A Holistic Perspective on Sustainable Machining of Al6082: Synergistic Effects of Nano-Enhanced Bio-Lubricants

Abstract

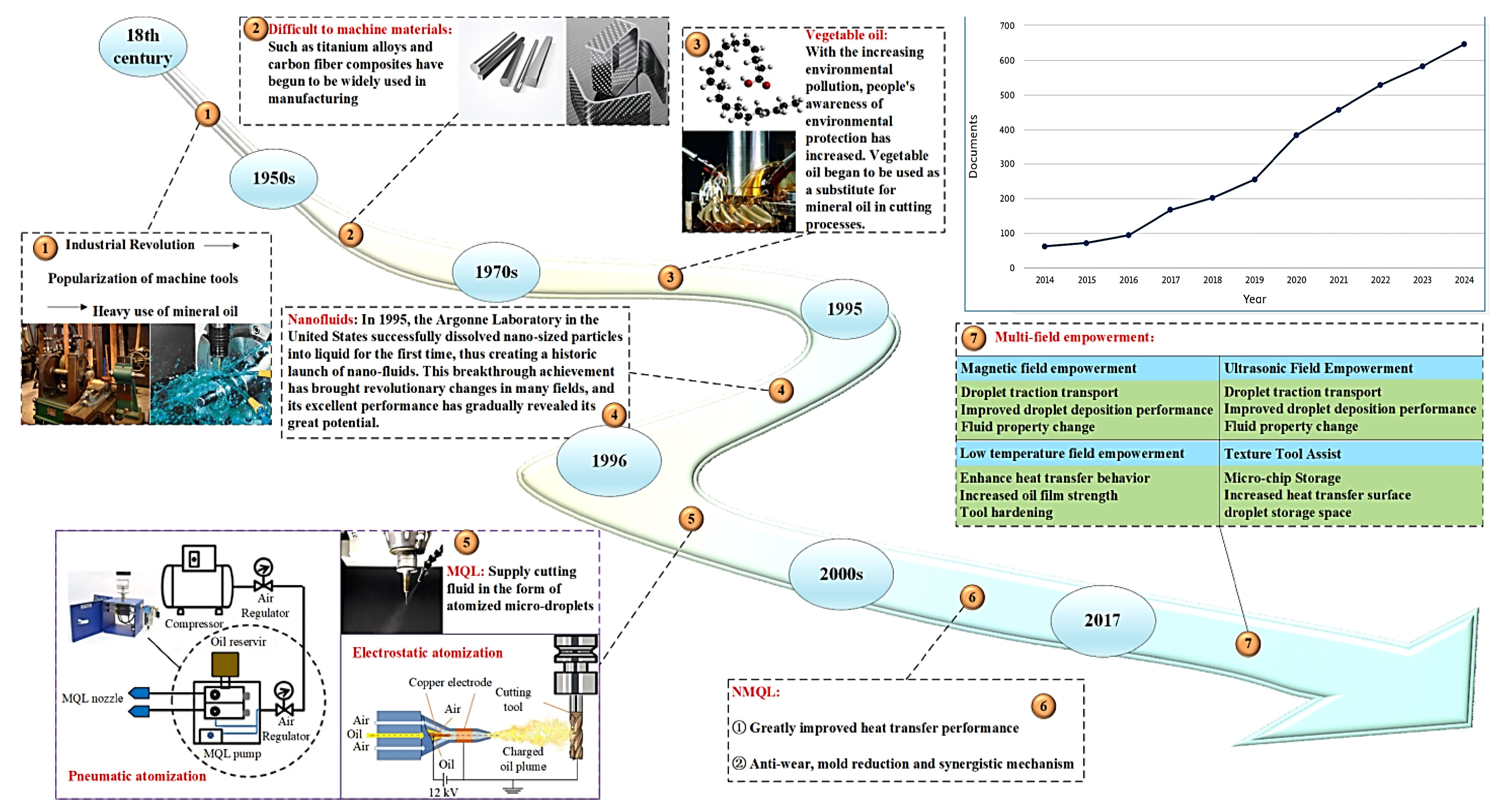

1. Introduction

1.1. Literature

1.2. Novelty and Literature Gap

