3.1. Two-Mass Oscillator

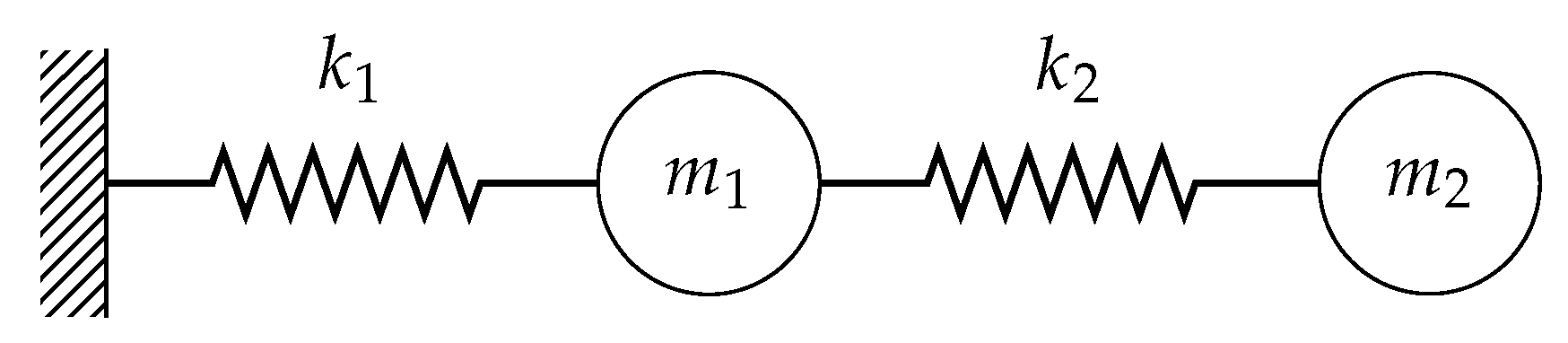

The method described above will be shown on an introductory example of the two-mass oscillator (

Figure 6). We have an original design of the following parameters:

