1. Introduction

With the rapid development of automation technology, industrial robots have been widely used in many manufacturing fields to perform various tasks, such as handing, welding, and assembly [

1,

2]. For repetitive tasks, robots can replace manual labor to complete high-intensity work, significantly improving production efficiency. Unlike traditional lightweight industrial robots [

3,

4], heavy-duty manipulators have different structures and working fields, such as tunnel drilling [

5,

6], coal mining [

7], aerospace assembly [

8], firefighting and emergency rescue [

9], and other large industrial environments [

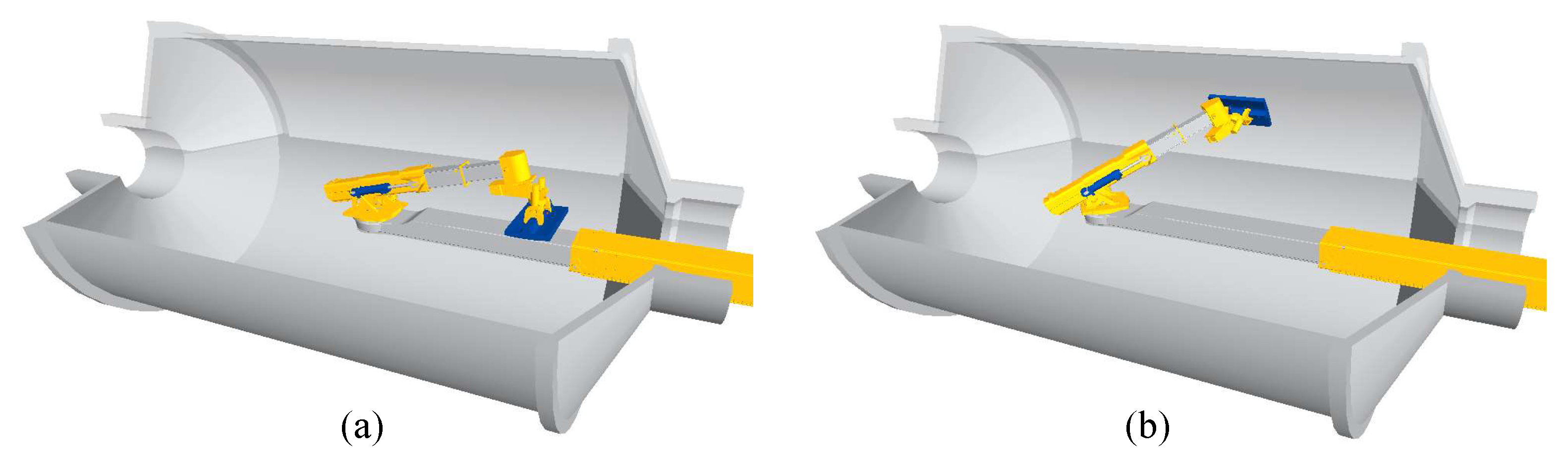

10]. The mill relining manipulator is a specialized heavy-duty robot arm designed for the maintenance of grinding mill equipment. Mill liners are installed on the inner surface of the grinding mill to protect the equipment from the severe impacts from the minerals and grinding balls [

11]. Therefore, the relining task involves replacing liners on time to avoid excessive wear and ensure safe operation. The degree of liner wear directly affects the particle size of crushed minerals. Regular replacement of mill liners is also essential to ensure productivity. Currently, the mill liner exchange task faces several challenges. First is the low efficiency problem, since end effector positioning mainly relies on the worker’s visually guidance and manual operation to control manipulator motion. Second, the working process exhibits poor adaptability. For different grinding mill equipment, it becomes difficult to quickly and safely plan an efficient motion path immediately due to changes in the mill’s inner structure.

To address the above problems, path planning algorithms and simulation analysis are introduced to improve working efficiency and environmental adaptability. Currently, extensive research on path planning has been applied in various fields, such as warehousing logistics [

12], aerial mapping [

13], agricultural harvesting [

14], and mobile manipulators [

15]. However, there is little research on heavy-duty manipulators, especially for mill relining manipulators. For path planning, most current studies focus on the optimization and improvement of existing algorithms, such as graph-based search algorithms [

16,

17,

18], sampling-based methods [

19,

20,

21,

22], artificial potential fields (APFs) [

23,

24], and heuristic evolutionary algorithms [

25]. In this study, the above methods are not applicable, since the mill relining manipulator faces three additional challenges: high-dimensional joint coupling during motion, end deformation caused by self-weight and gravity effects, and limited operation space within the grinding mill. Therefore, the traditional path planning methods cannot provide accurate end effector positioning. General offline finite element (FE) simulations cannot achieve real-time end deformation results under varying working conditions. As a result, although the planned path may be theoretically optimal, its practical performance often falls short of expectations.

In the early 21st century, Grieves [

26] first introduced the concept of a digital twin, defining it as a system comprising three core parts: physical entities in the real world, corresponding digital models in virtual space, and a data connection that enables interaction between the physical and virtual spaces. This novel digital twin system allows us to monitor and evaluate real-time working condition even in harsh environment [

27]. Benefiting from these advantages, virtual–reality mapping technology plays a significant role in driving the modernization of traditional manufacturing industries. Based on the dynamic digital model of the virtual space, the real-time working conditions of physical entities can be represented. Furthermore, computer-assisted technologies can be employed for analysis and simulation prior to the actual execution, such as CAD, CAE, and CAM. Conversely, the up-to-date simulation results in virtual space can be used for guidance to improve safety and reliability during manipulator motion. Therefore, the digital twin system provides a direction for the development of future intelligent manufacturing systems [

28]. In this paper, a five-dimensional digital twin system is established for the mill relining manipulator to complete mill liner exchange tasks.

Currently, digital twin technology has been widely applied in many industrial fields for different purposes. To realize grasping tasks, based on established digital twin systems, Liu et al. [

29] proposed a transfer mechanism and implemented deep reinforcement learning algorithms on industrial robots. Experimental results verified the effectiveness of the proposed sim-to-real transfer approach. For satellite mass assembly, Liu et al. [

30] proposed a digital twin-based production logistics synchronization framework to establish the manufacturing system and realize disturbance detection, logistics distribution determination, and production logistics synchronization in a novel and feasible way. Based on Unity and the robot operating system (ROS), Singh et al. [

31] proposed a comprehensive digital twin framework to address the challenges of real-time data exchange. Its feasibility and adaptability to real-world industrial robotic arms were further demonstrated through a case study. Using the boom crane as an example, Lai et al. [

32] integrated analytical, numerical, and artificial intelligence models to develop a shape–performance digital twin for heavy equipment structural analysis. Duan et al. [

33] developed a collaborative robotic arm monitoring system based on digital twins to enable real-time assembly process monitoring and intelligent decision-making. Farhadi et al. [

34] established a digital twin system for the robotic drilling process and realized the visualization of real-time working parameters. Taking the six-joint robot UR10 as the research object, Guo et al. [

35] constructed a digital twin assembly system and proposed a modified Q-learning algorithm to solve the path planning problem in product assembly. To improve the vibration stability of industrial robots, Hou et al. [

36] proposed an industry-oriented digital twin model to predict the posture-dependent frequency response functions. Simulations and experiments demonstrated that the proposed method is superior to the data-driven model in terms of both accuracy and interpretability. Based on the Unity platform and virtual reality technology, Garg et al. [

37] developed a digital twin model for the FANUC robot to realize virtual–real synchronization and achieved a desired robot trajectory. Liu et al. [

38] also used Unity as a virtual environment to study the path planning of mobile robots using genetic algorithms. Through the interaction of virtual and real data, the movement trajectory error is reduced. Wang et al. [

39] proposed a digital twin and multi-objective path planning algorithm for a large-span curved-arm gantry robot. In the wooden door processing task, operation safety and production efficiency have been demonstrated. In 2024, based on the finite element method and spring damping principle, Zuo et al. [

40] established a rigid–flexible coupled model for CFETR redundant robotic arm dynamic control. Furthermore, a digital twin-based prediction control system is proposed to monitor the stress strain change and end effector position errors. To improve the safety during human–robot interactions, Xiong et al. [

41] introduced a compliant control strategy and constructed a flexible contact dynamic equivalent twin system for redundant manipulators. The effectiveness and practicality of the method were verified through ROS-based simulations and experimental studies. To address the challenge of monitoring the extreme environment inside fusion reactor vacuum chambers, a digital twin system for the ultra-redundant snake endoscope manipulator (SEM) was developed by Liu et al. [

42] in 2025. Based on the proposed trajectory tracking algorithm, the control of SEM achieved low latency, high sync, and stable operation.

