Abstract

Rolling bearing fault diagnosis in electric hoists faces significant challenges due to heavy noise and complex vibration interferences, which obscure fault signatures and hinder conventional demodulation methods. While existing techniques like the Teager–Kaiser energy operator (TKEO) and its variants (e.g., HO-AEO, SD-AEO) offer filterless demodulation, their susceptibility to noise and dependency on preprocessing limit diagnostic accuracy. This study proposes a Multi-resolution Higher-order Symmetric Analytic Energy Operator (MHSAEO) to address these limitations. The MHSAEO integrates three innovations: (1) dynamic non-adjacent sampling to suppress stochastic errors, (2) AM-FM dual demodulation via symmetric energy orthogonality, and (3) adaptive spectral mining for full-band feature extraction. Experimental validation on a 10-ton electric hoist bearing system demonstrates that the MHSAEO achieves signal-to-noise ratio improvements (SNRIs) of −3.83 dB (outer race faults) and −2.12 dB (inner race faults), successfully identifying the characteristic fault frequencies of both inner (145.9 Hz) and outer races in electric hoist bearings with 2nd–5th harmonics. Compared to traditional methods, the MHSAEO reduces computational time by 30.1 × (0.0328 s vs. 0.9872 s) without requiring preprocessing. The results confirm its superior anti-interference capability and real-time performance over the TKEO, HO-AEO, and hybrid denoising–TKEO approaches.

1. Introduction

Complex operating conditions and high equipment loads pose critical challenges for rotary machinery in modern industrial systems [1]. As core mechanical components, bearings are pivotal to ensuring machine functionality and reliability through efficient load transmission—particularly roller bearings, whose durability directly governs the structural and operational integrity of entire systems [2]. In material handling applications such as electric hoists, bearings endure compounded alternating stresses, including static loads, dynamic impacts from frequent start-stop cycles, and sliding-rolling friction effects [3,4]. These multi-source excitations induce localized stress concentrations on bearing surfaces, triggering micro-crack initiation, fatigue spalling, and ultimately catastrophic failures if undiagnosed. Such failures compromise equipment stability, endanger personnel safety, and disrupt operational efficiency [5], underscoring the imperative for robust condition monitoring and fault diagnosis in electric hoist rolling bearings to ensure safe and efficient operations.

Vibration signals can directly reflect the operating status of bearings and have become one of the most commonly used monitoring means for rolling bearing fault diagnosis [6,7]. Theoretically, the vibration signals of rolling bearing faults exhibit typical amplitude–frequency modulation (AM-FM) characteristics, where the carrier corresponds to the resonance frequency of the bearing system, and the fundamental frequency (envelope) of the modulation signal reflects the bearing fault characteristic frequency [8,9]. However, vibration signals collected in engineering are often contaminated by on-site environmental noise and vibration interference, resulting in the weak bearing fault signal features being submerged. Therefore, accurately extracting the modulated rolling bearing fault information from vibration signals with strong noise and multiple interferences is an urgent need and an important challenge [10,11].

In recent years, researchers have developed numerous signal-processing methods for weak fault feature extraction. Liu et al. [12] proposed a local maximum instantaneous extraction transform based on an extended autocorrelation function (LMIET-EACF) to capture bearing fault signals under low signal-to-noise ratios Li et al. [13] developed an impulse feature enhancement-weighted sparse representation (IFEWSR) algorithm for precise detection of weak impact features in early-stage bearing faults from condition monitoring (CM) signals. Zhu et al. [14] addressed the challenge of periodic impulse component extraction in strong noise backgrounds through a transmission path elimination-enhanced variational mode decomposition (TPE-EVMD) method. Li et al. [15] introduced a local mean decomposition (LMD) approach based on an improved composite interpolation envelope (ICIE) for bearing fault feature extraction. Zhou et al. [16] proposed a hybrid method combining parameter-adaptive variational mode decomposition (VMD) with multipoint optimal minimum entropy deconvolution (MOMEDA). Chen et al. [17] established a novel fault diagnosis framework integrating wavelet threshold denoising, complete ensemble empirical mode decomposition with adaptive noise (CEEMDAN) energy entropy, and particle swarm optimization-least squares support vector machine (PSO-LSSVM). Zheng et al. [18] further developed an adaptive group sparse feature decomposition guided by envelope derivative operator harmonic-to-noise ratio (AEDOHNR-AGSFD) achieving early fault identification under heavy noise and random impact interference. While these approaches have demonstrated notable advances in fault feature extraction, they remain constrained by persistent challenges including parameter sensitivity, computational complexity, and real-time processing capabilities.

The Teager–Kaiser energy operator (TKEO), as a parameter-free and filterless demodulation method, effectively captures frequency/amplitude variations and energy fluctuations in raw signals, finding extensive applications in rotating machinery fault diagnosis [19]. Wang et al. [20] combined TKEO frequency-domain demodulation with improved cyclic stationary analysis (CMS/Fast-SC) to achieve a robust diagnosis of motor rotor bar breakage and bearing outer race faults under multiple operating conditions. Agah et al. [21] proposed a hybrid diagnostic approach for motor rotor eccentricity faults using discrete wavelet transform (DWT), the TKEO, and power spectral density (PSD). Song et al. [22] utilized low-pass Teager energy operators to extract and enhance low-frequency vibration components, effectively suppressing noise interference. Krishnendu et al. [23] developed a TKEO-based optimal energy concentration time–frequency transformation for bearing fault diagnosis. Nevertheless, the TKEO’s inherent susceptibility to noise contamination compromises its effectiveness in high-noise scenarios, mandating supplementary integration with preprocessing techniques like wavelet threshold denoising (WTD), empirical mode decomposition (EMD), or variational mode decomposition (VMD) for noise suppression [24,25,26,27], which increases algorithm complexity and computational costs and introduces additional parameter optimization burdens.

Recent efforts to enhance energy operators have achieved incremental progress. For instance, symmetric differential-analytic energy operators (SD-AEOs) [9] reduced noise sensitivity via symmetric differencing but remained constrained by single-resolution analysis. Similarly, high-order differential analytic energy operators (HO-AEOs) [28] improved transient feature extraction through cascaded differentiation but amplified high-frequency noise, elevating misdiagnosis risks in low-SNR conditions. The Multi-resolution Higher-Order Symmetric Envelope-Derivative Operator (MHOS-EDO) [29] represents a significant advancement in energy-based demodulation, achieving robust signal-to-interference ratio (SIR) enhancement through its innovative envelope-derivative framework. While this method excels in harmonic extraction, its energy-centric design intrinsically limits sensitivity to low-amplitude fundamental frequencies—a critical gap for weak-fault diagnosis. Building upon the MHOS-EDO’s multi-resolution paradigm, our study proposes the use of the Multi-resolution Higher-order Symmetric Analytic Energy Operator (MHSAEO) to overcome this limitation by replacing the energy-dependent envelope derivative with analytic signal orthogonality and dynamic non-adjacent sampling. The main contributions of this article are as follows:

(1) Dynamic k-interval non-adjacent sampling: The non-adjacent modified symmetric difference method reduces sensitivity to high-frequency noise by expanding the sampling interval. It jointly suppresses random errors and aliasing interference through time–frequency synergy while preserving the integrity of low-frequency signal trends.

(2) AM-FM dual demodulation via high-order symmetric energy orthogonality: We propose a noise-immune mechanism enabling synchronous amplitude–frequency demodulation and broadband feature extraction for compound modulated signals, leveraging symmetric energy orthogonality and signal smoothness optimization to eliminate preprocessing and narrowband limitations of traditional envelope analysis.

(3) Self-adaptive spectral energy mining: This automatically extracts fault signatures across full frequency bands without prior knowledge, overcoming manual parameter tuning in conventional envelope analysis.

This framework embodies a paradigm shift from energy-dependent envelope derivatives to analytic signal orthogonality and dynamic non-adjacent sampling. Compared to the traditional TKEO, the MHSAEO robustly extracts fault features from noise-corrupted signals without preprocessing (e.g., WTD, EMD, VMD), while demonstrating superior real-time performance and computational efficiency.

