Development of a Four Omni-Wheeled Mobile Robot Using Telescopic Legs

Abstract

1. Introduction

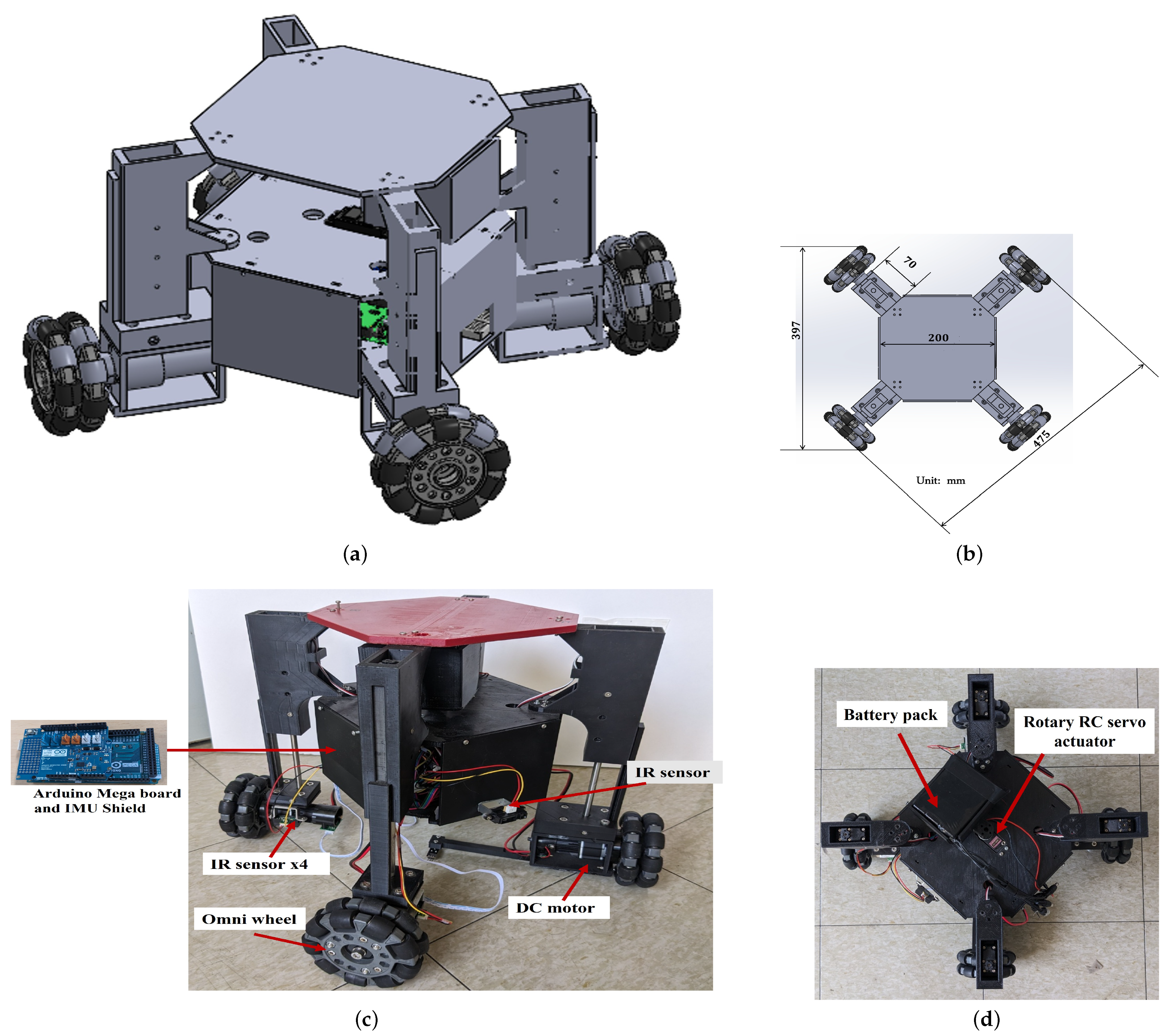

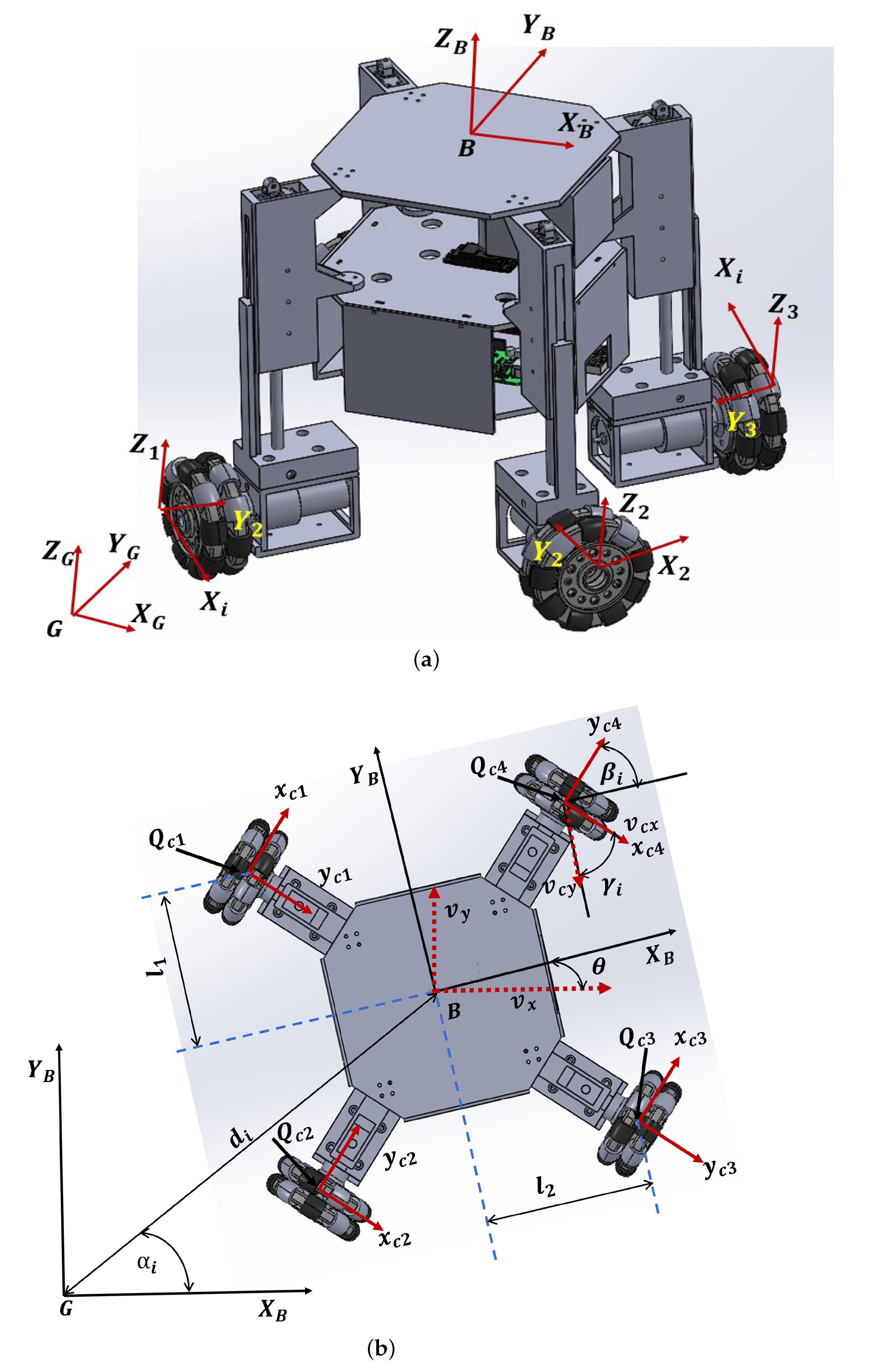

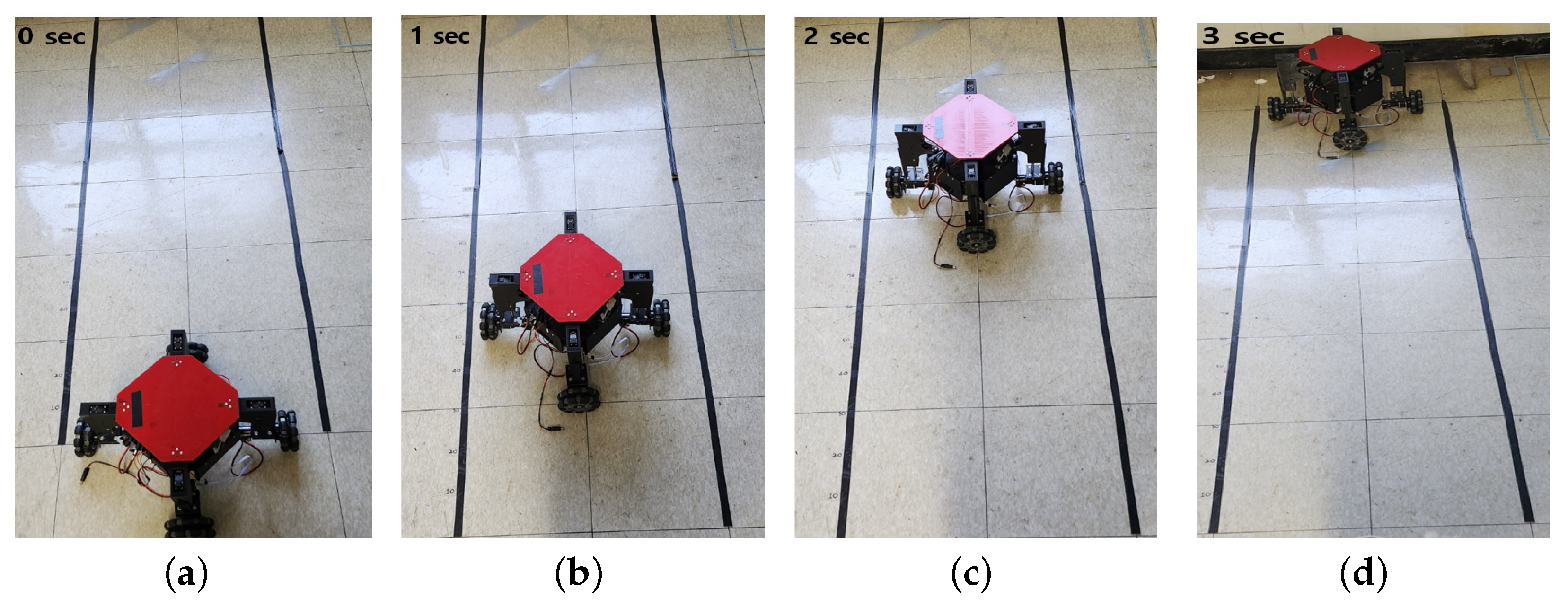

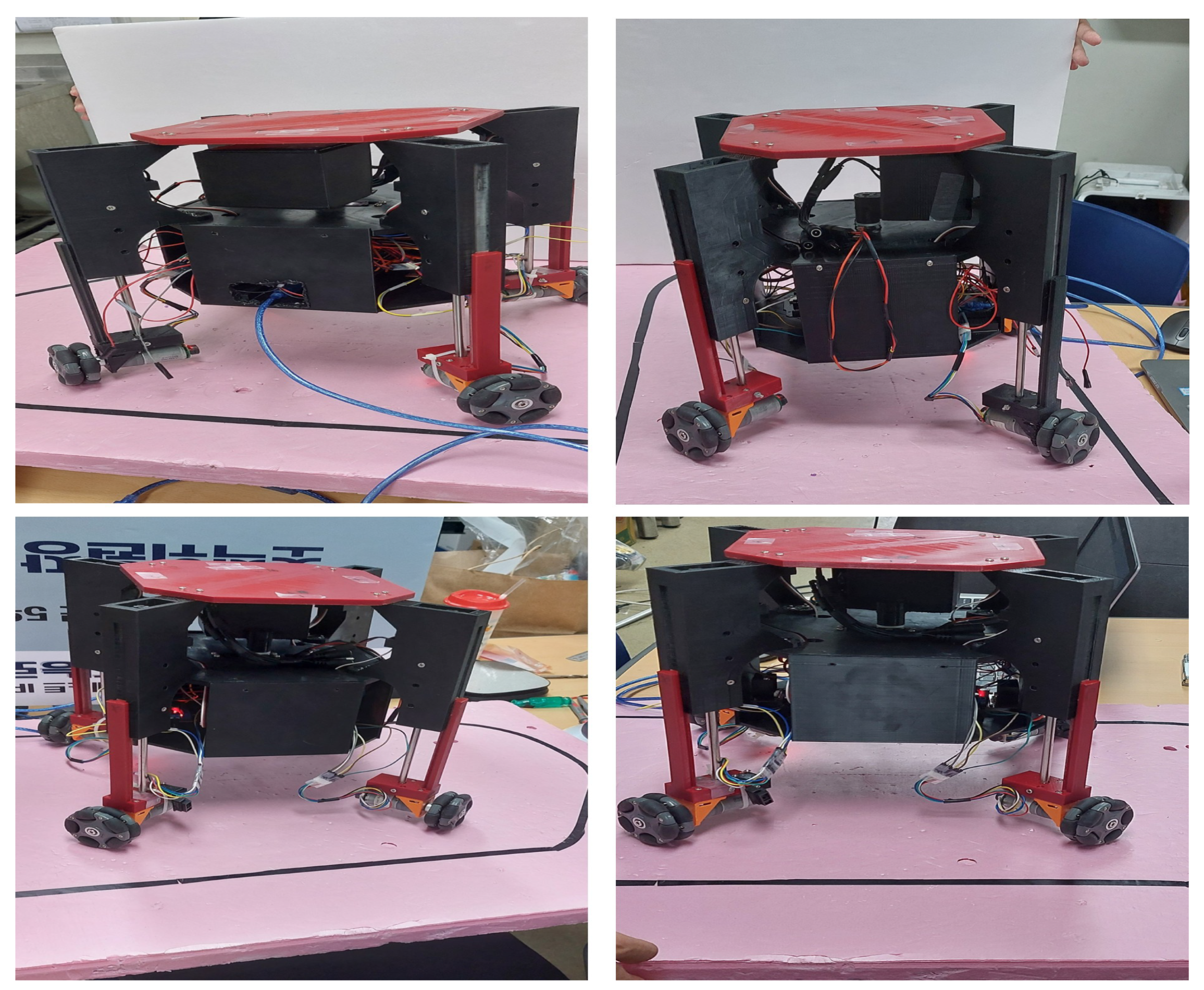

2. System Design

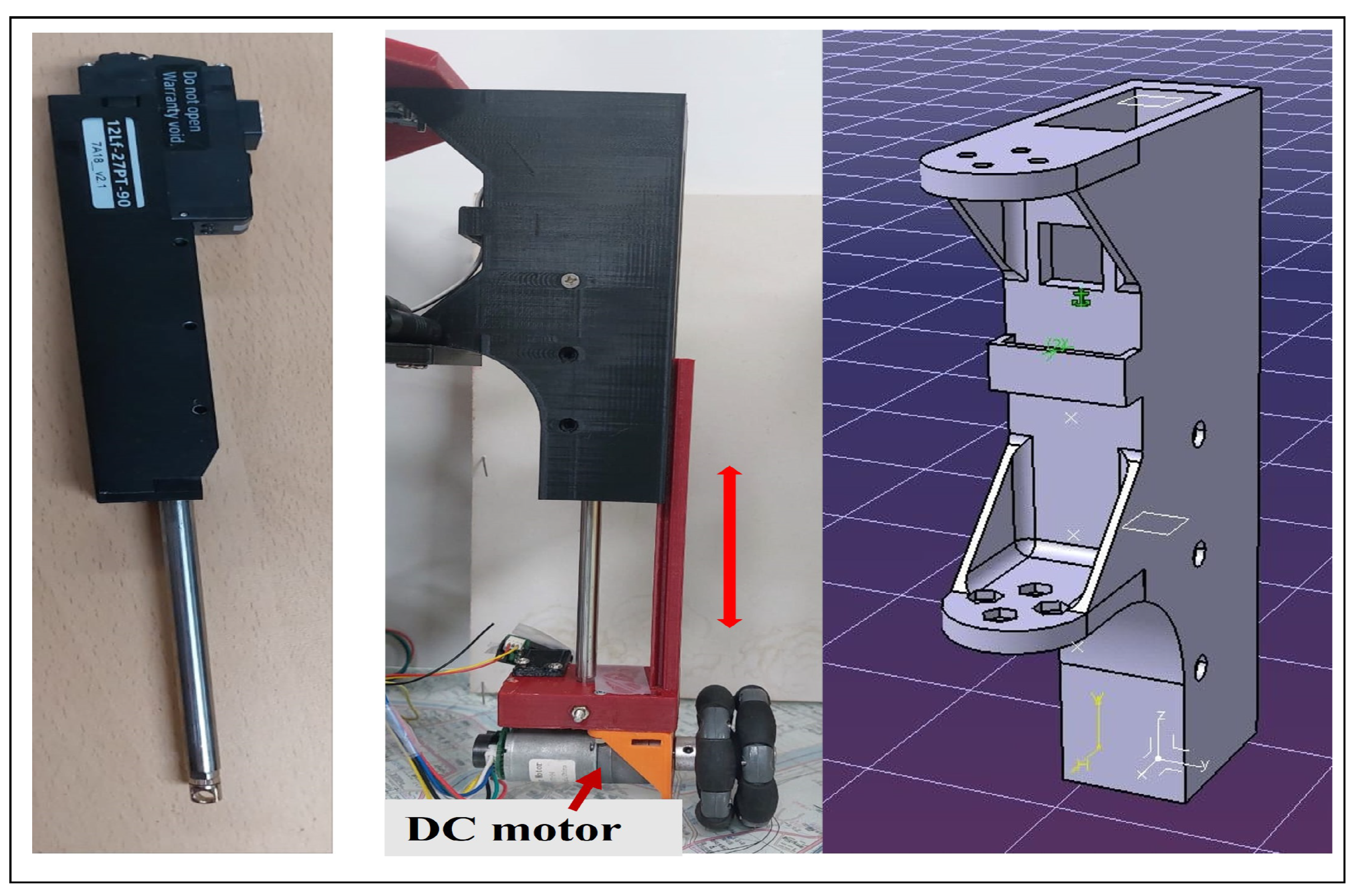

