Six-Dimensional Spatial Dimension Chain Modeling via Transfer Matrix Method with Coupled Form Error Distributions

Abstract

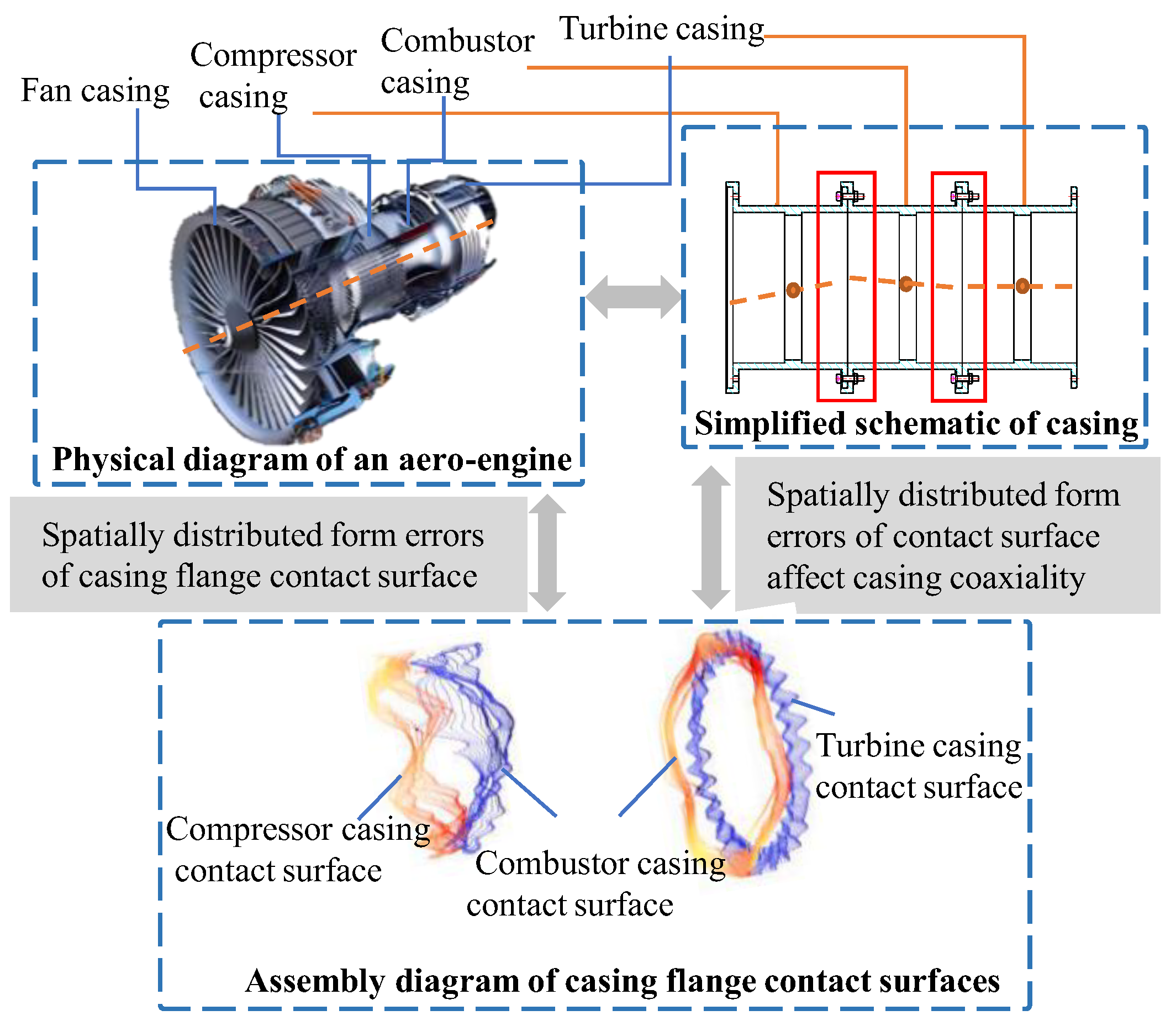

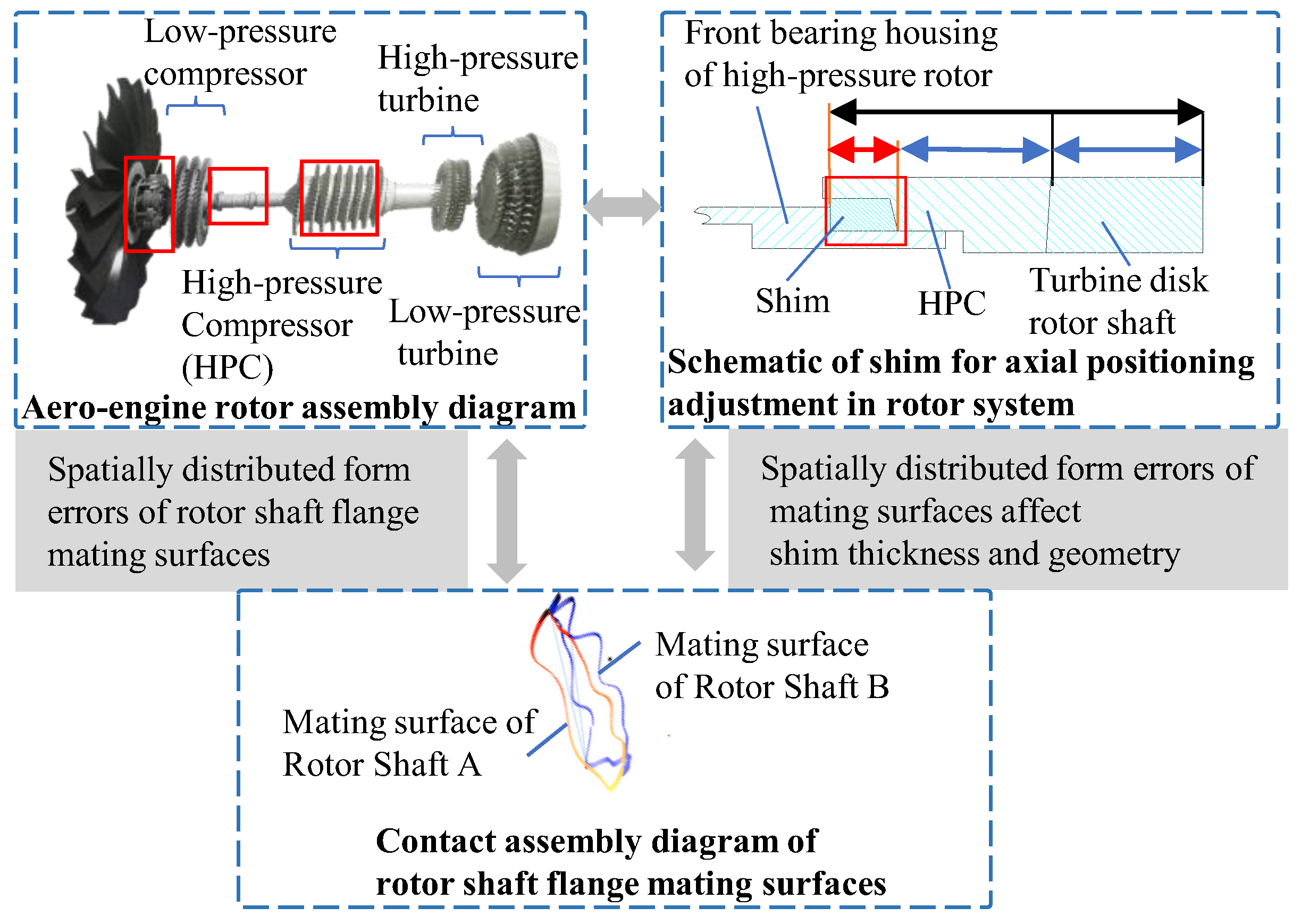

1. Introduction

2. Six-Dimensional Spatial Dimension Chain Modeling

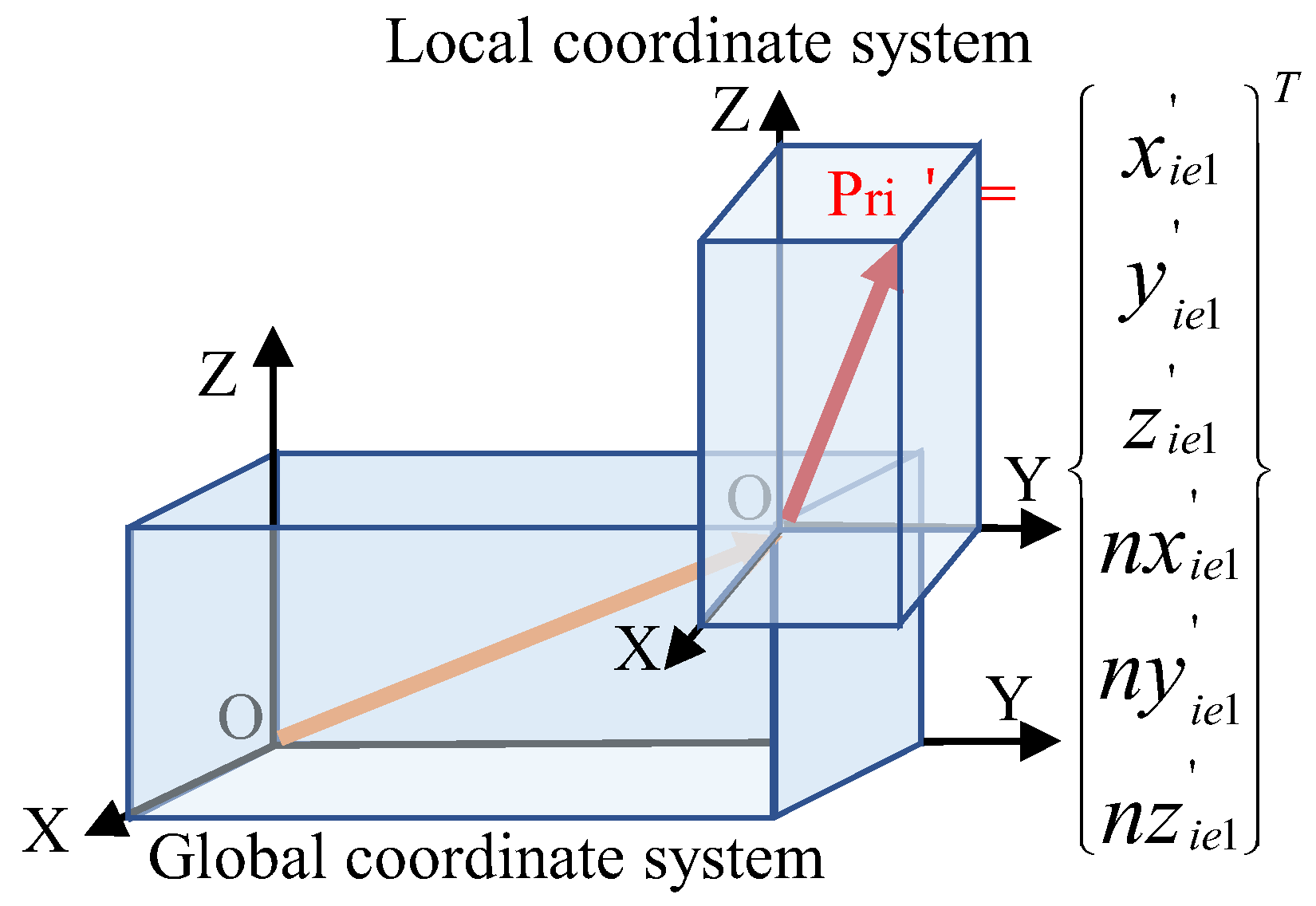

2.1. Definition of Modeling Data

- Mating-constrained datum planes: The coordinate systems are established at both the ideal mating positions (e.g., surface b or c) and the actual mating positions (e.g., surface b′), referred to as the ideal mating-constrained datum and actual mating-constrained datum, respectively;

- Non-mating-constrained datum planes: The coordinate systems are defined at the ideal locations of critical surfaces (e.g., surfaces a and d) and their actual locations (e.g., surfaces a′ and d′), designated as the ideal non-mating-constrained datum and actual non-mating-constrained datum, respectively.

