A Scoping Review of Energy Consumption in Industrial Robotics

Abstract

1. Introduction

2. Background: Characteristics of Industrial Robots

2.1. Definition and Types of Industrial Robots

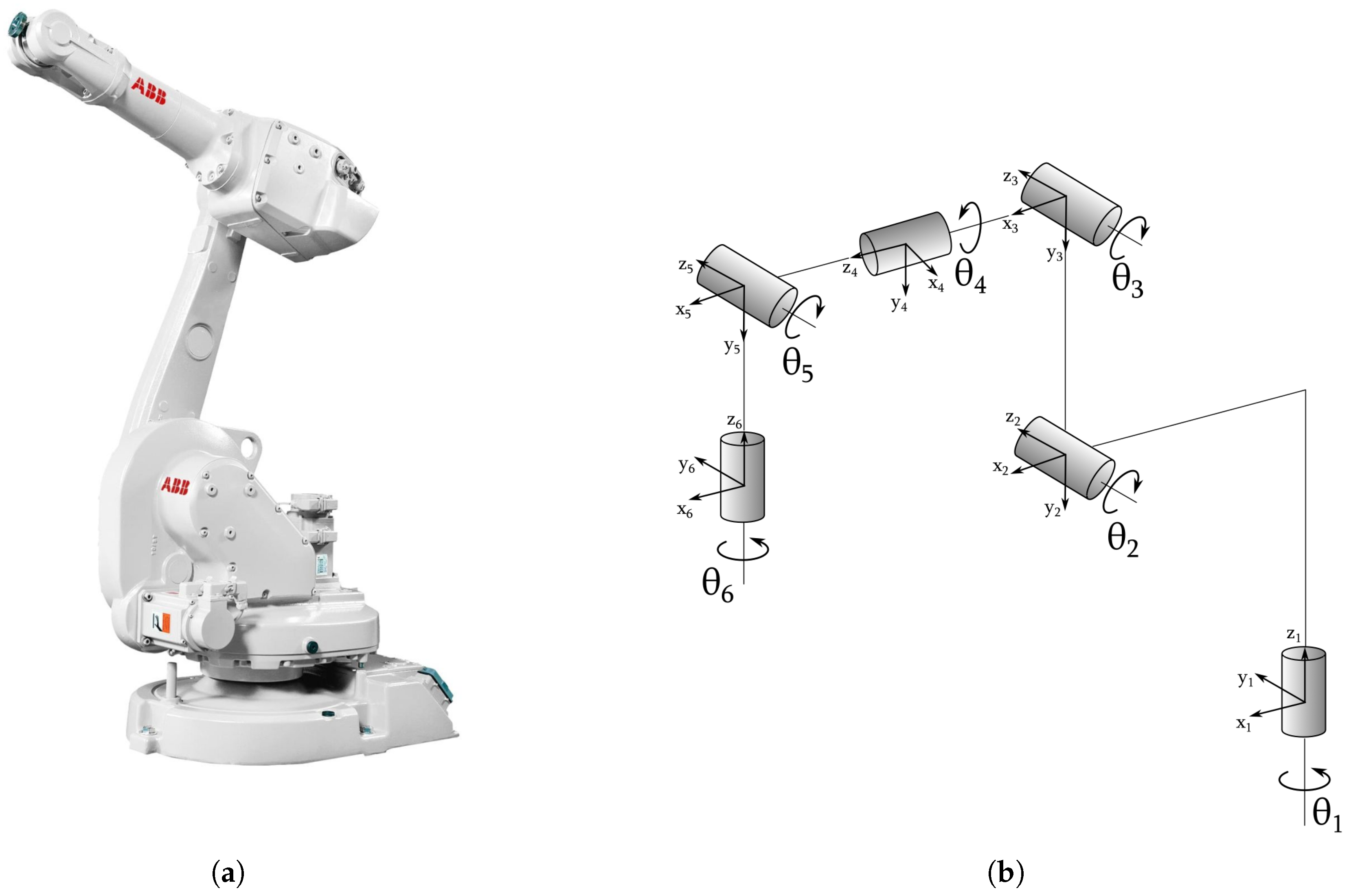

- Articulated robot;

