1. Introduction

In the past few decades, industrial robots have been widely used in practical engineering scenarios, including welding, material handling, assembly and so on [

1,

2,

3]. With the development of manufacturing technology and robot key parts, its application scope is no longer limited to the above simple or repeated tasks but has gradually expanded to drilling, milling and other processing fields with a high material removal rate (MRR) [

4,

5,

6]. The workspace of CNC machine tools is constrained by their maximum travel limits. They are considerably more expensive, demand high environmental standards, and are difficult to integrate with external devices. In comparison, industrial robots offer a larger workspace [

7], are more affordable (typically one-tenth the cost of CNC machine tools), can operate stably in dusty environments, and due to their open structure, facilitate the implementation of integrated machining and measurement systems. However, they tend to have relatively lower stiffness (often below 1 N/µm) than CNC machine tools (often exceeding 50 N/µm) [

8]. Hence, when subjected to the same cutting force, the deformation observed in the robotic machining process is significantly greater than that in the traditional cutting process, leading to reduced machining accuracy. Hence, when subjected to the same cutting force, the deformation encountered during robotic machining is significantly greater than that in traditional cutting processes, leading to reduced machining accuracy and consequently restricting its widespread application in high-precision machining fields [

9]. The stiffness of a robot varies according to its posture within its workspace, and its body structure and materials are inherently difficult to alter [

10]. Consequently, for robots possessing redundant degrees of freedom, selecting an appropriate posture during the processing is an effective strategy to enhance processing accuracy [

11].

The robotic static stiffness model elucidates the theoretical mapping relationship between end-effector stiffness and joint stiffness [

12]. Although robots are subjected to dynamic forces during the machining process, research has demonstrated that when the frequency components of the cutting forces do not approximate the natural frequency of the robot, notable optimization can be achieved through the application of a static model [

13]. The stiffness/flexibility ellipsoid represents the distribution of stiffness for robot in a specific posture, garnering widespread attention due to its intuitive geometric properties [

14]. In recent years, researchers have introduced numerous evaluation indices grounded in the ellipsoid to quantitatively characterize the stiffness performance of robots [

15], for instance, the process of machining a planar elliptical area [

16], the optimal semi-axis lengths [

17], the magnitude of force required to produce unit deformation, i.e., Rayleigh entropy [

18], translational compliance indicators [

19] proportional to overall compliance, etc. However, they typically lack directionality and smoothness, failing to accurately reflect stiffness in specific directions. Therefore, drawing on GUO et al.’s [

20] perspective, researchers initially introduced normal direction factors into the machining plane. Based on the relationship between external forces on the robot end-effector (EE) and deformation, Peng et al. [

21] proposed the normal stiffness performance index (NSPI) derived from the comprehensive stiffness performance index (CSPI), clearly revealing the anisotropic characteristics of robot stiffness. Chen et al. [

22], simultaneously considering deformation caused by spindle weight and cutting forces, proposed a comprehensive deformation index. They validated the effectiveness of the proposed deformation index and posture optimization method through simulations and experiments. Lin et al. [

23] developed the deformation evaluation index (DEI) for drilling tasks. Liao et al. [

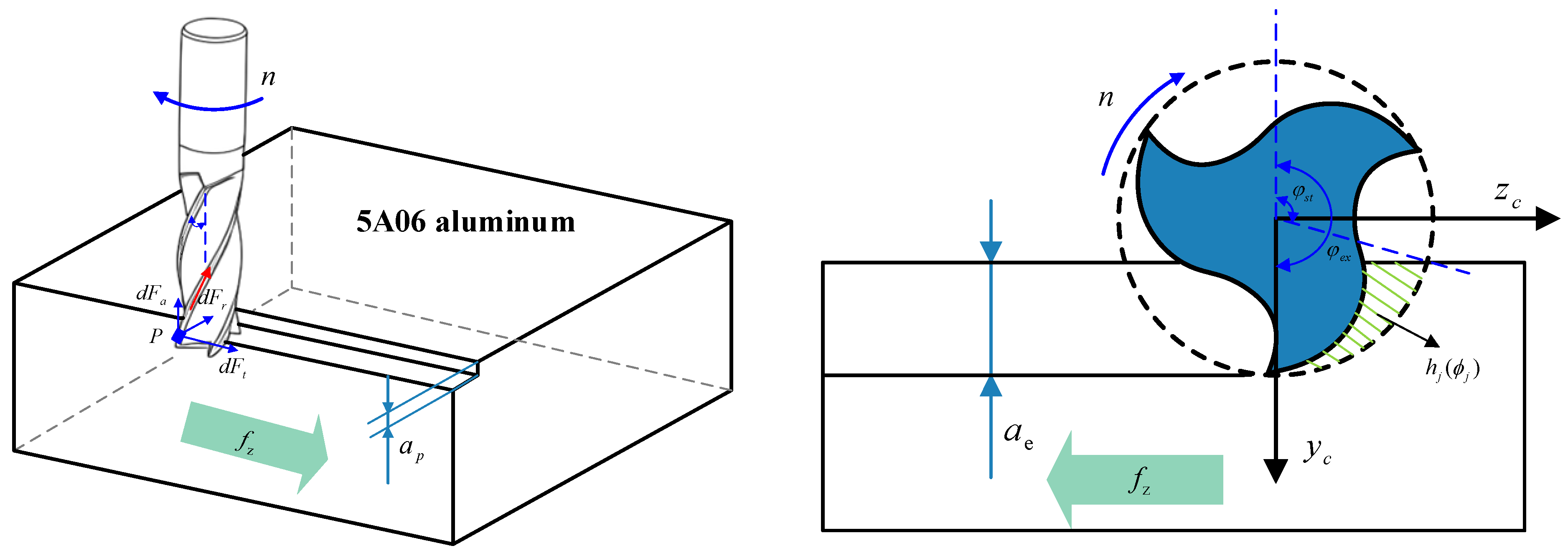

24] introduced the stiffness and MRR matching evaluation index to ensure milling force stability and robot stiffness. The essence of milling force lies in the total resistance generated during the interaction between the tool and the workpiece material, primarily originating from the elastic–plastic deformation, separation, and friction of the material. It is represented in a spatial coordinate system, and its magnitude and direction are significantly influenced by tool geometry, cutting parameters, and workpiece material properties. Milling force models, developed based on oblique cutting theory, serve as an effective method for predicting milling forces and are widely applied in research and practice [

