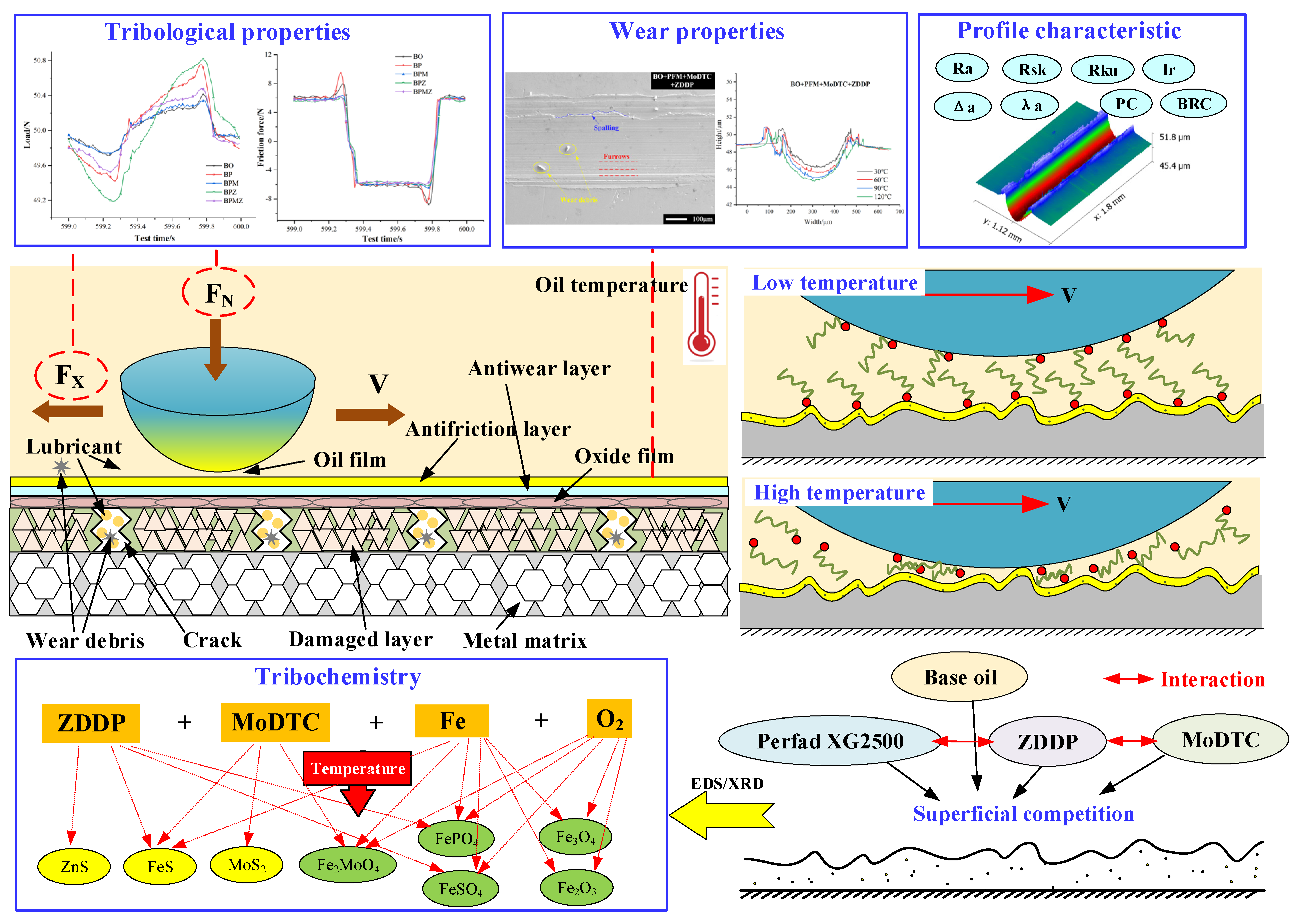

Tribological Properties of Polymer Friction Improvers Combined with MoDTC/ZDDP at Different Temperatures