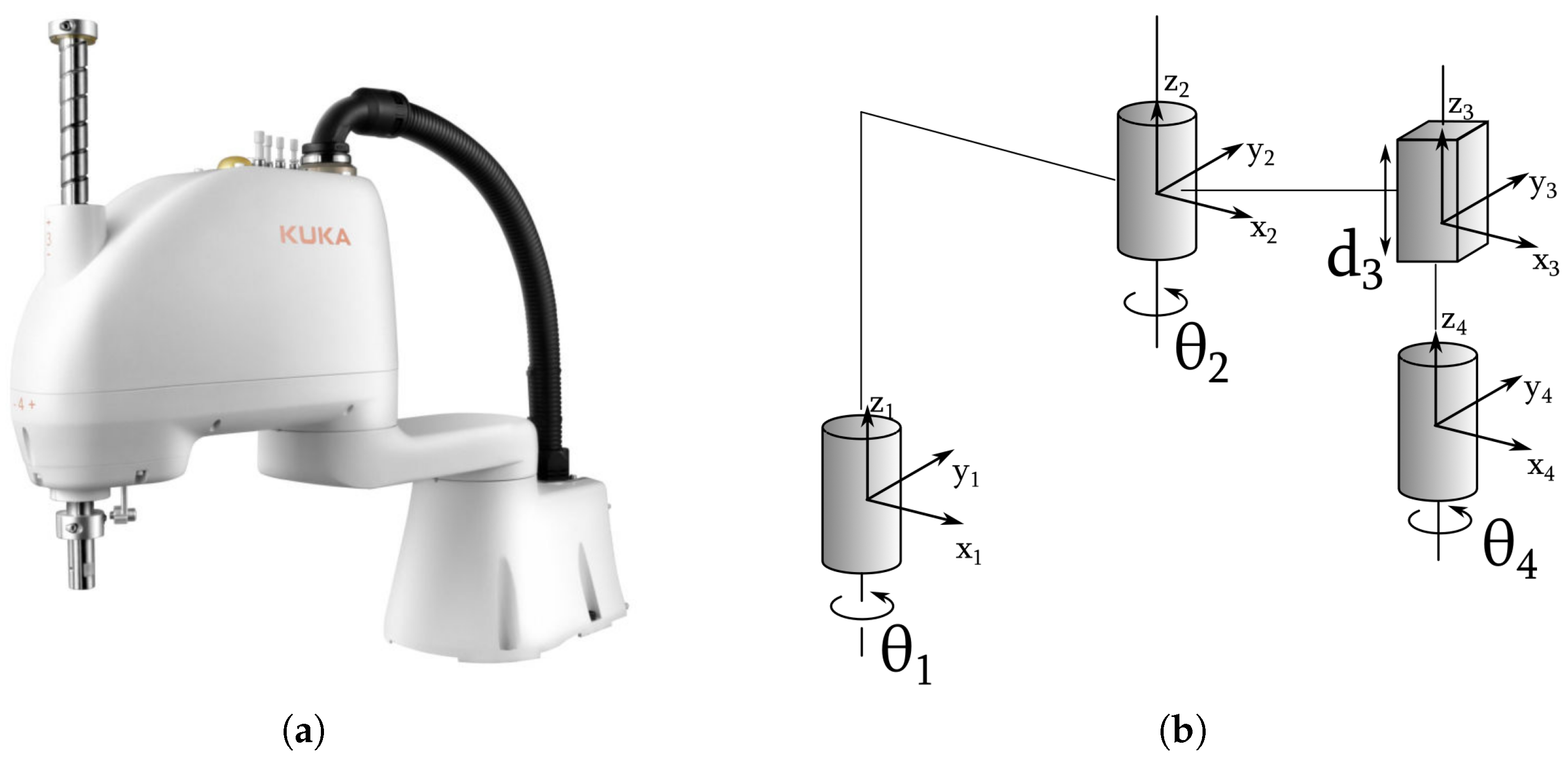

- SCARA robot;

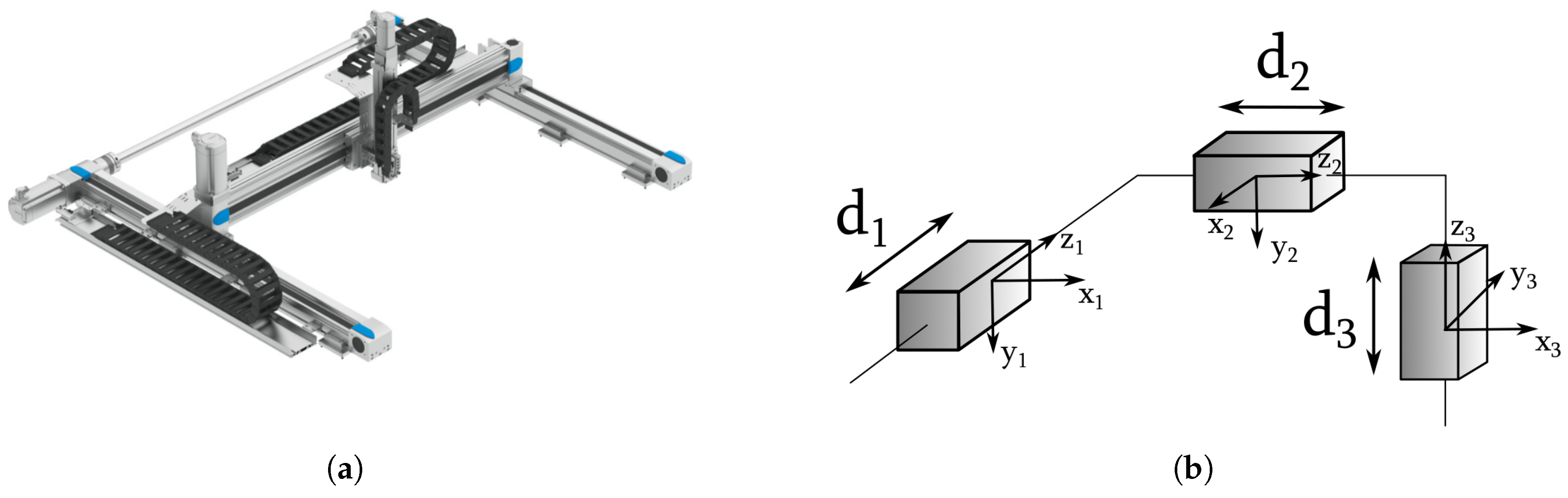

- Cartesian robot;