Although the above methods provide more directions for digital twin technologies, some challenges also exist and need further research. On the one hand, most current research relies on established platforms, such as Unity and ROS, which not only brings potential copyright issues but also restricts development flexibility. On the other hand, few studies have been conducted on the combination of a mill relining manipulator and digital twin technology. In addition, unmeasured factors are not considered during virtual–real mapping, such as the end effector deformation caused by gravity. According to the above considerations, this paper focuses on establishing a five-dimensional digital twin system based on OpenGL to realize virtual–real interaction. To balance the number of pages in this paper and the explanation of the involved technologies, the technical analysis is discussed for an appropriate length, rather than in-depth elaboration. Furthermore, a path planning algorithm is proposed and simulated in virtual space to reduce the end effector deformation errors caused by gravity effects. The simulation comparison experiments not only demonstrate the efficiency of the improved path sequence but also prove the effectiveness of the end compensation strategy. The main contributions are as follows:

- (1)

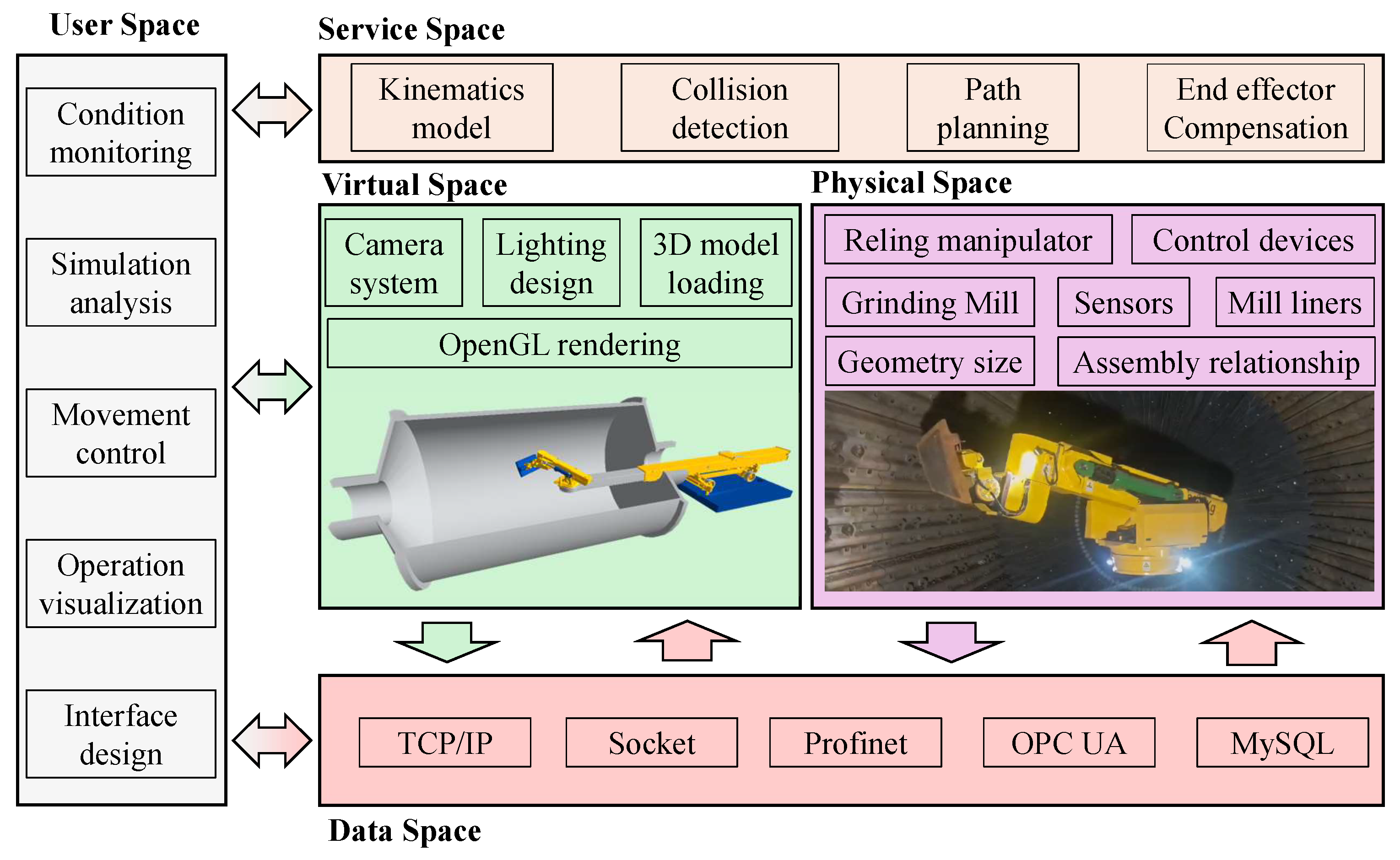

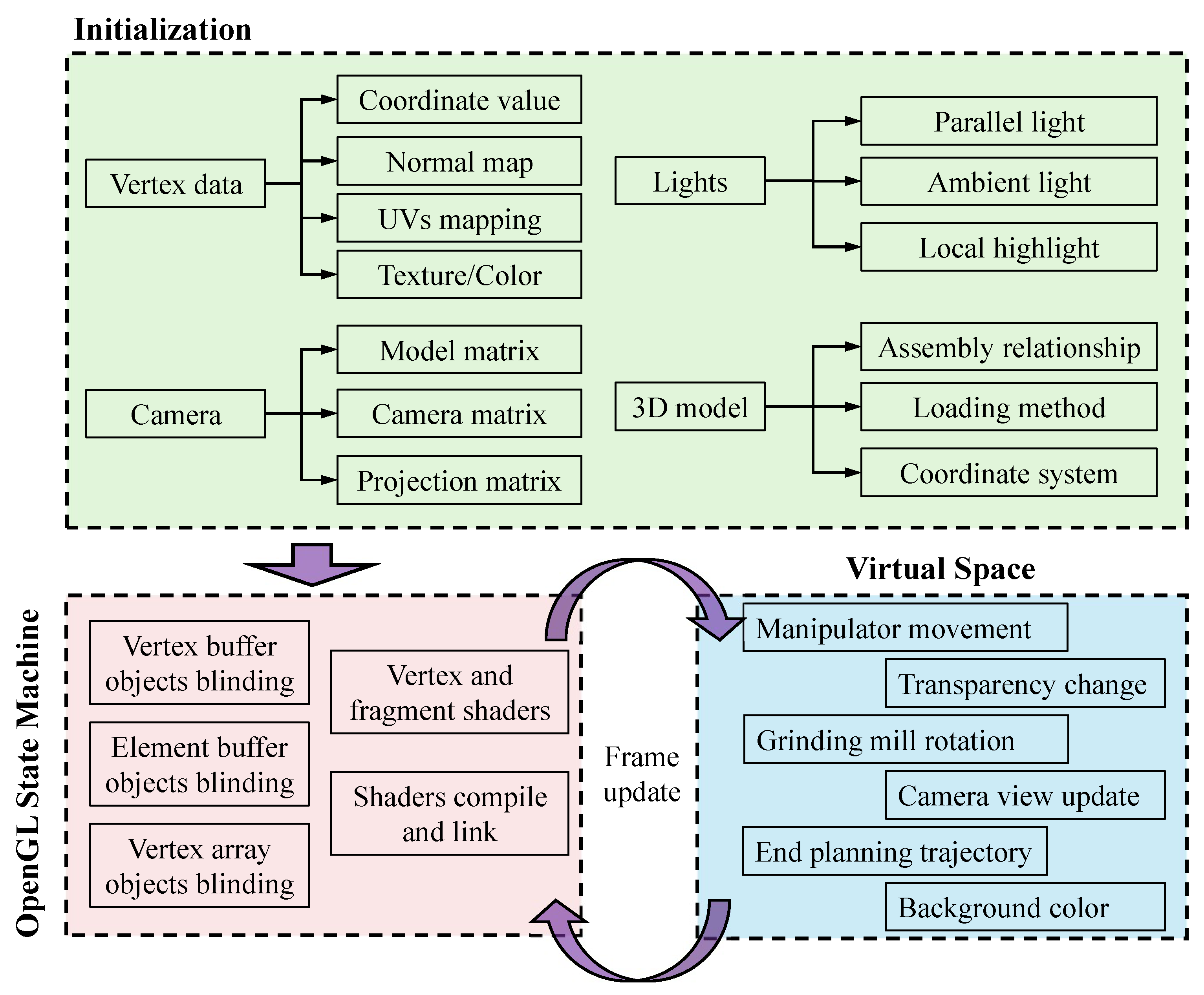

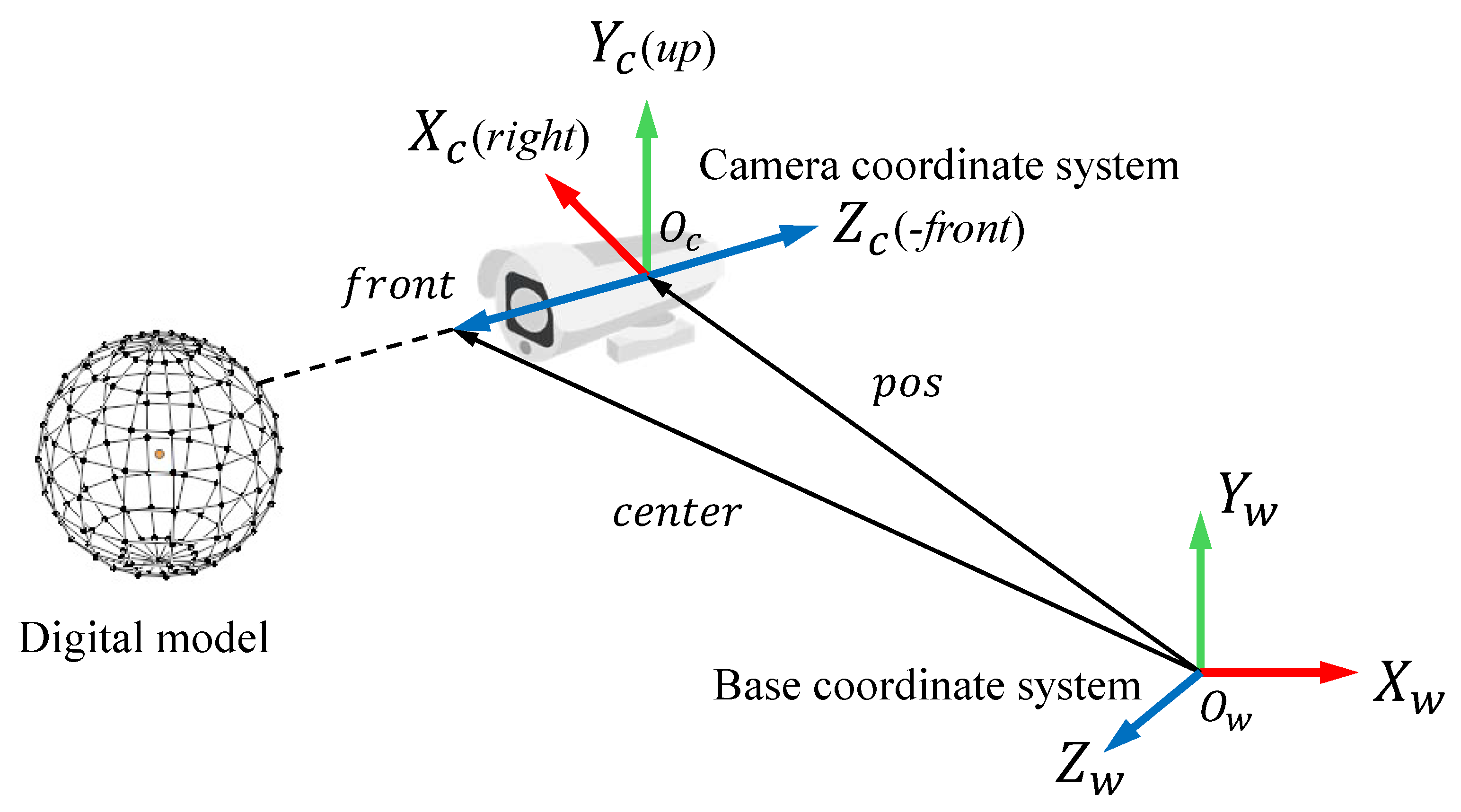

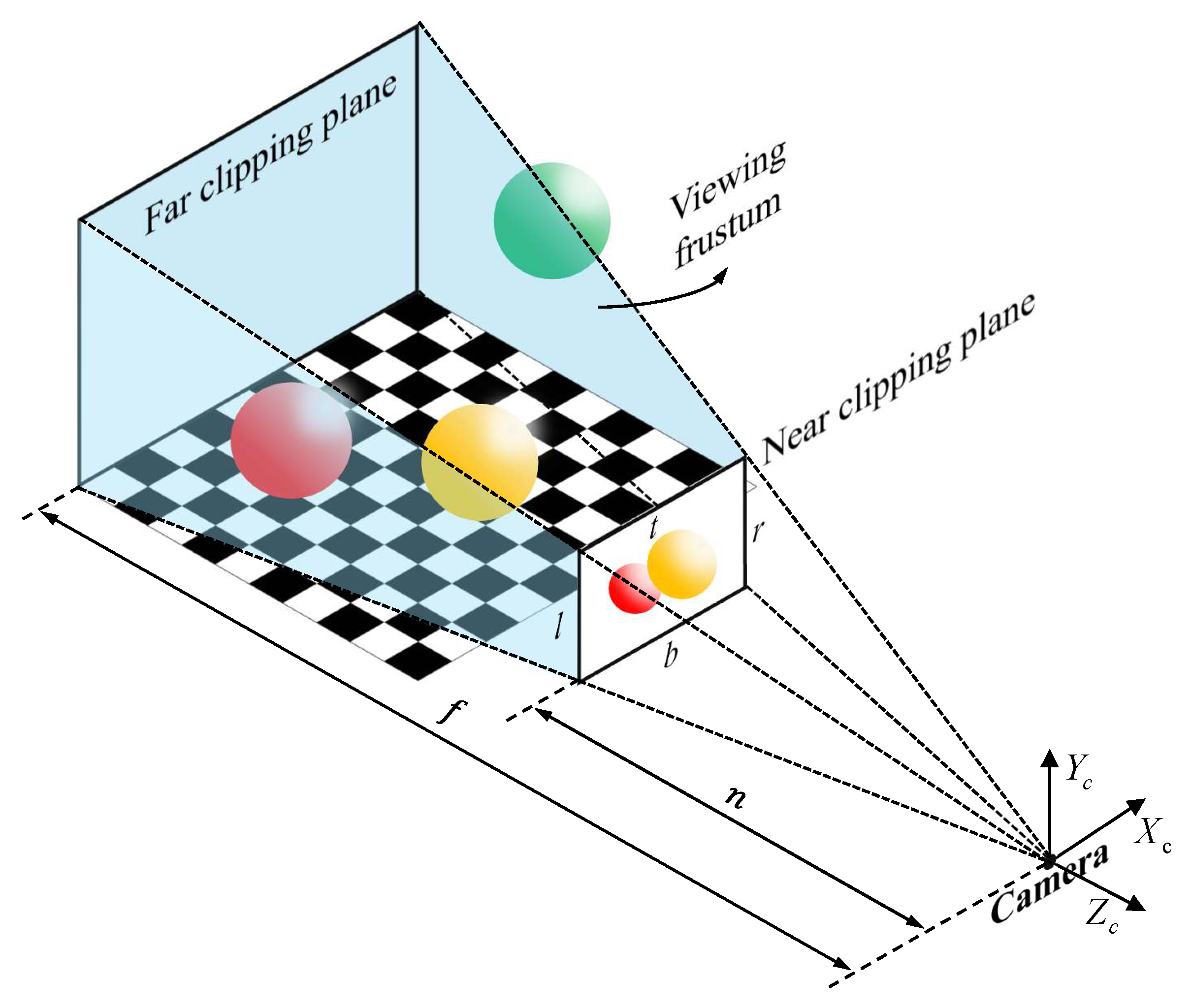

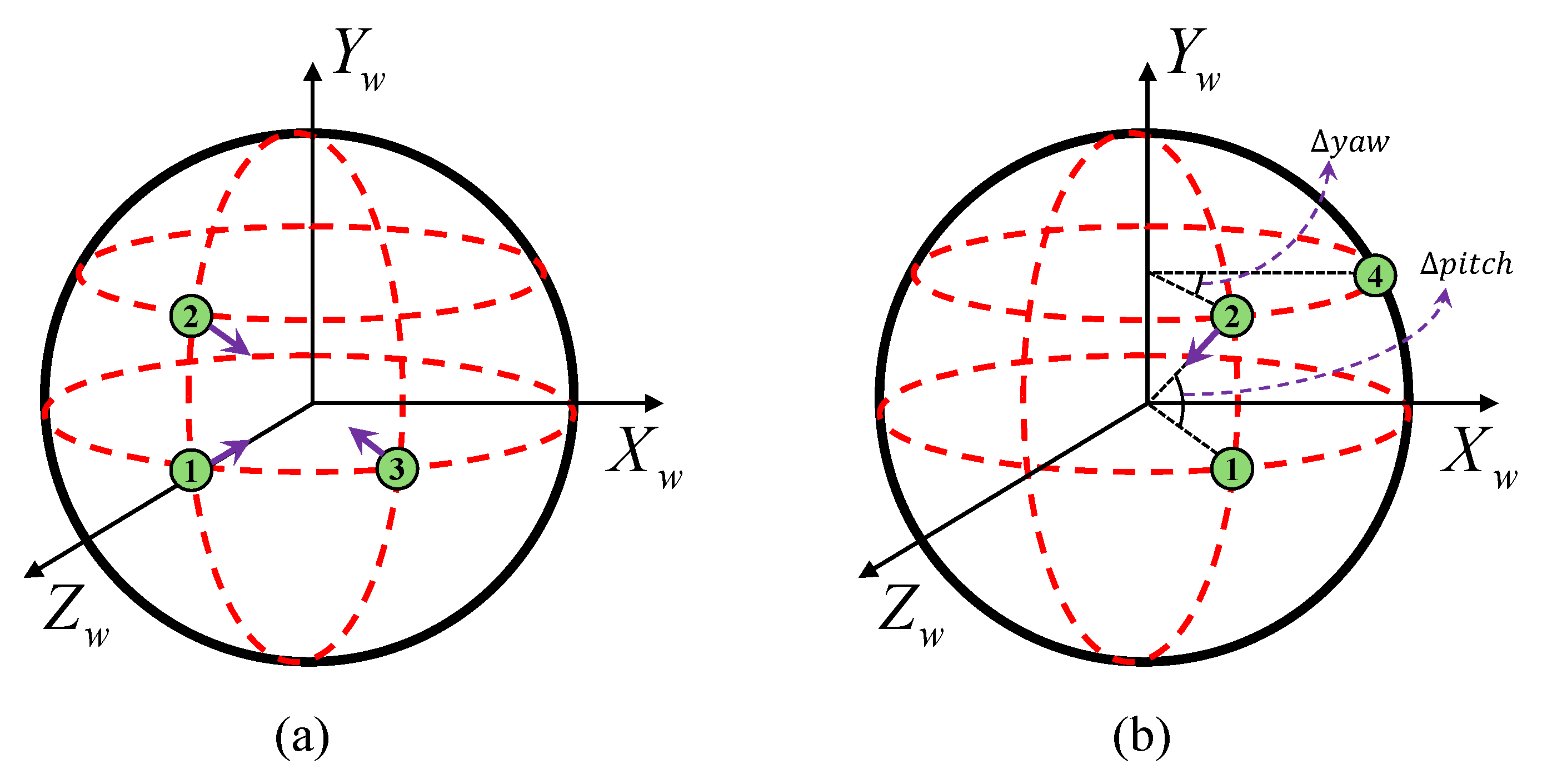

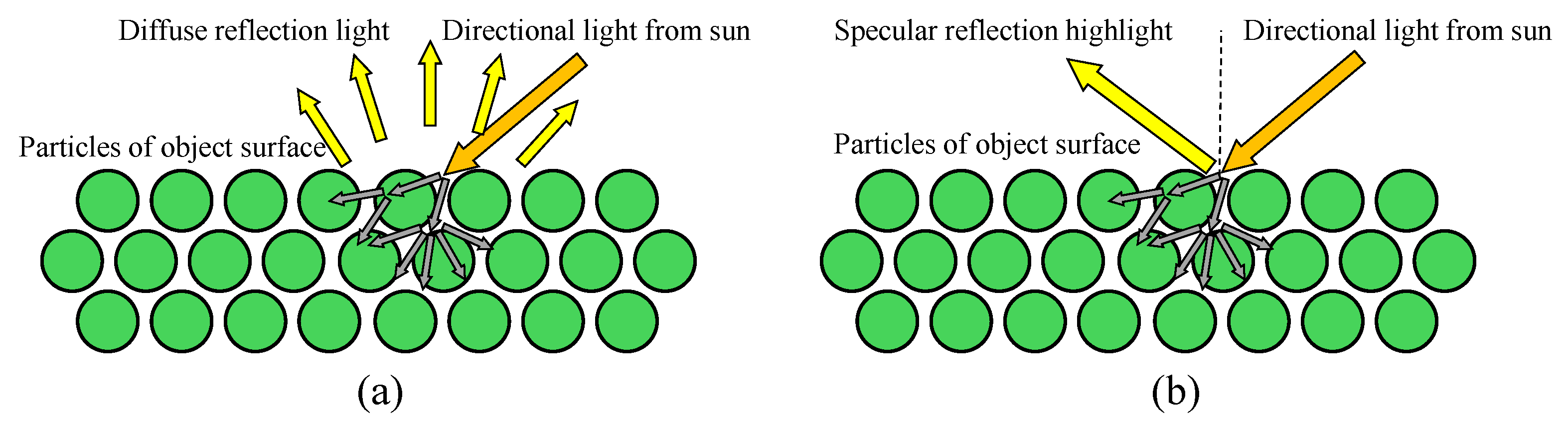

Based on OpenGL, a five-dimensional digital twin framework is proposed for mill relining manipulator to realize the virtual–real mapping of the mill liner exchange process.

