Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

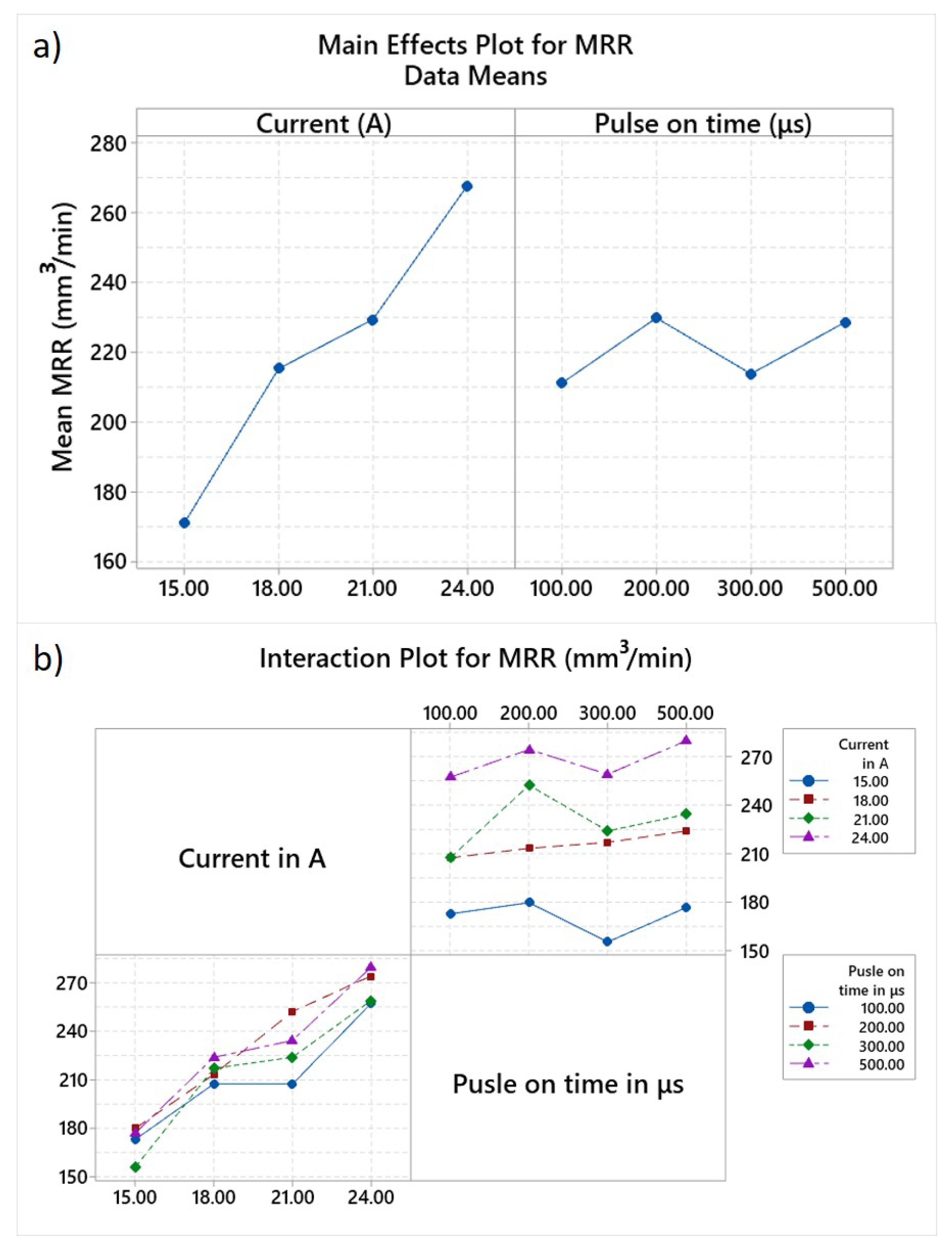

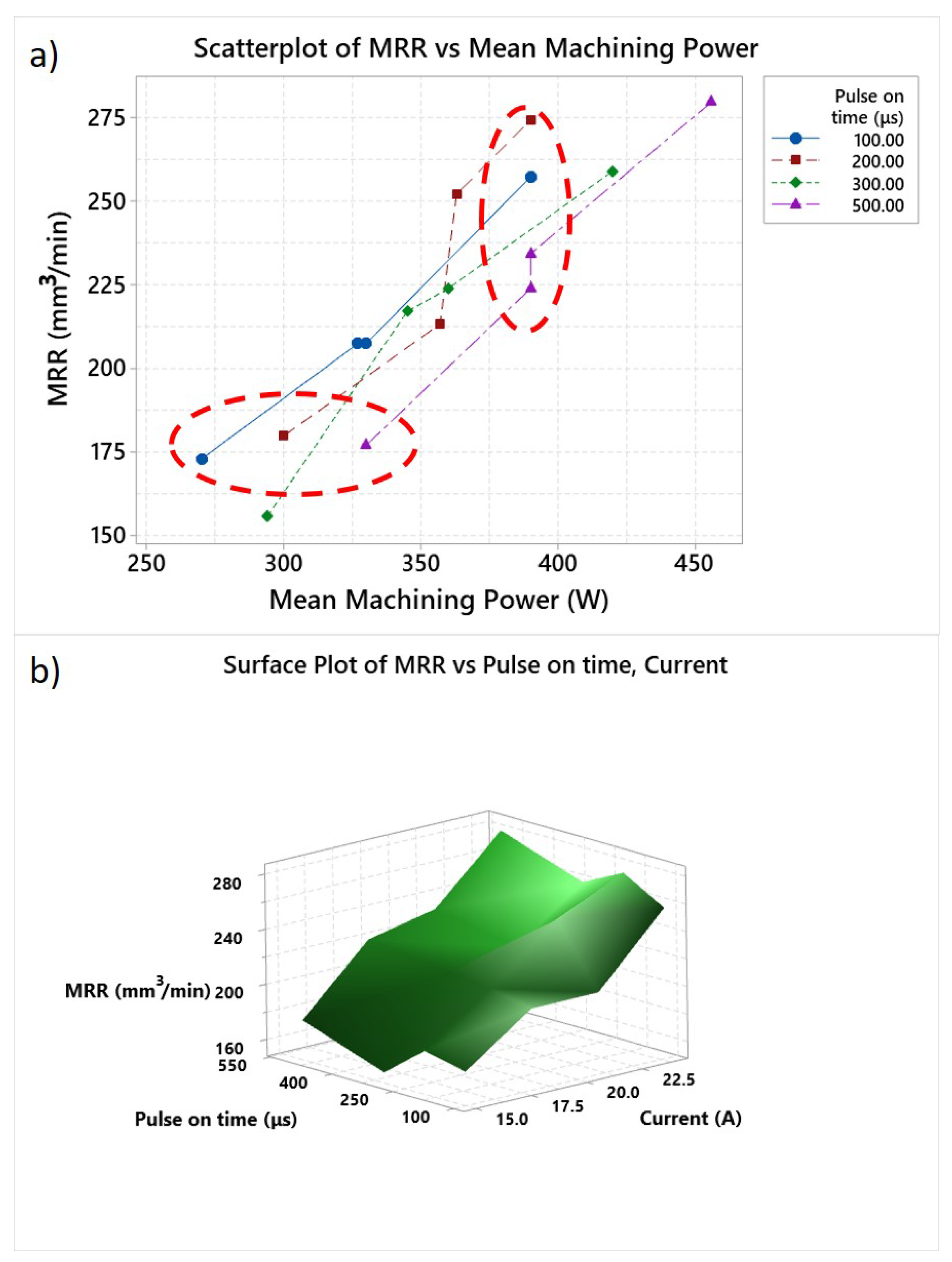

3.1. Material Removal Rate

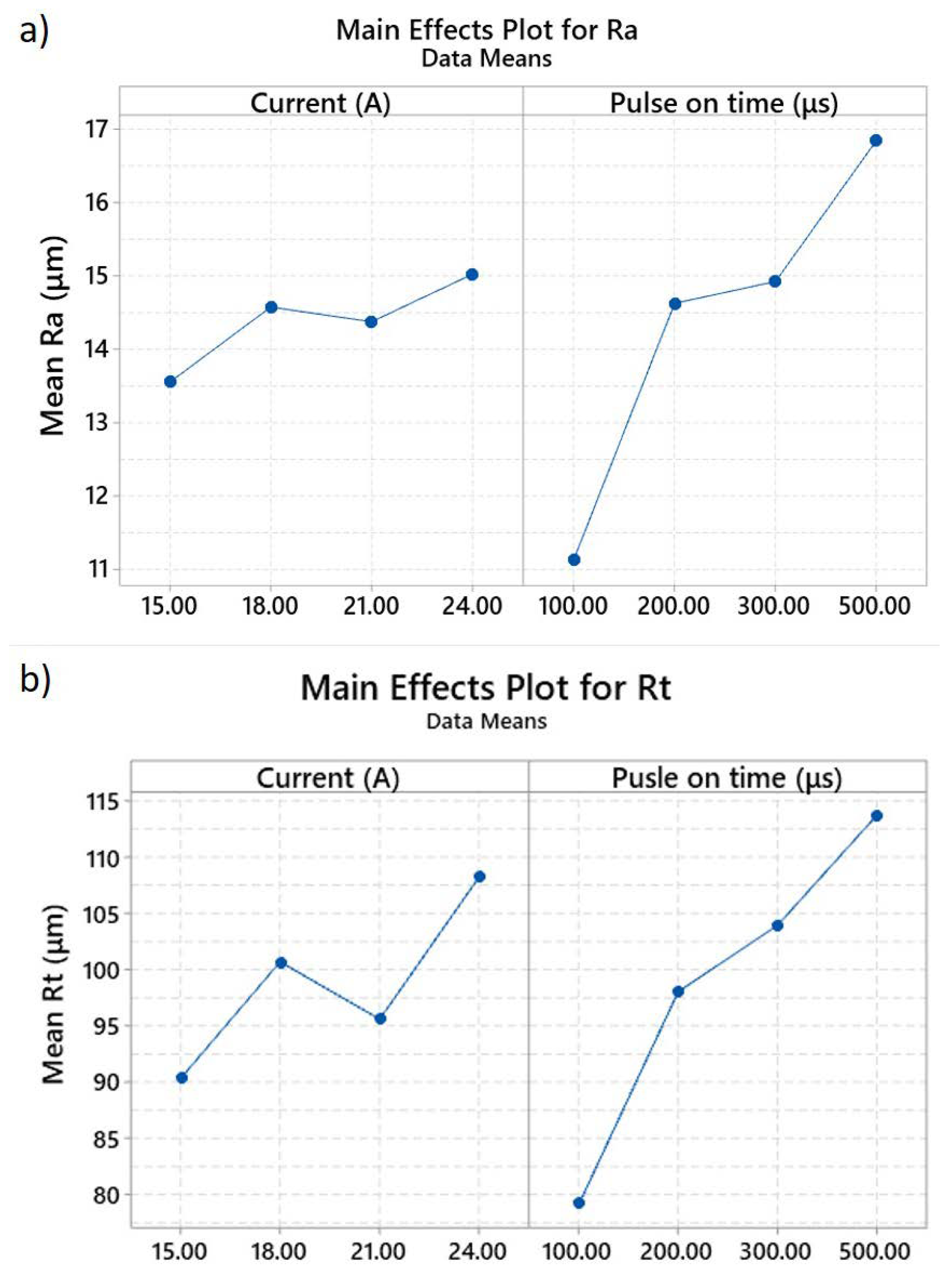

3.2. Surface Roughness

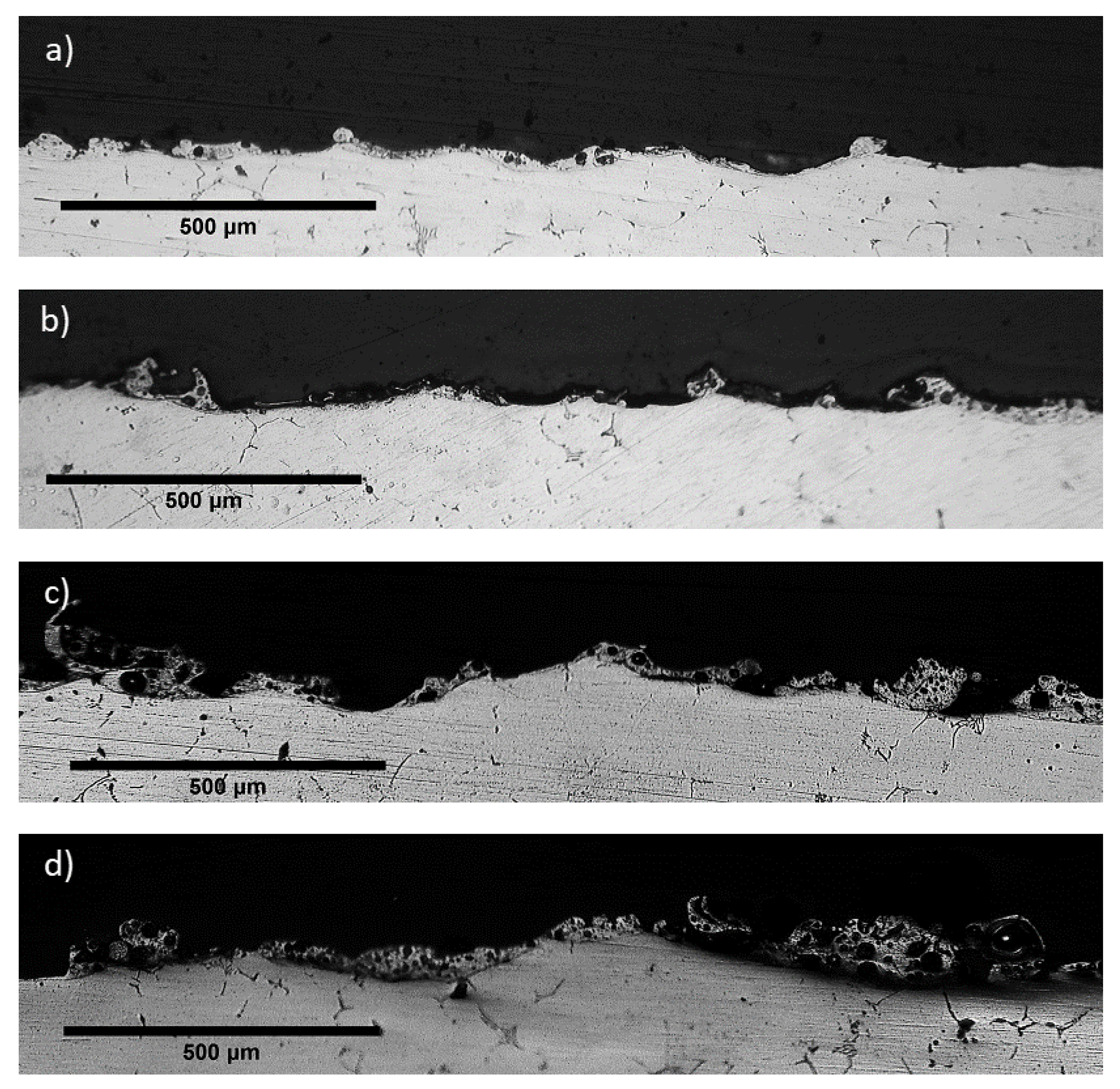

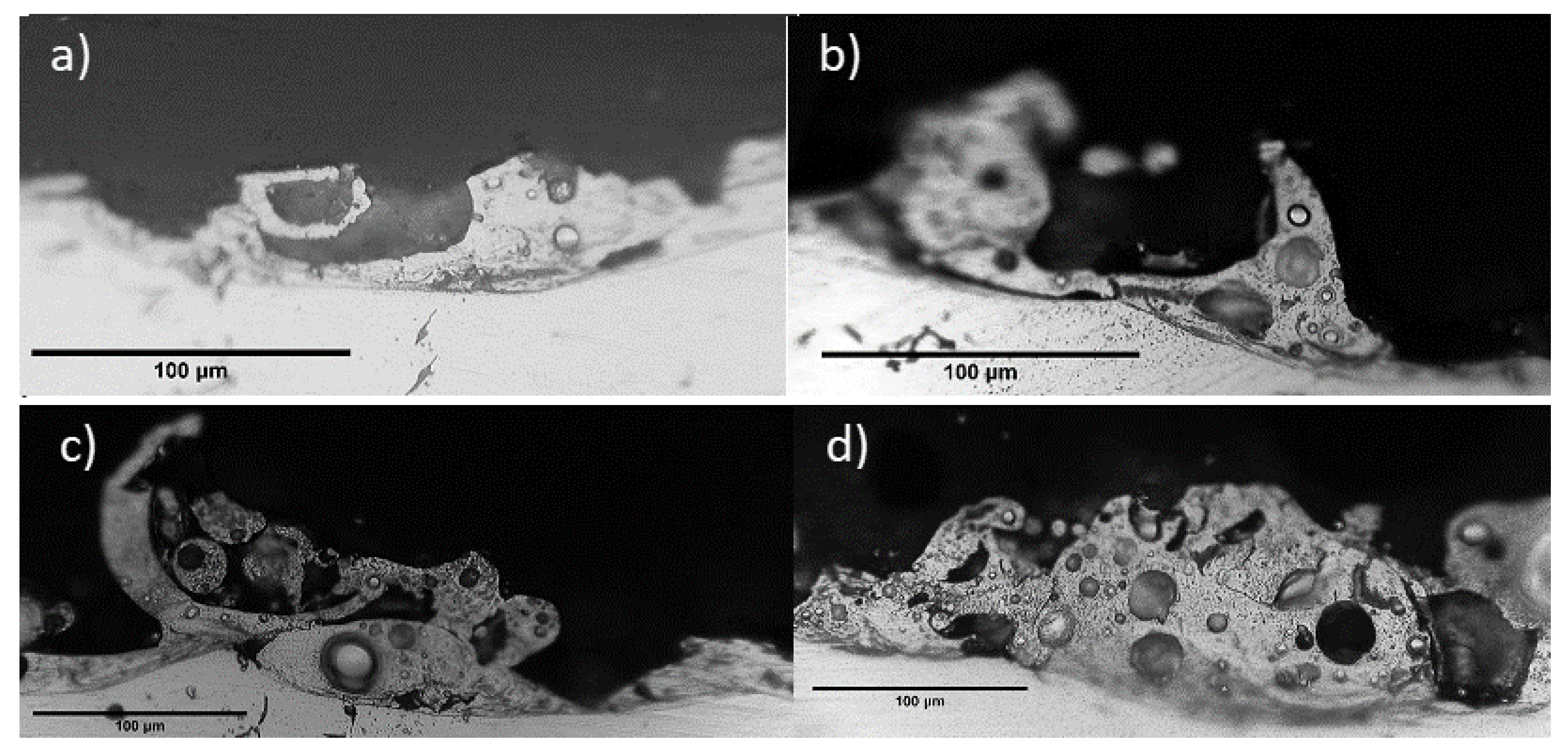

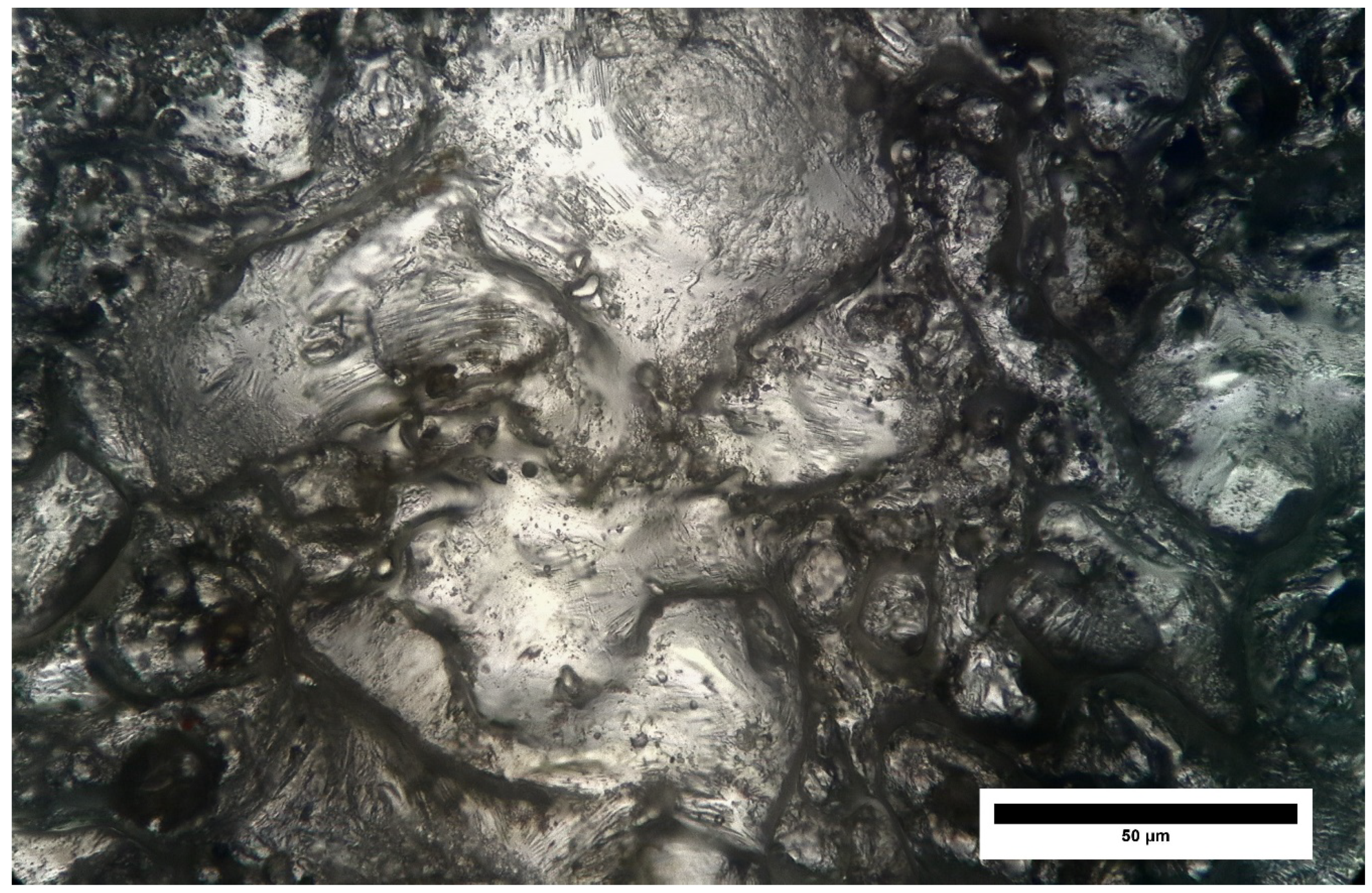

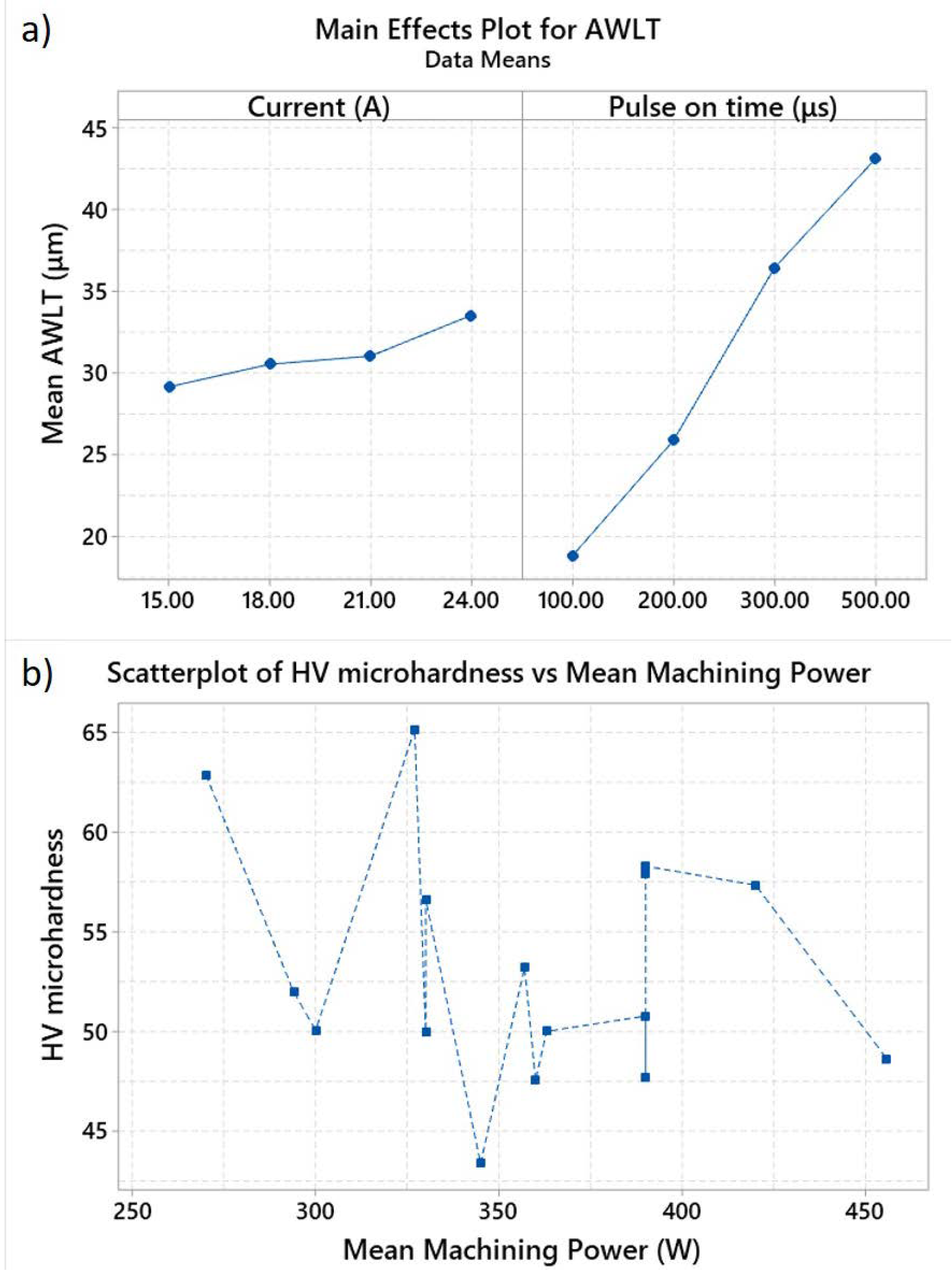

3.3. White Layer and Heat Affected Zone’s Micro-Hardness

4. Conclusions

- The main factor which affects the MRR is the pulse current IP.

