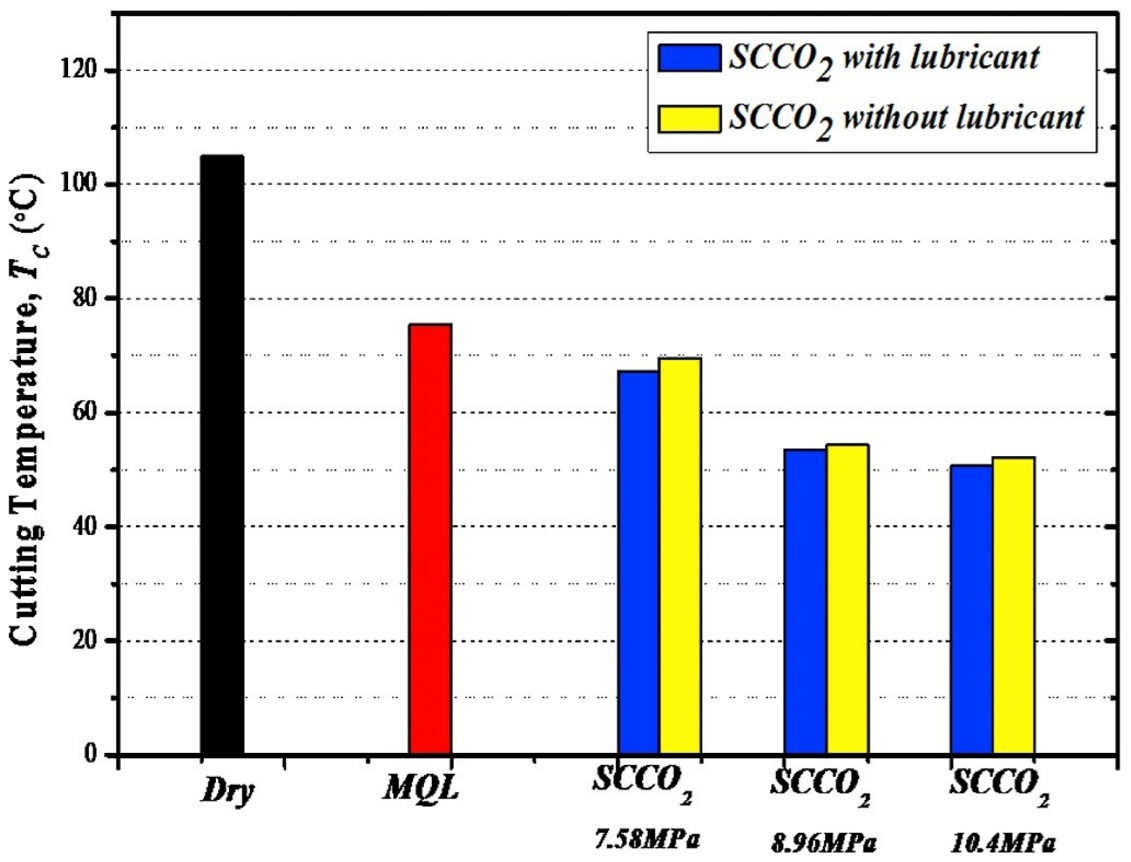

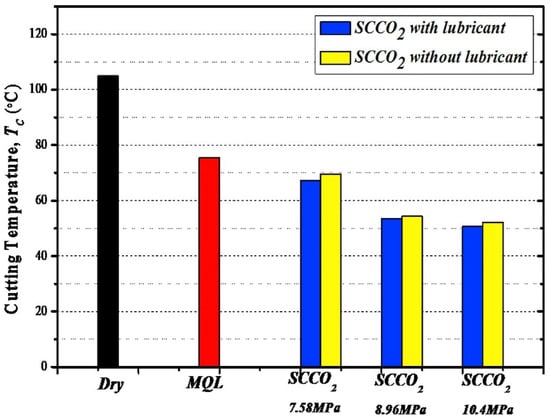

Figure 3 illustrates the cutting temperature profile during the machining of high-grade steel under various cooling conditions, including dry machining, minimum quantity lubrication (MQL), and supercritical carbon dioxide (SCCO2), at different pressures. The study specifically investigated the performance of SCCO2, both with and without the addition of lubricant, to better understand its thermal control capabilities in steel machining applications. The results indicate that SCCO2 with lubricant at a pressure of 10.4 MPa led to a significant temperature reduction of approximately 55% compared to dry machining, and around 35% compared to the MQL approach. This substantial decrease highlights the enhanced cooling efficiency achieved by the combined action of supercritical CO2 and lubrication, which improves heat dissipation at the cutting zone. In contrast, SCCO2 without lubricant showed only marginal improvement over the other methods, suggesting that the presence of lubricant is critical for maximizing the thermal performance of supercritical fluids in machining. These findings emphasize the importance of optimizing both pressure and lubrication when using SCCO2 as a cooling strategy in high-performance steel cutting. Computational fluid dynamics (CFD) analysis of cryo-CO2 in high-speed milling revealed a 40% improvement in cooling efficiency and a substantial reduction in peak tool temperature, enhancing heat dissipation and machining stability [60].

Figure 3.

Cutting temperature at different cooling conditions for high thermal steel [19].

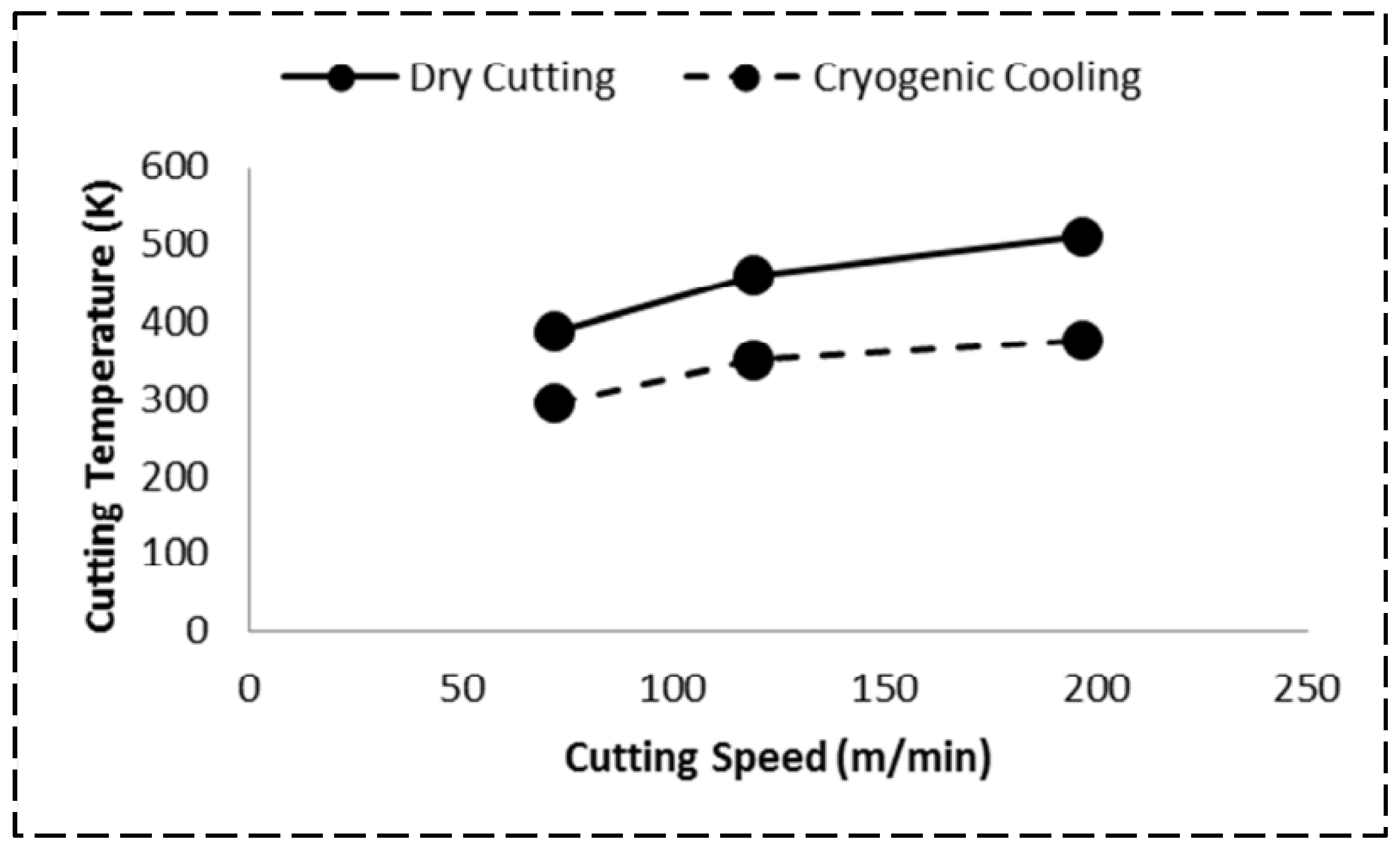

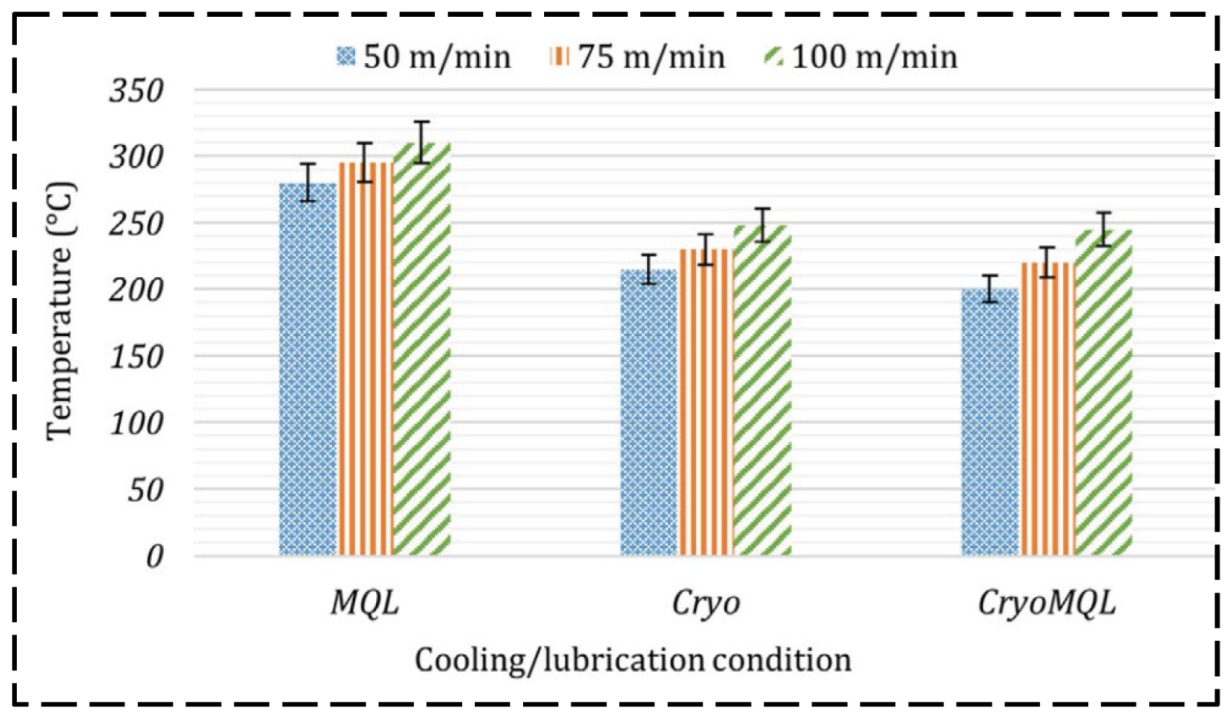

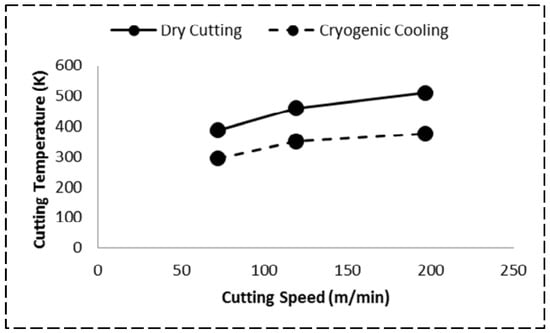

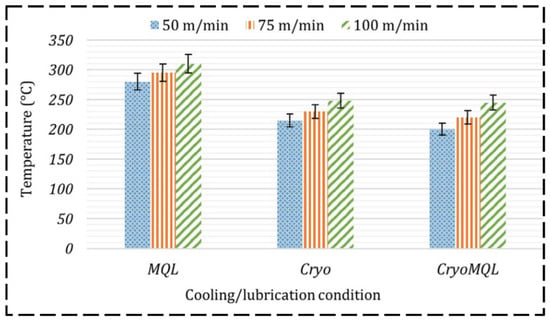

Figure 4 represents the temperature of the experiment at different cutting speeds. As from the metal cutting theory, the cutting temperature increases as the cutting speed increases. In Figure 4, the cutting properties of duplex stainless steel are investigated at a feed rate of 0.11 mm/rev, and the cutting depth is 1 mm using cryogenic cooling; the dry cutting condition is contrasted with the cryogenic cooling condition. The cutting temperature is decreased extensively, which is more than 50% compared to the dry machining. The liquid nitrogen is utilized in cryogenic cooling to reduce the temperature of the cutting tool. Figure 5 shows the performance of a nickel alloy under different cooling conditions. The temperature is increased, according to the metal cutting theory, by increasing the feed rate or cutting speed. In the experimentation, the feed rate and depth of cut are constant at 0.12 mm/rev and 0.5 mm, respectively, while the cutting speed varies from 50 to 100 m/min. The highest temperature was observed using the MQL system, and it was reduced by around 22% using liquid nitrogen. The hybrid technique reduced further by up to 25% compared with the MQL system. The mixture of cryo and MQL showed the best result over all other techniques available.

Figure 4.

Cutting temperature of duplex stainless steel at different cutting speeds [27].

Figure 5.

Cutting temperature at the different cooling conditions for Ni-based alloys [31].

4.2. Cutting Forces

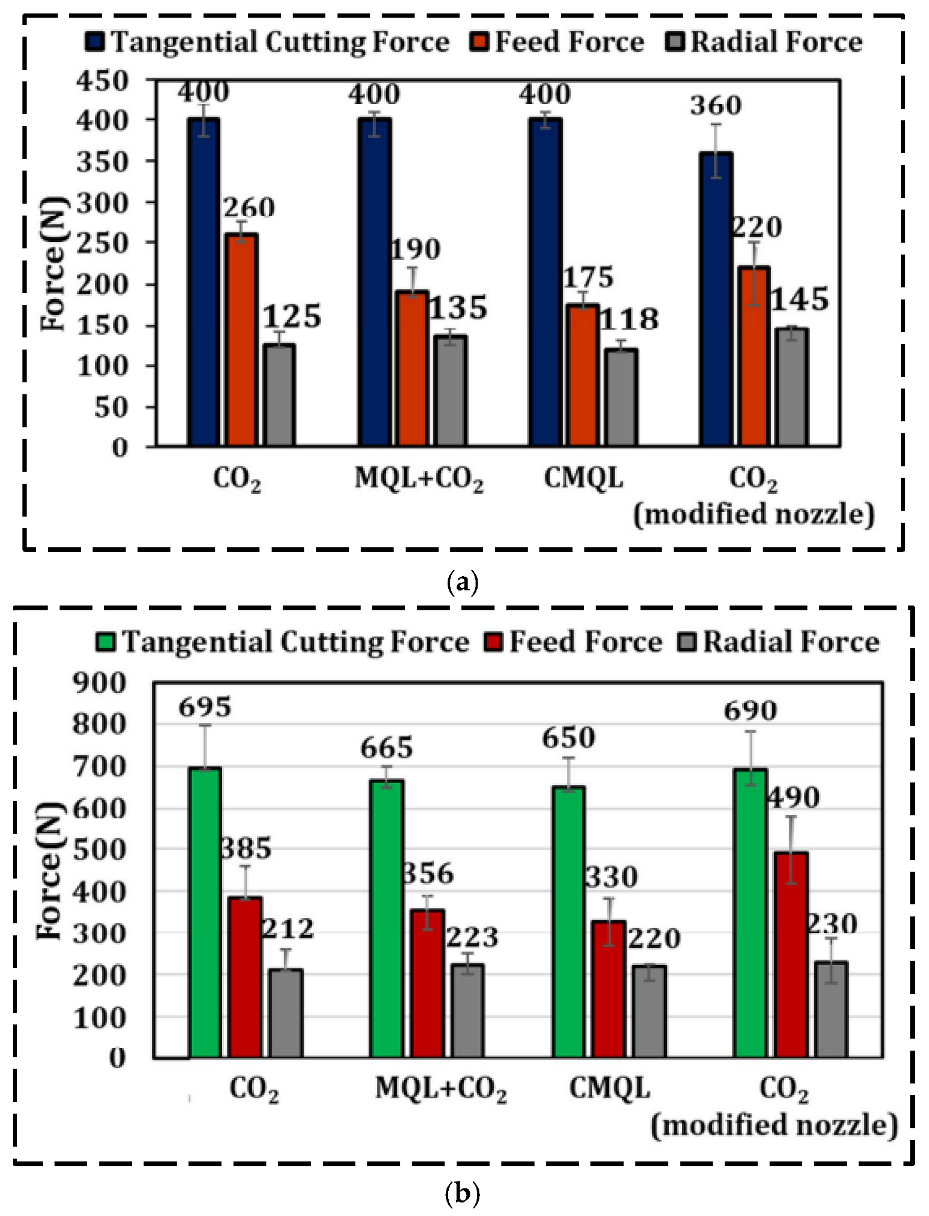

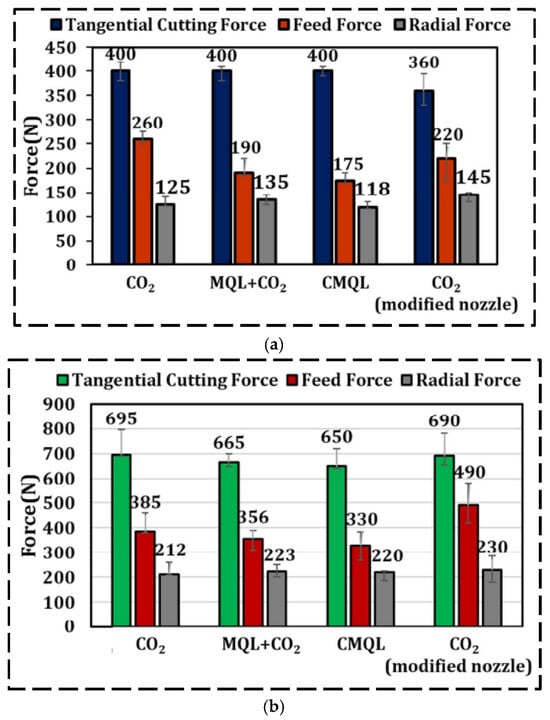

The cutting forces are also one of the essential factors during machining. The cutting forces of two different materials, Inconel 718 and Ti6Al4V, were investigated for different cutting conditions. Researchers examined cutting forces using CO2, MQL + CO2, CMQL, and nozzle modifications at CO2. The researchers examine the radial, tangential, and feed forces at a constant cutting speed of 150 m/min and a feed rate of 0.2 mm/rev. Figure 6a shows the cutting forces for the different cooling conditions with the optimum value found using the CMQL technique, where both the feed and radial forces decreased compared to all other cooling methods. Hybrid cryogenic/MQL helical milling of Inconel 718 reduced cutting forces by 23%, improved hole dimensional accuracy by 28%, and extended tool life by over 35%, compared to conventional methods [61].

Figure 6.

Cutting forces at the different cooling conditions at a feed rate of 0.2 mm/rev and cutting speed of 150 m/min: (a) Ti6-Al-4V and (b) Inconel 718 [3].

Similarly, Inconel 718 showed the same behavior as titanium alloy. Tangential and feed forces decrease in MQL + CO2 and CMQL almost simultaneously, but the radial forces are almost constant irrespective of the cooling method. In the machining of titanium alloy, the tangential temperature is 400, as observed in other conditions. However, the feed and radial forces decreased by around 32% compared to the MQL, and radial forces decreased by around 5%. For the machining of the Inconel, both hybrid and CMQL showed almost the same tangential and feed forces, which are 6% and 14%, respectively.

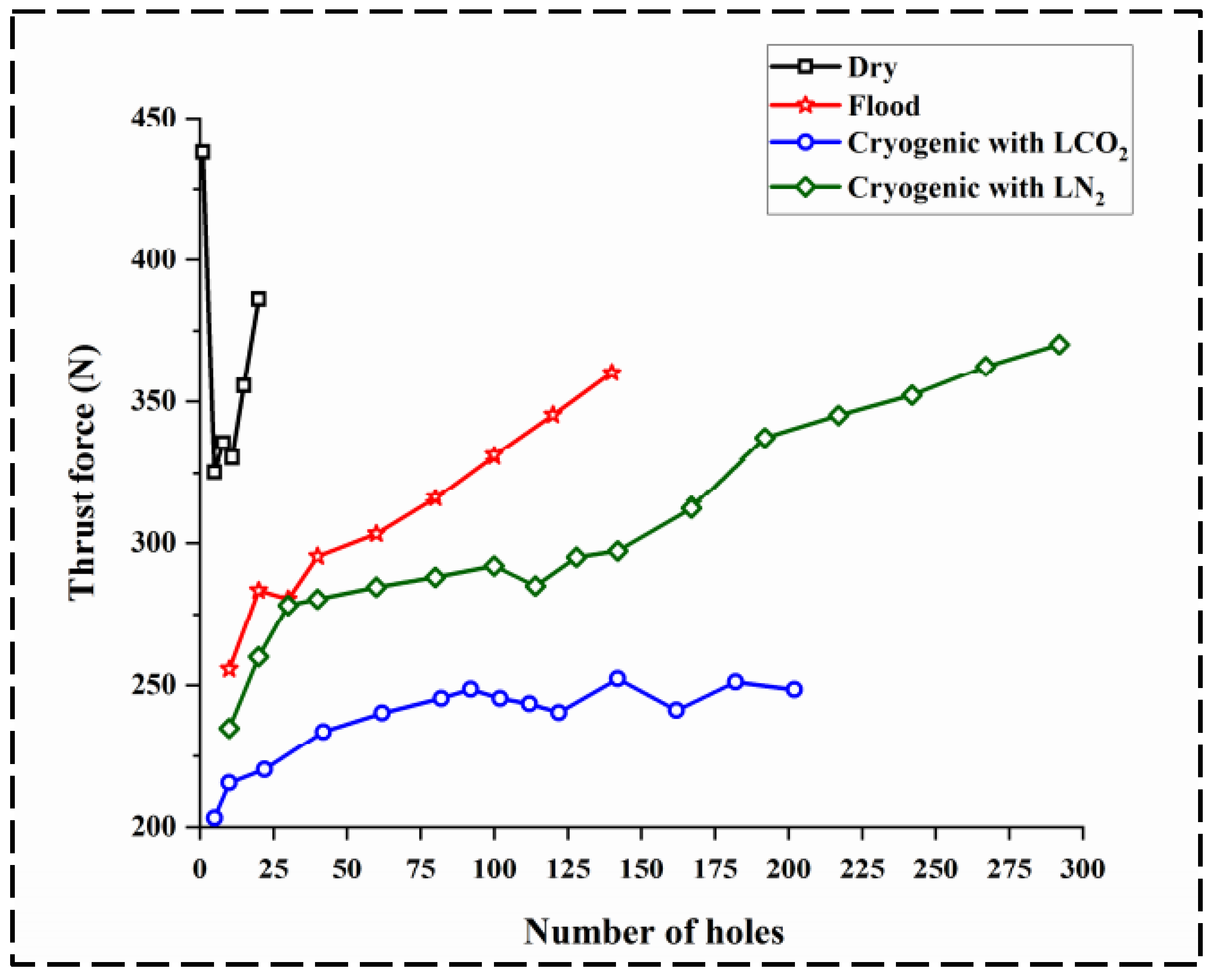

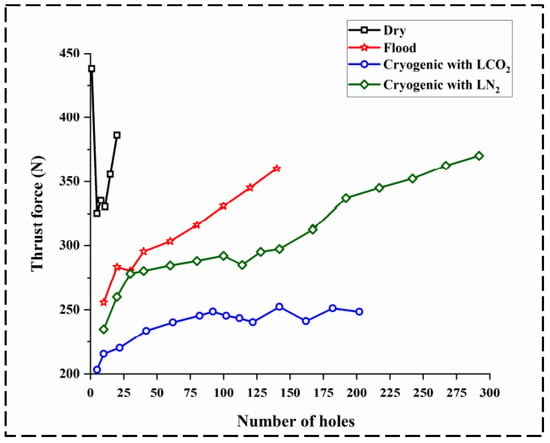

Force analysis is a critical aspect of machining studies, as cutting forces directly impact power consumption and, consequently, the overall sustainability of the process. In this study, drilling operations were conducted under various cooling conditions to evaluate their influence on machining sustainability. The cooling strategies included dry machining, conventional flooded (wet) machining, and two cryogenic coolants: liquid carbon dioxide (LCO2) and liquid nitrogen (LN2) shown in Figure 7. Among all the methods tested, cryogenic machining using LN2 demonstrated the most favorable performance in terms of force reduction. Specifically, the use of LN2 as a cooling medium led to a reduction in thrust force by approximately 75% compared to dry machining, 29% compared to flooded machining, and 18% compared to LCO2. This significant decrease in cutting forces is attributed to the superior cooling capacity of LN2, which minimizes tool–workpiece interface temperature and reduces friction. These findings highlight the potential of LN2-based cryogenic cooling as a sustainable and energy-efficient alternative for high-performance drilling operations.