giving the following eigenfrequencies of the system

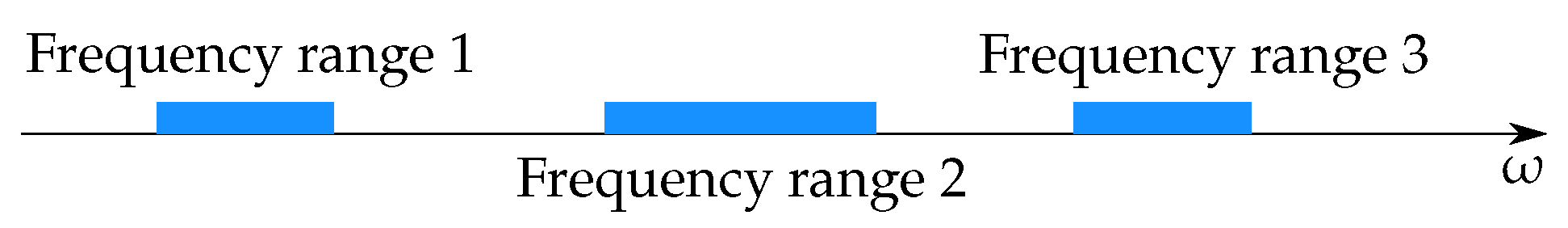

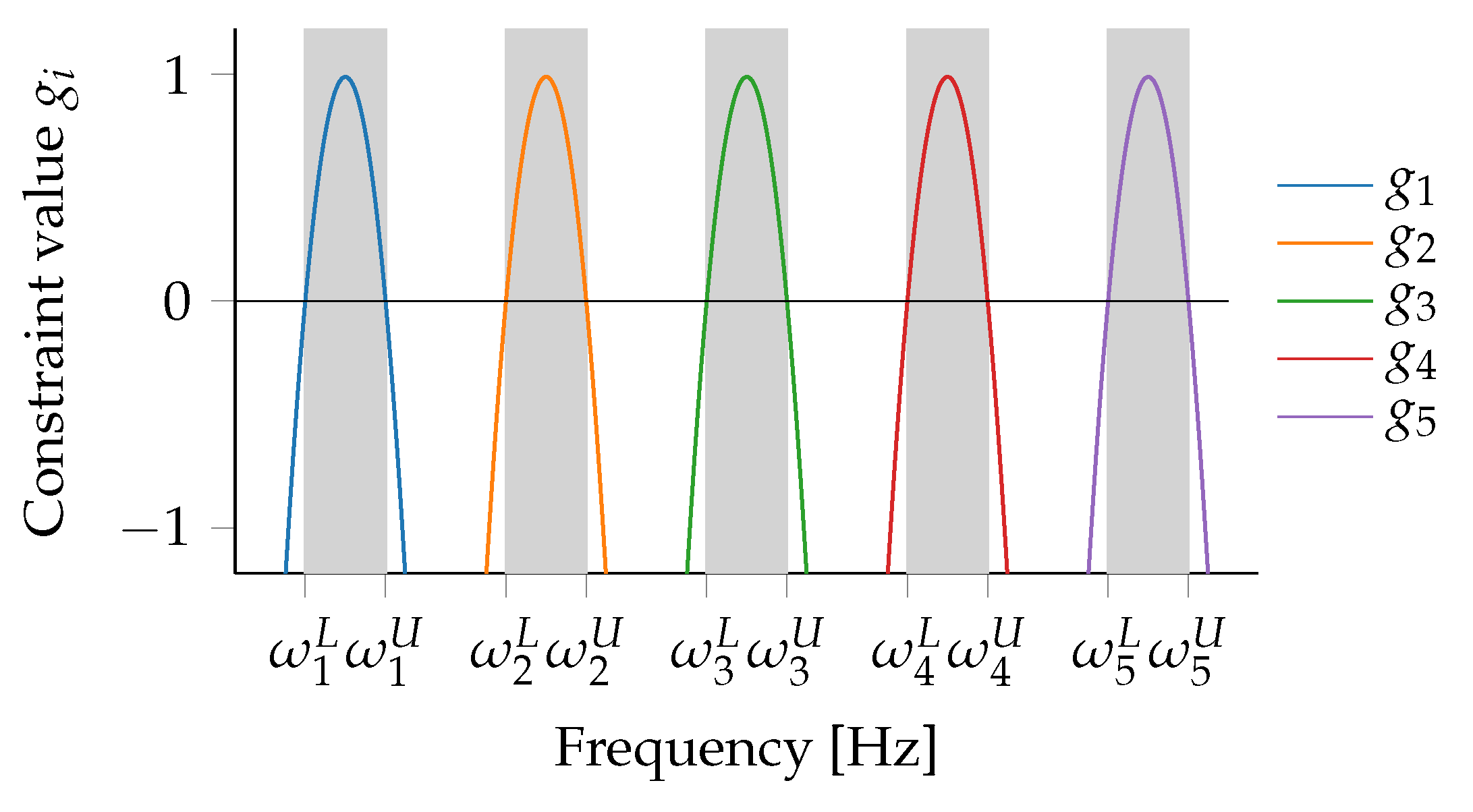

It is now assumed that the eigenbehavior of the system has shifted due to wear or fault, or that the requirements have changed. The constrained regions are defined by