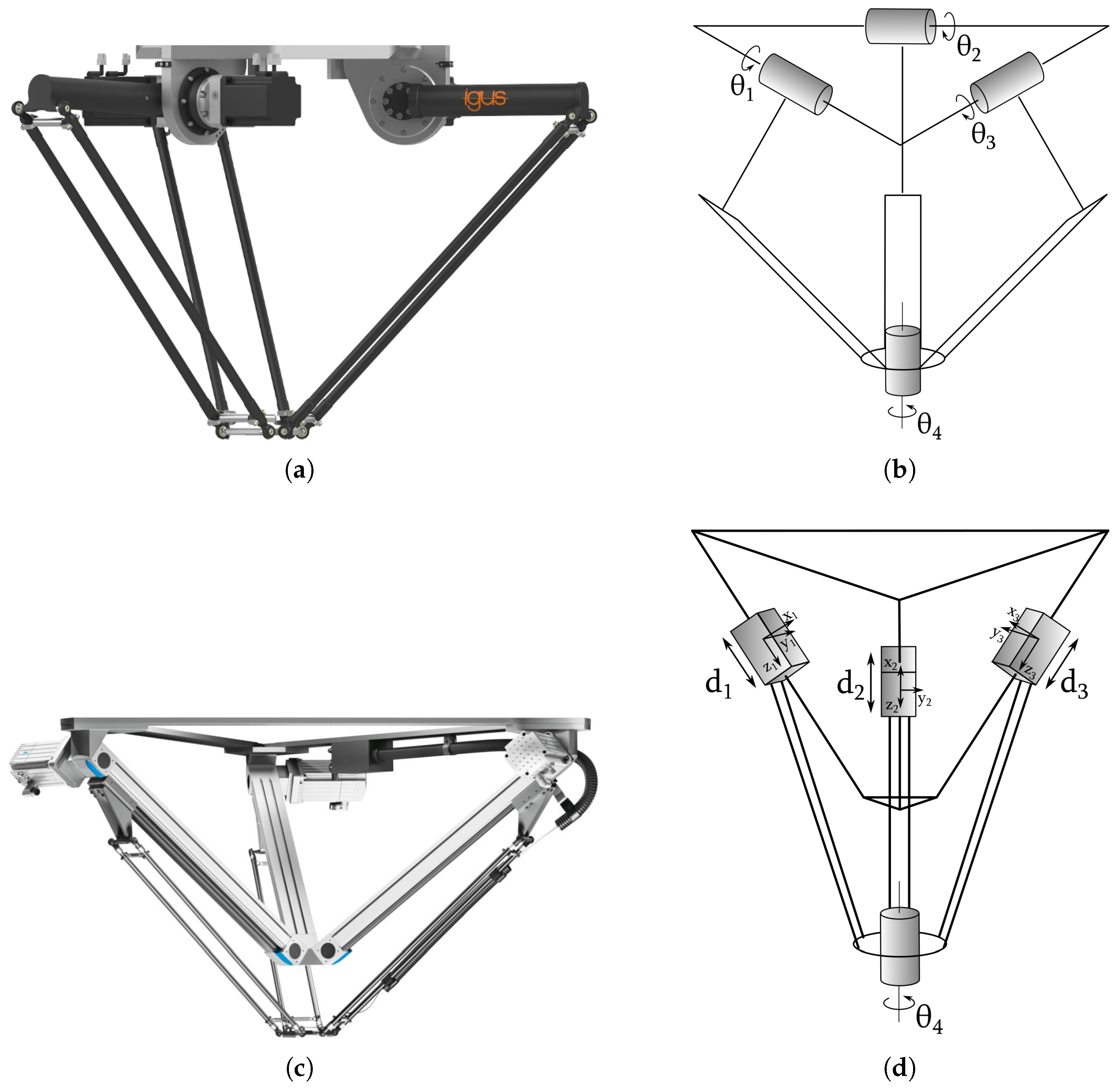

- Parallel/Delta robot;

- Cylindrical robot;

- Polar robot.

2.2. Fundamentals of Energy Consumption in Industrial Robots

2.3. Assessing the Energy Performance of an IR

- Standard—baseline cycle with fixed parameters defined by the statistical data used to create the reference trajectory.

- Performance—cycle with maximum speed and acceleration to analyze the maximal performance.

- Efficient—cycle with incrementally reduced velocity and acceleration to explore energy–cycle time trade-offs and identify optimal operating points.

3. Comparative Review of ECO Techniques

3.1. Software

3.1.1. Parameter Optimization

3.1.2. Task Scheduling

3.1.3. Trajectory Optimization

3.2. Hardware

3.2.1. Structural Design

3.2.2. Energy Recovery and Reuse

3.2.3. Functional Redundancy

4. Discussion

- Development of a universal energy optimization tool that is usable with standardized robotic hardware across multiple manufacturers.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IFR. Record of 4 Million Robots in Factories Worldwide. Available online: https://ifr.org/ifr-press-releases/news/record-of-4-million-robots-working-in-factories-worldwide (accessed on 1 November 2024).

- ISO 8373; Robotics—Vocabulary. ISO (International Organization for Standardization): Geneva, Switzerland, 2021.

- Parliament, E. Parliament Adopts New Rules to Boost Energy Savings|News|European Parliament. Available online: https://www.europarl.europa.eu/news/en/press-room/20230707IPR02421/parliament-adopts-new-rules-to-boost-energy-savings (accessed on 15 November 2024).

- Eurostat. Final Energy Consumption in Industry—Detailed Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Final_energy_consumption_in_industry_-_detailed_statistics (accessed on 15 November 2024).

- IFR. TOP 5 Global Robotics Trends 2025. Available online: https://ifr.org/ifr-press-releases/news/top-5-global-robotics-trends-2025 (accessed on 29 April 2025).

- Barosz, P.; Gołda, G.; Kampa, A. Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators. Appl. Sci. 2020, 10, 2862. [Google Scholar] [CrossRef]

- Huang, G.; He, L.Y.; Lin, X. Robot adoption and energy performance: Evidence from Chinese industrial firms. Energy Econ. 2022, 107, 105837. [Google Scholar] [CrossRef]

- Wang, E.Z.; Lee, C.C.; Li, Y. Assessing the impact of industrial robots on manufacturing energy intensity in 38 countries. Energy Econ. 2022, 105, 105748. [Google Scholar] [CrossRef]

- Barnett, N.; Costenaro, D.; Rohmund, I. Direct and Indirect Impacts of Robots on Future Electricity Load. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, Denver, CO, USA, 15–18 August 2017. [Google Scholar]

- Liu, Y.; Zhao, C.; Kong, Z.; Taghizadeh-Hesary, F. Pathways to stable economic policy: The role of industrial robotics and energy transition. Renew. Energy 2025, 244, 122751. [Google Scholar] [CrossRef]

- Carabin, G.; Wehrle, E.; Vidoni, R. A Review on Energy-Saving Optimization Methods for Robotic and Automatic Systems. Robotics 2017, 6, 39. [Google Scholar] [CrossRef]

- Sękala, A.; Blaszczyk, T.; Foit, K.; Kost, G. Selected Issues, Methods, and Trends in the Energy Consumption of Industrial Robots. Energies 2024, 17, 641. [Google Scholar] [CrossRef]

- Vásárhelyi, J.; Salih, O.M.; Rostum, H.M.; Benotsname, R. An Overview of Energies Problems in Robotic Systems. Energies 2023, 16, 8060. [Google Scholar] [CrossRef]

- Yao, M.; Shao, Z.; Zhao, Y. Review on Energy Consumption Optimization Methods of Typical Discrete Manufacturing Equipment. In Proceedings of the Intelligent Robotics and Applications, Yantai, China, 22–25 October 2021; Liu, X.J., Nie, Z., Yu, J., Xie, F., Song, R., Eds.; Springer: Cham, Switzerland, 2021; pp. 48–58. [Google Scholar] [CrossRef]

- Bukata, L.; Sucha, P.; Hanzalek, Z.; Burget, P. Energy Optimization of Robotic Cells. IEEE Trans. Ind. Inform. 2017, 13, 92–102. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef]

- IFR. Industrial Robots. Available online: https://ifr.org/industrial-robots (accessed on 10 April 2025).