Figure 7.

Investigation of the different cooling systems at different number of holes for titanium alloy [4].

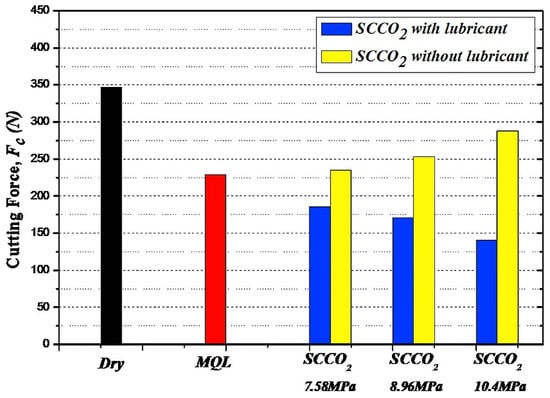

The cutting forces observed during the machining of high-grade steel under various cooling and lubrication conditions are presented in Figure 8. The study evaluates the effects of dry machining, minimum quantity lubrication (MQL), and supercritical carbon dioxide (SCCO2) at varying pressure levels, with and without the addition of lubricant. The results clearly indicate that SCCO2 with lubricant at a pressure of 10.4 MPa produced the lowest cutting forces across all tested conditions. Specifically, a reduction of approximately 40% in cutting force was recorded when compared to MQL, demonstrating the superior performance of this cooling strategy. This significant force reduction can be attributed to the enhanced penetration and lubrication efficiency of the supercritical fluid, which improves chip evacuation, reduces friction at the tool–chip interface, and lowers mechanical resistance during cutting. These findings confirm that SCCO2 with lubricant at optimized pressure levels offers a highly effective solution for minimizing cutting forces and improving machining efficiency in high-grade steel applications.

Figure 8.

Cutting forces at different cooling regimes [19].

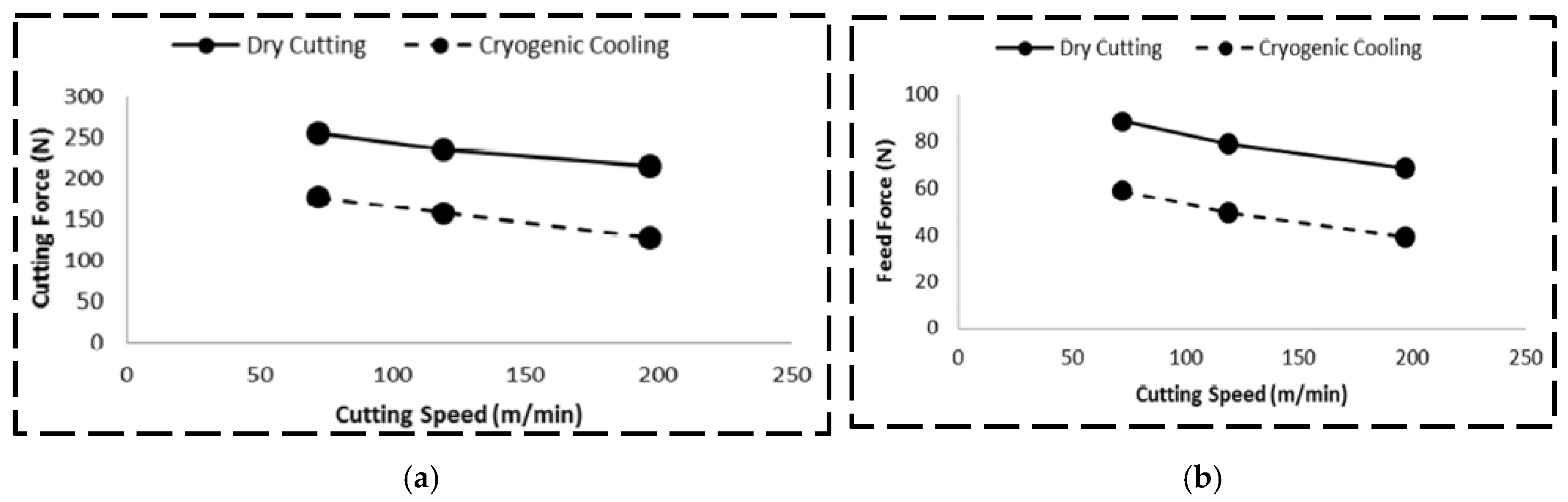

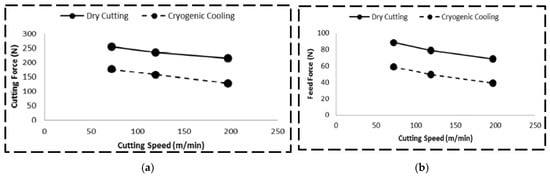

Researchers examined the cutting force and feed force properties of duplex stainless steel 2205 under dry and cryogenic conditions. As shown in Figure 9, the cutting force decreased under the cryogenic condition. The main cutting force decreases by 30–41%, and the feed force decreases by 33–43% when using cryogenic cooling under the same machining condition. By using the cryogenic, the forces are decreased, as shown below. The forces at the cutting speed of 200 m/min in dry cutting are 216 N, reduced to less than 150 N using the cryo technique. Similarly, the feed force decreased from 80 to 40 N by using the cryogenic technique at 200 m/min cutting speed.

Figure 9.

Variation in forces at different cutting speeds and cooling conditions: (a) cutting force and (b) feed force [27].

4.3. Surface Roughness

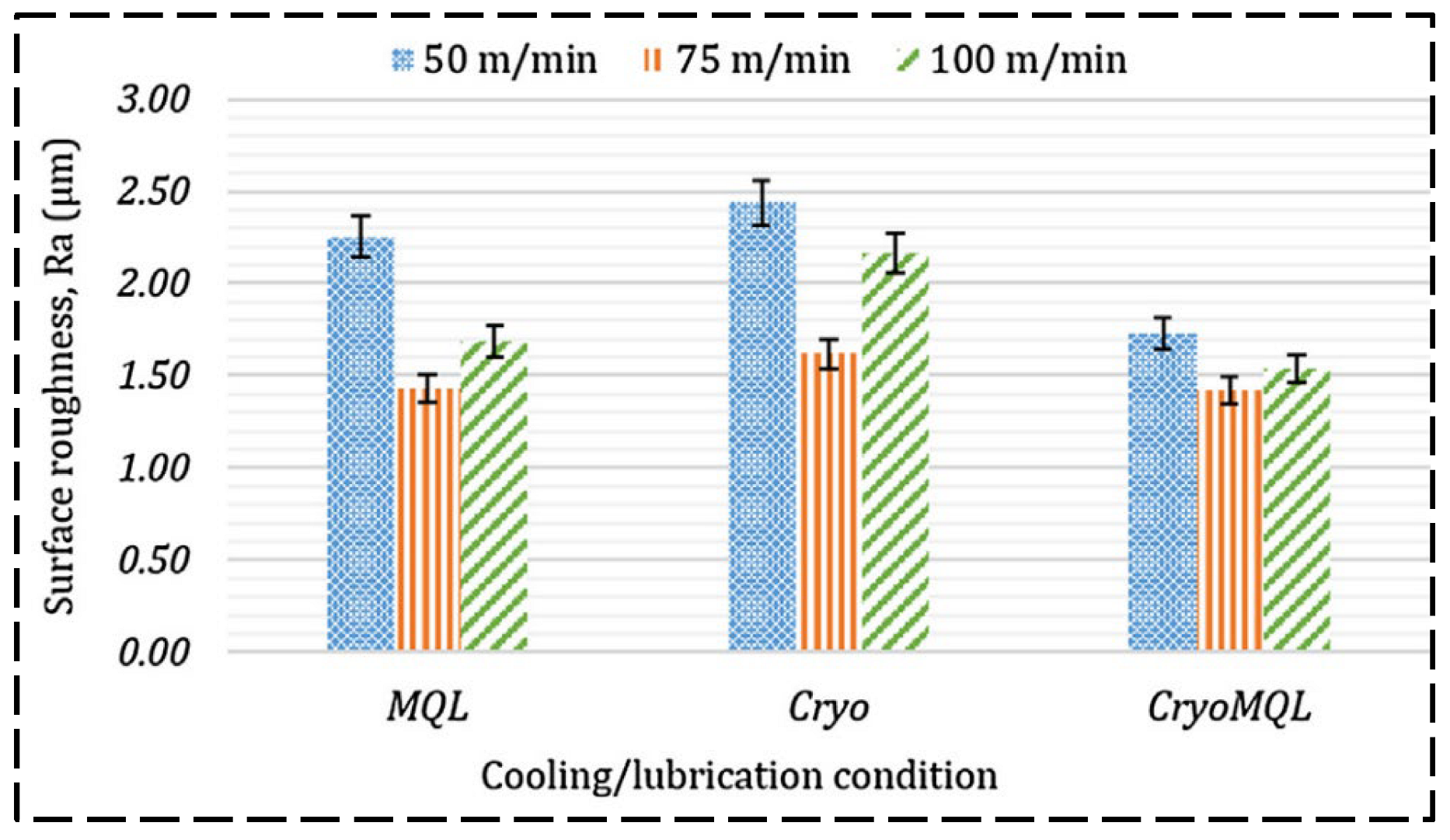

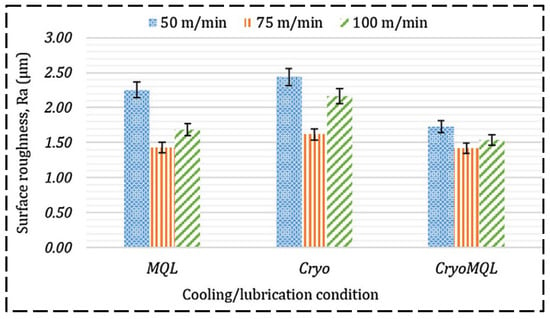

The surface roughness is also one of the parameters for measuring the performance of the cutting operation. In Figure 10 below, the study presented the surface roughness at different cutting speeds and different coolant methods. Here, the surface roughness Ra is measured from the primary line. The data below shows that the hybrid technique reduces the surface roughness more than all the other cooling conditions. In this experimentation, the researcher used the constant feed rate and depth of cut, but the cutting speed varied from 50 to 100 m/min. The cryogenic showed the highest roughness value compared to it by using MQL and CryoMQL; the surface roughness decreased by 14% and 25%. The study investigates how cryogenic cooling during machining affects surface integrity and corrosion resistance of Monel-400 alloy, highlighting its potential as a sustainable manufacturing approach [62]. The paper experimentally examines how cryogenic machining influences the surface integrity of maraging steel, demonstrating improvements in surface finish, hardness, and reduced thermal damage [63]. Cryogenic machining of wrought Ti6Al4V improved fatigue strength by 21%, reduced tensile residual stress by 36%, and enhanced surface integrity through a 31% decrease in surface roughness compared to conventional dry machining [64]. Cryogenic machining of aluminum MMCs with biomimetic textured tools reduced cutting forces by up to 25%, decreased tool wear by 30%, and improved surface finish by 22%, enhancing overall sustainability [65]. In cryogenic abrasive air-jet machining of PDMS, increasing the cooling rate led to a 40% reduction in abrasive embedding and improved surface integrity by enhancing material brittleness and minimizing elastic recovery [66].

Figure 10.

Effects of different cooling conditions on surface roughness [31].

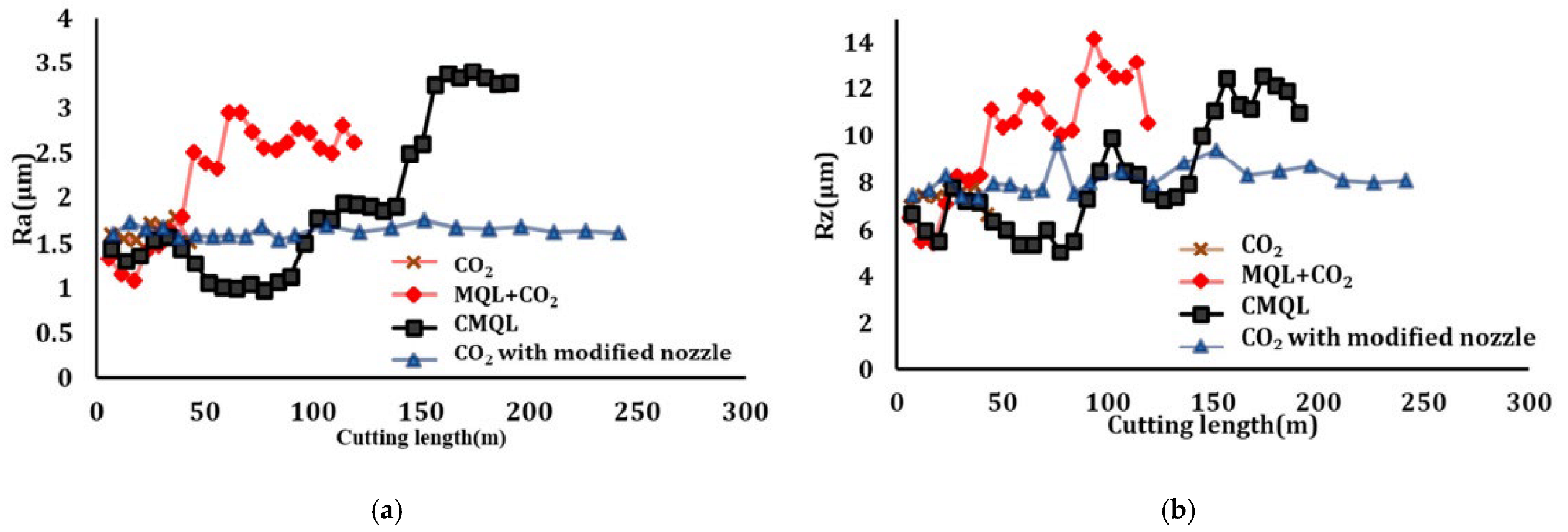

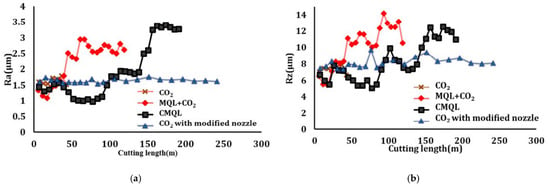

The cryogenic machining technique was employed to evaluate its influence on surface finish during the turning of Ti6Al4V alloy. As illustrated in Figure 11, surface roughness was measured under various cryogenic lubrication strategies, including pure CO2, MQL + CO2 hybrid, Cryogenic Minimum Quantity Lubrication (CMQL), and CO2 applied with a modified nozzle design. Across a machining length of 150 mm, the CMQL approach demonstrated a remarkable improvement in surface quality, with surface roughness reducing significantly from approximately 3 µm to 1 µm compared to the use of CO2 alone.The study showed that implementing cryogenic machining combined with a scaled conjugate gradient-based machine learning model improved machinability predictions with over 90% accuracy and reduced surface roughness and cutting forces by approximately 30% [67].

Figure 11.

The surface roughness of TiAl4V under different cooling condition a cutting speed of 150 m/min and feed rate of 0.2 mm/rev: (a) average roughness Ra and (b) mean roughness Rz [3].

This improvement can be attributed to the enhanced cooling and lubrication synergy offered by CMQL, which minimizes tool–workpiece interface temperature and reduces built-up edge formation. The combination of cryogenic CO2 with minimal oil-based lubrication likely provides superior chip evacuation and a stable cutting zone, leading to improved surface integrity. Additionally, while the CO2 with a modified nozzle maintained consistent roughness along the workpiece, it did not achieve the same reduction in roughness magnitude as CMQL. The feed rate was varied between 7 mm/rev and 11 mm/rev to assess the effect of cutting speed on surface finish, and the results consistently showed lower roughness values with CMQL, especially at moderate feed rates. This suggests that CMQL not only enhances thermal management but also stabilizes the tool–chip interaction, resulting in smoother surface textures even under variable cutting parameters. Overall, these findings underscore the potential of CMQL as a highly effective method for improving surface finish in cryogenic machining of titanium alloys.

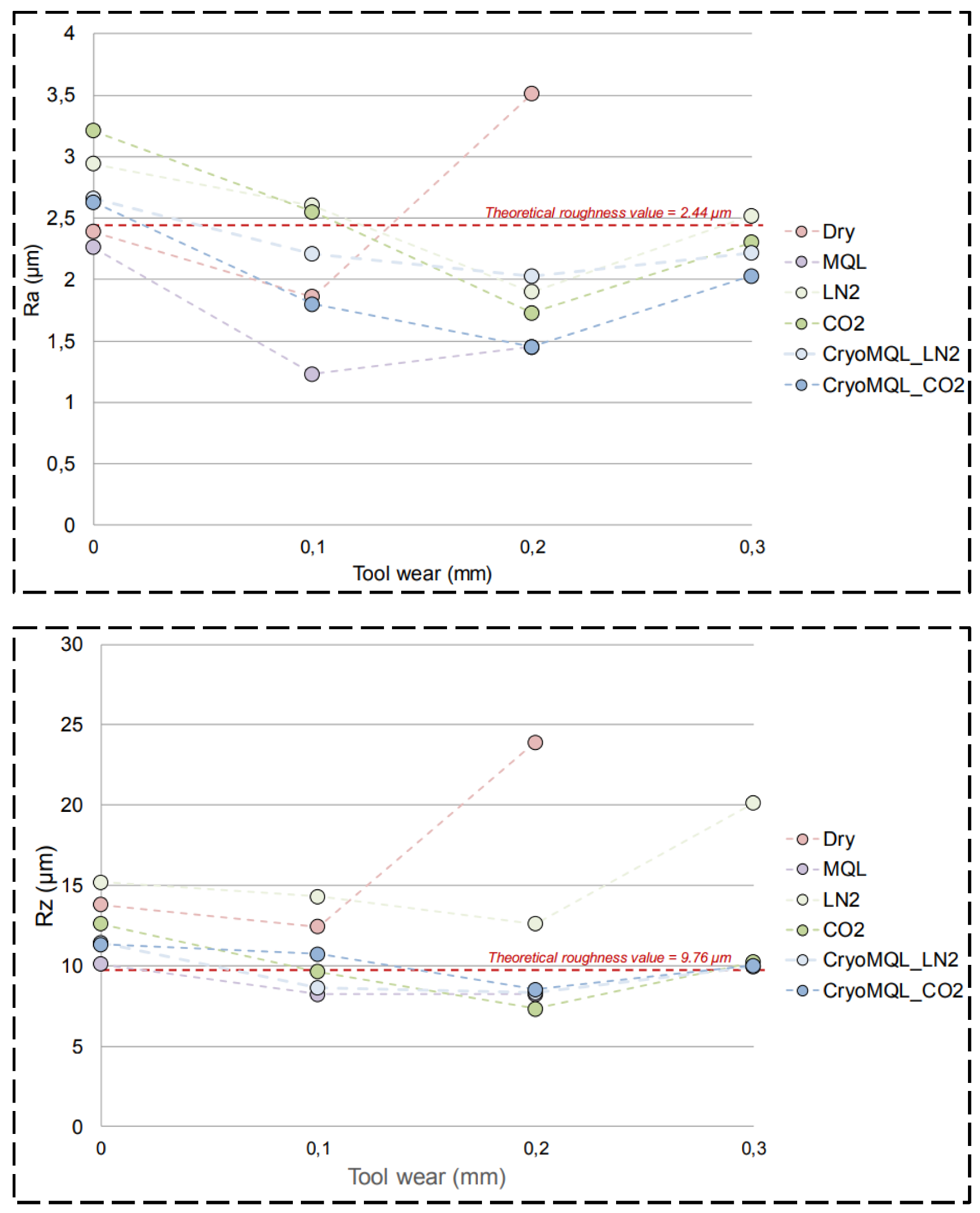

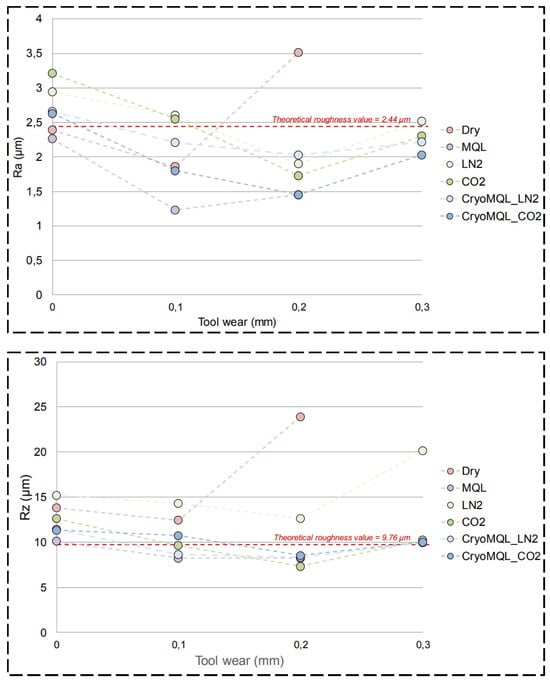

Surface roughness evaluation in machining processes can be approached through various analytical techniques, including scanning electron microscopy (SEM), chip morphology assessment, microstructural analysis, and topological surface profiling. In addition to surface finish, material deformation plays a critical role in determining the overall quality and performance of the machined component. This study compares the effectiveness of different cooling and lubrication strategies—namely dry machining, minimum quantity lubrication (MQL), liquid nitrogen (LN2), carbon dioxide (CO2), and hybrid combinations such as MQL–CO2 and MQL–LN2—on surface roughness and tool wear progression shown in Figure 12.

Figure 12.

Surface roughness in terms of tool wear at different cooling conditions [25].

The experimental setup involved comparative analysis at different stages of tool usage, starting with a fresh cutting insert. Initially, theoretical values of surface roughness were established as a reference, with subsequent experimental measurements capturing the influence of cooling techniques under identical cutting conditions. The average theoretical surface roughness was calculated as 2.44 µm, while the experimentally obtained mean surface roughness was reduced to 0.76 µm using the MQL–CO2 hybrid technique. This represents a significant 41% reduction in surface roughness compared to the theoretical model. Furthermore, it was observed that MQL effectively maintained low surface roughness values up to a tool wear level of 0.2 mm, beyond which the surface integrity began to deteriorate. This trend highlights the coolant’s critical role in delaying wear-induced degradation and improving surface finish. The results confirm that hybrid lubrication systems like MQL-CO2 not only enhance cooling and lubrication but also contribute to better chip formation, lower friction, and extended tool life, all of which are pivotal for high-precision machining applications.