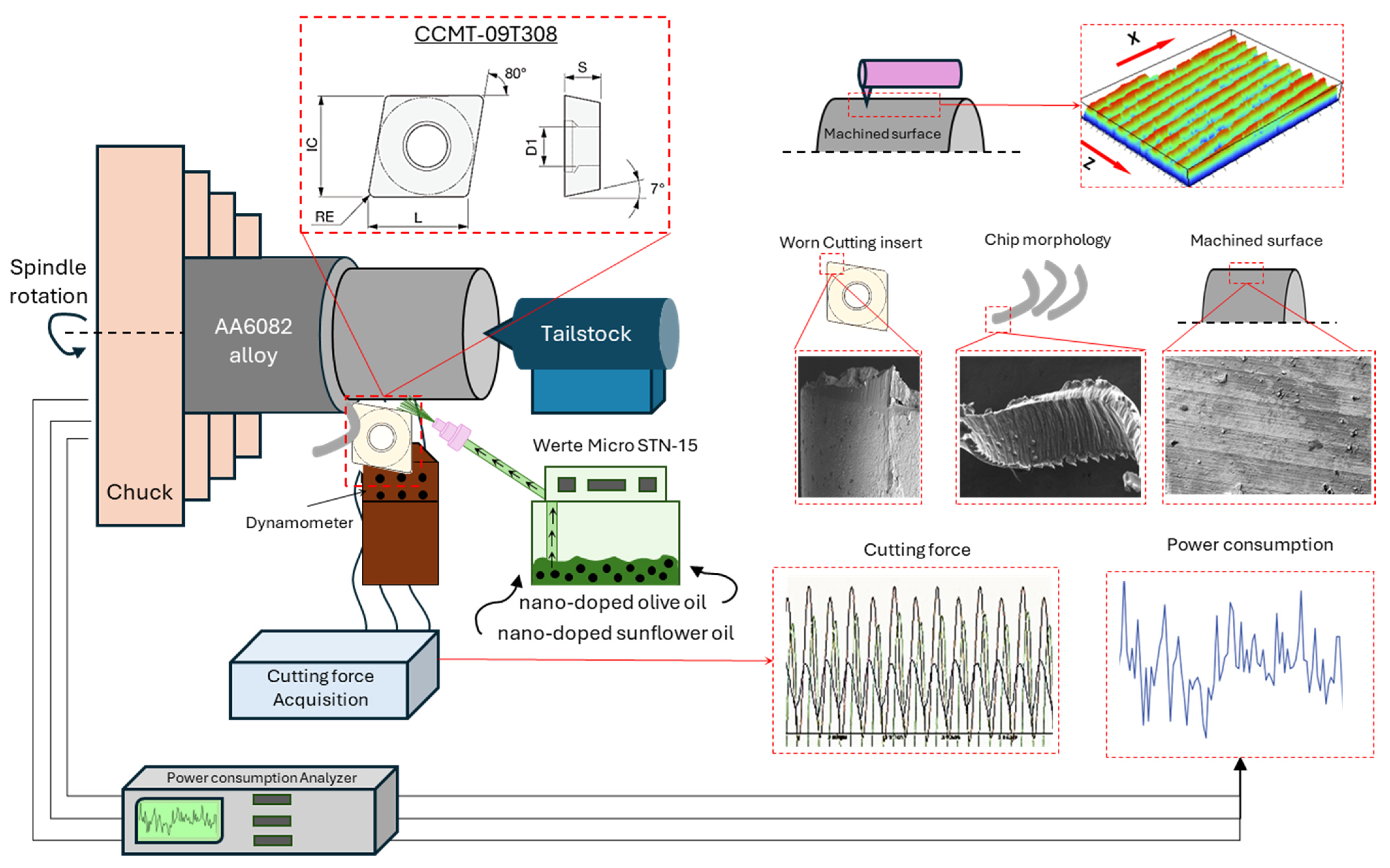

2. Materials and Methods

3. Results and Discussion

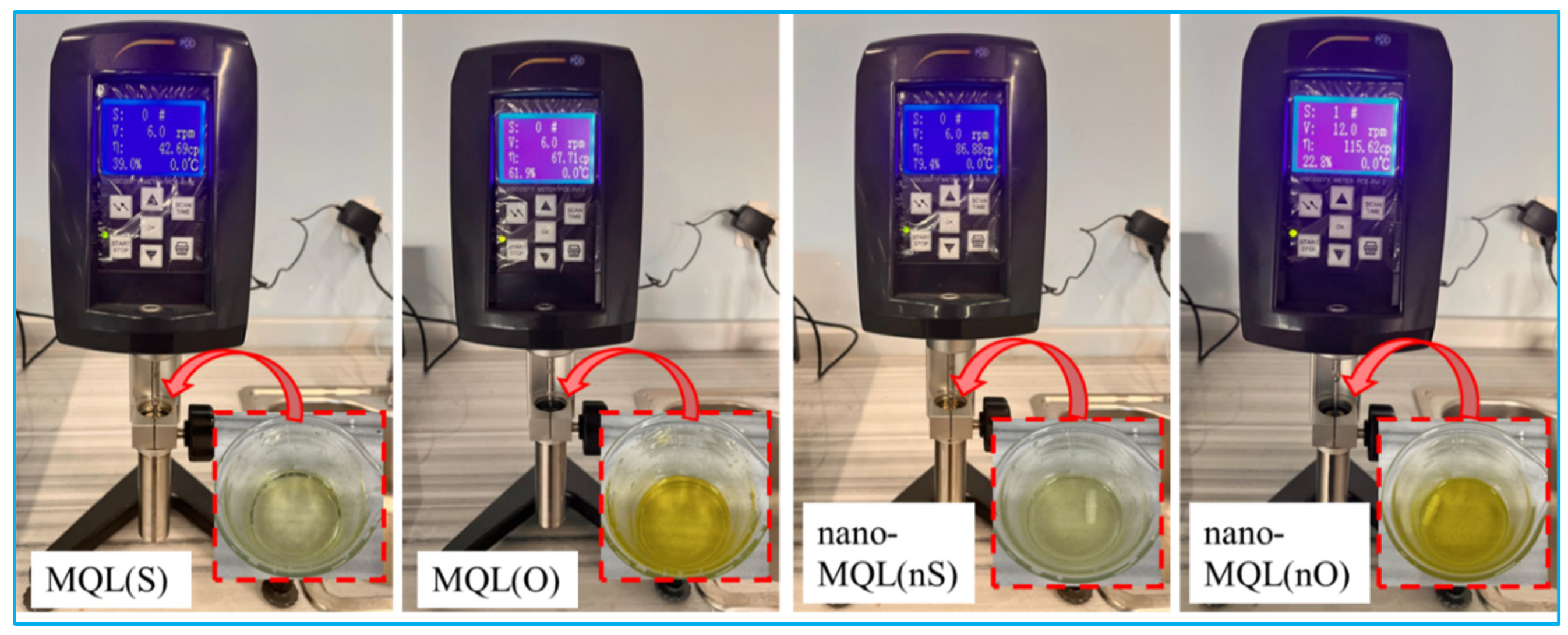

