Optimization of Laser Surface Texturing Parameters for Improving Friction and Wear Resistance of GCr15 Bearing Steel Sliding Pairs

Abstract

1. Introduction

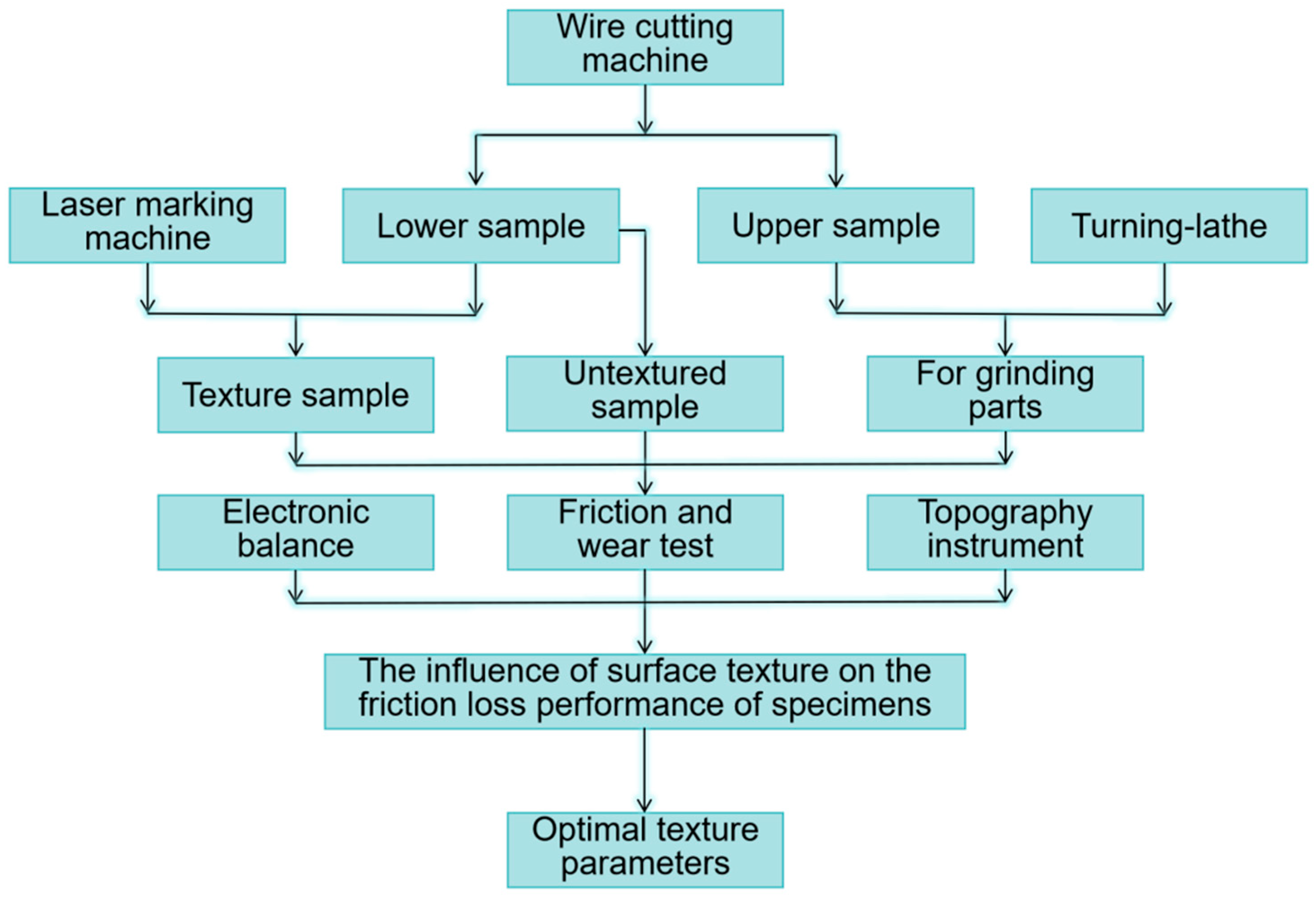

2. Materials and Methods

2.1. Friction and Wear Test Procedure

