Tribocorrosive Aspects of Tungsten Carbide, Silicon Nitride, and Martensitic Steel under Fretting-like Conditions

Abstract

1. Introduction

1.1. Water-Based Lubrication

1.2. Hard-Phase Materials Selected for Water-Based Lubrication

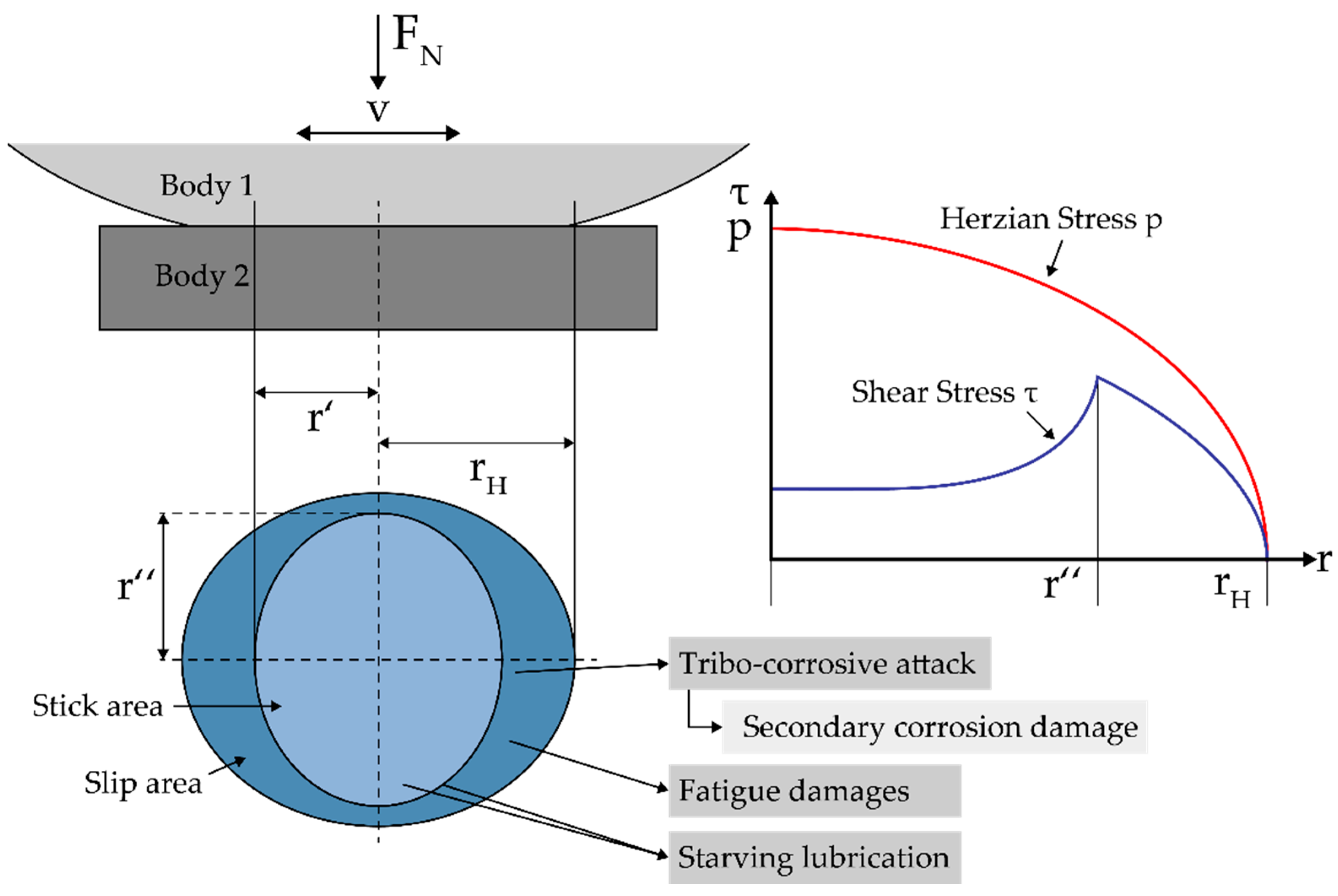

1.3. Fretting Conditions

- Surface oxidation processes driven by energy dissipation;

- (Mechanical or chemical) removal of the protective or passive layer.