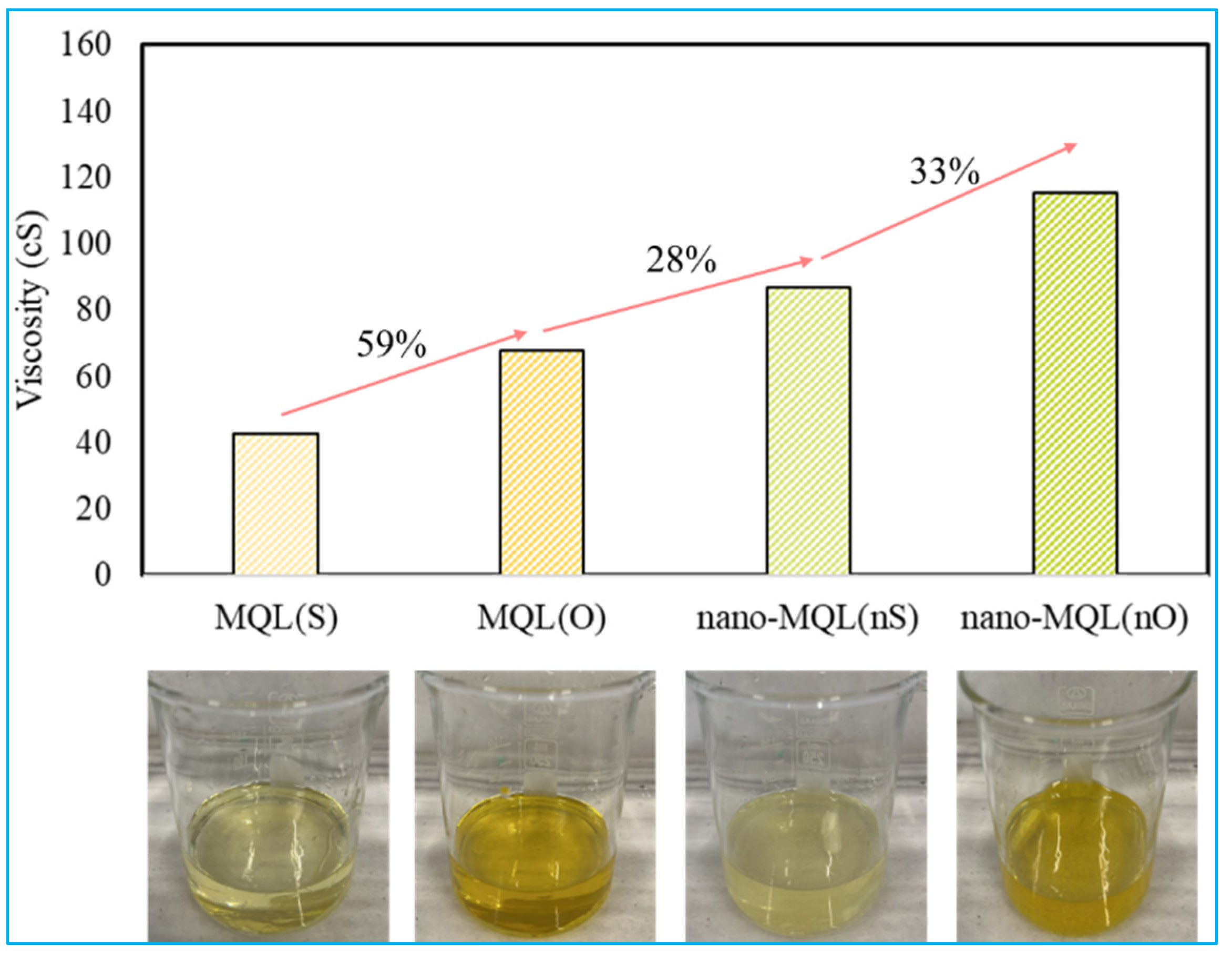

3.1. Viscosity Assessment

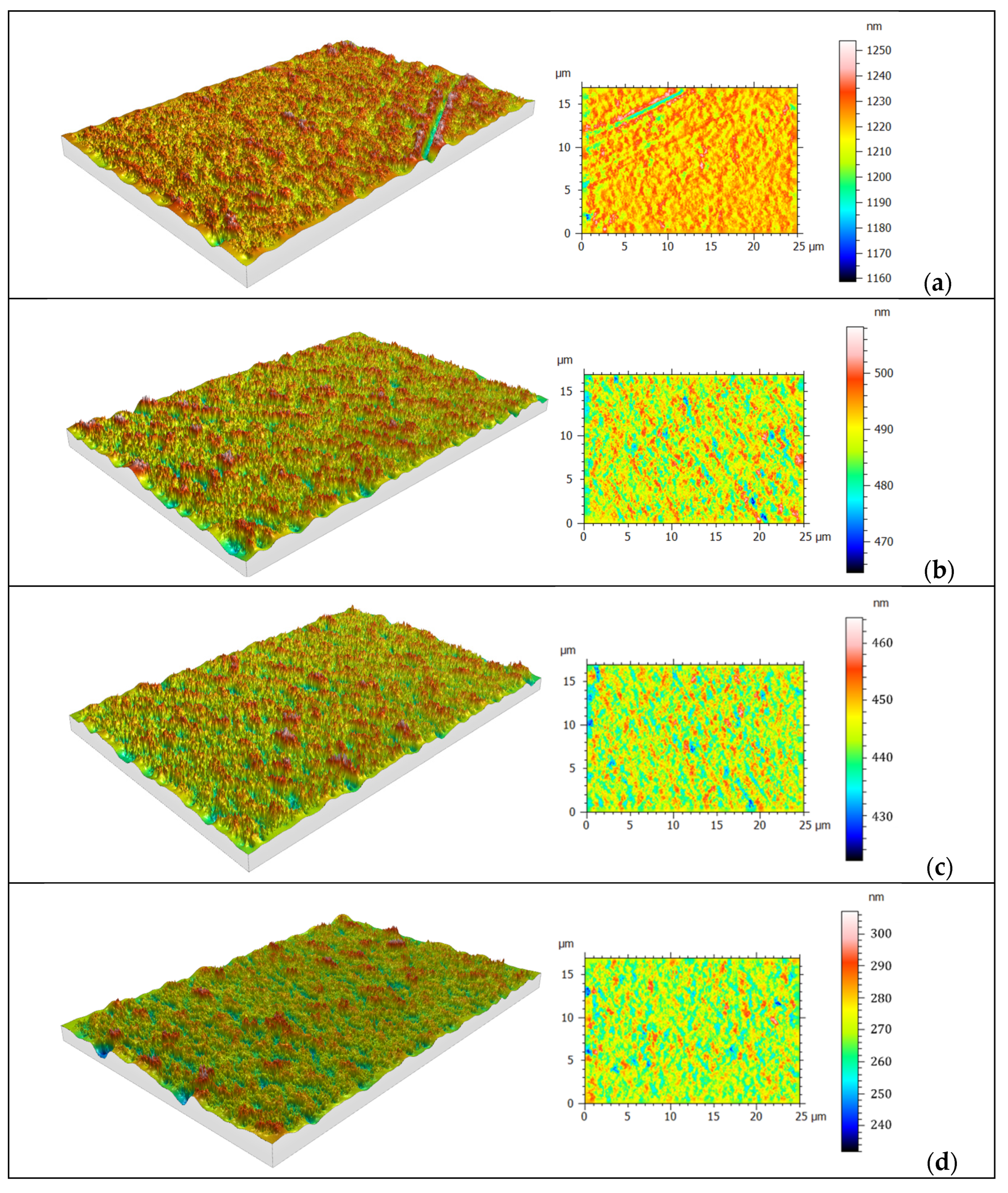