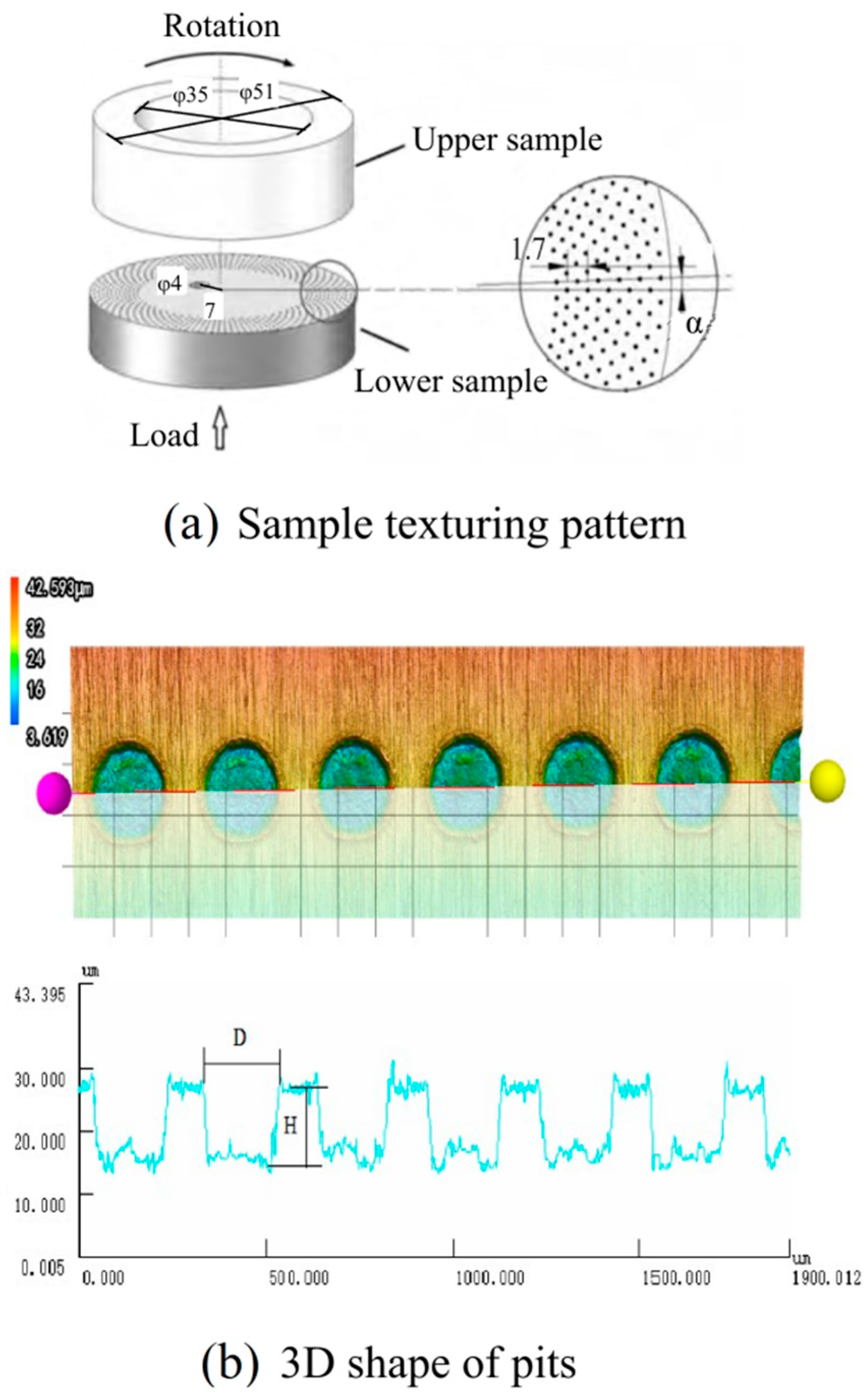

2.2. Preparation of Upper and Lower Samples

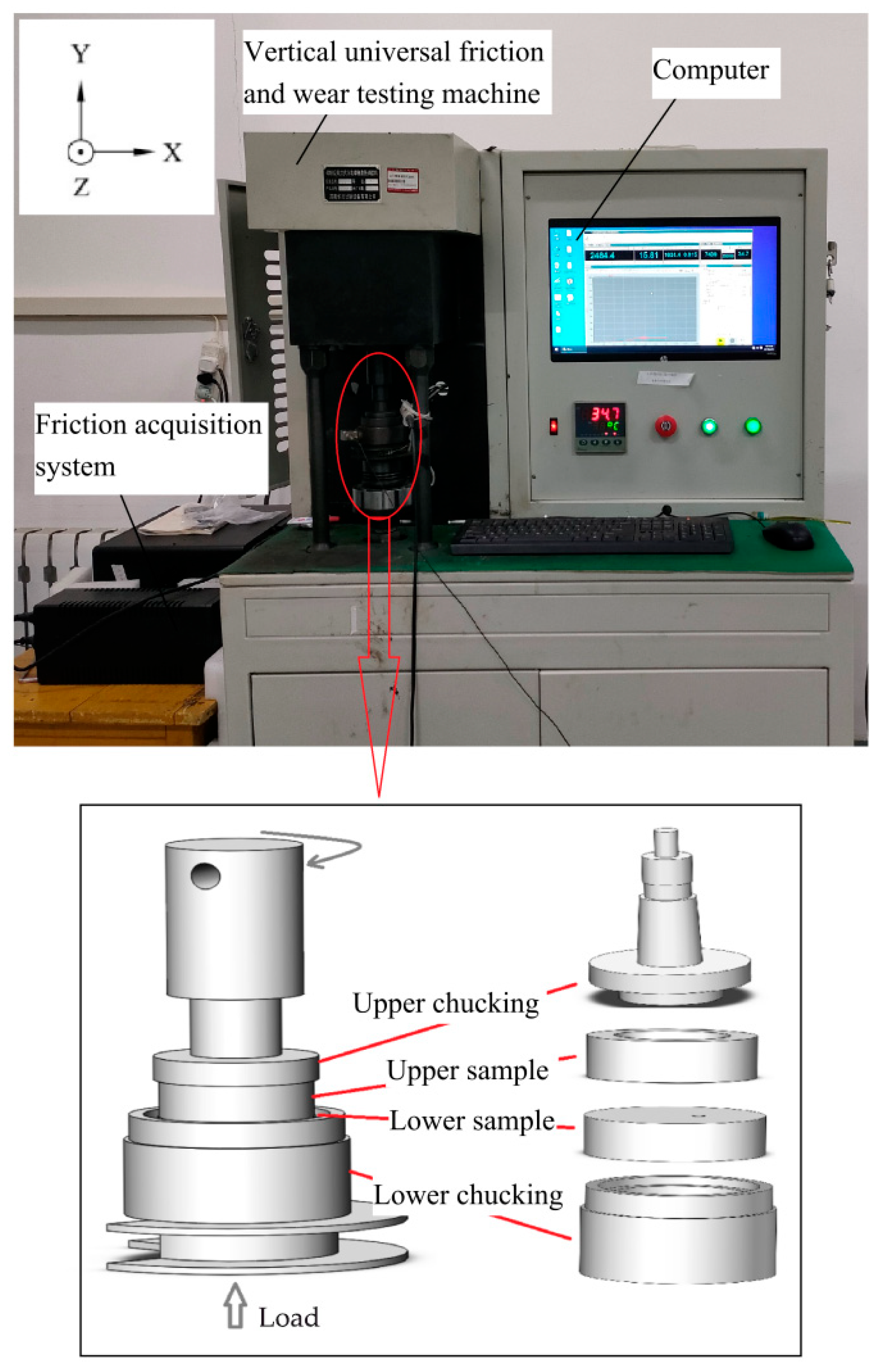

2.3. Friction Wear Test

3. Results and Analysis

3.1. Determination of Laser Pit Texturing Parameters