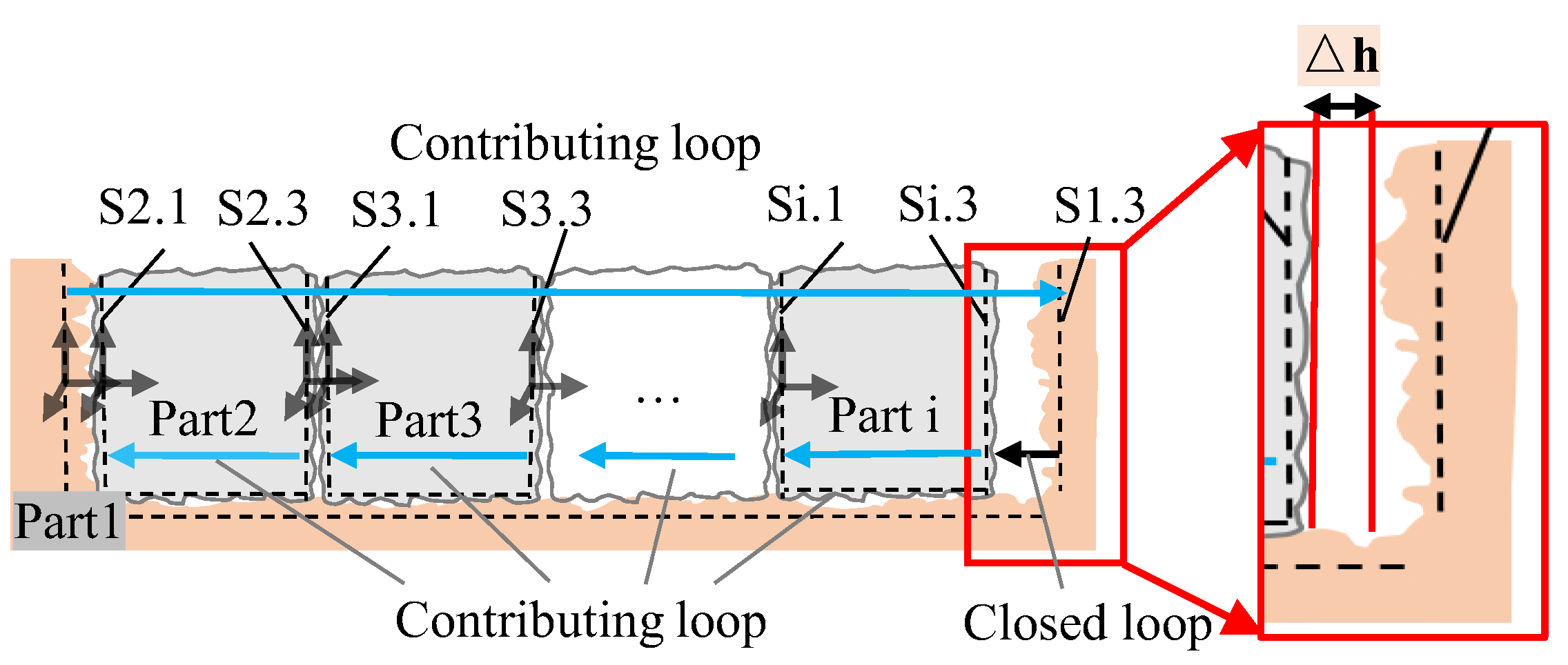

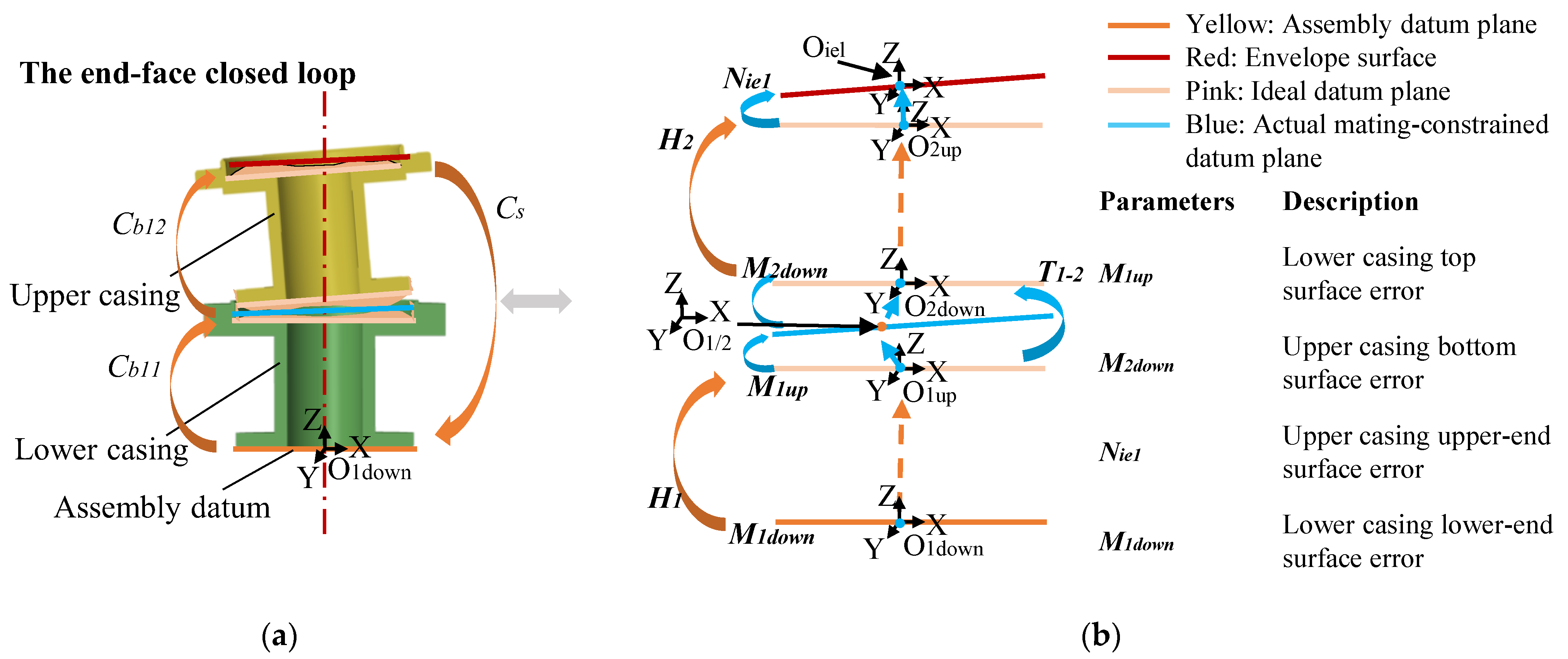

2.2. Establishment of SDC

- The assembly datum plane of the component is selected as the primary reference for the global coordinate system of the SDC model;

- Local coordinate systems are then established on the critical surfaces of the part, with their relationship to the global coordinate system illustrated in Figure 6;

- The SDC model is then decomposed into two branches:

- First branch: Starting from the assembly datum (i.e., the origin of the global coordinate system), local coordinate systems are sequentially constructed along the transmission path of the contributing loops until reaching the datum plane at one end of the closed loop.

- Second branch: Similarly, starting from the assembly datum, the process continues until reaching the datum plane at the other end of the closed loop.

- Figure 7 illustrates the implementation of this principle via a distributed-form-error-based multidimensional SDC framework, covering both its construction and application (specific variables are detailed in the following two paragraphs).