Abstract

1. Introduction

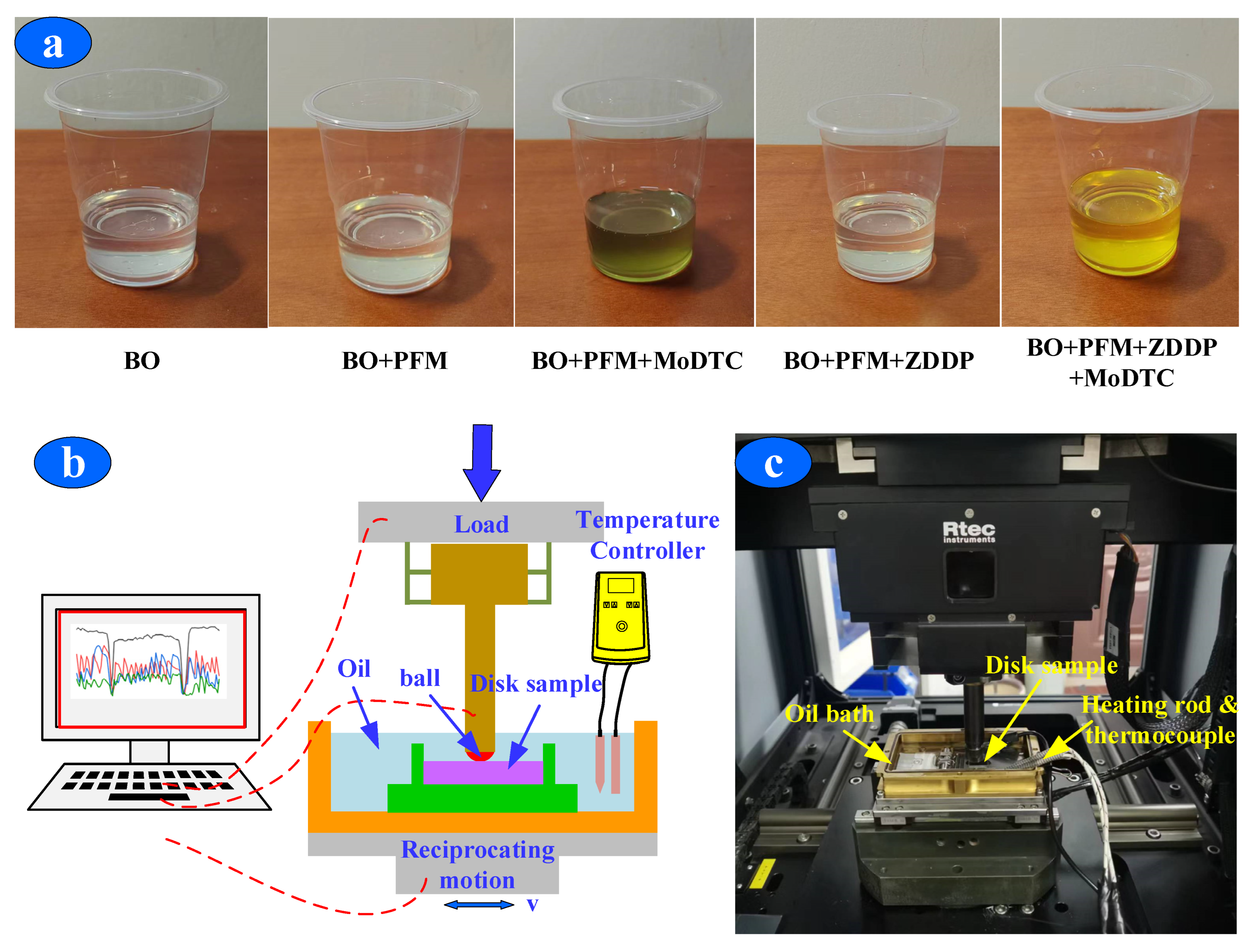

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Procedures

3. Results and Discussions

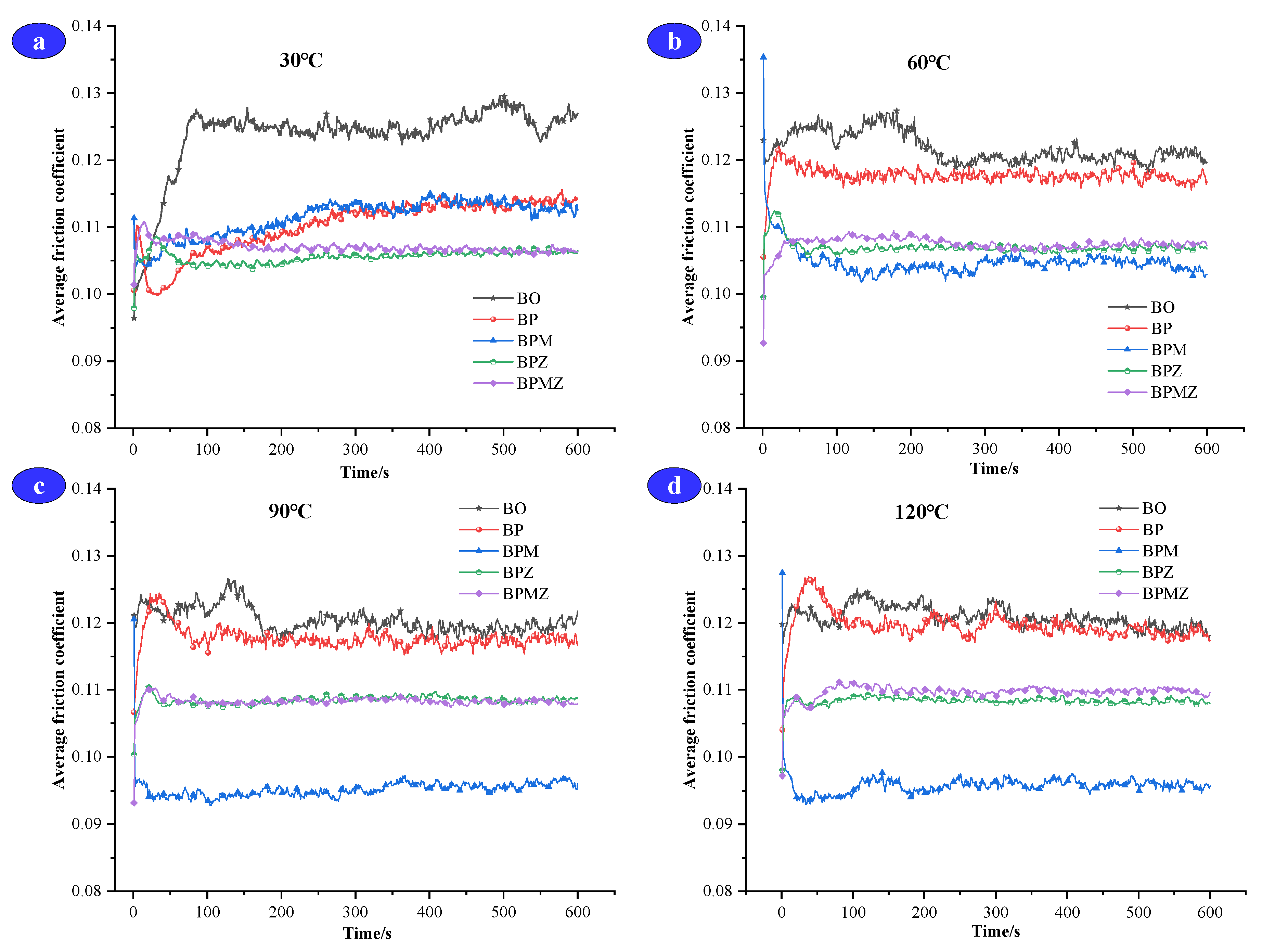

3.1. Tribological Properties of Samples

3.1.1. Average Friction Coefficients

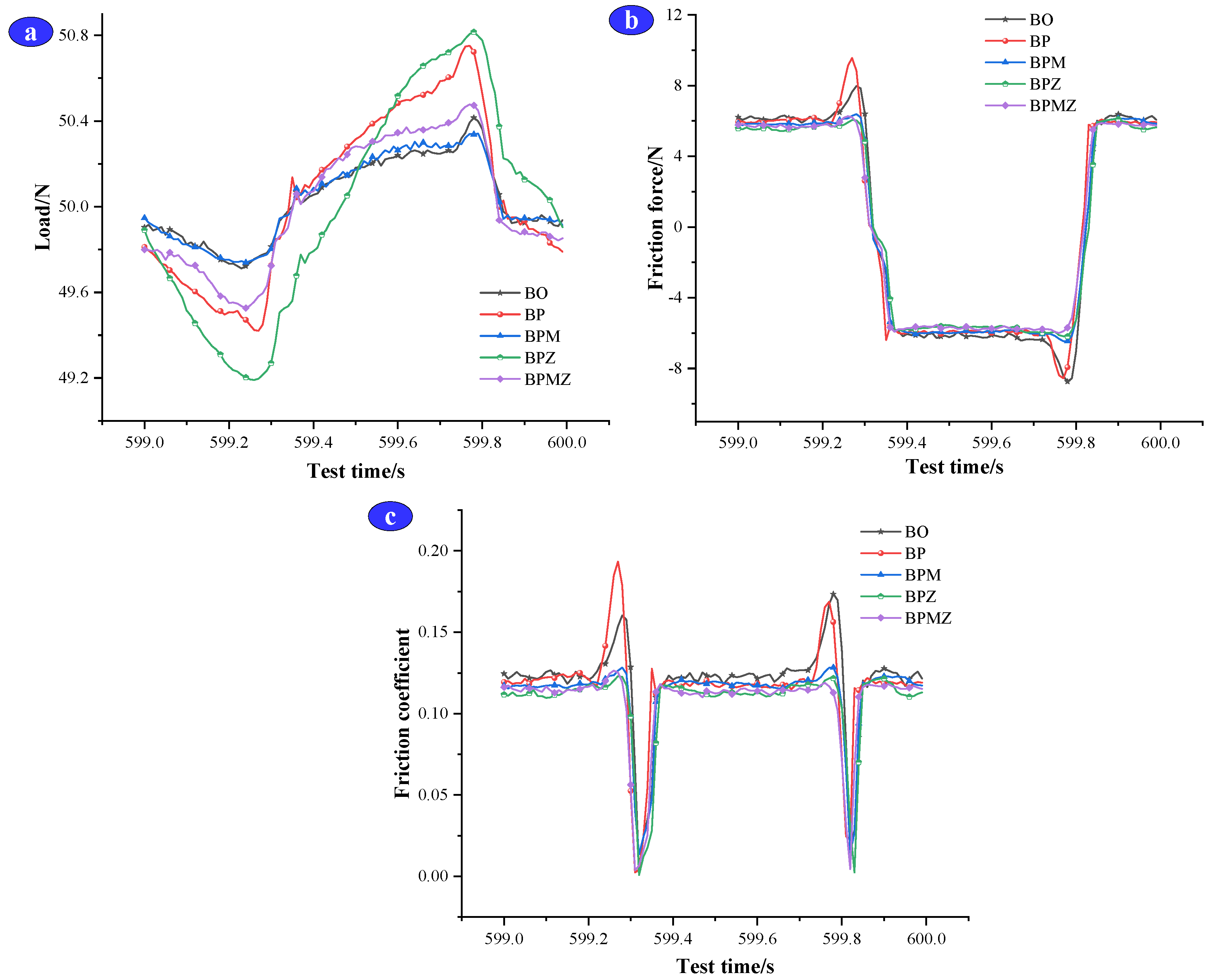

3.1.2. Analysis of Instantaneous Characteristics

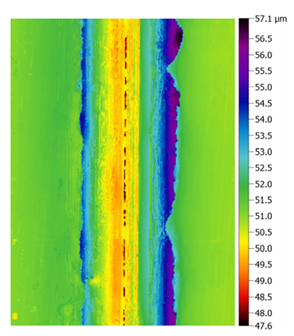