3.2. Surface Roughness Assessment

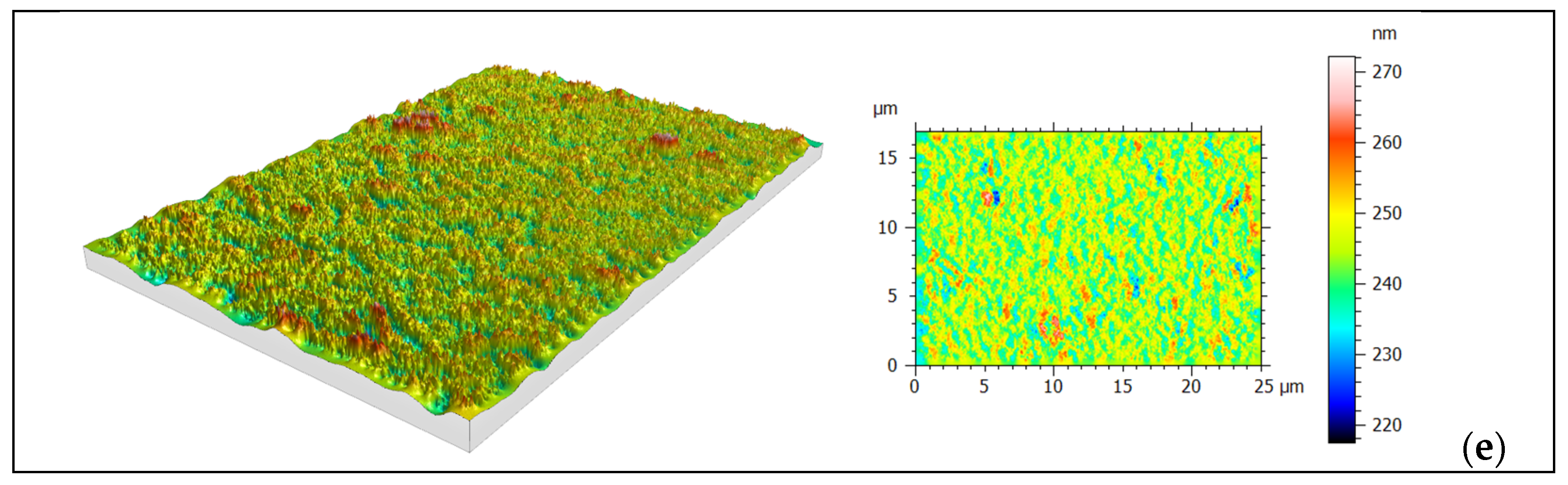

3.3. Cutting Force Assessment

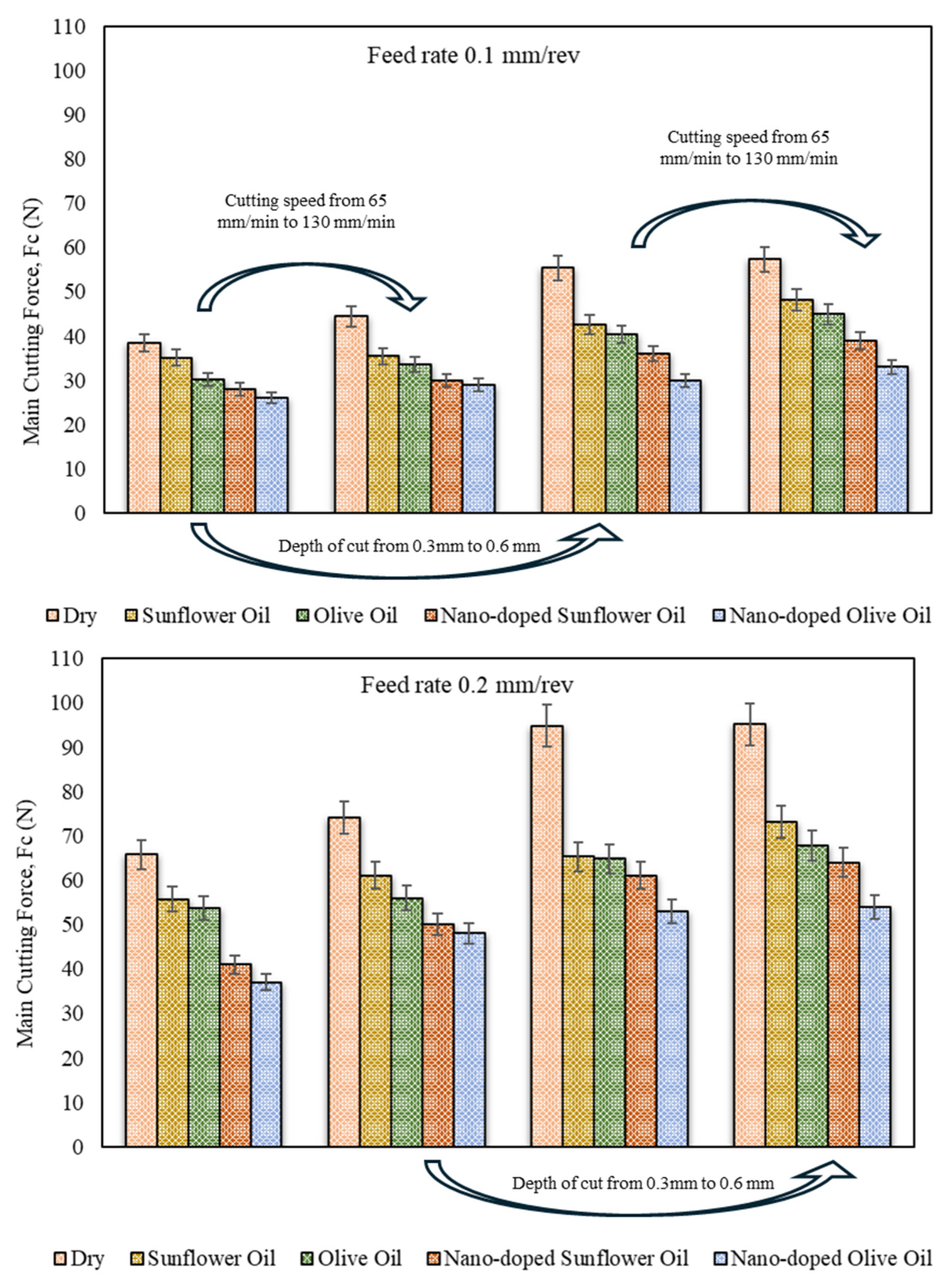