The remainder of this paper is structured as follows: Section 2 derives the theoretical foundation of the MHSAEO indicator. Section 3 analyzes the noise and interference resistance capabilities of the MHSAEO. In Section 4, the proposed energy operator is investigated through an electric hoist bearing fault diagnosis experiment. Finally, Section 5 concludes the paper.

2. Theoretical Foundation of the MHSAEO

For a continuous signal , its analytic form is derived via the Hilbert Transform:

where H[·] denotes the Hilbert Transform (HT).

According to Equation (1), the instantaneous envelope of the signal x(t) is given by

while the instantaneous phase and instantaneous frequency are, respectively, defined as

From Equation (4), we derive

This expression simultaneously encapsulates both amplitude modulation (AM, ) and frequency modulation (FM, ) information. Based on this, the Analytic Energy Operator (AEO) [30] is derived in Equation (6):

whose discrete form is

As a nonlinear demodulation method, the TKEO exhibits strong adaptability to transient signal variations. For an arbitrary discrete signal x(n), its definition is as follows:

It can be seen from Equation (8) that the TKEO tracks transient energy at any discrete time using only three samples, requiring minimal computational resources [25,31]. However, its reliance on adjacent samples leads to three key limitations: (1) sensitivity to strong background noise; (2) frequency/amplitude fluctuations at endpoints/sudden change points; and (3) insufficient smoothness of the output signal.

To tackle these challenges, symmetric differencing is employed to improve noise robustness through data smoothing [32]. Specifically, a three-sample symmetric differencing sequence (Equation (9)) is used to substitute the forward/backward differencing in the TKEO:

Next, a recursive formula is adopted to improve Equation (9) for constructing high-order symmetric differences to enhance the signal-to-interference ratio (SIR) [33], leading to Equation (10):

where p denotes the order of the high-order energy operator. Furthermore, a multi-resolution sampling strategy is incorporated by replacing adjacent samples with three symmetric samples spaced at intervals of k, reducing the impact of random errors. The multi-resolution high-order symmetric differencing sequence is defined as follows:

Substituting Equation (11) into Equation (7) yields the multi-resolution high-order symmetric analytic energy operator, as shown in Equation (12):

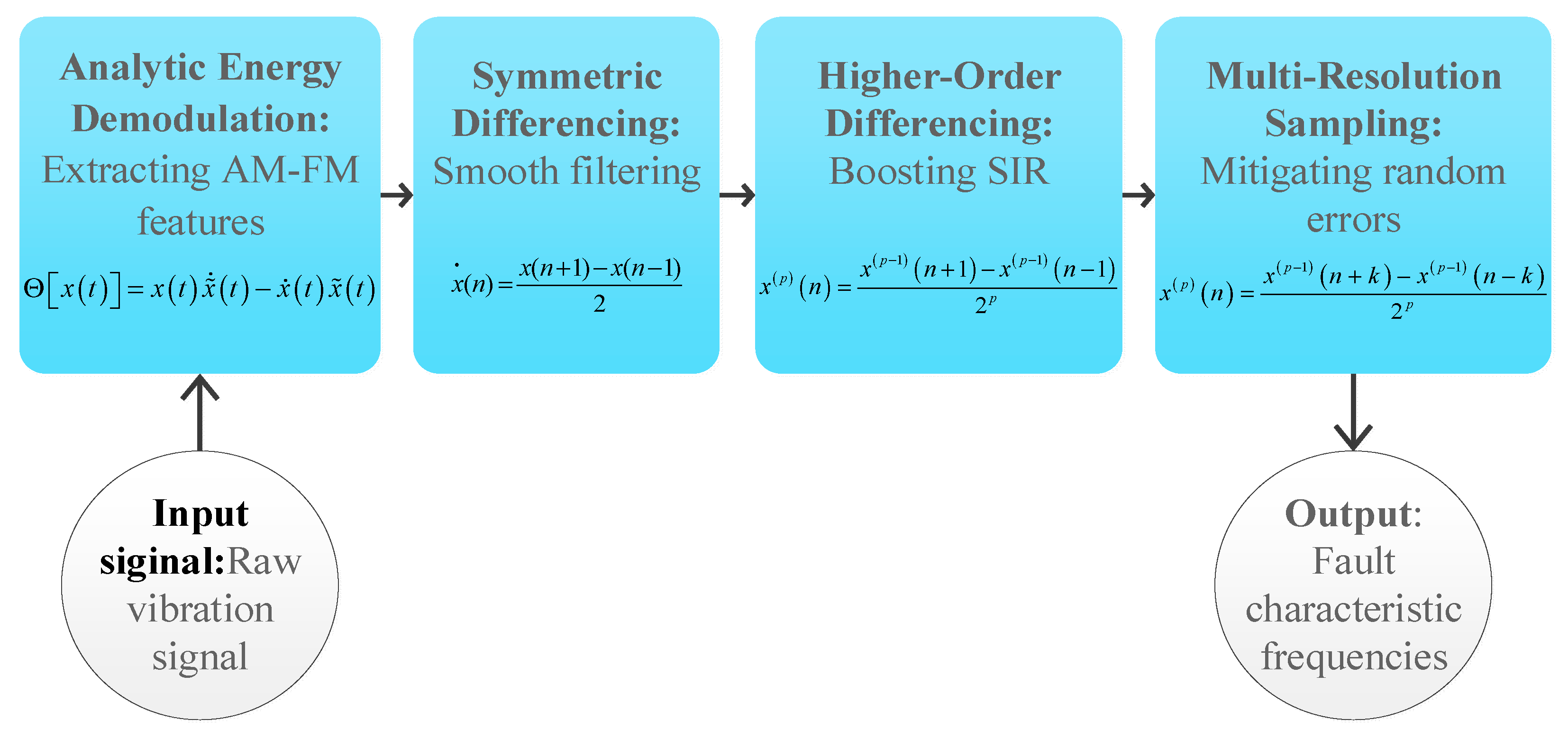

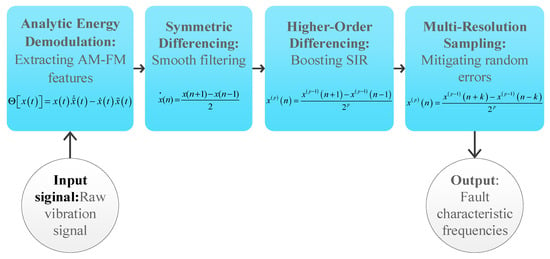

This operator integrates three enhancements: (1) symmetric differencing to suppress noise; (2) high-order differencing to boost SIR; and (3) multi-resolution sampling to mitigate random errors. The block-diagram framework for the proposed method is as shown in Figure 1.

Figure 1.

The framework for the proposed method.

By synergizing these strategies, the MHSAEO effectively overcomes the performance limitations of traditional energy operators, achieving superior noise resistance, stability, and smoothness in demodulation tasks.

3. Property Analysis of the MHSAEO

3.1. Anti-Interference Characteristic Analysis

A pure rolling bearing fault signal can be modeled as the impulse response of a single-degree-of-freedom mass-spring-damper system, expressed as Equation (13):

where A is the fault impulse amplitude, is the resonant frequency, and is the damping factor. By introducing harmonic interference into the bearing fault impulse sequence, the composite signal becomes

where represents the amplitude of the m-th fault pulse, while and denote the amplitude and frequency of the l-th harmonic interference, respectively.

The first three-order analytic forms of the composite signal are derived as Equations (15)–(17).

where

where

where

The analytical decomposition reveals that the first three-order MHSAEO outputs comprise three distinct constituents: amplitude demodulation components, the high-frequency part, and the interference component. Among them, the amplitude demodulation part includes three pieces of information related to rolling bearing faults—spectral energy, exponential decay factor, and high-frequency resonance frequency—and it is independent of vibration interference. The amplitude demodulation term’s orthogonality to interference establishes the theoretical foundation for the MHSAEO’s superior performance in isolating fault characteristic frequencies (FCFs) from harmonic-corrupted vibration signatures. Through spectral energy concentration and interference rejection mechanisms, the operator enables precise FCF extraction even under severe harmonic polluting conditions.