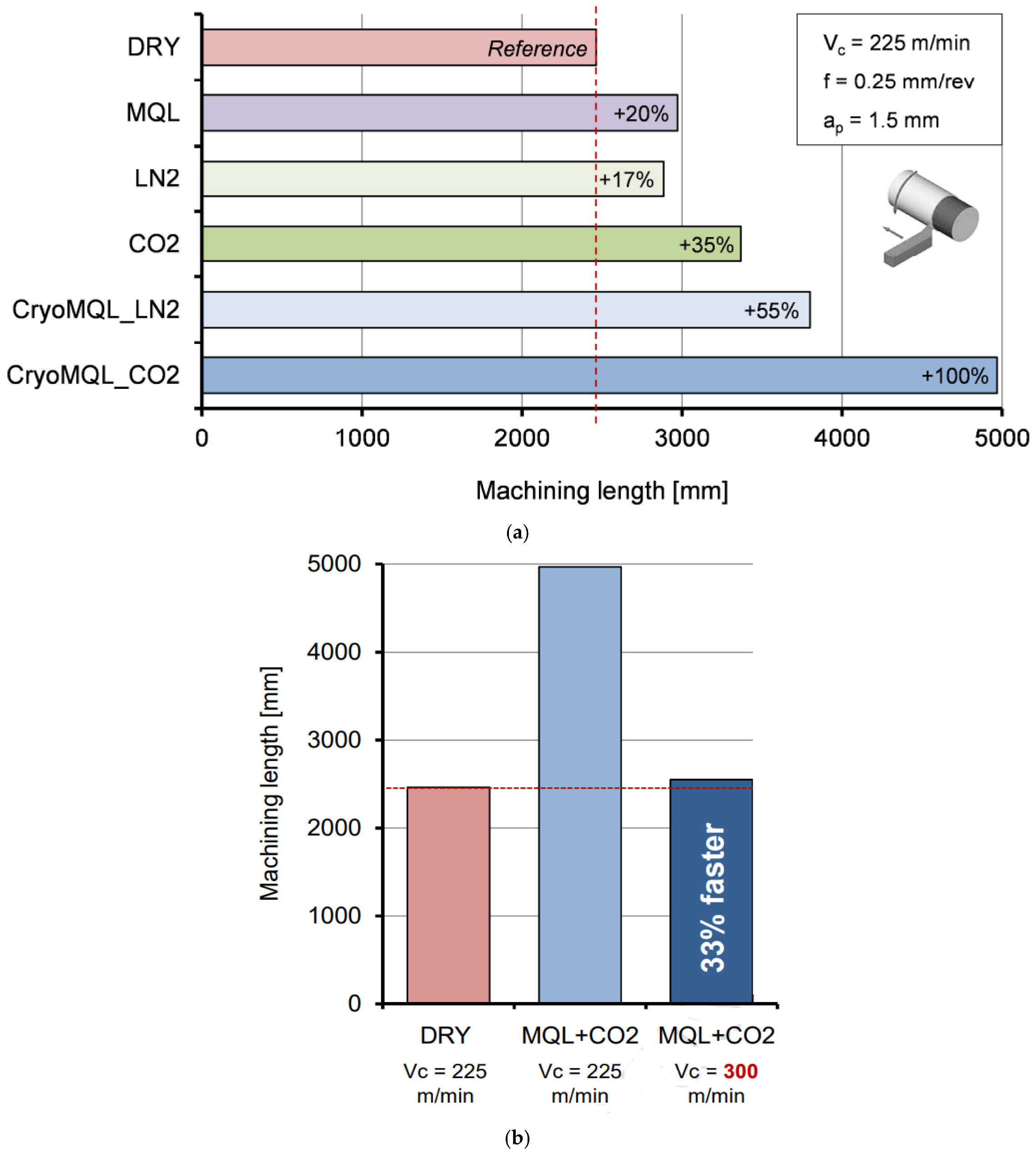

4.4. Tool Wear

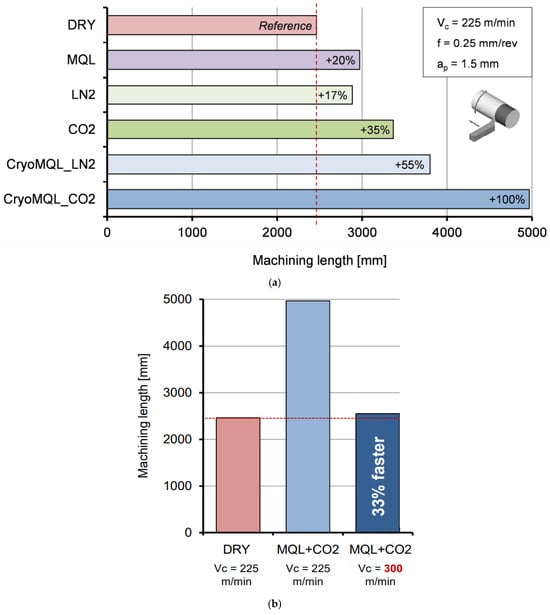

The machining of AISI 304 stainless steel was conducted under various cutting speeds and cooling conditions to evaluate the impact on tool wear and machining efficiency. Tool wear progression was assessed by measuring the total machining length achieved before reaching a defined wear threshold. As illustrated in Figure 13b, the application of the MQL + CO2 hybrid cooling technique at a cutting speed of 225 m/min significantly extended the machining length from 2200 mm (dry machining) to 5000 mm, demonstrating a substantial improvement in tool life. Although machining length tends to decrease at higher cutting speeds due to increased thermal loads and wear rates, the overall machining time is reduced by approximately 33%, thereby improving productivity. Interestingly, at the optimal cutting speed of 225 m/min and feed rate of 0.25 mm/rev, the tool wear rate remained nearly constant across different cooling methods, indicating a balanced thermal–mechanical performance. Under these optimal conditions, the cutting length increased by 55% using CryoMQL-LN2 and by 100% using CryoMQL-CO2 when compared to standard MQL. These results highlight the superior performance of the CryoMQL-CO2 technique in enhancing both tool life and machining efficiency. The combination of cryogenic cooling and minimal lubrication effectively reduces cutting zone temperatures, minimizes adhesion and wear, and supports extended uninterrupted operation. Based on experimental data and observed trends, CryoMQL-CO2 is concluded to be the most effective strategy for optimizing the machining of AISI 304, particularly in high-speed, precision-critical applications. The study on the tribological and thermal aspects of cryogenic machining of Inconel 718 highlights that improved cooling significantly reduces tool wear while enhancing surface integrity through better heat dissipation and lower friction at the tool–workpiece interface [68]. Machining of Haynes 25/L605 superalloy using sustainable cooling methods, including cryo-MQL and nanofluid MQL, reduced tool wear by up to 38%, and improved surface quality and chip morphology compared to dry and conventional approaches [69]. Cryogenic machining of additively manufactured Nitinol significantly reduced tool wear—by up to 35% at optimized cutting speeds—while maintaining surface integrity, due to minimized heat-affected zones and improved chip control [70].

Figure 13.

Comparative analysis of different cooling techniques: (a) Effect of varying cutting speeds on machining performance; (b) Influence of machining length on tool wear and temperature across cooling methods [25].

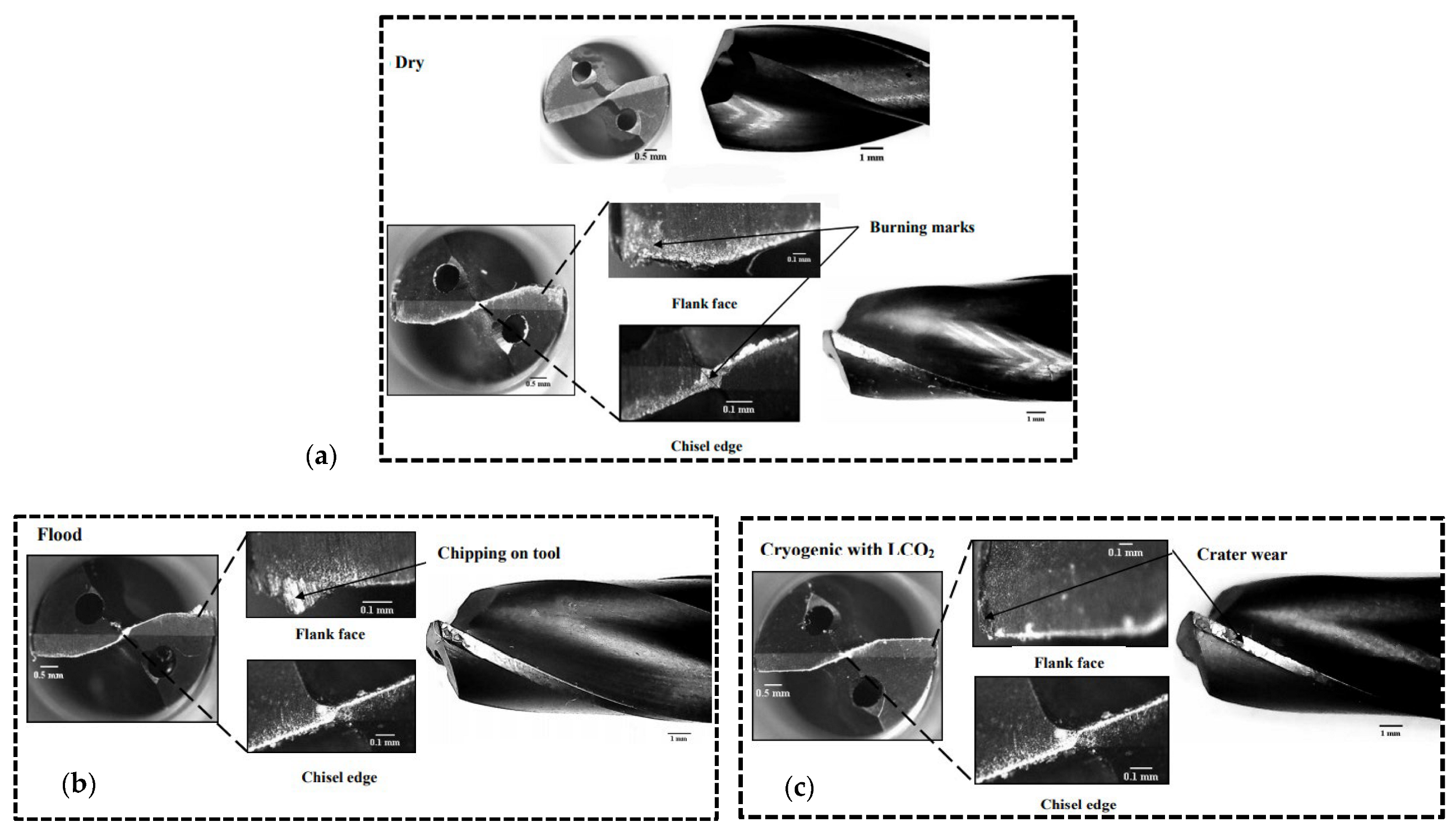

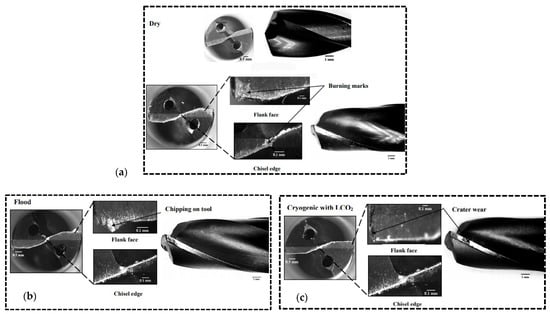

Tool wear is associated with surface roughness, which comes from different parameters such as adhesion, friction, and abrasion. The researcher performed tests at a specific number of drilling holes using different techniques. Dry condition, flooded, and cryogenic cooling with LCO2 and LN2 were utilized to study the effect on tool wear. In dry machining, due to excessive heat, many burns are visible on the tool, reducing the tool life. Both dry and flooded cooling have built-up edges on the tool, reducing tool life. The tool wear was reduced significantly by using the cryogenic technique compared with the dry and flooded cooling. The cryogenic technique utilizes less coolant than the flooded cooling, making it environmentally friendly. The study explores the combined effect of tool texturing and deep cryogenic treatment in reducing friction, wear, and improving tool performance during the machining of Ti6Al4V alloy [71].

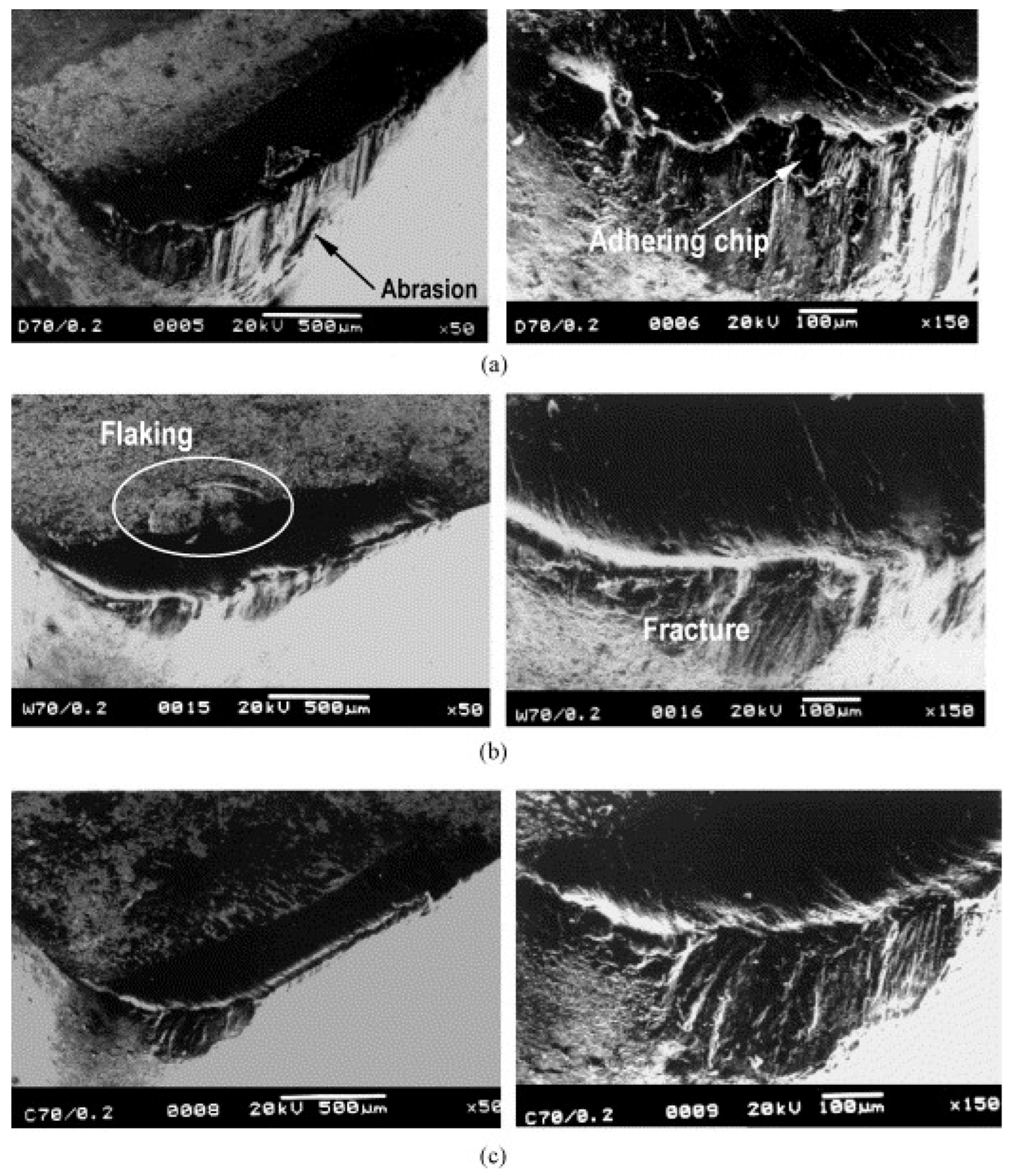

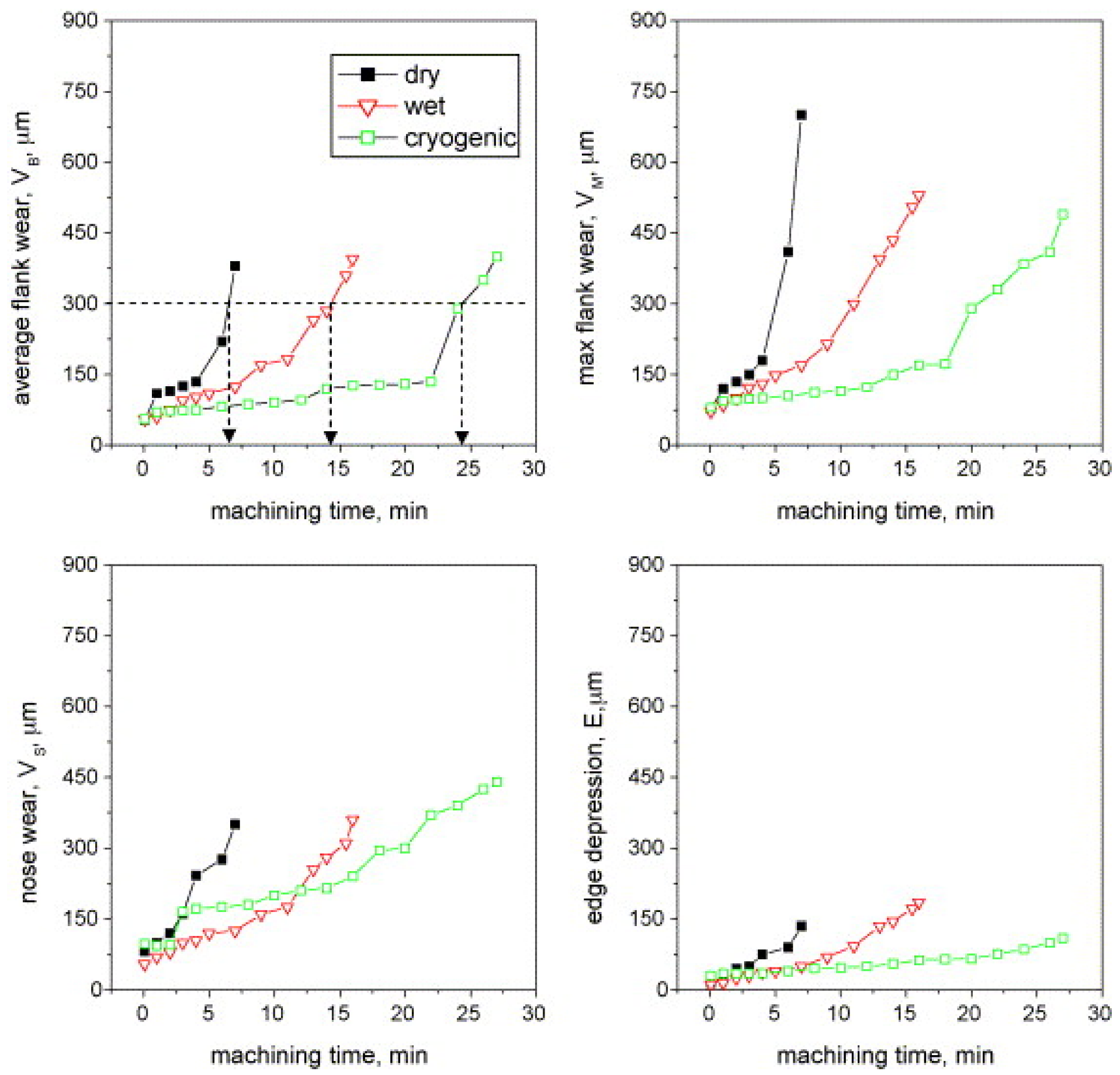

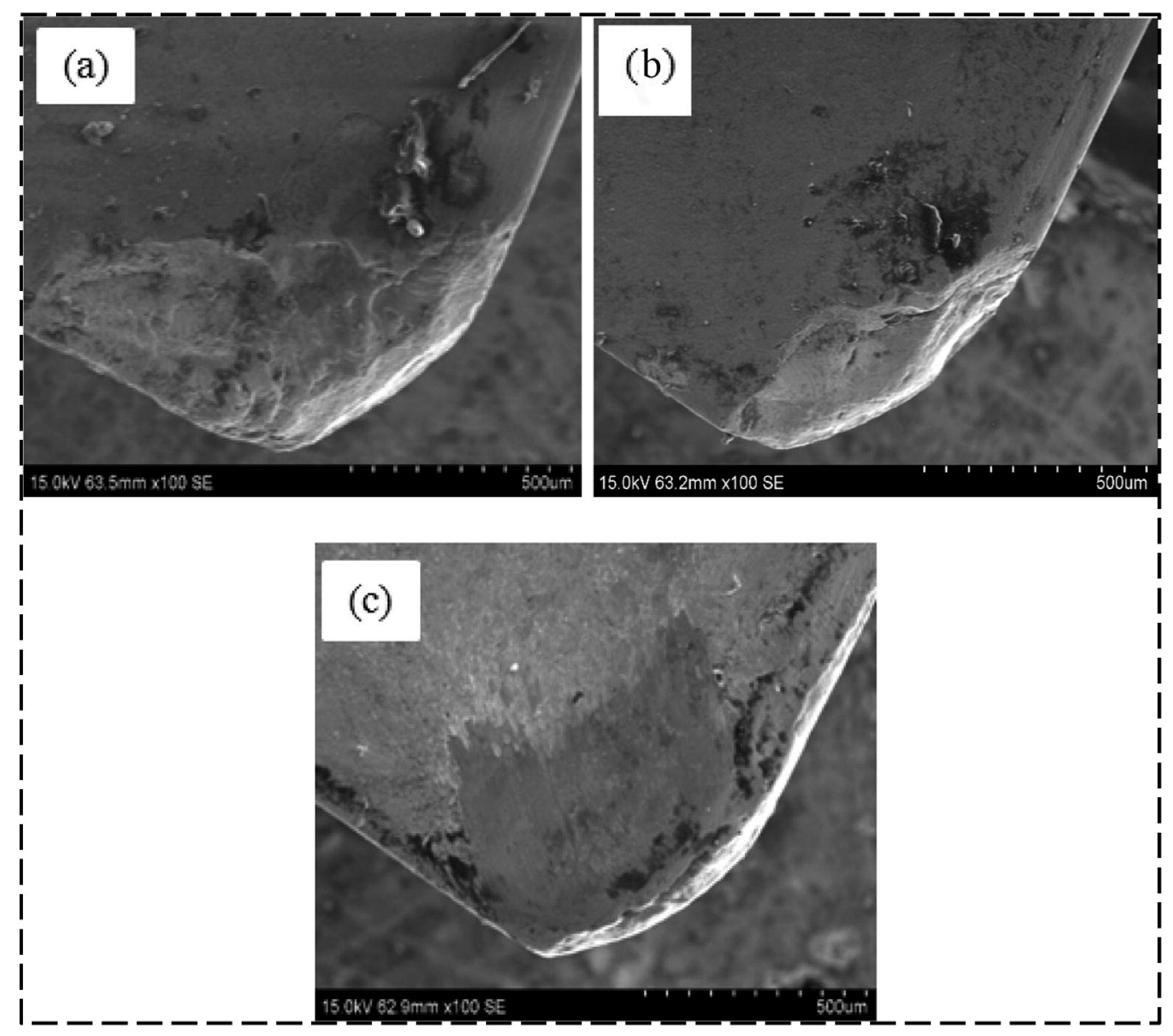

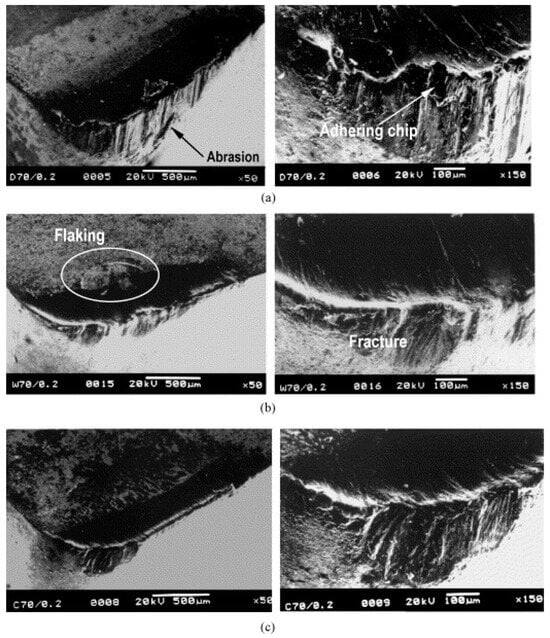

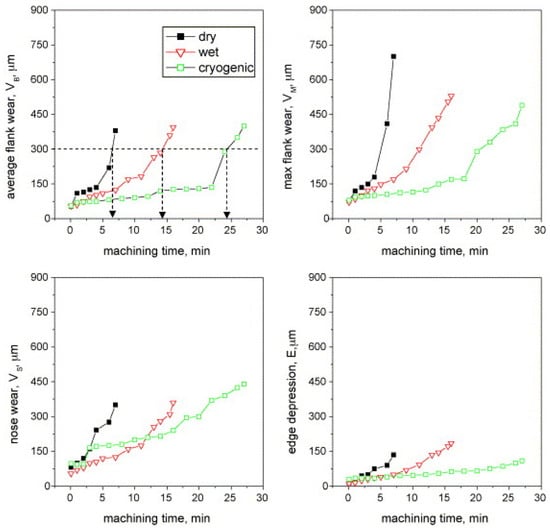

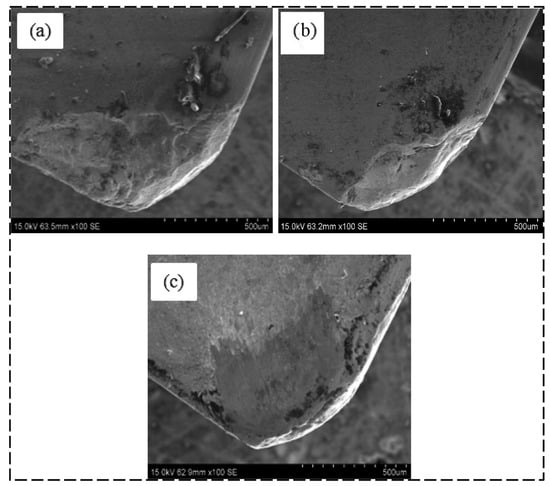

Figure 14 shows the SEM views of the worn tool, and Figure 15 shows the nose and flank wear under different conditions. The turning operation was performed on Ti-6Al-4V at a feed rate of 0.2 mm/rev and a cutting speed of 70 m/min. The optimal result for tool wear was found under these conditions. Figure 14a shows the SEM for dry machining after 7 min of machining titanium alloy, while Figure 14b shows tool wear under wet machining after 16 min. Figure 14c shows the tool under cryogenic conditions after 27 min. The SEM images show that more material adheres to dry machining. In wet machining, the fracture showed at the face. The most optimized result for cryogenic machining was found, which increased the machining time of titanium by around 75% compared with the dry machining. The nose and flank wear are presented in Figure 15 under different types of cooling strategies. Both wear rates are fixed at a certain level and compared with the machining time to optimize the result. From the figure, it is clearly indicated that flank and nose wear are reduced by using the cryogenic lubrication condition. Due to the utilization of the cryogenic technique, the machining time increased to 76% compared with the dry machining at the exact extent of average flank wear. With the cryogenic cooling method at nose wear, the machining time increased to 78% compared with dry machining.