25]. For milling operations, the milling force is primarily concentrated in the radial direction of the cut. Its direction can be arbitrary in Cartesian space and depends on cutting parameters and the workpiece. Thus, optimizing only axial stiffness is insufficient. Due to the complex structure of force sensors, integrating them into the spindle is difficult and costly. They are usually fixed to the workpiece being machined. However, when workpiece dimensions increase significantly, limited sensor structures cannot adapt, necessitating the establishment of accurate and reliable milling force prediction models. These studies did not consider the stability of prediction results under conditions of multiple postures and various machining parameters [

26,

27].

In research on milling path stiffness optimization, it is commonly assumed that robot stiffness performance remains quasi-constant within small regions. The entire trajectory is thus discretized into multiple discrete CL points. Researchers optimized redundant degrees of freedom under performance indicator constraints to achieve posture optimization, such as joint limit indices [

28], dexterity indices, and smoothness indices [

29]. Guo et al. [

20] proposed a novel method based on the Jacobian matrix. However, this optimization approach is only applicable to machining at individual CL points (e.g., drilling). Ding et al. [

30] introduced an efficient sequential quadratic programming (SQP)-based algorithm targeting a weighted sum of machining width and tool path smoothness criteria, effectively resolving tool orientation and robot redundancy issues. Vosniakos et al. [

31] optimized their model using genetic algorithm. Xiong et al. [

17] addressed the optimization problem via a simple discretized search algorithm capable of accommodating joint limits, singularity avoidance, and robot trajectory smoothness constraints. Nevertheless, CL points are optimized sequentially from the first to the last point. This optimization strategy can easily lead to subsequent CL points falling into the deterioration area and being unable to jump out, thus hindering the attainment of the global trajectory optimum. Ye et al. [

32] established a global performance indicator for robot path smoothness under joint acceleration constraints, thereby obtaining smoother tooltip feed rate profiles. Xue et al. [

33] proposed a discrete Dijkstra-based optimization method to solve for the global optimum by minimizing a deformation index while considering kinematic constraints. Most existing algorithms rely on greedy strategies: starting exclusively from the stiffness-optimal initial position, selecting the vertex with the current minimum weight among unprocessed points, and incrementally expanding the search scope. This inflexible approach lacks adaptability, and the loss function fails to update dynamically.

Thus, current research suffers from the following limitations:

Few studies take the influence of both robot postures and milling parameters into account comprehensively. The stability of identified milling force coefficients should be systematically validated.

Often, only the system deformation caused by the axial component of the milling force is taken into account. However, optimizing solely for axial stiffness performance lacks comprehensiveness.

When addressing a specific milling path, many existing algorithms typically start from the stiffness-optimal posture at the beginning. However, due to kinematic constraints, such approaches are prone to local optima and exhibit limited flexibility.