The signal interference ratio (SIR) of is defined in Equation (18):

Substituting Equation (15) into Equation (18) gives Equation (19):

For ,

For ,

Substituting Equation (17) into Equation (18) gives Equation (22):

By comparing SIR values across different orders (Equations (22) and (21)), the SIR enhancement ratio is derived in Equation (23):

Under the assumptions that , , and B = 3A, L = 3, Equation (23) further simplifies to Equation (24):

This demonstrates that the higher-order MHSAEO significantly improves SIR.

3.2. Signal-to-Noise Ratio Enhancement

The resolution parameter k enhances noise robustness. To quantify this improvement, the signal-to-noise ratio improvement (SNRI) metric is defined in Equation (25):

where is the noisy signal, is the MHSAEO-processed signal, and N is the length of the signal.

The simulated bearing fault signal is generated using Equation (26):

where the amplitude of the m-th fault pulse is Am = 5, the damping factor is α = 1500 N s/m, the fault period is T = 0.01 s, and the corresponding fault characteristic frequency (FCF) is 100 Hz. ωr represents the excitation resonant frequency, which is set at 2048 Hz. The larger the SNRI value, the stronger the fault feature extraction capability of the MHSAEO.

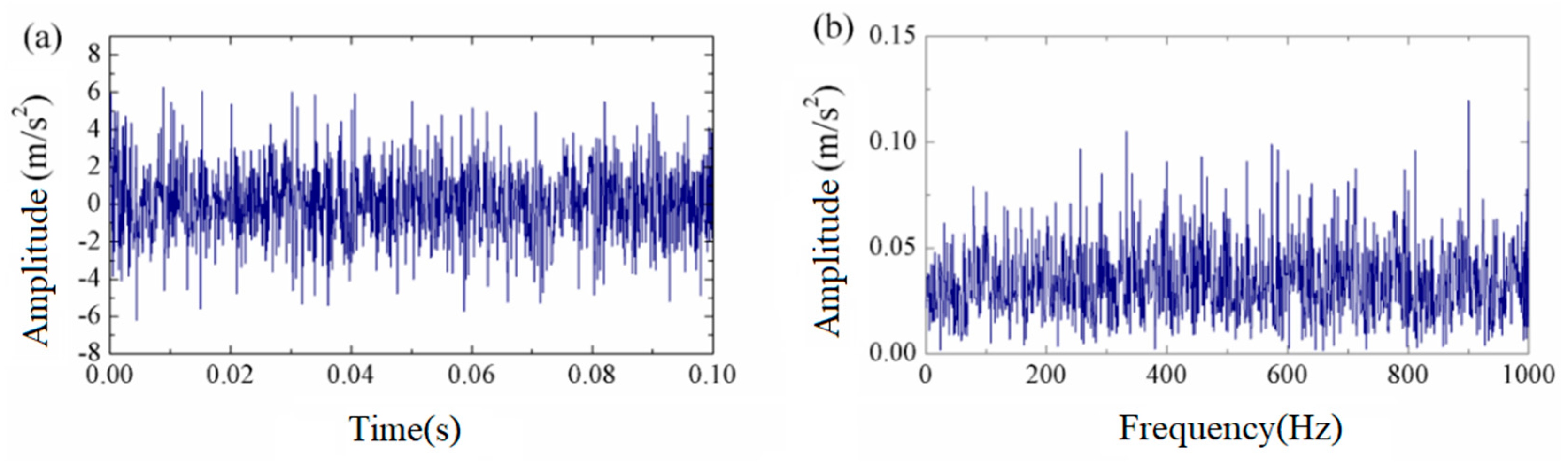

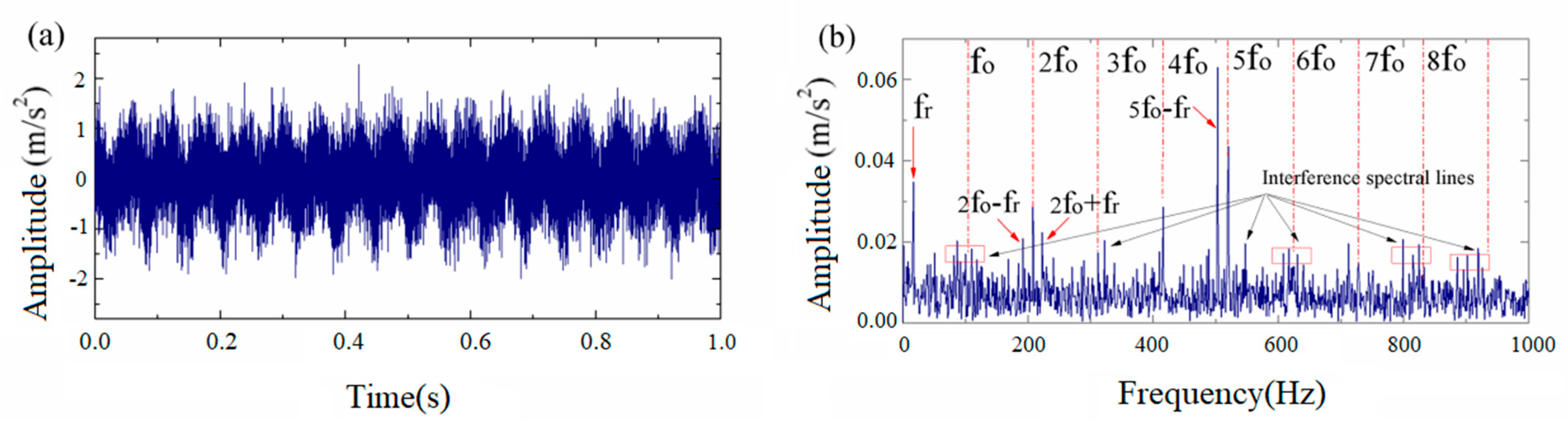

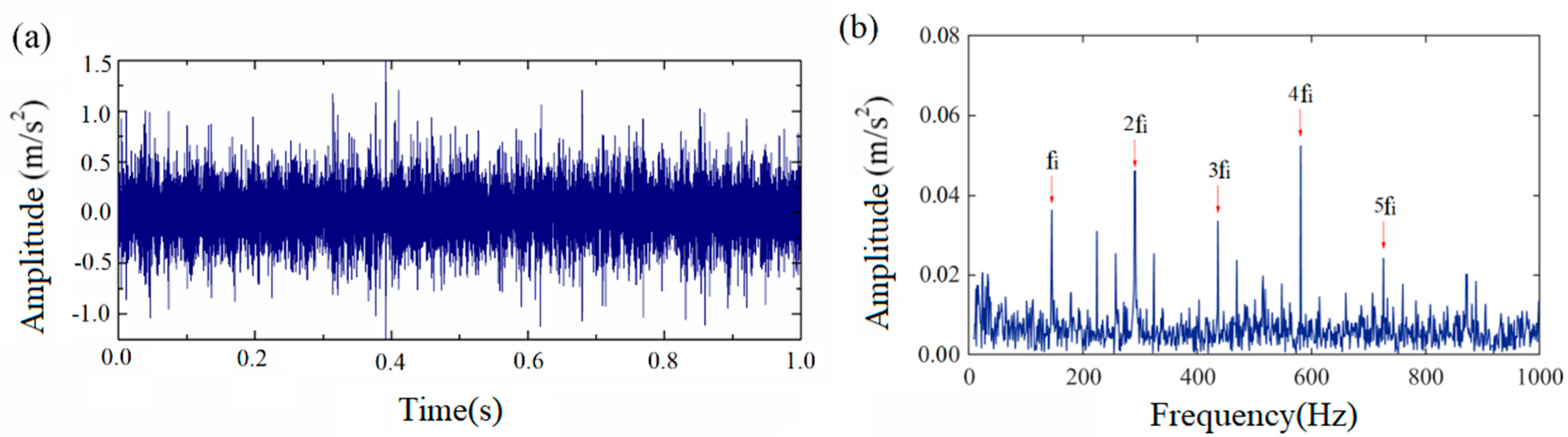

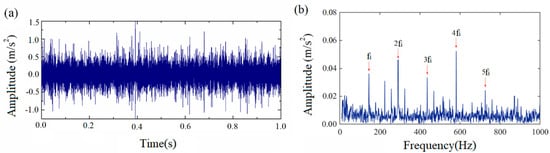

Gaussian white noise with a signal-to-noise ratio (SNR) of −10 dB is injected into the simulated bearing fault signal. The resultant composite signal and its frequency spectrum (Figure 2) demonstrate complete obscuration of the bearing fault characteristic frequency (FCF) within the noise-dominated spectrum, rendering conventional spectral diagnostics ineffective.