- For optimization of the machining efficiency, the interactions between machining parameters must be considered. For the same mean machining power, different MRR were measured; however, the same MRR resulted with different mean machining powers. This is the result of interactions between pulse current and pulse-on time and the manner each parameter affects the material removal mechanism.

- The surface roughness mainly depends on the pulse-on time, with the measured values having statistically significant difference, when changing from 100 μs to 200, 300, and 500 μs.

- The morphology of the WL depends on the discharge energy, mostly by the pulse-on time. Increase of the pulse energy results to a thicker WL, more continuous, with bigger globule formations and more intense porosity. The AWLT can be expressed as a function of IP and Ton.

- The material of the HAZ has decreased micro-hardness.

Author Contributions

Funding

Conflicts of Interest

References

- Jahan, M.P. Electrical Discharge Machining (EDM) Types, Technologies and Applications; Nova Science Publishers: New York, NY, USA, 2015; p. 507. [Google Scholar]

- Abbas, N.M.; Solomon, D.G.; Bahari, M.F. A review on current research trends in electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2007, 47, 1214–1228. [Google Scholar] [CrossRef]

- Khan, A.A. Electrode wear and material removal rate during EDM of aluminum and mild steel using copper and brass electrodes. Int. J. Adv. Manuf. Technol. 2008, 39, 482–487. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Iuliano, L. Performance Optimization