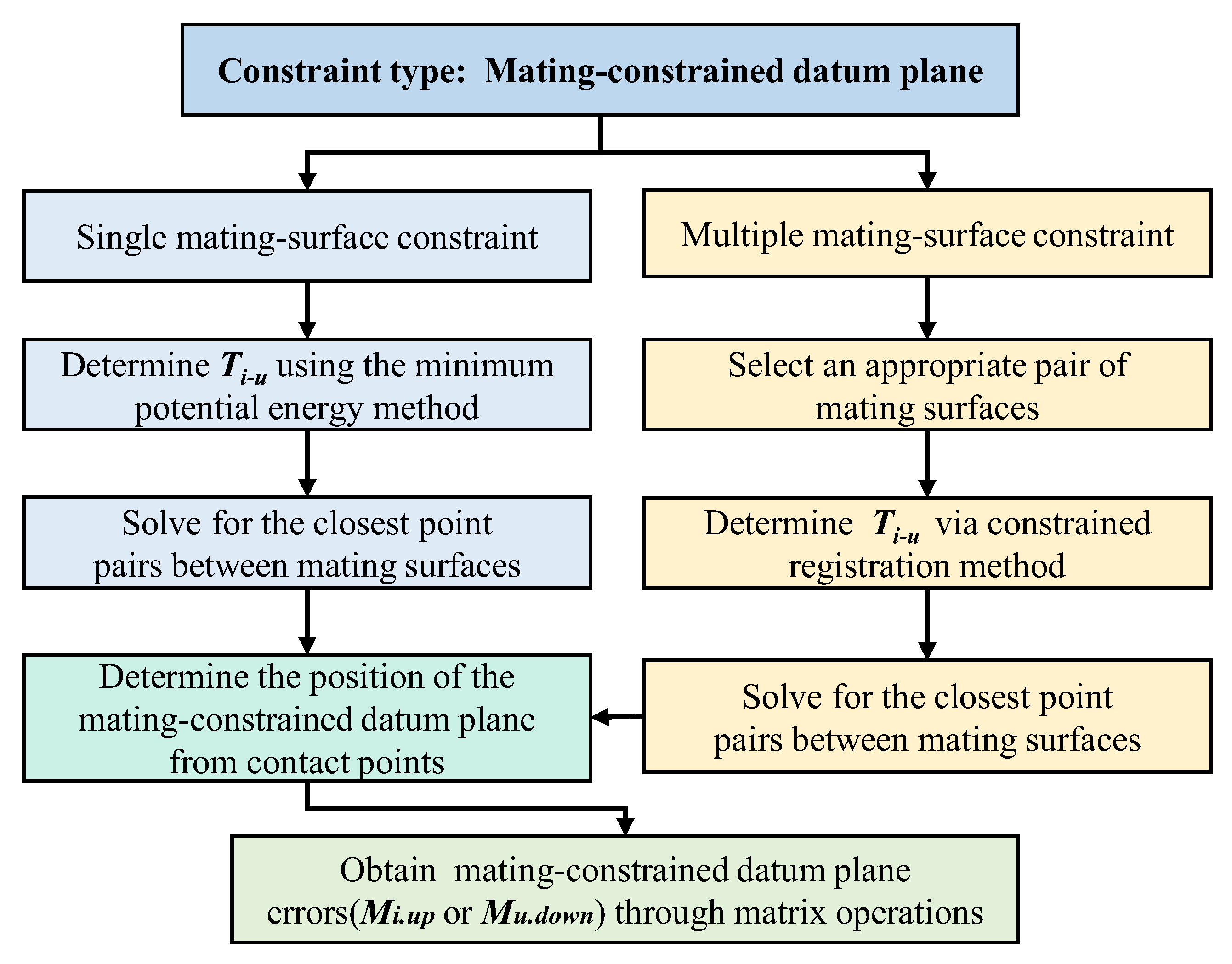

2.3. Characterization for Mating-Constrained Datum Error

2.4. Characterization for Non-Mating-Constrained Datum Error

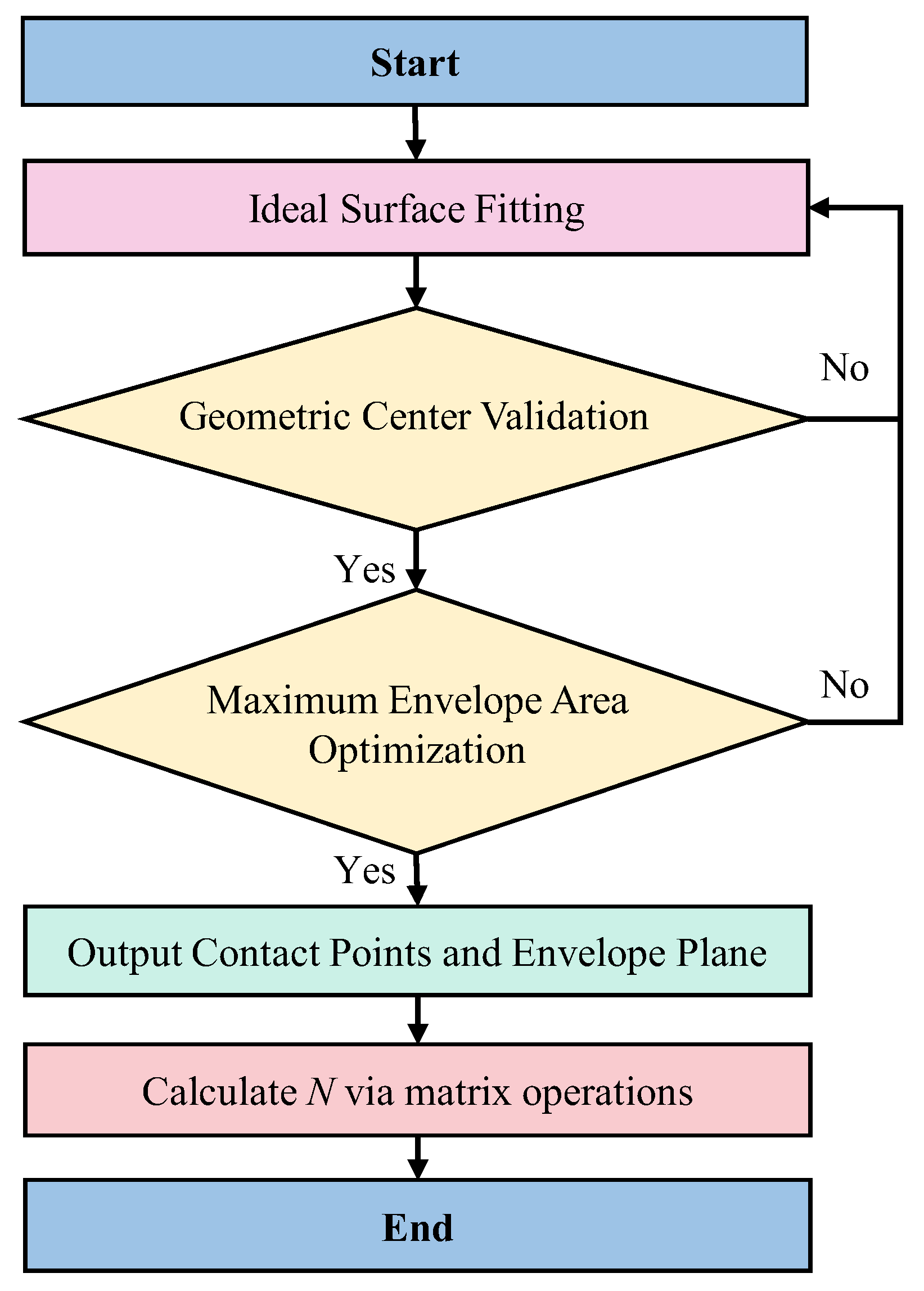

- Envelope condition definition: The envelope condition is an error analysis method. The envelope condition bounds all elements of the spatially distributed form errors within the envelope surface, controlling the surface’s position, orientation, and form to meet interchangeability and assembly quality requirements.

- Envelope surface definition: In a given direction, an ideal surface approximates the actual surface, with its position and form satisfying the envelope condition (criterion 1 above).

- Envelope area definition: The envelope surface and actual plane must intersect at ≥3 points, forming a triangular area termed the envelope area.

- Maximization requirement: The envelope area must be maximized to closely conform to the actual error surface.

- Ideal Surface Fitting

- 2.

- Geometric Center Validation

- 3.

- Maximum Envelope Area Optimization

- 4.

- Output Contact Points and Envelope Plane

- 5.

- Non-Mating-Constrained Datum Error Calculation

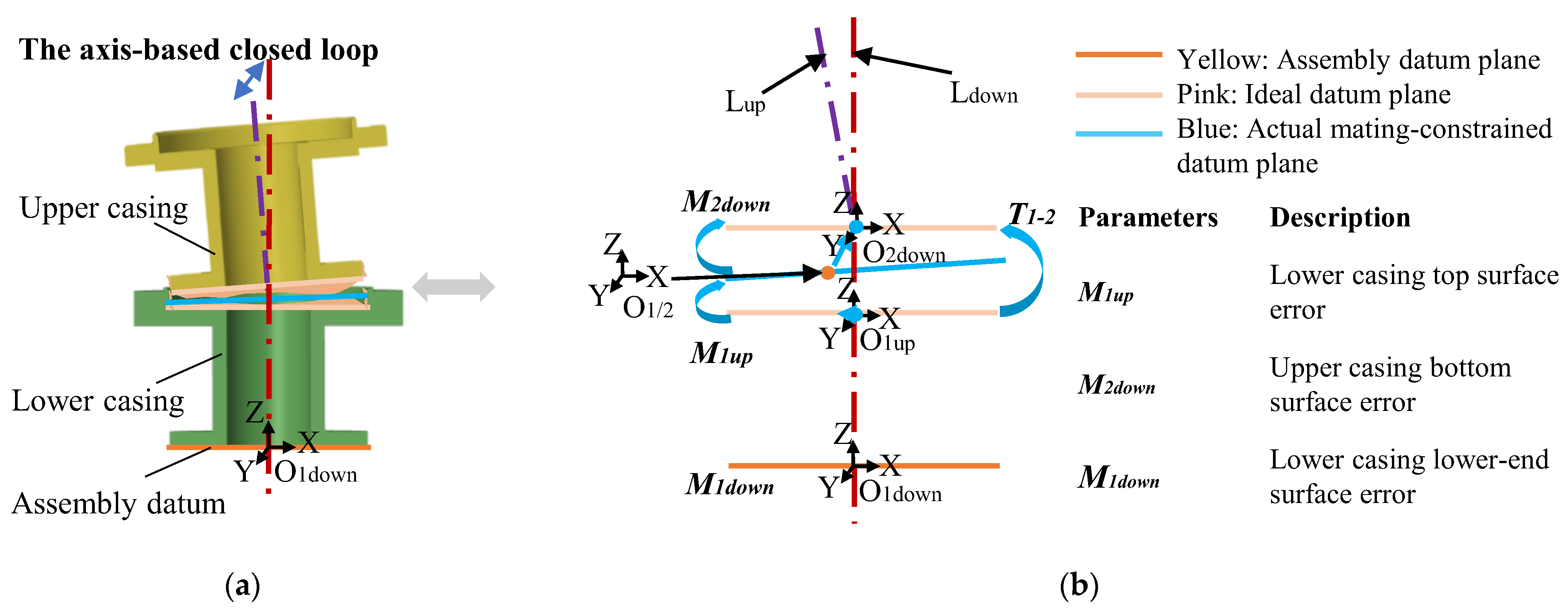

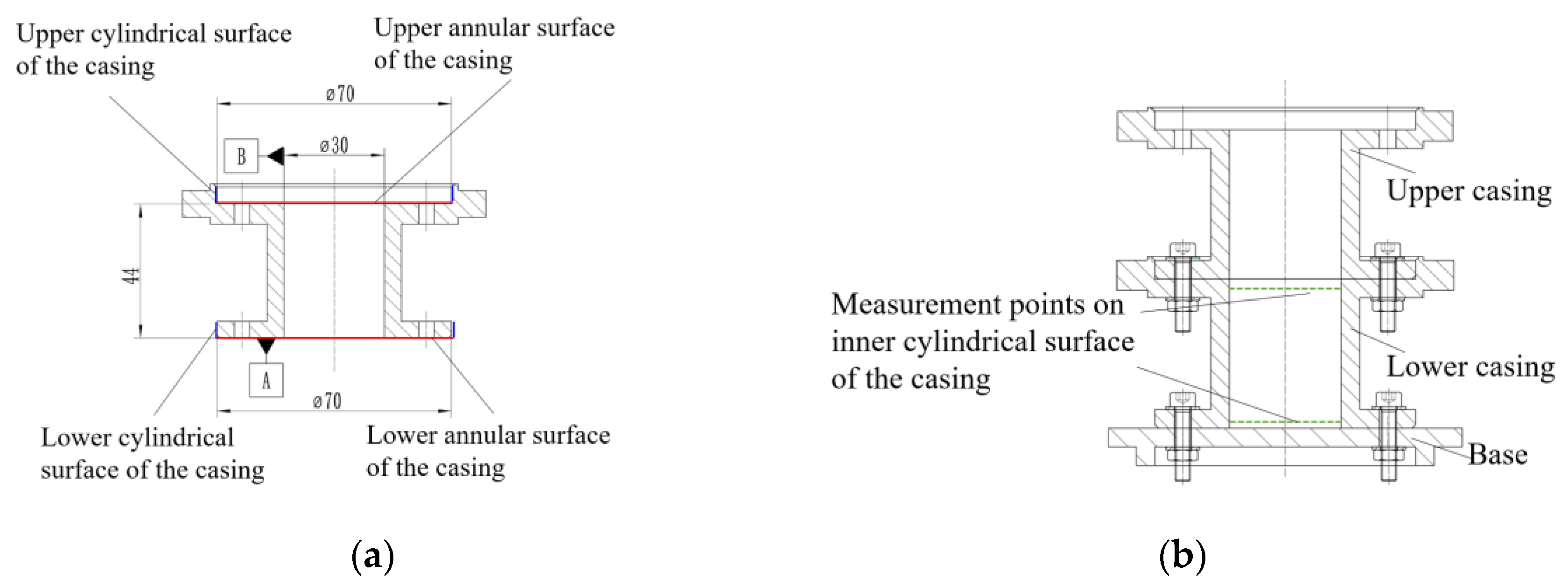

2.5. Six-Dimensional Modeling for Aero-Engine Casing Assembly

- The mating-constrained datum plane error M1up of the lower casing top surface Olup (comprising two constrained surfaces—the flange end face and flange spigot cylindrical face);

- The mating-constrained datum plane error M2down of the upper casing bottom surface O2down (also including two constrained surfaces—the flange end face and flange spigot cylindrical face);

- The non-mating-constrained datum plane error Nie1 at the end face of the upper casing’s top surface;

- The mating-constrained datum plane error M1down at the end face of the lower casing’s bottom surface.

- The mating-constrained datum plane error M1up of the lower casing’s top surface (including two constraint surfaces—the flange end face and the flange spigot cylindrical surface);

- The mating-constrained datum plane error M2down of the upper casing’s bottom surface (similarly comprising the flange end face and spigot cylindrical surface).