3.1.1. Effect of Processing Speed on Texture Parameters

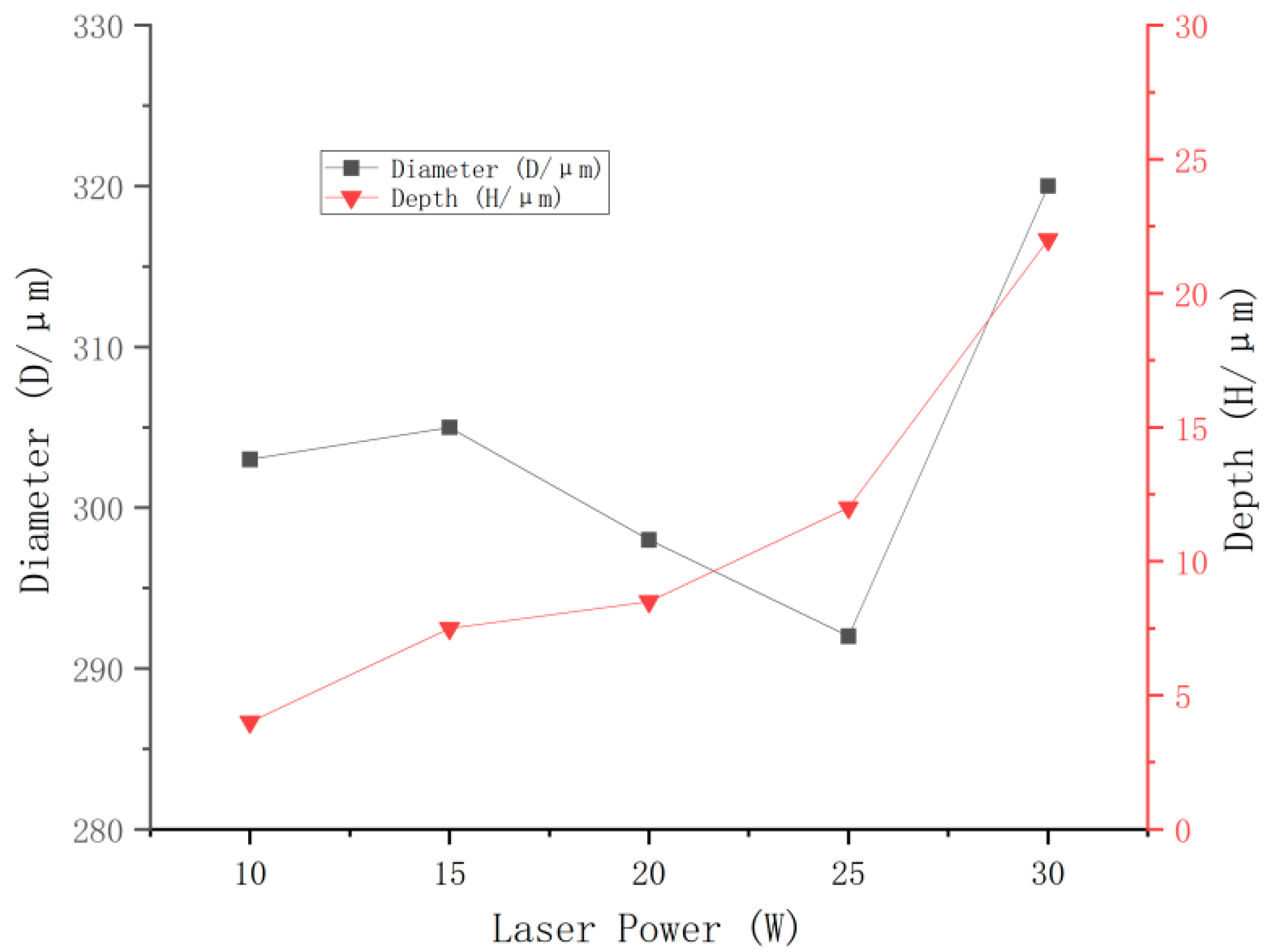

3.1.2. Effect of Power on Texture Parameters

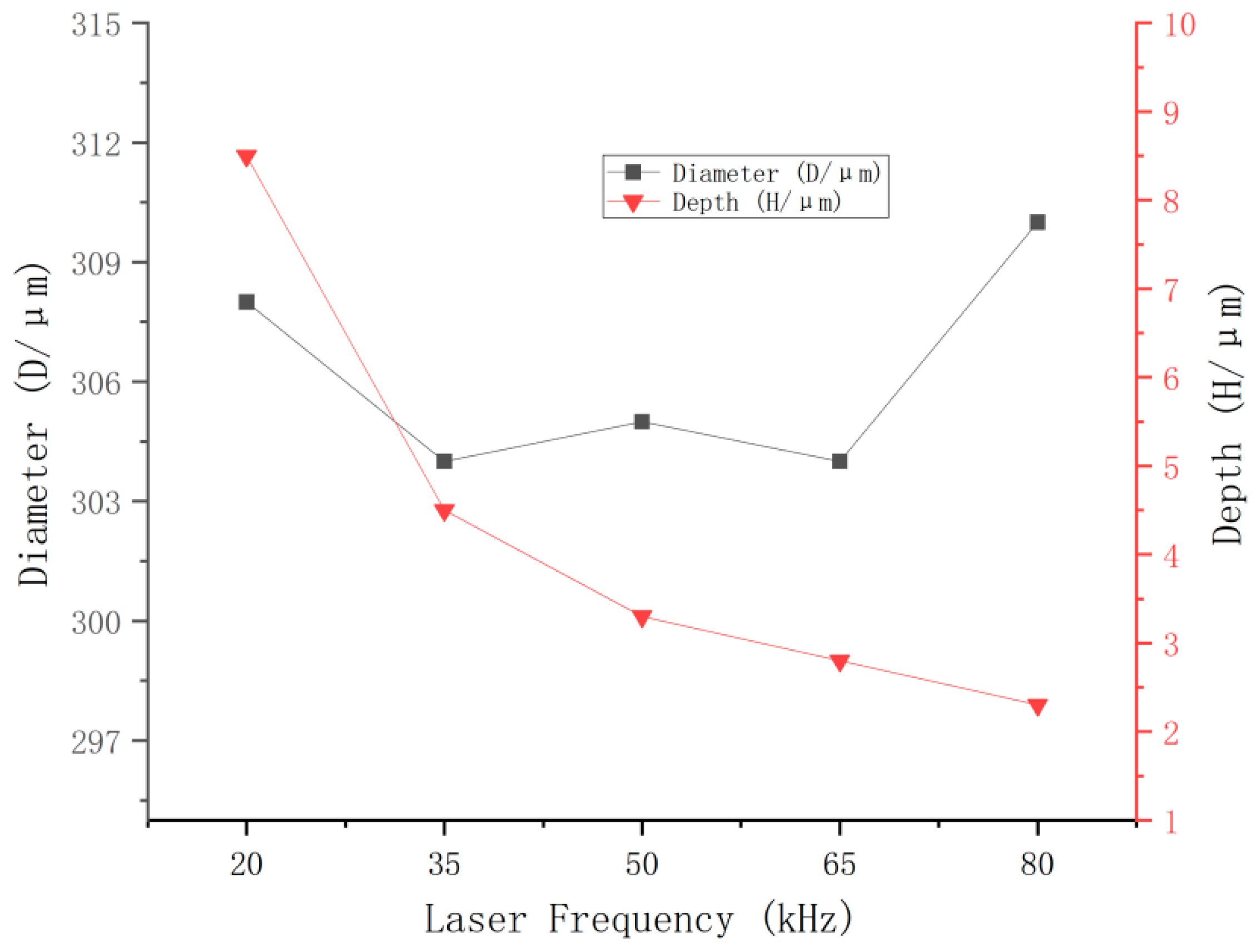

3.1.3. Effect of Frequency on Texture Parameters

3.2. Effect of Depth-to-Diameter Ratio on