Figure 2.

Fault simulation signal: (a) time-domain diagram; (b) spectrum diagram.

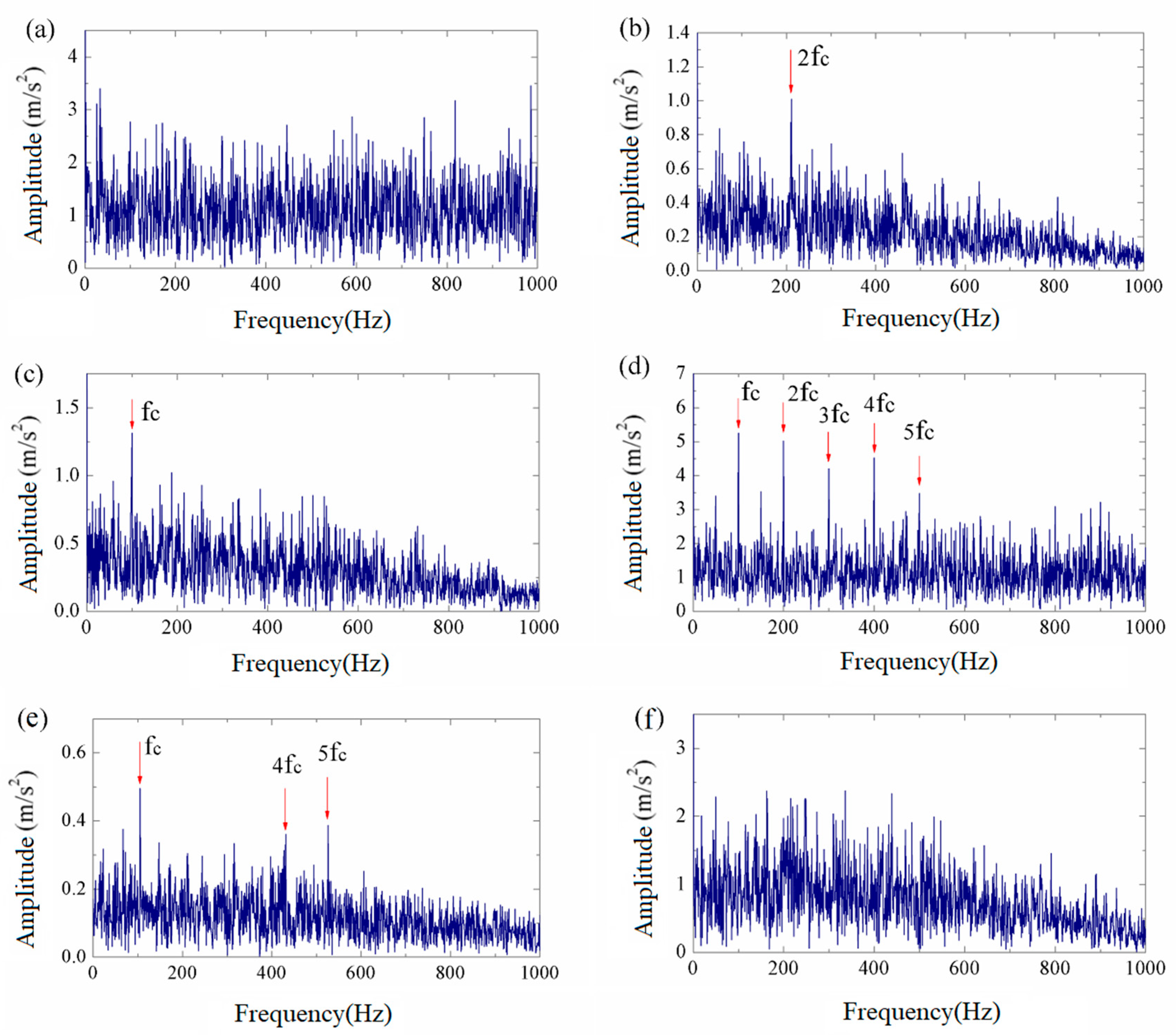

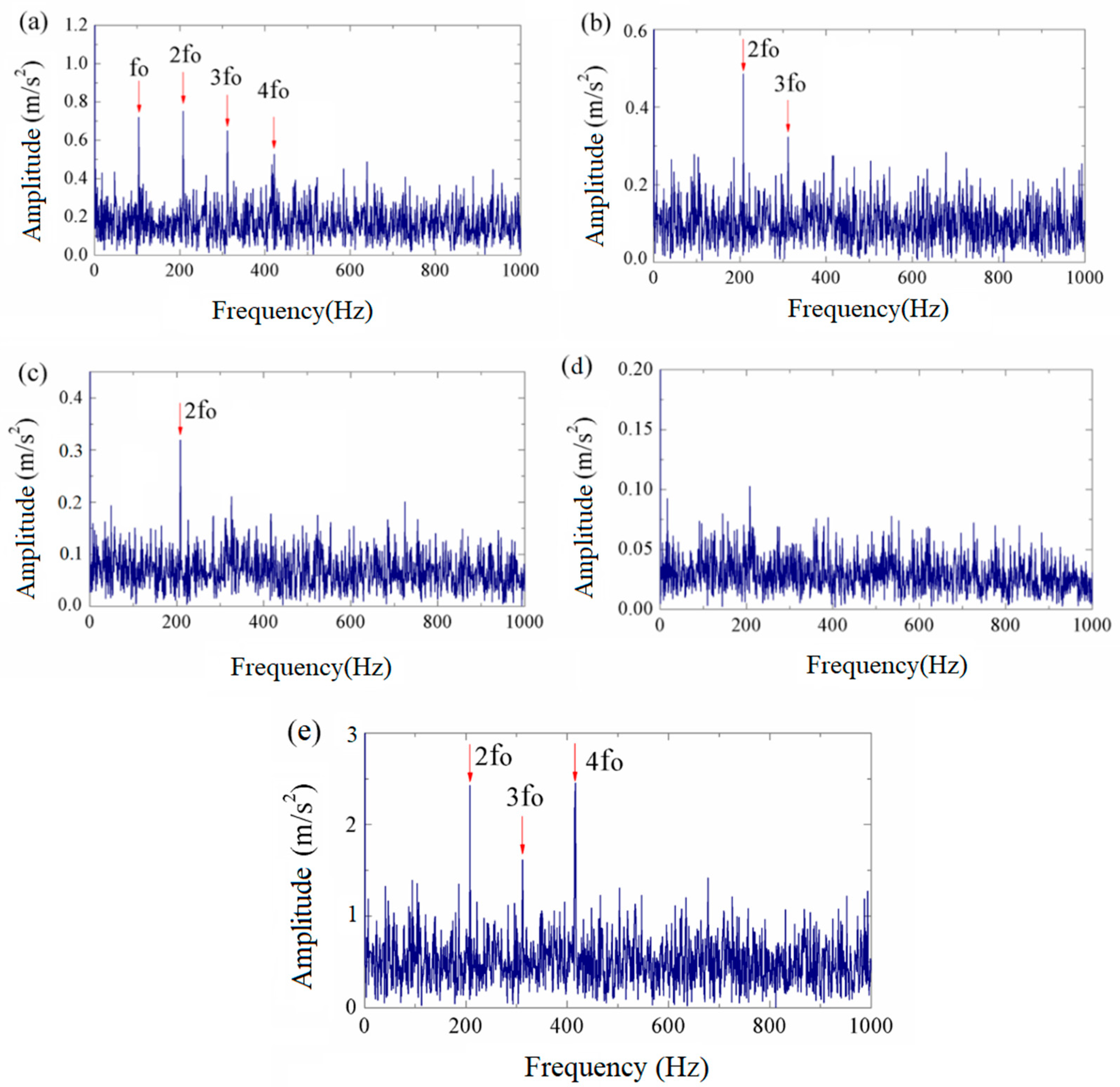

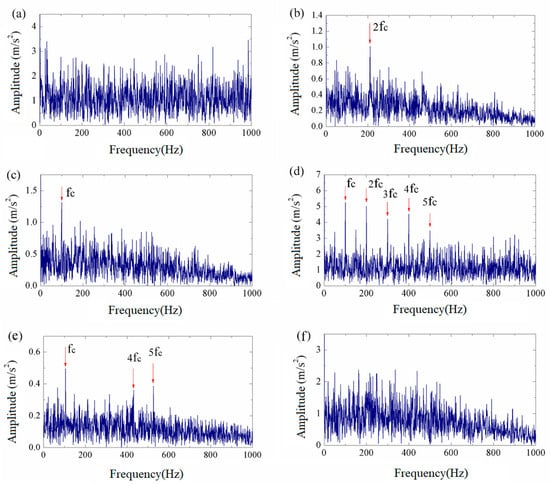

The values of the SNRI are computed for the MHSAEO with resolution parameters k = 1, 2, 3, 4, 5, as tabulated in Table 1. The maximum SNRI is observed at k = 3. Comparative analysis of the TKEO- and MHSAEO-processed signals (k = 1~5) is presented in Figure 3. No discernible FCF-related components are detectable at the TKEO spectrum. The MHSAEO (k = 3) spectrum resolves the fundamental FCF (fc) and its 2nd~5th harmonics, outperforming other parameter configurations. It also verifies that the feature extraction ability of the MHSAEO is the best when the SNRI is at its maximum value.

Table 1.

SNRI of MHSAEO with different resolutions.

Figure 3.

(a) TKEO spectrum; (b) k = 1, MHSAEO spectrum; (c) k = 2, MHSAEO spectrum; (d) k = 3, MHSAEO spectrum; (e) k = 4, MHSAEO spectrum; (f) k = 5, MHSAEO spectrum.

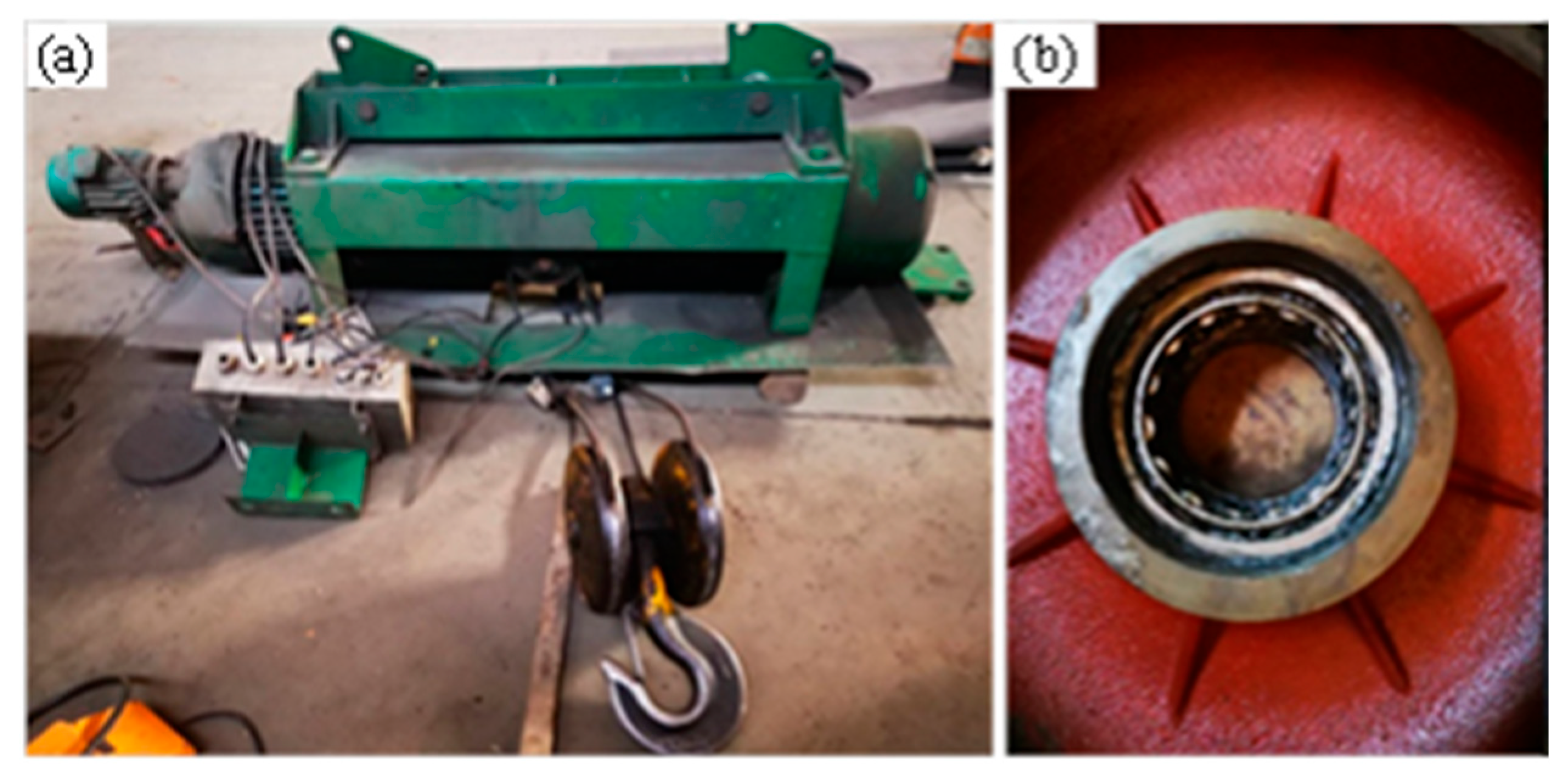

4. Bearing Fault Diagnosis Experiment for Electric Hoist

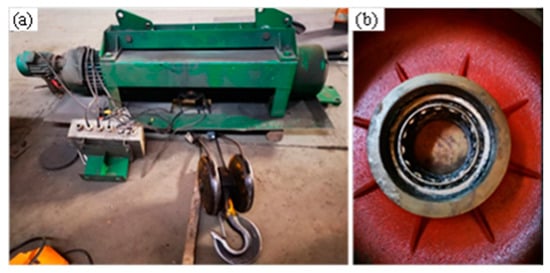

The experimental investigation was conducted at the Laboratory of Reliability Engineering (LRE) of Xianyang Institute of Special Equipment Inspection using a 10-ton electric hoist system (Figure 4). Vibration signals were collected from a Type 208 cylindrical roller bearing (specifications detailed in Table 2) installed on the hoist’s exciter under simulated inner and outer race fault conditions. A Dytran 3225F1 piezoelectric accelerometer, mounted on the bearing housing via magnetic bases, was employed to acquire vibration data. To ensure measurement accuracy, the contact surface was polished to minimize roughness, and direct mechanical coupling was maintained to reduce vibration propagation interference. Signal acquisition utilized the INV3018C high-performance data acquisition system (developed by Beijing Oriental Vibration and Noise Technology Research Institute) and DASP software (DASP V10), operating at a sampling frequency of 20 kHz to collect 20,000 data points per trial. Five experimental trials were performed for each fault type to validate the reliability of the results. During testing, the main shaft operated at a rotational frequency of fr = 16.7 Hz. The fault characteristic frequencies of the theoretical outer/inner rings are calculated using rolling bearing frequency formulas (Equations (27) and (28)):

where fo and fi are the outer and inner race fault frequencies, respectively. Z is the total number of rolling elements, D is the pitch diameter, d is the roller diameter, and is the contact angle.

Figure 4.

Experimental setup: (a) electric hoist; (b) cylindrical roller bearings.

Table 2.

Bearing specifications.

