Investigation of the Friction and Wear Behavior of Cr-Mo-V Steel with Different Surface Treatment Processes

Abstract

1. Introduction

2. Sample Preparation and Testing

2.1. Coating Preparation

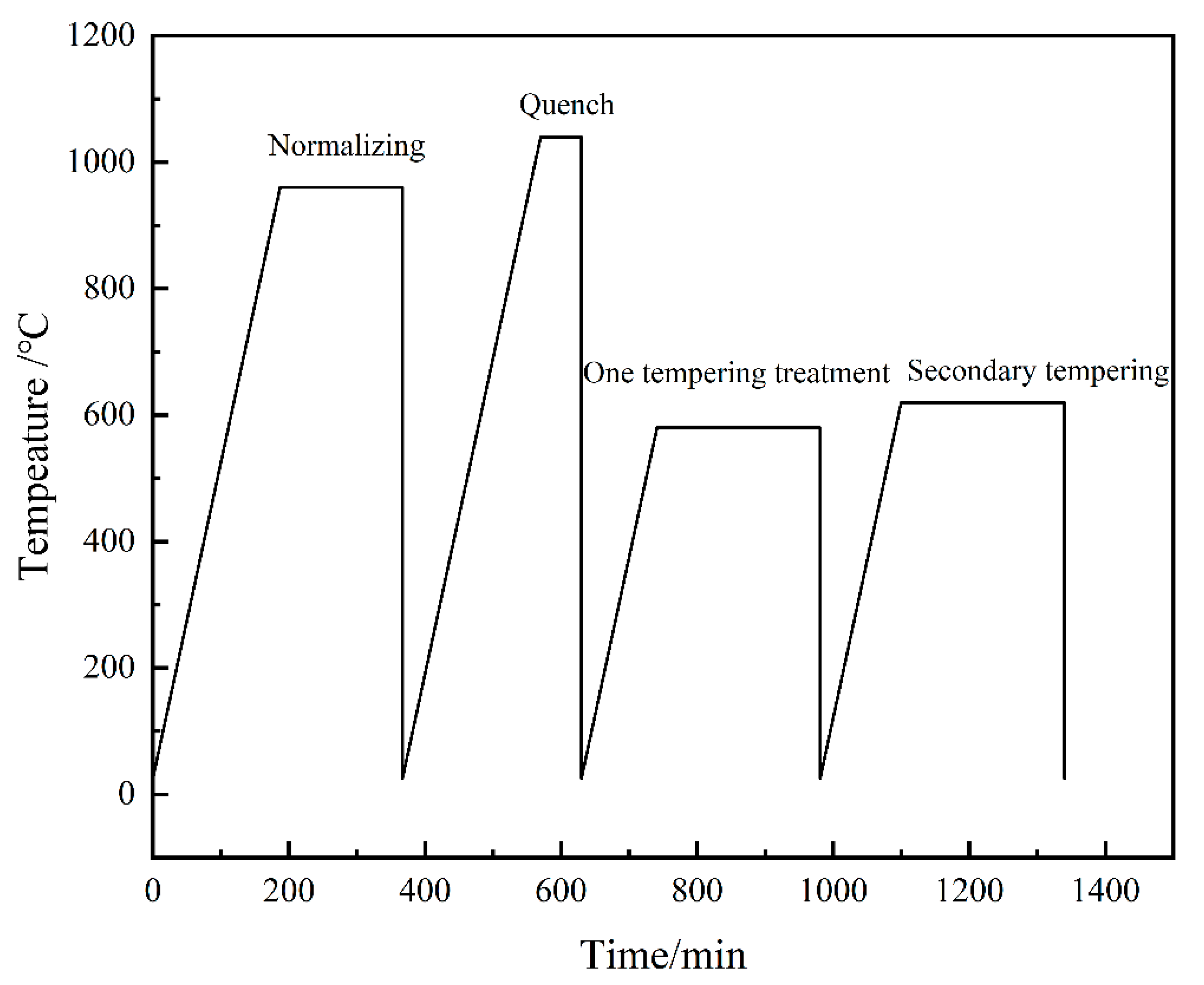

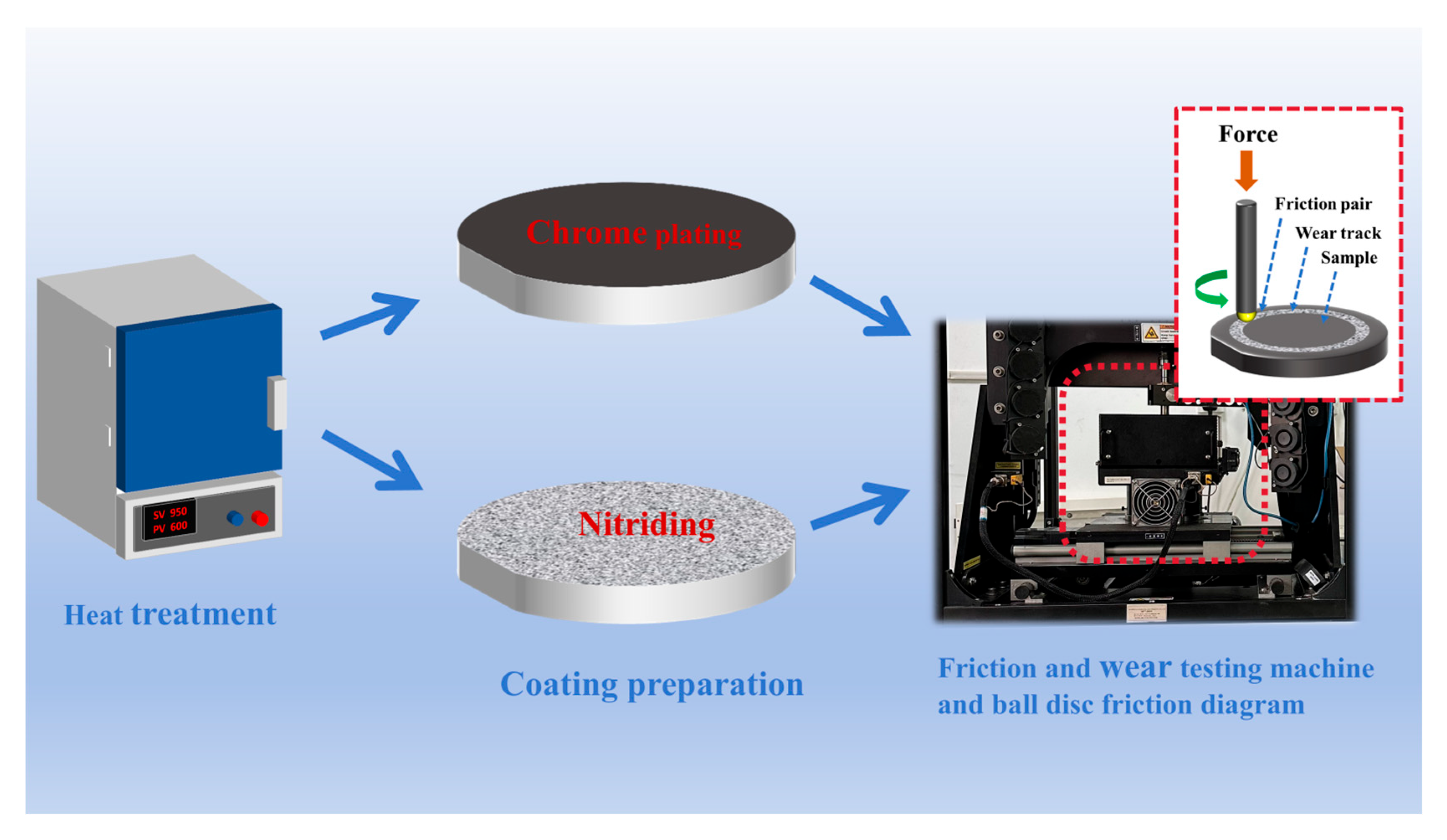

2.1.1. Surface Treatments

2.1.2. Microstructural and Property Characterization of Chromium Plating/Nitriding