- Position vector of the coordinate origin: [olx, oly, olz, 1]T;

- Unit normal vector of the datum axis: [nlox, nlox, nlox, 0]T (e.g., [0, 0, 1, 0]T for Z-axis alignment).

3. Experimental Validation of the SDC Model for Casing Assembly

3.1. Experimental Design

3.2. Experimental Procedure

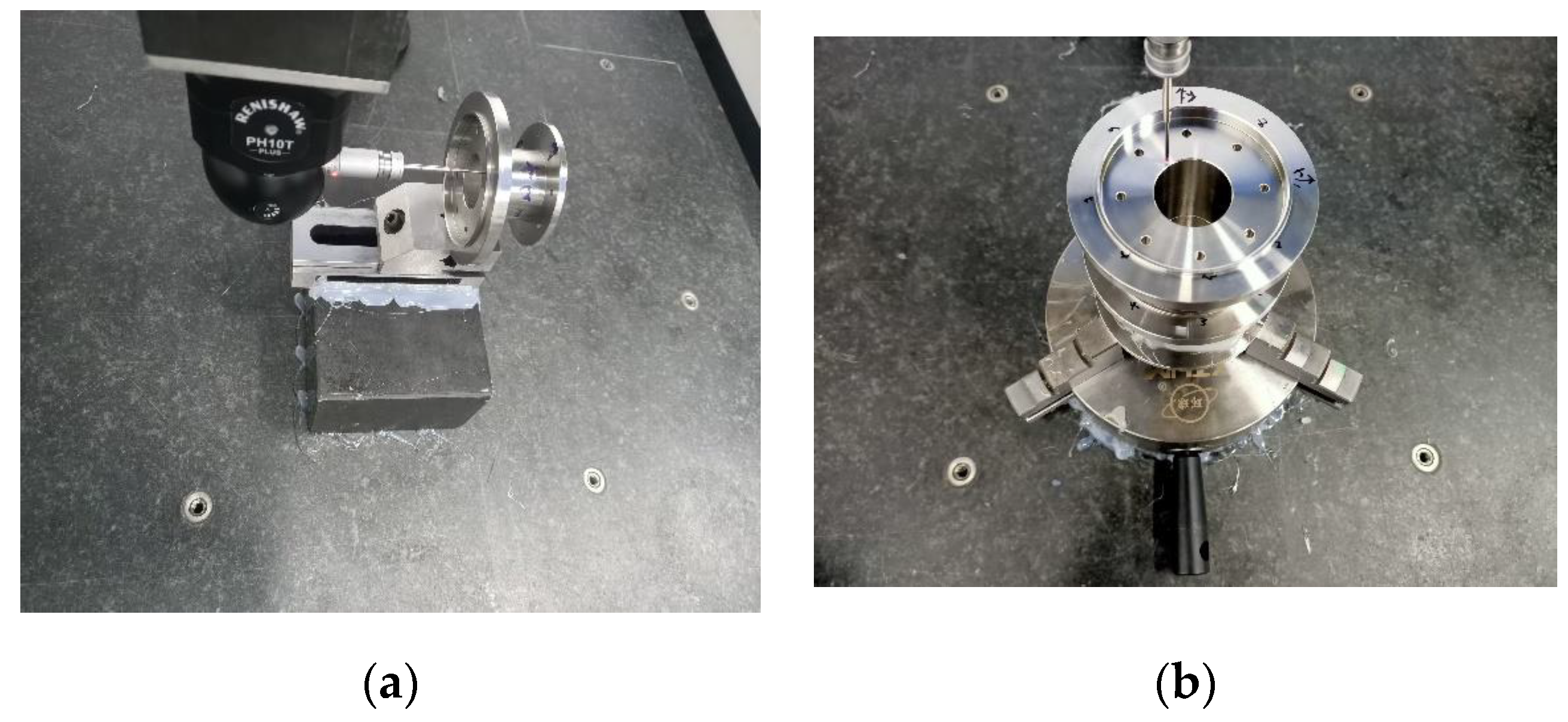

3.2.1. Component Measurement

3.2.2. Assembly Measurement

3.3. Results and Analysis