1.4. Tribocorrosion of Water-Lubricated Hard-Phase Materials

2. Materials and Methods

2.1. Hard-Phase Materials and Electrolytes

2.2. Tribometer Configuration

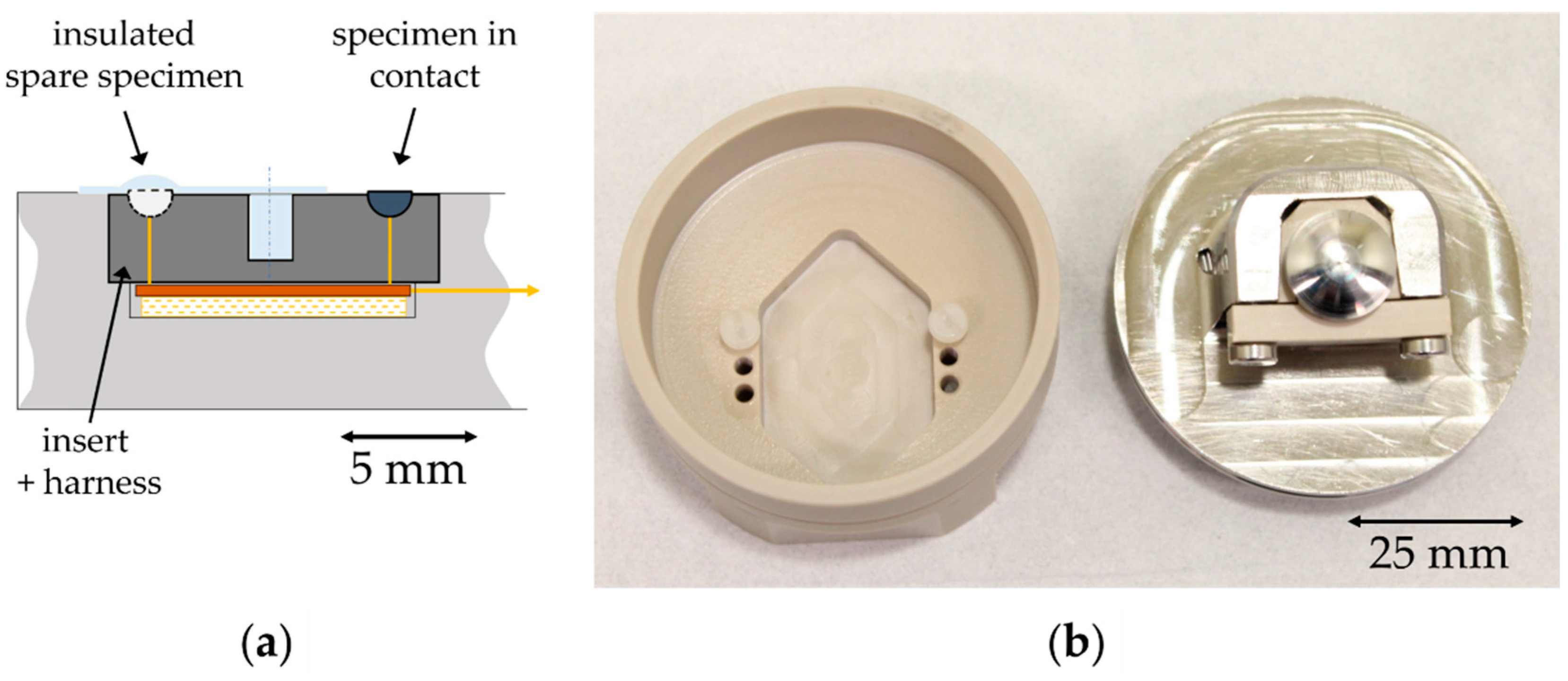

2.3. Electrochemical Measurements

2.3.1. Specimen Preparation

2.3.2. Electrochemical Experimental Setup

2.4. Surface Analysis

3. Results and Discussion: Triboexperiments

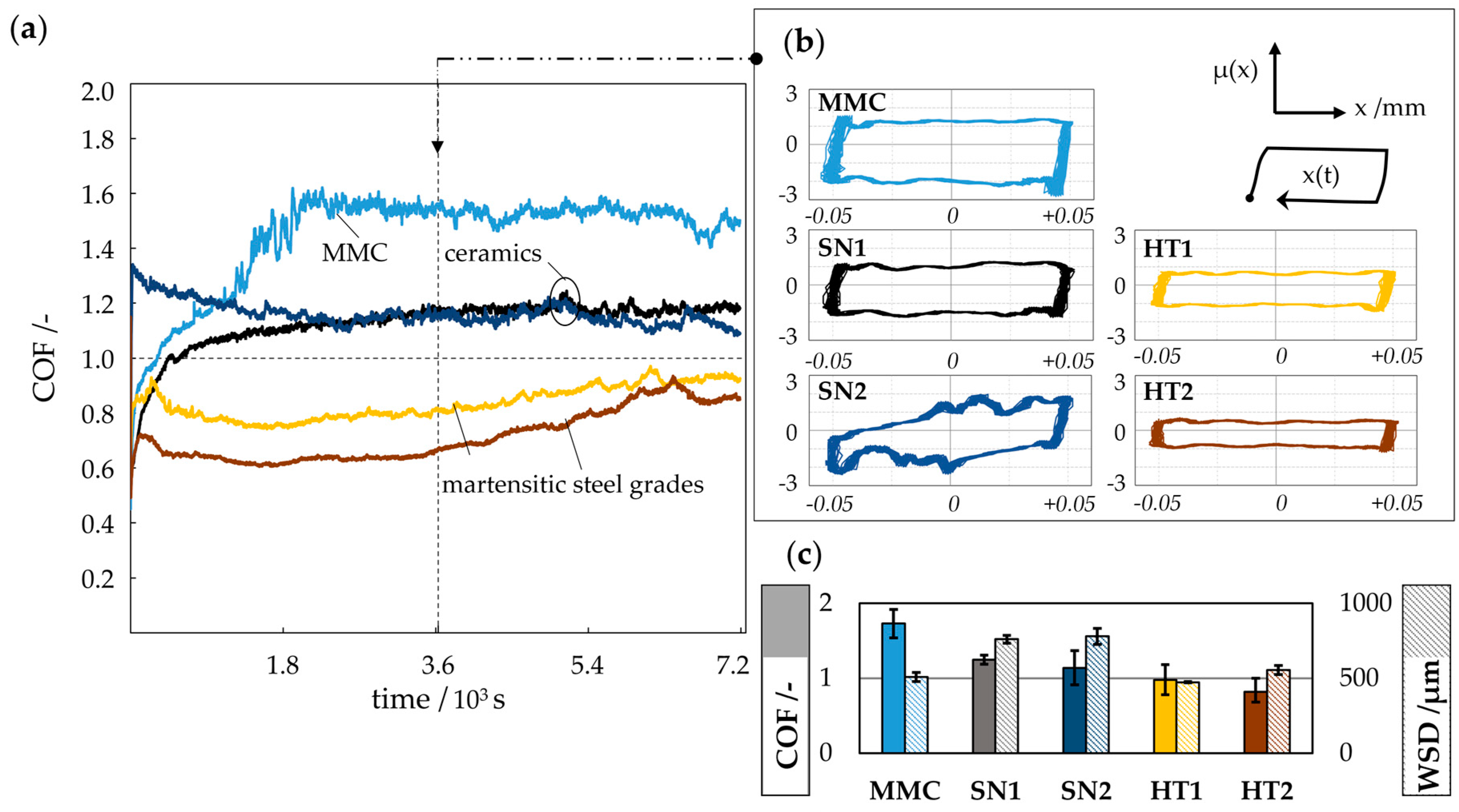

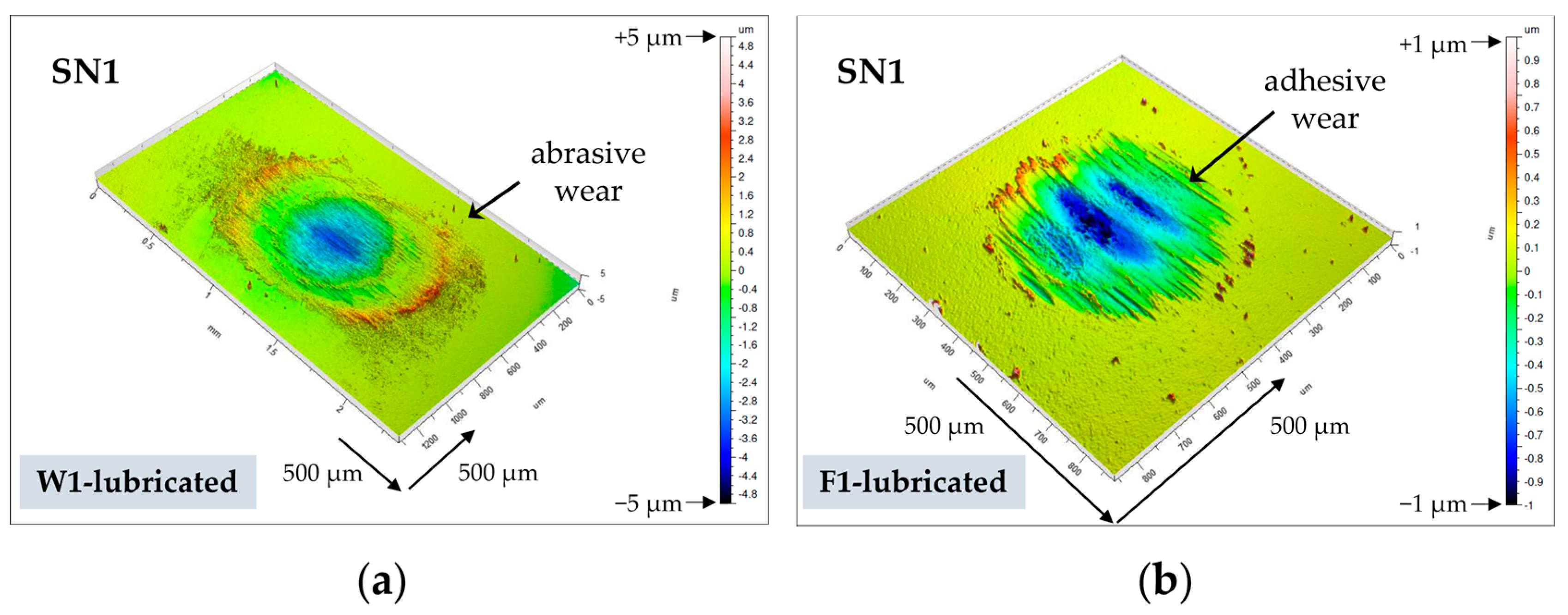

3.1. Experiments in Electrolyte W1

- High friction, high wear: SN1, SN2;

- High friction, moderate wear: MMC;

- Moderate friction, moderate wear: HT1, HT2.

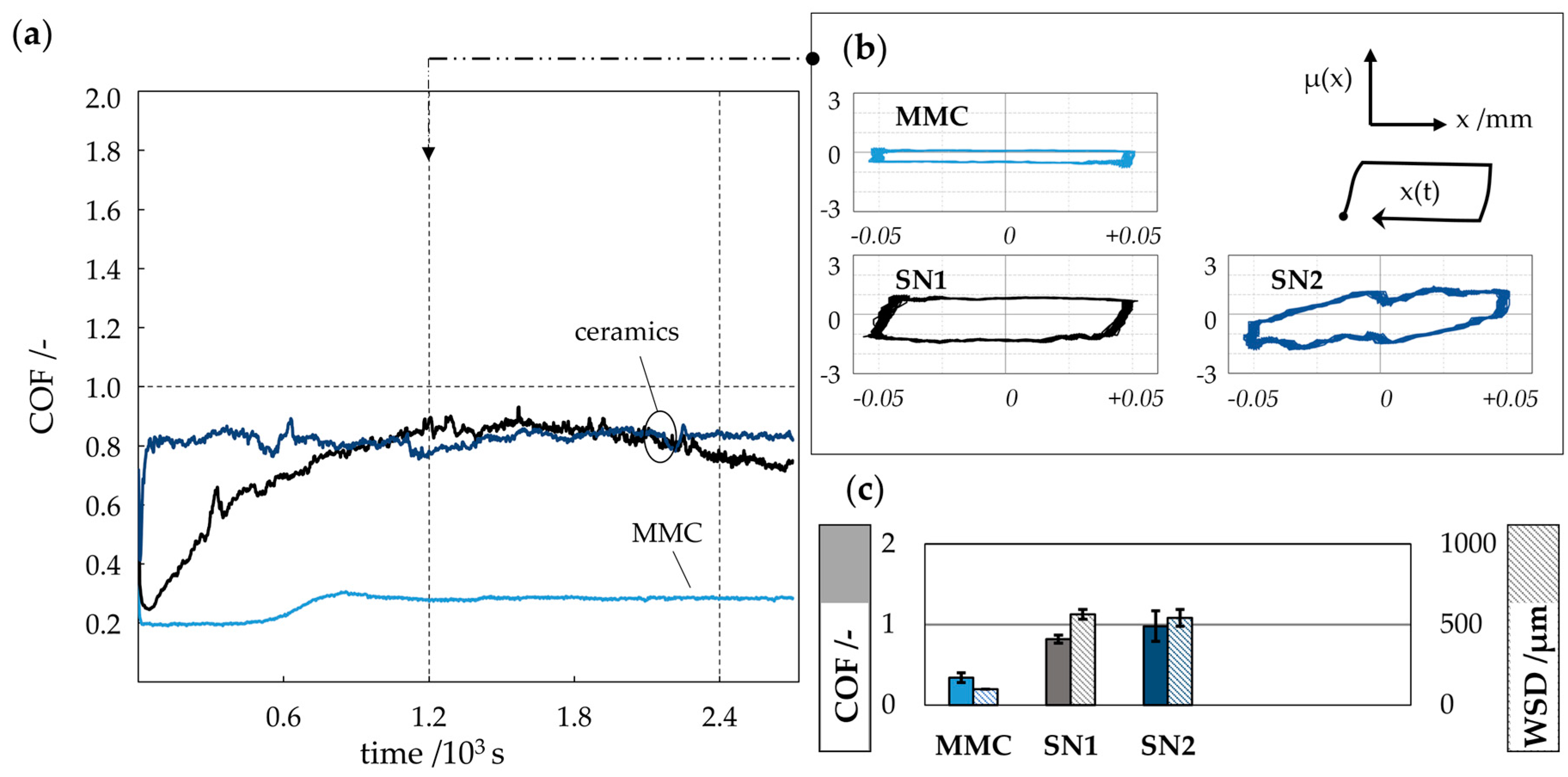

3.2. Experiments in Electrolyte F1

- Moderate friction, moderate wear: SN1, SN2;

- Low friction, low wear: MMC;