This study is structured as follows: In

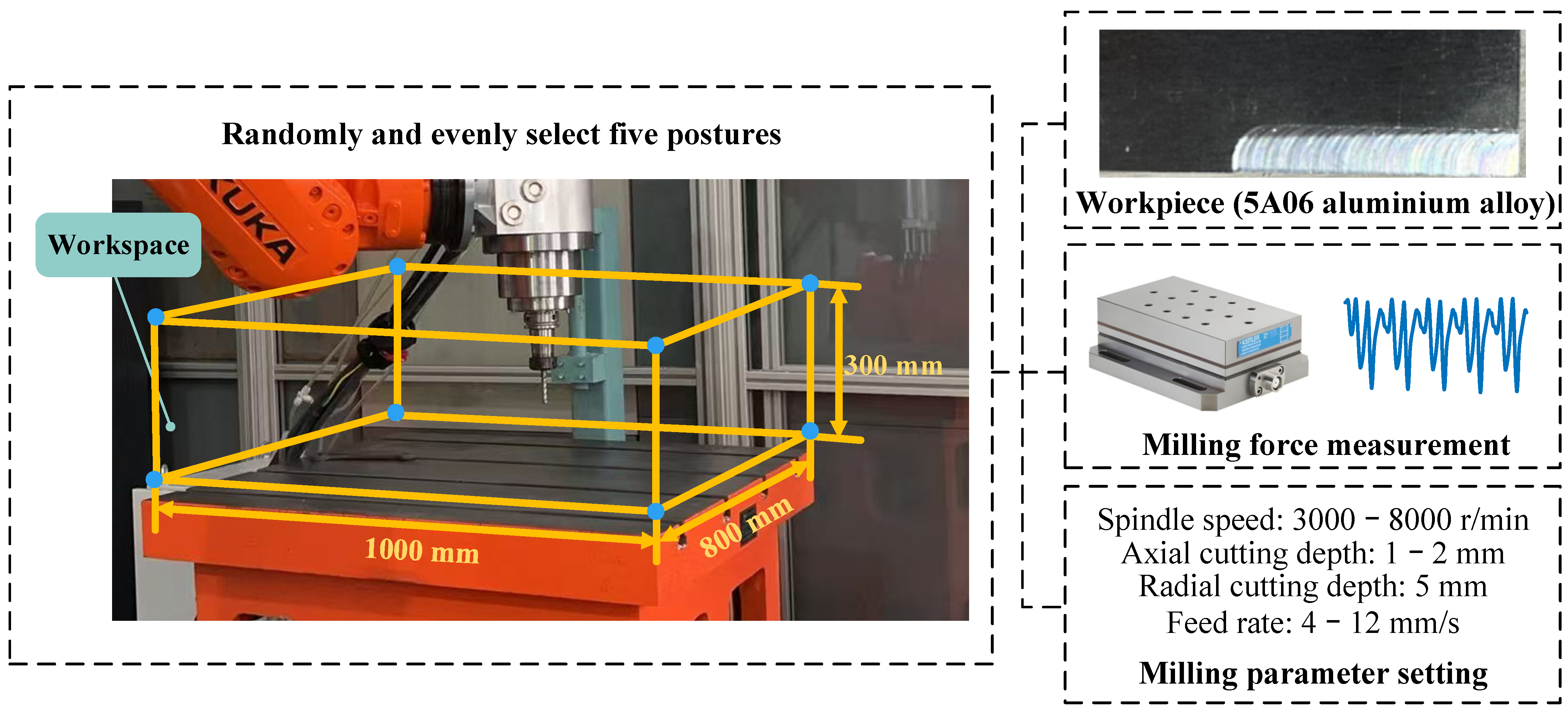

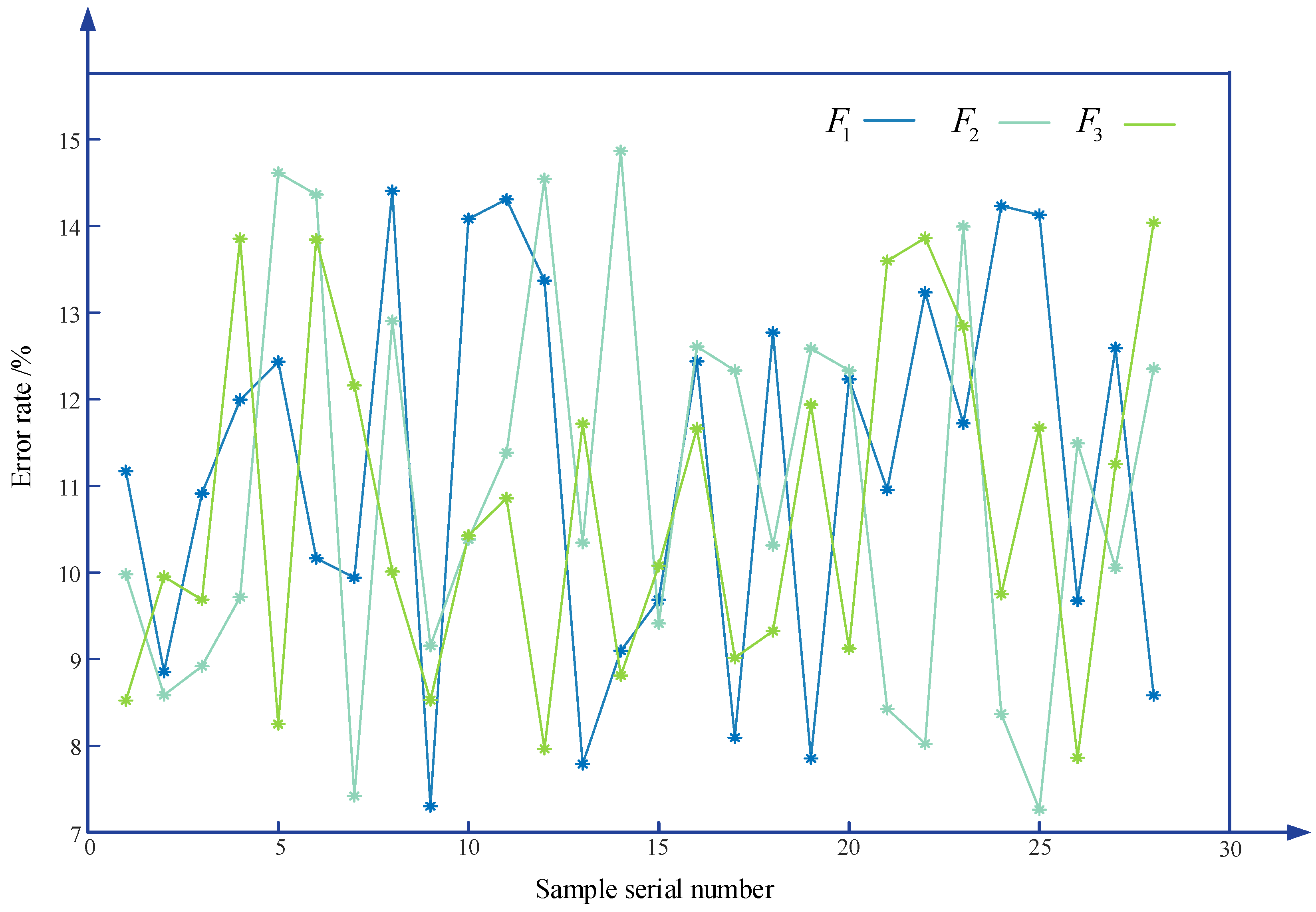

Section 2, a milling force prediction model is established, and the stability of the milling force prediction results is verified under the condition of multi-position posture variable milling parameters. In