- (2)

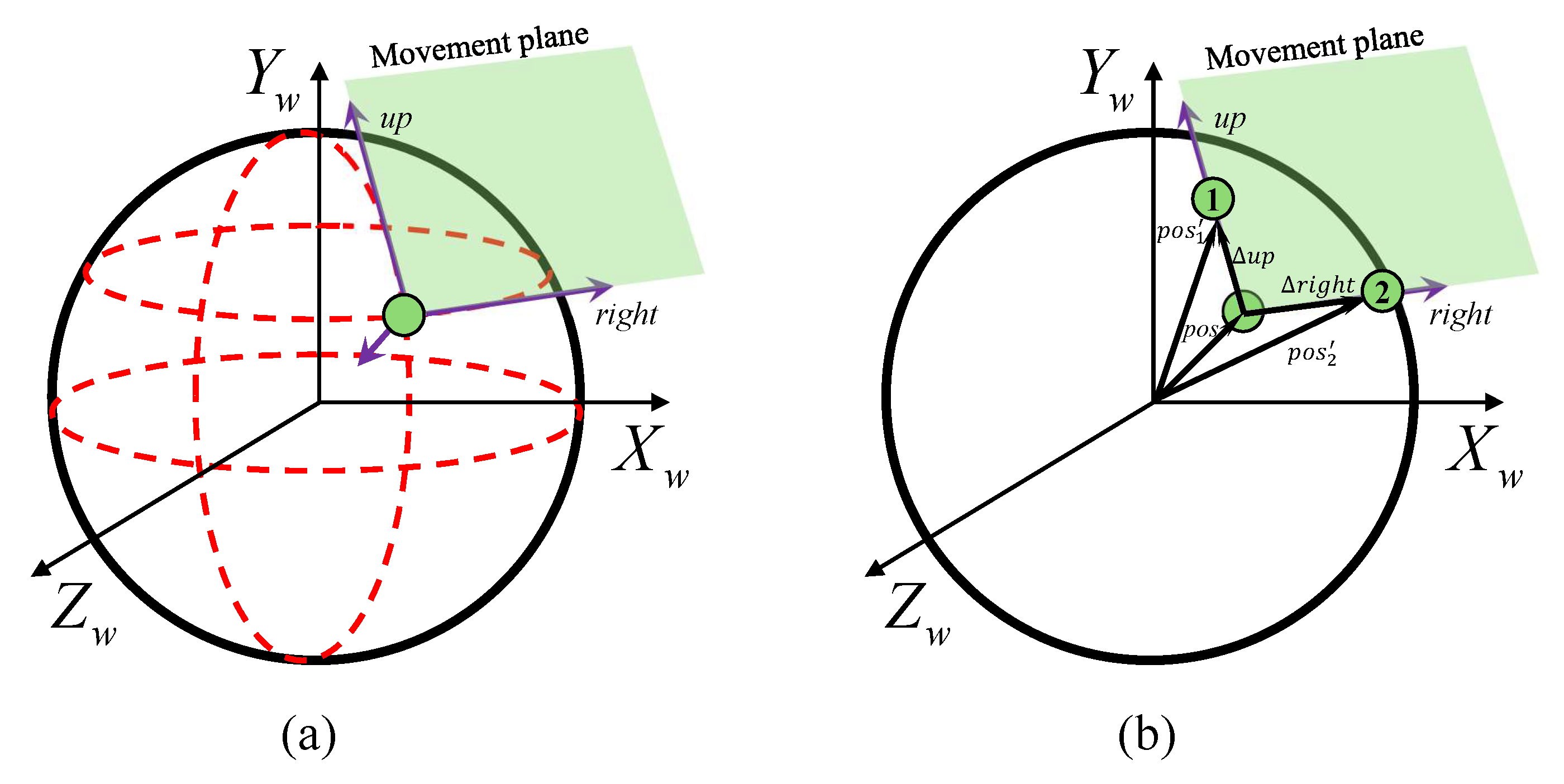

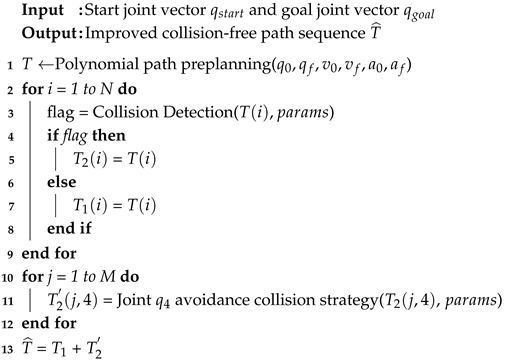

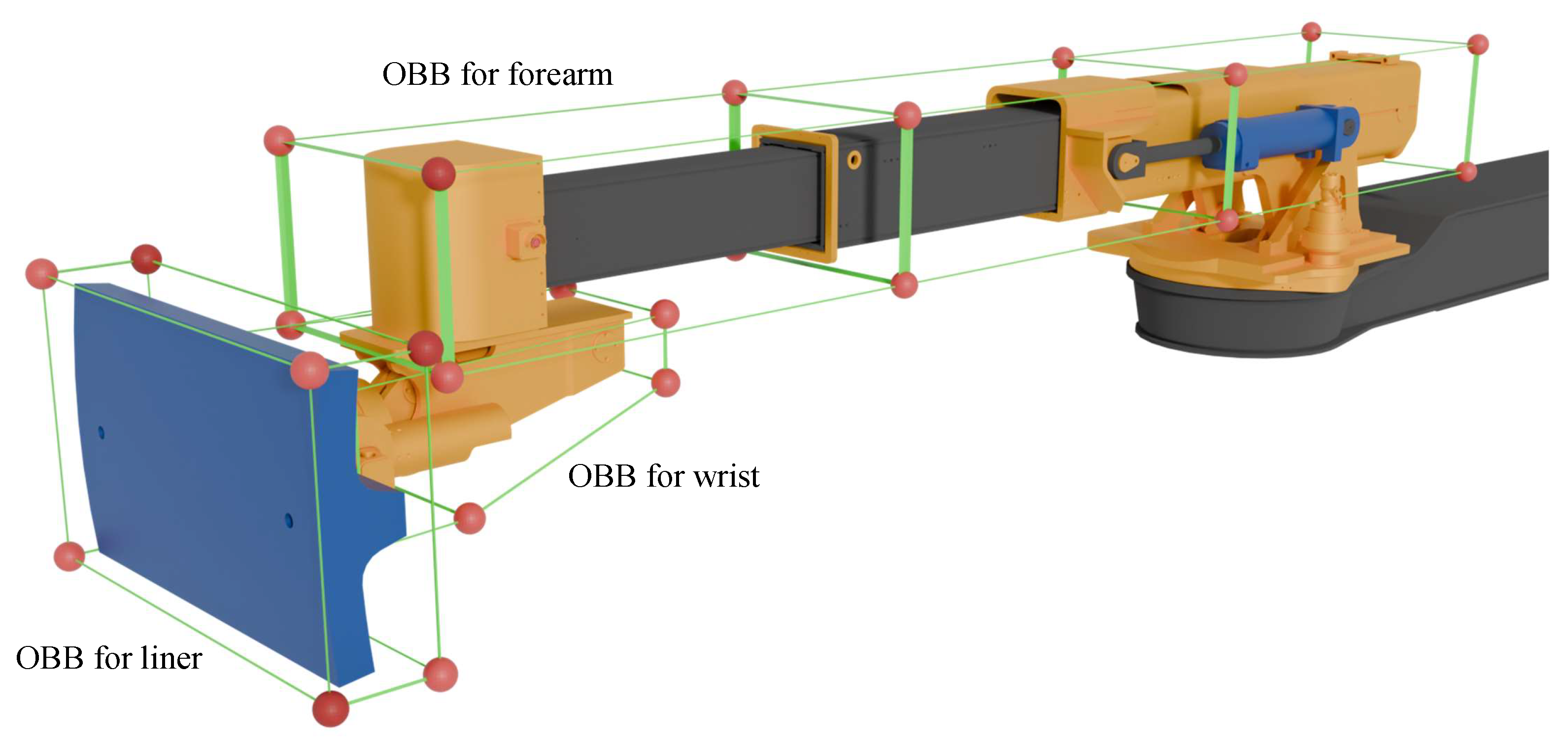

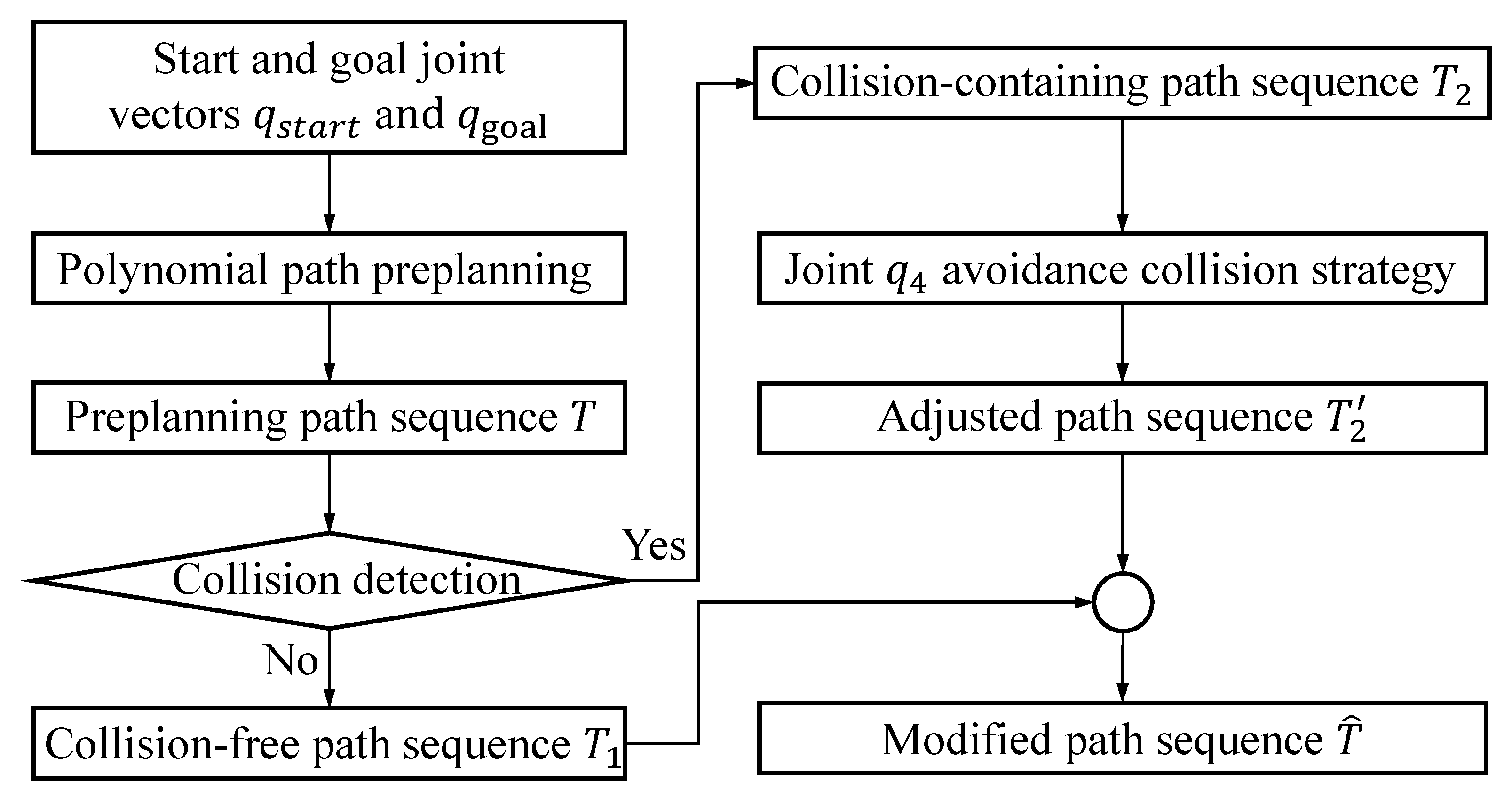

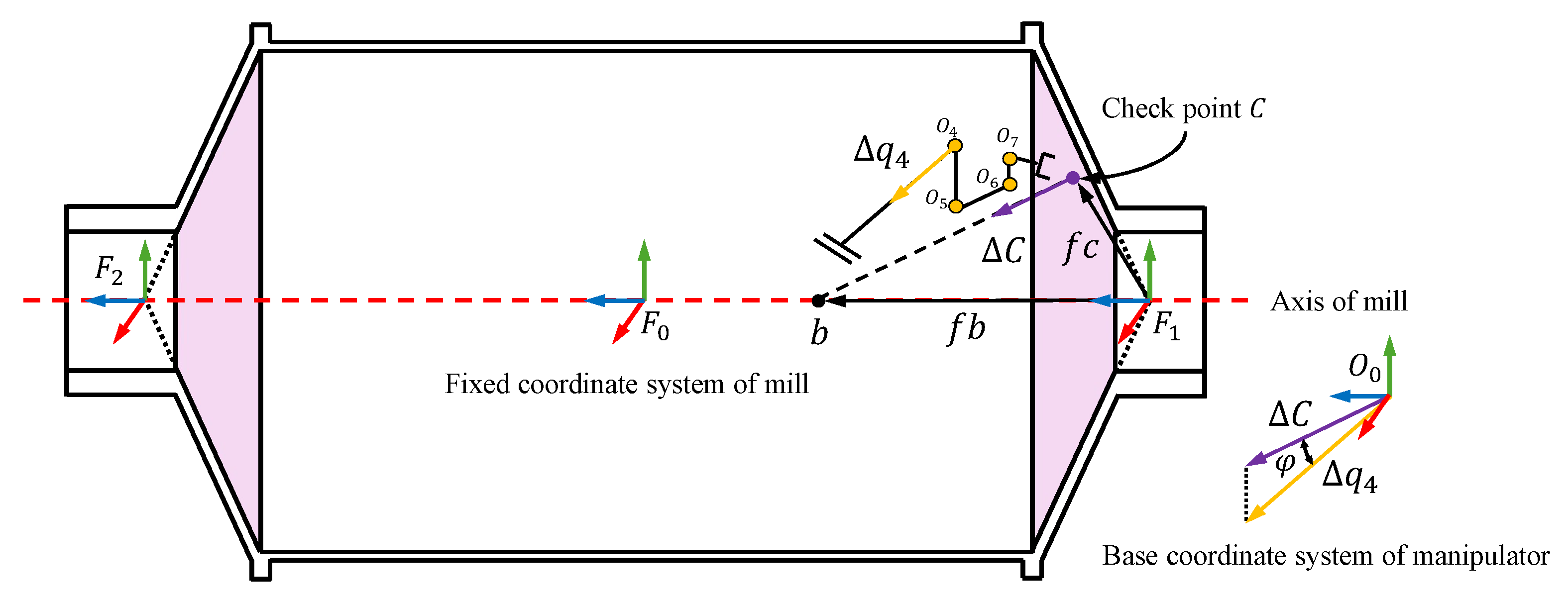

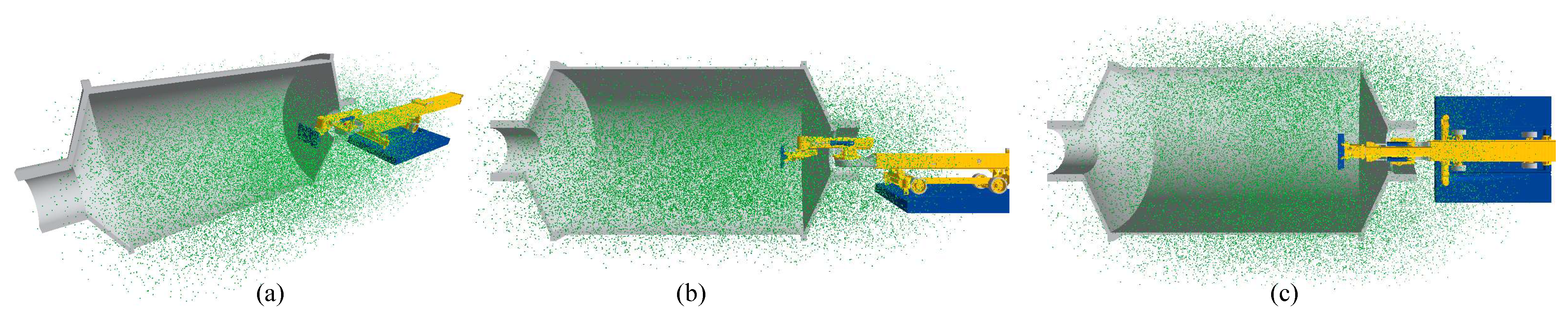

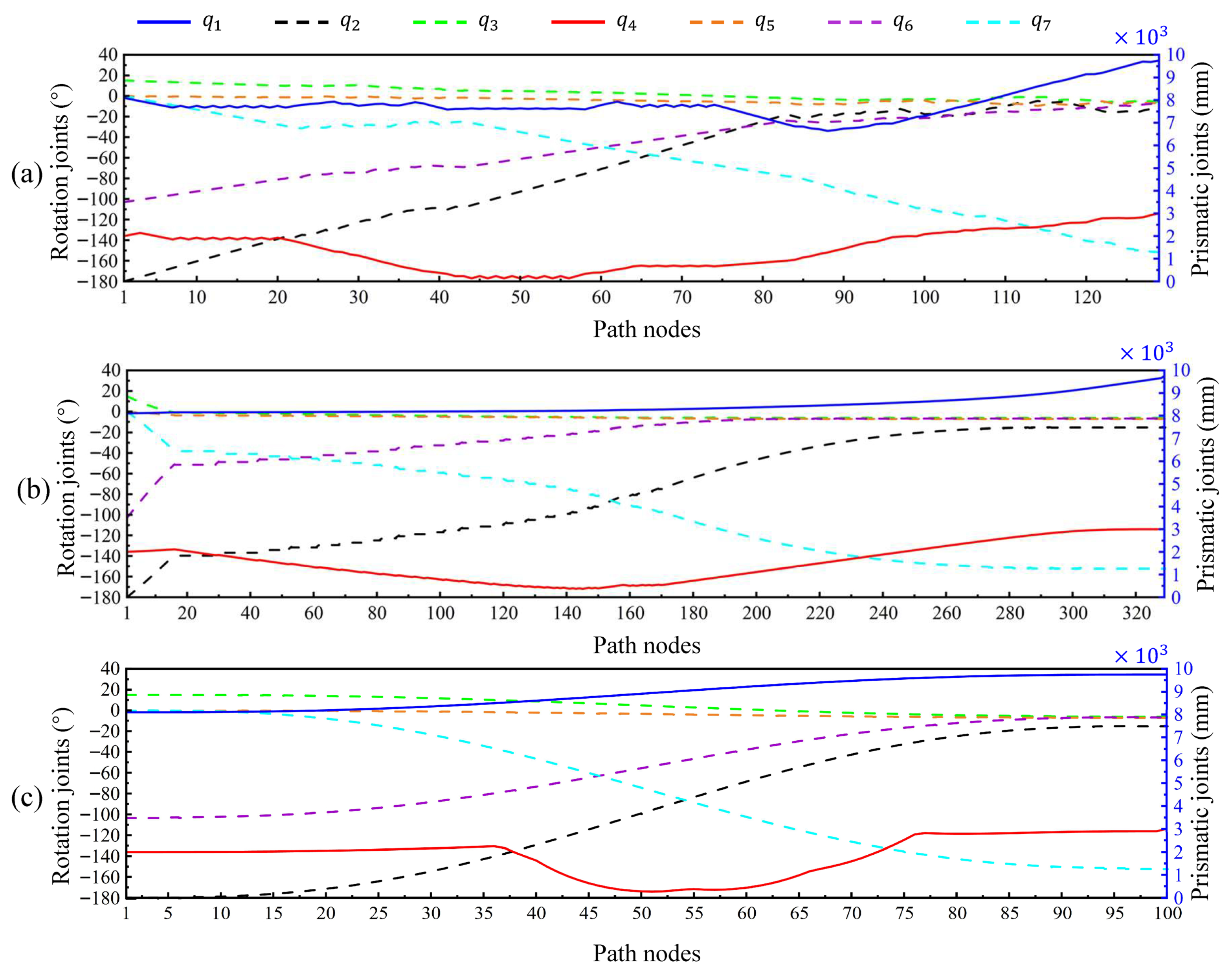

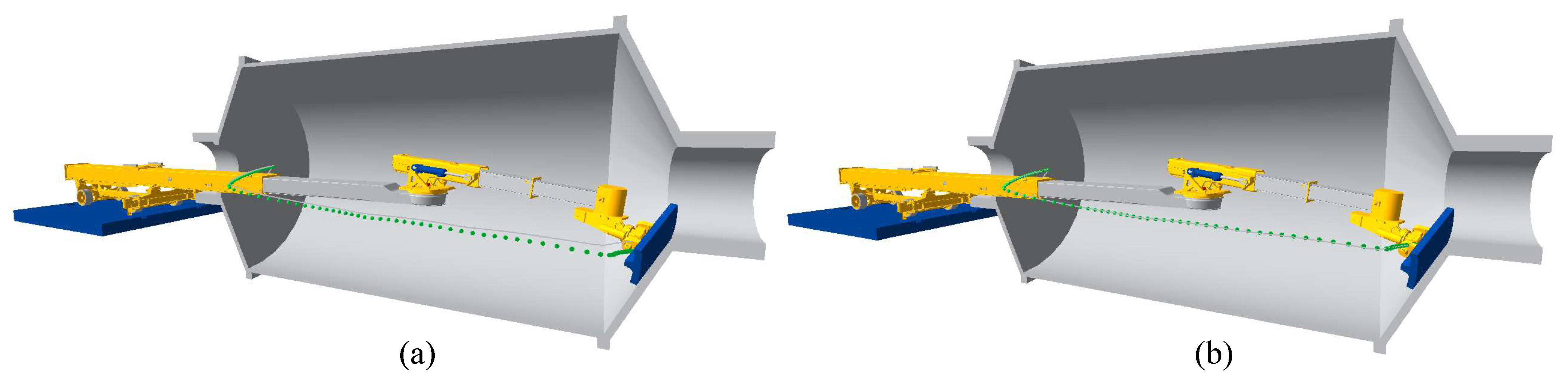

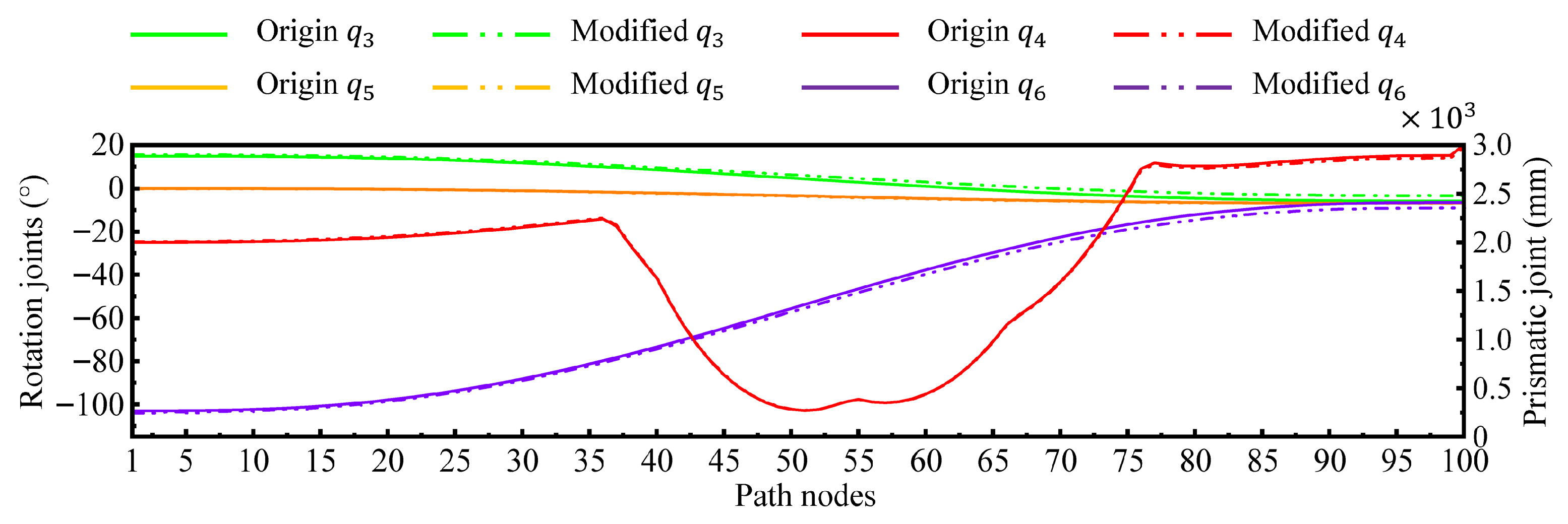

The forward kinematics, collision detection, analytical-based path planning algorithm, and end effector deformation compensation are presented and integrated to support the simulation analysis in virtual space.

- (3)

A desktop user application was developed for user interface, working condition monitoring, and workspace visualization.

- (4)

Comparison and simulation experiments were conducted to demonstrate the effectiveness of the proposed path planning algorithm and end effector compensation method.

The rest of this paper is organized as follows.