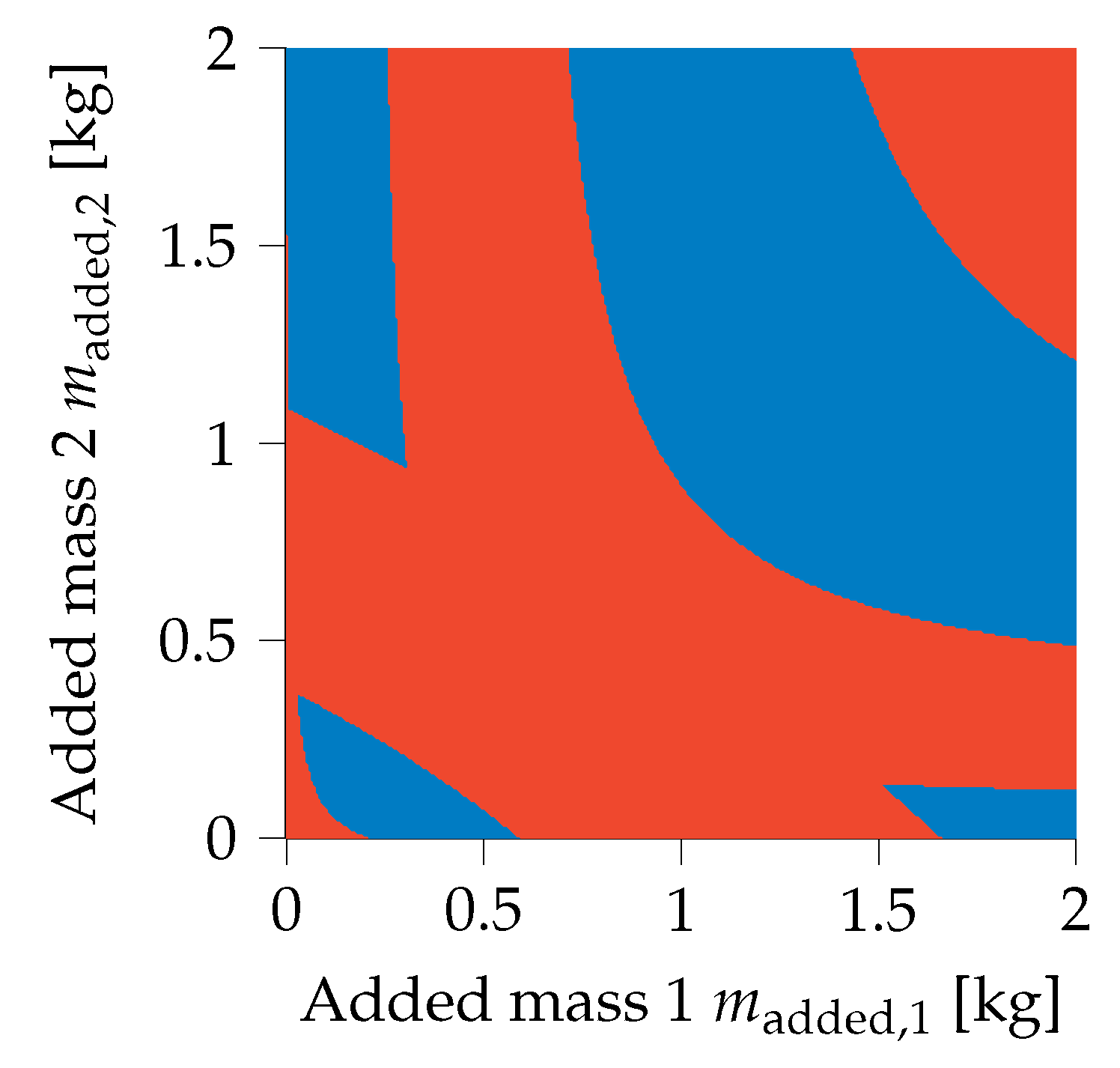

which gives a nonfeasible initial design. A design is to be found in which these frequency ranges are avoided by adding a minimum mass to the system. The resulting design domain of this two-dimensional problem is displayed above in

Figure 5. The optimization formulation is

As added mass can only lower the eigenfrequency, the ballistic constraint function is used here with constant values

and

, resulting in a continuous saw-tooth form, cf.

Section 2.2 and

Figure 4. The optimal design of a two-mass oscillator is solved using the first-order optimization algorithm,

method of moving asymptotes (MMA) [

18] with the above-described analytical sensitivity method. Despite the non-convex design domain as a result of the frequency-band constraints (cf.

Section 2.2 and

Figure 2), it has been shown in [

9,

14,

15] that gradient-based optimization algorithms are efficient and effective. The main design goal here is achieving a feasible design and therefore the risk of the optimum being not globally optimal is acceptable.