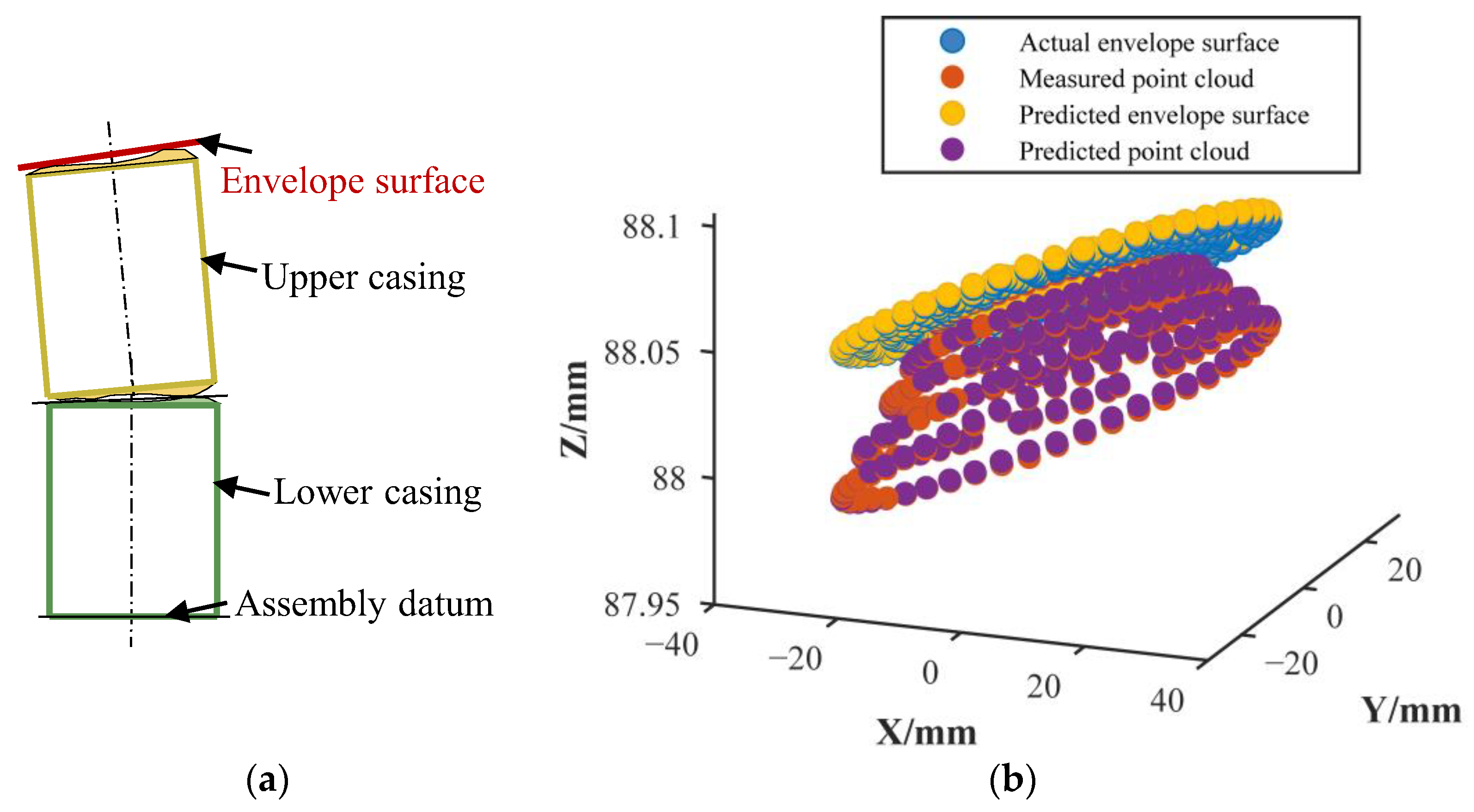

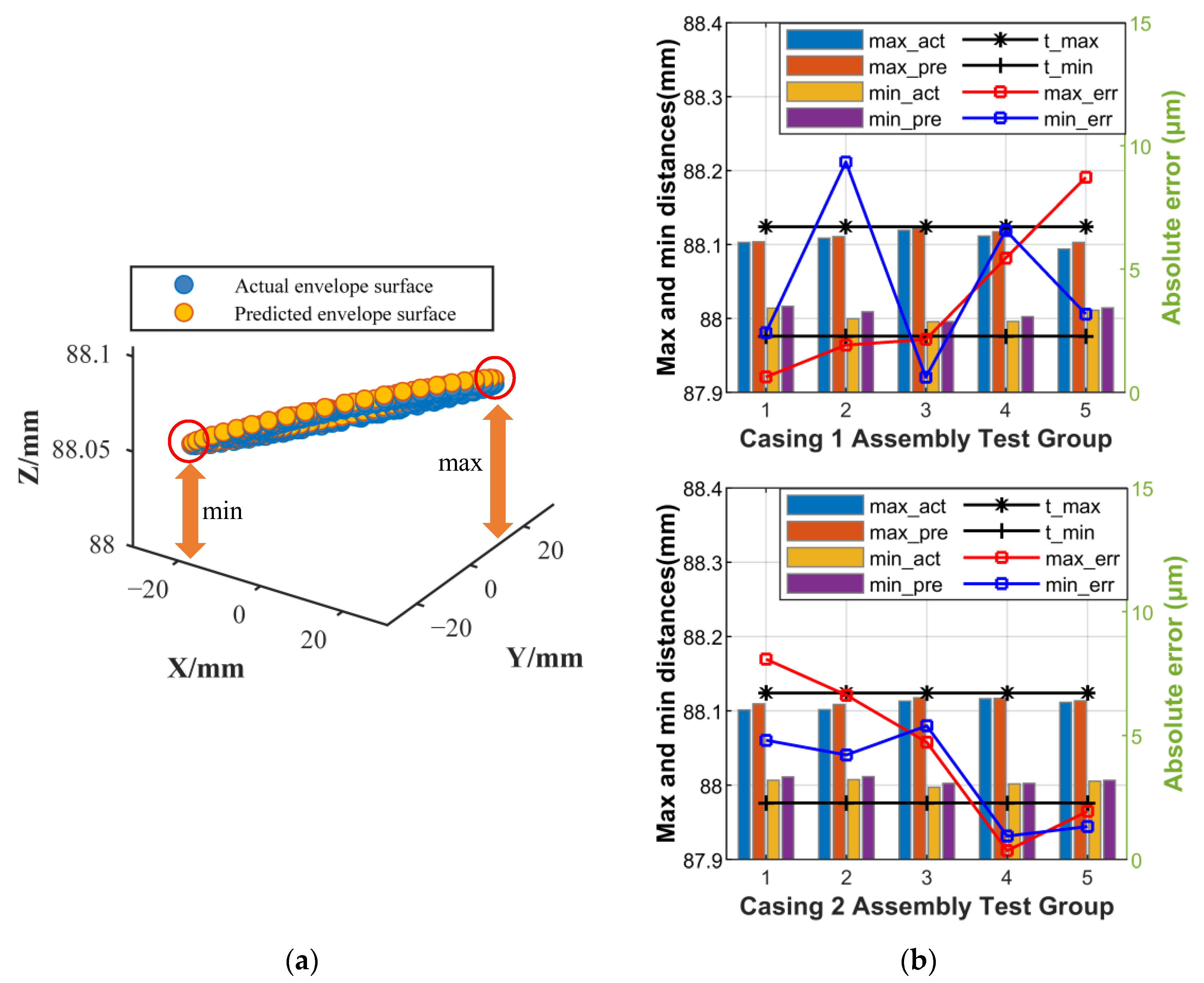

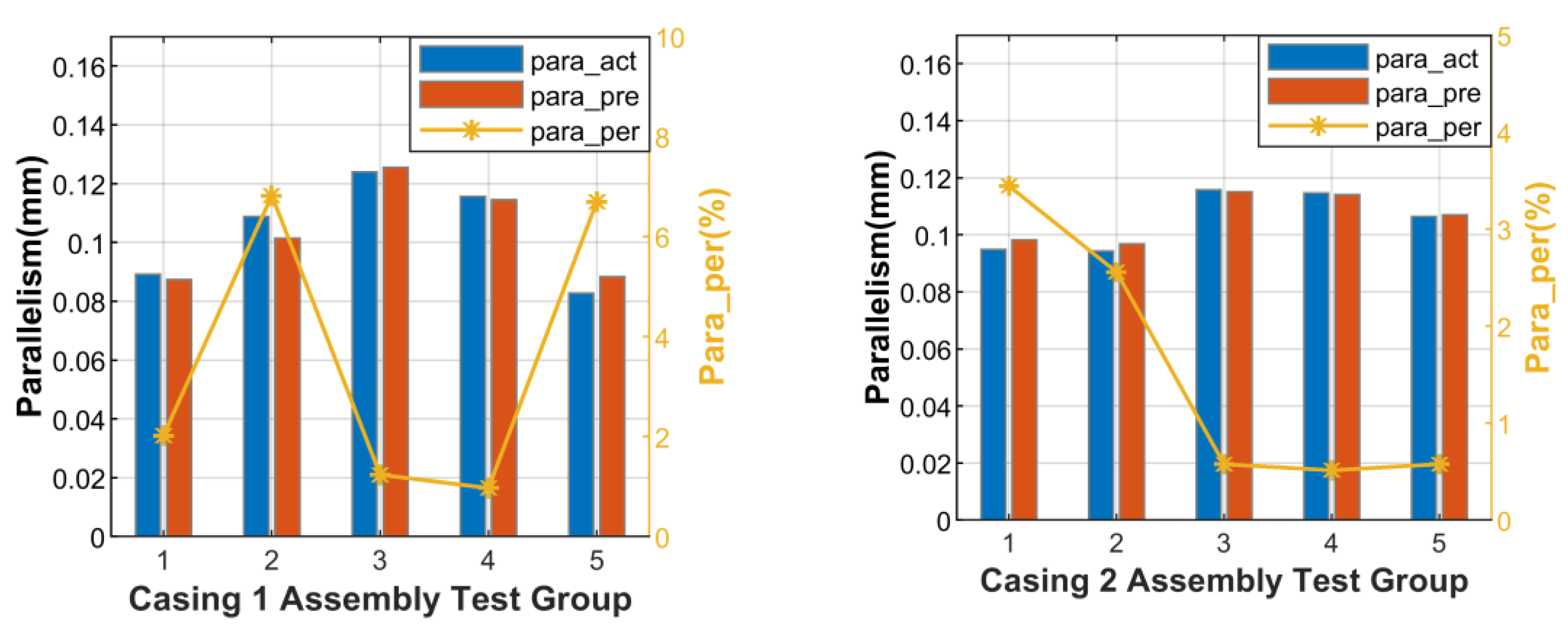

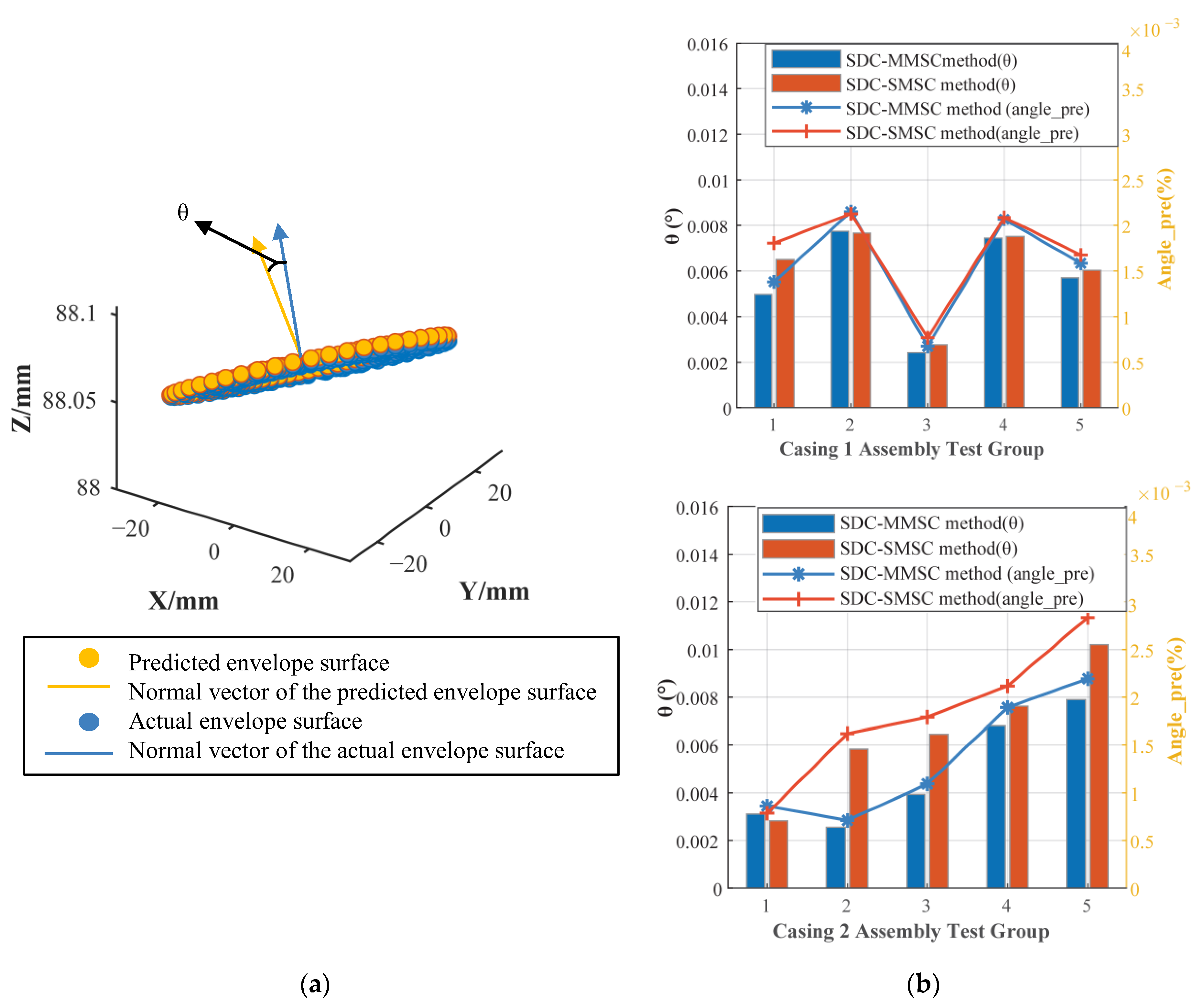

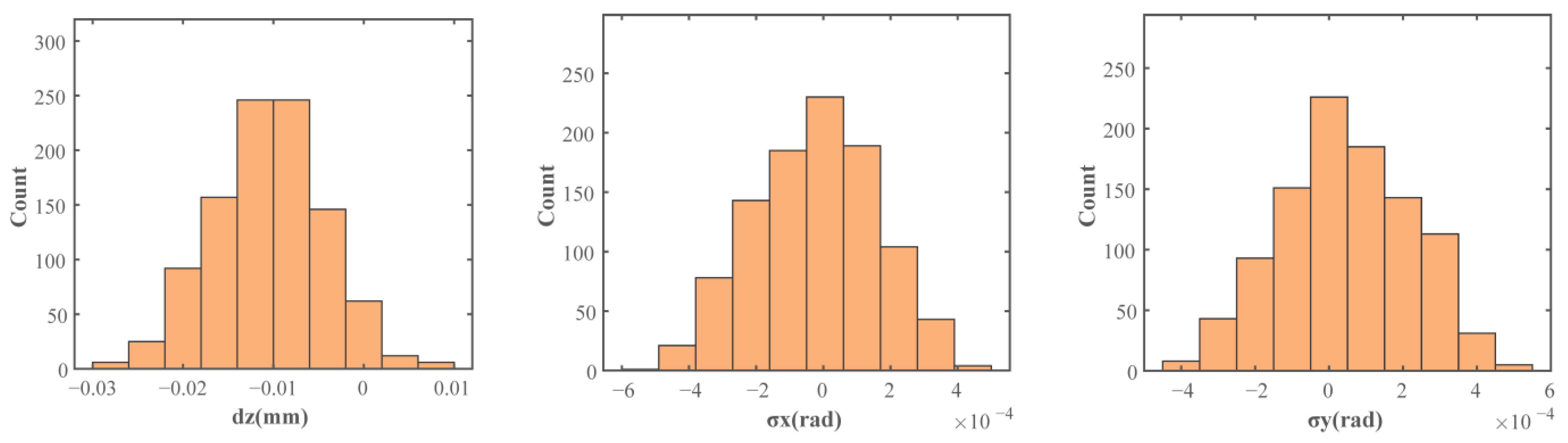

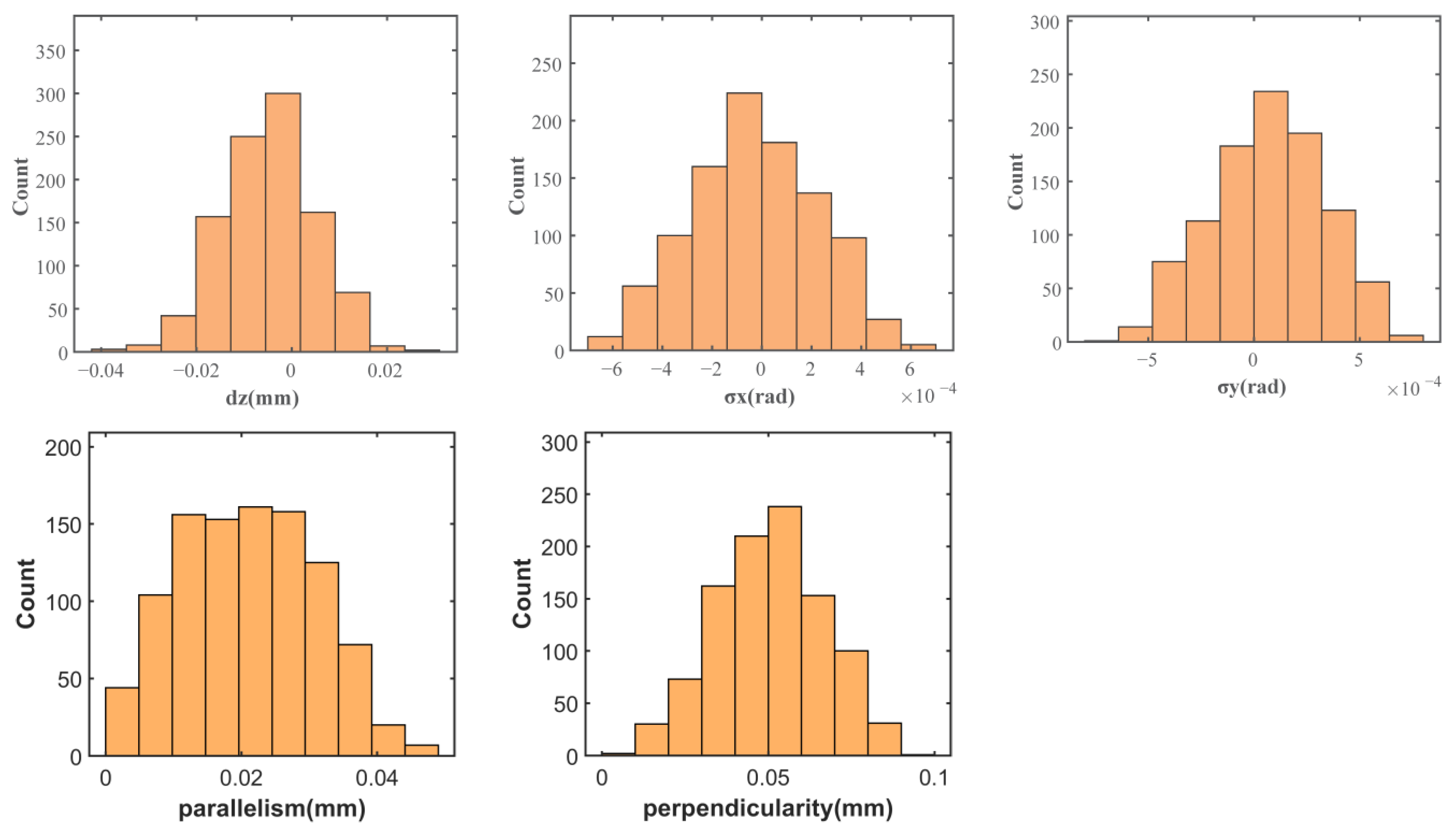

3.3.1. Prediction Results of the Datum Plane for the End Face SDC Closed Loop

- Characterization results of the closed-loop datum plane

- 2.