2.1. Conceptual Design

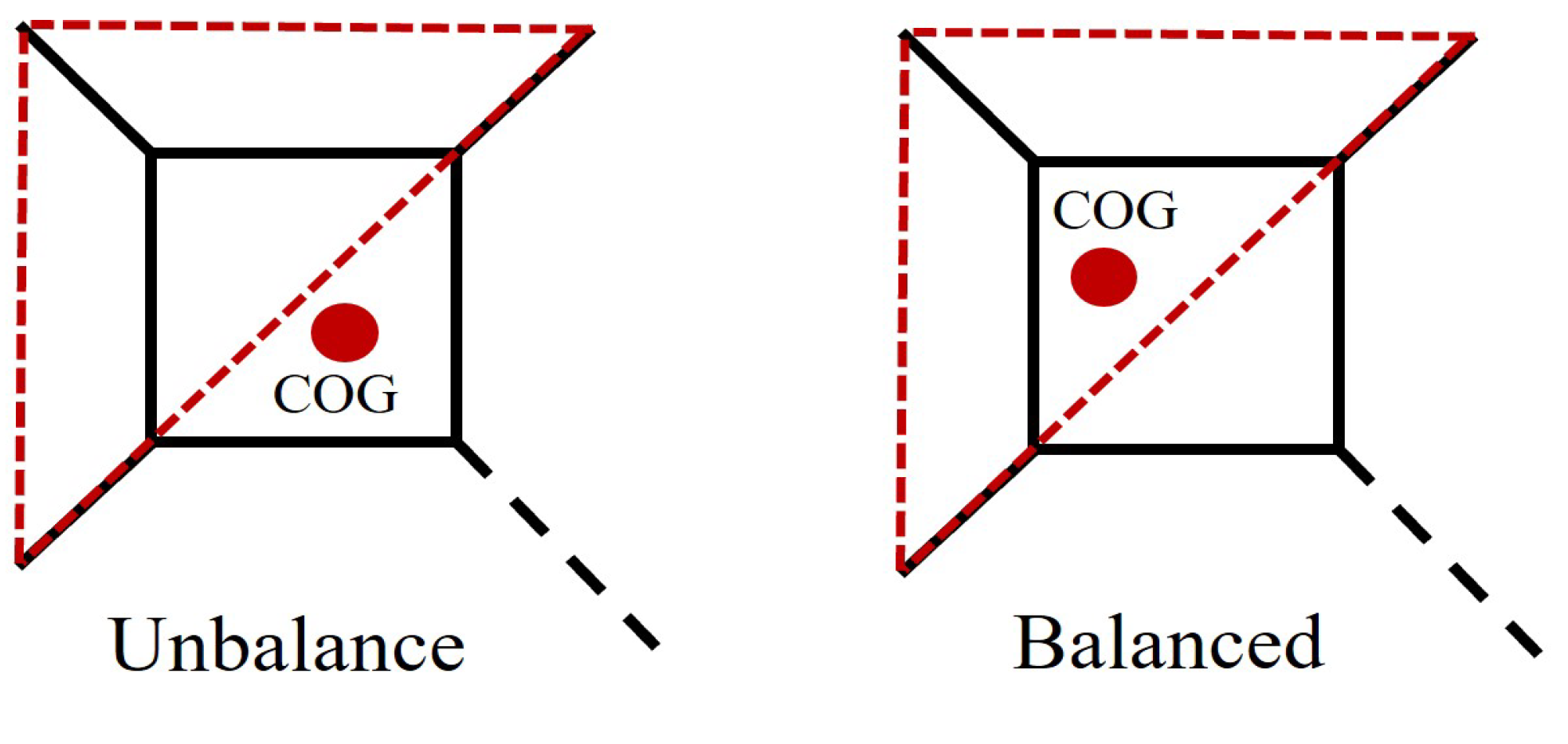

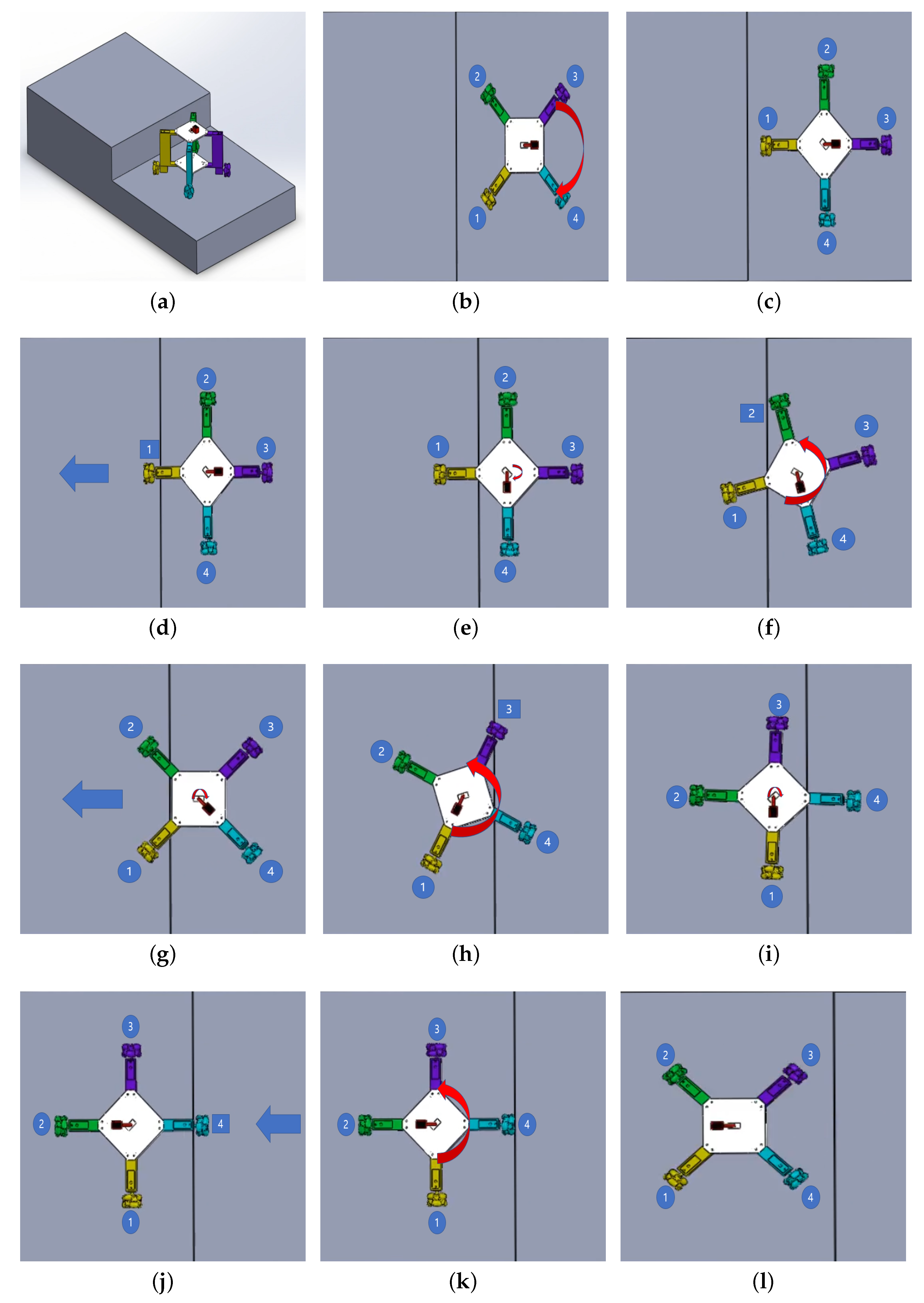

2.2. Gait Control

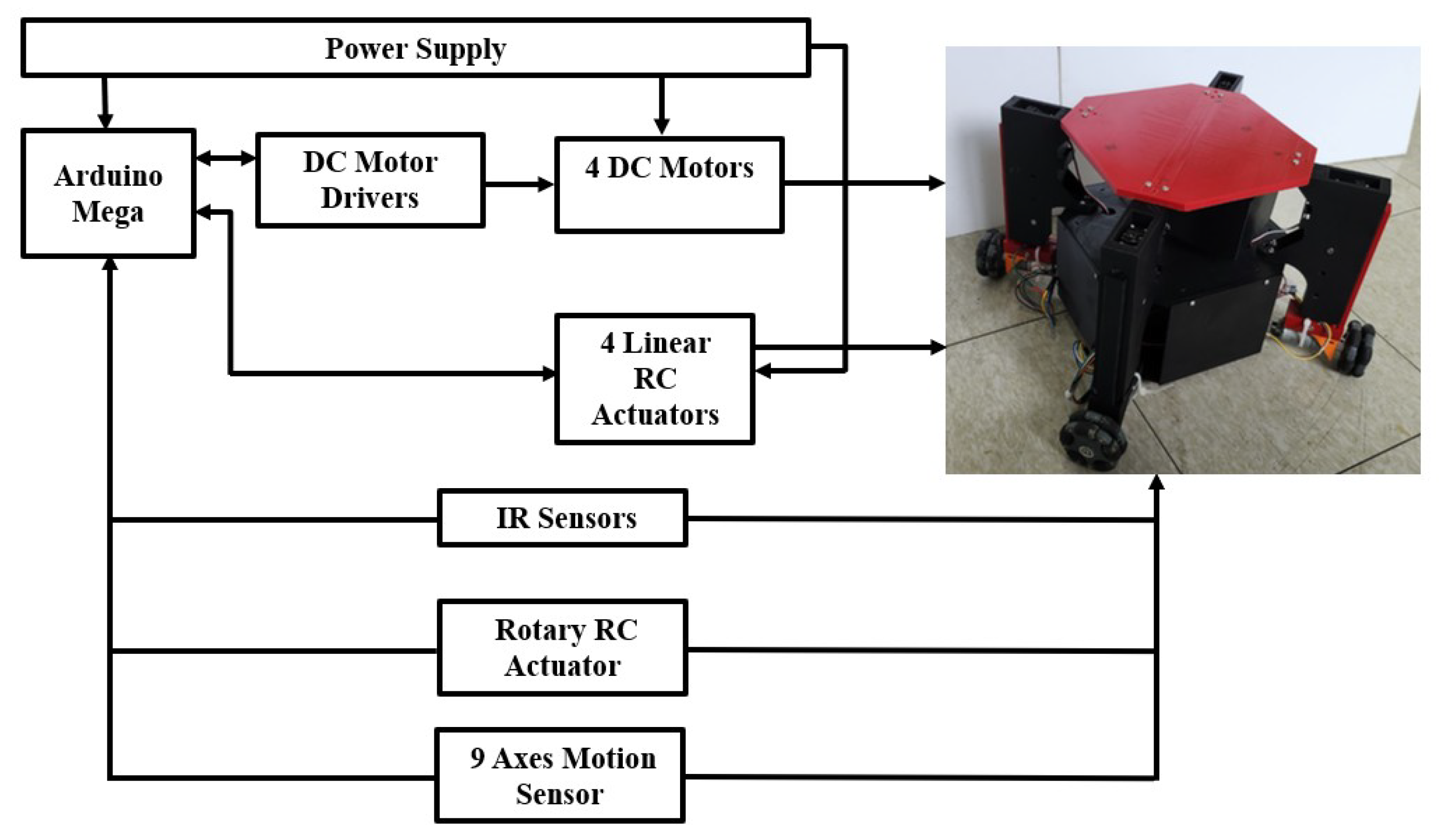

2.3. Control System Design

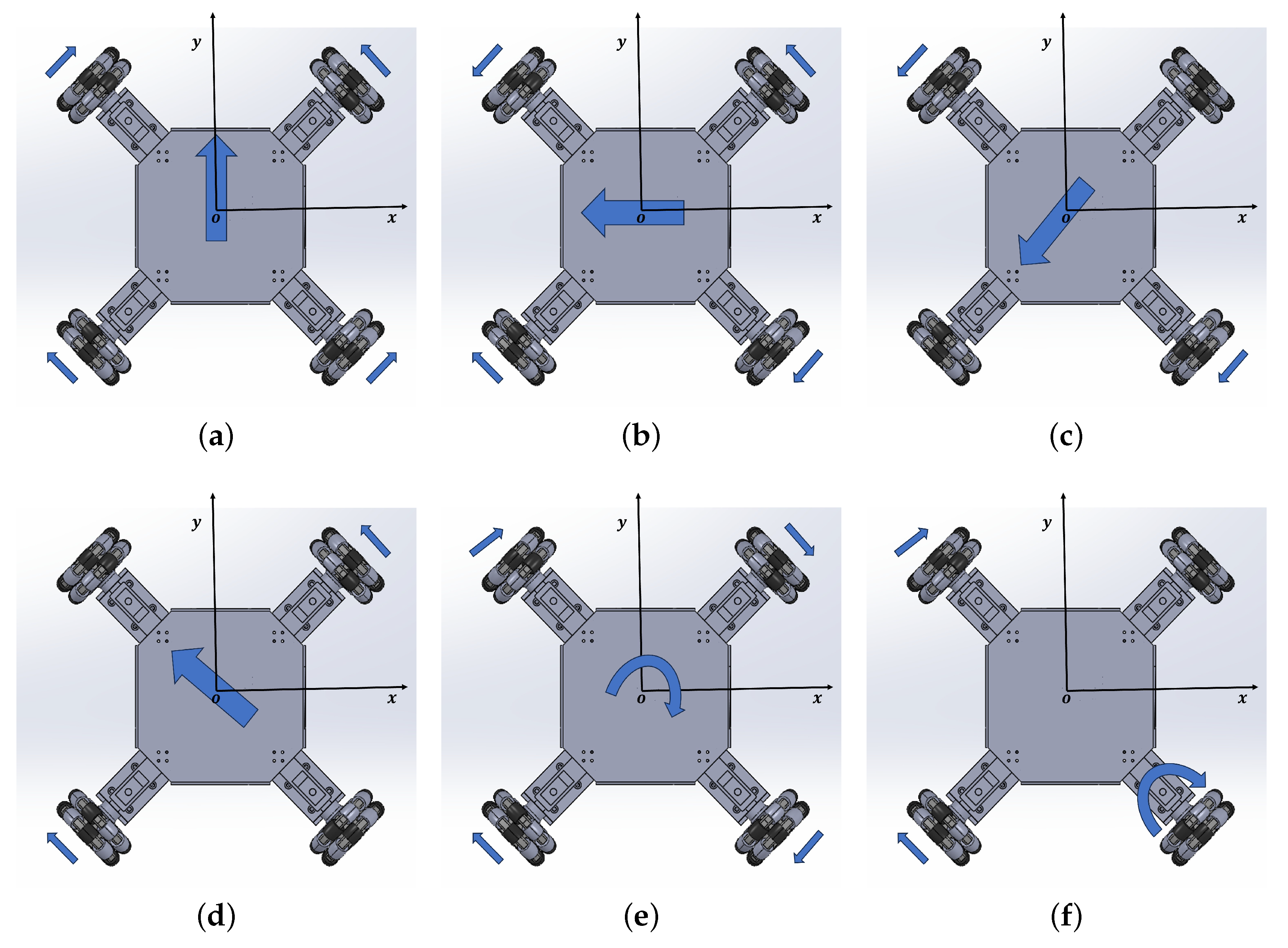

2.4. Locomotion Principle of the Robot

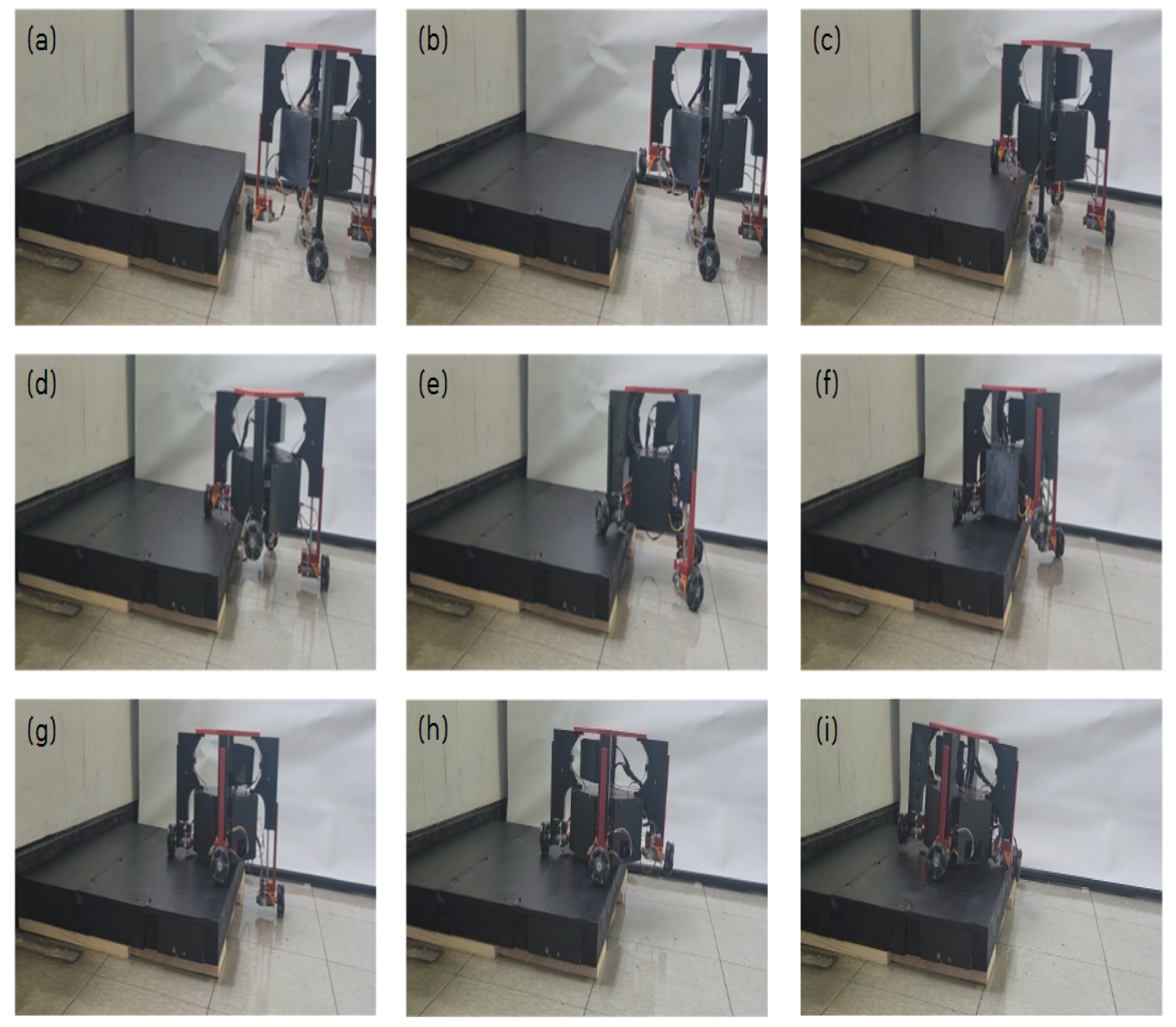