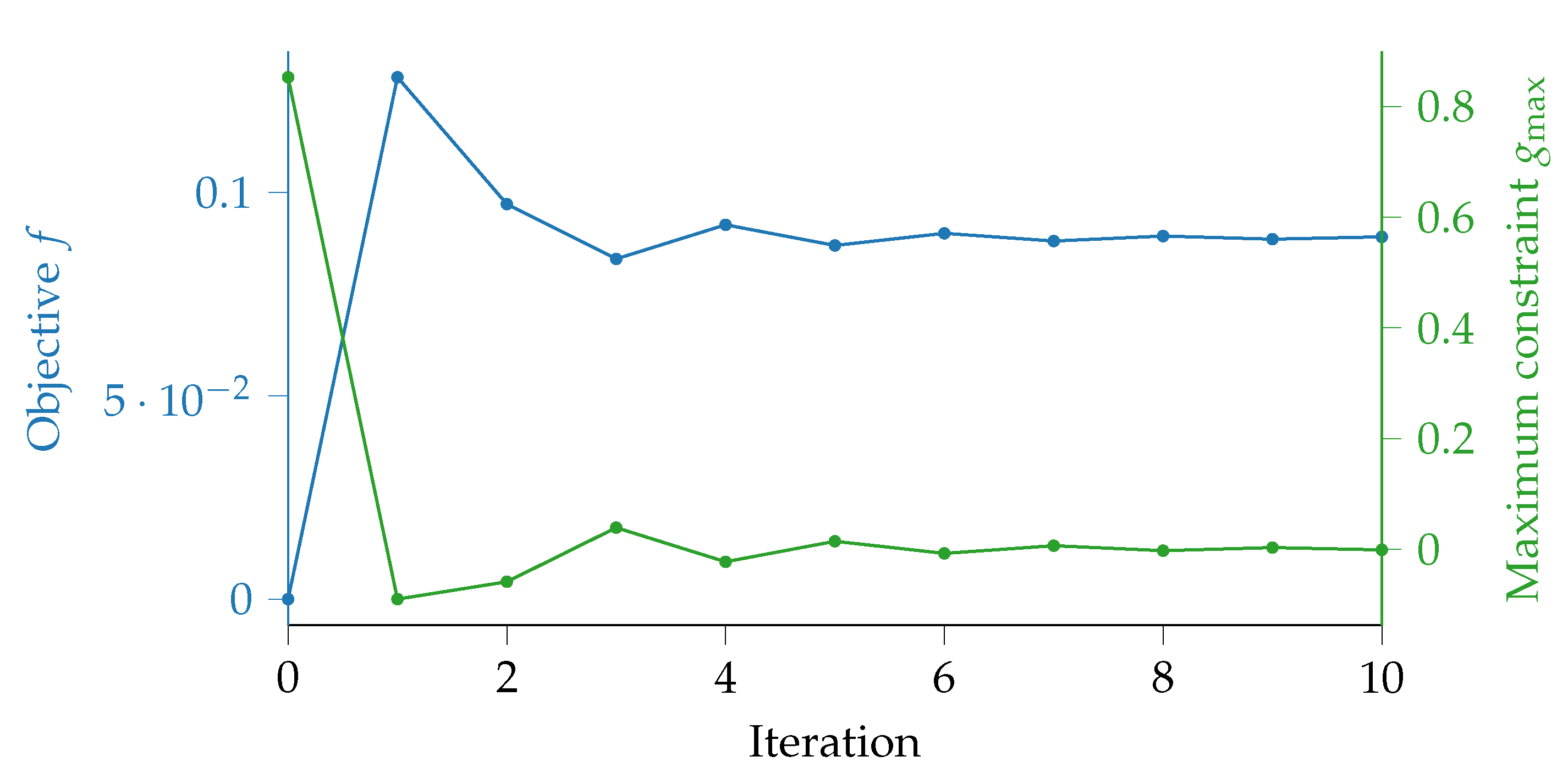

Starting from the lower limit, i.e., the original design, this optimization problem quickly finds a valid design with minimum amount off added mass. With MMA, this needs 11 iterations, which in turn requires 11 system evaluations and 11 sensitivity evaluations. The convergence plot is seen in

Figure 7. The start and optimal values are found in

Table 1.

3.2. Gear Housing

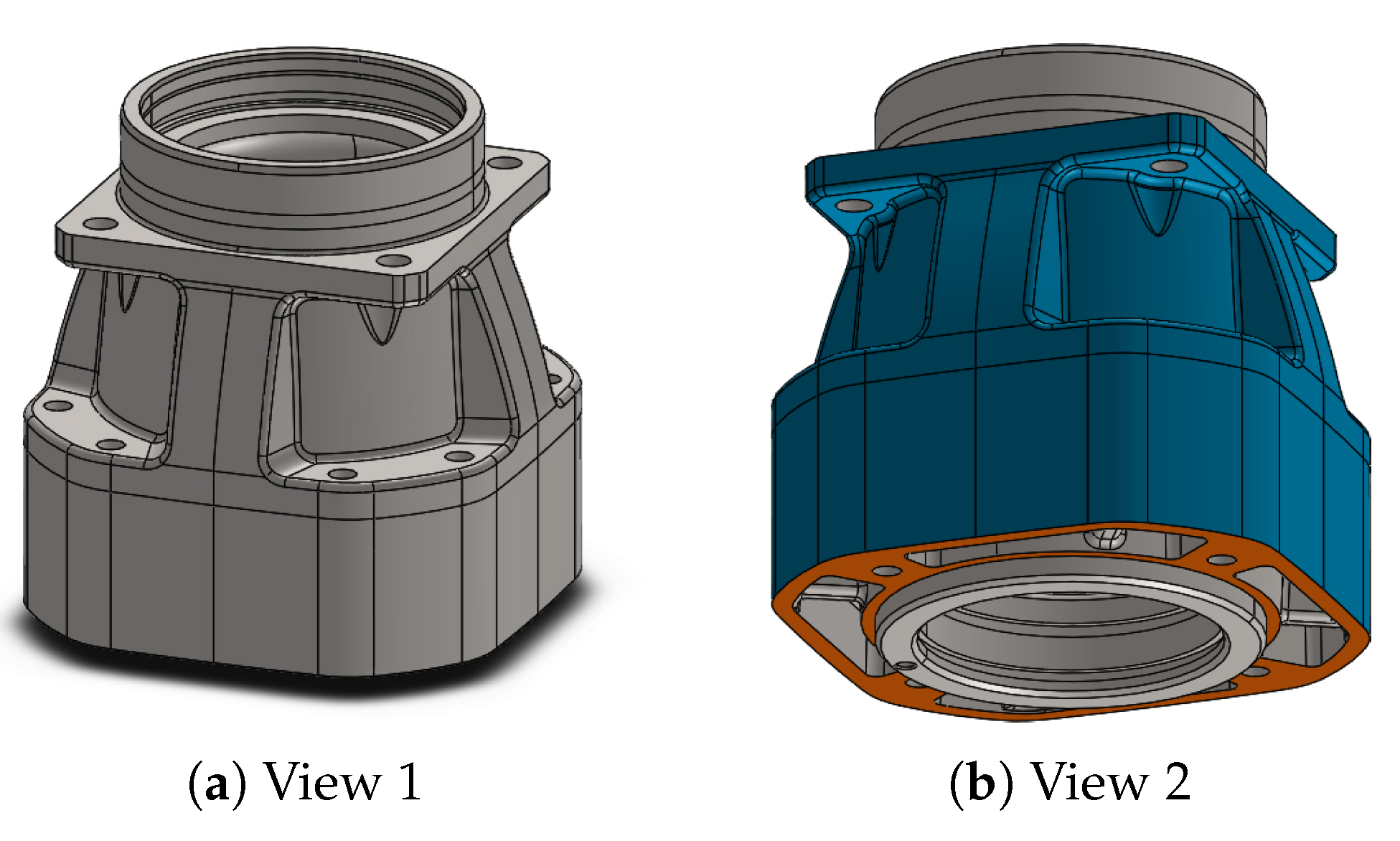

Here, we will show the application of the developed methodology to a large-scale engineering example. A housing of a planetary gear set will be redesigned to find the position and amount of added mass to move it out of critical frequency ranges.