- Maximum and minimum distances of the closed loop

- 3.

- Parallelism of the envelope surface

- 4.

- Perpendicularity of the envelope surface

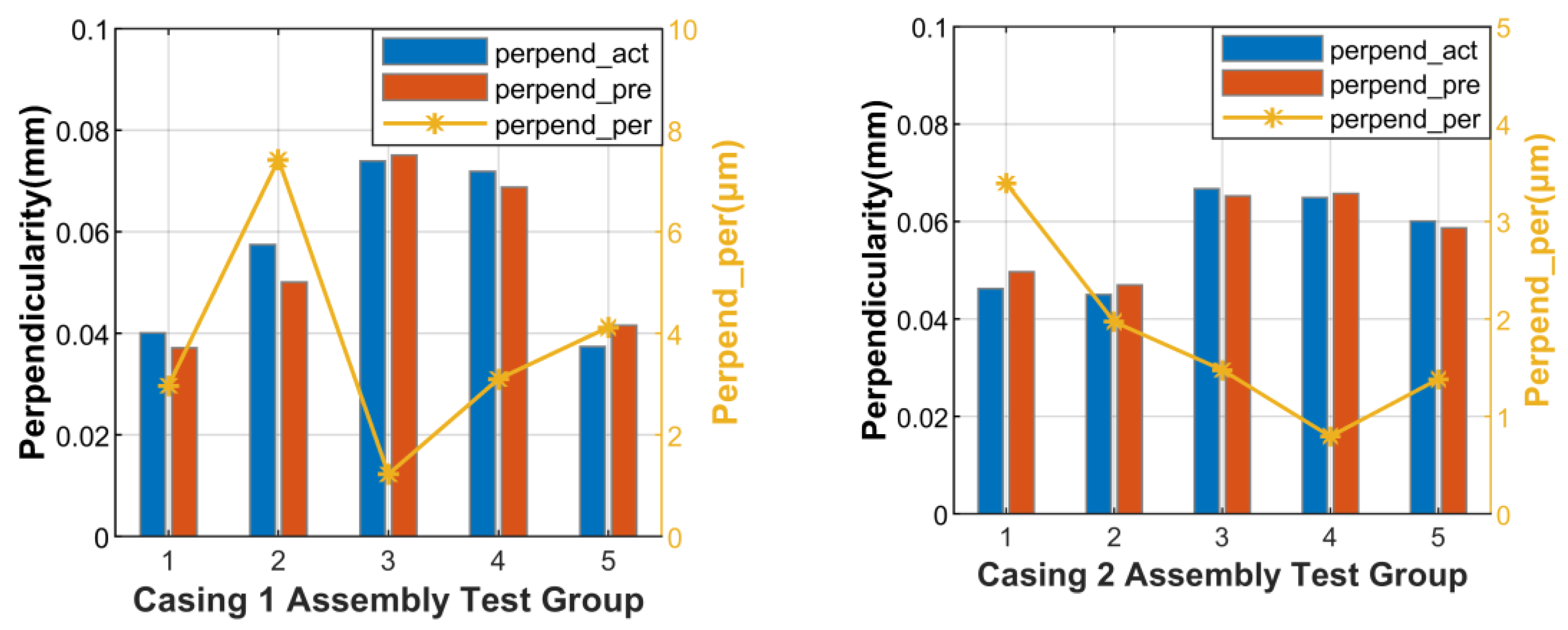

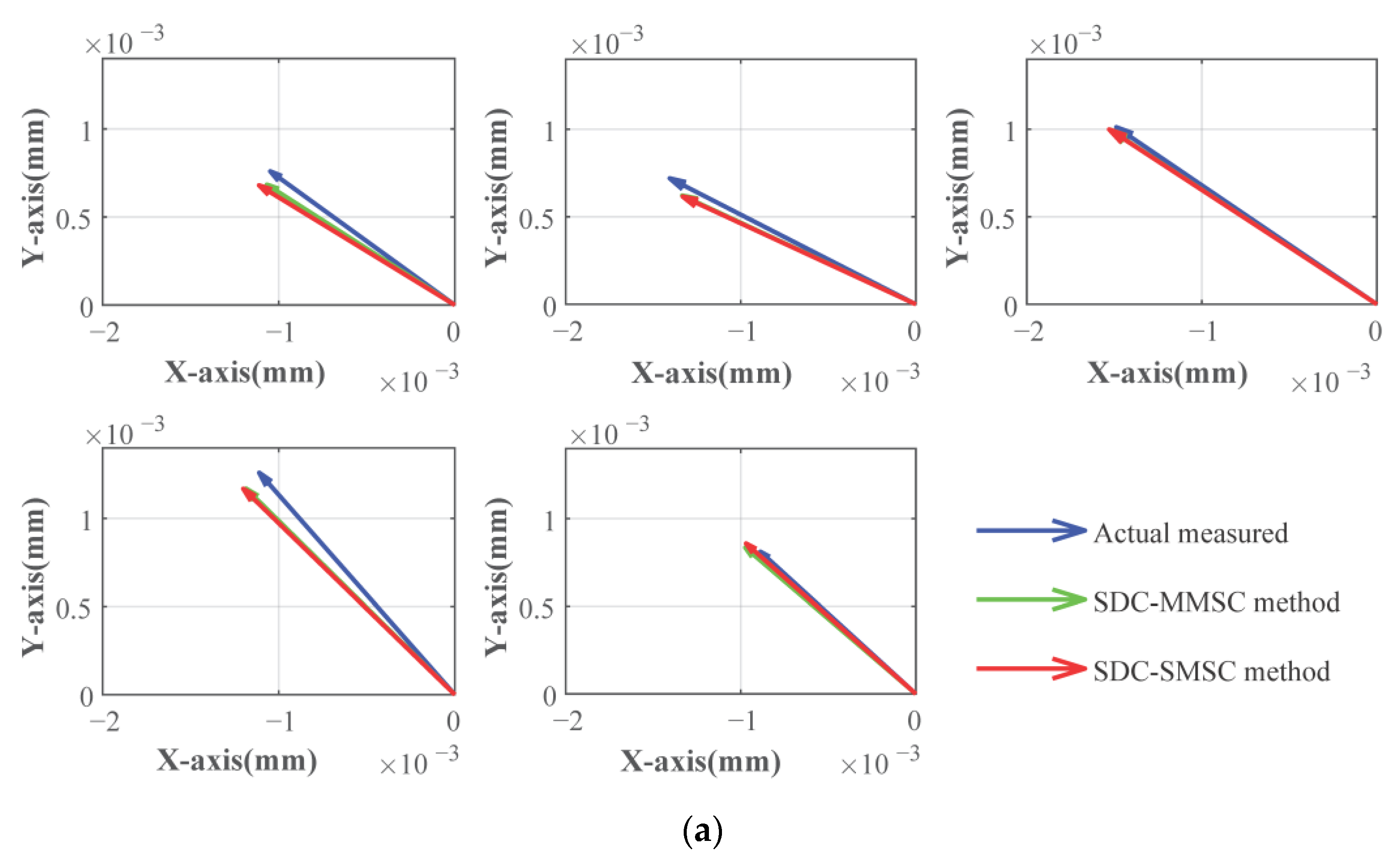

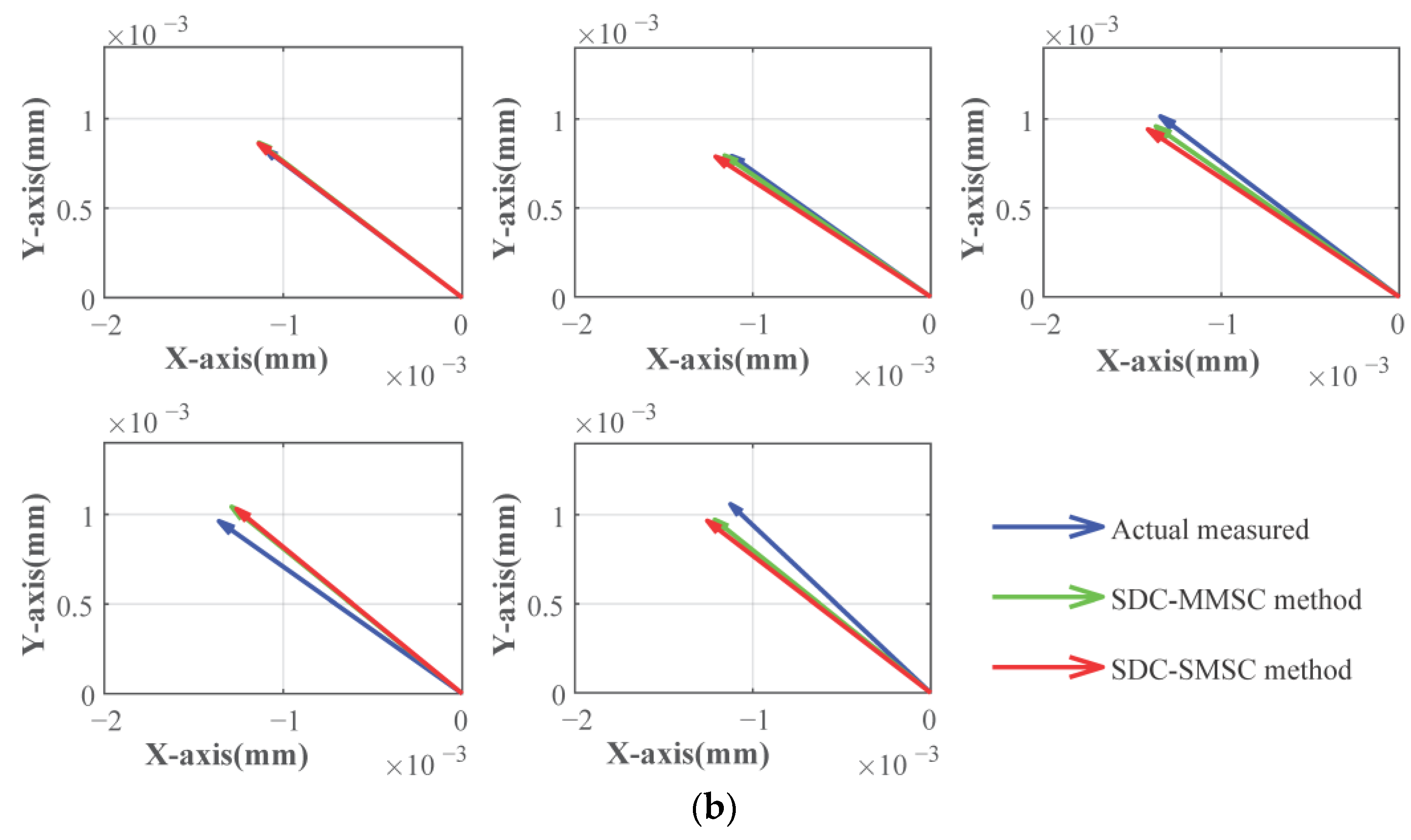

3.3.2. Effect of SMSC and MMSC on End Face Closed-Loop Accuracy

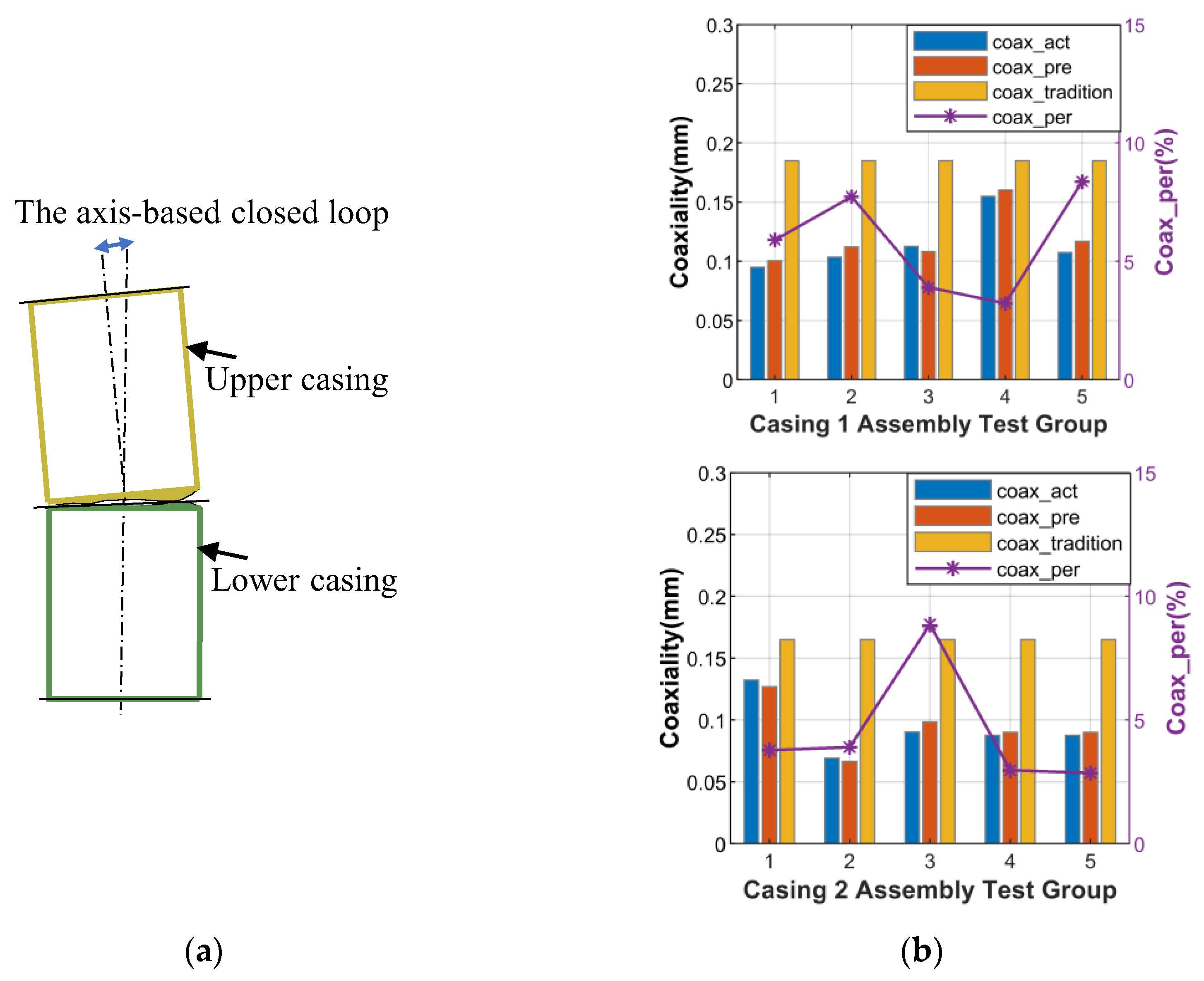

3.3.3. Coaxiality Prediction in Axis-Based Closed Loop

4. Application of SDC Model for Tolerance Allocation Optimization

- Define the assembly’s functional requirements: The parallelism of the envelope surface derived from the upper casing’s top face must be ≤0.03 mm.

- Identify contributing loops: The specific parameters are illustrated in Figure 15.

- Assign tolerances: Based on design experience and process capability, tolerances are allocated to each contributing loop (see case 1).

- Establish the SDC model: Based on the tolerance range defined in step 3, previously machined casings within this tolerance are inspected. Systematic errors are extracted and separated using NURBS-based surface regression [35], serving as the error component in the SDC model. The actual mating-constrained datum surface and non-mating-constrained datum surface are characterized, and their respective errors (M and N) are solved. The SDC model is then established, followed by Monte Carlo simulation.A critical point is that form tolerances must comply with orientation tolerances; for instance, in design and simulation, the generated form errors (e.g., flatness) must be smaller than the corresponding orientation errors (e.g., parallelism).To elucidate the connection between steps 3 and 4, we provide illustrative examples that demonstrate their interrelationship in the geometric error generation process.

- (1)

- Form Error (e.g., Flatness)Evaluation method: Two parallel planes minimally enclose the actual surface (minimum zone method).

- (2)

- Orientation Error (e.g., Parallelism)Evaluation method: First, an ideal reference plane is fitted from the measured datum surface using a mathematical method such as least squares regression. Second, the maximum vertical deviation of all measured surface points from this reference plane is calculated, which defines the parallelism error value.