- Amiri, P.; Müller, M.; Southgate, M.; Theodoridis, T.; Wei, G.; Richards-Brown, M.; Holderbaum, W. A Statistical Analysis of Commercial Articulated Industrial Robots and Cobots. J. Manuf. Mater. Process. 2024, 8, 216. [Google Scholar] [CrossRef]

- ABB. IRB 160. Available online: https://new.abb.com/products/robotics/robots/articulated-robots/irb-1600 (accessed on 20 May 2025).

- my.KUKA. KR 6 R500 Z200-2. Available online: https://my.kuka.com/s/product/kr-6-r500-z2002/01t1i0000025DCIAA2 (accessed on 20 May 2025).

- FESTO. Three-Dimensional Gantry YXCR. Available online: https://www.festo.com/ee/en/p/three-dimensional-gantry-id_YXCR/ (accessed on 20 May 2025).

- Bouri, M.; Clavel, R. The Linear Delta: Developments and Applications. In Proceedings of the ISR 2010 (41st International Symposium on Robotics) and ROBOTIK 2010 (6th German Conference on Robotics), Munich, Germany, 7–9 June 2010; pp. 1–8. [Google Scholar]

- Kong, X.; Gosselin, C.; Richard, P.L. Type Synthesis of Parallel Mechanisms With Multiple Operation Modes. J. Mech. Des. 2006, 129, 595–601. [Google Scholar] [CrossRef]

- Jia, G.; Huang, H.; Wang, S.; Li, B. Type Synthesis of Plane-Symmetric Deployable Grasping Parallel Mechanisms Using Constraint Force Parallelogram Law. Mech. Mach. Theory 2021, 161, 104330. [Google Scholar] [CrossRef]

- Igus. 3-Axis Delta Robot. Available online: https://www.igus.com/product/22609?artNr=LCA-DR1000-03 (accessed on 20 May 2025).

- FESTO. Parallel Kinematic System, Delta Robot EXPT. Available online: https://www.festo.com/us/en/p/parallel-kinematic-system-delta-robot-id_EXPT/ (accessed on 20 May 2025).

- Liu, Y.; Liang, L.; Han, H.; Zhang, S. A Method of Energy-Optimal Trajectory Planning for Palletizing Robot. Math. Probl. Eng. 2017, 5862457. [Google Scholar] [CrossRef]

- Garcia, R.R.; Bittencourt, A.C.; Villani, E. Relevant factors for the energy consumption of industrial robots. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 464. [Google Scholar] [CrossRef]

- Izagirre, U.; Arcin, G.; Andonegui, I.; Eciolaza, L.; Zurutuza, U. Torque-based methodology and experimental implementation for industrial robot standby pose optimization. Int. J. Adv. Manuf. Technol. 2020, 111, 2065–2072. [Google Scholar] [CrossRef]

- Boscariol, P.; Caracciolo, R.; Richiedei, D.; Trevisani, A. Energy Optimization of Functionally Redundant Robots through Motion Design. Appl. Sci. 2020, 10, 3022. [Google Scholar] [CrossRef]

- Boscariol, P.; Richiedei, D. Trajectory Design for Energy Savings in Redundant Robotic Cells. Robotics 2019, 8, 15. [Google Scholar] [CrossRef]

- Ma, J.; Lian, B.; Wang, M.; Dong, G.; Li, Q.; Wu, J.; Yang, Y. Optimal design of a parallel assembling robot with large payload-to-mass ratio. Robot. Comput.-Integr. Manuf. 2023, 80, 102474. [Google Scholar] [CrossRef]

- Khalil, W.; Dombre, E. Introduction to geometric and kinematic modeling of parallel robots. In Modeling, Identification and Control of Robots, 1st ed.; Elsevier Science & Technology: Amsterdam, The Netherlands, 2004; pp. 171–190. [Google Scholar]

- Vodovozov, V.; Lehtla, M.; Raud, Z.; Semjonova, N.; Petlenkov, E. Managing Energy Consumption of Linear Delta Robots Using Neural Network Models. Energies 2024, 17, 4081. [Google Scholar] [CrossRef]

- Balderas Hill, R.; Briot, S.; Chriette, A.; Martinet, P. Minimizing the Energy Consumption of a Delta Robot by Exploiting the Natural Dynamics. In ROMANSY 23—Robot Design, Dynamics and Control; Venture, G., Solis, J., Takeda, Y., Konno, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; Volume 601, pp. 213–221, Series Title: CISM International Centre for Mechanical Sciences. [Google Scholar] [CrossRef]

- Li, Y.; Bone, G. Are Parallel Manipulators More Energy Efficient? In Proceedings of the the 2001 IEEE International Symposium on Computational Intelligence in Robotics and Automation, Banff, AB, Canada, 29 July–1 August 2001; pp. 41–46, Cat. No. 01EX515. [Google Scholar]

- Kurilova-Palisaitiene, J.; Permin, E.; Mannheim, T.; Buhse, K.; Lorenz, M.; Schmitt, R.; Corves, B.; Björkman, M. Industrial energy efficiency potentials: An assessment of three different robot concepts. Int. J. Sustain. Eng. 2017, 10, 185–196. [Google Scholar] [CrossRef]