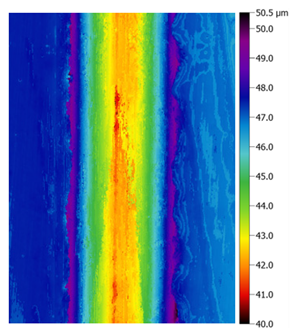

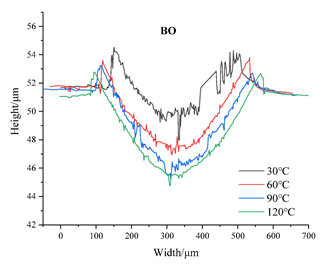

3.2. Worn Surface Analysis

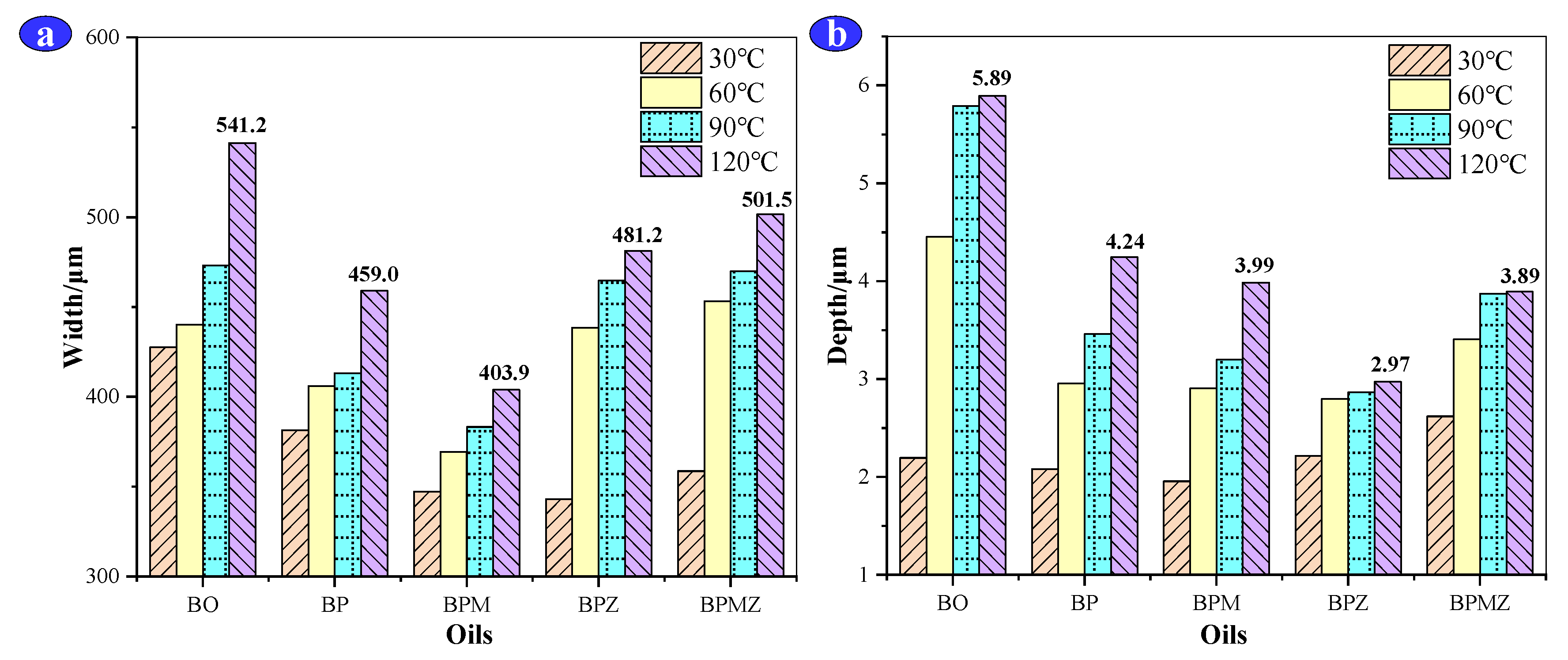

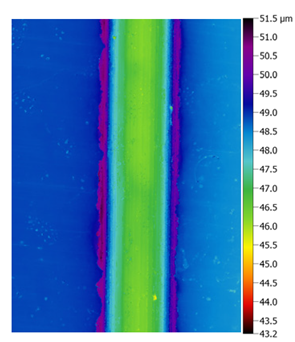

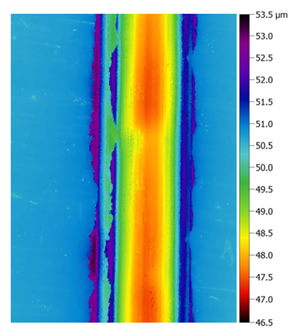

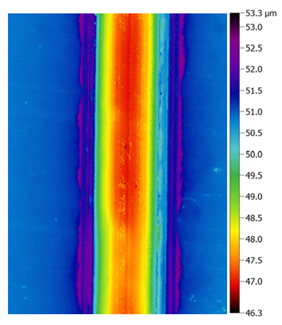

3.2.1. Analysis of Wear Morphology

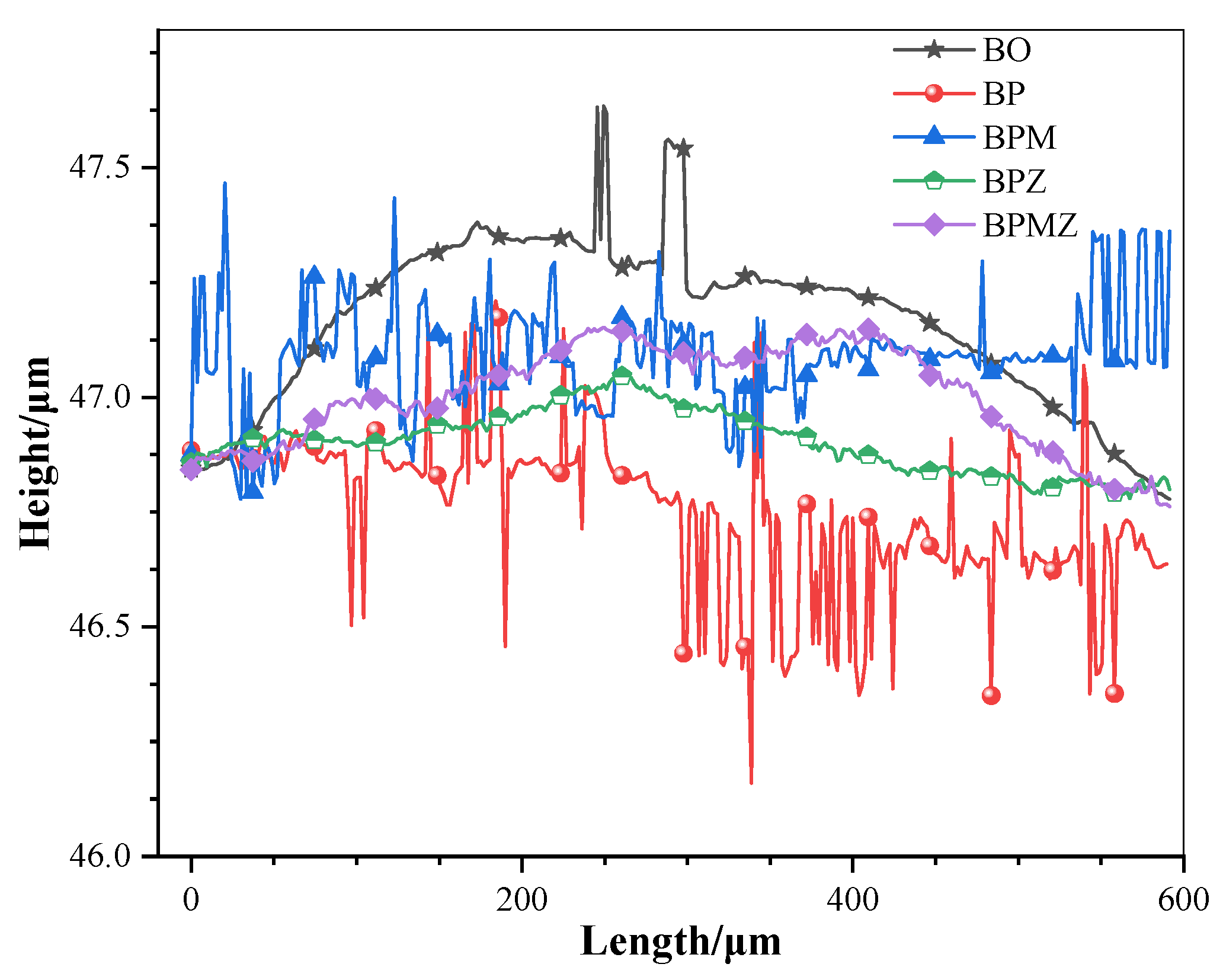

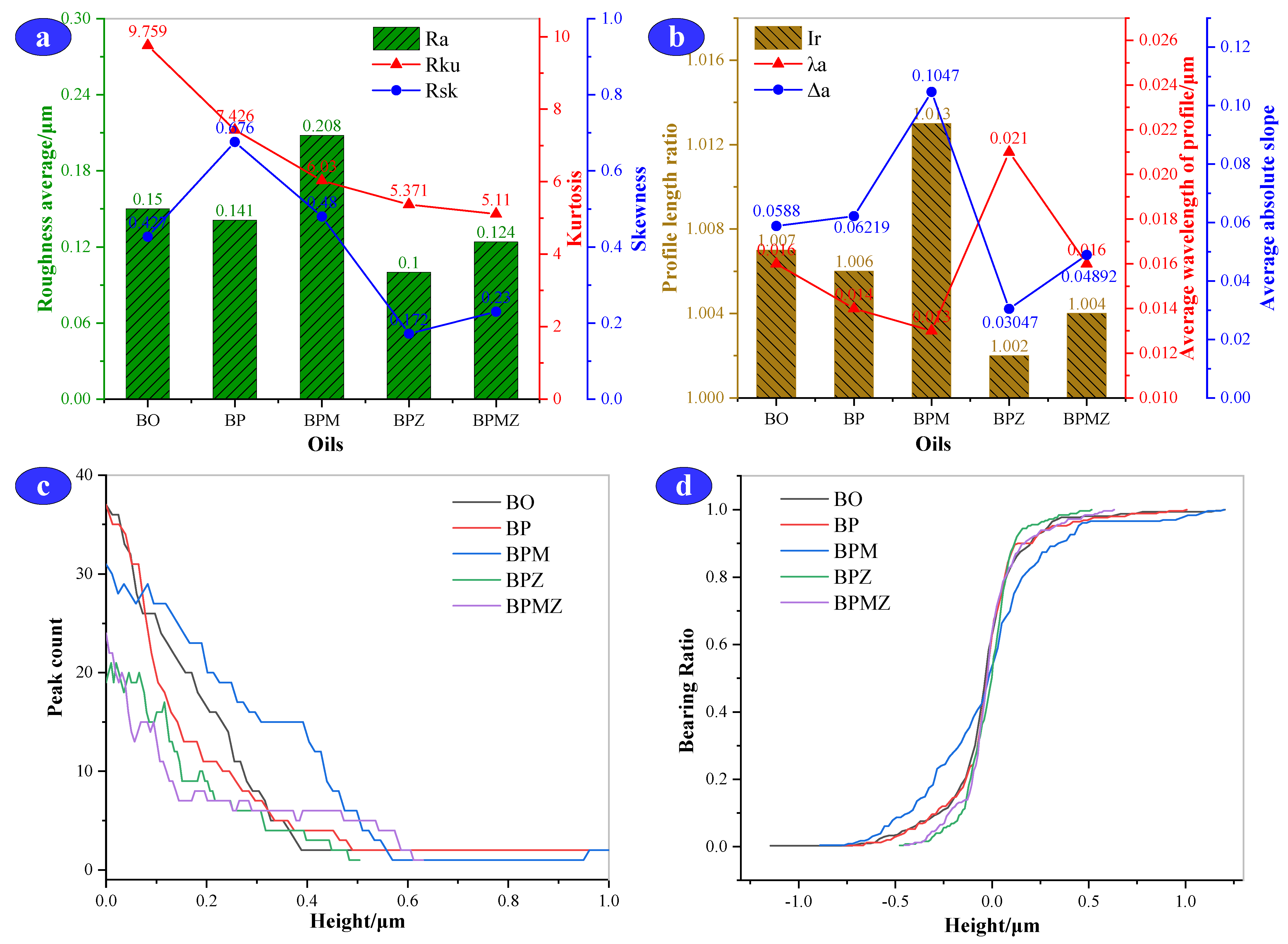

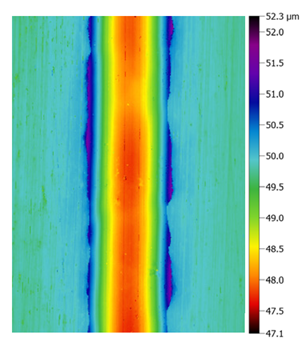