4.1. Outer Race Fault Diagnosis

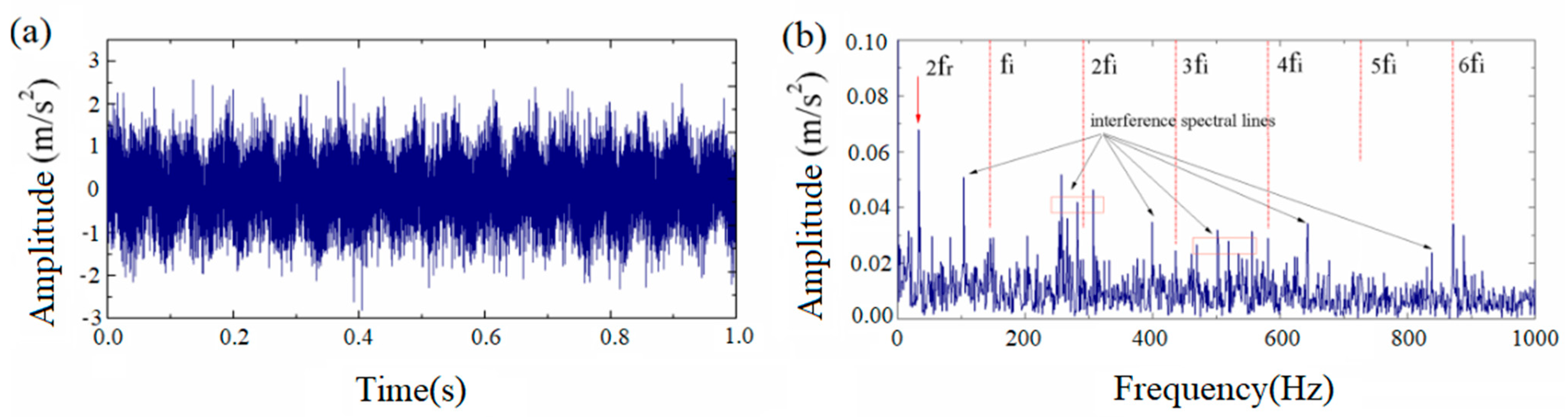

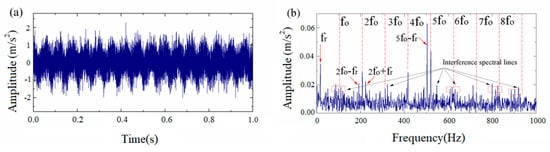

The time-domain waveform of the vibration signal from the electric hoist bearing with an outer race fault is shown in Figure 5a. Notably, no discernible periodic fault impulses with uniform spacing can be observed in the raw time-domain signal. Envelope analysis was subsequently applied to the outer race fault signal, with the results depicted in Figure 5b. The envelope spectrum exhibits numerous interference harmonics and significant background noise, failing to identify distinct fault-related spectral components.

Figure 5.

Outer race fault signal: (a) time-domain waveform; (b) envelope spectrum.

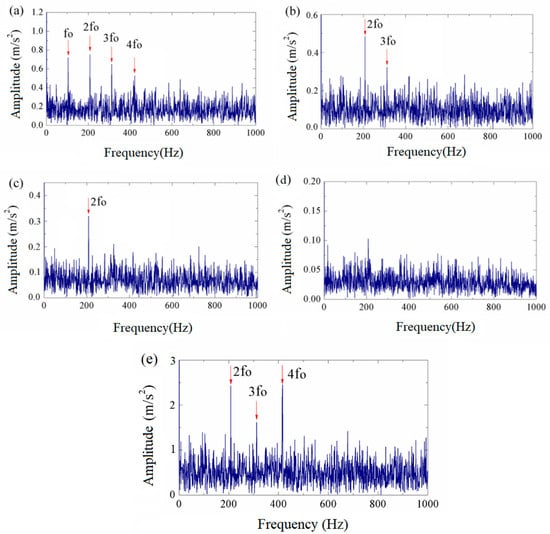

The proposed MHSAEO was implemented for outer race fault signal analysis. First, the SNRI values under different resolution parameters were calculated (Table 3). Selecting the optimal resolution parameter k = 2 corresponding to the maximum SNRI, the two-MHSAEO demodulation of the raw signal reveals clear extraction of the outer race fault characteristic frequency fo and its 2nd~4th harmonics from the noise-corrupted vibration signal, as demonstrated in Figure 6a.

Table 3.

SNRI of MHSAEO with different resolutions.

Figure 6.

Energy spectrum of outer race fault signal: (a) MHSAEO spectrum; (b) HO-AEO spectrum; (c) SD-AEO spectrum; (d) TEO spectrum; (e) MHOS-EDO spectrum.

To verify the superiority of the proposed method, the time-domain vibration signals with outer race faults were simultaneously analyzed using the TKEO, the high-order analytical energy operator (HO-AEO) proposed in Reference [28], and the symmetric difference analytical energy operator (SD-AEO) proposed in Reference [9], and the Multi-resolution Higher-Order Symmetric Envelope-Derivative Operator (MHOS-EDO) proposed in Reference [29]. The results are shown in Figure 6b–e. Although the SD-AEO spectrum can identify the second harmonic of the outer race fault characteristic frequency, the HO-AEO spectrum detects the second and third harmonics, and the MHOS-EDO spectrum extracts the second to fourth harmonics, all fail to effectively extract the fundamental frequency fo. Crucially, the MHOS-EDO spectrum (Figure 6e) exhibits this limitation due to its inherent energy-suppression effects—where energy-bound amplification attenuates low-energy components like fo under noise interference. In stark contrast, our MHSAEO (Figure 6a) successfully recovers fo–5fo through energy-decoupling design, confirming its superiority in weak-signal extraction. Consequently, the aforementioned energy operators (including the TEO, SD-AEO, HO-AEO, and MHOS-EDO) exhibit limitations in the fault diagnosis of electric hoist rolling bearings.

No fault-related information can be observed in the TKEO spectrum. Although the second harmonic of the outer race fault characteristic frequency can be identified in the SD-AEO spectrum and the second and third harmonics of the outer race fault characteristic frequency can be identified in the HO-AEO spectrum, neither can extract the outer race fault characteristic frequency fo. Therefore, the three energy operators (TEO, SD-AEO, and HO-AEO) fail in the fault diagnosis of electric hoist rolling bearings.