- Yigit, A.; Breton, D.; Zhou, Z.; Laliberte, T.; Gosselin, C. Kinematic Analysis and Design of a Novel (6+3)-DoF Parallel Robot with Fixed Actuators. arXiv 2023, arXiv:2304.12499. [Google Scholar]

- Fabris, G.; Scalera, L.; Gasparetto, A. Dynamic Modelling and Energy-Efficiency Optimization in a 3-DOF Parallel Robot. Int. J. Adv. Manuf. Technol. 2024, 132, 2677–2699. [Google Scholar] [CrossRef]

- Morikawa, K.; Katsura, S. In-Link Actuators for Low-Inertia Robots. IEEE/ASME Trans. Mechatron. 2024, 30, 2122–2131. [Google Scholar] [CrossRef]

- Pham, A.D.; Ahn, H.J. High Precision Reducers for Industrial Robots Driving 4th Industrial Revolution: State of Arts, Analysis, Design, Performance Evaluation and Perspective. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 519–533. [Google Scholar] [CrossRef]

- Peta, K.; Suszyński, M.; Wiśniewski, M.; Mitek, M. Analysis of Energy Consumption of Robotic Welding Stations. Sustainability 2024, 16, 2837. [Google Scholar] [CrossRef]

- Zhou, J.; Jiang, P.; Huang, C.; Ping, K. An energy-saving optimization method for robot laser welding systems based on multi-objective metaheuristic algorithms. J. Meas. Eng. 2025, 13, 24349. [Google Scholar] [CrossRef]

- Torayev, A.; Martínez-Arellano, G.; Chaplin, J.C.; Sanderson, D.; Ratchev, S. Online and Modular Energy Consumption Optimization of Industrial Robots. IEEE Trans. Ind. Inform. 2024, 20, 1198–1207. [Google Scholar] [CrossRef]

- Uhlmann, E.; Reinkober, S.; Hollerbach, T. Energy Efficient Usage of Industrial Robots for Machining Processes. Procedia CIRP 2016, 48, 206–211. [Google Scholar] [CrossRef]

- Almurib, H.A.F.; Al-Qrimli, H.F.; Kumar, N. A review of application industrial robotic design. In Proceedings of the 2011 Ninth International Conference on ICT and Knowledge Engineering, Bangkok, Thailand, 12–13 January 2012; pp. 105–112. [Google Scholar] [CrossRef]

- Šitum, Z. Fluid power drives in robotic systems. In Proceedings of the International Conference Fluid Power 2017, Maribor, Slovenia, 14–15 September 2017; pp. 11–24. [Google Scholar] [CrossRef][Green Version]

- Habibi, S.; Richards, R.; Goldenberg, A. Hydraulic actuator analysis for industrial robot multivariable control. In Proceedings of the 1994 American Control Conference—ACC ’94, Baltimore, MD, USA, 29 June–1 July 1994; Volume 1, pp. 1003–1007. [Google Scholar] [CrossRef]

- Lischinsk, P.; Canudas-de Wit, C.; Morel, G. Friction compensation for an industrial hydraulic robot. IEEE Control Syst. 1999, 19, 25–32. [Google Scholar] [CrossRef]

- Pustavrh, J.; Hočevar, M.; Podržaj, P.; Trajkovski, A.; Majdič, F. Comparison of hydraulic, pneumatic and electric linear actuation systems. Sci. Rep. 2023, 13, 20938. [Google Scholar] [CrossRef] [PubMed]

- Mykhailyshyn, R.; Savkiv, V.; Maruschak, P.; Xiao, J. A systematic review on pneumatic gripping devices for industrial robots. Transport 2022, 37, 201–231. [Google Scholar] [CrossRef]

- Maeda, S.; Tsujiuchi, N.; Koizumi, T.; Sugiura, M.; Kojima, H. Development and Control of a Pneumatic Robot Arm for Industrial Fields. Int. J. Adv. Robot. Syst. 2012, 9, 59. [Google Scholar] [CrossRef]

- Shi, Y.; Cai, M.; Xu, W.; Wang, Y. Methods to Evaluate and Measure Power of Pneumatic System and Their Applications. Chin. J. Mech. Eng. 2019, 32, 42. [Google Scholar] [CrossRef]

- Bonfà, F.; Salvatori, S.; Benedetti, M.; Introna, V.; Ubertini, S. Monitoring compressed air systems energy performance in industrial production: Lesson learned from an explorative study in large and energy-intensive industrial firms. Energy Procedia 2017, 143, 396–403. [Google Scholar] [CrossRef]

- Meike, D.; Pellicciari, M.; Berselli, G. Energy Efficient Use of Multirobot Production Lines in the Automotive Industry: Detailed System Modeling and Optimization. IEEE Trans. Autom. Sci. Eng. 2014, 11, 798–809. [Google Scholar] [CrossRef]

- Grebers, R.; Gadaleta, M.; Paugurs, A.; Senfelds, A.; Avotins, A.; Pellicciari, M. Analysis of the Energy Consumption of a Novel DC Power Supplied Industrial Robot. Procedia Manuf. 2017, 11, 311–318. [Google Scholar] [CrossRef]

- Gutwald, B.; Liu, H.; Barth, M.; Reichenstein, T.; Römer, P.; Franke, J. Conversion of Industrial Robots to DC Power Supply: Efficiency, Protection Concepts and Recuperation Potential. In Proceedings of the 2024 IEEE 3rd Industrial Electronics Society Annual On-Line Conference (ONCON), Virtual Event, 8–10 December 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Senfelds, A.; Avotins, A.; Ribickis, L.; Apse-Apsitis, P. DC Microgrid for Robotic Manufacturing—Field demonstration and laboratory experience. RE&PQJ 2024, 17, 194–197. [Google Scholar] [CrossRef]

- Meike, D.; Ribickis, L. Recuperated energy savings potential and approaches in industrial robotics. In Proceedings of the 2011 IEEE International Conference on Automation Science and Engineering, Shanghai, China, 10–12 June 2011; pp. 299–303. [Google Scholar] [CrossRef]