2.1.3. Tribological Properties

3. Results and Discussion

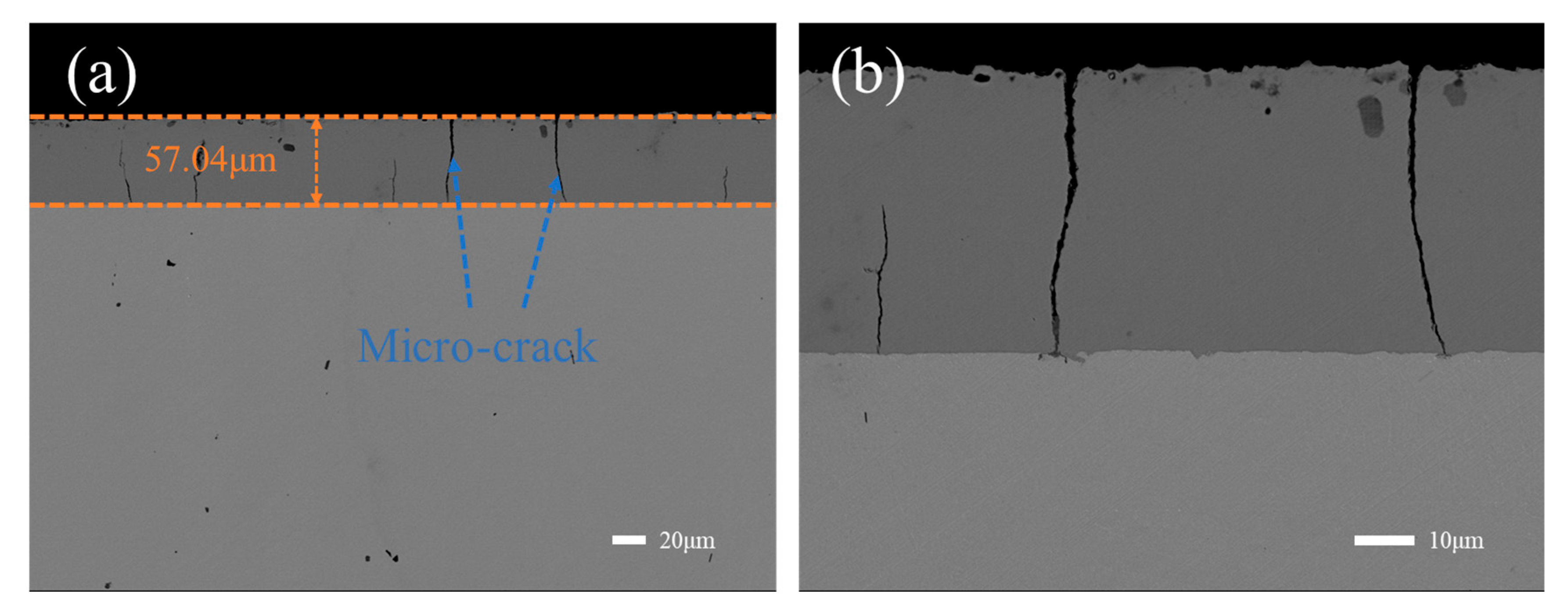

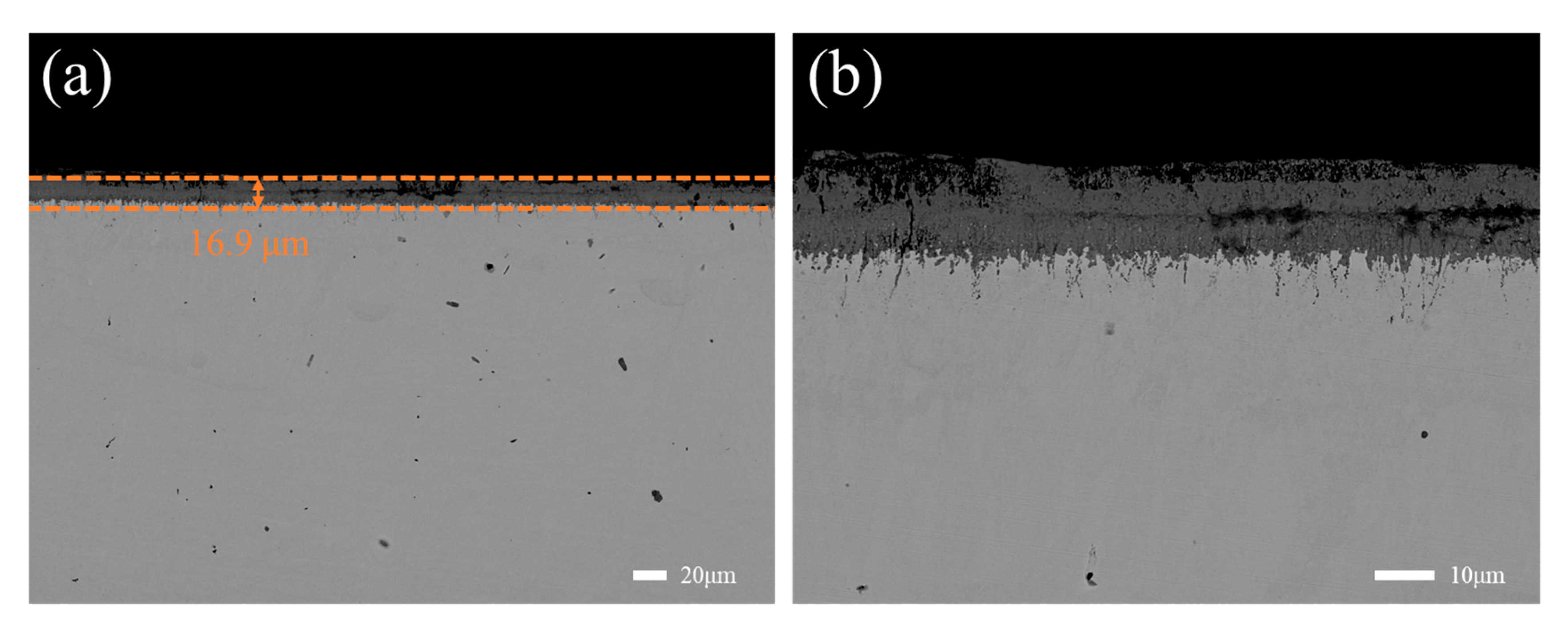

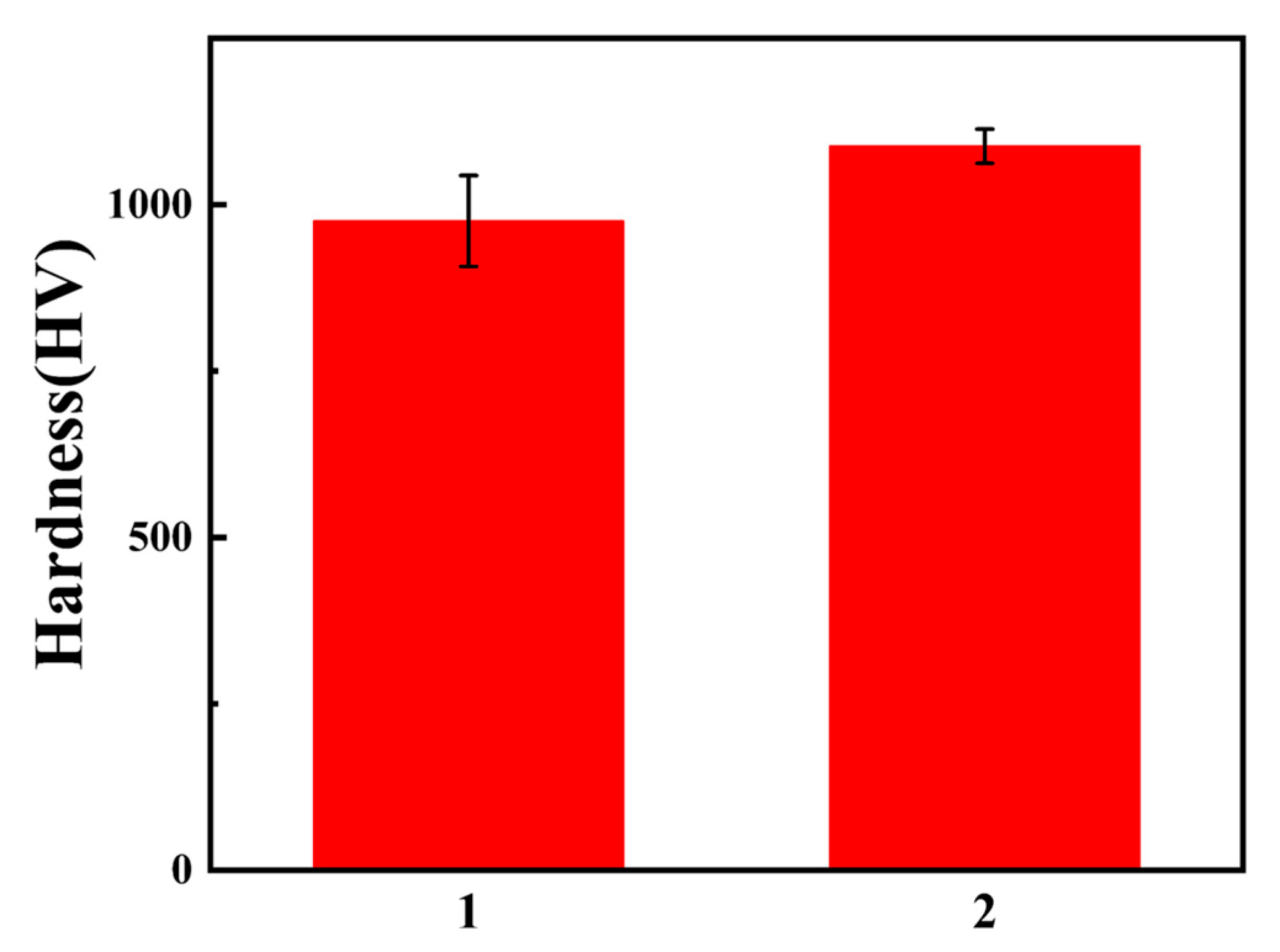

3.1. Microstructure of the Coating

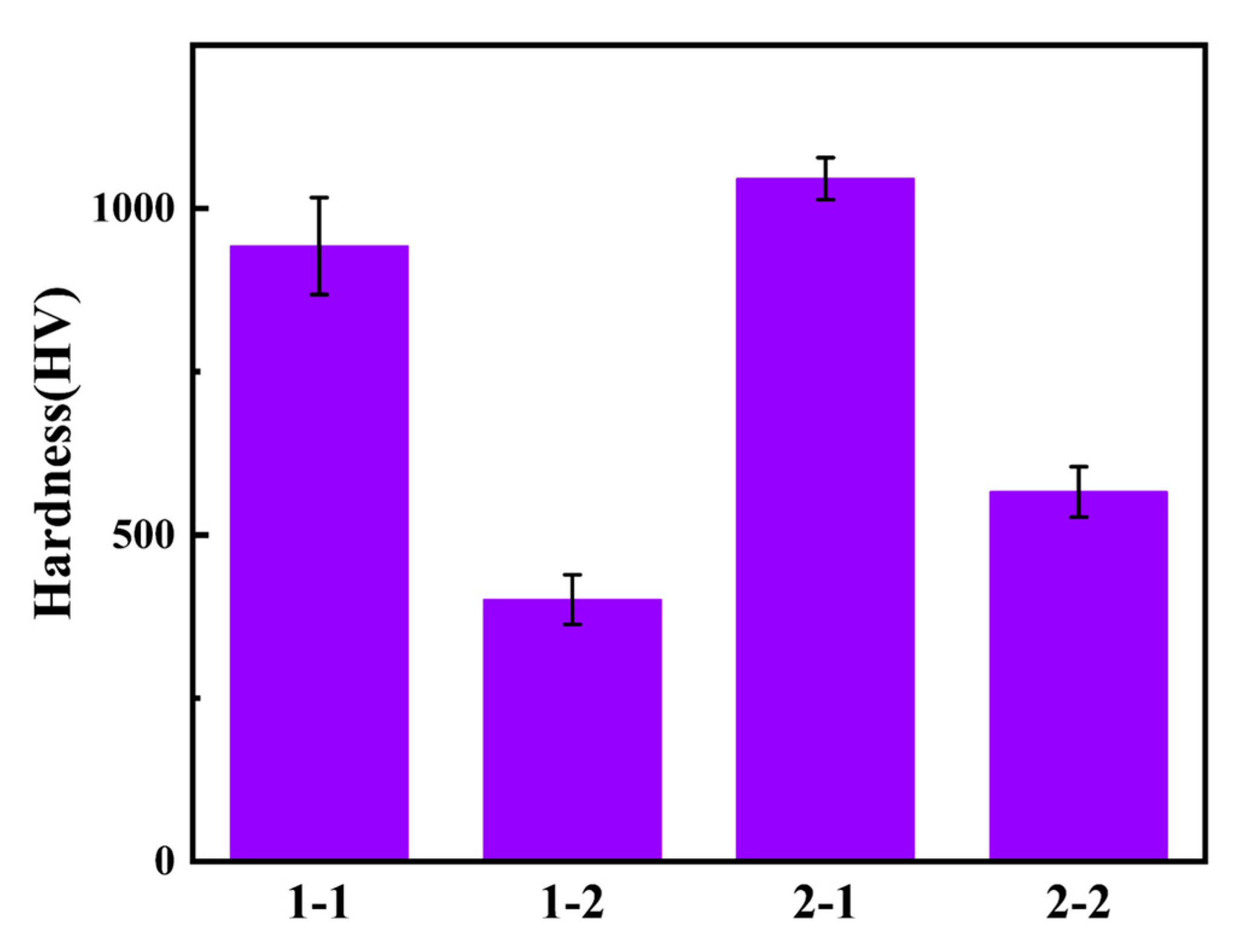

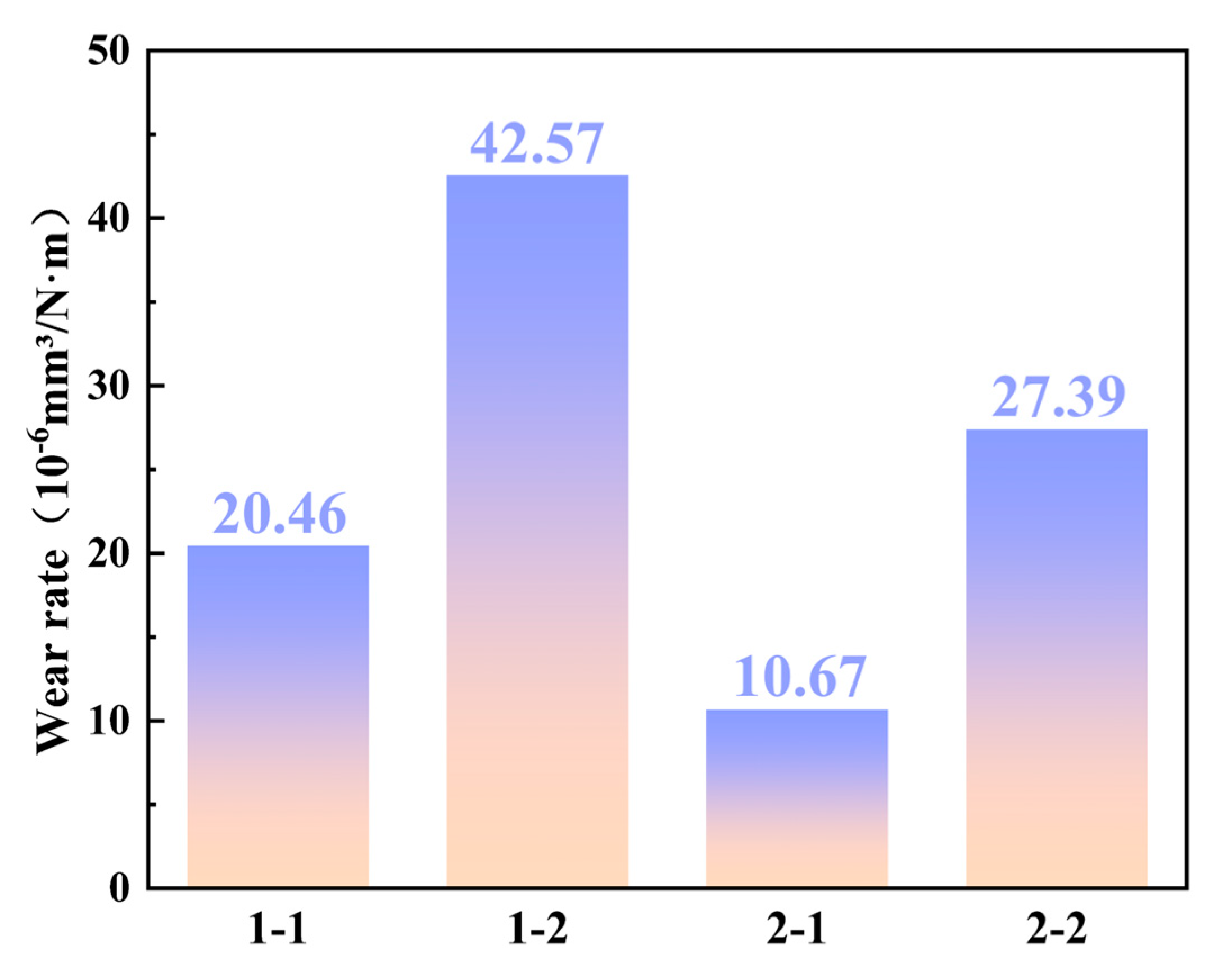

3.2. Friction Coefficient and Wear Rate of the Coating