Figure 14.

Images of drill bits after drilling operations using different cooling systems: (a) Dry machining, (b) Minimum Quantity Lubrication (MQL), (c) Cryogenic cooling [4].

Figure 15.

SEM images of the tool at a cutting speed of 70 m/min and feed rate of 0.20 mm/rev under three environments: (a) dry machining, (b) wet machining, and (c) cryogenic machining [6].

Wear Mechanisms and Summary of Findings

Each of the many connected mechanisms that affect tool wear during machining has the potential to have a substantial impact on tool life, surface quality, and the sustainability of the process as a whole. Whether dry, flooded, cryogenic (LN2 or LCO2), or hybrid CryoMQL, the kind and degree of tool wear in this investigation differed significantly according to the cooling approach used. Each cooling technique changed the typical wear processes seen by interacting differently with the mechanical and thermal stresses at the cutting contact. The following are the primary wear mechanisms found in the experiments:

- Adhesive Wear: High temperatures during dry machining increased adhesion between the workpiece and cutting tool, resulting in built-up edge development and faster wear. This was visible in Figure 15, where SEM images revealed considerable material adhesion and fracture damage on the tool surface.

- Abrasive Wear: Abrasive wear was present in both settings due to hard particles and workpiece microstructure, but it was less noticeable during cryogenic cooling because lower temperatures assisted in maintaining tool hardness and limited abrasive plowing.

- Thermal Fatigue and Oxidation: High temperatures during both dry and wet machining accelerated the wear development by causing thermal cracking and oxidation layers on the cutting edge. On the other hand, these thermal impacts were reduced by cryogenic cooling, which dramatically lowered cutting zone temperatures.

Tool wear was clearly reduced by using cryogenic cooling methods such as liquid nitrogen (LN2), liquid carbon dioxide (LCO2), and the hybrid CryoMQL approach. These cutting-edge cooling techniques successfully decreased heat production at the cutting zone, decreased friction, and postponed the initial stages of oxidation and adhesion. In contrast to dry and flooded machining conditions, cryogenic environments resulted in a notable slowing in the growth of flank and nose wear, as illustrated in Figure 16 and Figure 17. Additionally, cryogenic machining resulted in a 75–78% longer period before tools reached critical wear levels, indicating improved thermal stability and tool longevity. Smoother, less damaged tool surfaces were found by SEM examinations, suggesting less mechanical stress on the cutting edge and built-up edge development.

Figure 16.

Growth of tool wears under dry, wet, and cryogenic environments while turning Ti-6Al-4V at a cutting velocity of 70 m/min and a feed of 0.20 mm/rev [6].

Figure 17.

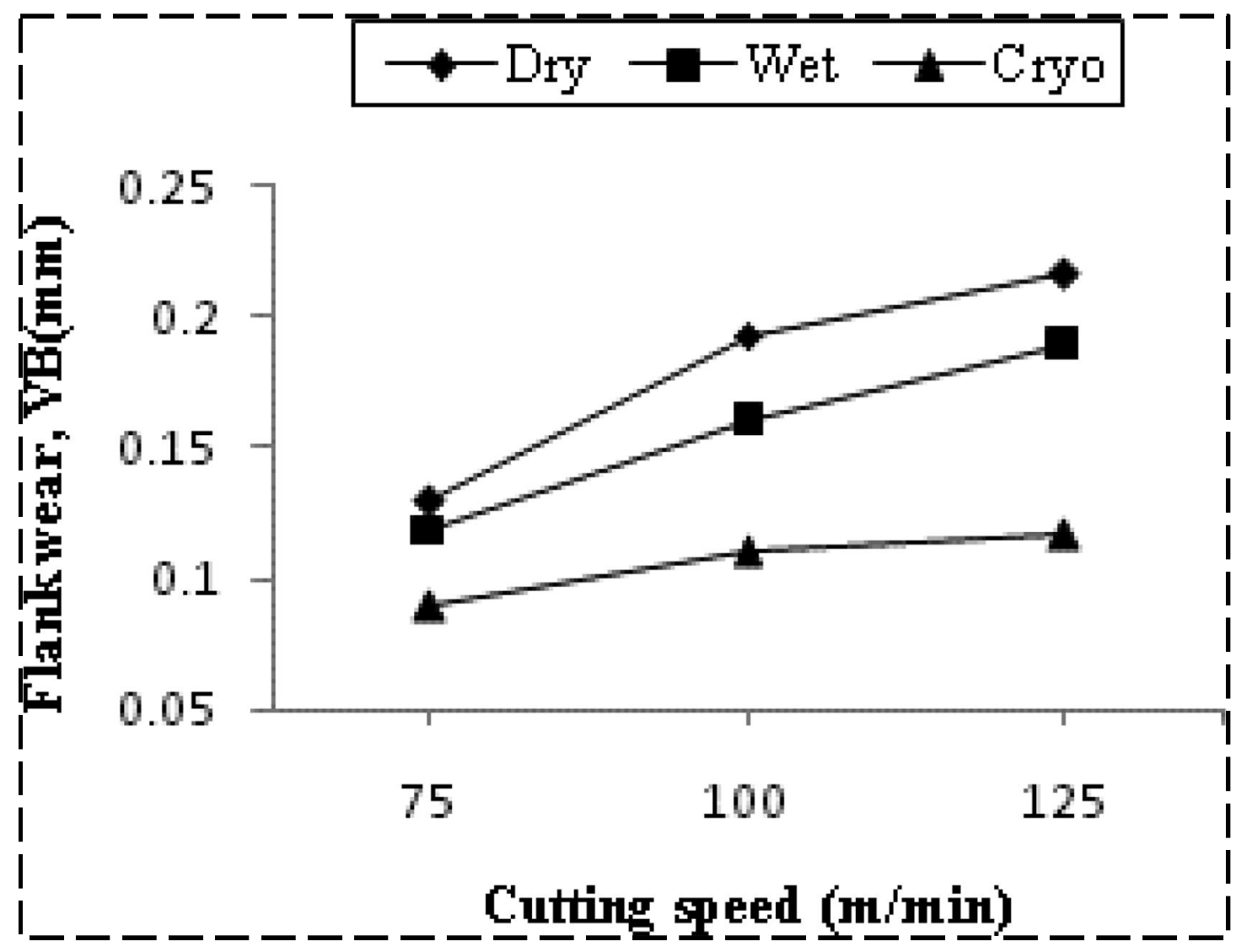

Flank wear at different cutting speeds at a feed rate of 0.02 mm/tooth [14].

In general, the experimental results show that cryogenic and hybrid cooling approaches are quite successful at improving tool performance during the machining of difficult-to-cut alloys. Optimal circumstances, especially with the CryoMQL-CO2 combo, can prolong tool life by up to 100%. The findings demonstrate the synergistic effect of efficient cooling and minimal lubrication, which minimize friction, thermal stress, and tool deterioration. These advantages ultimately lead to improved machining efficiency, less downtime, and a more sustainable production process.

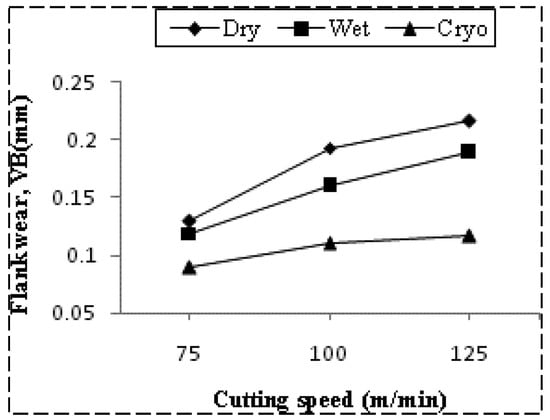

The wear of the tool and flanks investigated by altering both the cutting speed and cooling conditions when machining AISI P20 steel. The flank wears reduced remarkably by using the cryogenic irrespective of cutting speed. The flank decreased 50% using the cryogenic compared with the dry machining at 125 m/min cutting speed. The optimized cutting speed from the experiment was observed at 125 m/min. The electron microscope images were also represented to visualize the performance of the coolant. Figure 18 represents the rake face of the tool insert after the machining of AISI p20 steel for 30 min. The figure visualization shows that the most worn out of the tool is found in the dry machining. Following this, wet or flooded cooling showed less tool wear, and the least wear at the rake face was observed with the cryogenic cooling.

Figure 18.

SEM views of worn cutting tools at 125 m/min cutting speed and feed rate of 0.02 mm/tooth after 30 min of machining: (a) dry, (b) wet or flooded cooling, and (c) cryogenic cooling [14].

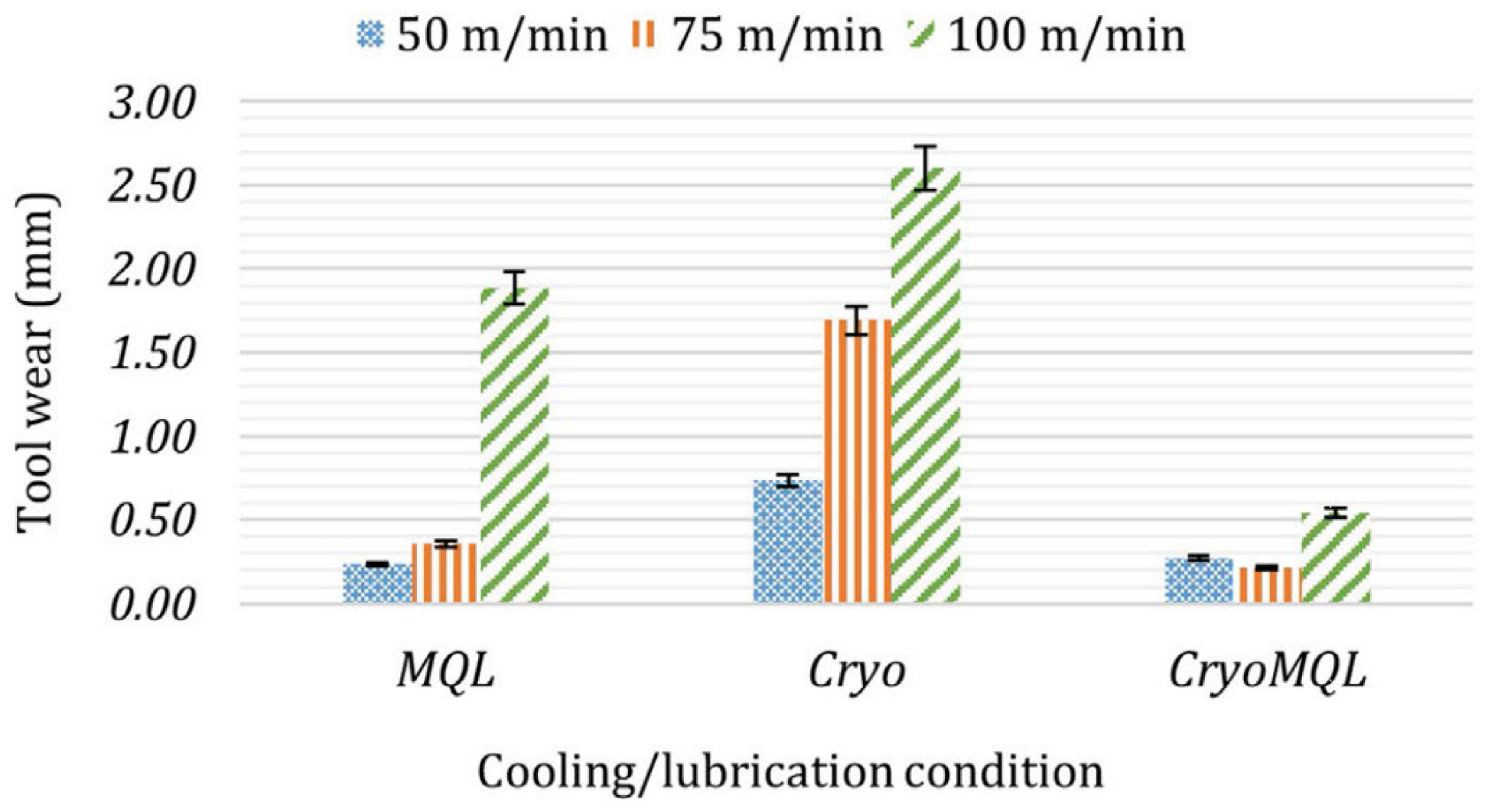

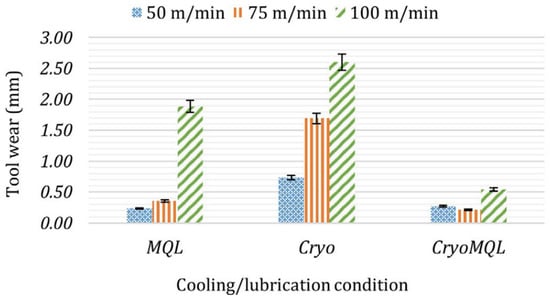

The study compared the performance of cutting tools for machining nickel-base alloy Inconel 625 for various cooling regimes. Figure 19 below shows that MQL is more prominent than the cryo in reducing the tool wear. The hybrid technique was utilized to obtain the optimized result. Tool wear reduced to 79.6% using the cryoMQL technique taking cryogenic as a reference. Similarly, the MQL showed a 51% decrease in tool wear compared to cryogenic.

Figure 19.

Variation in tool wear at different cutting speeds and with different lubrication techniques [31].

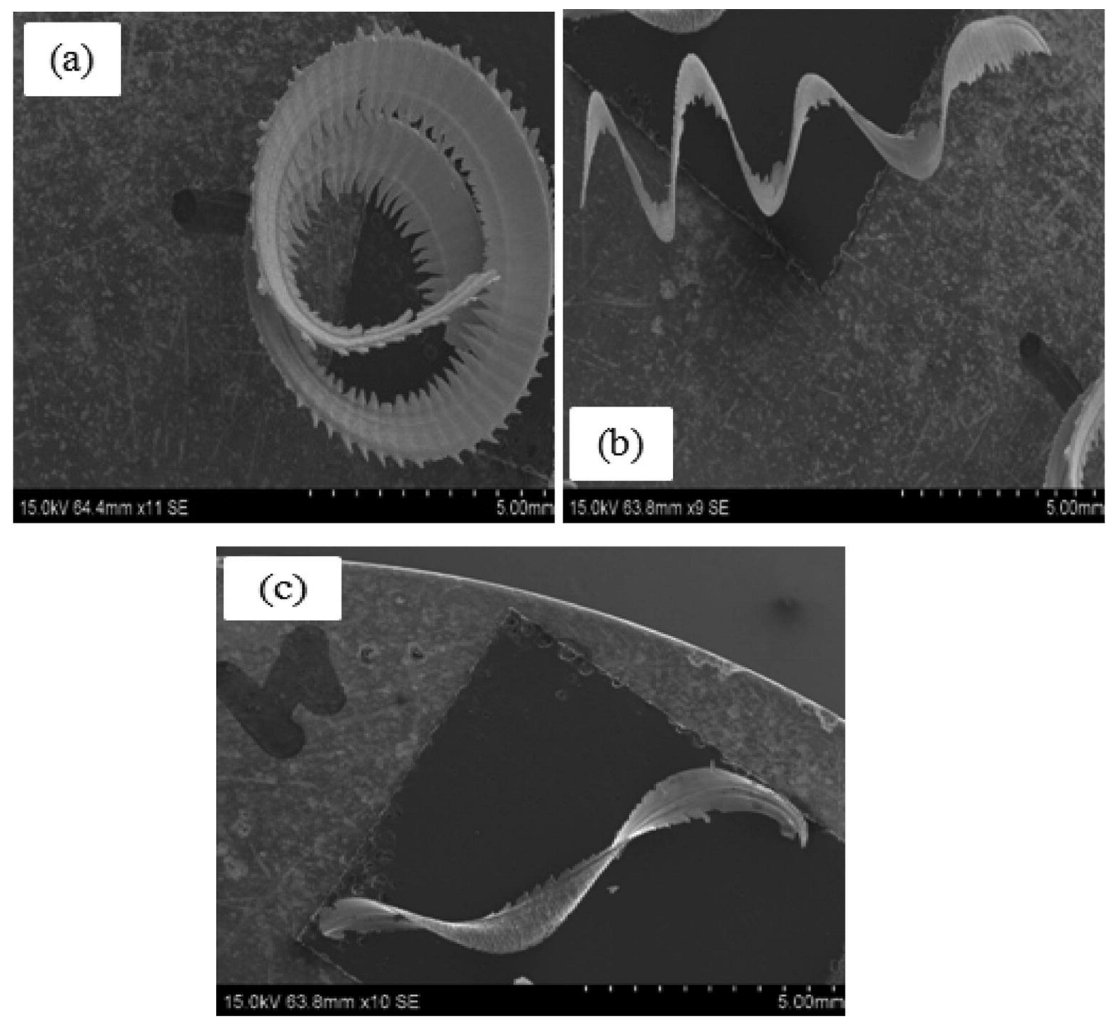

4.5. Chip Morphology

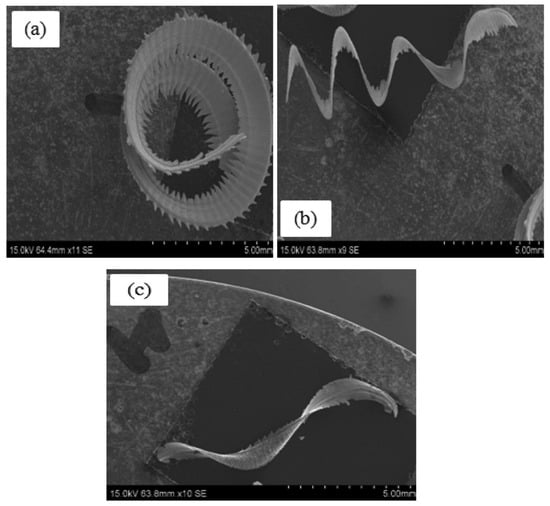

Figure 20 represents the chip shape of AISI P20 steel by performing the milling operation at the cutting speed of 75 m/min and feed rate of 0.02 mm/tooth. The breakability of the chips is essential in the milling process. The curl-shaped chips were formed under the dry condition, and these chips had a dark blue color, which shows the elevated temperature at the cutting zone. Also, the curly chips formed under the flooded cooling are less curly than those from the dry condition. The coolant also gets vaporized in the flooded cooling, which makes black-colored chips. Utilizing the cryogenic technique, the temperature of the cutting zone dropped drastically. The chips formed by using cryogenic are brittle, easy to break, and silver in color.

Figure 20.

SEM pictures of chips: (a) dry, (b) flooded, and (c) cryogenic [14].

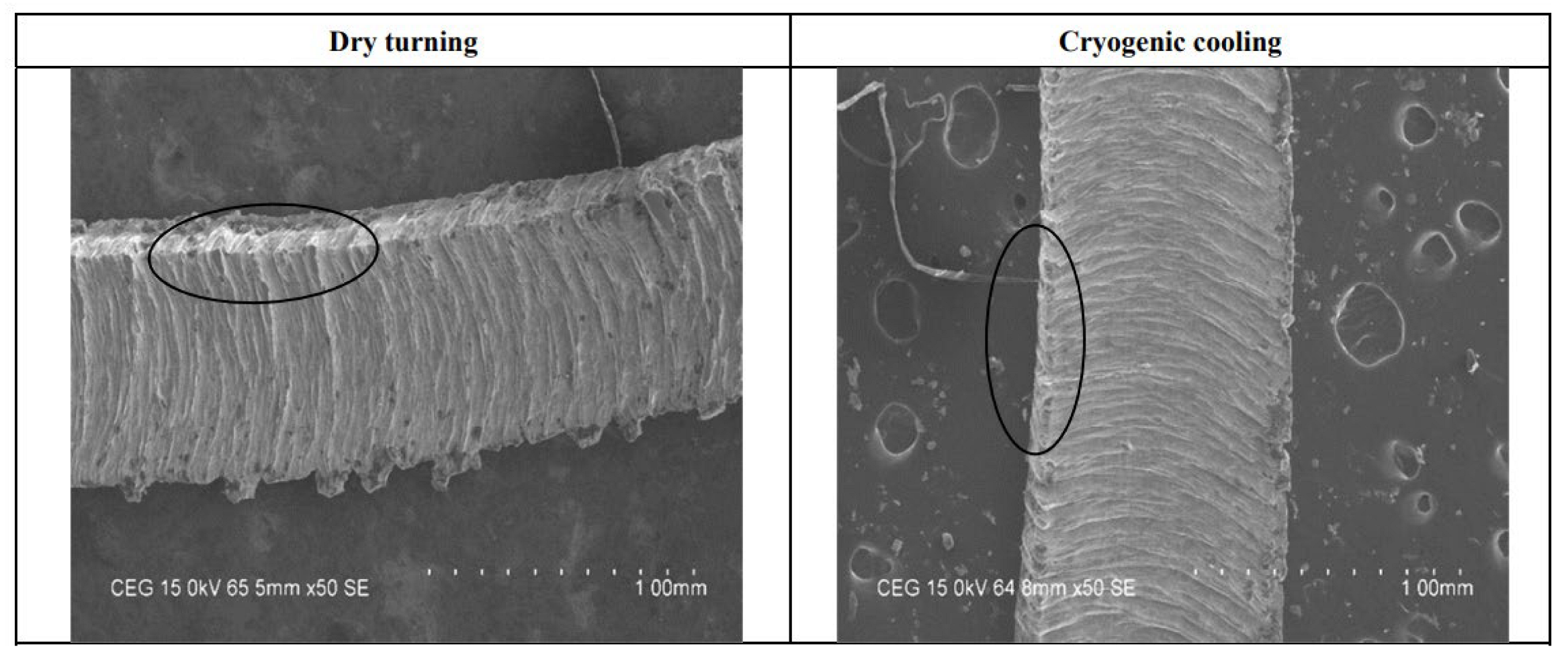

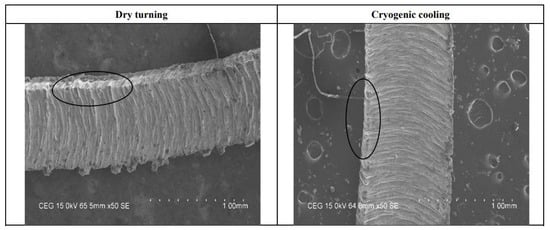

Figure 21 below represents the primary serrated teeth of the chips while performing the turning operation on the duplex stainless steel using a TiALN cutting insert. They used the insulated vacuum jacket hose to supply the liquid nitrogen at the cutting zone. Researchers performed experimentation under the cutting speed of 197 m/min and two different cooling regimes, dry and cryogenic. The adhesion of the tool–chip material was reduced by using the cryogenic technique, which reduced the temperature at the contact surface.