Section 3, the robot stiffness model is established. Combined with coordinate transformation, the comprehensive stiffness performance index considering the actual milling load direction is proposed. In

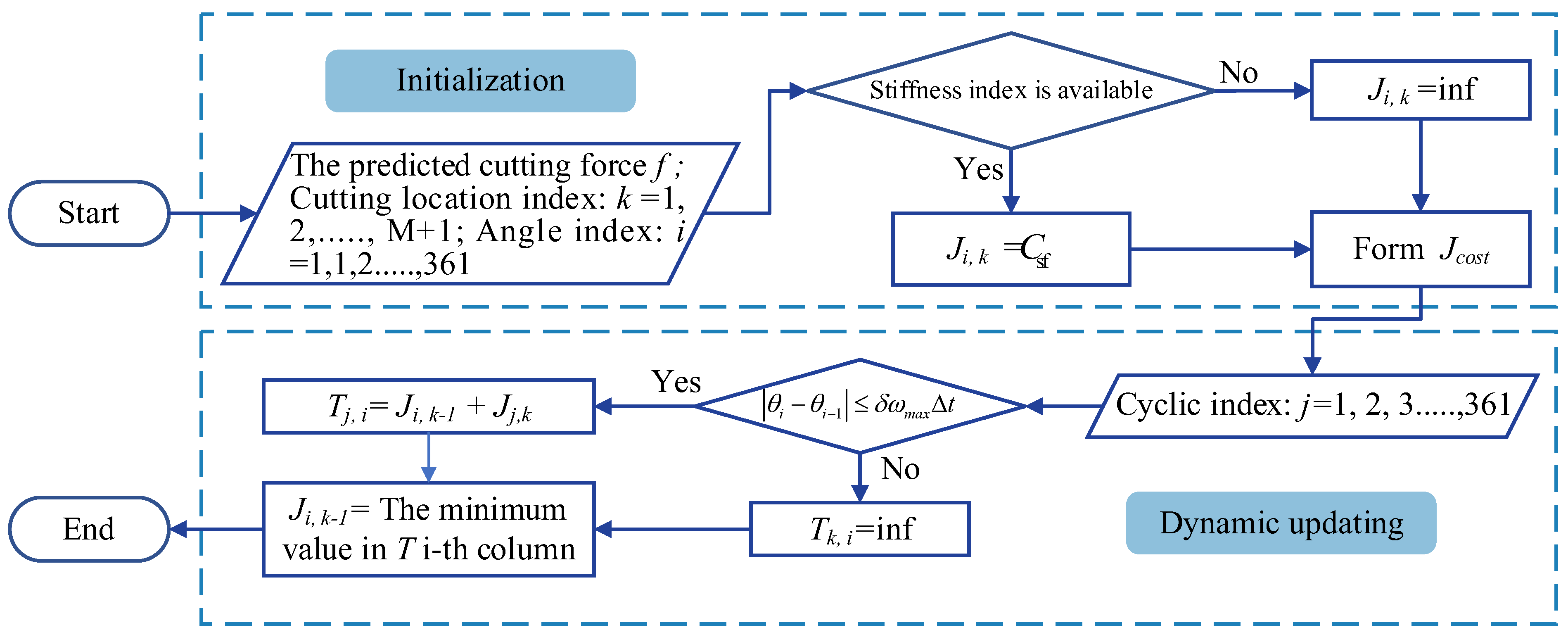

Section 4, a robotic milling posture optimization method over large ranges is proposed based on a dynamic programming algorithm, comprehensively considering constraints. This method obtained the optimal average stiffness from any CL point to the trajectory endpoint. Experiments validated the stiffness evaluation indices and posture optimization model.