the Friction and Wear Performance of the Sample Surface

3.2.1. Effect of Depth-to-Diameter Ratio on the Friction Coefficient of the Sample Surface

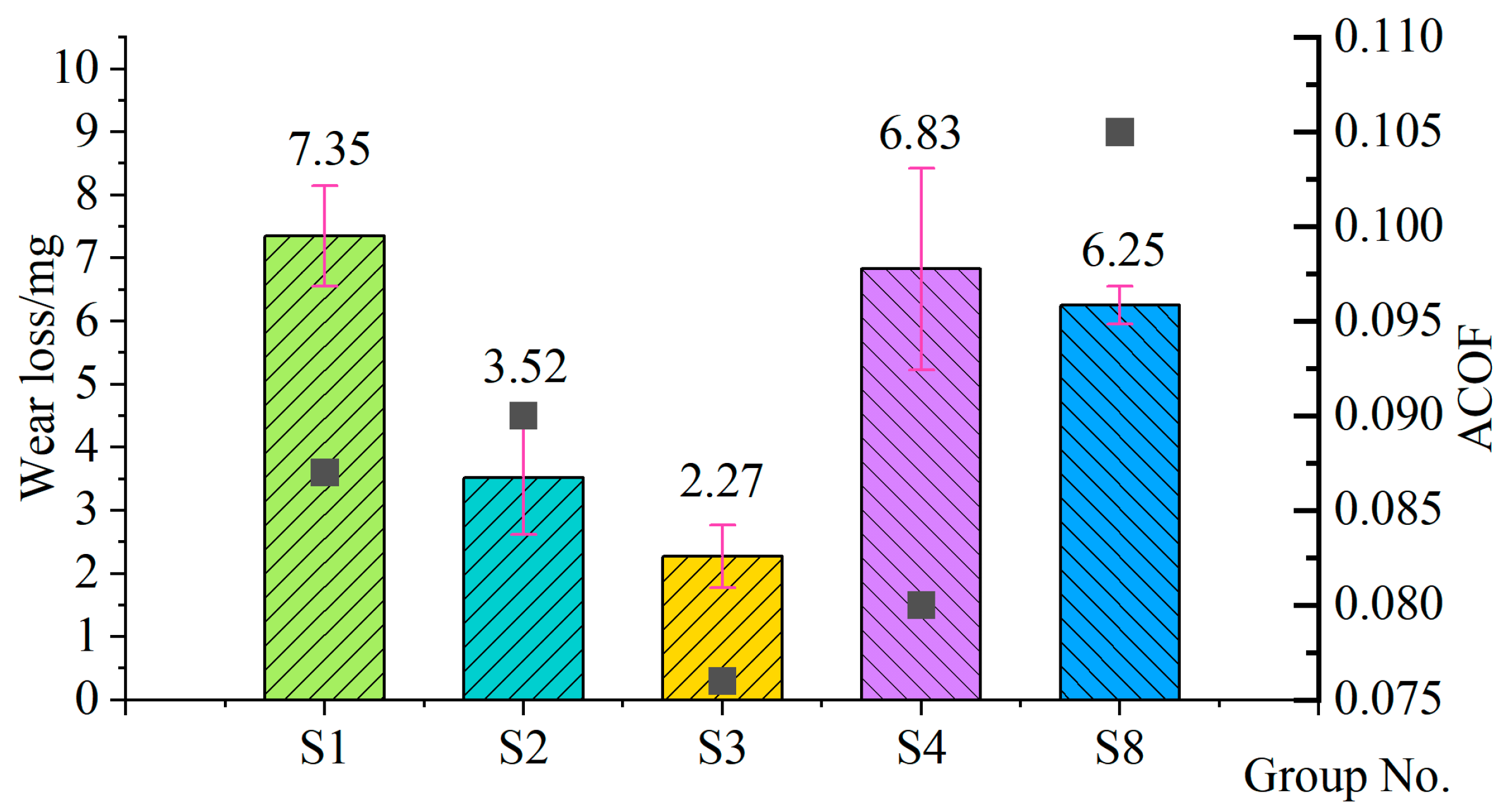

3.2.2. Effect of Depth-to-Diameter Ratio on the Wear Loss of the Specimens