The vibrational behavior of the gear housing is assessed via an eigenvalue analysis of a three-dimensional model with the finite-element method. The geometry is shown in

Figure 8. The base of the housing is sized

and its height is

. The eigenvalue problem of the structural-mechanical model with neglected damping and free vibration is given by

where

is the mass matrix,

is the stiffness matrix,

is the

jth eigenfrequency (the square root of the eigenvalue), and

is the corresponding

jth mode shape (eigenvector). This analysis is solved using the open software Kratos Multiphysics [

19,

20]. The finite-element model consists of 195,970 nodes and 1,077,626 volume elements. It is made of steel and a linear elastic material model is applied with the parameters shown in

Table 2. The bottom face (highlighted in orange in

Figure 8b) is clamped to restrict the structure.

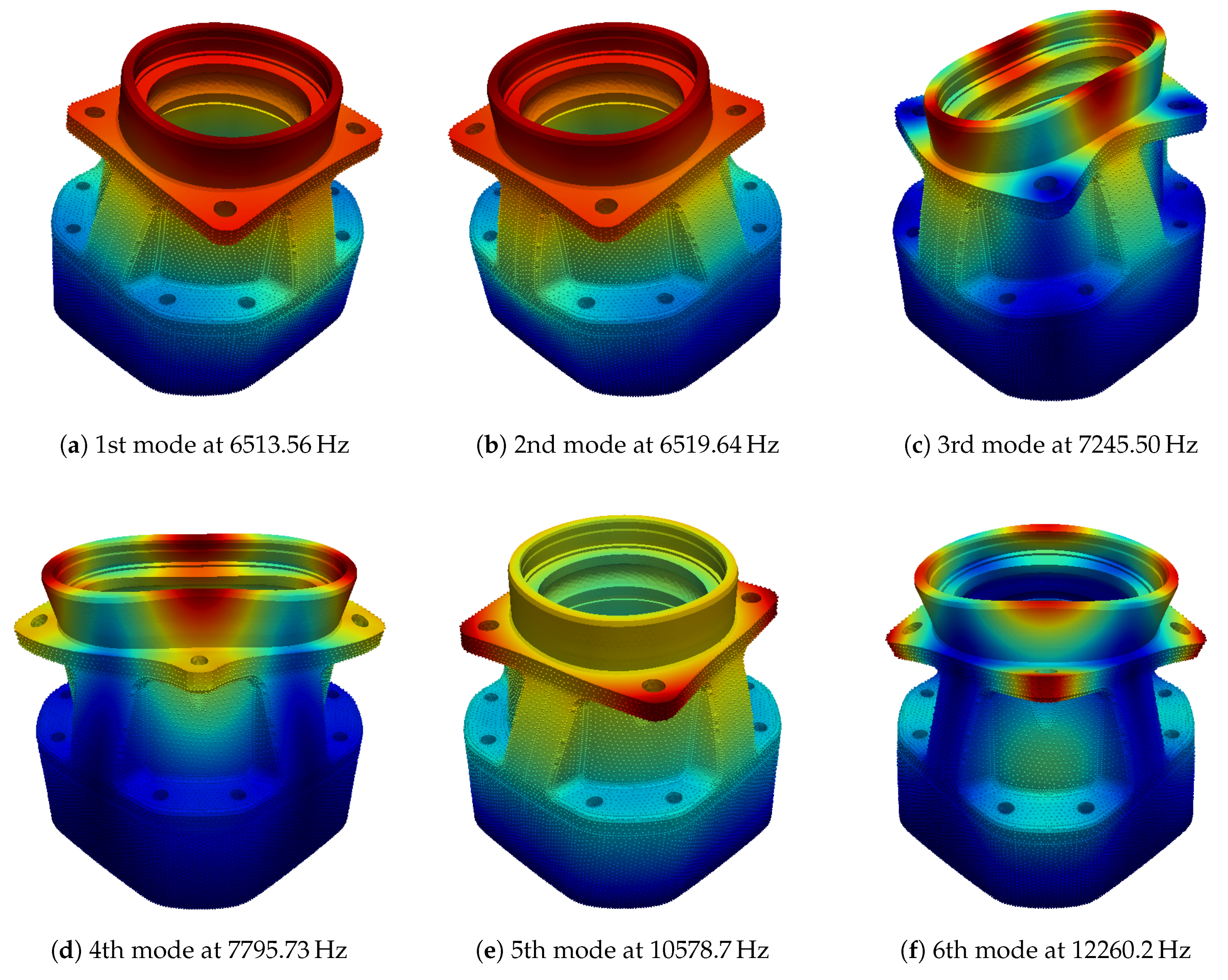

We limit the scope of the analysis and optimal design to the first six eigenfrequencies, whose mode shapes can be seen in

Figure 9.

Studies about the modeling of vibrational behavior of planetary gear sets and the determination of the uncertain eigenfrequencies are introduced by Wehrle et al. [

14], Wehrle et al. [

15].