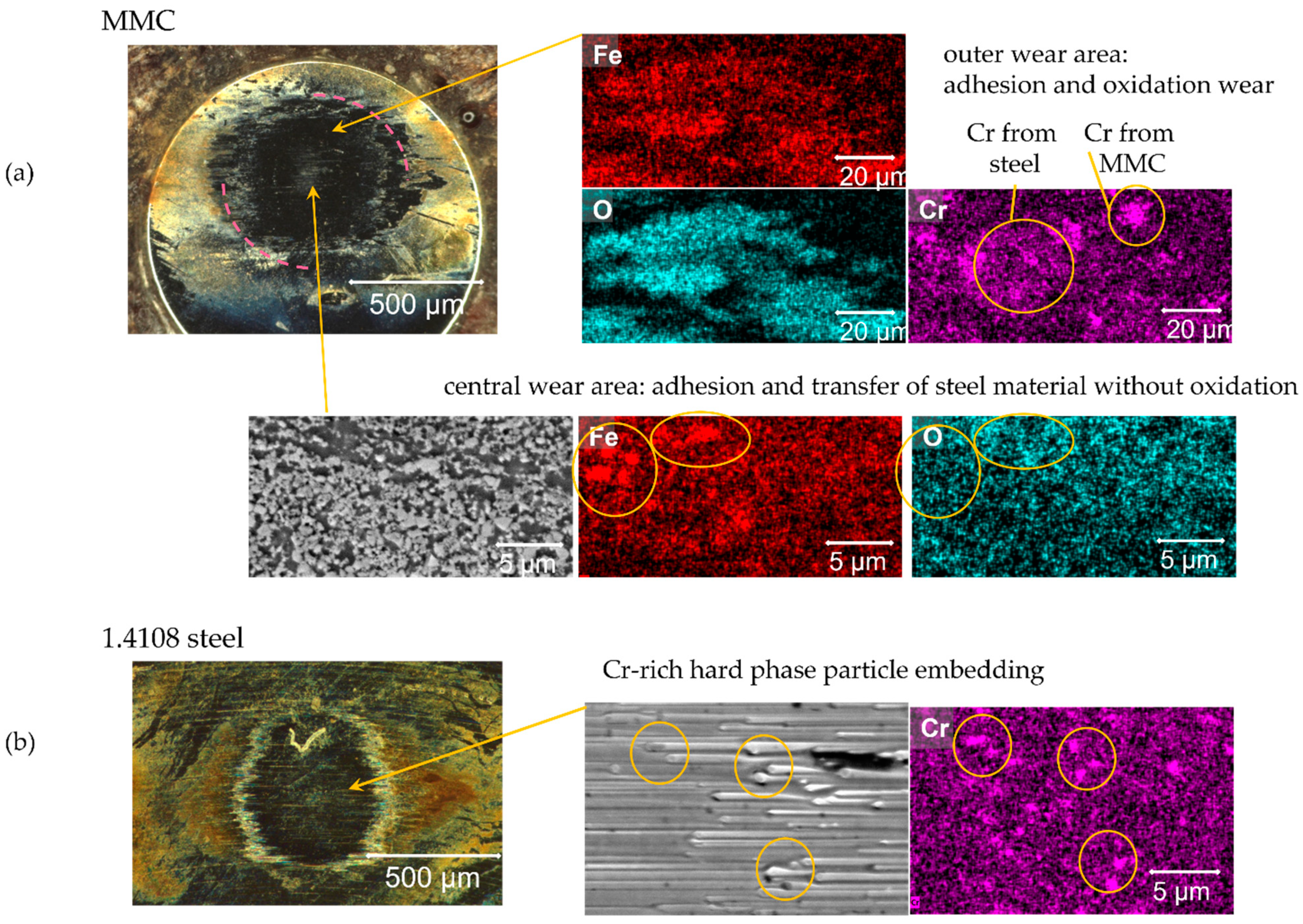

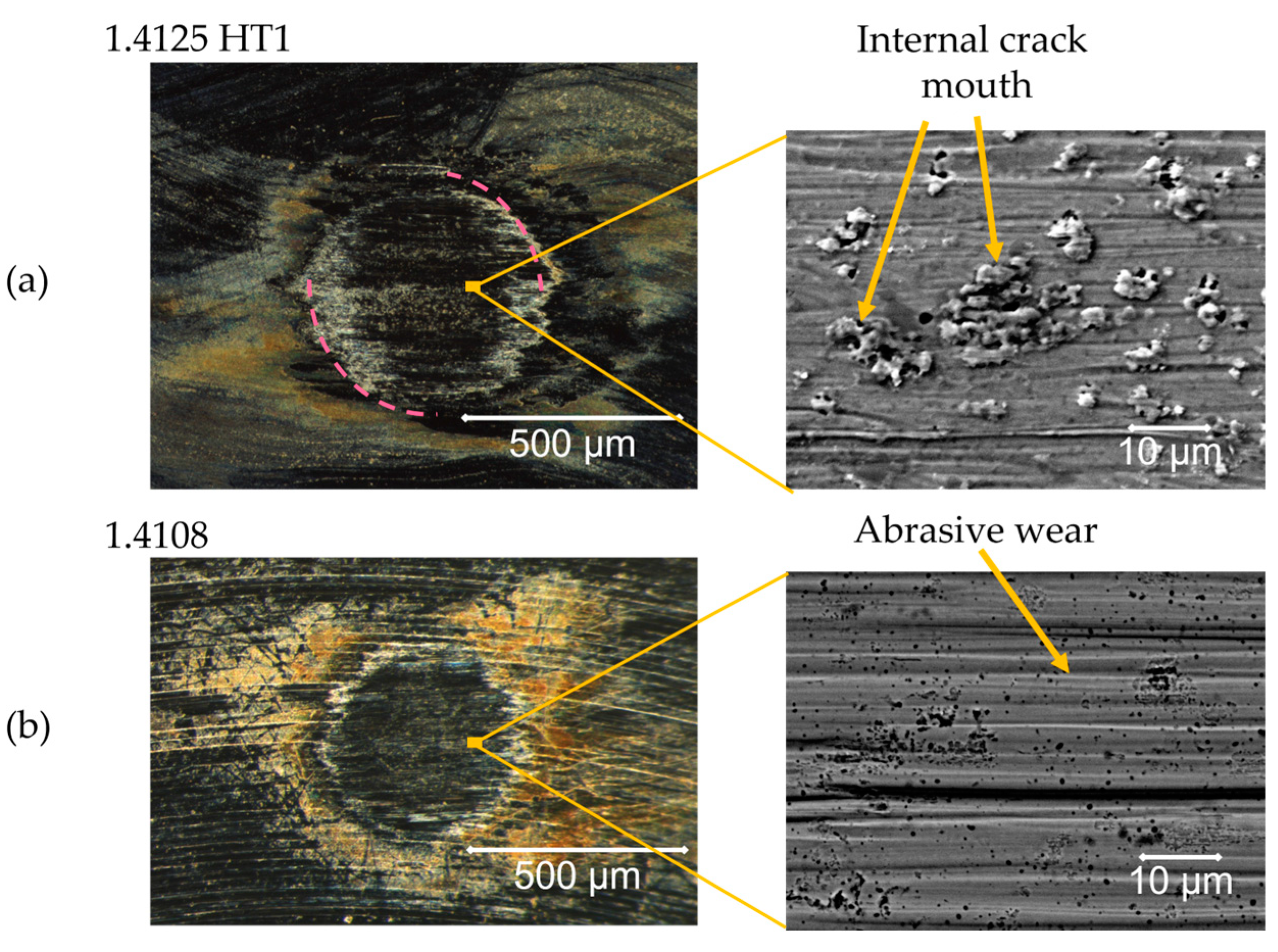

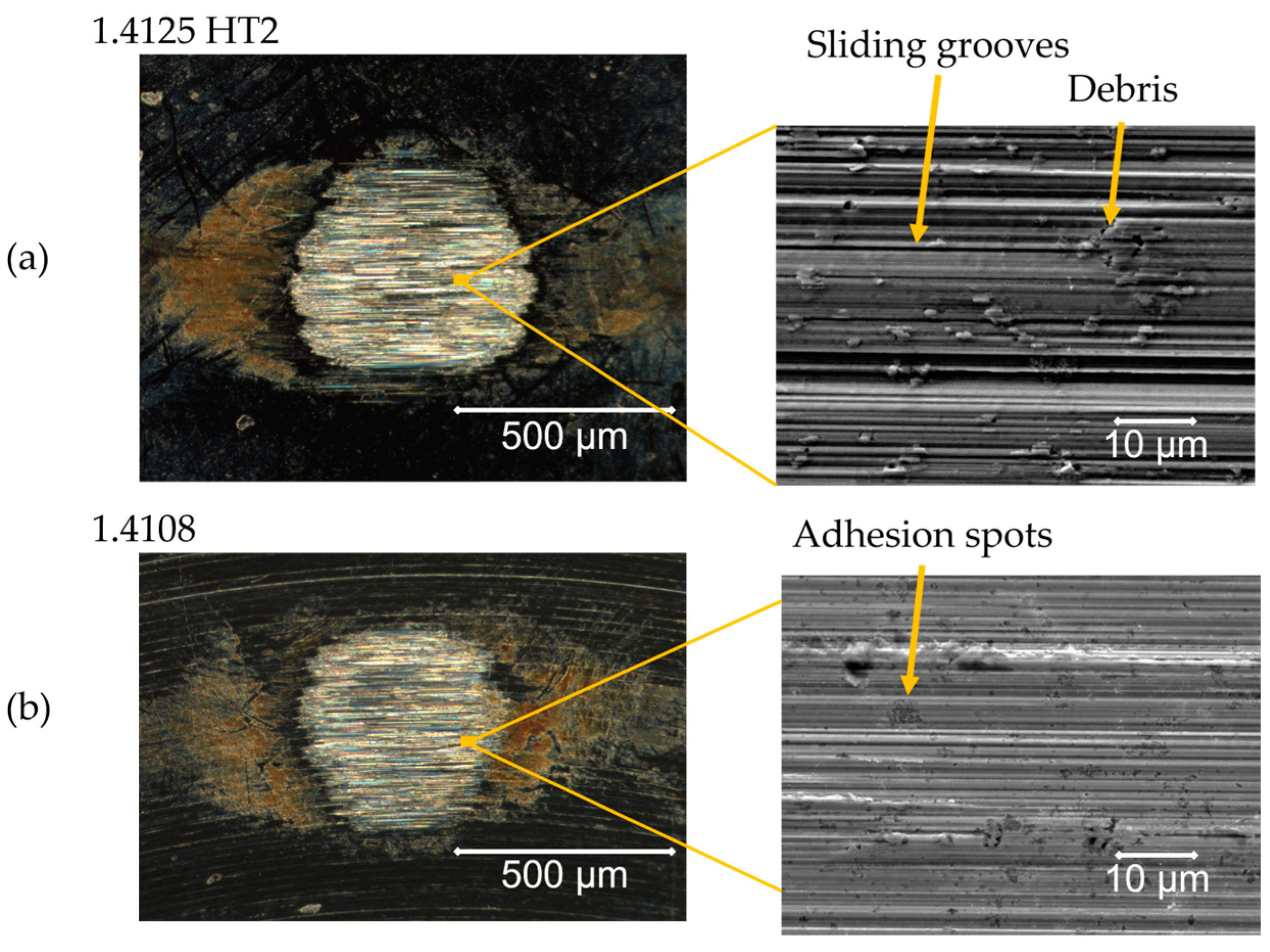

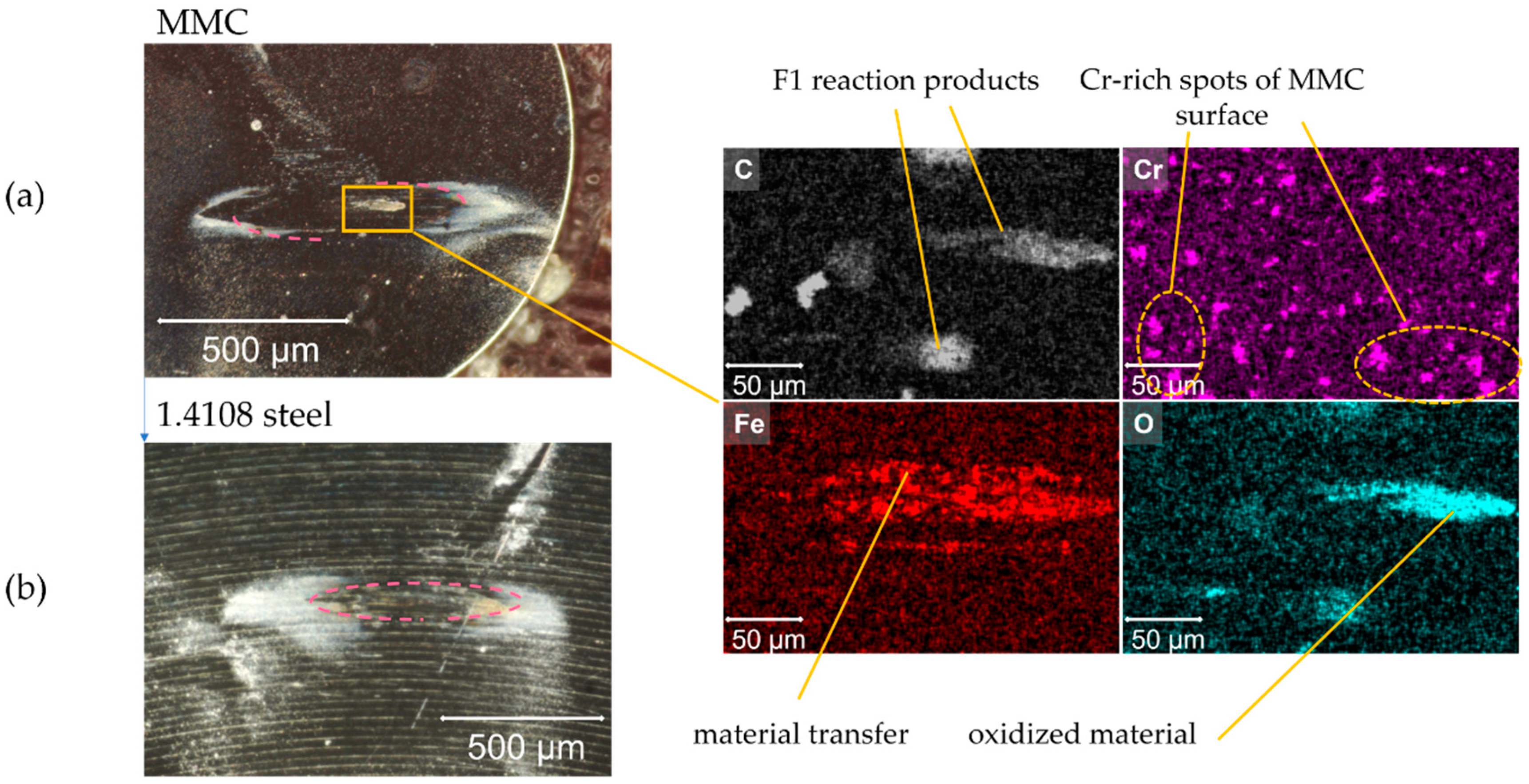

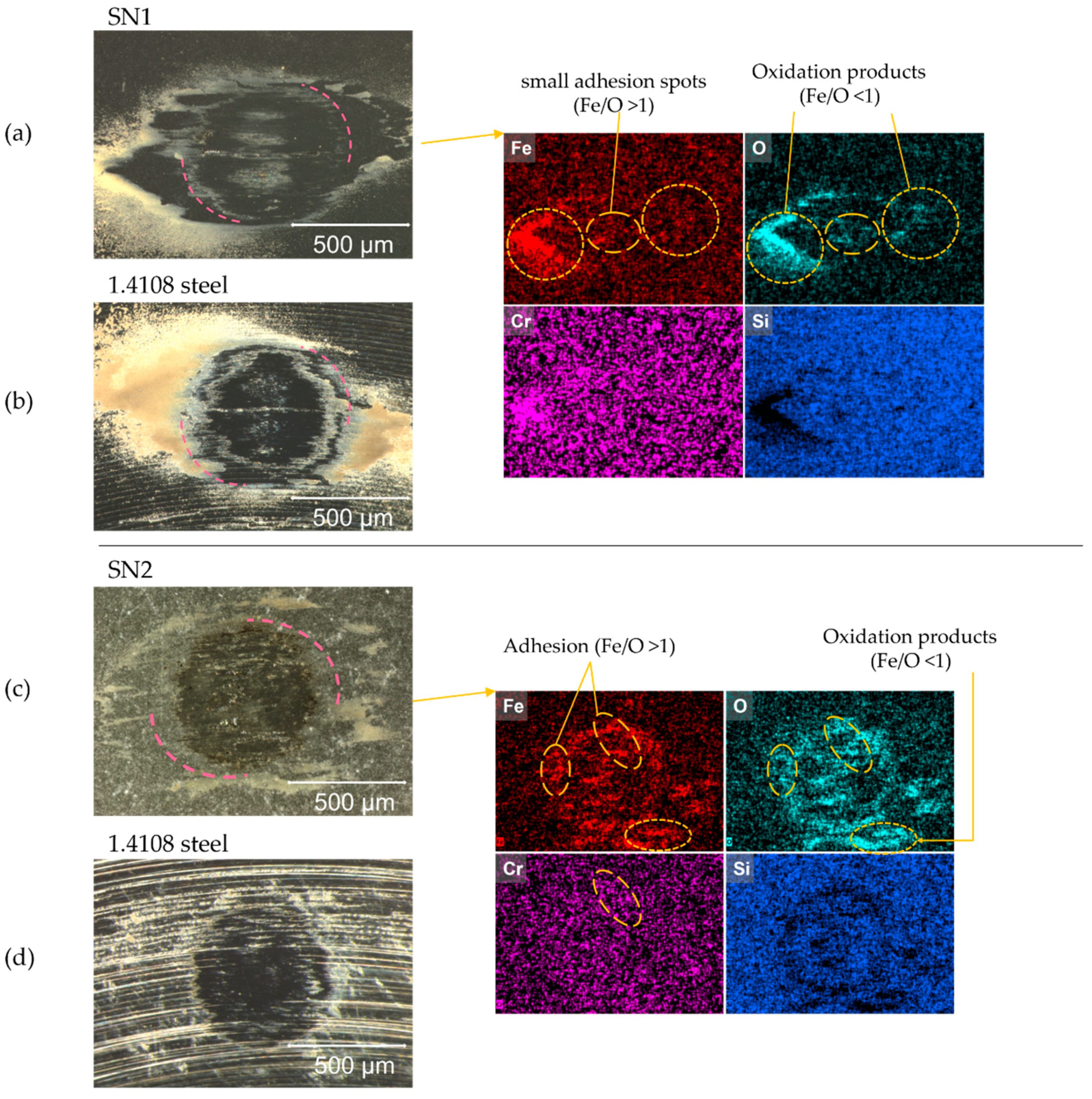

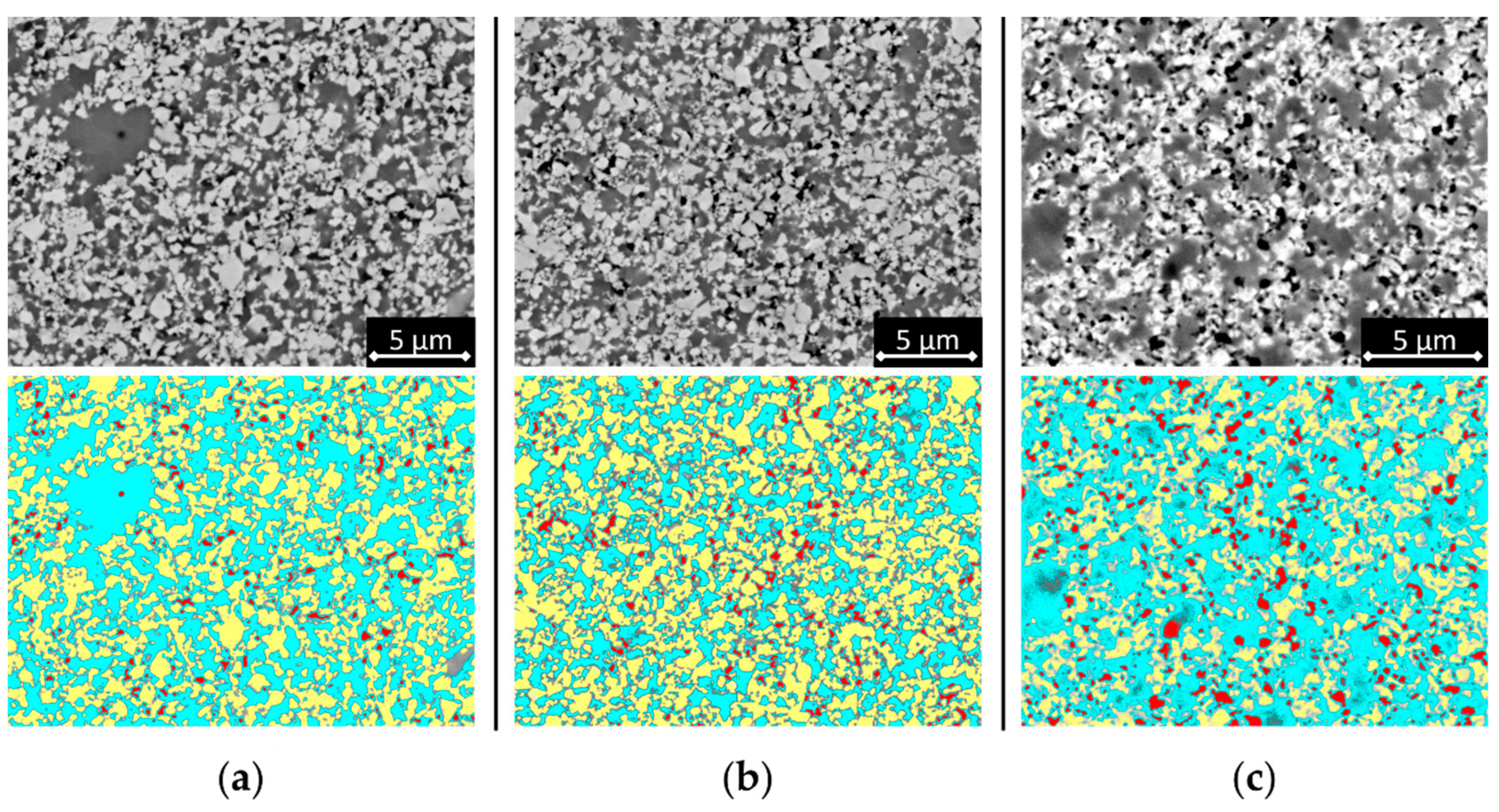

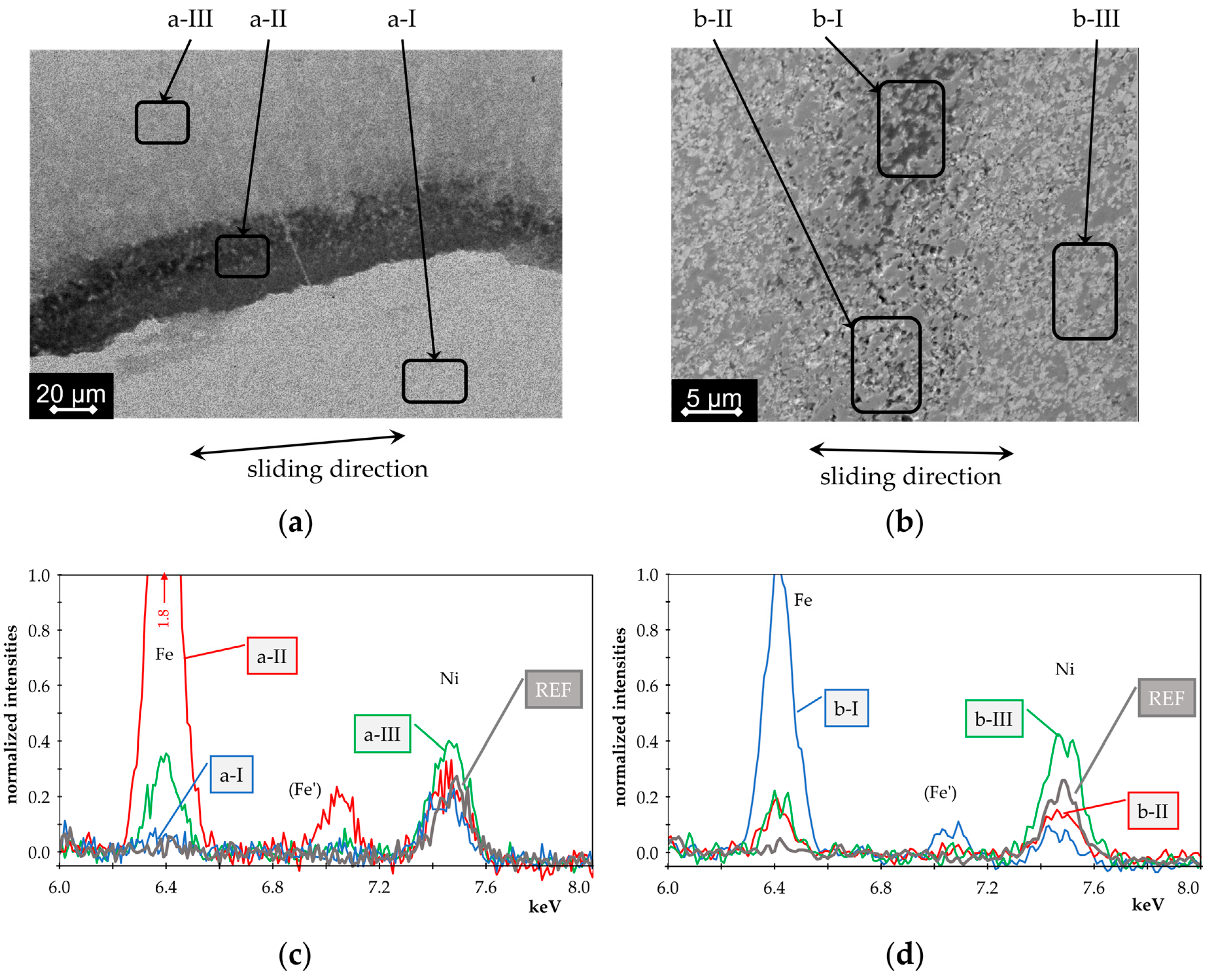

3.3. Contact Surface Analysis

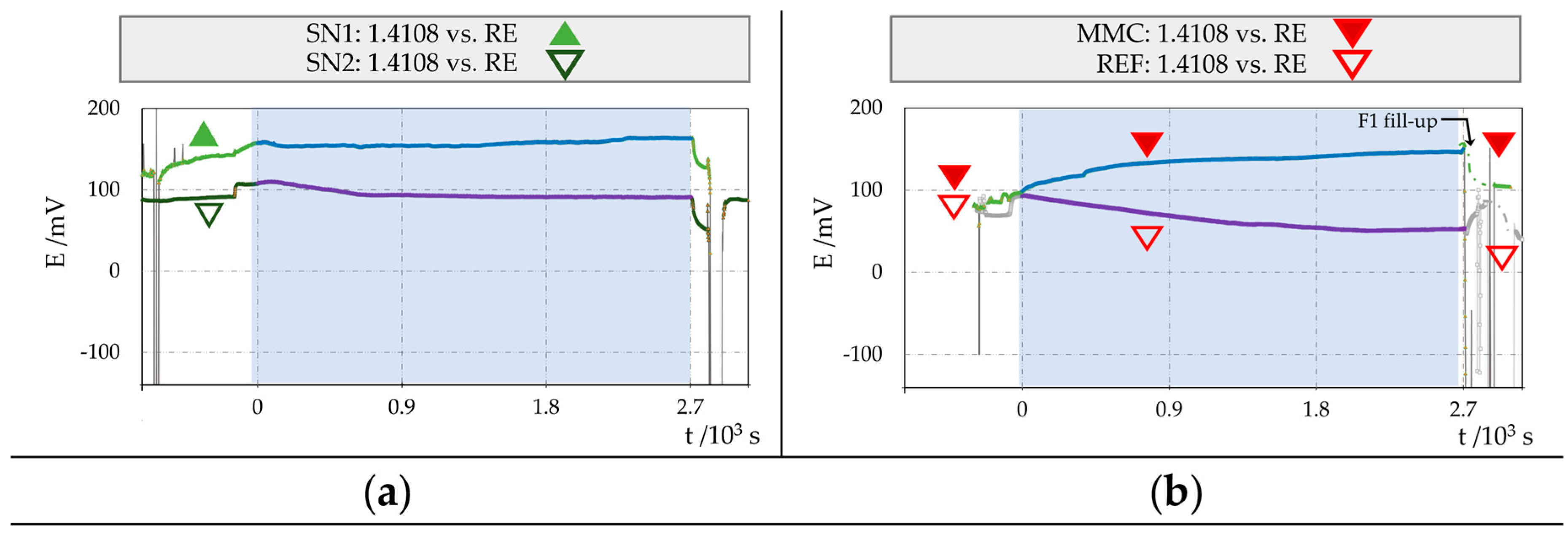

3.4. Triboexperiments Combined with OCP Measurement in Electrolyte W1

- Fretting-assisted adsorption of a hydrogen donor such as acid or water followed by cathodic reduction and the migration of atomic hydrogen across the depassivated metal surface into bulk material;