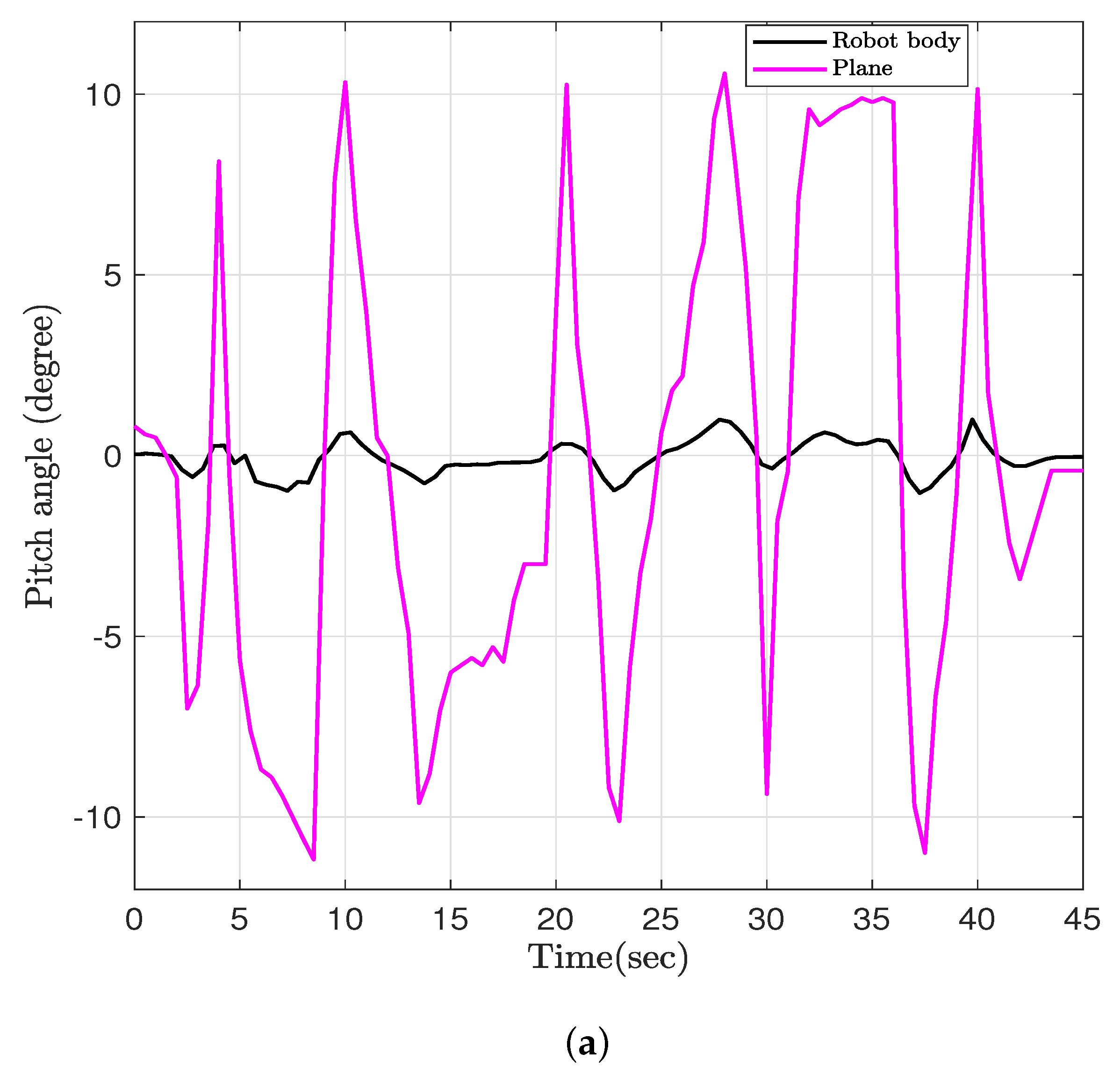

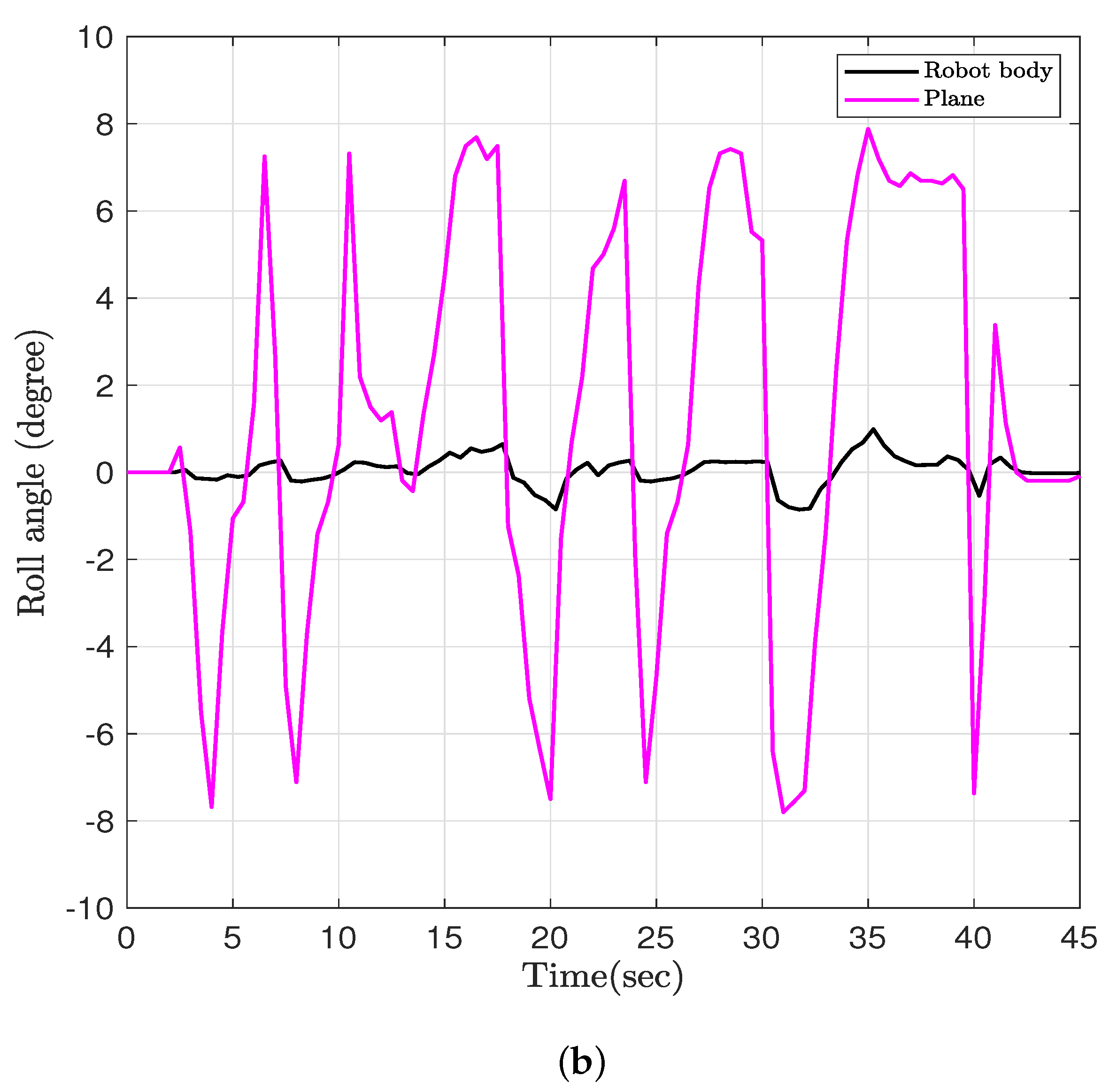

3. Simulation and Experimental Results

4. Conclusions and Future Work

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Yao, J.T.; Wang, Y.B.; Liu, Z.S.; Xu, Y.D.; Zhao, Y.S. Design and motion analysis of reconfigurable wheel-legged mobile robot. Def. Technol. 2022, 18, 1023–1040. [Google Scholar]