Table 3 summarizes the frequency ranges which should be avoided by the eigenfrequencies of the housing.

A comparison of these frequency ranges and the computed values show that some eigenfrequencies of the housing are in the forbidden ranges. To move the eigenfrequencies outside of the forbidden frequency ranges, mass can be added to the housing. In this application, mass can be added to all mesh nodes which are on the external surface of the housing, highlighted in blue in

Figure 8b.

The engineering design problem described above is implemented as a numerical optimization problem of the following form:

where the constraint index

. The objective function is the minimization of the added mass. The constraint formulation and sensitivity analysis are performed as described above in

Section 2.2,

Section 2.3 and

Section 2.4. As added mass can only lower the eigenfrequency, the ballistic range constraint function is used with the constants

and

, which is like the two-mass oscillator results in a continuous saw-tooth form, cf.

Figure 4. Design variables are all surface nodes on the highlighted blue surface in

Figure 8b. With this, the vector of design variables are the values of the mass added to these 15,494 nodal mass elements. The lower bound of the design variables is set to zero,

and the upper bound of the design variables is set to a value of

The start vector of the design variables is set to the lower bound values, i.e., the initial structure with no added mass. The design optimization is performed using the toolbox DesOptPy [

21,

22] and the first-order optimization algorithm MMA [

18].

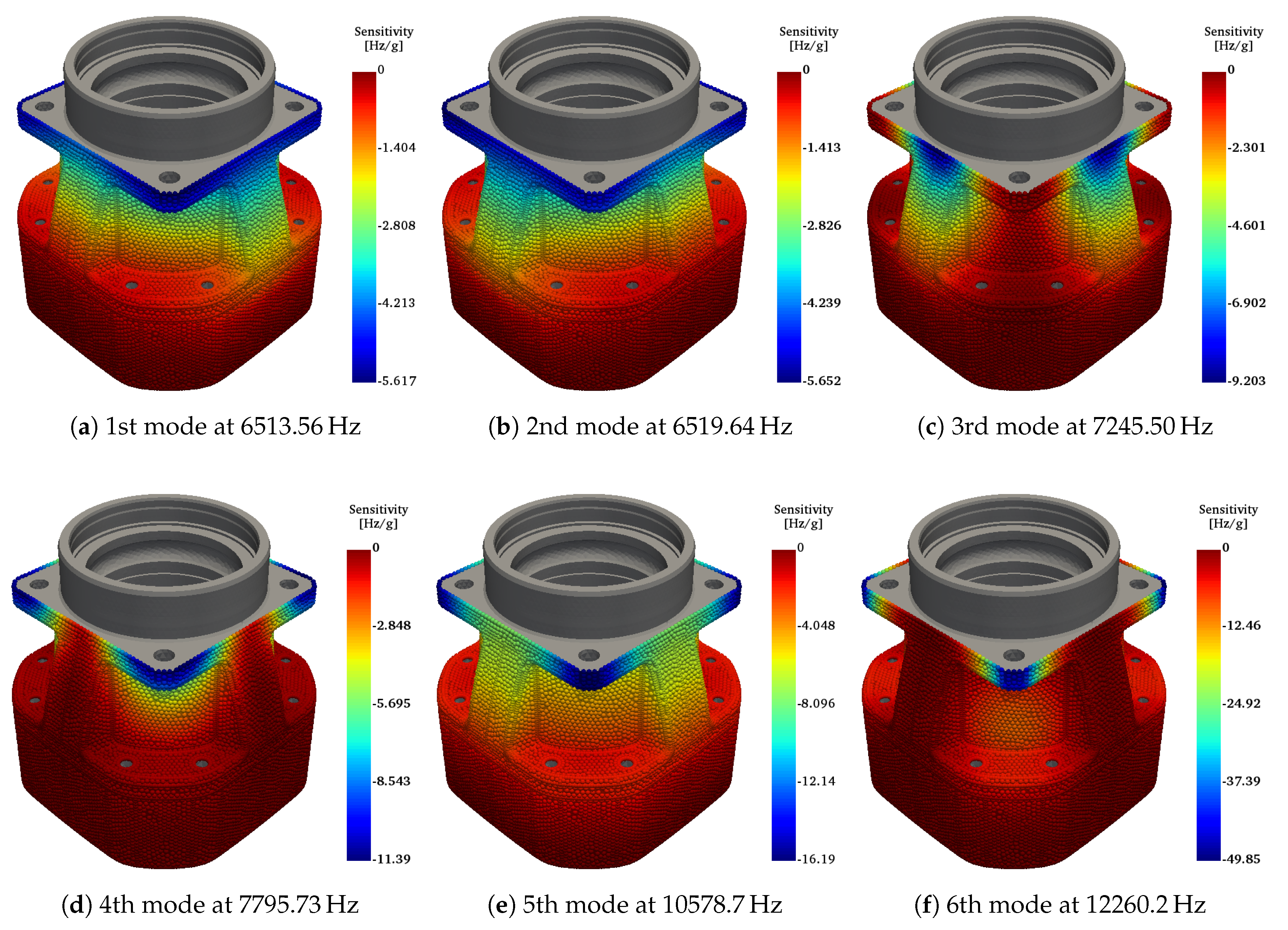

Figure 10 shows the values of eigenfrequency sensitivities

of the initial design (i.e., with no added mass). The sensitivities are calculated by eigenfrequency and the value of the sensitivity with respect to each design variable, i.e., nodal mass,

is represented by the color of the spheres shown in each subfigure. It should be noted that the flat gray (i.e., without spheres) has been designated as non-design domain. As per Equation (

17), the relation between mode shape and sensitivities can be clearly seen, cf.