- The formation of typical cleavages [87] initiated in bulk metal as by common HIC theory;

- Cleavage crack expansion to the steel-electrolyte interface;

- In presence of a reductant (e.g., O2, Fe3+), H2 oxidation to H3O+;

- Acidic attack of the pristine and highly active interior cleavage surface causing the drop of the potential;

- The cleavage surface repassivating after outgassing, leading to potential recovery.

3.5. Triboexperiments Combined with OCP Measurement in Electrolyte F1

4. Results and Discussion: Electrochemical Laboratory Experiments

4.1. Electrochemical Behavior of Selected Materials in Aqueous Environment

4.1.1. Cathodic Polarization, Cyclovoltammetric and Potentiodynamic Study

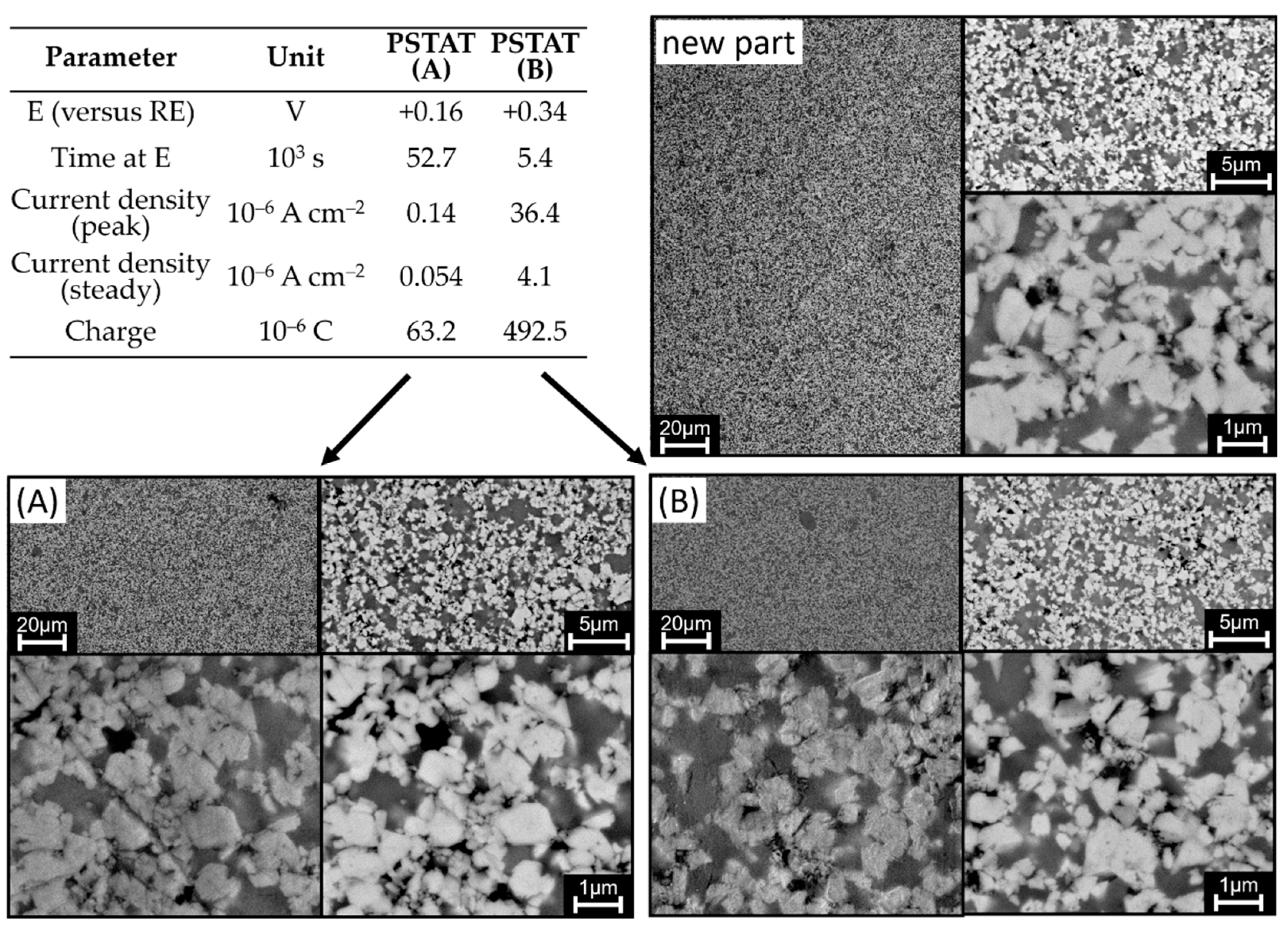

4.1.2. Potentiostatic Measurements of MMC

4.2. Surface Analysis by XPS

4.3. Correlation of Tribometrological and Electrochemical Results

- The distance between the anodic and cathodic site;

- The solution resistance between the sites and the polarization resistance of these sites;

- The concentration of the oxygen, which is limited by diffusion to the cathodic sites and the lubricant gap internal consumption, mainly by the oxidation of Fe2+ to Fe3+.