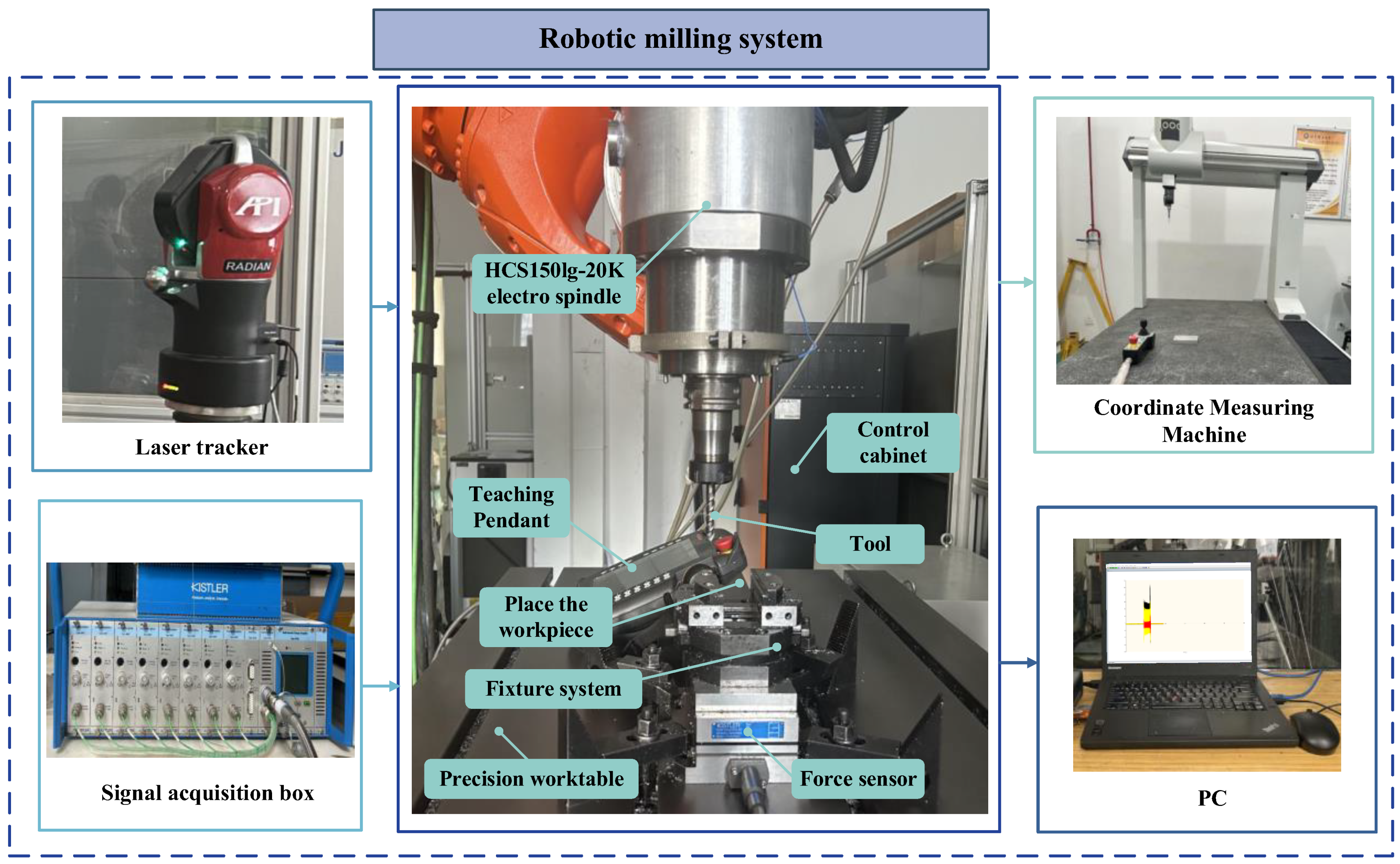

3. Stiffness Model and Stiffness Performance Index

3.1. The Stiffness Model of Robot

The robotic arm, connecting plate, and electric spindle constitute the primary components of the milling system in this study. Their load-bearing capacity directly influences cutting performance. Furthermore, the connecting plate, fabricated from high-strength material with a compact structure, exhibits exceptionally high stiffness. The stiffness of the electric spindle primarily depends on the structural characteristics of its internal shaft and bearings, typically on the order of 50 N/µm. Thus, to simplify the stiffness analysis of the milling system, the following assumptions are made: (1) the robot is considered the sole source of deformation and (2) cutting loads are rigidly transmitted sequentially and ultimately act at the center of the robot flange. The overall stiffness of the machining system is determined by the robot stiffness and is predominantly governed by the machining posture.

The Cartesian stiffness matrix of the robot is expressed as

where

is the end stiffness matrix.

is the Jacobian matrix under

and

is a 6 × 6 diagonal matrix representing the spatial stiffness of the robot. The complementary stiffness matrix is typically neglected when the load is significantly lighter than the payload capacity and the robot exhibits good maneuverability [

12].

By adjusting counterweights, total forces of 600 N, 800 N, 1000 N, and 1200 N were applied, as shown in

Figure 6. Using a laser tracker, a spatial vector between the force application point and fixed pulley 1 was established to derive three-dimensional forces under respective loads. Coordinates of measurement points were recorded under unloaded and different loaded states to calculate deformation. Combined with previous work [

36], the calculated

can effectively indicate the carrying capacity of the robot in any posture.

3.2. Stiffness Performance Evaluation Index

Combining the robot Cartesian compliance matrix,

, with the relationship between the force acting on the EE and the resulting generalized deformation,

, yields:

where

is the force–linear displacement compliance matrix,

is the force–angular displacement compliance matrix,

is the moment–linear displacement compliance matrix,

is the force–linear displacement compliance matrix, and

and

denote the translational and rotational deformation vectors of the EE, respectively.

In the milling process, the main factor affecting the machining quality is the linear displacement deformation of the cutting tool, so the torque applied on EE is ignored. Equation (6) can thus be simplified as Equation (7):

A compliance ellipsoid is constructed, with the square roots of the matrix eigenvalues , , and as the semi-principal axis lengths and the eigenvector directions , , and as the principal axes.