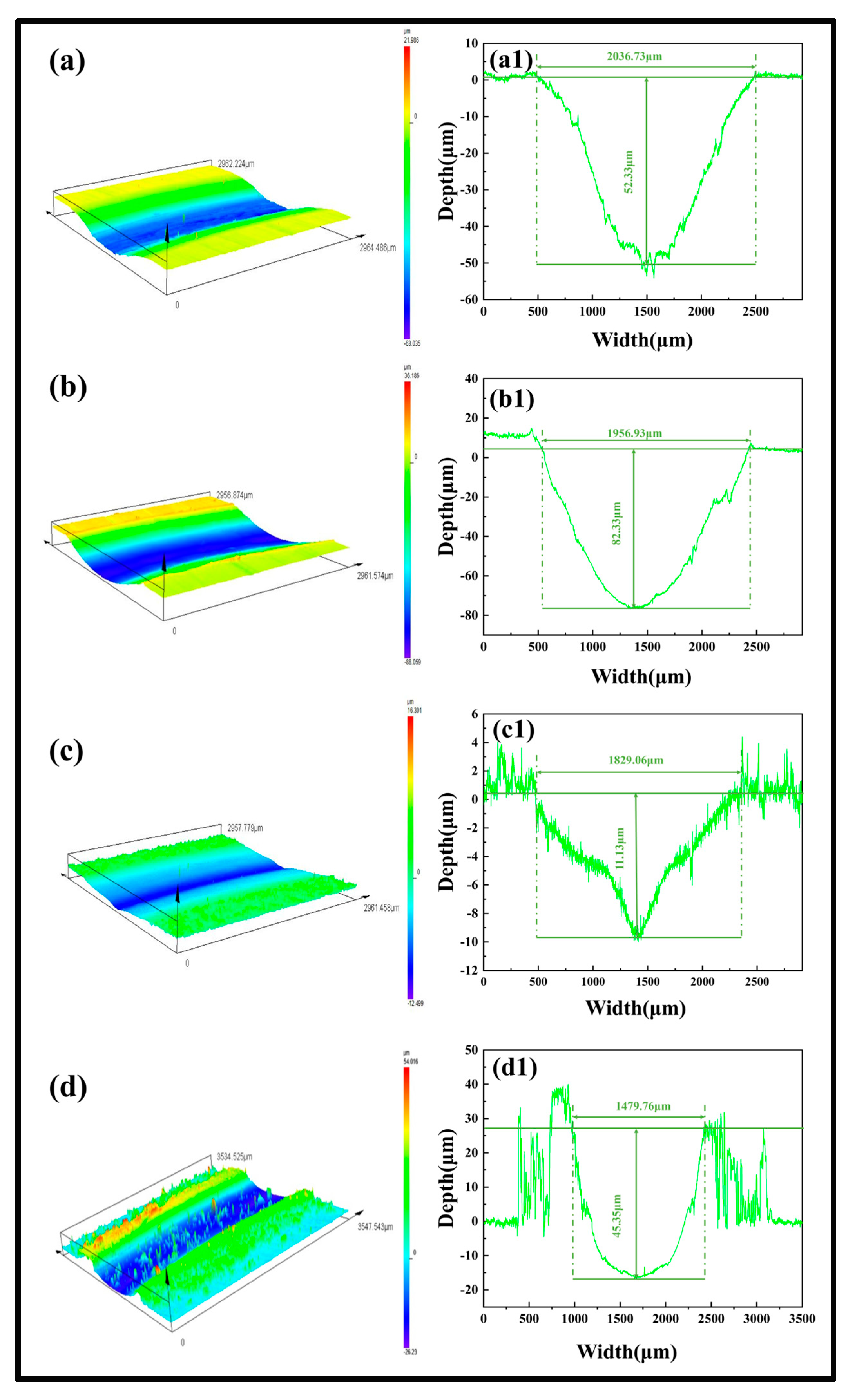

3.3. Morphology and Compositional Analysis of the Worn Surface

4. Conclusions

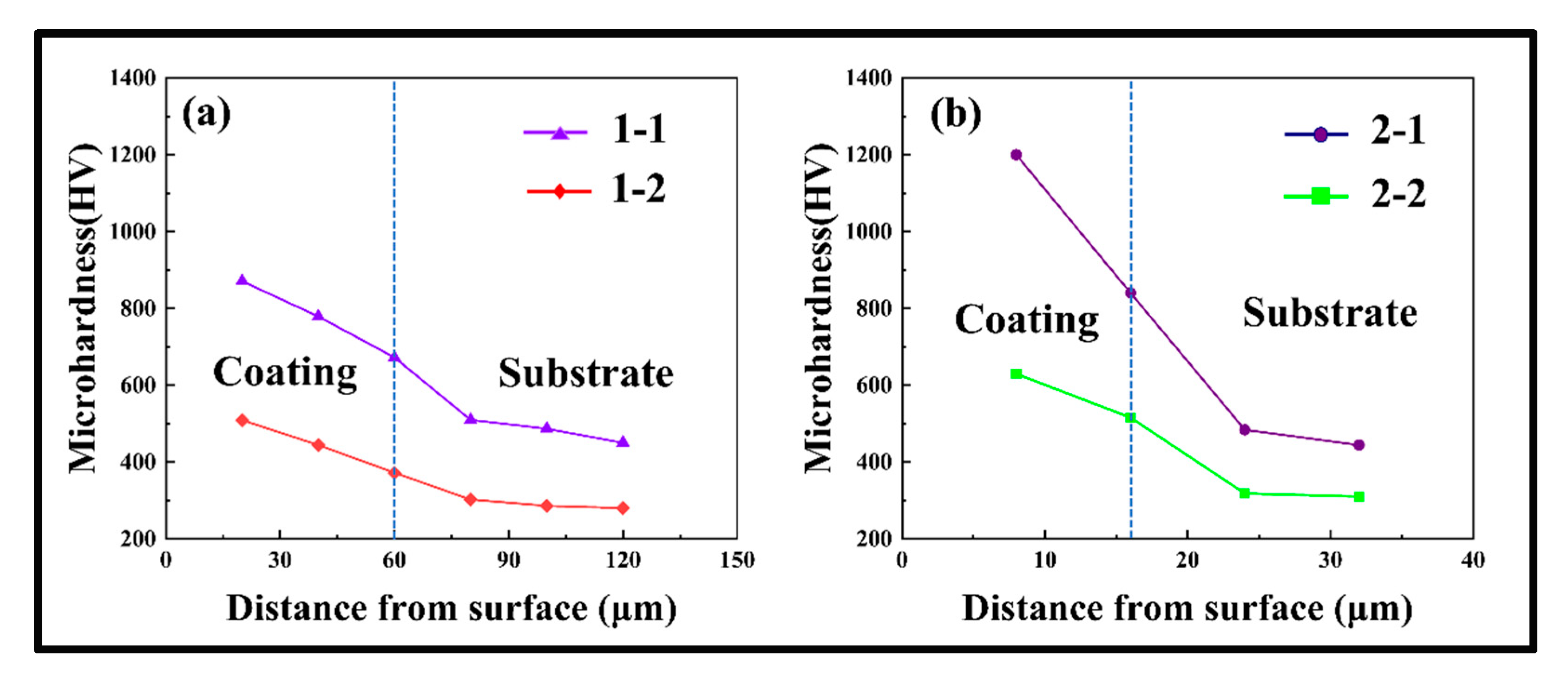

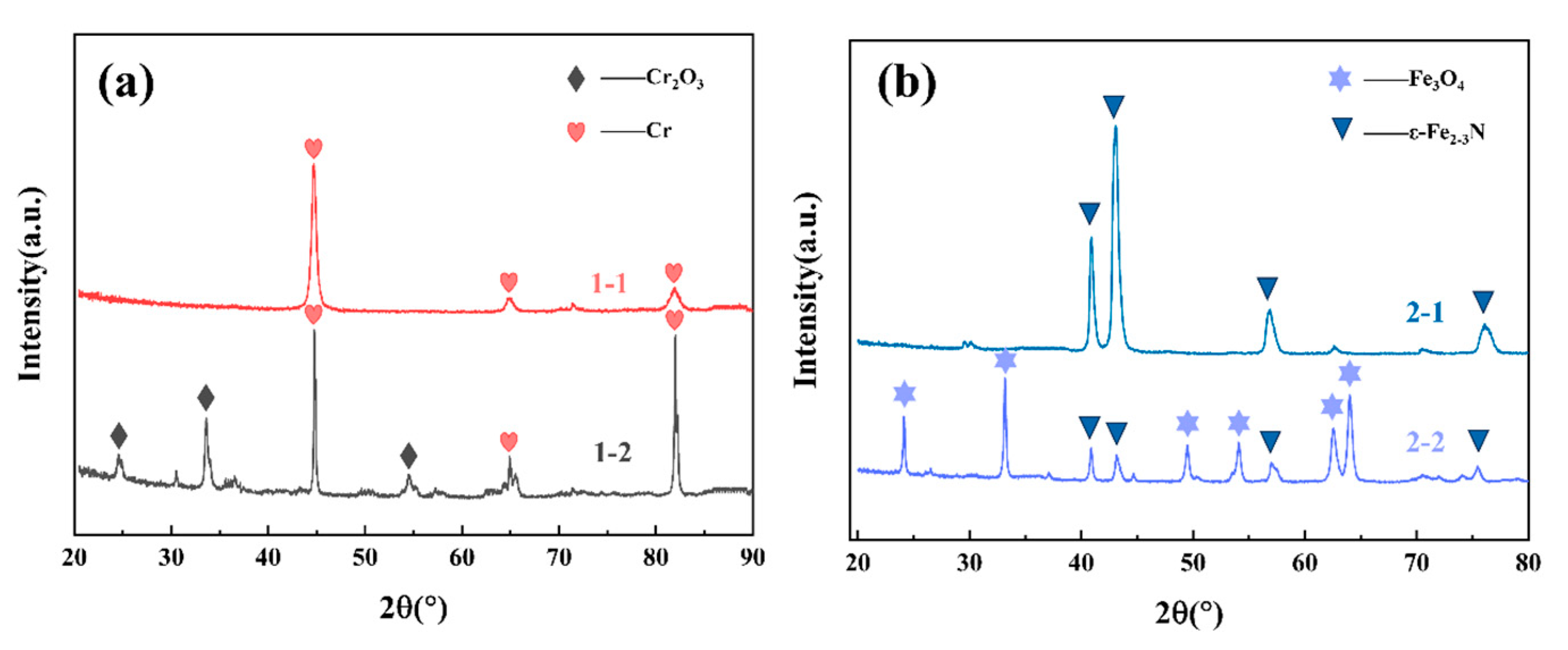

- The chromium plating layer and nitriding treatment on the surface of 2Cr3Mo3VA hot work die steel were effectively modified. The surface hardness and wear resistance of 2Cr3Mo3VA hot work die steel were improved due to the presence of ε phase (Fe2–3N) in the 2Cr3Mo3VA hot work die steel after nitriding surface treatment. As a result, the surface hardness of the nitrided layer is better than that of the chrome-plated layer.

- The surface hardness of the nitrided sample is higher than that of the chrome-plated sample after room-temperature wear or 700 °C high-temperature wear. At the same time, the wear rate of the nitrided layer at 700 °C is about 38% lower than that of the chromium plating layer, and the wear rate of the nitrided layer at room temperature is about 50% lower than that of the chromium plating layer, indicating that the nitrided layer has better wear resistance than the chromium plating layer.