3.2.3. Morphological Analysis of Surface Wear of Specimens with Different Depth-to-Diameter Ratios

3.3. Effect of Area Ratio on the Surface Friction and Wear Performance of Specimens

3.3.1. Effect of Area Ratio on the Friction Coefficient of Specimens’ Surfaces

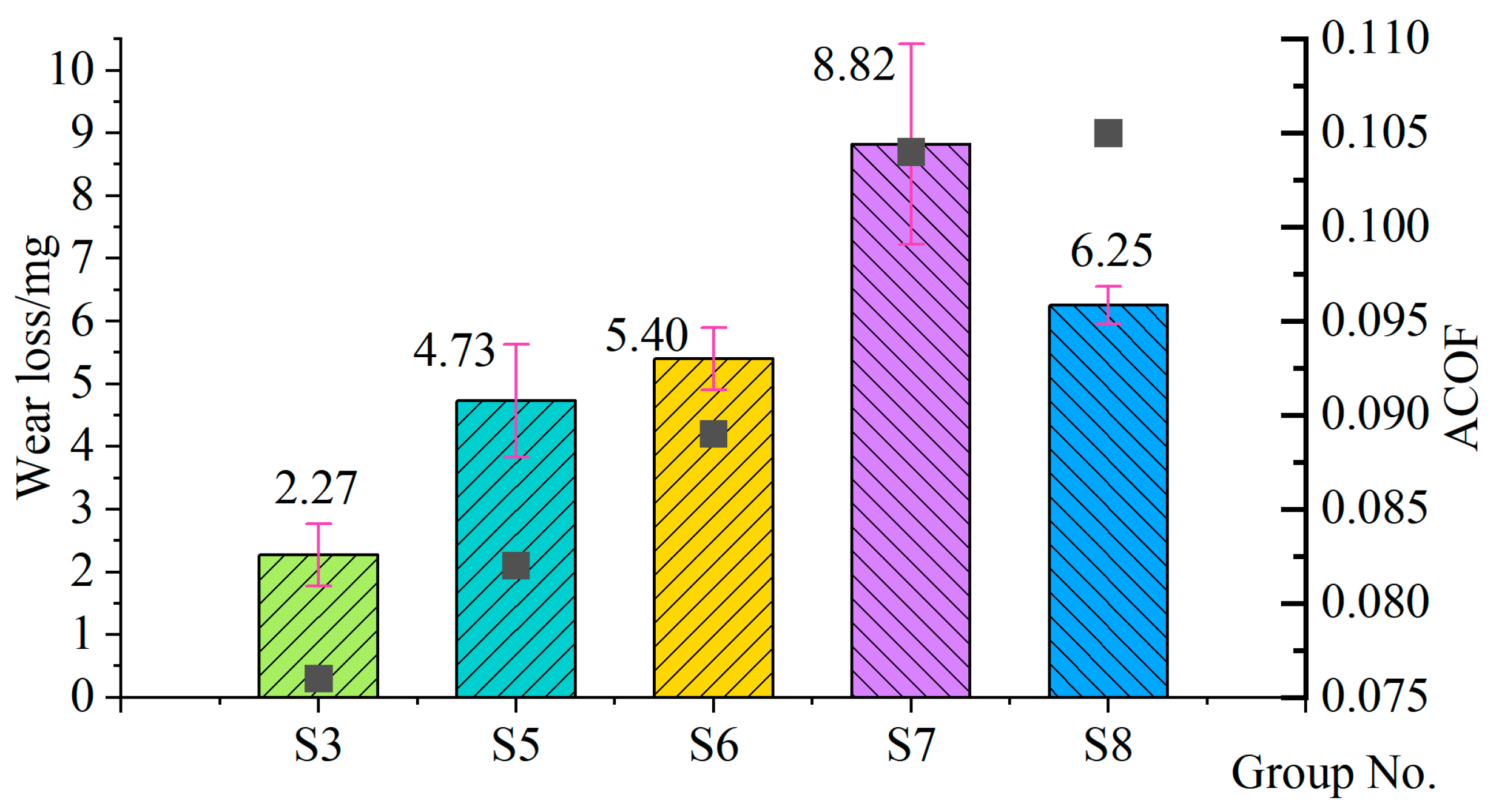

3.3.2. Effect of Area Ratio on the Wear Loss of Specimens

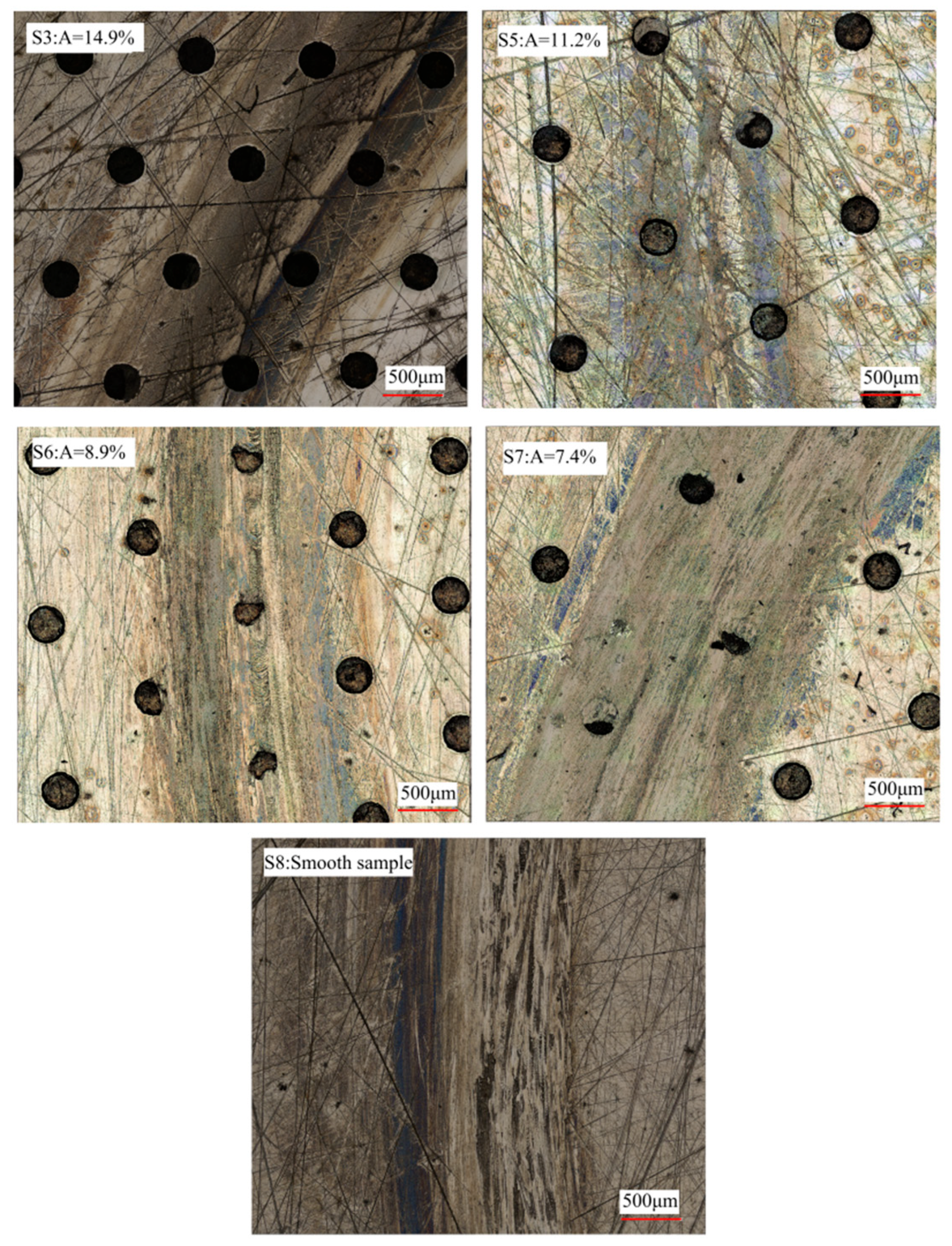

3.3.3. Surface Wear Morphology Analysis of Specimens with Different Area Ratios

4. Conclusions

- (1)