Figure 21.

SEM photographs of chips under dry and cryogenic conditions [27].

5. Sustainability Aspects

Machining sustainability is evaluated based on energy usage, power demand, environmental impact (CO2 emissions), and overall operational expenses. This section examines many studies that investigate these features under various machining processes, including drilling, turning, and general comparisons, using various cryogenic and hybrid cooling systems. The purpose is to back up the argument that cryogenic machining contributes positively to sustainable production, both environmentally and economically.

5.1. Drilling Process

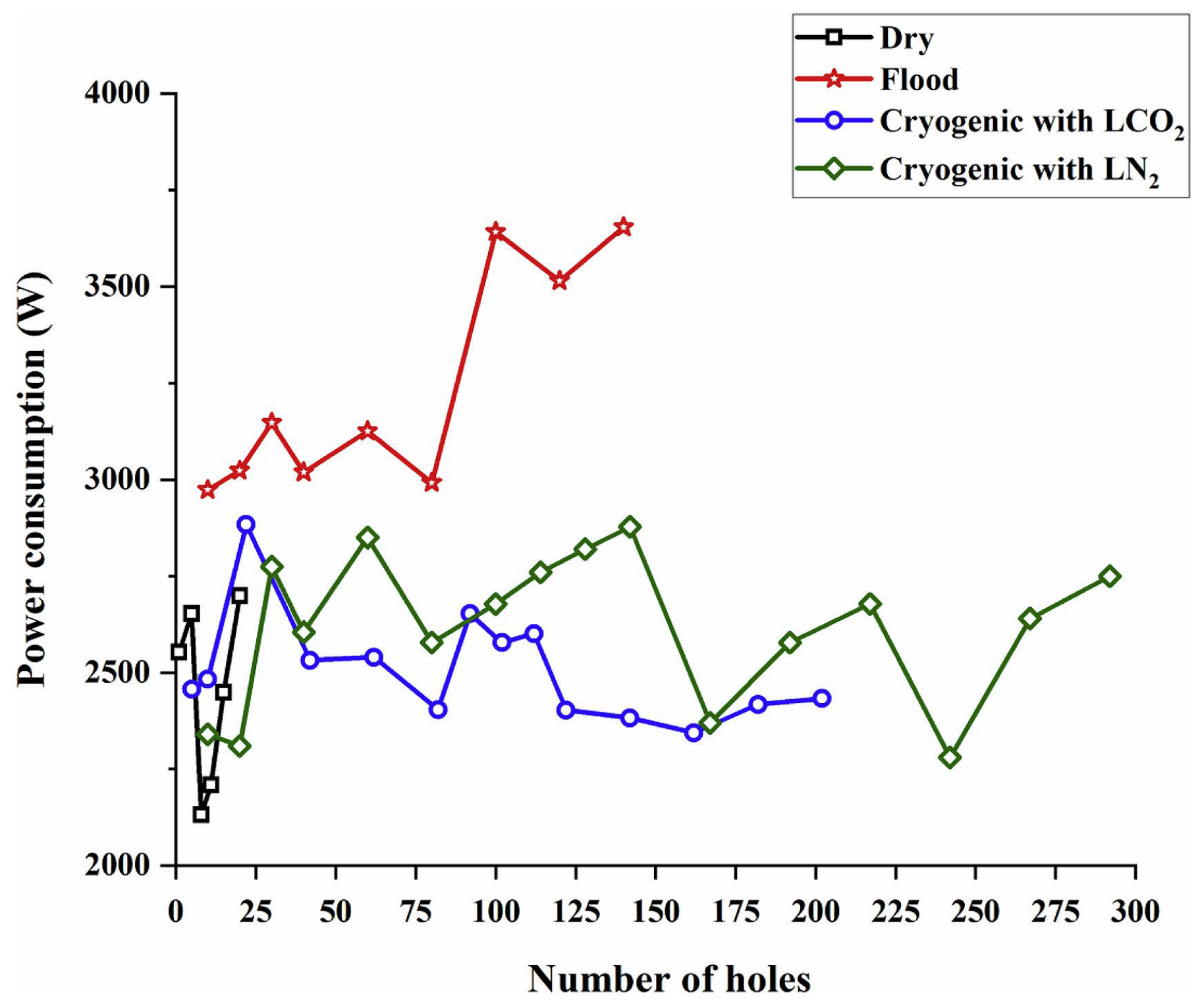

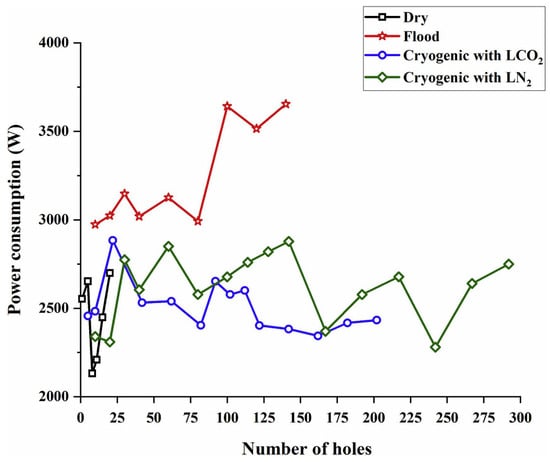

A study conducted on the power consumption of the different cooling processes during drilling is presented in Figure 22. It shows that power consumption is reduced when cryogenic cooling is employed with liquid LCO2. The highest power consumption was found in the flooded cooling due to the additional requirement of the pump. The maximum power used in the cryogenic LN2 is 27% less than the flooded cooling for the power consumption comparison. Cryogenic with LN2 showed the optimum result over the maximum power consumption.

Figure 22.

Power consumption comparison at different cooling regimes for number of holes [4].

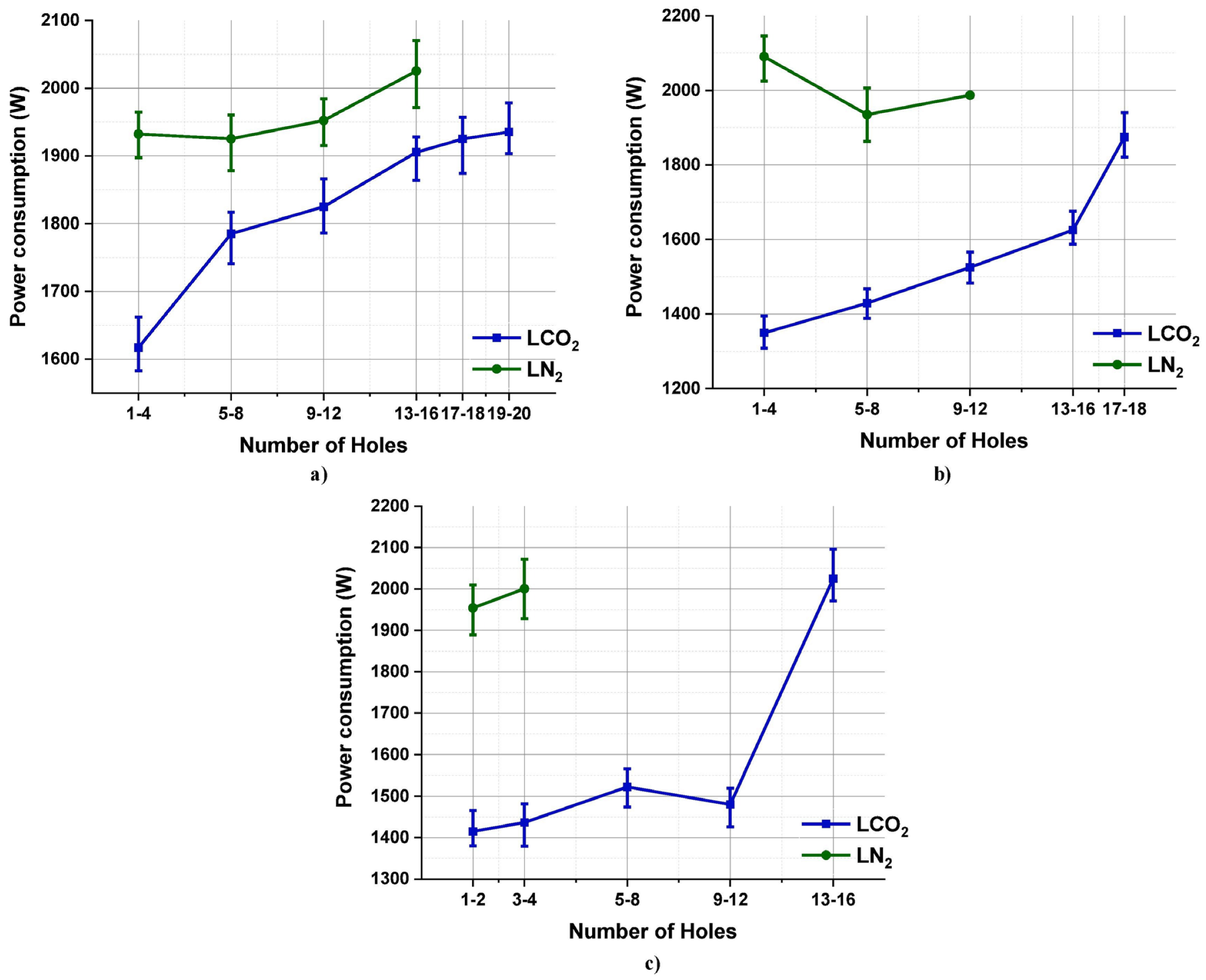

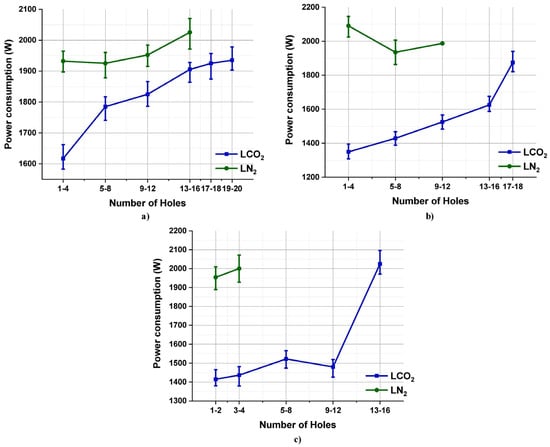

In Figure 23, the power consumption using LNCO2 and LN2 observed at different cutting speeds for different drilled holes. Researchers found that using the LNCO2, the power consumption reduced to an overall 19% compared to the LN2. The highest power consumption difference was found at the higher cutting speeds of 15 and 20 m/min, which showed 28%.

Figure 23.

Power consumption comparison with LN2 and LCO2 at (a) 10, (b) 15, and (c) 20 m/min cutting speed [39].

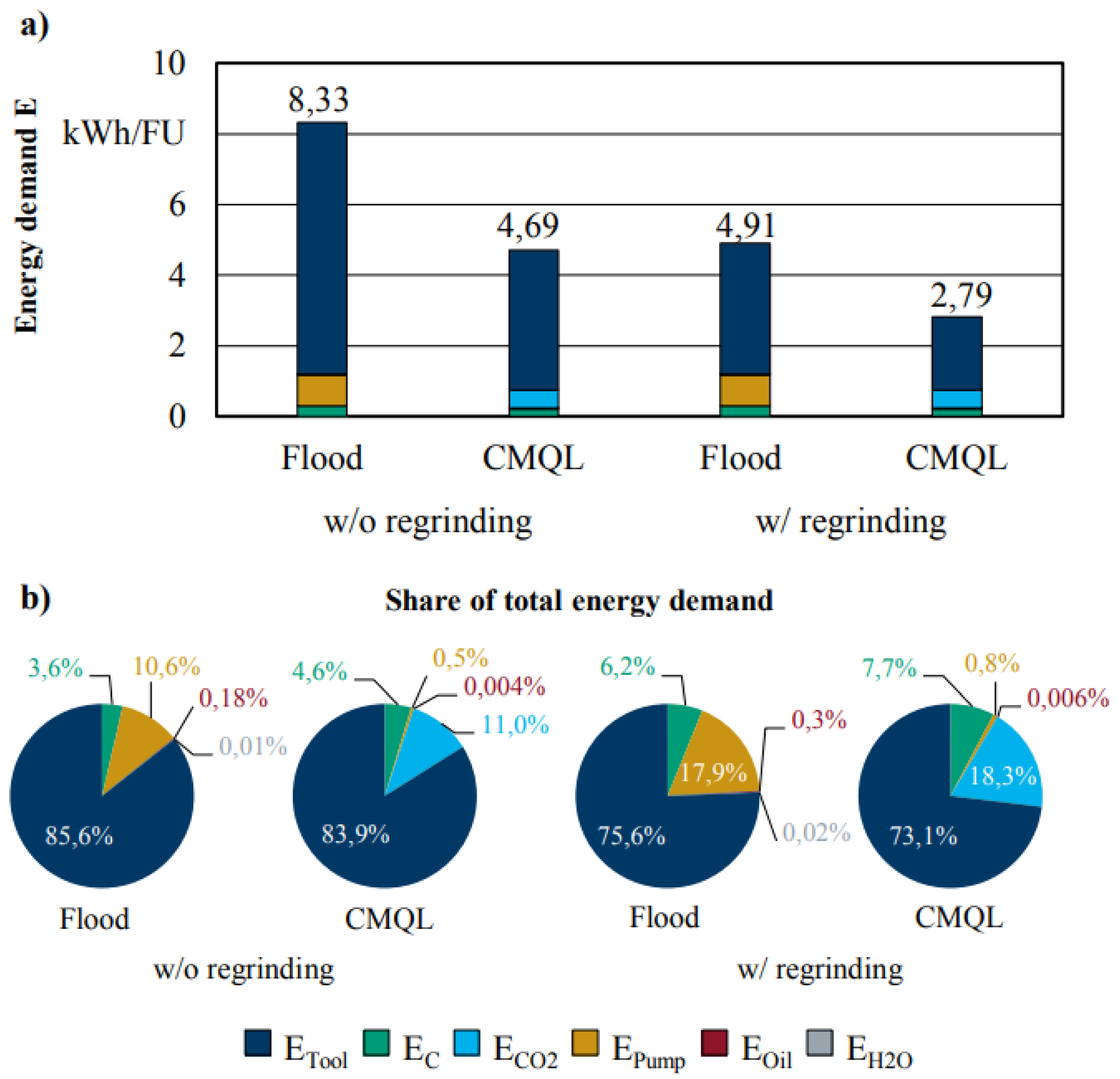

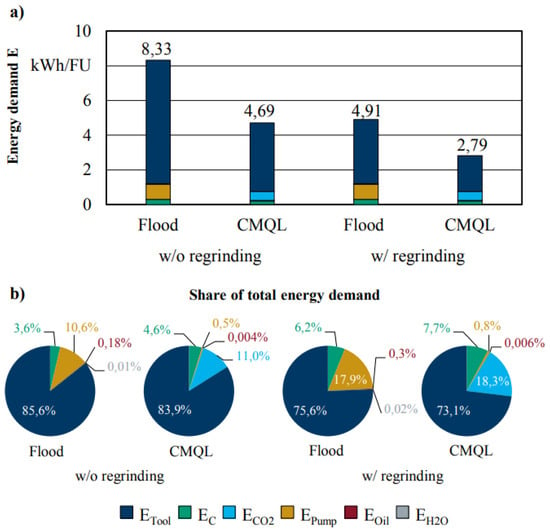

Figure 24 shows the total energy requirement for the cutting process using two different cooling strategies. The energy demand was compared three times when the tool was regrinding for the next operation. Flooded cooling showed a reduction of 41.1% using the regrinding technique. The CMQL cooling showed a 40.5% decrease in energy requirement by utilizing the regrinding technique. These findings underscore the environmental benefit of regrinding and its contribution to energy conservation and sustainability.

Figure 24.

Total energy demand comparison considering tool regrinding (three times) for (a) Flooded cooling, and (b) Cryogenic Minimum Quantity Lubrication (CMQL) cooling [41].

5.2. Turning Process

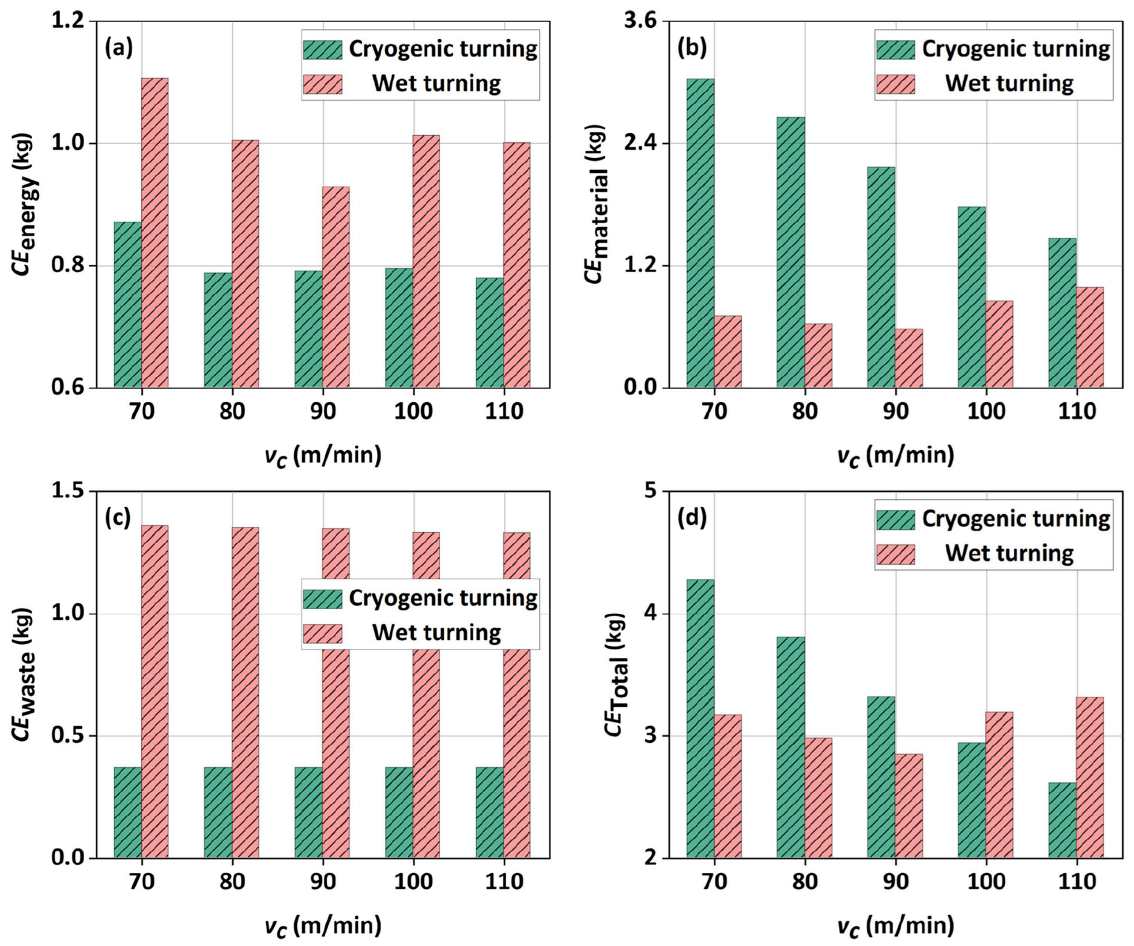

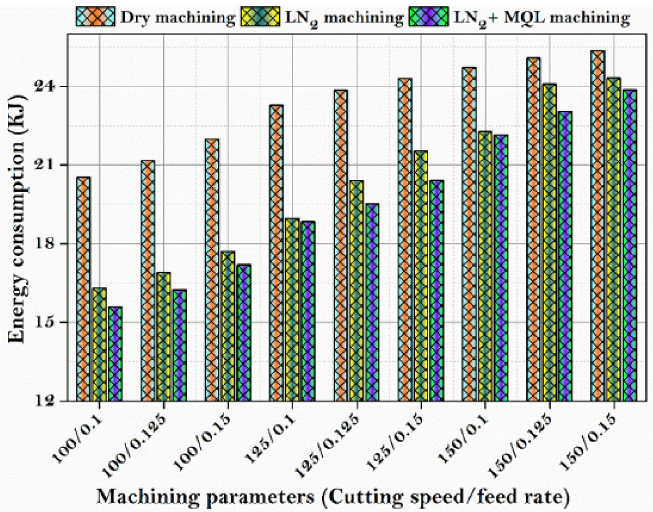

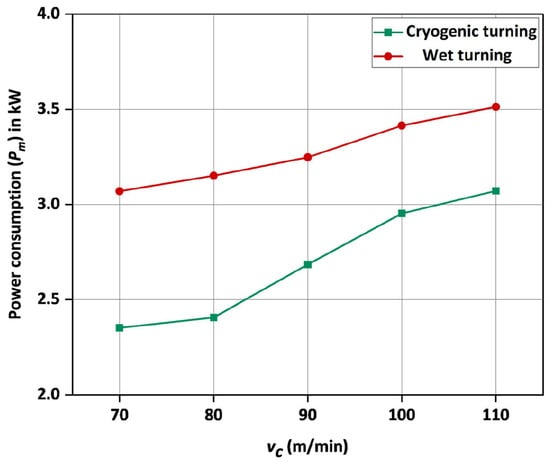

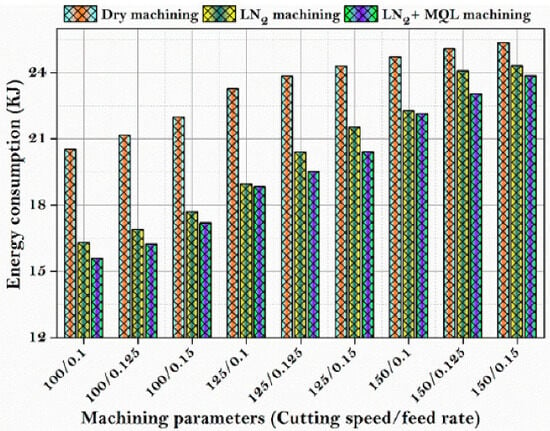

Figure 25 shows the energy power consumption during turning machining at different cutting speeds (100–150 m/min) and feed rates (0.1–0.15 mm/rev). Using LN2 + MQL resulted in a 15% reduction in energy usage compared to dry machining, whereas LN2 alone achieved a 12% reduction. This demonstrates the effectiveness of hybrid cryogenic approaches in minimizing energy input during turning.