- Meike, D.; Senfelds, A.; Ribickis, L. Power converter for DC bus sharing to increase the energy efficiency in drive systems. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 7199–7204. [Google Scholar] [CrossRef]

- Siciliano, B.; Khatib, O. Dynamics. In Springer Handbook of Robotics, 2nd ed.; Springer Handbooks; Springer: Cham, Switzerland, 2016; pp. 149–195. [Google Scholar]

- Park, S.B.; Kim, H.S.; Song, C.; Kim, K.J. Dynamics Modeling of a Delta-Type Parallel Robot. In Proceedings of the IEEE ISR 2013, Seoul, Republic of Korea, 24–26 October 2013; pp. 1–5. [Google Scholar]

- Thanh, T.D.; Kotlarski, J.; Heimann, B.; Ortmaier, T. On the Inverse Dynamics Problem of General Parallel Robots. In Proceedings of the 2009 IEEE International Conference on Mechatronics, Malaga, Spain, 14–17 April 2009; pp. 1–6. [Google Scholar]

- Lynch, K.M.; Park, F.C. Modern Robotics; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Tuli, T. Mathematical Modeling and Dynamic Simulation of Gantry Robot Using Bond Graph. In Proceedings of the Information and Communication Technology for Development for Africa, Bahir Dar, Ethiopia, 25–27 September 2017; Mekuria, F., Nigussie, E., Dargie, W., Edward, M., Tegegne, T., Eds.; Springer: Cham, Switzerland, 2018; pp. 228–237. [Google Scholar]

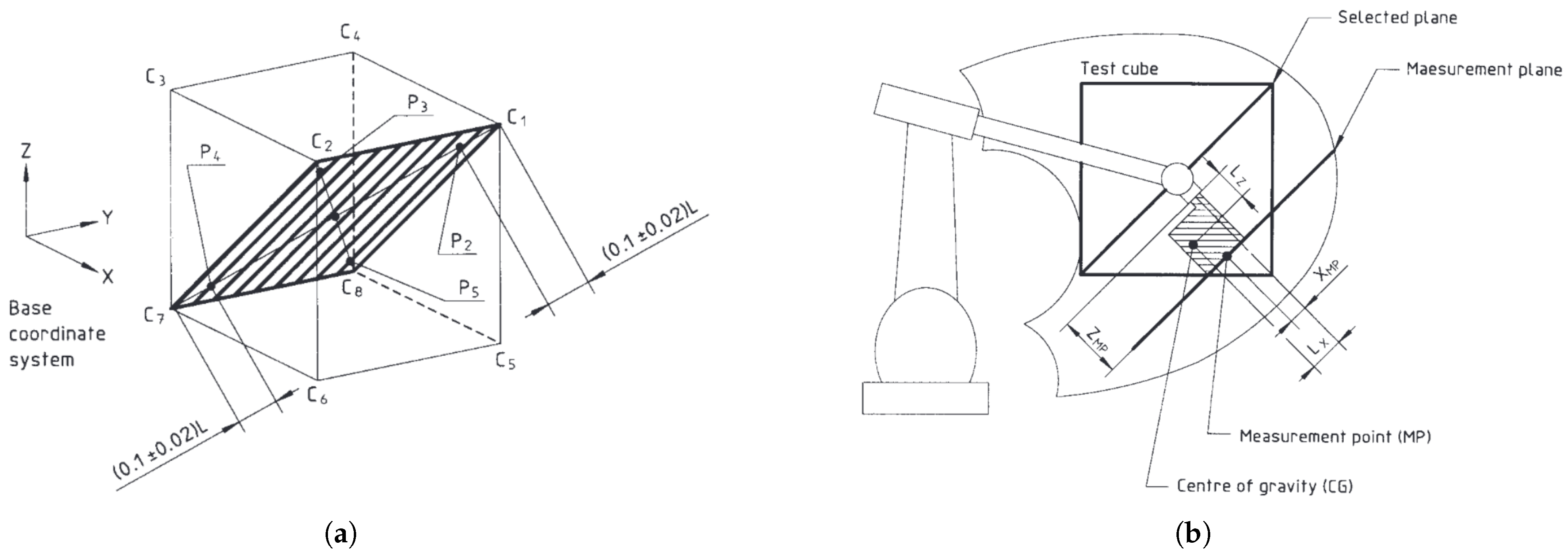

- ISO 9283; Manipulating Industrial Robots—Performance Criteria and Related Test Methods. ISO (International Organization for Standardization): Geneva, Switzerland, 1998.

- IRB 1660ID|ABB. Available online: https://new.abb.com/products/robotics/robots/articulated-robots/irb-1660id (accessed on 11 April 2025).

- VDMA 24608; Energy performance for industrial robots. VDMA (Verband Deutscher Maschinen- und Anlagenbau e.V.): Frankfurt/Main, Germany, 2013. Available online: https://www.dinmedia.de/en/technical-rule/vdma-24608/197844344 (accessed on 19 May 2025).

- Gadaleta, M.; Berselli, G.; Pellicciari, M.; Grassia, F. Extensive experimental investigation for the optimization of the energy consumption of a high payload industrial robot with open research dataset. Robot. Comput.-Integr. Manuf. 2021, 68, 102046. [Google Scholar] [CrossRef]

- Findeisen, M.; Todtermuschke, M.; Schaffrath, R.; Putz, M. A method for energetic comparison of 6-axis industrial robots and its further scope for resource-efficient plant design. Procedia Manuf. 2018, 21, 251–258. [Google Scholar] [CrossRef]

- Todtermuschke, M.; Findeisen, M.; Bauer, A. Methodology for Creation a Reference Trajectory for Energetic Comparability of Industrial Robots in Body Shop. Procedia CIRP 2014, 23, 122–126. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.A.; Luong, K.Y. Energy consumption parameter analysis of industrial robots using design of experiment methodology. Int. J. Sustain. Eng. 2021, 14, 996–1005. [Google Scholar] [CrossRef]