Figure 9 and

Figure 10. The solution of the eigenvalue problem for the first six modes at the initial design requires approximately nine minutes on a machine with an Intel Core i7-8700 CPU at 3.20 GHz × 12 and 31.4 GiB of random-access memory. The efficiency of the optimization technique is guaranteed with sensitivity computations, which with the method described in

Section 2.3 takes less than one second.

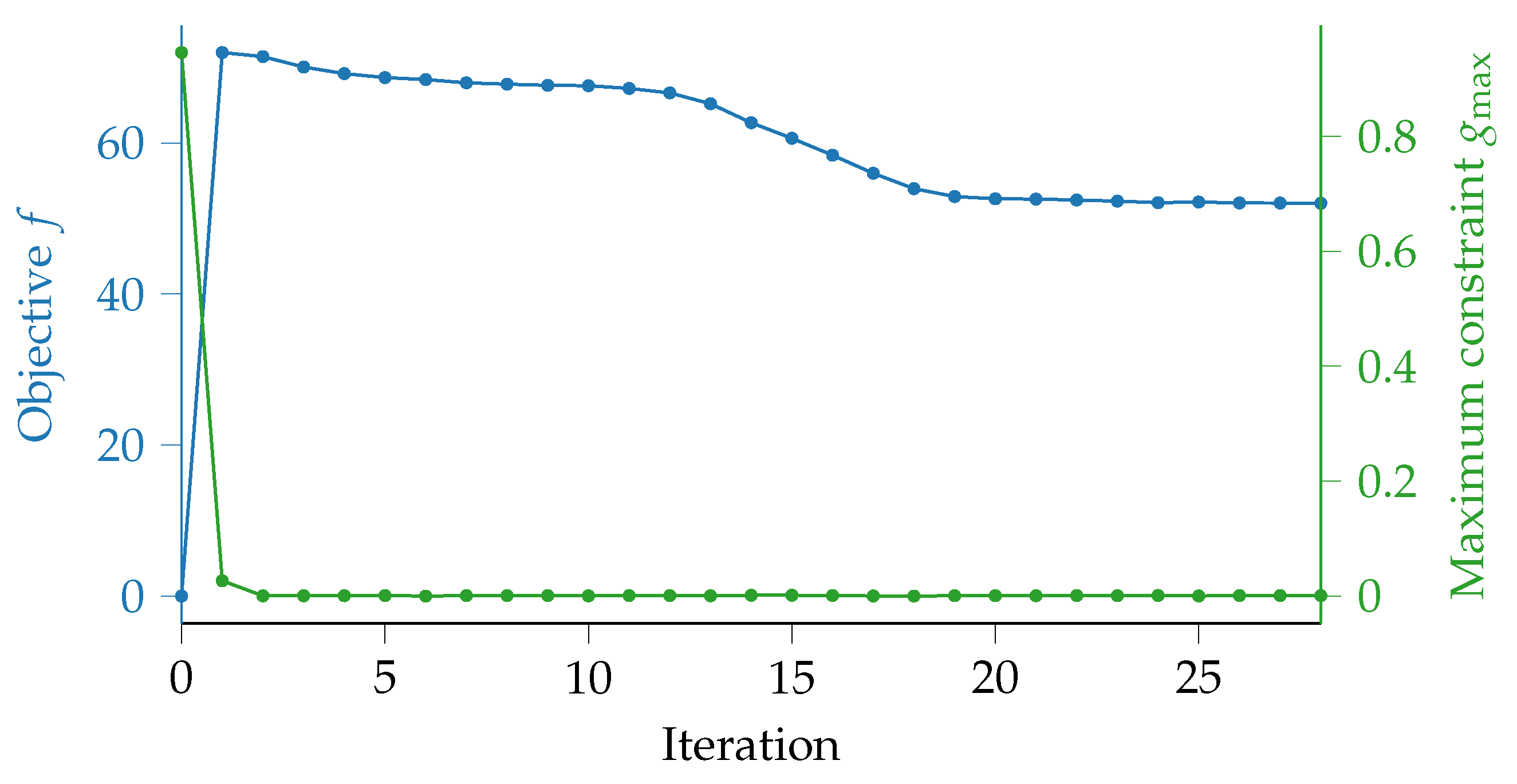

Figure 11 shows the values of the objective function and the maximum constraint function during the optimization run. Convergence was reached after 28 iterations and a feasible design is obtained. It is here to see that the problem immediately moves to a feasible design after the second iteration and after which the added mass is further reduced while staying at the active constraint limit. This excellent convergence behavior is obtained with the gradient-based algorithm despite the non-convex nature of the problem, including islands of feasibility (cf.