Figure 25.

Power consumption at different cutting speeds for different cooling conditions [42].

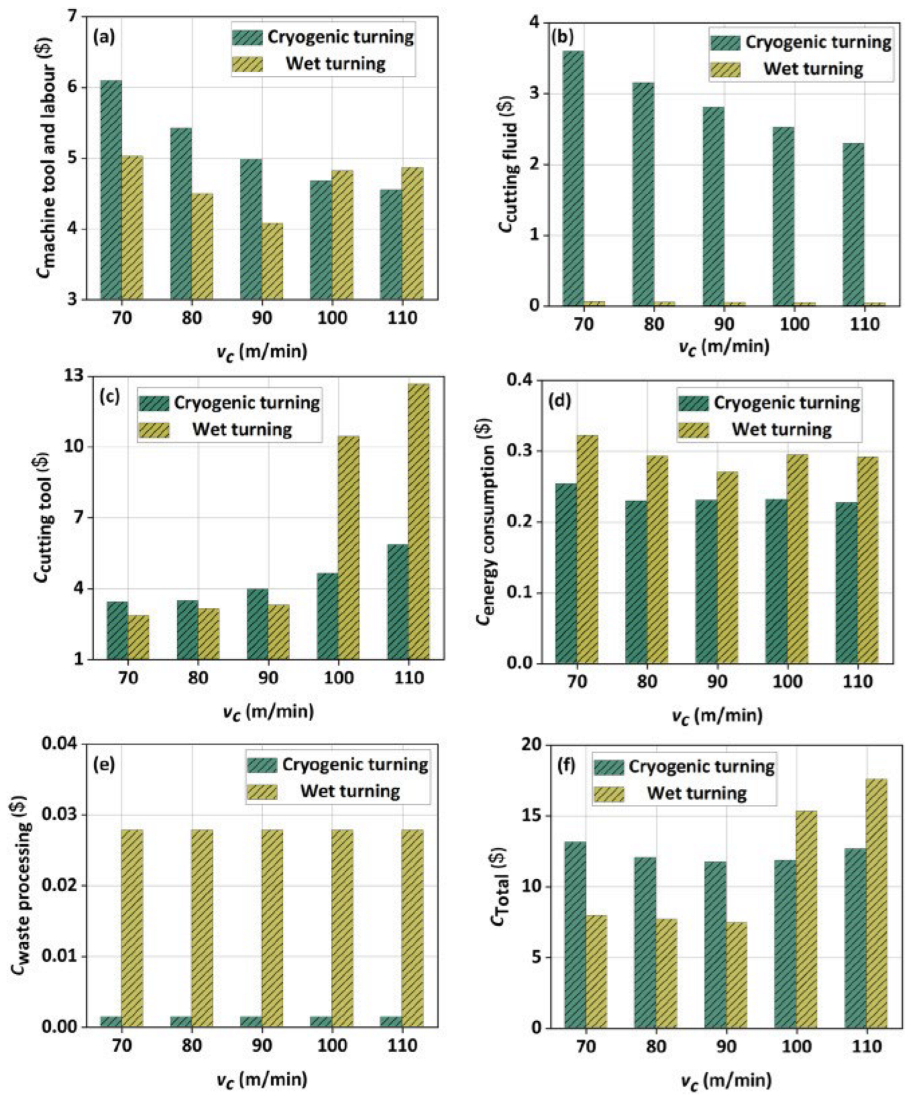

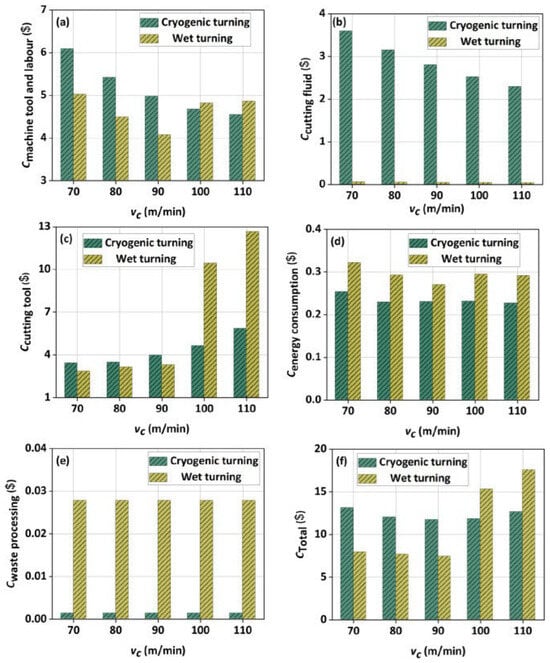

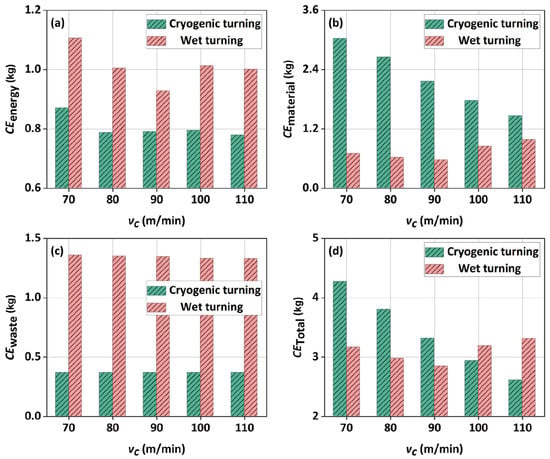

In Figure 26, Figure 27 and Figure 28, different costs are considered to determine the total machining cost. The analyzed cost includes tool and labor, cutting fluid, energy consumption, cutting tool, and waste processing. For the last figure, the cryogenic wet machining cost compared to the total cost. Research conducted experiments at different cutting speeds and found a 27% reduction in cryogenic conditions compared to wet machining. The cost reduction is found at a higher cutting speed.

Figure 26.

Cost analysis comparison of machining operations at varying cutting speeds: (a) Tool cost, (b) Energy cost, (c) Coolant cost, (d) Labor cost, (e) Overhead cost, and (f) Total machining cost [42].

Figure 27.

Emission level comparison at different cutting speeds: (a) Emissions from energy consumption, (b) Emissions from material usage, (c) Emissions from waste generation, and (d) Overall environmental impact [42].

Figure 28.

Consumption of energy values at different cooling regimes [44].

The emission of CO2 plays an essential role in sustainability analysis, and it decreased by up to 22% using the cryogenic coolant. The carbon emissions were reduced in cryogenic compared to wet machining due to the energy requirement. The material emission was reduced in wet cryogenic machining due to the unavailability of recycling in cryogenic machining.

The sector that consumes considerable energy is manufacturing, which is around 35% of the world’s power. M. Kumar et al. [44] performed different experiments at different cutting speeds and feed rates; cutting speeds varied from 100 to 150 m/min, and the feed rate ranged from 0.1 to 0.15 mm/rev. Figure 28 shows that the average consumption decreased by around 15% compared to dry machining, using LN2 + MQL. Similarly, LN2 reduced energy consumption by up to 12%, taking dry machining as a reference.

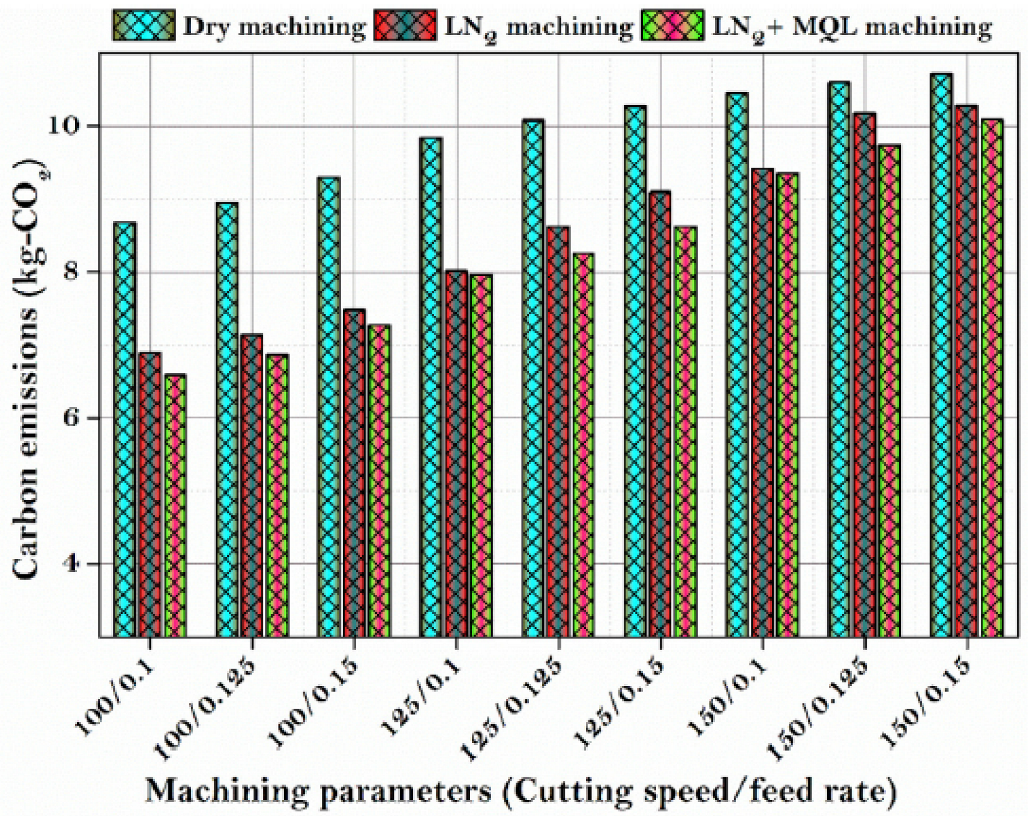

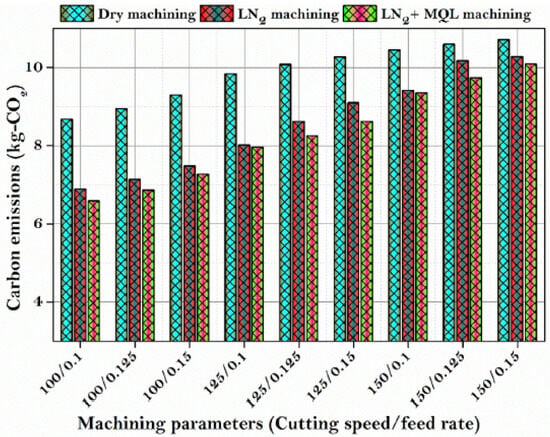

Figure 29 presents the carbon dioxide emissions measured under various cutting speeds and feed rates using different cooling strategies, including dry machining, liquid nitrogen (LN2), and a hybrid LN2 combined with minimum quantity lubrication (MQL). Among the tested parameters, the optimized condition was identified at a cutting speed of 100 m/min and a feed rate of 0.1 mm/rev. Under this condition, the hybrid LN2–MQL technique resulted in a reduction of carbon emissions by up to 35% compared to dry machining. This demonstrates the environmental advantage of cryogenic-assisted lubrication in minimizing the carbon footprint while maintaining machining performance.

Figure 29.

Carbon emission values at different cooling regimes [44].

5.3. Integrated Sustainability Assessment

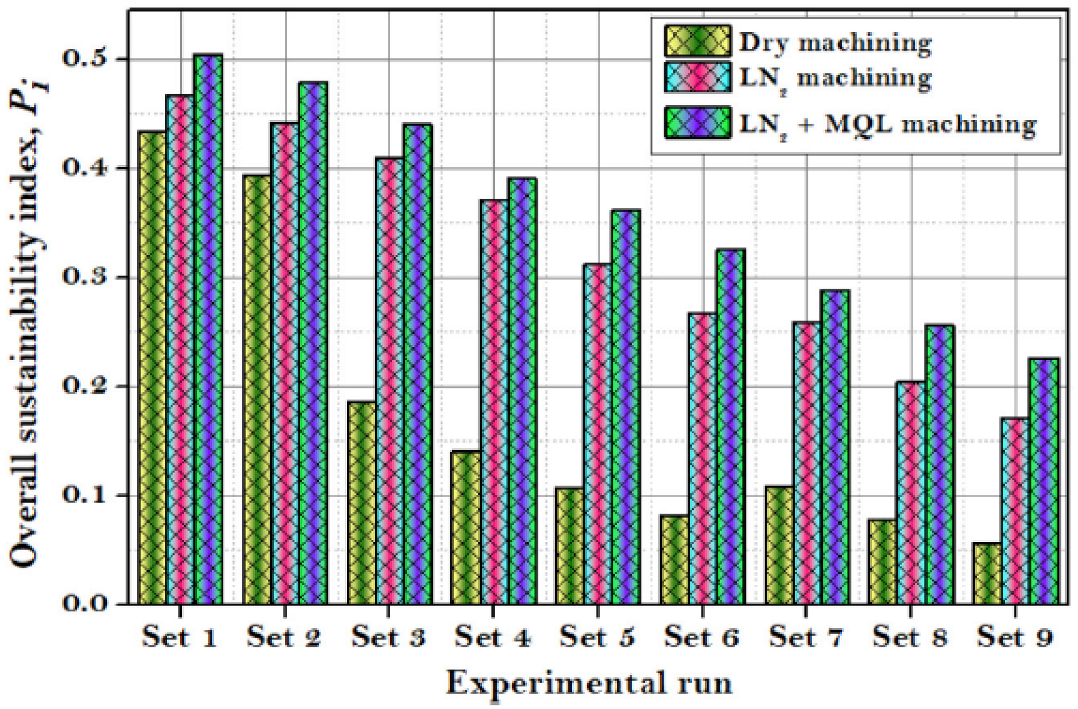

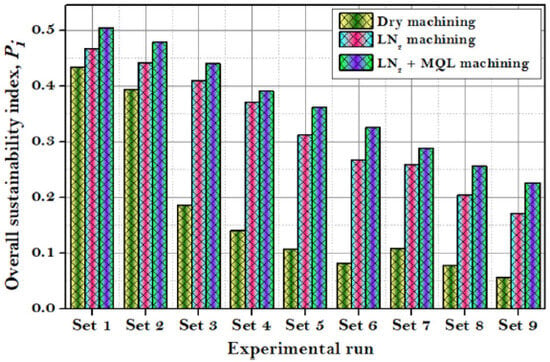

Social, economic, and environmental factors are analyzed for the sustainability index in Figure 30. In the matrix, every factor is properly weighted with the TOPSIS-AHP tool. Researchers found that set 9 showed the optimum condition, with a 100 m/min cutting speed and a feed rate of 0.1 mm/rev. It is worth mentioning that the hybrid system showed better performance than the other machining conditions. So, the combination of MQL and LN2 is more environmentally friendly for the cutting operation.

Figure 30.

Overall sustainability index at different cooling regimes [44].

6. Cryogenic Processing

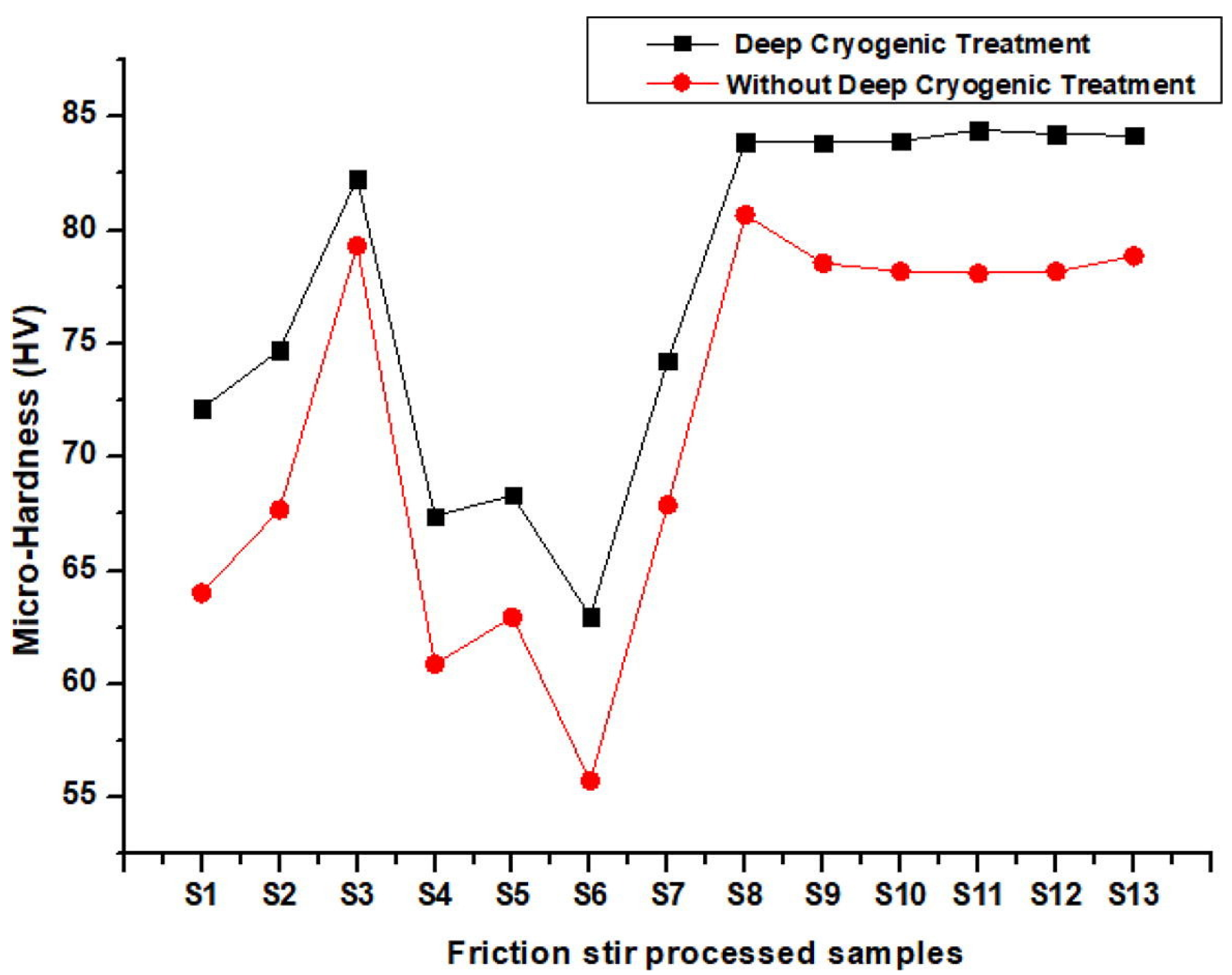

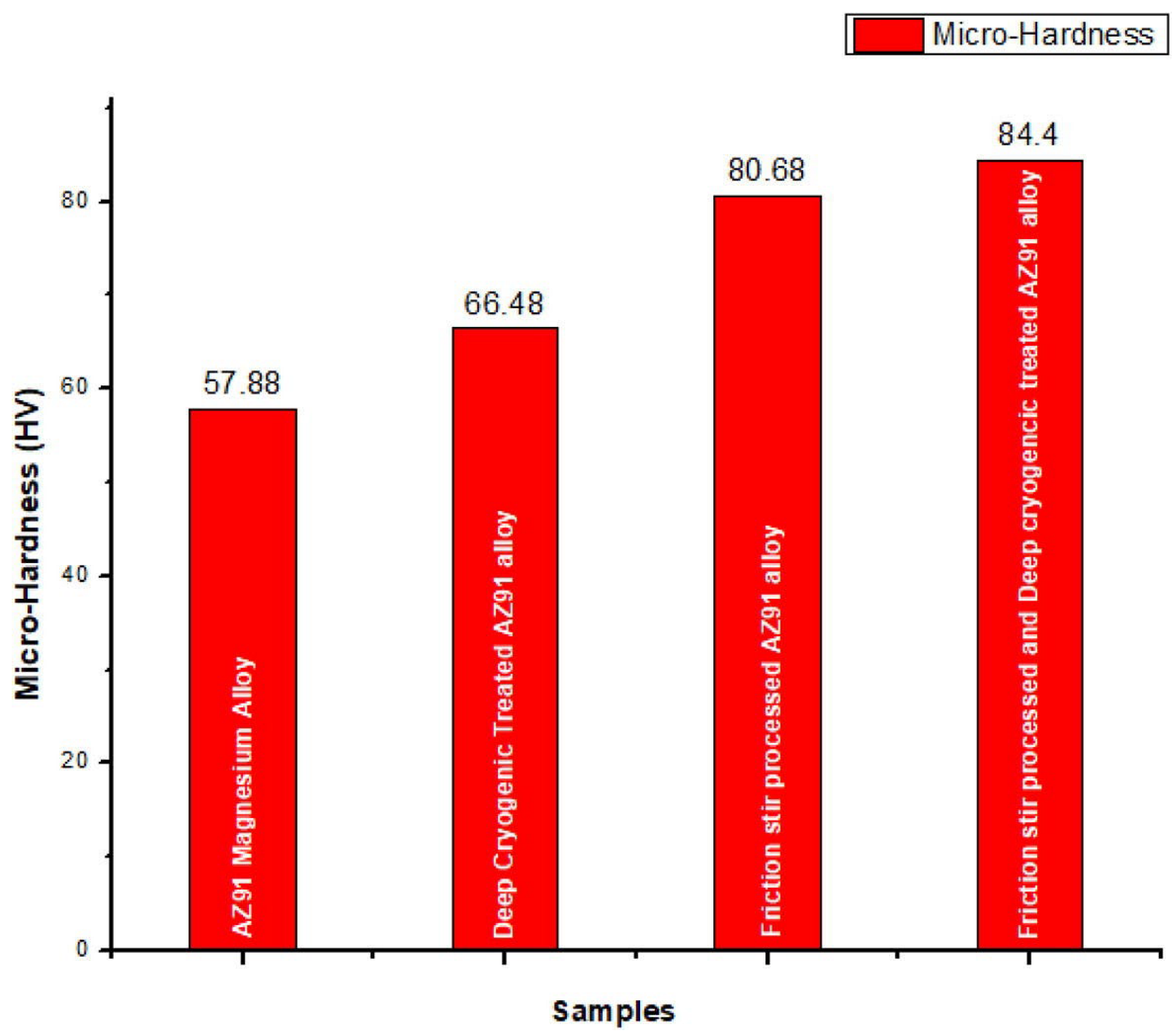

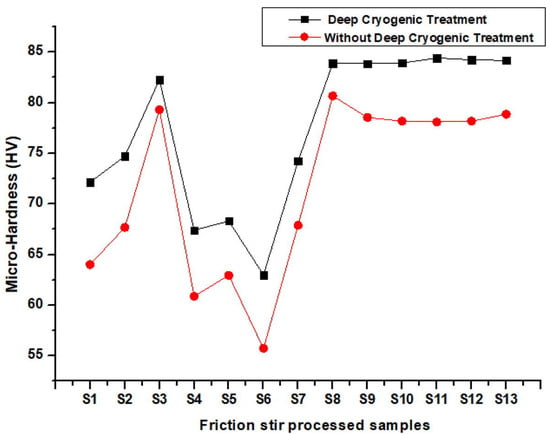

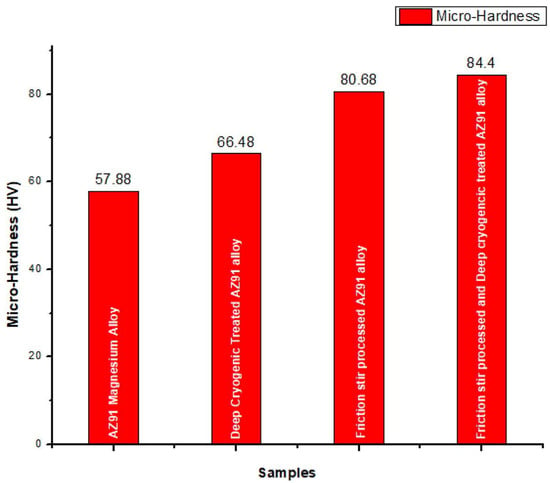

Vickers microhardness testing performed by taking an average of five indentions on the surface. From Figure 31, Figure 32 and Figure 33, it can be seen that using the deep cryogenic treatment (DCT) improved the microhardness of magnesium alloy. The improvement in the hardness is due to the formation of refined grains in the structure using DCT. The graphical representation showed the improvement of the microhardness by using the DCT with friction stir process. The average value of improving microhardness using DCT is around 12%.