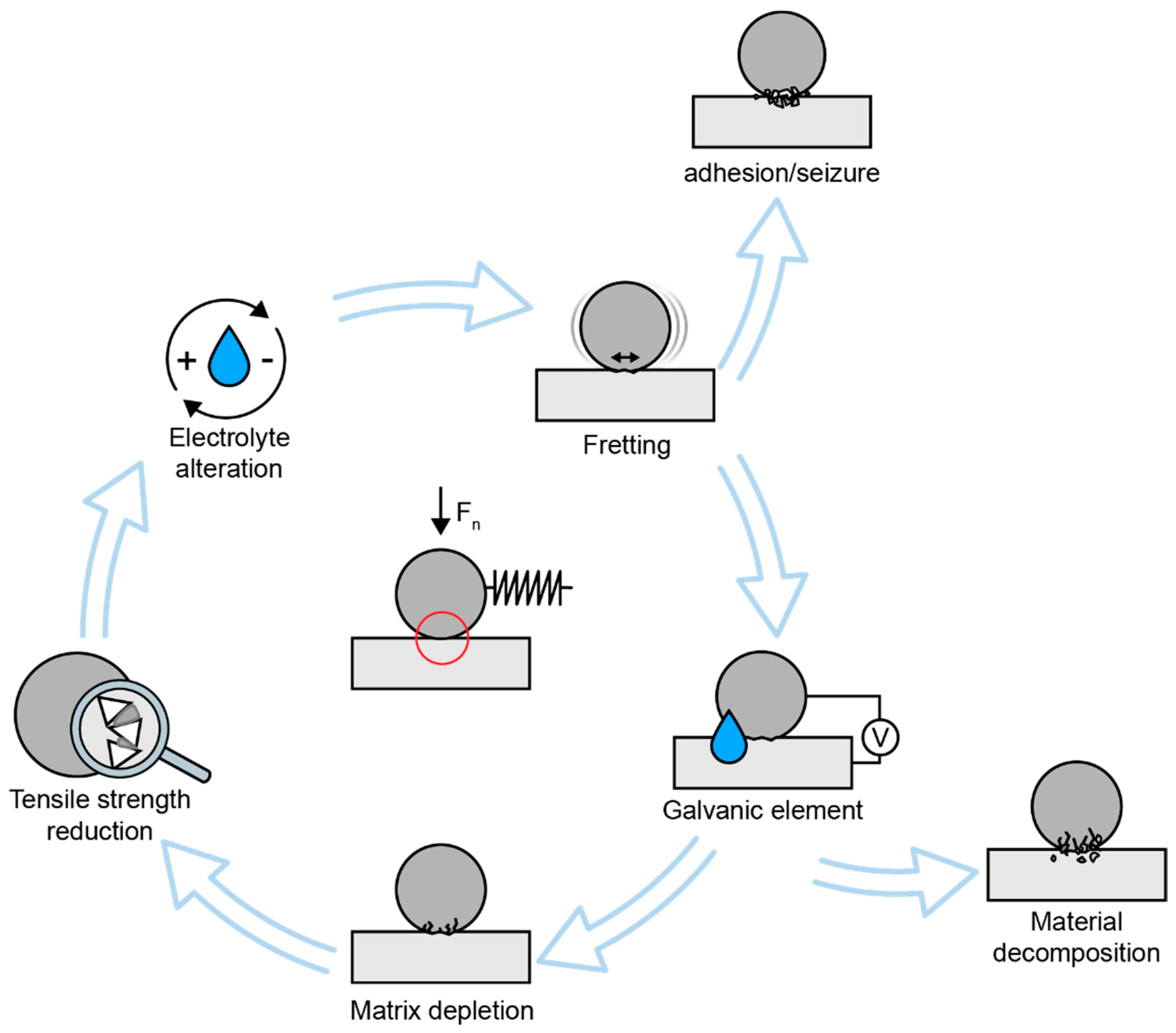

4.4. Implication of the Experimental Tribocorrosion Results: A Dynamic Fretting Crevice Corrosion Model

4.5. Interpretation of Tribocorrosion in Electrolyte F1

5. Conclusions

- The degradation of non-conductive silicon nitride-base ceramics in a fretting contact follows in aqueous lubrication a pattern of non-corrosive tribochemical decomposition, which results in abrasion-promoting nanocrystalline SiO2 particles;

- For conductive materials, cathodic reactions could be limited by the low conductivity of W1 to a narrow circular segment around the contact area, while anodic dissolution would occur directly in the depassivated wear scar. Driving mechanisms would be primarily the reduction of oxygen on the cathodic side and the constant formation of wear particles, leading to anodic dissolution of iron from the counter material;

- With progressing wear and expansion of the contact area, oxygen depletion may occur at the central contact due to excess Fe2+ concentration. This is proposed to be accompanied by local pH reduction and the emergence of anoxic reactions mechanisms. Hydrogen may be the product of the cathodic reaction. With ultra-hardened martensitic steel, typical indicators of HIC (blisters and post-experimental potential drops by relayed blister cracking) were found in central parts of the wear tracks;

- Related to pH reduction, MMC tribocorrosion mechanisms may become inverted compared to the scenario at the original pH of the electrolyte. While WC grain boundary preferably dissolves under neutral conditions, pH reduction would promote Ni dissolution. This effect is supported by thermodynamic data of the metal dissolution reactions and confirmed by EDX measurements in the proximity of the central contact. A redox reaction of Ni with tungstate was elaborated, which may play a key role in this localized corrosion phenomenon;

- These mechanisms are valid in particular in fretting contacts, where an electrolyte is under small convective flows. Under reciprocating slide conditions, aeration might occur at the entire wear area, leading to partial repassivation of the surfaces and therefore to conventional “film formation–film abrasion” scenarios. This reaction pattern shows also that MMCs with a corrosion-resistant NiCr binder may fail under fretting conditions;

- The low friction and wear of the MMC/1.4108 steel couple in F1 can therefore be explained to some extent by the absence of partial binder dissolution. Nevertheless, an alternation of aqueous and (wet) organic lubrication of MMC/steel couples, which might be of technical interest, could lead to a stack order of localized cathodic reduction in one medium and forced oxidation on the same location in the other medium. Thus, binder dissolution and ejection of hard phase carbide would be the consequence.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Xue, Q.; Wei, J. Tribochemistry in Ceramic Lubrication. Lubr. Sci. 1996, 8, 369–377. [Google Scholar] [CrossRef]

- Jahanmir, S.; Ozmen, Y.; Ives, L.K. Water Lubrication of Silicon Nitride in Sliding. Tribol. Lett. 2004, 17, 409–417. [Google Scholar] [CrossRef]

- Basu, B.; Kalin, M. (Eds.) Friction and Wear of Oxide Ceramics in an Aqueous Environment. In Tribology of Ceramics and Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 485–501. [Google Scholar]

- Yamamoto, Y.; Takashima, T. Friction and Wear of Water Lubricated PEEK and PPS Sliding Contacts. Wear 2002, 253, 820–826. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Hashimoto, M. Friction and Wear of Water Lubricated PEEK and PPS Sliding Contacts Part 2. Composites with Carbon or Glass Fibre. Wear 2004, 257, 181–189. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Tribological Performance of Different DLC Coatings in Water-Lubricated Conditions. Wear 2001, 249, 267–271. [Google Scholar] [CrossRef]

- Tokoro, M.; Aiyama, Y.; Masuko, M.; Suzuki, A.; Ito, H.; Yamamoto, K. Improvement of Tribological Characteristics under Water Lubrication of DLC-Coatings by Surface Polishing. Wear 2009, 267, 2167–2172. [Google Scholar] [CrossRef]

- Reuter, S.; Weßkamp, B.; Büscher, R.; Fischer, A.; Barden, B.; Löer, F.; Buck, V. Correlation of Structural Properties of Commercial DLC-Coatings to Their Tribological Performance in Biomedical Applications. Wear 2006, 261, 419–425. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The Wetting of Steel, DLC Coatings, Ceramics and Polymers with Oils and Water: The Importance and Correlations of Surface Energy, Surface Tension, Contact Angle and Spreading. Appl. Surf. Sci. 2014, 293, 97–108. [Google Scholar] [CrossRef]

- Majdič, F.; Velkavrh, I.; Kalin, M. Improving the Performance of a Proportional 4/3 Water-Hydraulic Valve by Using a Diamond-like-Carbon Coating. Wear 2013, 297, 1016–1024. [Google Scholar] [CrossRef]

- Strmčnik, E.; Majdič, F.; Kalin, M. Water-Lubricated Behaviour of AISI 440C Stainless Steel and a DLC Coating for an Orbital Hydraulic Motor Application. Tribol. Int. 2019, 131, 128–136. [Google Scholar] [CrossRef]

- Majdič, F.; Pezdirnik, J.; Kalin, M. Experimental Validation of the Lifetime Performance of a Proportional 4/3 Hydraulic Valve Operating in Water. Tribol. Int. 2011, 44, 2013–2021. [Google Scholar] [CrossRef]

- Sagraloff, N.; Dobler, A.; Tobie, T.; Stahl, K.; Ostrowski, J. Development of an Oil Free Water-Based Lubricant for Gear Applications. Lubricants 2019, 7, 6–8. [Google Scholar] [CrossRef]

- Zhang, K.; Yan, W.; Simic, R.; Benetti, E.M.; Spencer, N.D. Versatile Surface Modification of Hydrogels by Surface-Initiated, Cu 0-Mediated Controlled Radical Polymerization. ACS Appl. Mater. Interfaces 2020, 12, 6761–6767. [Google Scholar] [CrossRef] [PubMed]

- de Assis Severiano, J.; Silva, A.S.; Sussushi, E.M.; da Silva Sant’Anna, M.V.; da Cunha, M.A.; Bergmann, C.P.; Griza, S. Corrosion Damages of Flow Regulation Valves for Water Injection in Oil Fields. Eng. Fail. Anal. 2019, 96, 362–373. [Google Scholar] [CrossRef]

- Virtanen, S. Corrosion and Passivity of Metals and Coatings. In Tribocorrosion of Passive Metals and Coatings; Landolt, D., Mischler, S., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 3–28. ISBN 9781845699666. [Google Scholar]

- Santana-Casiano, J.M.; González-Dávila, M.; Millero, F.J. Oxidation of Nanomolar Levels of Fe(II) with Oxygen in Natural Waters. Environ. Sci. Technol. 2005, 39, 2073–2079. [Google Scholar] [CrossRef] [PubMed]

- Uhlig, H.H. Uhlig’s Corrosion Handbook; Revie, R.W., Ed.; The Electrochemical Society Series; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 9780470080320. [Google Scholar]

- Mischler, S.; Spiegel, A.; Landolt, D. The Role of Passive Oxide Films on the Degradation of Steel in Tribocorrosion Systems. Wear 1999, 225–229, 1078–1087. [Google Scholar] [CrossRef]

- Batchelor, A.W.; Stachowiak, G.W. Tribology in Materials Processing. J. Mater. Process. Technol. 1995, 48, 503–515. [Google Scholar] [CrossRef]

- Bhagat, R.B.; Conway, J.C.; Amateau, M.F.; Brezler, R.A. Tribological Performance Evaluation of Tungsten Carbide-Based Cermets and Development of a Fracture Mechanics Wear Model. Wear 1996, 201, 233–243. [Google Scholar] [CrossRef]

- Gopi, R.; Saravanan, I.; Devaraju, A.; Ponnusamy, P. Tribological Behaviour of Thermal Sprayed High Velocity Oxy-Fuel Coatings on Tungsten Carbide—A Review. Mater. Today Proc. 2021, 39, 292–295. [Google Scholar] [CrossRef]

- Veinthal, R.; Tarbe, R.; Kulu, P.; Käerdi, H. Abrasive Erosive Wear of Powder Steels and Cermets. Wear 2009, 267, 1838–1844. [Google Scholar] [CrossRef]

- Vilhena, L.; Domingues, B.; Fernandes, C.; Senos, A.; Ramalho, A. Mechanical and Tribological Characterization of WC-Co and WC-AISI 304 Composites by a Newly Developed Equipment. Materials 2022, 15, 1187. [Google Scholar] [CrossRef] [PubMed]

- García, J.; Collado Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Micallef, C.; Zhuk, Y.; Aria, A.I. Recent Progress in Precision Machining and Surface Finishing of Tungsten Carbide Hard Composite Coatings. Coatings 2020, 10, 731. [Google Scholar] [CrossRef]

- Barbatti, C.F.; Sket, F.; Garcia, J.; Pyzalla, A. Influence of Binder Metal and Surface Treatment on the Corrosion Resistance of (W,Ti)C-Based Hardmetals. Surf. Coat. Technol. 2006, 201, 3314–3327. [Google Scholar] [CrossRef][Green Version]

- Kamdi, Z.; Apandi, M.N.M.; Ibrahim, M.D. Wear and Corrosion Behaviour of Tungsten Carbide Based Coatings with Different Metallic Binder. In Advanced Materials for Sustainability and Growth, Proceedings of the 3rd Advanced Materials Conference 2016 (3rd AMC 2016), Langkawi Island, Malaysia, 28–29 November 2016; AIP Publishing: Melville, NY, USA, 2017; p. 120005. [Google Scholar]