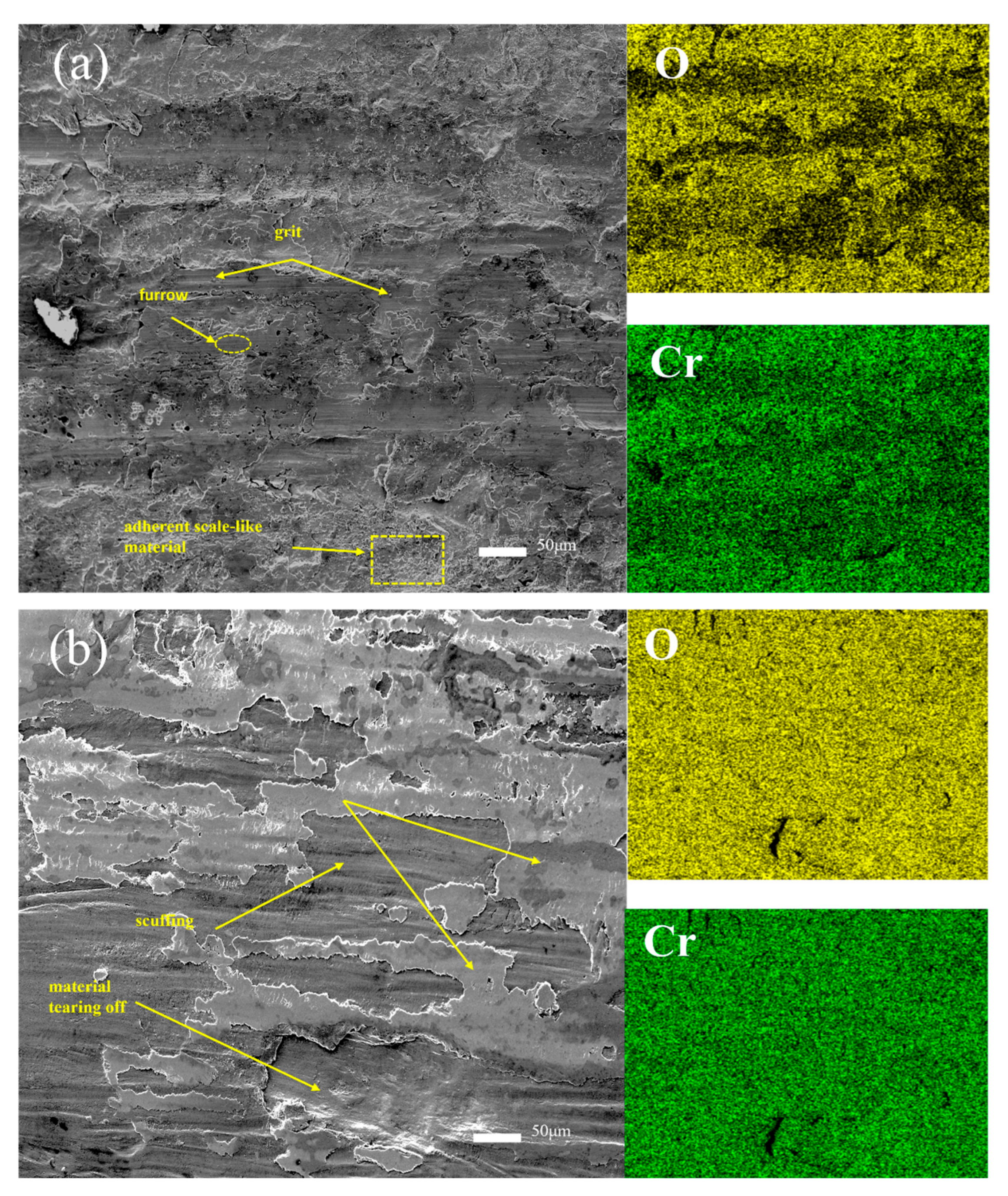

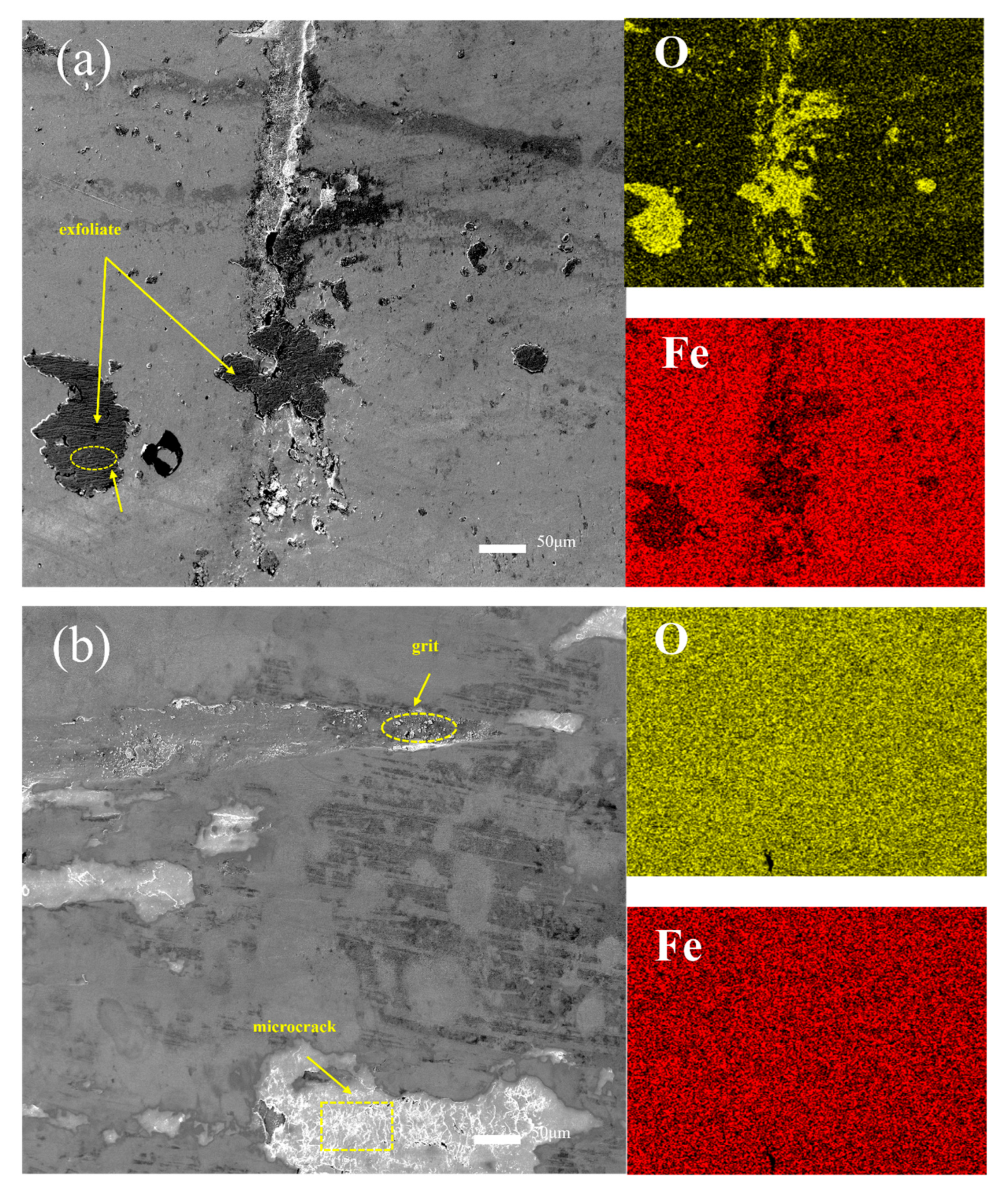

- The wear mechanism of chromium coating at room temperature is mainly abrasive wear accompanied by slight oxidation wear. The wear mechanism at 700 °C is the combined effect of oxidation wear, adhesive wear, and abrasive wear. The wear mechanism of the nitrided layer at room temperature is mainly adhesive wear, accompanied by slight oxidative wear. The wear mechanism at 700 °C is mainly oxidation wear and abrasive wear.

- The research results provide important theoretical and experimental basis for surface modification of hot work die steel, especially in improving die life and workpiece quality in high-temperature environment. Future work should focus on further research on the wear mechanism of the coating under more temperature parameters, and explore the high-temperature wear mechanism of more different surface modification technologies, so as to provide a more comprehensive solution for the surface modification technology of hot work die and aerospace parts, and promote technological progress and application expansion in related fields.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kashani, H.; Amadeh, A.; Ghasemi, H.M. Room and high temperature wear behaviors of nickel and cobalt base weld overlay coatings on hot forging dies. Wear 2007, 262, 800–806. [Google Scholar] [CrossRef]

- Kumar, S.; Maity, S.R.; Patnaik, L. Friction and tribological behavior of bare nitrided, TiAlN and AlCrN coated MDC-K hot work tool steel. Ceram. Int. 2020, 46, 17280–17294. [Google Scholar] [CrossRef]

- Mellouli, D.; Haddar, N.; Köster, A.; Ayedi, H.F. Hardness effect on thermal fatigue damage of hot-working tool steel. Eng. Fail. Anal. 2014, 45, 85–95. [Google Scholar] [CrossRef]

- Yang, C.; Jing, C.; Fu, T.; Lin, T.; Guo, W.; Liu, N. Effect of TiC addition on the microstructure and properties of laser cladding Ni60A coatings on H13 steel surface. Mater. Today Commun. 2024, 38, 107904. [Google Scholar] [CrossRef]

- Yang, X.; Li, C.; Zhang, Z.; Zhang, X.; Gu, J. Effect of cobalt-based coating microstructure on the thermal fatigue performance of AISI H13 hot work die steel. Appl. Surf. Sci. 2020, 521, 146360. [Google Scholar] [CrossRef]