Figure 31.

Comparison of hardness values using DCT and without using DCT [49].

Figure 32.

Hardness results of AZ91 magnesium alloys at different processing methods [49].

Figure 33.

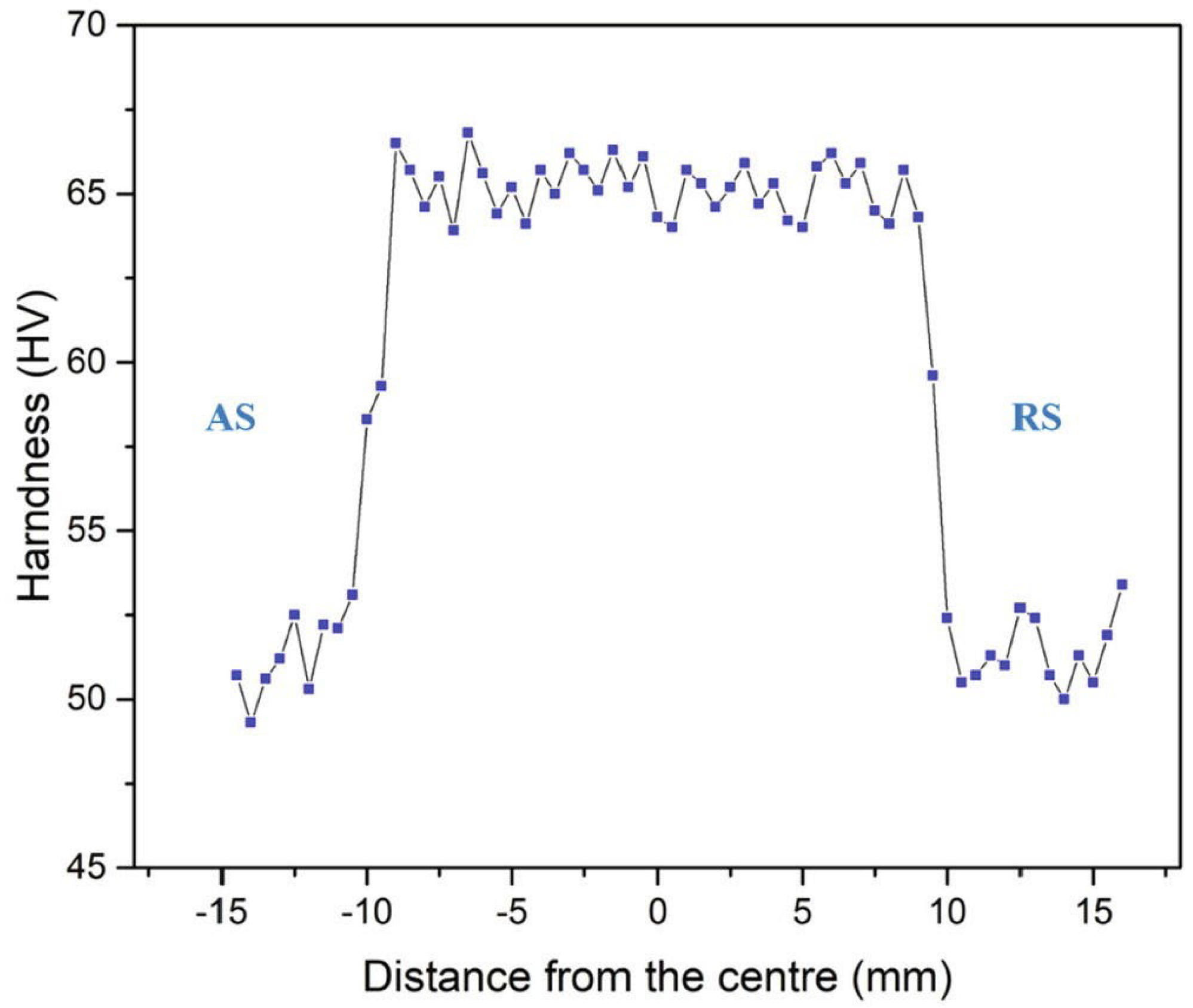

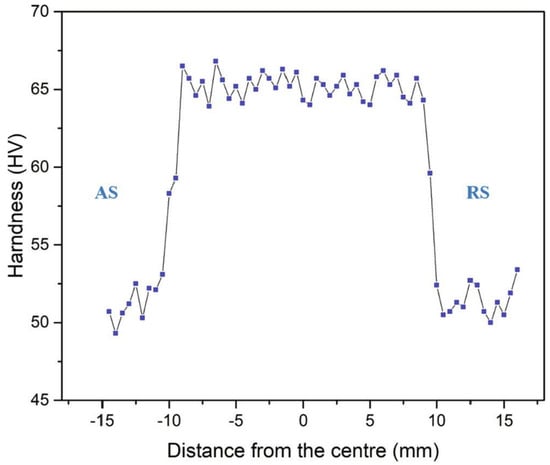

Hardness values on the overlap FSP [51].

The values of hardness improved using different strategies compared to using one sample. From the figure, values change from 57.88 HV to 84.4 using the friction stir method in combination with DCT. The comparison of values with the untreated magnesium alloy found that hardness increased by up to 31%.

In this study, the hardness profile of the samples was examined. The hardness decreases due to the thermal softening effect. The elongation is significantly improved using the overlapped FSP method for aluminum. The figure below shows the hardness values at different dog-bone-shaped sample positions prepared for analysis.

In recent years, several cryogenic MQL systems of both commercial and research quality have emerged. For example, the industrial deployment of these technologies, especially in aircraft applications, has been made possible by AccuCool (Erath, LA, USA) by 5 ME and hybrid LN2-MQL devices developed by CryoTech (San Diego, CA, USA). Advanced nozzles with angular adjustability and built-in flow regulators are frequently included in these systems, enabling accurate coolant targeting at the tool–workpiece interface. Nowadays, modular systems may be integrated into CNC platforms, and CFD simulation-based nozzle design optimization is being utilized more and more to increase efficiency. The development of these commercial solutions demonstrates how cryogenic MQL technologies are ready for practical application and how their economic and environmental worth is becoming increasingly recognized.

7. Computational Analysis

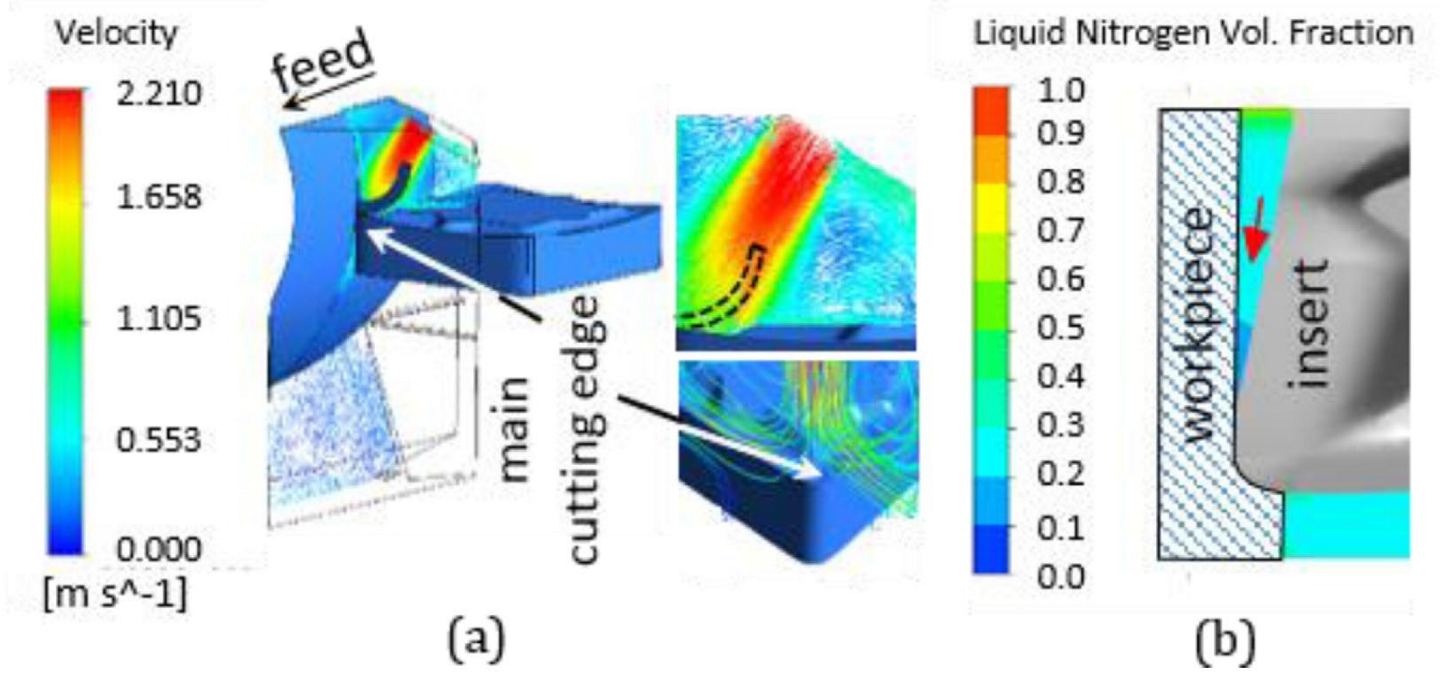

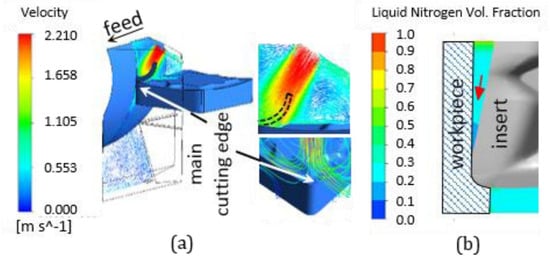

Experimentation was performed on the aerospace material that is Ti-6Al-4V. Figure 34 shows the liquid nitrogen near the cutting edge and flow streamlines of the CFD simulations. The LN2 jet is acting at the rake side of the tool, and it removes heat by emerging a free jet at high pressure. The high volume of LN2 reaches the rake surface due to the high-pressure jet along the insert surface. In this way, a considerable amount of extra energy is removed from the surface.

Figure 34.

Case 1: (a) streamline flow and (b) volumetric fraction of liquid nitrogen [11].

The hybrid system is shown in Figure 35. Damir et al. [11] used the MQL air at the rake side and LN2 at the flank side of the cutting tool. The air in MQL pushes the LN2 at the flank side and keeps it in the gap flank side and the machine surface. The simulation concluded that the temperature at the cutting zone was reduced effectively using the hybrid system. This, in turn, reduces the flank and rake wear and increases the tool life.

Figure 35.

Case 2: (a) streamline flow and (b) volumetric fraction of liquid nitrogen [11].

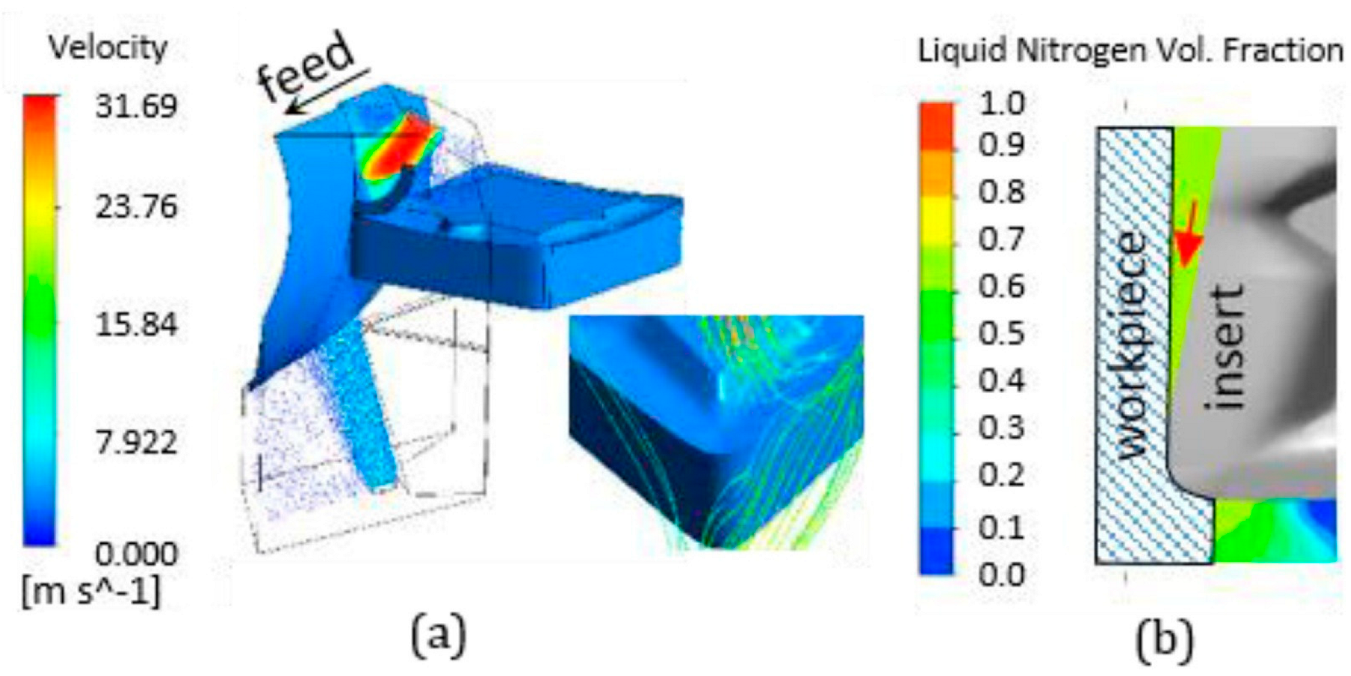

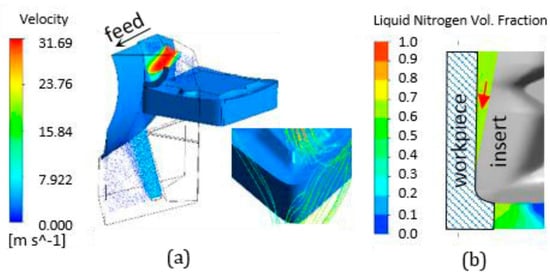

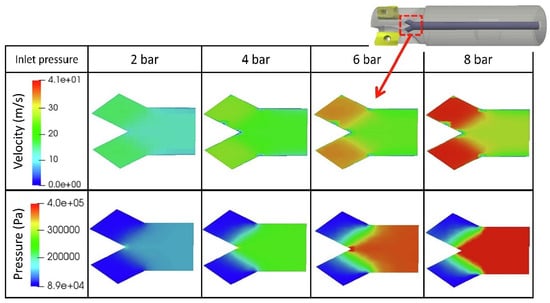

A cut plane near the branch and injector’s end shown with flow velocity and pressure distributions. Due to the divergence in geometry, local vorticities in the channel branch increase due to increased coolant pressure. According to Figure 36, the lower row demonstrates how the coolant pressure increases with increasing inlet pressure. When approaching the nozzle end, it decreases, with the atmospheric outlet pressure now updating the coolant pressure.

Figure 36.

Flow velocity and pressure distribution along a cross-section near the outlet. Various coolant pressures were used for simulations [52].

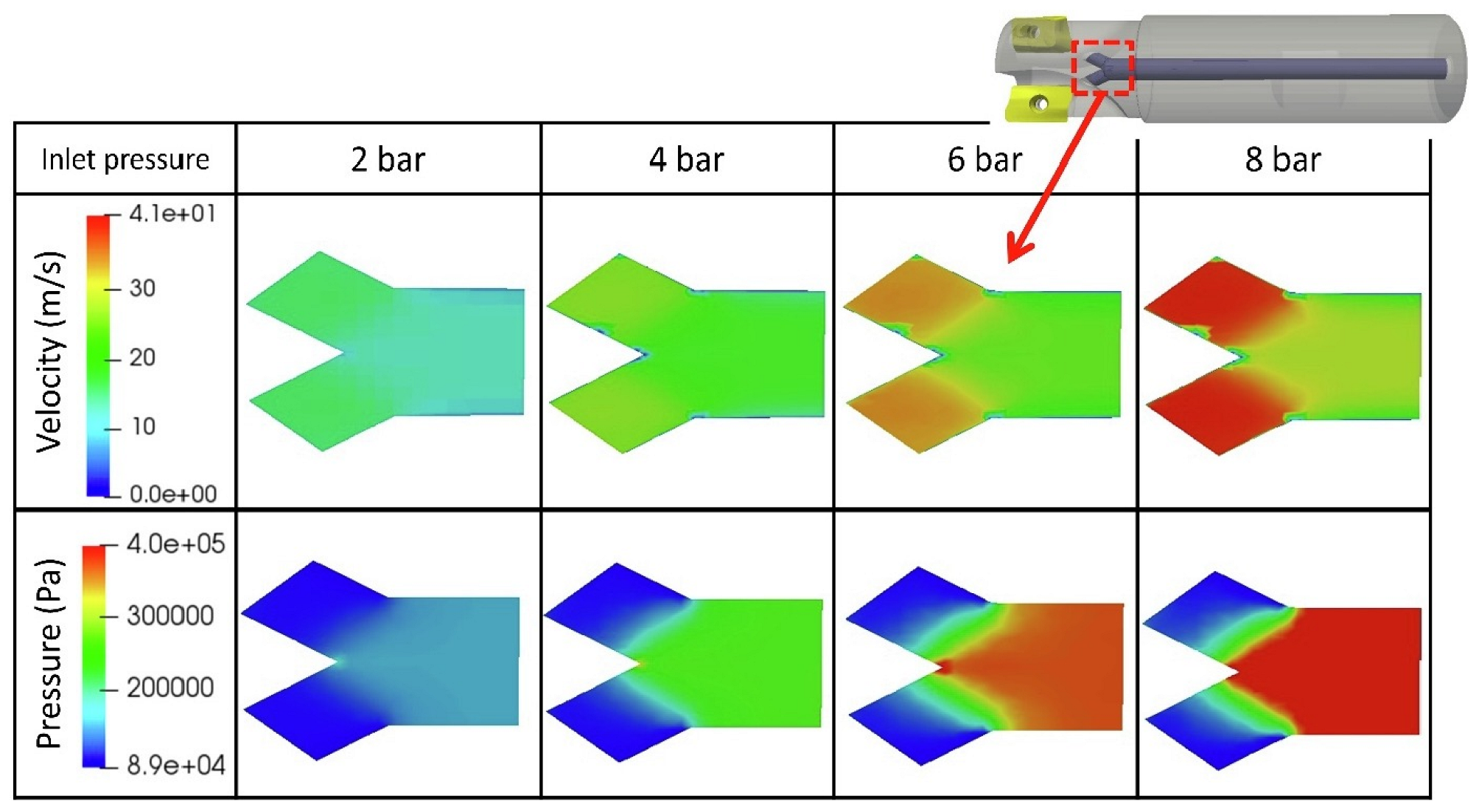

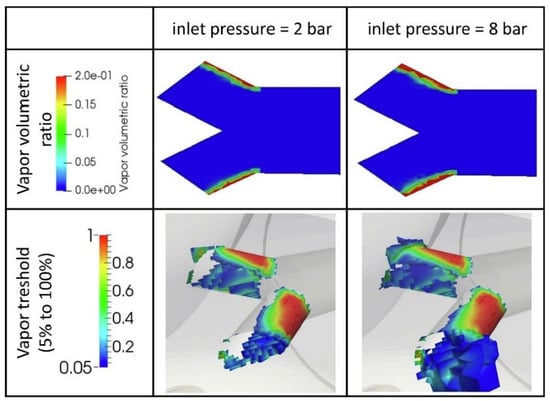

In Figure 37, cavitation is depicted north of the end of the nozzle for two different inlet pressure assumptions: 2 and 8 bars. When the pressure in a liquid drops below its saturation pressure at that temperature, cavitation occurs. Figure 36 illustrates the larger cavitation area seen in the study with higher inlet pressure than the low inlet pressure. Increased velocity and a sharp change in section area close to the solid wall result in multiplied vorticity and, consequently, a reduction in local pressure.

Figure 37.

Comparison of cavitation regimes of coolant with 2 and 8 bars: calculation of maximum vapor volume ratio at the injector outlet for cells with 5% vapor [52].