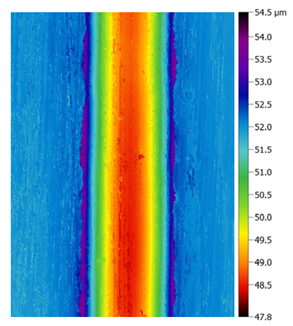

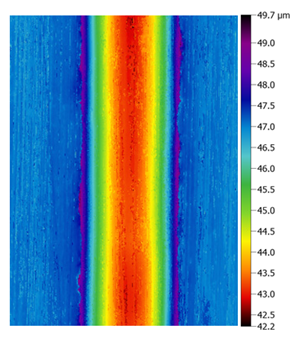

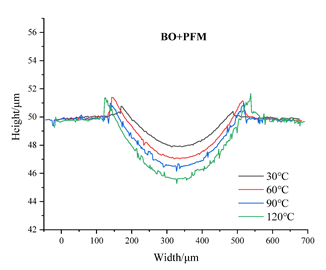

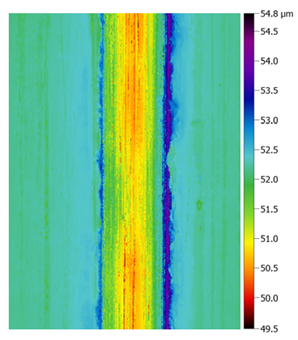

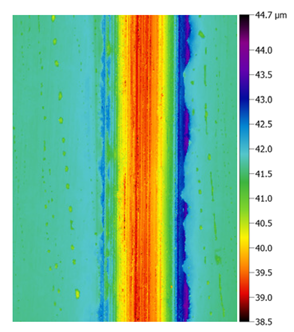

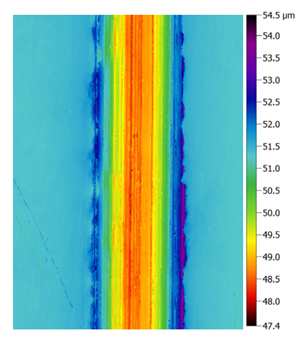

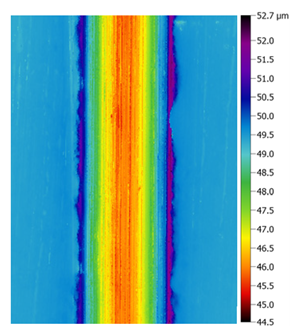

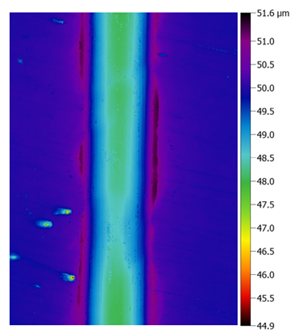

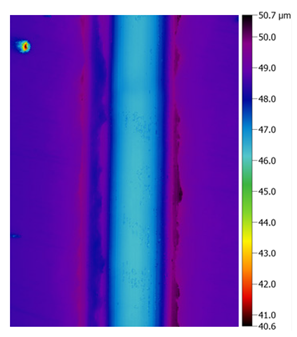

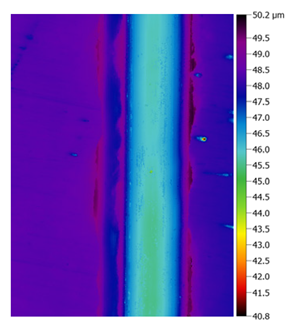