- Lu, J.Z.; Cao, J.; Lu, H.F.; Zhang, L.Y.; Luo, K.Y. Wear properties and microstructural analyses of Fe-based coatings with various WC contents on H13 die steel by laser cladding. Surf. Coat. Technol. 2019, 369, 228–237. [Google Scholar] [CrossRef]

- Liu, B.; Wang, B.; Yang, X.; Zhao, X.; Qin, M.; Gu, J. Thermal fatigue evaluation of AISI H13 steels surface modified by gas nitriding with pre-and post-shot peening. Appl. Surf. Sci. 2019, 483, 45–51. [Google Scholar] [CrossRef]

- Beake, B.; Ning, L.; Gey, C.; Veldhuis, S.; Kornberg, A.; Weaver, A.; Khanna, M.; Fox-Rabinovich, G. Wear performance of different PVD coatings during hard wet end milling of H13 tool steel. Surf. Coat. Technol. 2015, 279, 118–125. [Google Scholar] [CrossRef]

- Xue, S.; Yang, T.; Guo, R.; Deng, A.; Liu, X.; Zheng, L. Crack analysis of Cr-Mo-V-Si medium-carbon alloy steel in casting die. Eng. Fail. Anal. 2021, 120, 105083. [Google Scholar] [CrossRef]

- Klobčar, D.; Tušek, J.; Taljat, B. Thermal fatigue of materials for die-casting tooling. Mater. Sci. Eng. A 2008, 472, 198–207. [Google Scholar] [CrossRef]

- Gu, Y.; Xia, K.; Wu, D.; Mou, J.; Zheng, S. Technical Characteristics and Wear-Resistant Mechanism of Nano Coatings: A Review. Coatings 2020, 10, 233. [Google Scholar] [CrossRef]

- Qian, H.; Chen, S.; Wang, T.; Cheng, G.; Chen, X.; Xu, Z.; Zeng, Q.; Liu, Y.; Yan, D. Silicon nitride modified enamel coatings enable high thermal shock and corrosion resistances for steel protection. Surf. Coat. Technol. 2021, 421, 127474. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H. Development of offshore wind power and foundation technology for offshore wind turbines in China. Ocean Eng. 2022, 266, 113256. [Google Scholar] [CrossRef]

- Chen, H.; Wang, W.; Le, K.; Liu, Y.; Gao, X.; Luo, Y.; Zhao, X.; Liu, X.; Xu, S.; Liu, W. Effects of substrate roughness on the tribological properties of duplex plasma nitrided and MoS2 coated Ti6Al4V alloy. Tribol. Int. 2024, 191, 109123. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Yang, Z.; He, L.; Zeng, G.; Zhang, W.; Long, J.; Chang, H. Microstructure, high-temperature corrosion resistance and oxidation properties of (TiVZrCrAl)N high entropy nitride coatings with different N2/Ar ratios. Surf. Coat. Technol. 2024, 476, 130226. [Google Scholar] [CrossRef]