in Machining of Aluminium Alloys for Moulds Production: HSM and EDM. In Aluminium Alloys, Theory and Applications; Kvackaj, T., Ed.; IntechOpen: Rijeka, Croatia, 2011; pp. 355–376. [Google Scholar]

- Radhika, N.; Sudhamshu, A.R.; Chandran, G.K. Optimization of Electrical Discharge Machining Parameters of Aluminium Hybrid Composites Using Taguchi Method. J. Eng. Sci. Technol. 2014, 9, 502–512. [Google Scholar]

- Imran, M.; Shah, M.; Mehmood, S.; Arshad, R. EDM of Aluminum Alloy 6061 Using Graphite Electrode Using Paraffin Oil and Distilled Water as Dielectric Medium. Adv. Sci. Technol. Res. J. 2017, 11, 72–79. [Google Scholar] [CrossRef][Green Version]

- Kandpal, B.C.; Kumar, J.; Singh, H. Machining of Aluminium Metal Matrix Composites with Electrical Discharge Machining - A Review. Mater. Today Proc. 2015, 2, 1665–1671. [Google Scholar] [CrossRef]

- Selvarajan, L.; Rajavel, J.; Prabakaran, V.; Sivakumar, B.; Jeeva, G. A Review Paper on EDM Parameter of Composite material and Industrial Demand Material Machining. Mater. Today Proc. 2018, 5, 5506–5513. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Golbabaei, P.; Givi, M.K.B.; Molaiekiya, F. Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2012, 37, 458–464. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Kovac, P.; Sekulic, M.; Skoric, B. Influence of discharge energy on machining characteristics in EDM. J. Mech. Sci. Technol. 2012, 26, 173–179. [Google Scholar] [CrossRef]

- Jameson, E.C. Electrical Discharge Machining; Society of Manufacturing Engineers: Dearborn, MI, USA, 2001; p. 342. [Google Scholar]