- Tomlinson, W.J.; Linzell, C.R. Anodic Polarization and Corrosion of Cemented Carbides with Cobalt and Nickel Binders. J. Mater. Sci. 1988, 23, 914–918. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Herd, S.; Thakare, M.R. A Critical Review of the Tribocorrosion of Cemented and Thermal Sprayed Tungsten Carbide. Tribol. Int. 2018, 119, 491–509. [Google Scholar] [CrossRef]

- Souza, V.A.D.; Neville, A. Linking Electrochemical Corrosion Behaviour and Corrosion Mechanisms of Thermal Spray Cermet Coatings (WC-CrNi and WC/CrC-CoCr). Mater. Sci. Eng. A 2003, 352, 202–211. [Google Scholar] [CrossRef]

- Pereira, P.; Rocha, A.M.F.; Sacramento, J.; Oliveira, F.J.; Senos, A.M.R.; Malheiros, L.F.; Bastos, A.C. Corrosion Resistance of WC Hardmetals with Different Co and Ni-Based Binders. Int. J. Refract. Met. Hard Mater. 2022, 104, 105799. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, N.; He, Y. Effects of Mo Additions on the Corrosion Behavior of WC-TiC-Ni Hardmetals in Acidic Solutions. Int. J. Refract. Met. Hard Mater. 2013, 38, 15–25. [Google Scholar] [CrossRef]

- Stojadinović, J.; Bouvet, D.; Mischler, S. Prediction of Removal Rates in Chemical-Mechanical Polishing (CMP) Using Tribocorrosion Modeling. J. Bio- Tribo-Corros. 2016, 2, 8. [Google Scholar] [CrossRef]

- Anik, M.; Cansizoglu, T. Dissolution Kinetics of WO3 in Acidic Solutions. J. Appl. Electrochem. 2006, 36, 603–608. [Google Scholar] [CrossRef]

- Lillard, R.S.; Kanner, G.S.; Butt, D.P. The Nature of Oxide Films on Tungsten in Acidic and Alkaline Solutions. J. Electrochem. Soc. 1998, 145, 2718–2725. [Google Scholar] [CrossRef]

- Anik, M.; Osseo-Asare, K. Effect of pH on the Anodic Behavior of Tungsten. J. Electrochem. Soc. 2002, 149, B224. [Google Scholar] [CrossRef]

- Wang, Y.S.; Narasimhan, S.; Larson, J.M.; Barber, G.C. A Review of Ceramic Tribology and Application of Si-Based Ceramics to Engine Valves/Seat Inserts. SAE Trans. 1996, 105, 330–342. [Google Scholar] [CrossRef]

- Erdemir, A.; Erck, R.A.; Fenske, G.R.; Hong, H. Solid/Liquid Lubrication of Ceramics at Elevated Temperatures. Wear 1997, 203–204, 588–595. [Google Scholar] [CrossRef]

- Hara, Y. Application of Fine Ceramics in Industrial Fields. Corros. Eng. 1989, 38, 493–499. [Google Scholar] [CrossRef][Green Version]

- Eichler, J. Industrial Applications of Si-Based Ceramics. J. Korean Ceram. Soc. 2012, 49, 561–565. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Fedorov, S.V.; Hamdy, K. Materials, Properties, Manufacturing Methods and Cutting Performance of Innovative Ceramic Cutting Tools—A Review. Manuf. Rev. 2019, 6, 19. [Google Scholar] [CrossRef]

- Cao, G.Z.; Metselaar, R. A′-Sialon Ceramics: A Review. Chem. Mater. 1991, 3, 242–252. [Google Scholar] [CrossRef]

- Izhevskiy, V.A.; Genova, L.A.; Bressiani, J.C.; Aldinger, F. Progress in SiAlON Ceramics. J. Eur. Ceram. Soc. 2000, 20, 2275–2295. [Google Scholar] [CrossRef]

- Cao, G.Z.; Metselaar, R.; Ziegler, G. Microstructure and Properties of Mixed α’+β’-Sialons. In Proceedings of the 4th International Symposium on Ceramic Materials and Components for Engine; Carlsson, R., Johansson, T., Kahlman, L., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 188–195. [Google Scholar]

- Reis, P.; Filho, V.; Davim, J.P.; Xu, X.; Ferreira, J.M.F. Wear Behavior on Advanced Structural Ceramics: α-Sialon Matrix Reinforced with β-Sialon Fibers. Mater. Des. 2005, 26, 417–423. [Google Scholar] [CrossRef]

- Bhushan, B. Wear Maps. In Modern Tribology Handbook; CRC Press LLC: Boca Raton, FL, USA, 2001; Volume I, ISBN 0-8493-8403-6. [Google Scholar]

- Hsu, S.M.; Shen, M.C. Wear Mapping of Materials. In Wear—Materials, Mechanisms and Practice; John Wiley & Sons Ltd.: Chichester, UK, 2014; pp. 369–423. [Google Scholar]

- Fischer, T.E.; Tomizawa, H. Interaction of Tribochemistry and Microfracture in the Friction and Wear of Silicon Nitride. Wear 1985, 105, 29–45. [Google Scholar] [CrossRef]

- Tomizawa, H.; Fischer, T.E. Friction and Wear of Silicon Nitride and Silicon Carbide in Water: Hydrodynamic Lubrication at Low Sliding Speed Obtained by Tribochemical Wear. ASLE Trans. 1987, 30, 41–46. [Google Scholar] [CrossRef]

- Tomizawa, H.; Fischer, T.E. Friction and Wear of Silicon Nitride at 150° C to 800 °C. ASLE Trans. 1986, 29, 481–488. [Google Scholar] [CrossRef]

- Gates, R.S.; Hsu, S.M. Silicon Nitride Boundary Lubrication: Lubrication Mechanism of Alcohols. Tribol. Trans. 1995, 38, 645–653. [Google Scholar] [CrossRef]

- Waterhouse, R.B. Fretting Corrosion. Proc. Inst. Mech. Eng. 1955, 169, 1157–1172. [Google Scholar] [CrossRef]

- ASTM G204-10; Standard Test Method for Damage to Contacting Solid Surfaces under Fretting Conditions. ASTM (American Society for Testing and Materials) International: West Conshohocken, PA, USA, 2010. [CrossRef]

- Nesládek, M.; Španiel, M.; Jurenka, J.; Růžička, J.; Kuželka, J. Fretting Fatigue—Experimental and Numerical Approaches. Int. J. Fatigue 2012, 44, 61–73. [Google Scholar] [CrossRef]

- Kapsa, P. Environmental Effects of Fretting. In Tribocorrosion of Passive Metals and Coatings; Landolt, D., Mischler, S., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 100–118. ISBN 2013206534. [Google Scholar]

- Landolt, D.; Mischler, S.; Stemp, M. Electrochemical Methods in Tribocorrosion: A Critical Appraisal. Electrochim. Acta 2001, 46, 3913–3929. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Alves, A.C.; Silva, F.S.; Toptan, F. Electrochemical Characterization of Hot Pressed CoCrMo-HAP Biocomposite in a Physiological Solution. Mater. Corros. 2015, 66, 790–795. [Google Scholar] [CrossRef]

- Stemp, M.; Mischler, S.; Landolt, D. The Effect of Mechanical and Electrochemical Parameters on the Tribocorrosion Rate of Stainless Steel in Sulphuric Acid. Wear 2003, 255, 466–475. [Google Scholar] [CrossRef]

- Guennouni, N.; Maisonnette, D.; Grosjean, C.; Andrieu, E.; Poquillon, D.; Blanc, C. Influence of Hydrogen on the Stress-Relaxation Properties of 17-4PH Martensitic Stainless Steel Manufactured by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2022, 831, 142125. [Google Scholar] [CrossRef]

- Bargel, H.-J.; Schulze, G. (Eds.) Werkstoffkunde; Springer-Lehrbuch; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-17716-3. [Google Scholar]

- Toptan, F.; Rocha, L.A. Tribocorrosion in Metal Matrix Composites. In Processing Techniques and Tribological Behavior of Composite Materials; Tyagi, R., Davim, J.P., Eds.; IGI Global: Hershey, PS, USA, 2015; pp. 149–167. [Google Scholar]

- Human, A.M.; Exner, H.E. Electrochemical Behaviour of Tungsten-Carbide Hardmetals. Mater. Sci. Eng. A 1996, 209, 180–191. [Google Scholar] [CrossRef]

- Sutthiruangwong, S.; Mori, G.; Kösters, R. Passivity and Pseudopassivity of Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2005, 23, 129–136. [Google Scholar] [CrossRef]

- Hochstrasser, S.; Mueller, Y.; Latkoczy, C.; Virtanen, S.; Schmutz, P. Analytical Characterization of the Corrosion Mechanisms of WC-Co by Electrochemical Methods and Inductively Coupled Plasma Mass Spectroscopy. Corros. Sci. 2007, 49, 2002–2020. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Heino, V.; Isotahdon, E.; Kilpi, L.; Ronkainen, H. Tribocorrosion Behaviour of Thermally Sprayed Cermet Coatings in Paper Machine Environment. Tribol. Int. 2020, 142, 106006. [Google Scholar] [CrossRef]

- Thakare, M.R.; Wharton, J.A.; Wood, R.J.K.; Menger, C. Exposure Effects of Strong Alkaline Conditions on the Microscale Abrasion—Corrosion of D-Gun Sprayed WC-10Co-4Cr Coating. Tribol. Int. 2008, 41, 629–639. [Google Scholar] [CrossRef]

- Thakare, M.R.; Wharton, J.A.; Wood, R.J.K.; Menger, C. Investigation of Micro-Scale Abrasion-Corrosion of WC-Based Sintered Hardmetal and Sprayed Coating Using in Situ Electrochemical Current-Noise Measurements. Wear 2009, 267, 1967–1977. [Google Scholar] [CrossRef]

- Pourbaix, M. Atlas of Electrochemical Equilibria in Aqueous Solutions, 2nd ed.; Pourbaix, M., Ed.; CEBELCOR: Brussels, Belgium, 1974; ISBN 978-0915567980. [Google Scholar]

- Thakare, M.R.; Wharton, J.A.; Wood, R.J.K.; Menger, C. Exposure Effects of Alkaline Drilling Fluid on the Microscale Abrasion-Corrosion of WC-Based Hardmetals. Wear 2007, 263, 125–136. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, L.; Chen, Y.; Zhang, H.; Zhou, L. Corrosion and Strength Degradation Behaviors of Binderless WC Material and WC-Co Hardmetal in Alkaline Solution: A Comparative Investigation. Int. J. Refract. Met. Hard Mater. 2017, 68, 1–8. [Google Scholar] [CrossRef]

- Lin, N.; He, Y.; Wu, C.; Liu, S.; Xiao, X.; Jiang, Y. Influence of TiC Additions on the Corrosion Behaviour of WC-Co Hardmetals in Alkaline Solution. Int. J. Refract. Met. Hard Mater. 2014, 46, 52–57. [Google Scholar] [CrossRef]