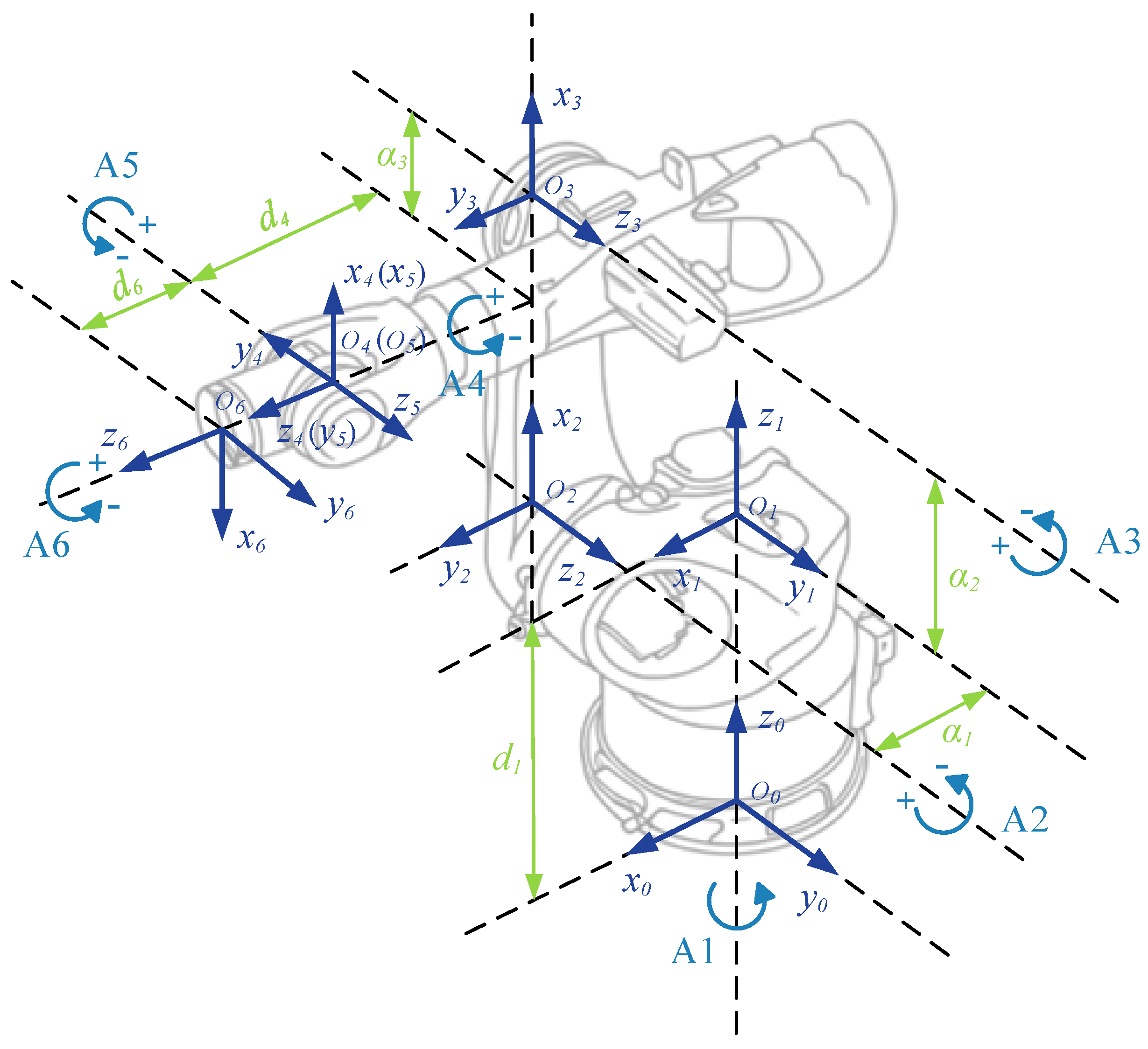

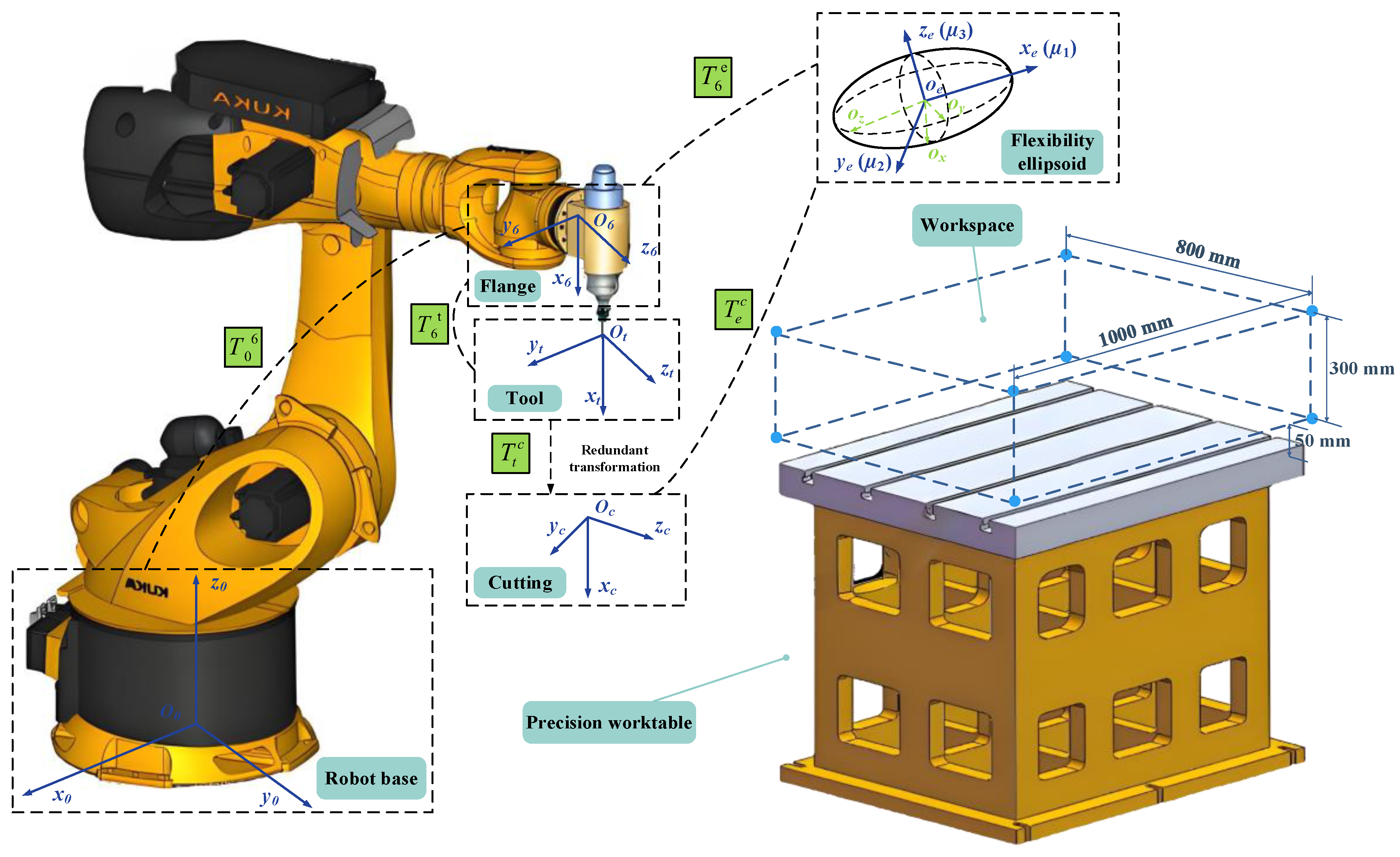

During milling tasks, the robot system achieves spatial position description and control by establishing collaborative relationships between local coordinate systems of components. As shown in

Figure 7, the following coordinate systems are defined:

Ellipsoidal coordinate system : The origin is located at the center of the robot flange, with the axis, axis, and axis directions being the eigenvector directions , , and .

Tool coordinate system : The origin is located at the end of the tool. The -axis coincides with the cutter axis vector. The -axis is in the same direction as the -axis of the flange coordinate system.

Cutting coordinate system : The origin and -axis coincides with the tool coordinate system, and the positive direction of -axis coincides the feed direction.

The center of this ellipsoid coincides with the end-flange center. Its posture varies with the robot’s posture changes and serves to quantitatively evaluate the robot resistance to deformation at a given posture. Specifically, shorter semi-axis lengths formed between the ellipsoid surface and center indicate higher stiffness when operating along that direction.

A fixed installation posture exists between the tool holder, electric spindle, connecting plate, and end flange. Thus, after determining the tool overhang, the coordinate transformation relationship between and remains constant and can be calibrated based on the mechanical interfaces between intermediate components. Since the three-dimensional column vectors and denote the direction cosine parameters of the three coordinate axes (, and ) in . Attitude matrix between and can be described.

At the same time,

and

have a rotation relationship,

determined by redundancy angle

. When further combining with

and

, matrix

, which describes the relationship between

and

, is formed.

The milling force direction,

, is expressed in the cutting coordinate system

, so flexibility indices

,

, and

in the actual load direction can be calculate.