Section 2 introduces a five-dimensional digital twin framework based on OpenGL. In addition, it presents the associated technologies in detail. Furthermore, sensor data collection and the transmission method are discussed to enable virtual–real interaction.

Section 3 provides the kinematics model of the mill relining manipulator and the working process of the mill liner exchange. On this basis, the collision detection, path planning algorithm, and online end deformation compensation method are proposed for simulation analysis within the digital twin system.

Section 4 presents the user application development, workspace virtualization, comparison simulation experiments, and result discussion.

Section 5 concludes this paper with a summary and future research directions.

5. Conclusions

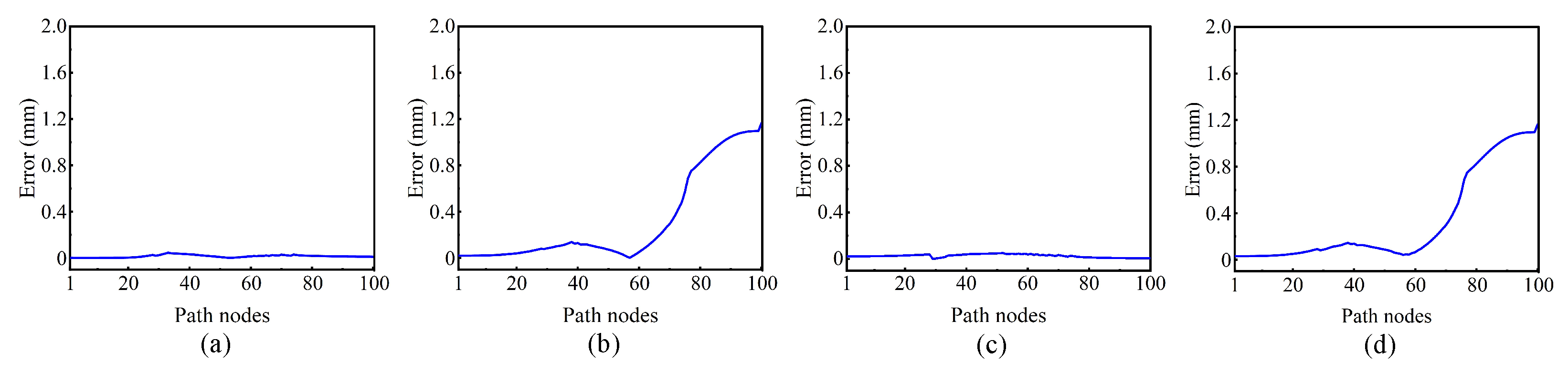

This paper not only establishes a digital twin system but also proposes a path planning algorithm and end effector compensation method for the mill relining manipulator. First, a digital twin framework is proposed, comprising five interconnected spaces responsible for physical entity