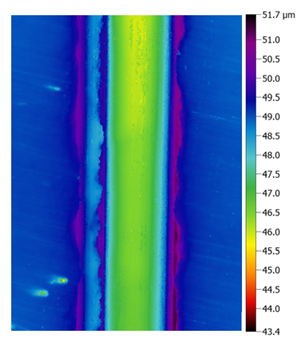

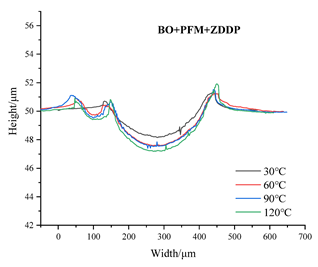

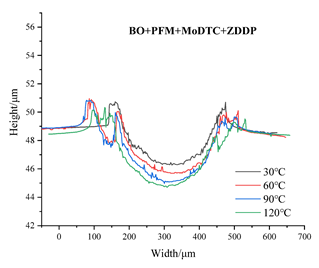

3.2.2. Surface Profile Characteristics

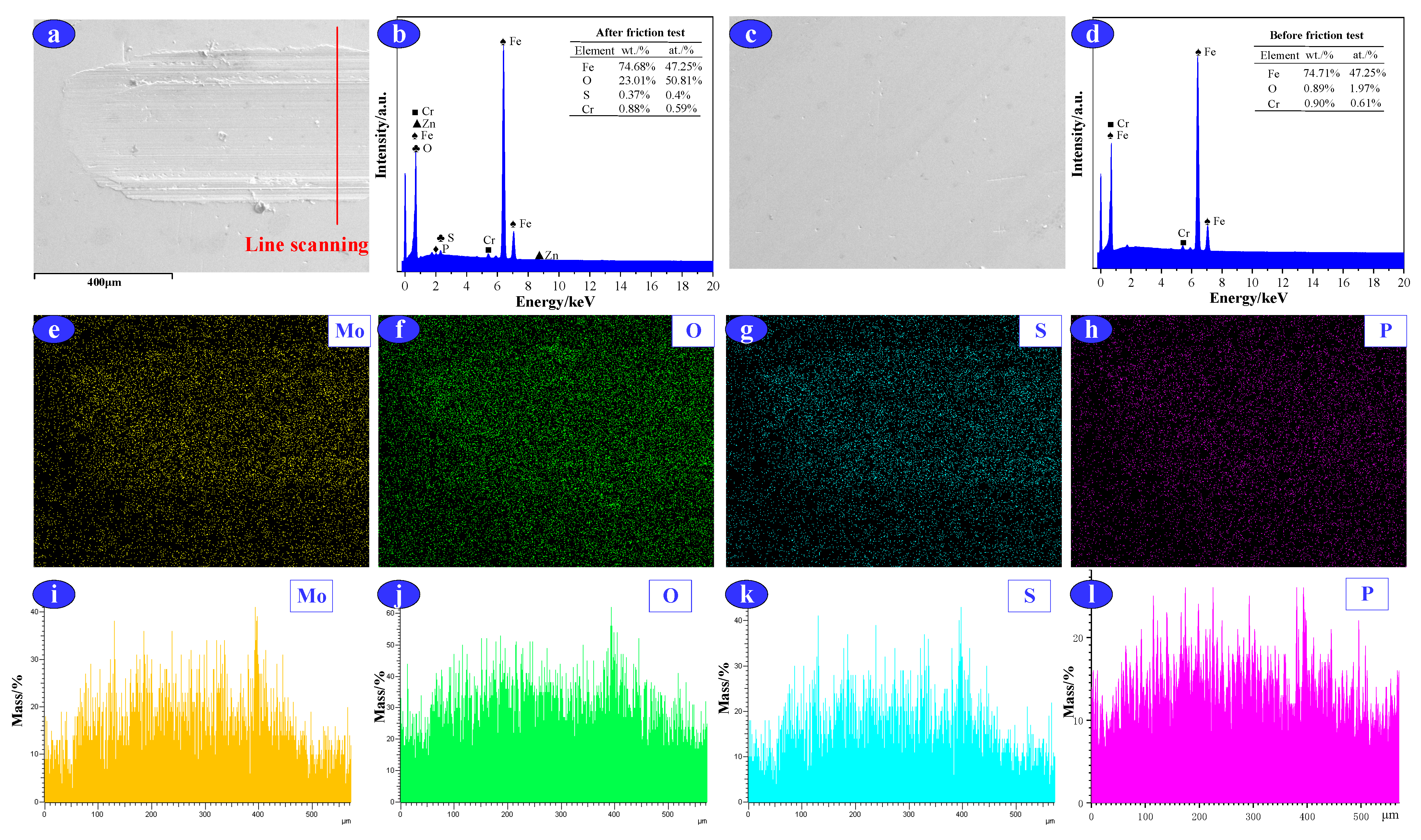

3.2.3. Element Analysis of Worn Surface

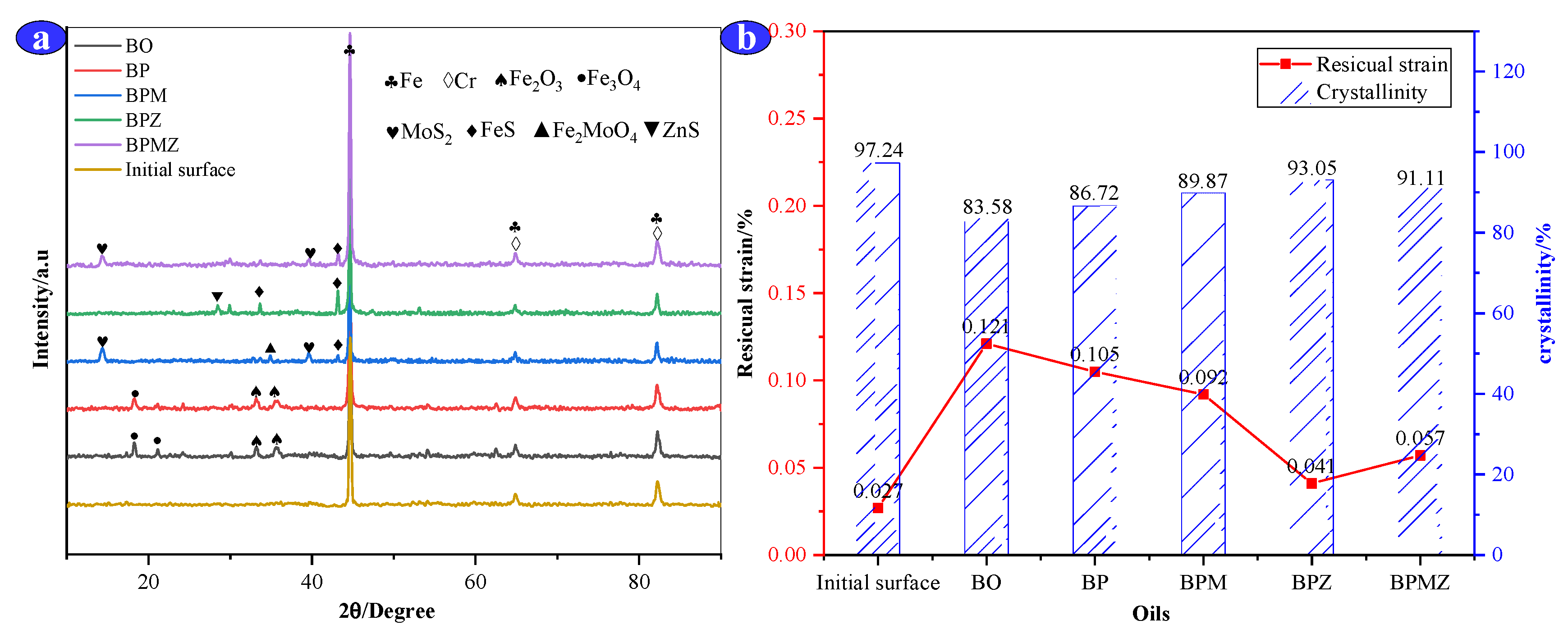

3.2.4. XRD

3.3. Interaction Mechanism of PFM with MoDTC/ZDDP

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tormos, B.; Ramírez, L.; Johansson, J.; Björling, M.; Larsson, R. Fuel consumption and friction benefits of low viscosity engine oils for heavy duty applications. Tribol. Int. 2017, 110, 23–34. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Z.; Feng, Y.; Diao, Z.; Liu, Z. The Effects of Ultra-Low Viscosity Engine Oil on Mechanical Efficiency and Fuel Economy. Energies 2021, 14, 2320. [Google Scholar] [CrossRef]