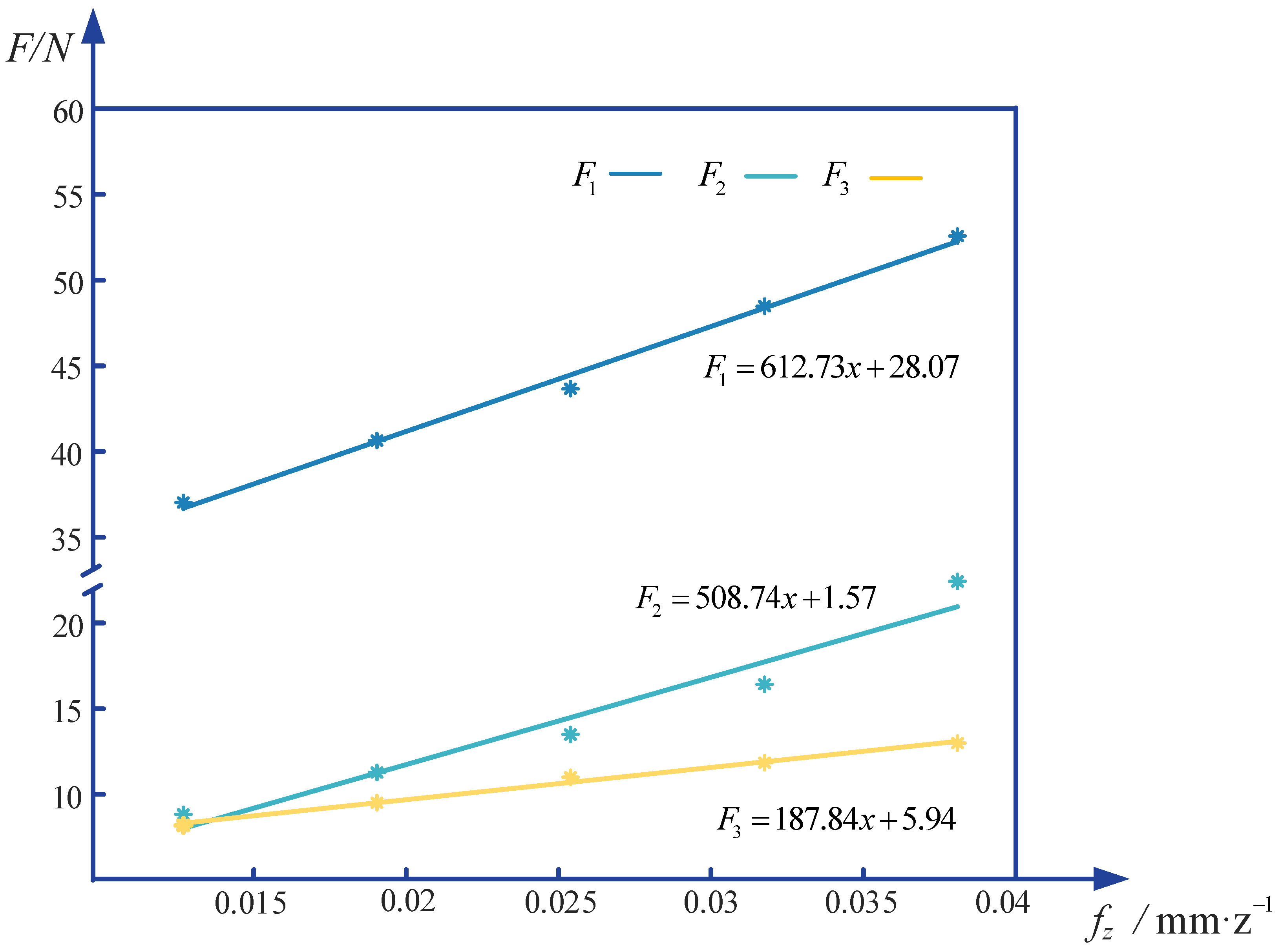

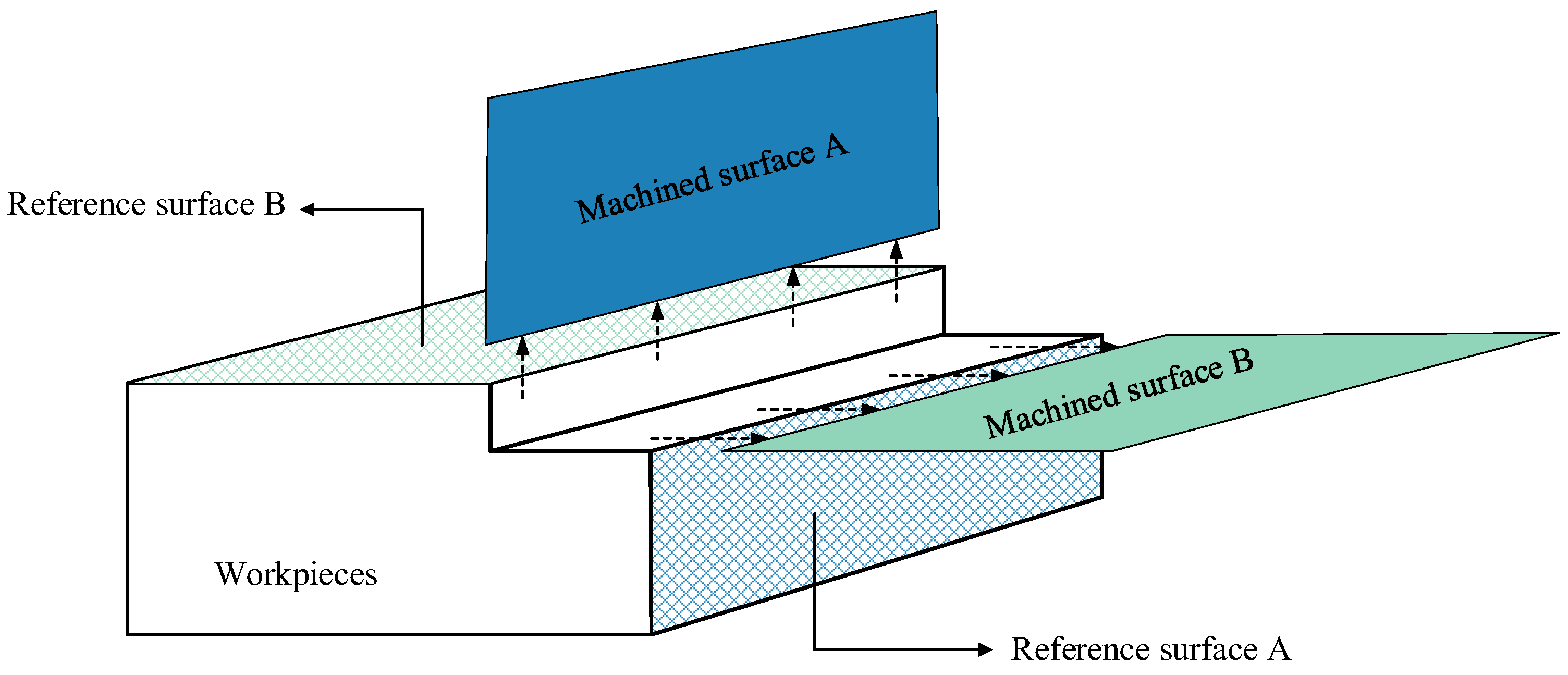

The stiffness coupling effects are negligible, given the use of industrial robot in this research with high payload capacity for milling relatively soft aluminum alloy workpieces. Consequently, machining accuracy is primarily addressed in the milling plane normal direction and path lateral direction, focusing exclusively on and .

During milling, periodic dynamic milling forces act on the EE. These forces can always be decomposed into components along the feed direction, perpendicular to the feed direction, and the axial direction. A direct proportional relationship is assumed between the EE’s translational displacement and the force applied in the same direction. The industrial robot used possesses six joint angles, granting the milling system six degrees of freedom. The rotational degree of freedom, , around the tool axis is redundant for five-axis machining. By optimizing the robot’s stiffness performance, the optimal redundancy angle, , can be obtained, after which joint angles are resolved through inverse kinematics.

Within the workspace, the variation patterns of

and

with the actual machining posture are complex and lack precise quantitative relationships. As shown in

Table 4, when the robot transitions from posture (150 mm, 1830 mm, 1100 mm,

) to posture (550 mm, 1830 mm, 1100 mm,

), both the magnitude and trend of changes in

and

differ. To comprehensively address machining accuracy in both the milling plane normal direction and path lateral direction, appropriate weighting factors must be assigned. This is achieved by introducing milling forces

and

along corresponding directions to represent deformations under actual cutting load orientations. The comprehensive stiffness performance index

is defined such that a smaller value indicates superior stiffness performance.