- Seo, T.; Ryu, S.; Won, J.H.; Kim, Y.; Kim, H.S. Stair-Climbing Robots: A Review on Mechanism, Sensing, and Performance Evaluation. IEEE Access 2023, 11, 60539–60561. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, M.; Li, M.; Zhang, X. Design and Analysis of a Wheel-Leg Hybrid Robot with Passive Transformable Wheels. Symmetry 2023, 15, 800. [Google Scholar] [CrossRef]

- Mohamed, S.; Im, Y.; Shin, H.; Kim, Y.; Shin, B. Development of a novel quadruped hybrid wheeled-legged mobile robot with telescopic legs. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 10785–10797. [Google Scholar] [CrossRef]

- Rubio, F.; Valero, F.; Llopis-Albert, C. A review of mobile robots: Concepts, methods, theoretical framework, and applications. Int. J. Adv. Robot. Syst. 2019, 16, 1729881419839596. [Google Scholar]

- Russo, M.; Ceccarelli, M. A Survey on Mechanical Solutions for Hybrid Mobile Robots. Robotics 2020, 9, 32. [Google Scholar] [CrossRef]

- Farooq, M.U.; Eizad, A.; Bae, H.K. Power solutions for autonomous mobile robots: A survey. Robot. Auton. Syst. 2023, 159, 104285. [Google Scholar]

- Mohamed, S.; Schäfle, T.R.; Uchiyama, N. Robust control of a redundant wheeled drive system for energy saving and fail safe motion. Adv. Mech. Eng. 2017, 9, 1687814017702343. [Google Scholar]