control, virtual model simulation, service function drivers, bidirectional data transmission, and user space interaction. Consequently, based on OpenGL, the scene rendering, camera system, light designs, digital model importation, and joint controls are explained to establish a comprehensive digital twin system. The sensor data collection and transmission method are also discussed to support the virtual–real interaction. Second, based on the kinematics model and collision detection, a path planning algorithm is proposed to simulate the mill liner exchange task within the digital twin system. In addition, an online end effector deformation calculation method is proposed to reduce the end trajectory tracking error caused by gravity effects. Finally, a user desktop application is developed based on the above-mentioned methods to realize mill relining manipulator real-time condition monitoring and simulation analysis visualization. Furthermore, comparison experiments were conducted on path planning to demonstrate the superiority of the proposed algorithm in terms of planning speed, path length, and motion smoothness. Not limited to the theoretical path, an end effector deformation simulation experiment is presented to demonstrate the effectiveness of the proposed online compensation method. The joint path sequence is improved, and the end effector absolute tracking error is satisfied for practical application.

However, there are also some limitations of this study. For instance, due to article length limitations, further technical discussion and algorithmic insight for each method is not presented in this paper. In addition, since the prototype platform is still under development, the effectiveness of the proposed digital twin system cannot be demonstrated through hardware experiments at this time. In the future, we will continue to explore mill relining manipulator control strategies and prototype development works. The effectiveness of the proposed digital twin system and path planning algorithm will be further verified on the hardware platform.