- When creating surface pit textures, the processing speed, laser power, and laser frequency significantly affect the integrity of the pit texture. When the laser parameters are set to a processing speed of 200 mm/s, laser power of 10 W, and laser frequency of 80 kHz, the pit texture integrity is high, with clear edges and a smooth bottom, resulting in good pit texture morphology.

- (2)

- Surface pit textures can effectively collect and store wear debris. Compared to smooth specimens, the centrifugal force during high-speed rotation significantly reduces the amount of abrasive particles remaining on the sliding contact surface. As the test progresses, the lubrication oil on the sliding friction pair is gradually depleted, and the oil that is stored in the pit is expelled, extending the lubrication of the friction pair. The pit texture can store excess lubrication oil and provide secondary lubrication to the system when the friction pair is not lubricated.

- (3)

- The depth-to-diameter ratio and area ratio of the pit texture on the contact surface significantly influence the friction and wear performance of GCr15 bearing steel sliding friction pairs. When the pit texture has a depth-to-diameter ratio β = 0.083 and an area ratio A = 14.9%, the friction coefficient and wear loss are 0.076 and 2.27 mg, respectively, which are reduced by 27.6% and 63.7% compared to the smooth specimen values of 0.105 and 6.25 mg. The specimen with this surface pit texture exhibits the best friction- and wear-reducing effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, S.; Huang, P.; Tian, Y.; Ma, L. Tribological Principles, 5th ed.; Tsinghua University Press: Beijing, China, 2018. [Google Scholar]

- El-Thalji, I.; Jantunen, E. Dynamic modelling of wear evolution in rolling bearings. Tribol. Int. 2015, 84, 90–99. [Google Scholar] [CrossRef]

- Maldonado-Cortés, D.; Peña-Parás, L.; Martínez, N.R.; Leal, M.P.; Correa, D.I.Q. Tribological characterization of different geometries generated with laser surface texturing for tooling applications. Wear 2021, 477, 203856. [Google Scholar] [CrossRef]

- Senatore, A.; Risitano, G.; Scappaticci, L.; D’andrea, D. Investigation of the Tribological Properties of Different Textured Lead Bronze Coatings Under Severe Load Conditions. Lubricants 2021, 9, 34. [Google Scholar] [CrossRef]

- Li, D.; Yang, X.; Wang, S.; Liu, W.; Wang, Z.; Xia, G. Research Status and Progress of Micro/Nano Texture on Workpiece Surface. J. Mech. Strength 2020, 42, 1348–1355. [Google Scholar] [CrossRef]

- Zhong, B.; Xing, Z.; Wang, H.; Lv, X.; Huang, Y.; Guo, W.; Zhang, Z. Research progress on Tribological properties of textured surfaces. Mater. Rev. 2020, 34, 23171–23178. [Google Scholar] [CrossRef]

- Chang, Q.; Qi, Y.; Wang, B.; Qi, J. Influence of laser surface texture on dry Friction properties of 45 steel. J. Mech. Eng. 2017, 53, 148–154. [Google Scholar] [CrossRef]

- Liu, S.; Sai, Q.; Wang, S.; Williams, J. Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact. Lubricants 2022, 10, 10. [Google Scholar] [CrossRef]

- Sun, T.; Zheng, S.; Yao, J.; Qiu, J.; Zhao, Y. The influence of laser texturing on the surface of GCr15 steel on its tribological properties. Electroplat. Finish. 2020, 44, 70–80. [Google Scholar] [CrossRef]

- Opia, A.C.; Abdul Hamid, M.K.; Daud, Z.H.; Syahrullail, S.; Johnson, C.N.; Izmi, M.I.; Rahim, A.B. Effect of Surface Texturing on Organic Carbon Nanotubes Tribological Performance on Sliding Contact Lubrication. In Lecture Notes in Mechanical Engineering, Proceedings of the 3rd Malaysian International Tribology Conference, Langkawi, Malaysia, 28–30 September 2022; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Chen, S.; Wang, W.; Cong, J.; Yuan, W.; Guo, Q.; Zhu, S.; Yu, J. Research on Friction Modification Method of GCr15 Surface Coating and Fabric Composite. Mod. Manuf. Eng. 2023, 5, 1–5. [Google Scholar] [CrossRef]

- Zhao, J. Research on Tribological Properties of Surface Texture of Sliding Bearing Friction Pairs. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2022. [Google Scholar] [CrossRef]

- Li, S. Test on Friction and Wear Performance of Laser Textured GCr15 Steel Lubricated with oil. Lab. Res. Explor. 2020, 39, 35–40. [Google Scholar]