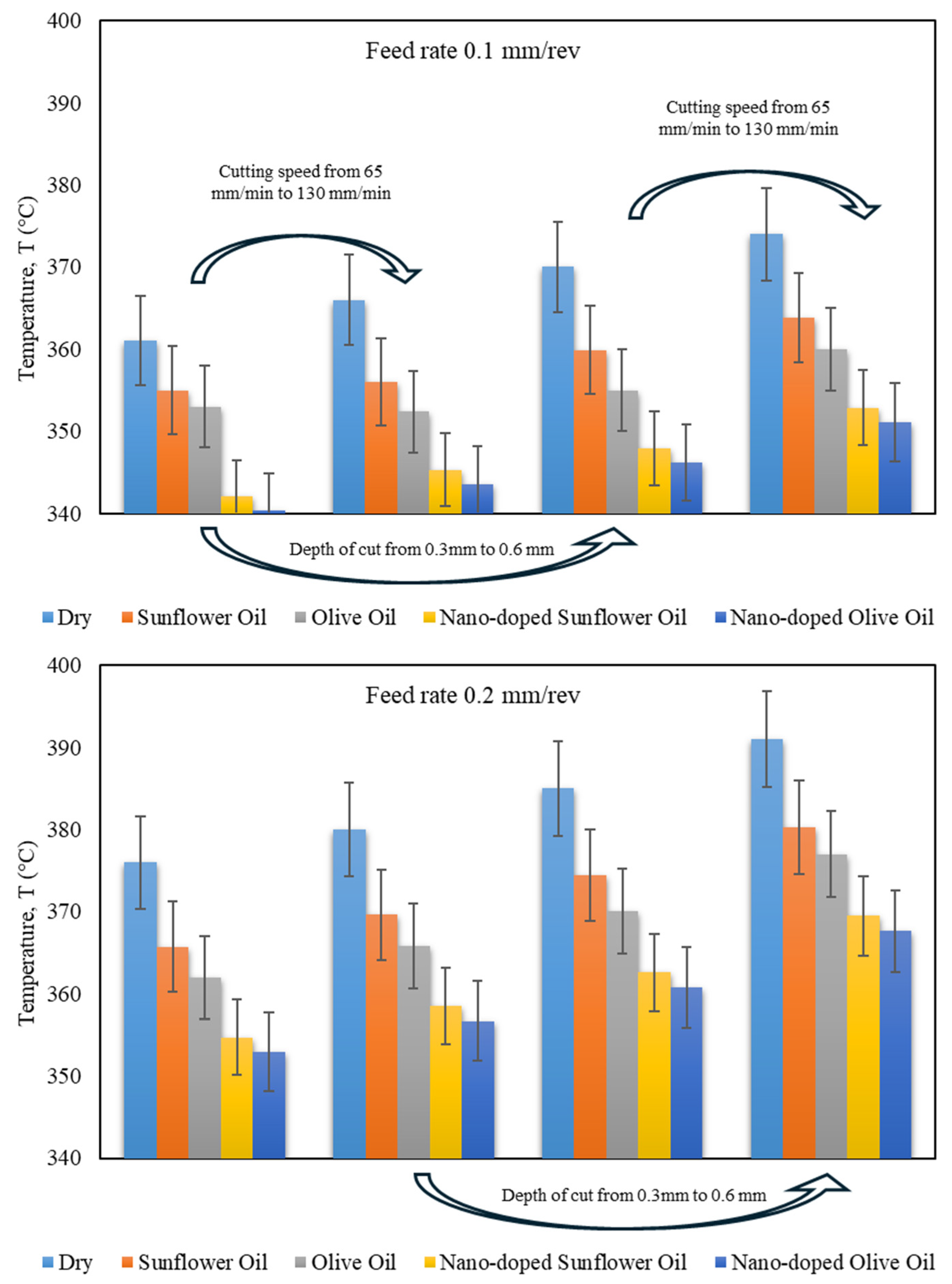

3.4. Cutting Temperature Assessment

- Plastic deformation in the primary zone: Significant heat is generated due to high strain rates as the workpiece material deforms to form chips.