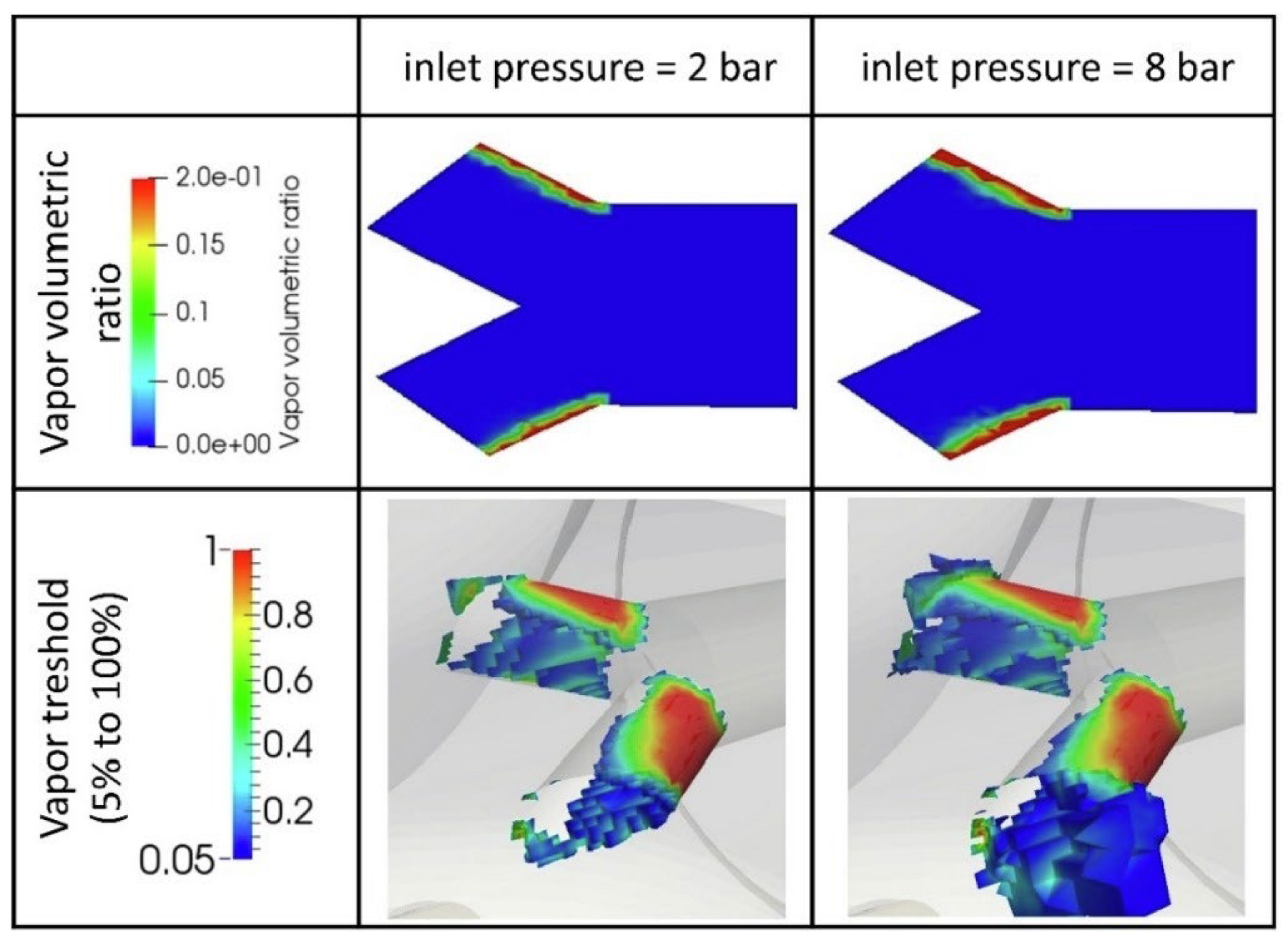

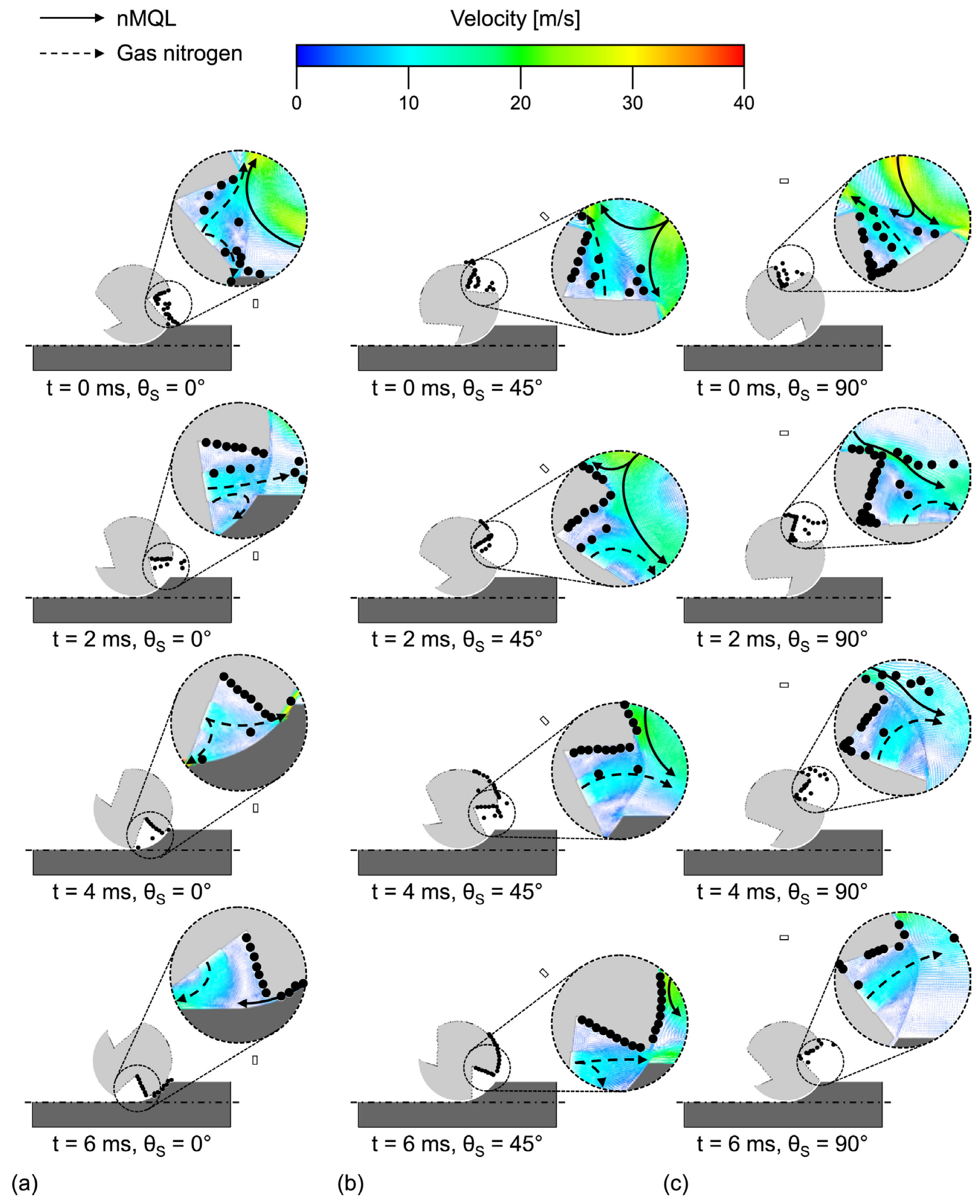

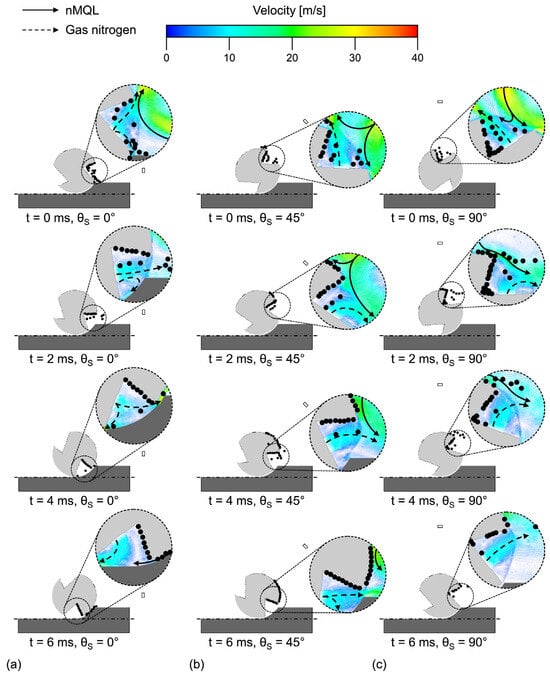

Figure 38 shows sequential images of nMQL droplets near the tool flute and cutting edge for each of the three θS values of the sensible cooling system separated by 2 ms. The nMQL drops enter the tool flute via the nMQL jet. Numerous droplets adhere to the outer surface of the tool and the cutting edge. A few N2 droplets are driven away from the tool’s flute by the jet of gas. The tool’s rotation removes lubricant, and the heat drops from its cutting zone through droplets attached to the cutting edge and its outer surface. A pressure difference above and below causes few droplets to be drawn into the cutting zone. The 45° angle has the most droplets attached to the cutting zone and the tool body, out of all angles of θS. Most single droplets flow through the cutting zone when θS = 0°. The cutting zone offers the least number of droplets passing through (attached and unattached) when θS = 90°.

Figure 38.

Behavior of nMQL droplets under sensible cooling observed at different angles: (a) 0°, (b) 45°, and (c) 90°, with frames separated by 2 ms [53].

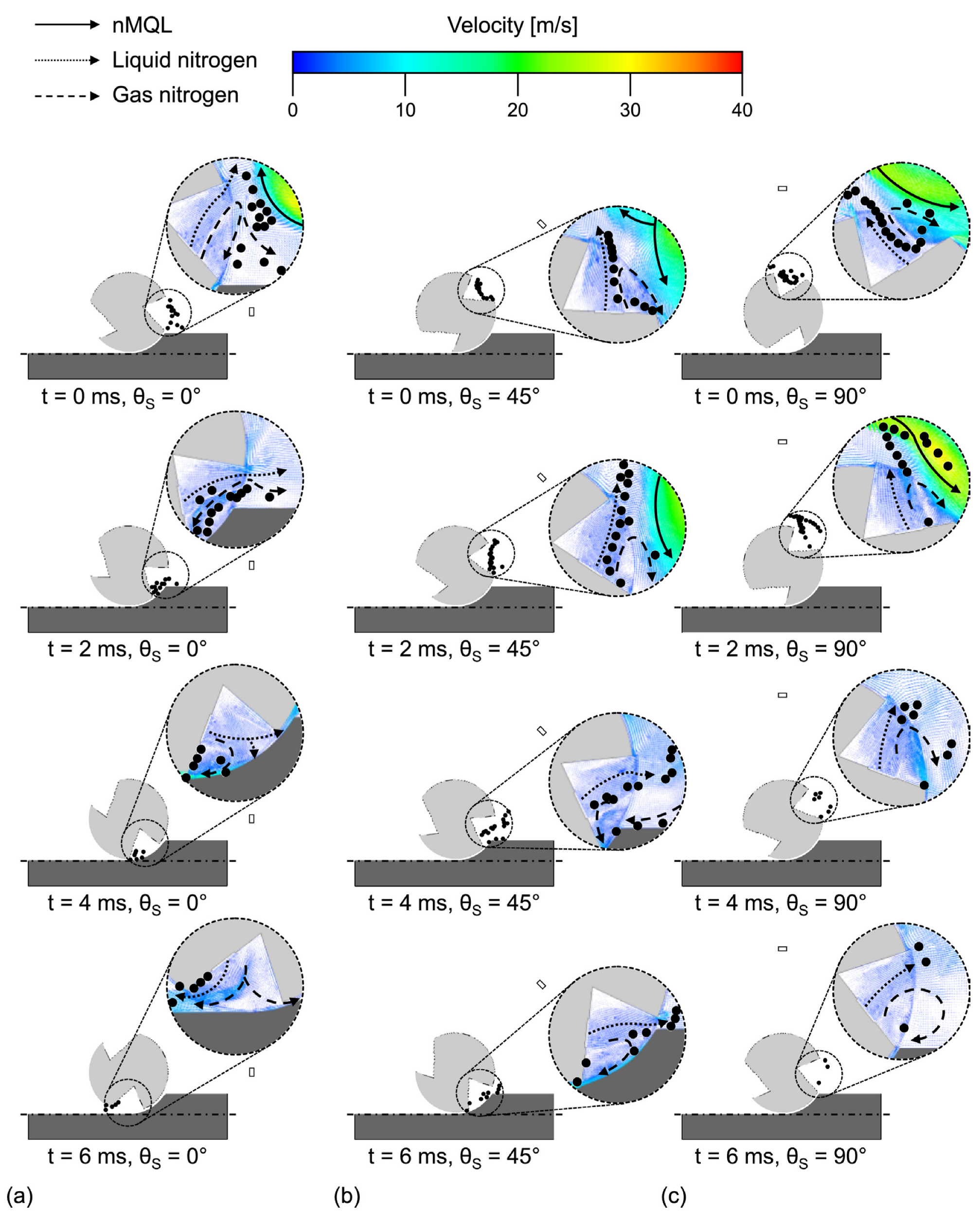

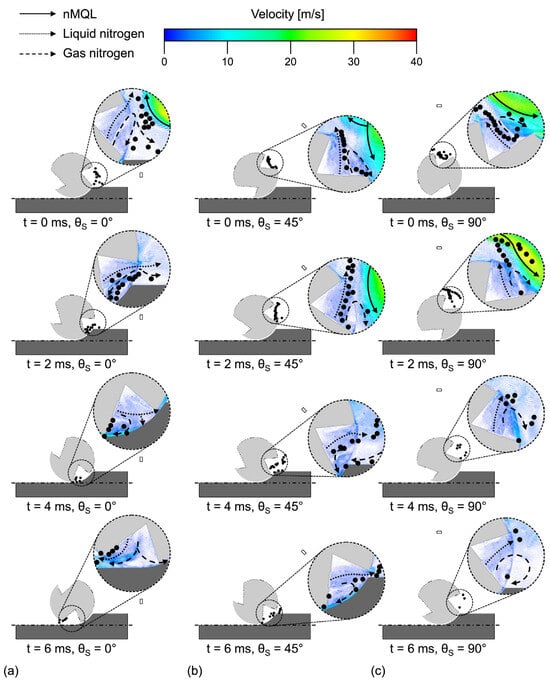

Figure 39 illustrates three sequential images of nMQL droplets forming in the latent cooling system, separated by two milliseconds. A latent cooling technique does not attach nMQL droplets to the center of the cutting edge and the outer tool surface. Several droplets pushed away from the flute region by the LN2 jet, and the phase changes N2 flow. Upon collision of N2 and nMQL, droplets get stuck. Droplets trapped on the tool surface are released and carried into the cutting zone as the tool rotates. At an angle of θS = 0°, most droplets are flowing through the cutting zone, while at another angle of θS, there are minor drops present.

Figure 39.

Behavior of nMQL droplets under latent cooling observed at different angles: (a) 0°, (b) 45°, and (c) 90°, with frames separated by 2 ms [53].

In addition to the fluid type, the precise position and angle of supply affect cryogenic cooling efficiency. CFD models show that the temperature gradient across the tool–chip contact is significantly influenced by the nozzle orientation. Coolant jets that are not properly focused might cause inefficient cooling and localized overheating. On the other hand, better nozzle designs provide uniform cooling and reduced tool wear, especially when LN2 is aimed at the flank and rake faces. Researchers are increasingly adopting advanced CFD techniques to simulate multi-phase flows in hybrid cryogenic systems in order to study pressure changes and vaporization behavior near the cutting zone. These insights allow for more targeted and efficient cutting fluid application strategies, which enhance tool life and process sustainability (Table 1).

Table 1.

Comparison of machining performance under different cooling/lubrication methods based on thermal, mechanical, environmental, and economic factors.

8. Conclusions

This article reviews different light-weight alloys, Mg, Al, steel, and Ti, for machinability and sustainability. Based on this detailed review, the following conclusions have been drawn:

- During machining, the cutting temperature is the essential factor. Different lightweight materials with varying cooling conditions are described in the review. The literature indicates that CO2 in combination with MQL gives the best results. The temperature dropped by approximately 40–50% in comparison to dry machining.

- The effectiveness of machining is also significantly influenced by cutting forces. Studies have shown that using cryogenic technology with MQL reduced cutting forces significantly, around 20–30% for high-performance materials.

- When using the cryogenic CO2 with the MQL system, it significantly reduced surface roughness. The literature has found that the surface finishes improved by approximately 40% over theoretical figures.

- Tool wear is linked to surface roughness as it is caused by adhesion, abrasion, etc. As mentioned above, a combination of Cryo and MQL improved surface roughness. Tool wear due to high-performance materials exhibits similar characteristics. Compared with dry machining, wear on tools reduced by 79%.

- It is rare in the literature to find morphological descriptions of chips. According to the available chip morphology information, cryogenic reduced the chip’s cutting zone temperature, silvery appearance, and brittleness.

- Sustainability is a crucial component of article machining. Power consumption, energy requirements, and carbon dioxide emissions play a significant role in determining the carbon footprint. Cryogenic technology reduced energy demand, power consumption, and CO2 by 40%, 28%, and 35%.

- The article uses computational techniques to determine the implications before starting the experiment. Simulations using CFD and FEA have been conducted to illustrate the operation of cryogenic + MQL machining. In summation, the reduction in machining parameters and improvement in sustainability is evident in the simulation and later verified through experimentation.

Despite the positive outcomes of cryogenic machining, some limits remain. These include a high initial setup cost, a lack of standardized nozzle configurations, and insufficient research into material-specific concerns to cryogenic conditions. Furthermore, reported benefits in energy and emission reductions are frequently process-dependent and require additional confirmation through extensive life cycle assessment (LCA) studies across various material types.

Future research should explore the following directions:

- ○

- Creation of real-time thermal monitoring adaptive cryogenic MQL systems powered by AI.

- ○

- CNC programming incorporating LCA metrics to automatically choose the most environmentally friendly machining technique.

- ○

- Investigation of substitute cryogenic fluids, such as hybrid refrigerants or bio-cryogens.

Author Contributions

Conceptualization, S.A. (Shafahat Ali), S.P. and I.D.; methodology, S.A. (Shafahat Ali) and S.A. (Said Abdallah); validation, S.A. (Shafahat Ali) and S.A. (Said Abdallah); formal analysis, S.A. (Shafahat Ali); resources, S.P. and I.D.; data curation, S.A. (Shafahat Ali); writing—original draft preparation, S.A. (Shafahat Ali), S.A. (Said Abdallah), S.P. and I.D.; writing—review and editing, S.A. (Shafahat Ali), S.A. (Said Abdallah), S.P. and I.D.; supervision, S.P. and I.D.; project administration, S.P. and I.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ali, S.; Pervaiz, S. Machinability analysis of AZ31 magnesium alloys using the Taguchi gray relational analysis. Int. J. Adv. Manuf. Technol. 2023, 126, 4171–4190. [Google Scholar] [CrossRef]

- Kaynak, Y.; Lu, T.; Jawahir, I.S. Cryogenic machining-induced surface integrity: A review and comparison with dry, mql, and flood-cooled machining. Mach. Sci. Technol. 2014, 18, 149–198. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Budak, E. Investigation of machinability in turning of difficult-to-cut materials using a new cryogenic cooling approach. Tribol. Int. 2018, 119, 510–520. [Google Scholar] [CrossRef]

- Shah, P.; Khanna, N. Chetan Comprehensive machining analysis to establish cryogenic LN2 and LCO2 as sustainable cooling and lubrication techniques. Tribol. Int. 2020, 148, 106314. [Google Scholar] [CrossRef]

- Strano, M.; Chiappini, E.; Tirelli, S.; Albertelli, P.; Monno, M. Comparison of Ti6Al4V machining forces and tool life for cryogenic versus conventional cooling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1403–1408. [Google Scholar] [CrossRef]

- Venugopal, K.A.; Paul, S.; Chattopadhyay, A.B. Growth of tool wear in turning of Ti-6Al-4V alloy under cryogenic cooling. Wear 2007, 262, 1071–1078. [Google Scholar] [CrossRef]

- Stampfer, B.; Golda, P.; Schießl, R.; Maas, U.; Schulze, V. Cryogenic orthogonal turning of Ti-6Al-4V: Analysis of nitrogen supply pressure variation and subcooler usage. Int. J. Adv. Manuf. Technol. 2020, 111, 359–369. [Google Scholar] [CrossRef]

- Suhaimi, M.A.; Yang, G.D.; Park, K.H.; Hisam, M.J.; Sharif, S.; Kim, D.W. Effect of Cryogenic Machining for Titanium Alloy Based on Indirect, Internal and External Spray System. Procedia Manuf. 2018, 17, 158–165. [Google Scholar] [CrossRef]

- Abdallah, S.; Ali, S.; Pervaiz, S.; Kannan, S. Conventional Machining of Single Crystal Metals and Super Alloys: A Review. J. Manuf. Sci. Eng. 2022, 144, 1–21. [Google Scholar] [CrossRef]

- Aramcharoen, A. Influence of Cryogenic Cooling on Tool Wear and Chip Formation in Turning of Titanium Alloy. Procedia CIRP 2016, 46, 83–86. [Google Scholar] [CrossRef]

- Damir, A.; Shi, B.; Attia, M.H. Flow characteristics of optimized hybrid cryogenic-minimum quantity lubrication cooling in machining of aerospace materials. CIRP Ann. 2019, 68, 77–80. [Google Scholar] [CrossRef]

- Dhananchezian, M.; Pradeep Kumar, M. Cryogenic turning of the Ti-6Al-4V alloy with modified cutting tool inserts. Cryogenics 2011, 51, 34–40. [Google Scholar] [CrossRef]

- Sales, W.F.; Schoop, J.; Jawahir, I.S. Tribological behavior of PCD tools during superfinishing turning of the Ti6Al4V alloy using cryogenic, hybrid and flood as lubri-coolant environments. Tribol. Int. 2017, 114, 109–120. [Google Scholar] [CrossRef]

- Ravi, S.; Gurusamy, P. Cryogenic machining of AISI p20 steel under liquid nitrogen cooling. Mater. Today Proc. 2021, 37, 806–809. [Google Scholar] [CrossRef]

- Paul, S.; Dhar, N.R.; Chattopadhyay, A.B. Beneficial effects of cryogenic cooling over dry and wet machining on tool wear and surface finish in turning AISI 1060 steel. J. Mater. Process. Technol. 2001, 116, 44–48. [Google Scholar] [CrossRef]

- Bertolini, R.; Ghiotti, A.; Bruschi, S. Machinability of polyamide 6 under cryogenic cooling conditions. Procedia Manuf. 2020, 48, 419–427. [Google Scholar] [CrossRef]

- Sartori, S.; Ghiotti, A.; Bruschi, S. Hybrid lubricating/cooling strategies to reduce the tool wear in finishing turning of difficult-to-cut alloys. Wear 2017, 376–377, 107–114. [Google Scholar] [CrossRef]

- Neto, O.M.P.; Calleja-Ochoa, A.; Ayesta, I.; Rodríguez, A.; González-Barrio, H.; de Lacalle, L.N.L. A Cleaner Milling Process Replacing Emulsion Coolant by Cryogenics CO2. Int. J. Precis. Eng. Manuf.-Green Technol. 2024, 11, 21–32. [Google Scholar] [CrossRef]

- Mulyana, T.; Rahim, E.A.; Md Yahaya, S.N. The influence of cryogenic supercritical carbon dioxide cooling on tool wear during machining high thermal conductivity steel. J. Clean. Prod. 2017, 164, 950–962. [Google Scholar] [CrossRef]

- Klocke, F.; Settineri, L.; Lung, D.; Claudio Priarone, P.; Arft, M. High performance cutting of gamma titanium aluminides: Influence of lubricoolant strategy on tool wear and surface integrity. Wear 2013, 302, 1136–1144. [Google Scholar] [CrossRef]

- Tapoglou, N.; Lopez, M.I.A.; Cook, I.; Taylor, C.M. Investigation of the Influence of CO2 Cryogenic Coolant Application on Tool Wear. Procedia CIRP 2017, 63, 745–749. [Google Scholar] [CrossRef]

- Busch, K.; Hochmuth, C.; Pause, B.; Stoll, A.; Wertheim, R. Investigation of Cooling and Lubrication Strategies for Machining High-temperature Alloys. Procedia CIRP 2016, 41, 835–840. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Barreiro, J.; Fernández-Abia, A.I.; de Lacalle, L.N.L. Nozzle design for combined use of MQL and cryogenic gas in machining. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 87–95. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Ali, S.; Alshibi, A.; Nasreldin, A.; Pervaiz, S. Artifical intelligence inspired approach to numerically investigate chip morphology in machining AISI630. Int. J. Interact. Des. Manuf. 2024, 18, 6655–6672. [Google Scholar] [CrossRef]

- Dhananchezian, M.; Priyan, M.R.; Rajashekar, G.; Narayanan, S.S. Study the Effect of Cryogenic Cooling on Machinability Characteristics during Turning Duplex Stainless Steel 2205. Mater. Today Proc. 2018, 5, 12062–12070. [Google Scholar] [CrossRef]

- Ranjith, R.; Somu, C.; Tharanitharan, G.; Venkatajalapathi, T.; Naveenkumar, M. Integrated taguchi cum grey relational experimental analysis (great) for optimization and machining characterization of cryogenic cooled AA6063 aluminium alloys. Mater. Today Proc. 2019, 18, 3597–3605. [Google Scholar] [CrossRef]

- Kane, S.N.; Mishra, A.; Dutta, A.K. Preface: International Conference on Recent Trends in Physics (ICRTP 2016). J. Phys. Conf. Ser. 2016, 755, 011001. [Google Scholar] [CrossRef]

- Ali, S.; Pervaiz, S.; Kannan, S. Current Research Trends in Variants of Minimum Quantity Lubrication (MQL): A Review. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Yildirim, Ç.V.; Kivak, T.; Sarikaya, M.; Şirin, Ş. Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J. Mater. Res. Technol. 2020, 9, 2079–2092. [Google Scholar] [CrossRef]

- Krishnamurthy, G.; Bhowmick, S.; Altenhof, W.; Alpas, A.T. Increasing efficiency of Ti-alloy machining by cryogenic cooling and using ethanol in MRF. CIRP J. Manuf. Sci. Technol. 2017, 18, 159–172. [Google Scholar] [CrossRef]

- Kesavan, J.; Senthilkumar, V. Experimental investigations on cryo-machining of Hastelloy C-276 with tool wear characteristics. Sadhana-Acad. Proc. Eng. Sci. 2020, 45, 240. [Google Scholar] [CrossRef]

- Akıncıoğlu, S.; Gökkaya, H.; Uygur, İ. The effects of cryogenic-treated carbide tools on tool wear and surface roughness of turning of Hastelloy C22 based on Taguchi method. Int. J. Adv. Manuf. Technol. 2016, 82, 303–314. [Google Scholar] [CrossRef]

- Dhananchezian, M. Study the machinability characteristics of Nicked based Hastelloy C-276 under cryogenic cooling. Meas. J. Int. Meas. Confed. 2019, 136, 694–702. [Google Scholar] [CrossRef]

- Venugopal, K.A.; Paul, S.; Chattopadhyay, A.B. Tool wear in cryogenic turning of Ti-6Al-4V alloy. Cryogenics 2007, 47, 12–18. [Google Scholar] [CrossRef]

- Aramcharoen, A.; Chuan, S.K. An experimental investigation on cryogenic milling of inconel 718 and its sustainability assessment. Procedia CIRP 2014, 14, 529–534. [Google Scholar] [CrossRef]