- Mirhosseini, S.S.; Mahboubi, F.; Azadfalah, M. Effect of different plasma nitriding durations on the tribological characteristics of nickel-boron-nanodiamond electroless nanocomposite coatings. Surf. Coat. Technol. 2024, 476, 130181. [Google Scholar] [CrossRef]

- He, Z.; Wei, W.; Hu, J.; Gu, J. Aluminum-Modified Plasma Nitriding with High Efficiency and Enhanced Performance. Coatings 2024, 14, 1373. [Google Scholar] [CrossRef]

- Lausmann, G.A. Electrolytically deposited hardchrome. Surf. Coat. Technol. 1996, 86, 814–820. [Google Scholar] [CrossRef]

- Pan, P.; Gao, J.; Si, C.; Yao, Q.; Guo, Z.; Zhang, Y. Tribological properties of TIN coating on cotton picker spindle. Coatings 2023, 13, 959. [Google Scholar] [CrossRef]

- Sun, Y.; Liang, Y.; Zhao, O. Local—Flexural interactive buckling behaviour and resistances of high-chromium stainless steel slender welded I-section columns. Eng. Struct. 2020, 220, 111022. [Google Scholar] [CrossRef]

- Skripnyak, N.V.; Emelyanova, E.S.; Skripnyak, V.A.; Skripnyak, E.G. Damage of high-chromium steels under deformation in a wide temperature range. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017; p. 1909. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Wu, H. Effects of chromium on the microstructure and hot ductility of Nb-microalloyed steel. Int. J. Miner. Metall. Mater. 2021, 28, 1011–1021. [Google Scholar] [CrossRef]

- König, T.; Kimpel, T.; Kürten, D.; Kailer, A.; Dienwiebel, M. Influence of atmospheres on the friction and wear of cast iron against chromium plated steel at high temperatures. Wear 2023, 522, 204695. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, X.; Shi, X.; Yuan, Y.; Gao, J.; Zhang, Y. Failure mechanism analysis of electroplated chromium coating in repeated scratch tests under subcritical loads. Wear 2025, 564, 205708. [Google Scholar] [CrossRef]

- Beake, B.D.; Ogwu, A.A.; Wagner, T. Influence of experimental factors and film thickness on the measured critical load in the nanoscratch test. Mater. Sci. Eng. A 2006, 423, 70–73. [Google Scholar] [CrossRef]

- Fu, H.T.; Zhang, J.; Huang, J.F.; Lian, Y.; Zhang, C.; Gao, W. Comparison of nitrided hot work tool steel and chromium coated 30SiMn2MoVA. China Surf. Eng. 2015, 28, 1–6. [Google Scholar] [CrossRef]

- Kumar, A.; Keerti, S.; Jain, J.; Sinha, S.; Tekumalla, S.; Gupta, M. Investigations of Wear Response of Pure Mg and Mg-0.4 Ce-Y2O3/ZnO Nanocomposites Using a Single and Repeated Scratch Tests. Tribol. Trans. 2018, 61, 951–959. [Google Scholar] [CrossRef]

- Zhen-Yu, Z.; Zhi-Guo, J.; Qiu-Yang, Z.; Yu, L.; Zhi-Peng, Y.; Cong, D.; Zhong-Yu, P. Research on the construction of gradient nanostructure and anti-tribocorrosion behavior of aluminum alloy surface. Tribol. Int. 2024, 194, 109448. [Google Scholar] [CrossRef]

- King, P.C.; Reynoldson, R.W.; Brownrigg, A.; Long, J.M. Cr (N, C) diffusion coating formation on pre-nitrocarburised H13 tool steel. Surf. Coat. Technol. 2004, 179, 18–26. [Google Scholar] [CrossRef]

- Feng, L.; Hu, J.; Yan, S.; He, Z.; Shi, J.; Li, J. Effect of high-speed steel surface nitriding treatment on adhesion and wear resistance properties of nitrogen-doped diamond-like carbon coatings. Diamond Relat. Mater. 2023, 136, 110006. [Google Scholar] [CrossRef]

- Tima, R.; Mahboubi, F. Ability of plasma nitriding to improve tribological behavior of medium and high boron electroless nickel coatings. Tribol. Int. 2021, 156, 106822. [Google Scholar] [CrossRef]

- Jiang, W.; Wang, S.; Deng, Y.; Guo, X. Microstructure stability and high temperature wear behavior of an austenite aging steel coating by laser cladding. Mater. Charact. 2022, 184, 111700. [Google Scholar] [CrossRef]

- Derelizade, K.; Rincon, A.; Venturi, F.; Wellman, R.; Kholobystov, A.; Hussain, T. High temperature (900 °C) sliding wear of CrNiAlCY coatings deposited by high velocity oxy fuel thermal spray. Surf. Coat. Technol. 2022, 432, 128063. [Google Scholar] [CrossRef]

- Xing, Q.; Feltrin, A.C.; Akhtar, F. Processing, microstructure and high temperature dry sliding wear of a Cr-Fe-Hf-Mn-Ti-Ta-V high-entropy alloybased composite. Mater. Today Commun. 2021, 28, 102657. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Cr | Mo | V | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 2Cr3Mo3VA | 0.22 | 0.50 | 0.25 | 2.79 | 2.80 | 0.15 | <0.015 | <0.015 | Bal. |

| Sample Number | Surface Treatment | Wear Test Temperature |

|---|---|---|

| 1-1 | Chromium plating | Room |

| 1-2 | Chromium plating | 700 °C |

| 2-1 | Nitride | Room |

| 2-2 | Nitride | 700 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Zhang, J.; Wei, S.; Chen, L.; Zhang, W.; Sun, Z.; Chen, C.; Mao, F.; Wang, X.; Dou, C.; et al. Investigation of the Friction and Wear Behavior of Cr-Mo-V Steel with Different Surface Treatment Processes. Lubricants 2025, 13, 313. https://doi.org/10.3390/lubricants13070313

Zhang W, Zhang J, Wei S, Chen L, Zhang W, Sun Z, Chen C, Mao F, Wang X, Dou C, et al. Investigation of the Friction and Wear Behavior of Cr-Mo-V Steel with Different Surface Treatment Processes. Lubricants. 2025; 13(7):313. https://doi.org/10.3390/lubricants13070313

Chicago/Turabian StyleZhang, Wei, Jian Zhang, Shizhong Wei, Liuliang Chen, Wei Zhang, Zhenhuan Sun, Chong Chen, Feng Mao, Xiaodong Wang, Caihong Dou, and et al. 2025. "Investigation of the Friction and Wear Behavior of Cr-Mo-V Steel with Different Surface Treatment Processes" Lubricants 13, no. 7: 313. https://doi.org/10.3390/lubricants13070313

APA StyleZhang, W., Zhang, J., Wei, S., Chen, L., Zhang, W., Sun, Z., Chen, C., Mao, F., Wang, X., Dou, C., & Zhang, C. (2025). Investigation of the Friction and Wear Behavior of Cr-Mo-V Steel with Different Surface Treatment Processes. Lubricants, 13(7), 313. https://doi.org/10.3390/lubricants13070313