- Anderson, W.B.; Guinther, G.H. Engine Oil Fuel Economy: Benefits and Potential Debits of Low Viscosity Engine Oil. SAE Int. J. Adv. Curr. Pract. Mobil. 2019, 2, 368–375. [Google Scholar] [CrossRef]

- Ito, A.; Chubachi, Y.; Yamamoto, T.; Tanaka, N.; Moriizumi, Y.; Yari, K.; Otterholm, B. A study on effects of low viscosity engine oil and MoDTC on piston friction losses in a DI diesel engine (No. 2015-01-2044). SAE Tech. Pap. [CrossRef]

- Vaitkunaite, G.; Espejo, C.; Thiebaut, B.; Neville, A.; Morina, A. Low friction tribofilm formation and distribution on an engine cylinder tested with MoDTC-containing low viscosity engine lubricants. Tribol. Int. 2022, 171, 107551. [Google Scholar] [CrossRef]

- Sagawa, T.; Nakano, S.; Shouganji, I.; Okuda, S.; Nakajo, T. MR20DD Motoring Fuel Economy Test for 0W-12 and 0W-8 Low Viscosity Engine Oil (No. 2019-01-2295). SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Sander, D.E.; Allmaier, H.; Knauder, C.; Strömstedt, F. Potentials and Risks of Reducing Friction with Future Ultra-low-viscosity Engine Oils. MTZ Worldw. 2018, 79, 20–27. [Google Scholar] [CrossRef]

- Bordignon, R.; Salvaro, D.; Binder, C.; Klein, A.N.; Drago, V.; de Mello, J.D.B. Tribological Behaviour of Plasma-Functionalized Graphene as Low-Viscosity Oil Additive. Tribol. Lett. 2018, 66, 114. [Google Scholar] [CrossRef]

- Tang, Z.; Li, S. A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr. Opin. Solid State Mater. Sci. 2014, 18, 119–139. [Google Scholar] [CrossRef]

- Aoki, S.; Yamada, Y.; Fukada, D.; Suzuki, A.; Masuko, M. Verification of the advantages in friction-reducing performance of organic polymers having multiple adsorption sites. Tribol. Int. 2013, 59, 57–66. [Google Scholar] [CrossRef]

- Gmür, T.A.; Mandal, J.; Cayer-Barrioz, J.; Spencer, N.D. Towards a Polymer-Brush-Based Friction Modifier for Oil. Tribol. Lett. 2021, 69, 124. [Google Scholar] [CrossRef]

- Gmür, T.A. Polymeric Friction Modifiers in Oil: Synthesis, Adsorption and Tribological Evaluation. Ph.D. Dissertation, ETH Zurich, Zürich, Switzerland, 2021. [Google Scholar]

- Cyriac, F.; Yi, T.X.; Poornachary, S.K.; Chow, P.S. Boundary lubrication performance of polymeric and organic friction modifiers in the presence of an anti-wear additive. Tribol. Int. 2022, 165, 107256. [Google Scholar] [CrossRef]

- Shen, W.; Hirayama, T.; Yamashita, N.; Adachi, M.; Oshio, T.; Tsuneoka, H.; Tagawa, K.; Yagishita, K.; Yamada, N.L. Relationship between interfacial adsorption of additive molecules and reduction of friction coefficient in the organic friction modifiers-ZDDP combinations. Tribol. Int. 2022, 167, 107365. [Google Scholar] [CrossRef]

- Guegan, J.; Southby, M.; Spikes, H. Friction Modifier Additives, Synergies and Antagonisms. Tribol. Lett. 2019, 67, 83. [Google Scholar] [CrossRef]

- Kossoko, N.F.; Dubreuil, F.; Thiébaut, B.; Belin, M.; Minfray, C. Diblock polymeric friction modifier (PFM) in the boundary regime: Tribological conditions leading to low friction. Tribol. Int. 2021, 163, 107186. [Google Scholar] [CrossRef]

- Delamarre, S.; Gmür, T.; Spencer, N.D.; Cayer-Barrioz, J. Polymeric Friction Modifiers: Influence of Anchoring Chemistry on Their Adsorption and Effectiveness. Langmuir 2022, 38, 11451–11458. [Google Scholar] [CrossRef]

- Murdoch, T.J.; Pashkovski, E.; Patterson, R.; Carpick, R.W.; Lee, D. Sticky but Slick: Reducing Friction Using Associative and Nonassociative Polymer Lubricant Additives. ACS Appl. Polym. Mater. 2020, 2, 4062–4070. [Google Scholar] [CrossRef]

- Yamashita, N.; Hirayama, T.; Yamada, N.L.; Watanabe, H.; Onodera, K.; Sato, T. Highly Swollen Adsorption Layer Formed by Polymeric Friction Modifier Providing Low Friction at Higher Temperature. Tribol. Lett. 2021, 69, 65. [Google Scholar] [CrossRef]

- Moody, G.; Eastwood, J.; Ueno, K. The performance and mechanisms of organic polymeric friction modifiers in low viscosity engine oils (No. 2019-01-2204). SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Lundgren, S.M.; Eriksson, K.; Rossenaar, B. Boosting the Friction Performance of Amine Friction Modifiers with MoDTC. SAE Int. J. Fuels Lubr. 2015, 8, 27–30. [Google Scholar] [CrossRef]

- Yazawa, S.; Minami, I.; Prakash, B. Reducing Friction and Wear of Tribological Systems through Hybrid Tribofilm Consisting of Coating and Lubricants. Lubricants 2014, 2, 90–112. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, T.; Shang, W.; Sun, L.; Liu, D.; Tong, D.; Liu, S. Environmental friendly polyisobutylene-based ionic liquid containing chelated orthoborate as lubricant additive: Synthesis, tribological properties and synergistic interactions with ZDDP in hydrocarbon oils. Tribol. Int. 2017, 115, 297–306. [Google Scholar] [CrossRef]

- Somayaji, A.; Aswath, P.B. Antiwear Behavior of ZDDP and Fluorinated ZDDP in the Presence of Alkylated Diphenyl Amine Antioxidants. Tribol. Trans. 2008, 51, 403–412. [Google Scholar] [CrossRef]

- Liskiewicz, G.; Kula, P.; Neville, A.; Pietrasik, R.; Morina, A.; Liskiewicz, T. Hydrogen influence on material interaction with ZDDP and MoDTC lubricant additives. Wear 2013, 297, 966–971. [Google Scholar] [CrossRef]