- Carabin, G.; Scalera, L. On the Trajectory Planning for Energy Efficiency in Industrial Robotic Systems †. Robotics 2020, 9, 89. [Google Scholar] [CrossRef]

- Pellicciari, M.; Berselli, G.; Leali, F.; Vergnano, A. A method for reducing the energy consumption of pick-and-place industrial robots. Mechatronics 2013, 23, 326–334. [Google Scholar] [CrossRef]

- Zacharia, P.T.; Aspragathos, N.A. Optimal robot task scheduling based on genetic algorithms. Robot. Comput.-Integr. Manuf. 2005, 21, 67–79. [Google Scholar] [CrossRef]

- Pupa, A.; Van Dijk, W.; Brekelmans, C.; Secchi, C. A Resilient and Effective Task Scheduling Approach for Industrial Human-Robot Collaboration. Sensors 2022, 22, 4901. [Google Scholar] [CrossRef]

- Tejer, M.; Szczepanski, R.; Tarczewski, T. Robust and efficient task scheduling for robotics applications with reinforcement learning. Eng. Appl. Artif. Intell. 2024, 127, 107300. [Google Scholar] [CrossRef]

- Vergnano, A.; Thorstensson, C.; Lennartson, B.; Falkman, P.; Pellicciari, M.; Leali, F.; Biller, S. Modeling and Optimization of Energy Consumption in Cooperative Multi-Robot Systems. IEEE Trans. Autom. Sci. Eng. 2012, 9, 423–428. [Google Scholar] [CrossRef]

- Meike, D.; Pellicciari, M.; Berselli, G.; Vergnano, A.; Ribickis, L. Increasing the energy efficiency of multi-robot production lines in the automotive industry. In Proceedings of the 2012 IEEE International Conference on Automation Science and Engineering (CASE), Seoul, Republic of Korea, 20–24 August 2012; pp. 700–705. [Google Scholar] [CrossRef]

- Hansen, C.; Oltjen, J.; Meike, D.; Ortmaier, T. Enhanced approach for energy-efficient trajectory generation of industrial robots. In Proceedings of the 2012 IEEE International Conference on Automation Science and Engineering (CASE), Seoul, Republic of Korea, 20–24 August 2012; pp. 1–7. [Google Scholar] [CrossRef]

- Otani, T.; Nakamura, M.; Kimura, K.; Takanishi, A. Energy Efficient Path and Trajectory Optimization of Manipulators With Task Deadline Constraints. IEEE Access 2023, 11, 107441–107450. [Google Scholar] [CrossRef]

- Garriz, C.; Domingo, R. Trajectory Optimization in Terms of Energy and Performance of an Industrial Robot in the Manufacturing Industry. Sensors 2022, 22, 7538. [Google Scholar] [CrossRef]

- Knöchelmann, E.; Steinke, D.; Greenyer, J.; Spindeldreier, S.; Ortmaier, T. Trajectory Optimization Methods for Robotic Cells Considering Energy Efficiency and Collisions. In Annals of Scientific Society for Assembly, Handling and Industrial Robotics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 229–240. [Google Scholar] [CrossRef]

- Li, X.; Lan, Y.; Jiang, P.; Cao, H.; Zhou, J. An Efficient Computation for Energy Optimization of Robot Trajectory. IEEE Trans. Ind. Electron. 2022, 69, 11436–11446. [Google Scholar] [CrossRef]

- Liu, J.; Yap, H.; Khairuddin, A. Review on Motion Planning of Robotic Manipulator in Dynamic Environments. J. Sens. 2024, 2024, 5969512. [Google Scholar] [CrossRef]

- Zhang, S.; Zanchettin, A.M.; Villa, R.; Dai, S. Real-Time Trajectory Planning Based on Joint-Decoupled Optimization in Human-Robot Interaction. Mech. Mach. Theory 2020, 144, 103664. [Google Scholar] [CrossRef]

- Aziz, M.A.S.; Zhanibek, M.; Elsayed, A.S.A.; AbdulRazic, M.O.M.; Yahya, S.; Almurib, H.A.; Moghavvemi, M. Design and analysis of a proposed light weight three DOF planar industrial manipulator. In Proceedings of the 2016 IEEE Industry Applications Society Annual Meeting, Portland, OR, USA, 2–6 October 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Kim, Y.J. Anthropomorphic Low-Inertia High-Stiffness Manipulator for High-Speed Safe Interaction. IEEE Trans. Robot. 2017, 33, 1358–1374. [Google Scholar] [CrossRef]

- Nguyen, V.P.; Chow, W.T.; Dhyan, S.B.; Zhang, B.; Han, B.S.; Wong, H.Y.A. Low-Cost Cable-Driven Robot Arm with Low-Inertia Movement and Long-Term Cable Durability. Robotics 2024, 13, 128. [Google Scholar] [CrossRef]

- Jia, J.; Sun, X. Structural Optimization Design of a Six-Degrees-of-Freedom Serial Robot with Integrated Topology and Dimensional Parameters. Sensors 2023, 23, 7183. [Google Scholar] [CrossRef]

- Yin, H.; Huang, S.; He, M.; Li, J. An overall structure optimization for a light-weight robotic arm. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 1765–1770. [Google Scholar] [CrossRef]

- Thomsen, D.; Søe-Knudsen, R.; Balling, O.; Zhang, X. Vibration Control of Industrial Robot Arms by Multi-Mode Time-Varying Input Shaping. Mech. Mach. Theory 2021, 155, 104072. [Google Scholar] [CrossRef]

- Rankis, I.; Meike, D.; Senfelds, A. Utilization of Regeneration Energy in Industrial Robots System. Enerģētika Un Elektrotehnika 2013, 31, 95–100. [Google Scholar]

- Palomba, I.; Wehrle, E.; Carabin, G.; Vidoni, R. Minimization of the Energy Consumption in Industrial Robots through Regenerative Drives and Optimally Designed Compliant Elements. Appl. Sci. 2020, 10, 7475. [Google Scholar] [CrossRef]