4.2. Inner Race Fault Diagnosis

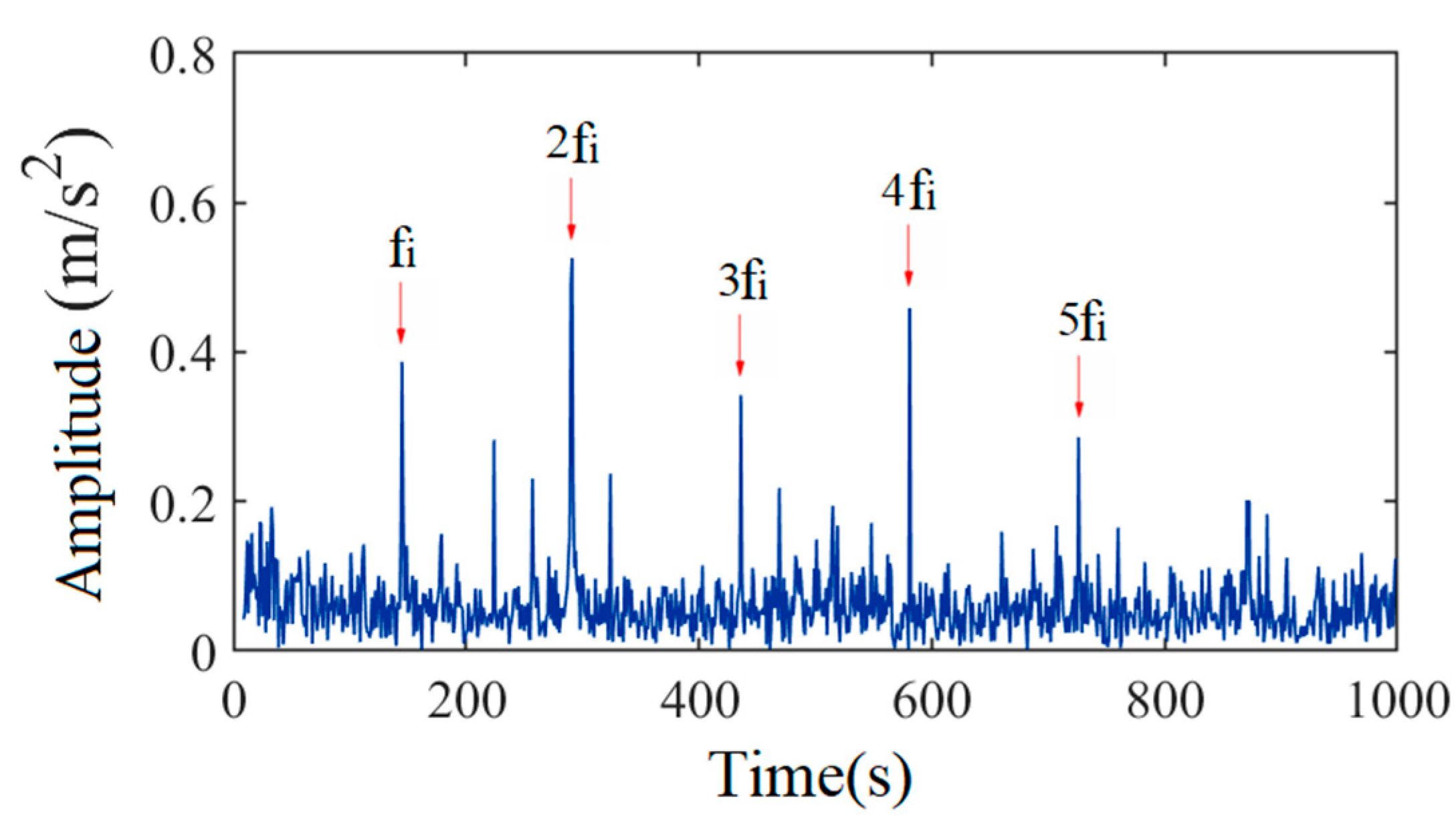

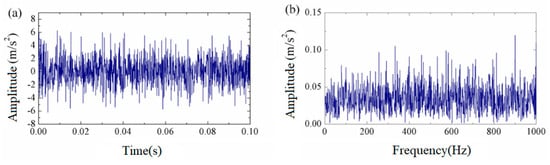

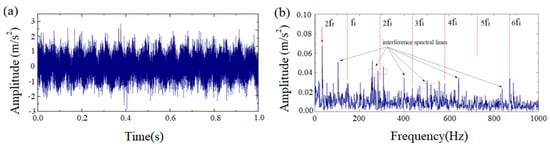

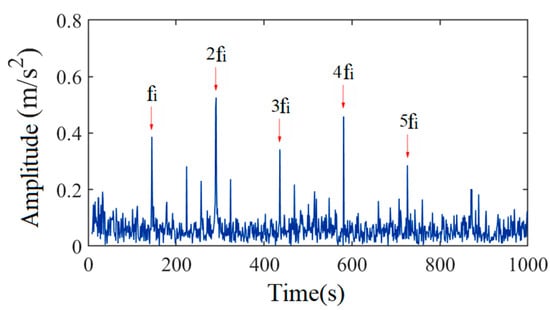

The vibration signal acquired from the electric hoist bearing with inner race defects is illustrated in Figure 7. Initial analysis of the time-domain waveform (Figure 7a) reveals an absence of discernible periodic fault impulses, and its corresponding envelope spectrum (Figure 7b) exhibits strong interference harmonics and significant background noise contamination. Rendering identification of the fundamental fault characteristic frequency (fi) and its harmonics is impossible through conventional spectral analysis.

Figure 7.

Inner race fault signal: (a) time-domain waveform; (b) envelope spectrum.

To resolve this detection dilemma, the proposed MHSAEO was implemented for feature extraction. First, the signal-to-noise ratio improvement (SNRI) metric was calculated for the MHSAEO across resolution parameters k ∈ {1,2,3,4,5}, with quantitative results documented in Table 4.

Table 4.

SNRI of MHSAEO with different resolutions.

The resolution parameter k = 2, corresponding to the maximum SNRI value, was selected for two-MHSAEO demodulation of the raw signal. As evidenced in Figure 8, the MHSAEO operator successfully resolves the inner race fault characteristic frequency fi = 145.9 Hz and its harmonics up to the fifth order (2fi~5fi), demonstrating effective feature extraction capability in challenging noise environments.

Figure 8.

MHSAEO spectrum of inner race fault signal.

To further validate the superiority of the MHSAEO, a comparative analysis was performed using the composite “wavelet threshold denoising + TEO” method proposed in [34]. As shown in Figure 9, the “wavelet threshold denoising + TEO” method can also extract the bearing inner race fault characteristic frequency and its consecutive fifth-order harmonics, but its amplitude is lower, and there are more interference spectral lines when compared with the MHSAEO method. It demonstrates that the feature extraction capability of the proposed MHSAEO operator is superior to the composite “preprocessing denoising + TKEO” method. Additionally, the denoising preprocessing step not only involves parameter selection challenges but also significantly increases computational complexity and running time, thereby reducing the algorithm’s execution efficiency.

Figure 9.

(a) Denoised signal by wavelet threshold denoising and its (b) TEO spectrum.

To establish rigorous computational benchmarks, we conducted efficiency evaluations under controlled experimental conditions. The test platform consisted of a commercial laptop equipped with an Intel® Core™ i5-8265U processor operating at 1.60 GHz base frequency. Execution time measurements were obtained through 10-cycle-averaged computations employing a dataset of 100,000 sampling points, with timing comparisons presented in Table 5. Our proposed MHSAEO algorithm demonstrated exceptional temporal efficiency, completing signal processing tasks in 0.0391 s—achieving a 30.1 × speed enhancement (t_ratio = 0.9872 s/0.0328 s) compared to the conventional wavelet–TEO hybrid approach.

Table 5.

Running time of the two methods.

5. Conclusions

Lifting machinery’s structural and operational dynamics induce substantial noise/vibration interference, complicating AM-FM bearing fault extraction. To address this, this study proposes the Multi-resolution Higher-order Symmetric Analytic Energy Operator (MHSAEO)—an improved energy operator combining symmetric differencing, high-order difference, and multi-resolution sampling, along with the SNRI index for parameter tuning. Experimental validation confirms that the MHSAEO robustly extracts fault features without preprocessing, enabling accurate diagnosis of inner and outer race faults in electric hoist rolling bearings. Its performance surpasses traditional energy operators (e.g., TKEO), advanced variants (e.g., HO-AEO, SD-AEO, and MHOS-EDO), and hybrid methods (e.g., wavelet denoising + TKEO) in terms of noise resistance, computational efficiency, and diagnostic precision. Crucially, while the MHOS-EDO advanced multi-resolution demodulation, its energy sensitivity limited weak-fault detection; the MHSAEO overcomes this limitation by unifying Hilbert orthogonality and dynamic sampling, as experimentally validated.

However, this study is currently limited to single faults under stationary conditions. The MHSAEO’s performance may degrade for compound faults due to overlapping modulation, and its applicability to dynamic industrial environments requires validation. Future work will focus on the following:

(1) Composite fault diagnosis under variable loads and non-stationary conditions;

(2) Validation of the MHSAEO’s robustness against non-Gaussian noise and complex interference spectra;

(3) Extension of the method to other rotating systems (e.g., wind turbines, gearboxes) and bearing types (e.g., ball bearings, tapered roller bearings).

Author Contributions

X.W.: Writing original draft and data collection; Y.W.: Methodology and study design; Y.H.: Formal analysis and literature search. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Program Project of Shaanxi Provincial Market Supervision Administration (Project No. 2022KY18) and the Natural Science Basic Research Program of Shaanxi Province (2024JC-YBQN-0446).

Data Availability Statement

All data are contained in this article.

Conflicts of Interest

Xinhui Wang is employed by the Xianyang Special Equipment Inspection Institute as the head of the institute. The research was funded by the Science and Technology Program Project of Shaanxi Provincial Market Supervision Administration (Project No. 2022KY18) and the Natural Science Basic Research Program of Shaanxi Province (2024JC-YBQN-0446). All authors confirm that there are no conflicts of interest.