- Roshan, R.; Priest, M.; Neville, A.; Morina, A.; Xia, X.; Warrens, C.P.; Payne, M.J. Friction Modelling in Boundary Lubrication Considering the Effect of MoDTC and ZDDP in Engine Oils. Tribol. Online 2011, 6, 301–310. [Google Scholar] [CrossRef]

- Balarini, R.; Diniz, G.A.S.; Profito, F.J.; Souza, R.M.D. Comparison of unidirectional and reciprocating tribometers in tests with MoDTC-containing oils under boundary lubrication. Tribol. Int. 2020, 149, 105686. [Google Scholar] [CrossRef]

- Lu, R.; Shiode, S.; Tani, H.; Tagawa, N.; Koganezawa, S. A study on the tribofilm growth and tribological properties of tribofilms formed from zinc dialkyl dithiophosphate (ZDDP) and molybdenu Lu m dialkyl dithiocarbamate (MoDTC). Tribol. Online 2018, 13, 157–165. [Google Scholar] [CrossRef]

- Xu, D.; Wang, C.; Espejo, C.; Wang, J.; Neville, A.; Morina, A. Understanding the Friction Reduction Mechanism Based on Molybdenum Disulfide Tribofilm Formation and Removal. Langmuir 2018, 34, 13523–13533. [Google Scholar] [CrossRef]

- De Feo, M.; Minfray, C.; Bouchet, M.I.D.B.; Thiebaut, B.; Martin, J.M. MoDTC friction modifier additive degradation: Correlation between tribological performance and chemical changes. RSC Adv. 2015, 5, 93786–93796. [Google Scholar] [CrossRef]

- Espejo, C.; Wang, C.; Thiébaut, B.; Charrin, C.; Neville, A.; Morina, A. The role of MoDTC tribochemistry in engine tribology performance. A Raman microscopy investigation. Tribol. Int. 2020, 150, 106366. [Google Scholar] [CrossRef]

- Mahdi, I.; Garg, R.; Srivastav, A. ZDDP-An inevitable lubricant additive for engine oils. Int. J. Eng. Invent. 2012, 1, 47–48. [Google Scholar]

- Kano, M.; Yasuda, Y.; Ye, J.P. The effect of ZDDP and MoDTC additives in engine oil on the friction properties of DLC-coated and steel cam followers. Lubr. Sci. 2004, 17, 95–103. [Google Scholar] [CrossRef]

- Peeters, S.; Restuccia, P.; Loehlé, S.; Thiebaut, B.; Righi, M.C. Tribochemical reactions of MoDTC lubricant additives with iron by quantum mechanics/molecular mechanics simulations. J. Phys. Chem. C 2020, 124, 13688–13694. [Google Scholar] [CrossRef]

- Chien, H.H.; Ma, K.J.; Vattikuti, S.P.; Kuo, C.H.; Huo, C.B.; Chao, C.L. Tribological behaviour of MoS2/Au coatings. Thin Solid Films 2010, 518, 7532–7534. [Google Scholar] [CrossRef]

- Manzoor, U.; Zahra, F.T.; Rafique, S.; Moin, M.T.; Mujahid, M. Effect of synthesis temperature, nucleation time, and postsynthesis heat treatment of ZnO nanoparticles and its sensing properties. J. Nanomater. 2015, 16, 9. [Google Scholar] [CrossRef]

| Base Oil (BO) + Additive | Additive Content | KV (40 °C)/cSt | KV (100 °C)/cSt | HTHS (150 °C)/cP |

|---|---|---|---|---|

| BO | Base oil + Compound functional additive package | 27.68 | 6.422 | 2.41 |

| BO + PFM (BP) | BO + Perfad XG 2500 (0.5 wt%) | 28.56 | 6.63 | 2.49 |

| BO + PFM + MoDTC (BPM) | BO+ Perfad XG 2500(0.5 wt%) + MoDTC (0.8 wt%) | 28.03 | 6.512 | 2.42 |

| BO + PFM + ZDDP (BPZ) | BO + Perfad XG 2500(0.5 wt%) + ZDDP (0.86 wt%) | 28.62 | 6.689 | 2.41 |

| BO + PFM + MoDTC + ZDDP (BPMZ) | BO + Perfad XG 2500(0.5 wt%) + MoDTC (0.8 wt%) + ZDDP (0.86 wt%) | 29.16 | 6.783 | 2.51 |

| Compositions | Yubase6 | Yubase4+ | Polymethacrylate | Sulfonate | Succinimide | Amine Antioxidant | Silicon Antifoaming Agent | Pour Point Depressant |

|---|---|---|---|---|---|---|---|---|

| wt% | 40 | 50.08 | 6 | 1 | 1.7 | 1 | 0.02 | 0.2 |

| Disc | Hardness | Compositions | Fe | Cr | Co | Mo | Ni | V | Si | Mn | C | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSS-42L | 40HRC | wt% | 65.355 | 13.8 | 13 | 4.5 | 2.11 | 0.6 | 0.25 | 0.21 | 0.15 | 0.025 |

| Ball | Hardness | Compositions | C | Fe | Si | Si3N4 | ||||||

| Si3N4 | 78HRC | wt% | 0.3 | 0.5 | 0.3 | 98.9 |

| Temperature (°C) | Reciprocating Displacement (mm) | Reciprocating Frequency (Hz) | Load (N) | Test Time (min) |

|---|---|---|---|---|

| 30/60/90/120 | 8 | 1 | 50 | 10 |

| Oils | 30 °C (10 min) | 60 °C (20 min) | 90 °C (30 min) | 120 °C (40 min) | Profile |

|---|---|---|---|---|---|

| BO |  |  |  |  |  |

| BP |  |  |  |  |  |

| BPM |  |  |  |  |  |

| BPZ |  |  |  |  |  |

| BPMZ |  |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Y.; Mo, Y.; Lv, J.; Wang, J. Tribological Properties of Polymer Friction Improvers Combined with MoDTC/ZDDP at Different Temperatures. Lubricants 2023, 11, 196. https://doi.org/10.3390/lubricants11050196

Hong Y, Mo Y, Lv J, Wang J. Tribological Properties of Polymer Friction Improvers Combined with MoDTC/ZDDP at Different Temperatures. Lubricants. 2023; 11(5):196. https://doi.org/10.3390/lubricants11050196

Chicago/Turabian StyleHong, Ye, Yimin Mo, Juncheng Lv, and Jun Wang. 2023. "Tribological Properties of Polymer Friction Improvers Combined with MoDTC/ZDDP at Different Temperatures" Lubricants 11, no. 5: 196. https://doi.org/10.3390/lubricants11050196

APA StyleHong, Y., Mo, Y., Lv, J., & Wang, J. (2023). Tribological Properties of Polymer Friction Improvers Combined with MoDTC/ZDDP at Different Temperatures. Lubricants, 11(5), 196. https://doi.org/10.3390/lubricants11050196