- Guo, D.; Zhang, P.; Jiang, Y.; Song, C.; Tan, D.; Yu, D. Effects of surface texturing and laminar plasma jet surface hardening on the tribological behaviors of GCr15 bearing steel. Tribol. Int. 2022, 169, 107465. [Google Scholar] [CrossRef]

- Lai, F.; Cao, C.; Chen, H.; Lin, C.; Song, C.; Lei, K.; Lin, Y.; Wu, Z. Influence of micro-groove surface texture on the lubrication tribological properties of GCr15 bearing steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2025, 239, 1337–1354. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, W.; Guo, Q.; Wang, N.; Chi, B.; Yu, J. Effect of picosecond laser surface texturing under Babbitt coating mask on friction and wear properties of GCr15 bearing steel surface. Eng. Fail. Anal. 2024, 157, 107878. [Google Scholar] [CrossRef]

- Wu, J.; Deng, J.; Lu, Y.; Zhang, Z.; Meng, Y.; Wang, R.; Sun, Q. Effect of textures fabricated by ultrasonic surface rolling on dry friction and wear properties of GCr15 steel. J. Manuf. Process. 2022, 84, 798–814. [Google Scholar] [CrossRef]

- Opia, A.C.; Kadirgama, K.; Mamah, S.C.; Ghazali, M.F.; Harun, W.S.W.; Adeboye, O.J.; Agi, A.; Alibi, S. Electric Vehicles as a Promising Trend: A Review on Adaptation, Lubrication Challenges, and Future Work. Lubricants 2025, 13, 474. [Google Scholar] [CrossRef]

- Opia, A.C.; Abdollah, M.F.; Amiruddin, H.; Abdul Hamid, M.K.; Mohd Zawawi, F. Assessment on tribological responsiveness of different polymers on AISI 52100 steel using a sensitive reciprocating tribometer. Tribol.—Mater. Surf. Interfaces 2024, 18, 20–30. [Google Scholar] [CrossRef]

- Liu, D. Experimental Study on the Influence of Surface Texture Treatment on the Tribological Properties of Polymer-Metal Pairs. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2016. [Google Scholar]

- Bhardwaj, V.; Pandey, R.K.; Agarwal, V.K. Performance studies of textured race ball bearing. Ind. Lubr. Tribol. 2019, 71, 1116–1123. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Gachot, C.; Costa, H.L. Surface Texturing in Machine Elements—A Critical Discussion for Rolling and Sliding Contacts. Adv. Eng. Mater. 2019, 21, 1900194. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Long, R. Influence of Pits on the Tribological Properties and Friction-Induced Vibration Noise of Textured Tapered Roller Bearings. Tribol. Trans. 2023, 66, 399–412. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Cr | Cu | Ni | Mo | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.96 | 0.32 | 0.24 | 0.008 | 0.001 | 1.49 | 0.22 | 0.08 | 0.03 | 0.0024 | Bal. |

| Serial Number | Parameter | Parameter Value |

|---|---|---|

| 1 | Processing Speed (mm/s) | 50/100/150/200/250 |

| 2 | Laser Power (W) | 10/15/20/25/30 |

| 3 | Laser Frequency (kHz) | 20/35/50/65/80 |

| No. | Diameter (D/μm) | Depth (H/μm) | Area Ratio (A) | Angle (α) | Depth–Diameter Ratio (β) |

|---|---|---|---|---|---|

| S1 | 300 | 15 | 14.9% | 1.5° | 0.050 |

| S2 | 300 | 20 | 14.9% | 1.5° | 0.067 |

| S3 | 300 | 25 | 14.9% | 1.5° | 0.083 |

| S4 | 300 | 30 | 14.9% | 1.5° | 0.100 |

| S5 | 300 | 25 | 11.2% | 2.0° | 0.083 |

| S6 | 300 | 25 | 8.9% | 2.5° | 0.083 |

| S7 | 300 | 25 | 7.4% | 3.0° | 0.083 |

| S8 | - | - | 0.0 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, X.; Hou, F.; Long, R.; Liu, T.; Tang, K.; Zhao, X. Optimization of Laser Surface Texturing Parameters for Improving Friction and Wear Resistance of GCr15 Bearing Steel Sliding Pairs. Lubricants 2025, 13, 536. https://doi.org/10.3390/lubricants13120536

Wang Y, Wang X, Hou F, Long R, Liu T, Tang K, Zhao X. Optimization of Laser Surface Texturing Parameters for Improving Friction and Wear Resistance of GCr15 Bearing Steel Sliding Pairs. Lubricants. 2025; 13(12):536. https://doi.org/10.3390/lubricants13120536

Chicago/Turabian StyleWang, Yueyong, Xuhui Wang, Fushun Hou, Risheng Long, Tianjiao Liu, Kaihong Tang, and Xiumei Zhao. 2025. "Optimization of Laser Surface Texturing Parameters for Improving Friction and Wear Resistance of GCr15 Bearing Steel Sliding Pairs" Lubricants 13, no. 12: 536. https://doi.org/10.3390/lubricants13120536

APA StyleWang, Y., Wang, X., Hou, F., Long, R., Liu, T., Tang, K., & Zhao, X. (2025). Optimization of Laser Surface Texturing Parameters for Improving Friction and Wear Resistance of GCr15 Bearing Steel Sliding Pairs. Lubricants, 13(12), 536. https://doi.org/10.3390/lubricants13120536