References

- Mikić, D.; Desnica, E.; Kiss, I.; Mikić, V. Reliability analysis of rolling ball bearings considering the bearing radial clearance and operating temperature. Adv. Eng. Lett 2022, 1, 16–22. [Google Scholar] [CrossRef]

- Desnica, E.; Ašonja, A.; Radovanović, L.; Palinkaš, I.; Kiss, I. Selection, dimensioning and maintenance of roller bearings. In Proceedings of the International Conference on Organization and Technology of Maintenance, Austin, TX, USA, 13–16 October 2022; pp. 133–142. [Google Scholar]

- Feng, C.; Zhang, D.; Chen, K.; Wang, D.; Li, X.; Cao, Y. Effect of Dynamic Load on Adhesive Friction at the Interface Between Friction Lining and Wire Rope of Hoist. J. Tribol. 2022, 144, 091704. [Google Scholar] [CrossRef]

- Wu, K.; Xiang, D.; Cai, D.; Feng, Y.; Xu, Y.; Jiang, Z. Extraction of incipient fault features of rolling bearings based on CWSSMD and 1.5 D-EDEO demodulation. Meas. Sci. Technol. 2023, 34, 045011. [Google Scholar] [CrossRef]

- Li, C.G.; Qi, Q.S.; Dong, Q.; Yu, Y.N.; Fan, Y. Research on fatigue remaining life of structures for a dynamic lifting process of a bridge crane. J. Mech. Sci. Technol. 2023, 37, 1789–1801. [Google Scholar] [CrossRef]

- Liu, T.; Li, X.; Lyu, M.; Yan, S. A bearing fault extraction method combining time–frequency mode decomposition based on local maxima with amplitude z-scores. Adv. Eng. Inform. 2025, 64, 103002. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, Y.; Zhang, L.; Ma, C.; Xu, Y. Frequency slice graph spectrum model and its application in bearing fault feature extraction. Mech. Syst. Signal Process. 2025, 226, 112383. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, K.; Sheng, Z.; Zhang, X.; Xu, Y. The amplitude modulation bispectrum: A weak modulation features extracting method for bearing fault diagnosis. Reliab. Eng. Syst. Saf. 2024, 250, 110241. [Google Scholar] [CrossRef]

- Xu, Y.; Fan, F.; Jiang, X. A fast iterative filtering decomposition and symmetric difference analytic energy operator for bearing fault extraction. ISA Trans. 2021, 108, 317–332. [Google Scholar] [CrossRef]

- Lv, J.; Yu, J. Average combination difference morphological filters for fault feature extraction of bearing. Mech. Syst. Signal Process. 2018, 100, 827–845. [Google Scholar] [CrossRef]

- Liao, J.-X.; He, C.; Li, J.; Sun, J.; Zhang, S.; Zhang, X. Classifier-guided neural blind deconvolution: A physics-informed denoising module for bearing fault diagnosis under noisy conditions. Mech. Syst. Signal Process. 2025, 222, 111750. [Google Scholar] [CrossRef]

- Liu, T.; Li, L.; Noman, K.; Li, Y. Local maximum instantaneous extraction transform based on extended autocorrelation function for bearing fault diagnosis. Adv. Eng. Inform. 2024, 61, 102487. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Liu, J. Incipient detection of bearing fault using impulse feature enhanced weighted sparse representation. Tribol. Int. 2023, 184, 108467. [Google Scholar] [CrossRef]

- Zhu, D.; Chen, J.; Yin, B. Fault feature extraction of rolling element bearing based on TPE-EVMD. Measurement 2021, 183, 109880. [Google Scholar] [CrossRef]

- Li, X.; Ma, J.; Wang, X.; Wu, J.; Li, Z. An improved local mean decomposition method based on improved composite interpolation envelope and its application in bearing fault feature extraction. ISA Trans. 2020, 97, 365–383. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Y.; Jiang, L.; Zhou, L. Fault feature extraction for rolling bearings based on parameter-adaptive variational mode decomposition and multi-point optimal minimum entropy deconvolution. Measurement 2021, 173, 108469. [Google Scholar] [CrossRef]

- Chen, W.; Li, J.; Wang, Q.; Han, K. Fault feature extraction and diagnosis of rolling bearings based on wavelet thresholding denoising with CEEMDAN energy entropy and PSO-LSSVM. Measurement 2021, 172, 108901. [Google Scholar] [CrossRef]

- Zheng, K.; Yao, D.; Shi, Y.; Wei, B.; Yang, D.; Zhang, B. An adaptive group sparse feature decomposition method in frequency domain for rolling bearing fault diagnosis. ISA Trans. 2023, 138, 562–581. [Google Scholar] [CrossRef]

- Yan, H.; Zhou, H.; Wang, Y.; Wu, N.; Zhou, W.; Zhou, J. Combining the synchrosqueezing generalized S-transform of variational mode decomposition with the Teager–Kaiser energy operator to calculate the attenuation gradient for identifying oil and gas reservoirs. Acta Geophys. 2023, 71, 795–812. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, J.; Li, H.; Zhen, D.; Gu, F.; Ball, A. Improved cyclostationary analysis method based on TKEO and its application on the faults diagnosis of induction motors. ISA Trans. 2022, 128, 513–530. [Google Scholar] [CrossRef]

- Agah, G.R.; Rahideh, A.; Khodadadzadeh, H.; Khoshnazar, S.M.; Hedayatikia, S. Broken rotor bar and rotor eccentricity fault detection in induction motors using a combination of discrete wavelet transform and Teager–Kaiser energy operator. IEEE Trans. Energy Convers. 2022, 37, 2199–2206. [Google Scholar]

- Song, X.; Huang, Z.; Liang, G.; Niu, J.; Jia, B.; Liao, Z. Rotating Machinery Structural Faults Feature Enhancement and Diagnosis Base on Low-pass Teager Energy Operator Intrinsic Time-scale Decomposition. Meas. Sci. Technol. 2025, 36, 036113. [Google Scholar] [CrossRef]

- Krishnendu, K.; Pradhan, P.M. Diagnosis of Bearing Faults using Optimal Teager-Kaiser Energy Concentrated Time-Frequency Transforms. IEEE Trans. Instrum. Meas. 2025, 74, 3516311. [Google Scholar] [CrossRef]

- Yang, N.; Liu, Y.; Wei, Y.; Feng, K. Iterative Laplace of Gaussian filter and improved Teager energy operator for bearing fault detection in gearboxes. Meas. Sci. Technol. 2024, 35, 096135. [Google Scholar] [CrossRef]

- Bendjama, H. Bearing fault diagnosis based on optimal Morlet wavelet filter and Teager-Kaiser energy operator. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 392. [Google Scholar] [CrossRef]

- Gu, R.; Chen, J.; Hong, R.; Wang, H.; Wu, W. Incipient fault diagnosis of rolling bearings based on adaptive variational mode decomposition and Teager energy operator. Measurement 2020, 149, 106941. [Google Scholar] [CrossRef]

- Bendjama, H. Feature extraction based on vibration signal decomposition for fault diagnosis of rolling bearings. Int. J. Adv. Manuf. Technol. 2024, 130, 821–836. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, L.; Xu, Y. Enhancement of bearing fault detection using an alternative analytic energy operator and sparse Bayesian step-filtering. J. Mech. Sci. Technol. 2021, 35, 905–920. [Google Scholar] [CrossRef]

- Wu, K.; Xu, Y.; Yang, N.; Zhao, L. A multiresolution higher-order symmetric envelope-derivative operator and its application to bearing fault detection. J. Mech. Sci. Technol. 2023, 37, 1165–1175. [Google Scholar] [CrossRef]

- Feldman, M. Hilbert transform in vibration analysis. Mech. Syst. Signal Process. 2011, 25, 735–802. [Google Scholar] [CrossRef]

- Han, T.; Ding, L.; Qi, D.; Li, C.; Fu, Z.; Chen, W. Compound faults diagnosis method for wind turbine mainshaft bearing with Teager and second-order stochastic resonance. Measurement 2022, 202, 111931. [Google Scholar] [CrossRef]

- Liao, Z.; Song, X.; Jia, B.; Chen, P. Bearing fault feature enhancement and diagnosis based on statistical filtering and 1.5-dimensional symmetric difference analytic energy spectrum. IEEE Sens. J. 2021, 21, 9959–9968. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Bu, P.; Ye, M. Incipient fault feature extraction of rolling element bearings based on SOSO boosting technique and improved energy operator. Meas. Sci. Technol. 2023, 35, 025012. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, H.; Zhang, H. Fault diagnosis of rolling bearing based on wavelet threshold denoising and energy operator. J. Beijing Inf. Sci. Technol. Univ. 2017, 32, 40–43. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).