- Cho, J.E.; Hwang, S.Y.; Kim, K.Y. Corrosion Behavior of Thermal Sprayed WC Cermet Coatings Having Various Metallic Binders in Strong Acidic Environment. Surf. Coat. Technol. 2006, 200, 2653–2662. [Google Scholar] [CrossRef]

- Trausmuth, A.; Kronberger, M.; Raghuram, H.; Rojacz, H.; Badisch, E.; Rodríguez Ripoll, M. Tribocorrosion Performance of Fe-Base and Ni-Base Wear Resistant Coatings in CO2 Anoxic Environments. Corros. Sci. 2022, 196, 110035. [Google Scholar] [CrossRef]

- Katiyar, P.K. A Comprehensive Review on Synergy Effect between Corrosion and Wear of Cemented Tungsten Carbide Tool Bits: A Mechanistic Approach. Int. J. Refract. Met. Hard Mater. 2020, 92, 105315. [Google Scholar] [CrossRef]

- Mizuhara, K.; Hsu, S.M. Tribochemical Reaction of Oxygen and Water on Silicon Surfaces. Tribol. Ser. 1992, 21, 323–328. [Google Scholar] [CrossRef]

- Kalin, M.; Vižintin, J.; Novak, S. Effect of Fretting Conditions on the Wear of Silicon Nitride against Bearing Steel. Mater. Sci. Eng. A 1996, 220, 191–199. [Google Scholar] [CrossRef]

- Kalin, M.; Vižintin, J.; Novak, S.; Dražič, G. Wear Mechanisms in Oil-Lubricated and Dry Fretting of Silicon Nitride against Bearing Steel Contacts. Wear 1997, 210, 27–38. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Kilpi, L.; Hakala, T.J.; Carpen, L.; Ronkainen, H. Tribocorrosion Study of Martensitic and Austenitic Stainless Steels in 0.01M NaCl Solution. Tribol. Int. 2016, 95, 358–371. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology, Gaithersburg, U.S. NIST X-Ray Photoelectron Spectroscopy Database, Version 4.1. Available online: http://srdata.nist.gov/xps/ (accessed on 21 December 2021).

- Goyal, V.; Sharma, S.K.; Kumar, B.V.M. Effect of Lubrication on Tribological Behaviour of Martensitic Stainless Steel. Mater. Today Proc. 2015, 2, 1082–1091. [Google Scholar] [CrossRef]

- Venske, A.F.; de Castro, V.V.; da Costa, E.M.; dos Santos, C.A. Sliding Wear Behavior of an AISI 440B Martensitic Stainless Steel Lubricated with Biodiesel and Diesel-Biodiesel Blends. J. Mater. Eng. Perform. 2018, 27, 5427–5437. [Google Scholar] [CrossRef]

- Basu, B.; Kalin, M. (Eds.) Case Study: Sialon Ceramics. In Tribology of Ceramics and Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 167–184. [Google Scholar]

- Hu, Q.; Ji, D.; Shen, M.; Zhuang, H.; Yao, H.; Zhao, H.; Guo, H.; Zhang, Y. Three-Body Abrasive Wear Behavior of WC-10Cr3C2-12Ni Coating for Ball Mill Liner Application. Materials 2022, 15, 4569. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Schreiber, P.; Schneider, J.; Greiner, C. Tribological Mechanisms of Slurry Abrasive Wear. Friction 2023, 11, 1079–1093. [Google Scholar] [CrossRef]

- Depover, T.; Wallaert, E.; Verbeken, K. Fractographic Analysis of the Role of Hydrogen Diffusion on the Hydrogen Embrittlement Susceptibility of DP Steel. Mater. Sci. Eng. A 2016, 649, 201–208. [Google Scholar] [CrossRef]

- Ghasali, E.; Ebadzadeh, T.; Alizadeh, M.; Razavi, M. Mechanical and Microstructural Properties of WC-Based Cermets: A Comparative Study on the Effect of Ni and Mo Binder Phases. Ceram. Int. 2018, 44, 2283–2291. [Google Scholar] [CrossRef]

- Totolin, V.; Rodríguez Ripoll, M.; Jech, M.; Podgornik, B. Enhanced Tribological Performance of Tungsten Carbide Functionalized Surfaces via In-Situ Formation of Low-Friction Tribofilms. Tribol. Int. 2016, 94, 269–278. [Google Scholar] [CrossRef]

- Haynes, W.M. (Ed.) CRC Handbook of Chemistry and Physics, 88th ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9780429170195. [Google Scholar]

- Kelly, R.G.; Scully, J.R.; Shoesmith, D.W.; Buchheit, R.G. Electrochemical Techniques in Corrosion Science and Engineering; Marcel Dekker, Inc.: New York, NY, USA, 2002; ISBN 0824799178. [Google Scholar]

| Material | Description | Hardness | Density (/g cm−3) | Tribometric | Electrochemical |

|---|---|---|---|---|---|

| MMC 1 2 | WC-TiC-NiCr | 2050 ± 50 (HV10) | 14.3 ± 0.3 | X | X |

| SN1 3 | β-SiAlON | 1550 (HV10) | 3.21 | X | |

| SN2 2 | α/β-SiAlON | 1500 (HV50) | 3.24 | X | |

| HT1 (1.4125 4) | Stainless martensitic steel | 835 ± 10 (HV10) | 7.7 | X | X |

| HT2 (1.4125 5) | 700 ± 10 (HV10) | X | |||

| 1.4108 | 700 ± 50 (HV10) | X | X | ||

| 1.4112 | X |

| Material | Unit | Hard Phase | Binder | Others | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W (as WC) | Ti (as TiC) | Cr (as Cr3C2) | Total | Ni (as NiCr) | Cr (as NiCr) | Mo | Total | |||

| MMC | ratio 1 (at.%) | 4 (±0.5): | 1: | 0.1 (±0.05) | 2.4 (±1): | 1: | 0.4 (±0.25) | |||

| wt.% | 90–92 | 8–10 | <1 | |||||||

| Material | Unit | Fe | C | Cr | Ni | Mo | V | Si | Mn | P | S | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.4112 | wt.% | balance | 0.85–0.95 | 17.0–19.0 | - | 0.90–1.30 | 0.07–0.12 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.015 | - |

| 1.4108 | balance | 0.28–0.35 | 14.4–16.0 | ≤0.53 | 0.90–1.10 | - | ≤1.05 | ≤1.03 | ≤0.025 | ≤0.005 | 0.35–0.45 | |

| 1.4125 | balance | 0.92–1.23 | 15.8–18.2 | - | 0.37–0.85 | - | ≤1.05 | ≤1.03 | ≤0.045 | ≤0.035 | - |

| Parameter | Unit | W1 | F1 |

|---|---|---|---|

| Description | Test water, aerated | Processing fluid | |

| Composition | mg L−1 | Cationic Ca/Mg/K 0.5; Na 4.0; Si 1.5 Anionic NO3 0.5; Cl 2.0; SO4 5.0; CH3COO 8.4 | |

| vol.% | Agents 1–2; W1 1.12 VOC 1 balance | ||

| Precipitate | None | None | |

| Density | g cm−3 | 0.99 | 0.79 |

| Dynamic viscosity | mPa s | 1.2 | 0.7 |

| Conductivity | µS cm−1 | 31 | 0.15 |

| Dielectric permittivity | – | 78.5 | 4.4 ± 0.5 |

| Tribometric | X | X | |

| Electrochemical | X |

| Tribometric Parameter | Unit | W1 | F1 |

|---|---|---|---|

| Base material 1 | MMC 2 SN1 2, SN2 3 | MMC 2 SN1 2, SN2 3 | |

| HT1 3, HT2 3 | |||

| Counter material 1 | 1.4108 | ||

| Normal load (pre-set normal load) | N | 2.0 ± 0.1 (1.5 ± 0.1) | |

| Stroke | µm | 100 | |

| Frequency | Hz | 50 | |

| Temperature | Room temperature | ||

| Duration | s | 7200 | 2700 |

| Track length | m | 72 | 27 |

| Experimental Section | Method | Step | RE Type | DAQ Rate | E vs. RE /V | Exposure Time or Scan Rate |

|---|---|---|---|---|---|---|

| Tribometric | OCP | et072 (gel) | 10 Hz | |||

| Potentiodynamic | OCP | 1 | K0265 (salt water) + gel bridge | 10 Hz | – | until stable |

| CC | 2 | −1.2 | 300 s | |||

| CV | 3 | as increment per 0.0010 V | {−1.2| + 0.8|−1.2} | 0.0025 V s−1 | ||

| PDYN | 4 | {−1.2| + 1.6 1 |−0.4} | 0.0010 V s−1 2 0.0050 V s−1 3 | |||

| Potentiostatic | OCP | 1 | K0265 (salt water) + gel bridge | 10 Hz | – | until stable |

| PSTAT | 2 | start: 10 Hz steady: 1 Hz | see text | see text |

| pH | c (W4+; W6+; Ni2+) /mol L−1 | W→W4+ (WO2) E/V | W→W6+ (WO3, WO42−) E/V | Ni→Ni2+ (Ni2+) E/V |

|---|---|---|---|---|

| 7 | 10−6 | −0.621 | −0.554 | −0.413 |

| 5 | −0.503 | −0.436 | −0.413 | |

| 3 | −0.385 | −0.318 | −0.413 | |

| 7 | 10−4 | −0.591 | −0.495 | −0.354 |

| 5 | −0.473 | −0.377 | −0.354 | |

| 3 | −0.355 | −0.259 | −0.354 |

| Wa 1 | E(x) /V | –Itot /10−6 A | –I(x) /10−6 A | |||||

|---|---|---|---|---|---|---|---|---|

| 0.1 | −0.25 | −0.183 | −0.053 | −0.026 | 10 | 7.3 | 2.2 | 1.0 |

| 0.04 | −0.152 | −0.021 | −0.001 | 6.1 | 0.8 | 0.2 | ||

| 0.01 | −0.092 | −0.002 | 0 | 3.7 | 0.07 | 0.003 | ||

| 0.004 | −0.051 | 0 | 0 | 2.1 | 0.004 | <0.0001 | ||

| @ position x/cm | 0 | 0.1 | 0.5 | 0.8 | 0 | 0.1 | 0.5 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kronberger, M.; Brenner, J. Tribocorrosive Aspects of Tungsten Carbide, Silicon Nitride, and Martensitic Steel under Fretting-like Conditions. Lubricants 2023, 11, 195. https://doi.org/10.3390/lubricants11050195

Kronberger M, Brenner J. Tribocorrosive Aspects of Tungsten Carbide, Silicon Nitride, and Martensitic Steel under Fretting-like Conditions. Lubricants. 2023; 11(5):195. https://doi.org/10.3390/lubricants11050195

Chicago/Turabian StyleKronberger, Markus, and Josef Brenner. 2023. "Tribocorrosive Aspects of Tungsten Carbide, Silicon Nitride, and Martensitic Steel under Fretting-like Conditions" Lubricants 11, no. 5: 195. https://doi.org/10.3390/lubricants11050195

APA StyleKronberger, M., & Brenner, J. (2023). Tribocorrosive Aspects of Tungsten Carbide, Silicon Nitride, and Martensitic Steel under Fretting-like Conditions. Lubricants, 11(5), 195. https://doi.org/10.3390/lubricants11050195