- Rebelo, J.C.; Dias, A.M.; Kremer, D.; Lebrun, J.L. Influence of EDM pulse energy on the surface integrity of martensitic steels. J. Mater. Process. Technol. 1998, 84, 90–96. [Google Scholar] [CrossRef]

| Si (max) | Fe (max) | Cu (max) | Mn (max) | Mg | Cr | Zn (max) | Others (max) | Density (g/mm3) | Hardness (HV) |

|---|---|---|---|---|---|---|---|---|---|

| 0.25% | 0.40% | 0.10% | 0.10% | 2.2–2.8% | 0.15–0.35% | 0.1% | 0.15% | 0.00268 | 98 |

| # | IP (A) | Ton (μs) | Duty Factor | MRR (mm3/min) | Ra (μm) | Rt (μm) | AWLT (μm) |

|---|---|---|---|---|---|---|---|

| 1 | 15 | 100 | 0.6 | 173 | 10.8 | 77.2 | 18 |

| 2 | 18 | 100 | 0.61 | 207 | 10.7 | 76.6 | 17 |

| 3 | 21 | 100 | 0.52 | 207 | 11.2 | 76.2 | 20 |

| 4 | 24 | 100 | 0.54 | 257 | 11.8 | 86.4 | 21 |

| 5 | 15 | 200 | 0.67 | 180 | 15.1 | 95.6 | 23 |

| 6 | 18 | 200 | 0.66 | 213 | 14.5 | 98 | 26 |

| 7 | 21 | 200 | 0.58 | 252 | 14.4 | 96.8 | 27 |

| 8 | 24 | 200 | 0.54 | 274 | 14.5 | 101.6 | 28 |

| 9 | 15 | 300 | 0.65 | 155 | 14.1 | 93.8 | 36 |

| 10 | 18 | 300 | 0.64 | 217 | 16 | 113.2 | 37 |

| 11 | 21 | 300 | 0.57 | 224 | 15.2 | 104.2 | 35 |

| 12 | 24 | 300 | 0.58 | 259 | 14.4 | 104.4 | 37 |

| 13 | 15 | 500 | 0.73 | 177 | 14.2 | 94.4 | 39 |

| 14 | 18 | 500 | 0.72 | 224 | 17.1 | 114.8 | 42 |

| 15 | 21 | 500 | 0.62 | 234 | 16.7 | 105 | 42 |

| 16 | 24 | 500 | 0.63 | 280 | 19.4 | 140.6 | 49 |

| Ra | IP (A) | Ra | Ton (μs) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rt | Rt | ||||||||||||

| IP (A) | 15 | 18 | 21 | 24 | Ton (μs) | 100 | 200 | 300 | 500 | ||||

| 15 | 0.57 | 0.605 | 0.469 | 100 | 0.000 | 0.002 | 0.014 | ||||||

| 18 | 0.35 | 0.917 | 0.84 | 200 | 0.002 | 0.558 | 0.131 | ||||||

| 21 | 0.54 | 0.67 | 0.754 | 300 | 0.006 | 0.252 | 0.192 | ||||||

| 24 | 0.24 | 0.62 | 0.39 | 500 | 0.043 | 0.213 | 0.425 | ||||||

| No. of Experiment | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AWLT (μm) | 18 | 17 | 20 | 21 | 23 | 26 | 27 | 28 | 36 | 37 | 35 | 37 | 39 | 42 | 42 | 49 |

| Micro-hardness (HV) | 63 | 65 | 50 | 51 | 50 | 53 | 50 | 48 | 52 | 43 | 48 | 57 | 57 | 58 | 58 | 49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markopoulos, A.P.; Papazoglou, E.-L.; Karmiris-Obratański, P. Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines 2020, 8, 12. https://doi.org/10.3390/machines8010012

Markopoulos AP, Papazoglou E-L, Karmiris-Obratański P. Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines. 2020; 8(1):12. https://doi.org/10.3390/machines8010012

Chicago/Turabian StyleMarkopoulos, Angelos P., Emmanouil-Lazaros Papazoglou, and Panagiotis Karmiris-Obratański. 2020. "Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052" Machines 8, no. 1: 12. https://doi.org/10.3390/machines8010012

APA StyleMarkopoulos, A. P., Papazoglou, E.-L., & Karmiris-Obratański, P. (2020). Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines, 8(1), 12. https://doi.org/10.3390/machines8010012