- Hijikata, M.; Miyagusuku, R.; Ozaki, K. Wheel arrangement of four omni wheel mobile robot for compactness. Appl. Sci. 2022, 12, 5798. [Google Scholar] [CrossRef]

- Bruzzone, L.; Baggetta, M.; Nodehi, S.E.; Bilancia, P.; Fanghella, P. Functional Design of a Hybrid Leg-Wheel-Track Ground Mobile Robot. Machines 2021, 9, 10. [Google Scholar] [CrossRef]

- Quaglia, G.; Visconte, C.; Scimmi, L.S.; Melchiorre, M.; Cavallone, P.; Pastorelli, S. Design of a UGV powered by solar energy for precision agriculture. Robotics 2020, 9, 13. [Google Scholar] [CrossRef]

- Mohamed, S.; Quang Le, H.; Kim, Y.; Shin, B. Design and modeling of hexapod robot using telescopic legs connected to pivot joints at the hips. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 3480–3497. [Google Scholar] [CrossRef]

- Hijikata, M.; Miyagusuku, R.; Ozaki, K. Omni wheel arrangement evaluation method using velocity moments. Appl. Sci. 2023, 13, 1584. [Google Scholar] [CrossRef]

- Sun, T.; Xiang, X.; Su, W.; Wu, H.; Song, Y. A transformable wheel-legged mobile robot: Design, analysis and experiment. Robot. Auton. Syst. 2017, 98, 30–41. [Google Scholar] [CrossRef]

- Mertyüz, I.; Tanyıldızı, A.K.; Taşar, B.; Tatar, A.B.; Yakut, O. FUHAR: A transformable wheel-legged hybrid mobile robot. Robot. Auton. Syst. 2020, 133, 103627. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, G.; Harabin, R.; Ivanov, S. Robotics in crisis management: A review. Technol. Soc. 2022, 68, 101935. [Google Scholar] [CrossRef]

- Shen, S.Y.; Li, C.H.; Cheng, C.C.; Lu, J.C.; Wang, S.F.; Lin, P.C. Design of a leg-wheel hybrid mobile platform. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 4682–4687. [Google Scholar]

- Wen, H.; Yang, H.; Chen, Y.; Zhou, L.; Wu, D. A robot with decoupled mechanical structure and adapted state machine control for both ground and staircase situations. Appl. Sci. 2019, 9, 5185. [Google Scholar] [CrossRef]

- Zhang, Q.; Ge, S.S.; Tao, P.Y. Autonomous stair climbing for mobile tracked robot. In Proceedings of the 2011 IEEE International Symposium on Safety, Security, and Rescue Robotics, Kyoto, Japan, 1–5 November 2011; pp. 92–98. [Google Scholar]

- Yang, D.; Bewley, T. A minimalist Stair Climbing Robot (SCR) formed as a leg balancing & climbing Mobile Inverted Pendulum (MIP). In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 2464–2469. [Google Scholar]

- Liu, F.; Wu, D.; Chen, K. The simplest creeping gait for a quadruped robot. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 227, 170–177. [Google Scholar] [CrossRef]

- Mihankhah, E.; Kalantari, A.; Aboosaeedan, E.; Taghirad, H.; Ali, S.; Moosavian, A. Autonomous staircase detection and stair climbing for a tracked mobile robot using fuzzy controller. In Proceedings of the 2008 IEEE International Conference on Robotics and Biomimetics, Bangkok, Thailand, 22–25 February 2009; pp. 1980–1985. [Google Scholar]

- Ma, Y.; Lyu, F. Design of A Wheel-Legged Stair Climbing Robot. In Proceedings of the 2021 7th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 23–26 April 2021; pp. 146–150. [Google Scholar] [CrossRef]

- Tanaka, M.; Tanaka, K. Stair climbing of an articulated mobile robot via sequential shift. In Proceedings of the 2015 IEEE/SICE International Symposium on System Integration (SII), Nagoya, Japan, 11–13 December 2015; pp. 877–881. [Google Scholar]

- Baishya, N.J.; Bhattacharya, B.; Ogai, H.; Tatsumi, K. Analysis and Design of a Minimalist Step Climbing Robot. Appl. Sci. 2021, 11, 7044. [Google Scholar] [CrossRef]

- Wei, Y.; Lee, K. CLAW: Cycloidal Legs-Augmented Wheels for Stair and Obstacle Climbing in Mobile Robots. IEEE/ASME Trans. Mechatron. 2024, 1–11. [Google Scholar] [CrossRef]

- Kim, D.; Hong, H.; Kim, H.S.; Kim, J. Optimal design and kinetic analysis of a stair-climbing mobile robot with rocker-bogie mechanism. Mech. Mach. Theory 2012, 50, 90–108. [Google Scholar] [CrossRef]

- Pappalettera, A.; Reina, G.; Mantriota, G. Design and Analysis of Tracked Stair-Climbing Robot Using Innovative Suspension System. Robotics 2024, 13, 45. [Google Scholar] [CrossRef]

- Taheri, H.; Qiao, B.; Ghaeminezhad, N. Kinematic model of a four mecanum wheeled mobile robot. Int. J. Comput. Appl. 2015, 113, 6–9. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Max Speed (no load) | 28 | mm/s |

| Related load | 27 | N |

| Input Voltage | 12 | V |

| Positional accuracy (unidirectional) | 50 | μm |

| Gear Ratio | 10:1 | - |

| Size | 151.5 (L) × 36 (W) × 18 (H) | mm |

| Weight | Approx. 177 | g |

| Stroke | 90 | mm |

| Motor Watt | 26 | W |

| Stall Force at Current (1.6 A/800 mA/1000 mA) | 160/96/12.8 | N |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, S.; Vellaiyan, V.; Kim, K.; Kim, Y.; Shin, B. Development of a Four Omni-Wheeled Mobile Robot Using Telescopic Legs. Machines 2025, 13, 292. https://doi.org/10.3390/machines13040292

Mohamed S, Vellaiyan V, Kim K, Kim Y, Shin B. Development of a Four Omni-Wheeled Mobile Robot Using Telescopic Legs. Machines. 2025; 13(4):292. https://doi.org/10.3390/machines13040292

Chicago/Turabian StyleMohamed, Shuaiby, Venkatesan Vellaiyan, Kangmin Kim, Youngshik Kim, and Buhyun Shin. 2025. "Development of a Four Omni-Wheeled Mobile Robot Using Telescopic Legs" Machines 13, no. 4: 292. https://doi.org/10.3390/machines13040292

APA StyleMohamed, S., Vellaiyan, V., Kim, K., Kim, Y., & Shin, B. (2025). Development of a Four Omni-Wheeled Mobile Robot Using Telescopic Legs. Machines, 13(4), 292. https://doi.org/10.3390/machines13040292