- (3)

- Generating Form Errors (e.g., Flatness)

- (a)

- Assign a flatness error magnitude V.

- (b)

- Incorporate the error distribution pattern from existing manufacturing processes.

- (c)

- Scale the Z-coordinates of measured point clouds:where denotes the original coordinate; denotes the measured flatness error.

- (4)

- Generating Orientation Errors (e.g., Parallelism)

- (a)

- Assign a parallelism error magnitude.

- (b)

- Rotate the form-corrected point cloud (about the x-axis, y-axis, or both axes) to control the quadrant of maximum Z-deviation.

- (5)

- Monte Carlo Simulation Workflow

- (a)

- Set tolerances for all relevant part surfaces.

- (b)

- Randomly sample error magnitudes within tolerance limits and generate corresponding error point clouds.

- (c)

- Map geometric features to functional dimensions using the 6-DOF vector function.

- (d)

- Calculate the functional parameters (e.g., assembly clearance)

- (e)

- Determine the batch assembly yield.

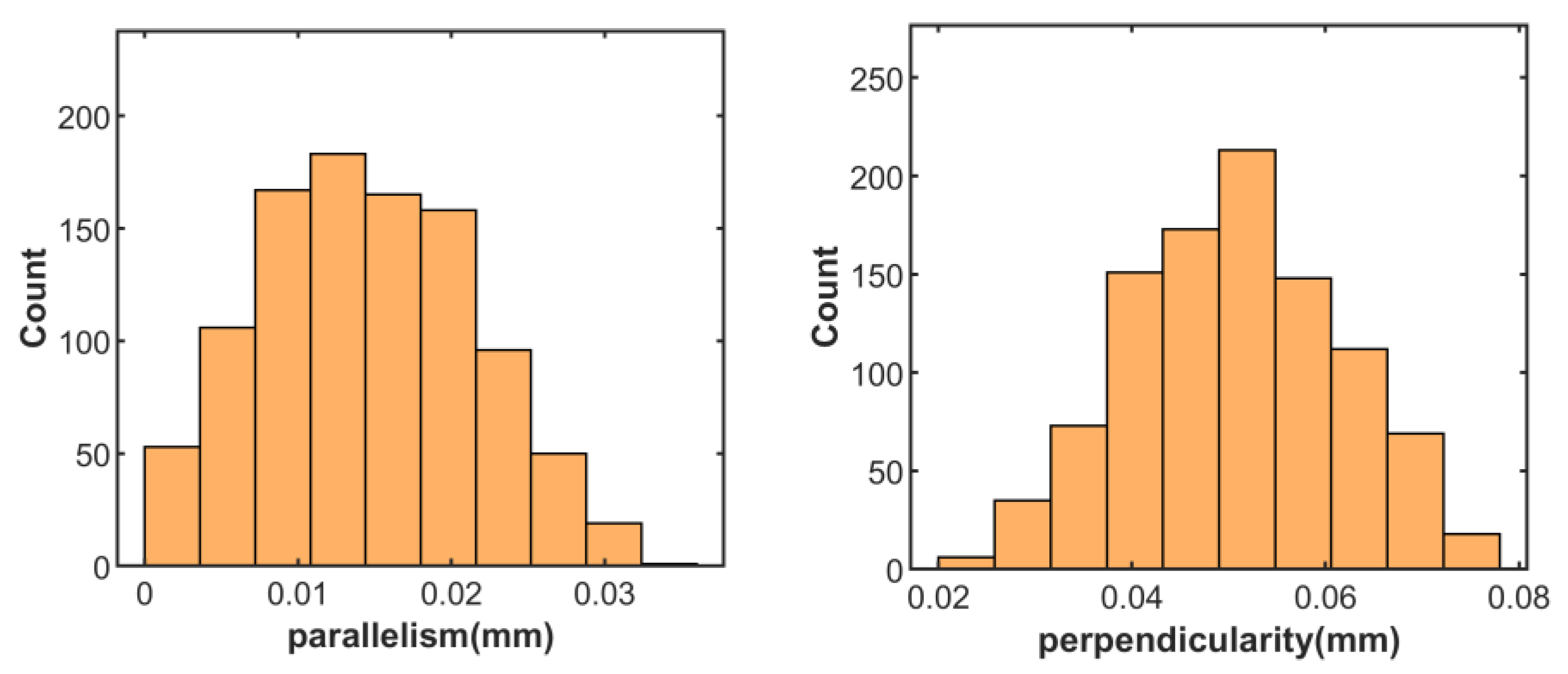

- Validate the tolerance design: For example, the rationality can be evaluated by assessing whether the compliance rate of positional errors (e.g., parallelism or perpendicularity) in the datum plane of the closed loop meets the design requirements. As shown in Figure 27, the parallelism of the envelope surface falls within [0, 0.025] mm with a 93% compliance rate, confirming compliance with the ≤0.03 mm requirement.

- Optimize the tolerances: Adjust the tolerances with lower process costs to improve the product accuracy and reduce manufacturing expenses. For instance, if the dimensional or parallelism tolerances of the upper or lower casings are overly stringent (leading to high machining costs), they can be relaxed per case 2. Repeating step 4 yields the results in Figure 28, where the parallelism within [0, 0.029] mm achieves a 78% compliance rate. If acceptable, this relaxation maintains precision while lowering costs.

- Cost reductions: Loosening the tolerances where possible without compromising assembly requirements reduces the machining costs.

- Design optimization: Refining the tolerance allocation process via the distributed-form-error-based SDC model enhances the part design accuracy.