Figure 5). For the optimal design,

of mass was added to the housing, which has a mass of

, or only a 2% increase in mass with respect to its initial mass. Furthermore, as the design is feasible, all eigenfrequencies have been shifted out of the constrained ranges. The numerical results can be seen in

Table 4 and

Table 5.

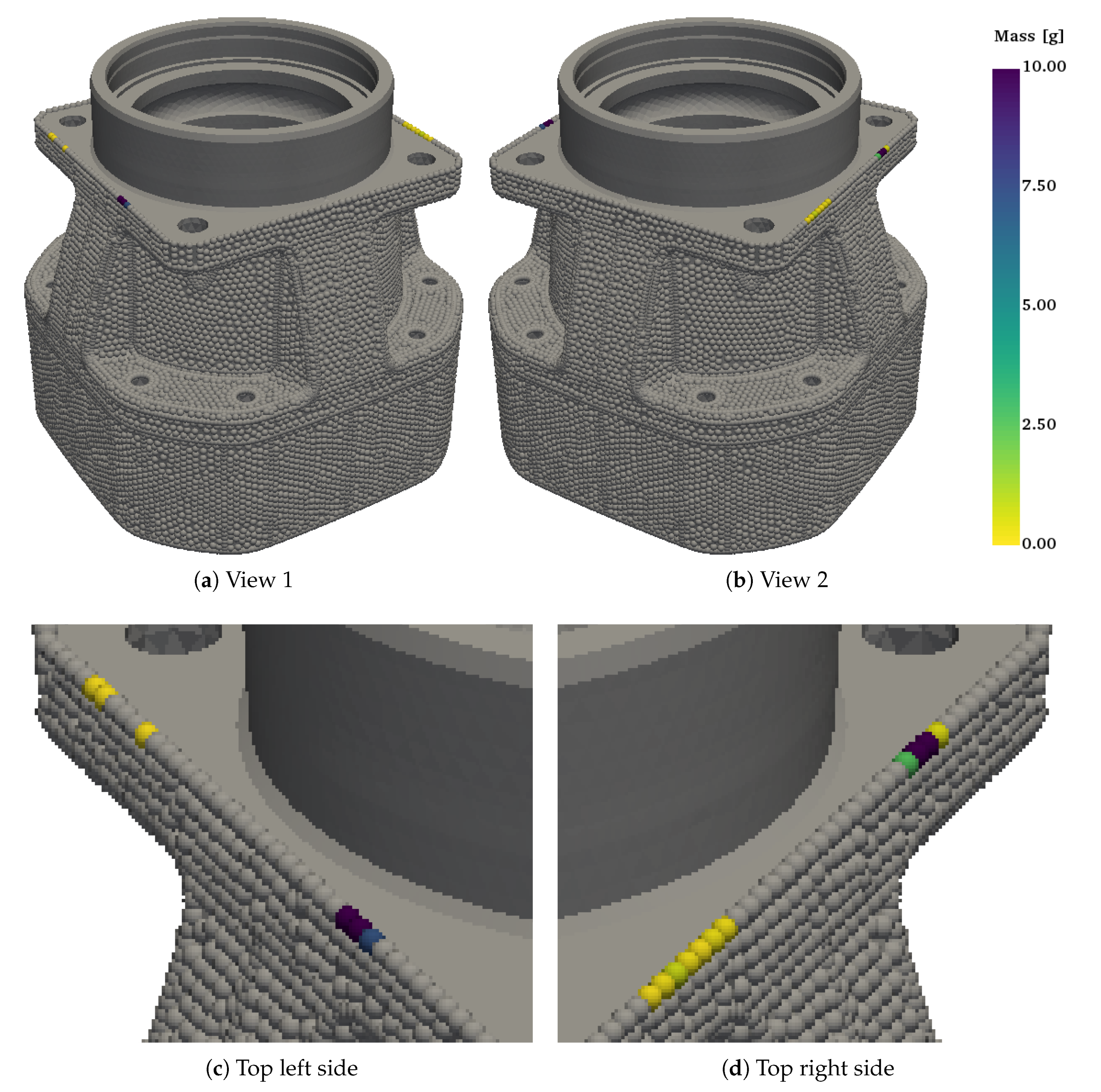

After the design optimization, the vast majority of design variable values are numerically zero, creating a favorably discrete solution. In fact, of the 15,494 design variables, there are only 17 with values larger than zero, i.e., only 17 nodal mass elements have added mass. The values of these are found in

Table 5.

Figure 12 shows the position of the zero design variables in gray and the design variables with different values in the scale of the color bar. Of the 17 design variables with an added mass, four optimal values are at the upper limit of

, one optimal value is approximately

, and a further optimal value is approximately

. The optimal values of the other 11 design variables are one to three magnitudes smaller and have values between

and

, which are identified in

Figure 12 as yellow mass nodes. The optimal positions are be nearly symmetrical at the top edge of the upper flange. That so few nodes of the optimal design have added mass is deemed to be positive and, therefore, easier to physically implement.