- Scalera, L.; Carabin, G.; Vidoni, R.; Wongratanaphisan, T. Energy efficiency in a 4-DOF parallel robot featuring compliant elements. Int. J. Mech. Control 2019, 20, 49–57. [Google Scholar]

- Khalaf, P.; Richter, H. Trajectory Optimization of Robots with Regenerative Drive Systems: Numerical and Experimental Results. arXiv 2018, arXiv:1804.00311. [Google Scholar] [CrossRef]

- Erdős, G.; Kovács, A.; Váncza, J. Optimized joint motion planning for redundant industrial robots. CIRP Ann. 2016, 65, 451–454. [Google Scholar] [CrossRef]

- Lee, G.; Sul, S.K.; Kim, J. Energy-saving method of parallel mechanism by redundant actuation. Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 345–351. [Google Scholar] [CrossRef]

- Di Martino, A.; Miraftabzadeh, S.M.; Longo, M. Strategies for the Modelisation of Electric Vehicle Energy Consumption: A Review. Energies 2022, 15, 8115. [Google Scholar] [CrossRef]

- Weiss, M.; Winbush, T.; Newman, A.; Helmers, E. Energy Consumption of Electric Vehicles in Europe. Sustainability 2024, 16, 7529. [Google Scholar] [CrossRef]

- Björkman, M.; NORRLÖF, M. A Method for Reducing the Energy Consumption of an Industrial Robot and an Industrial Robot System. WO WO2011042293A1, 14 April 2011. [Google Scholar]

- Biswas, P.; Rashid, A.; Biswas, A.; Nasim, M.A.A.; Chakraborty, S.; Gupta, K.D.; George, R. AI-driven approaches for optimizing power consumption: A comprehensive survey. Discov. Artif. Intell. 2024, 4, 116. [Google Scholar] [CrossRef]

- Tamizi, M.G.; Yaghoubi, M.; Najjaran, H. A review of recent trend in motion planning of industrial robots. Int. J. Intell. Robot. Appl. 2023, 7, 253–274. [Google Scholar] [CrossRef]

- Meyes, R.; Tercan, H.; Roggendorf, S.; Thiele, T.; Büscher, C.; Obdenbusch, M.; Brecher, C.; Jeschke, S.; Meisen, T. Motion Planning for Industrial Robots using Reinforcement Learning. Procedia CIRP 2017, 63, 107–112. [Google Scholar] [CrossRef]

- Wang, X.; Cao, J.; Cao, Y.; Zou, F. Energy-efficient trajectory planning for a class of industrial robots using parallel deep reinforcement learning. Nonlinear Dyn. 2025, 113, 8491–8511. [Google Scholar] [CrossRef]

- Yao, M.; Su, Y.; Shao, Z.; Huo, Y. Data-driven Energy Evaluation and Optimization Method for Industrial Robots. In Proceedings of the 2023 8th International Conference on Automation, Control and Robotics Engineering (CACRE), Hong Kong, China, 13–15 July 2023; pp. 287–293. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, J. A data-driven method for optimizing the energy consumption of industrial robots. J. Clean. Prod. 2021, 285, 124862. [Google Scholar] [CrossRef]

- Jiang, P.; Wang, Z.; Li, X.; Wang, X.V.; Yang, B.; Zheng, J. Energy consumption prediction and optimization of industrial robots based on LSTM. J. Manuf. Syst. 2023, 70, 137–148. [Google Scholar] [CrossRef]

- Jiang, P.; Zheng, J.; Wang, Z.; Qin, Y.; Li, X. Industrial Robot Energy Consumption Model Identification: A Coupling Model-Driven and Data-Driven Paradigm. Expert Syst. Appl. 2025, 262, 125604. [Google Scholar] [CrossRef]

- Dona’, D.; Franzese, G.; Della Santina, C.; Boscariol, P.; Lenzo, B. Real-Time Generation of Near-Minimum-Energy Trajectories via Constraint-Informed Residual Learning. arXiv 2025, arXiv:2501.09450. [Google Scholar] [CrossRef]

- Chang, Q.; Yuan, T.; Li, H.; Chen, Y.; Wang, X.; Gao, S.; Ren, H.; Zhao, X.; Wang, L. A Data-Driven Method for Predicting and Optimizing Industrial Robot Energy Consumption Under Unknown Load Conditions. Actuators 2024, 13, 516. [Google Scholar] [CrossRef]

| DOF/Motors | Robot Type | Typical Use Cases | ECO Priority |

|---|---|---|---|

| 3 | Cartesian | CNC machining, 3D printing | Low |

| 4 | SCARA, Delta, Articulated | High-speed assembly, sorting, packaging, pick-and-place, palletizing | High |

| 5 | Articulated | Pick and place, palletizing | High |

| 6 | Articulated | Welding, painting, machining, assembly | Low-Medium |

| 7 | Articulated | Human-robot collaboration, flexible tasks | Medium |

| Strengths | Weaknesses |

|---|---|

|

|

|

|

|

|

|

|

| Opportunities | Threats |

|

|

|

|

|

|

|

|

| Strengths | Weaknesses |

|---|---|

|

|

|

|

|

|

|

|

| Opportunities | Threats |

|

|

|

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muru, J.; Rassõlkin, A. A Scoping Review of Energy Consumption in Industrial Robotics. Machines 2025, 13, 542. https://doi.org/10.3390/machines13070542

Muru J, Rassõlkin A. A Scoping Review of Energy Consumption in Industrial Robotics. Machines. 2025; 13(7):542. https://doi.org/10.3390/machines13070542

Chicago/Turabian StyleMuru, Johannes, and Anton Rassõlkin. 2025. "A Scoping Review of Energy Consumption in Industrial Robotics" Machines 13, no. 7: 542. https://doi.org/10.3390/machines13070542

APA StyleMuru, J., & Rassõlkin, A. (2025). A Scoping Review of Energy Consumption in Industrial Robotics. Machines, 13(7), 542. https://doi.org/10.3390/machines13070542