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SDC | Spatial dimension chain |

| 6-DoF | Six-degree-of-freedom |

| NURBS | Non-uniform rational B-spline |

| SMSC | Single mating surface constraint |

| MMSC | Multiple mating surface constraint |

| RMSE | Root mean square error |

| SDC-MMSC | Spatial dimension chain-based multiple mating surface constraint |

| SDC-SMSC | Spatial dimension chain-based single mating surface constraint |

References

- Dantan, J.; Homri, L. Overview of mathematical concepts for tolerance analysis. Procedia CIRP 2024, 129, 73–78. [Google Scholar] [CrossRef]

- Jiang, Q.J.Q.; Feng, H.F.H.; Wang, Y.W.Y.; Fang, C.F.C. Batch circular form error characterization and evaluation. Precis. Eng. 2017, 47, 223–230. [Google Scholar] [CrossRef]

- Dantan, J.Y.; Qureshi, A.J. Worst-case and statistical tolerance analysis based on quantified constraint satisfaction problems and Monte Carlo simulation. Comput. Aided Des. 2009, 41, 1–12. [Google Scholar] [CrossRef]

- Mansuy, M.; Giordano, M.; Hernandez, P. A new calculation method for the worst case tolerance analysis and synthesis in stack-type assemblies. Comput. Aided Des. 2011, 43, 1118–1125. [Google Scholar] [CrossRef]

- Mansuy, M.; Giordano, M.; Hernandez, P. A Generic Method for the Worst Case and Statistical Tridimensional Tolerancing Analysis. Proc. CIRP 2013, 10, 276–282. [Google Scholar] [CrossRef]

- Sahani, A.K.; Jain, P.K.; Sharma, S.C.; Bajpai, J.K. Design Verification through Tolerance Stack up Analysis of Mechanical Assembly and Least Cost Tolerance Allocation. Procedia Mater. Sci. 2014, 6, 284–295. [Google Scholar] [CrossRef][Green Version]

- Bhide, S.; Davidson, J.K.; Shah, J.J. Areal Coordinates: The Basis of a Mathematical Model for Geometric Tolerances. Geom. Prod. Spec. Verif. Funct. Integr. 2003, 35–44. [Google Scholar] [CrossRef]

- Davidson, J.K.; Shah, J.J. Geometric tolerances: A new application for line geometry and screws. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 216, 95–104. [Google Scholar] [CrossRef]

- Mujezinovic, A.; Davidson, J.K.; Shah, J.J. A New Mathematical Model for Geometric Tolerances as Applied to Polygonal Faces. J. Mech. Des. 2003, 126, 504–518. [Google Scholar] [CrossRef]

- Chase, K.W.; Gao, J.; Magleby, S.P.; Sorensen, C.D. Including Geometric Feature Variations in Tolerance Analysis of Mechanical Assemblies. IIE Trans. 1996, 28, 795–807. [Google Scholar] [CrossRef]

- Chase, K.; Magleby, S.; Glancy, C.; Chase, K.; Magleby, S.; Glancy, C.; Chase, K.; Magleby, S.; Glancy, C. A Comprehensive System for Computer-Aided Tolerance Analysis of 2-D and 3-D Mechanical Assemblies. In Geometric Design Tolerancing: Theories, Standards and Applications; Springer Nature: Berlin/Heidelberg, Germany, 1998; pp. 294–307. [Google Scholar] [CrossRef]

- Chase, K.W.; Gao, J.; Magleby, S.P. General 2-D Tolerance Analysis of Mechanical Assemblies with Small Kinematic Adjustments. J. Design Manuf. 1995, 5, 263–274. [Google Scholar]

- Gao, J.; Chase, K.W.; Magleby, S.P. Generalized 3-D tolerance analysis of mechanical assemblies with small kinematic adjustments. IIE Trans. 1998, 30, 367–377. [Google Scholar] [CrossRef]

- Clément, A.; Desrochers, A.; Rivière, A. Theory and Practice of 3-D Tolerancing for Assembly. In Proceeding of CIRP Seminar on Computer Aided Tolerancing; Penn State University: University Park, PA, USA, 1991; Volume 25. [Google Scholar]

- Clément, A.; Bourdet, P. A Study of Optimal-Criteria Identification Based on the Small-Displacement Screw Model. CIRP Ann. Manuf. Technol. 1988, 37, 503–506. [Google Scholar] [CrossRef]

- Desrochers, A. Modeling Three Dimensional Tolerance Zones Using Screw Parameters. In Proceedings of the ASME 1999 Design Engineering Technical Conferences, Las Vegas, NV, USA, 12–16 September 1999; pp. 895–903. [Google Scholar]

- Desrochers, A.; Clément, A. A dimensioning and tolerancing assistance model for CAD/CAM systems. J. Adv. Manuf. Technol. 1994, 9, 352–361. [Google Scholar] [CrossRef]

- Laifa, M.; Sai, W.B.; Hbaieb, M. Evaluation of machining process by integrating 3D manufacturing dispersions, functional constraints, and the concept of small displacement torsors. Int. J. Adv. Manuf. Technol. 2014, 71, 1327–1336. [Google Scholar] [CrossRef]

- Legoff, O.; Villeneuve, F.; Bourdet, P. Geometrical tolerancing in process planning: A tridimensional approach. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 1999, 213, 635–640. [Google Scholar] [CrossRef]

- Teissandier, D.; Couétard, Y.; Gérard, A. A computer aided tolerancing model: Proportioned assembly clearance volume. Comput. Aided Des. 1999, 31, 805–817. [Google Scholar] [CrossRef]

- Desrochers, A.; Rivière, A. A matrix approach to the representation of tolerance zones and clearances. Int. J. Adv. Manuf. Technol. 1997, 13, 630–636. [Google Scholar] [CrossRef]

- Wang, H.; Ning, R.; Tang, C. Automatic generation of 3D as sembly dimension chains. Chin. J. Mech. Eng. 2005, 41, 7. [Google Scholar] [CrossRef]

- El Mouden, M.; Chahbouni, M.; Boutahari, S. A New Approach for Synthesis of 3D Tolerances with Consideration of Flatness Defects in Mechanical Assembly Using Jacobian Torsor Model. Int. J. Eng. Appl. 2024, 12, 169–179. [Google Scholar] [CrossRef]

- Zhang, J.; Qiao, L. Three Dimensional Manufacturing Tolerance Design Using Convex Sets. Procedia CIRP 2013, 10, 259–266. [Google Scholar] [CrossRef][Green Version]

- Jain, P. Unified approach for tolerance analysis, synthesis, and compensator selection. Appl. Optics 2022, 61, 8974–8981. [Google Scholar] [CrossRef]

- Tang, W.; Xu, G.; Zhang, S. Dimensional Variation Analysis for Rigid Part Assembly With an Improvement of Monte Carlo Simulation. IEEE Access 2020, 8, 5862–5872. [Google Scholar] [CrossRef]

- Rausch, C.; Nahangi, M.; Haas, C.; Liang, W. Monte Carlo simulation for tolerance analysis in prefabrication and offsite construction. Autom. Constr. 2019, 103, 300–314. [Google Scholar] [CrossRef]

- McGregor, D.J.; Bimrose, M.V.; Shao, C.; Tawfick, S.; King, W.P. Using machine learning to predict dimensions and qualify diverse part designs across multiple additive machines and materials. Addit. Manuf. 2022, 55, 102848. [Google Scholar] [CrossRef]

- Maltauro, M.; Meneghello, R.; Concheri, G. Enhancing tolerance stack-up analysis with variable-dependent admissible limits. CIRP Ann. 2025, in press. [Google Scholar] [CrossRef]

- Zhang, Q.; Jin, X.; Liu, Z.; Zhang, Z.; Fang, Y.; Zhang, Z.; Ledoux, Y. A New Approach of Surfaces Registration Considering Form Errors for Precise Assembly. Assem. Autom. 2018, 40, 789–800. [Google Scholar] [CrossRef]

- Zhang, Q.; Jin, X.; Zhang, Z.; Zhang, Z.; Shang, K. Assembly Method Based on Constrained Surface Registration. J. Mech. Eng. 2018, 54, 70–76. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, Q.; Cao, Y.; Yang, J. A generic approach for analysis of mechanical assembly. Precis Eng. 2018, 54, 361–370. [Google Scholar] [CrossRef]

- Shi, S.; Liu, J.; Gong, H.; Shao, N.; Anwer, N. Assembly accuracy analysis and phase optimization of aero-engine multistage rotors considering surface morphology and non-uniform contact deformation. Precis. Eng. 2024, 88, 595–610. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, Z.; Xiao, M.; Liu, H.; Zhang, Q. Tolerance optimization method based on flatness error distribution. Int. J. Adv. Manuf. Tech. 2021, 113, 1–15. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Jin, X.; Zhang, Q. A novel modelling method of geometric errors for precision assembly. Int. J. Adv. Manuf. Technol. 2018, 94, 1139–1160. [Google Scholar] [CrossRef]

- Anwer, N.; Schleich, B.; Mathieu, L.; Wartzack, S. From solid modelling to skin model shapes: Shifting paradigms in computer-aided tolerancing. CIRP Ann. Manuf. Technol. 2014, 63, 137–140. [Google Scholar] [CrossRef]

- Corrado, A.; Polini, W.; Moroni, G.; Petrò, S. 3D Tolerance Analysis with Manufacturing Signature and Operating Conditions. In Proceedings of the 14th CIRP CAT 2016—CIRP Conference on Computer Aided Tolerancing, Gothenburg, Sweden, 18–20 May 2016; Volume 43, pp. 130–135. [Google Scholar]

- Qie, Y.; Srinivasan, V.; Anwer, N. On Skin Model Describability using Laplace-Beltrami Operator for Geometrical Product Specification and Verification. Procedia CIRP 2024, 129, 67–72. [Google Scholar] [CrossRef]

- Humienny, Z. Can ISO GPS and ASME Tolerancing Systems Define the Same Functional Requirements? Appl. Sci. 2021, 11, 8269. [Google Scholar] [CrossRef]

- Shen, T.; Lu, C. An assembly accuracy analysis approach of mechanical assembly involving parallel and serial connections considering form defects and local surface deformations. Precis Eng. 2024, 88, 44–64. [Google Scholar] [CrossRef]

| Key Issue | Limitation of Conventional Methods | SDC-Based Solution | Application Value |

|---|---|---|---|

| Flange spatially distributed form errors | Tolerance-based dimension chain modeling | SDC model incorporating spatially distributed form errors | Solves high-precision prediction of mating surfaces |

| Multiconstrained flange structure | Single mating surface constraint assumption (end face only) | Multimating surface constraints for 3D coupled errors | Enables 3D coupled error analyses in SDCs |

| Functional dimension representation | Scalar-based expression | Six-dimension parameters (position + orientation vectors) | Supports multidimensional spatial characterization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Jin, X.; Guo, H.; Li, C. Six-Dimensional Spatial Dimension Chain Modeling via Transfer Matrix Method with Coupled Form Error Distributions. Machines 2025, 13, 545. https://doi.org/10.3390/machines13070545

Liu L, Jin X, Guo H, Li C. Six-Dimensional Spatial Dimension Chain Modeling via Transfer Matrix Method with Coupled Form Error Distributions. Machines. 2025; 13(7):545. https://doi.org/10.3390/machines13070545

Chicago/Turabian StyleLiu, Lu, Xin Jin, Huan Guo, and Chaojiang Li. 2025. "Six-Dimensional Spatial Dimension Chain Modeling via Transfer Matrix Method with Coupled Form Error Distributions" Machines 13, no. 7: 545. https://doi.org/10.3390/machines13070545

APA StyleLiu, L., Jin, X., Guo, H., & Li, C. (2025). Six-Dimensional Spatial Dimension Chain Modeling via Transfer Matrix Method with Coupled Form Error Distributions. Machines, 13(7), 545. https://doi.org/10.3390/machines13070545