- Friction at the tool–chip interface: The sliding motion of the chip on the tool rake face causes frictional heating, contributing to tool wear and increased cutting temperature.

- Friction at the tool–workpiece interface: Additional heat is generated due to the friction between the tool flank and the freshly cut workpiece surface. Figure 8 shows the areas that cause heat generation during the cutting process.

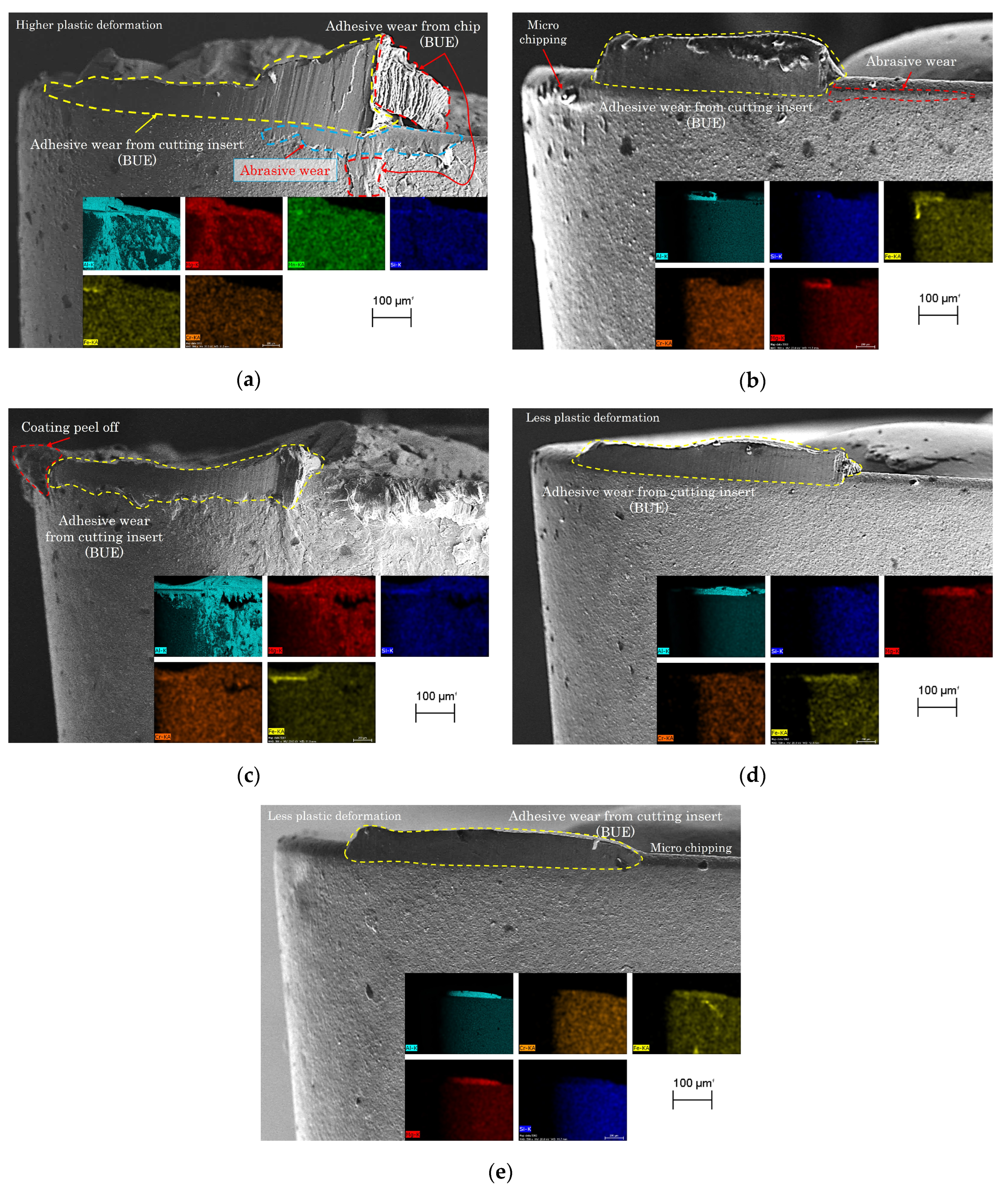

3.5. Tool Wear Assessment

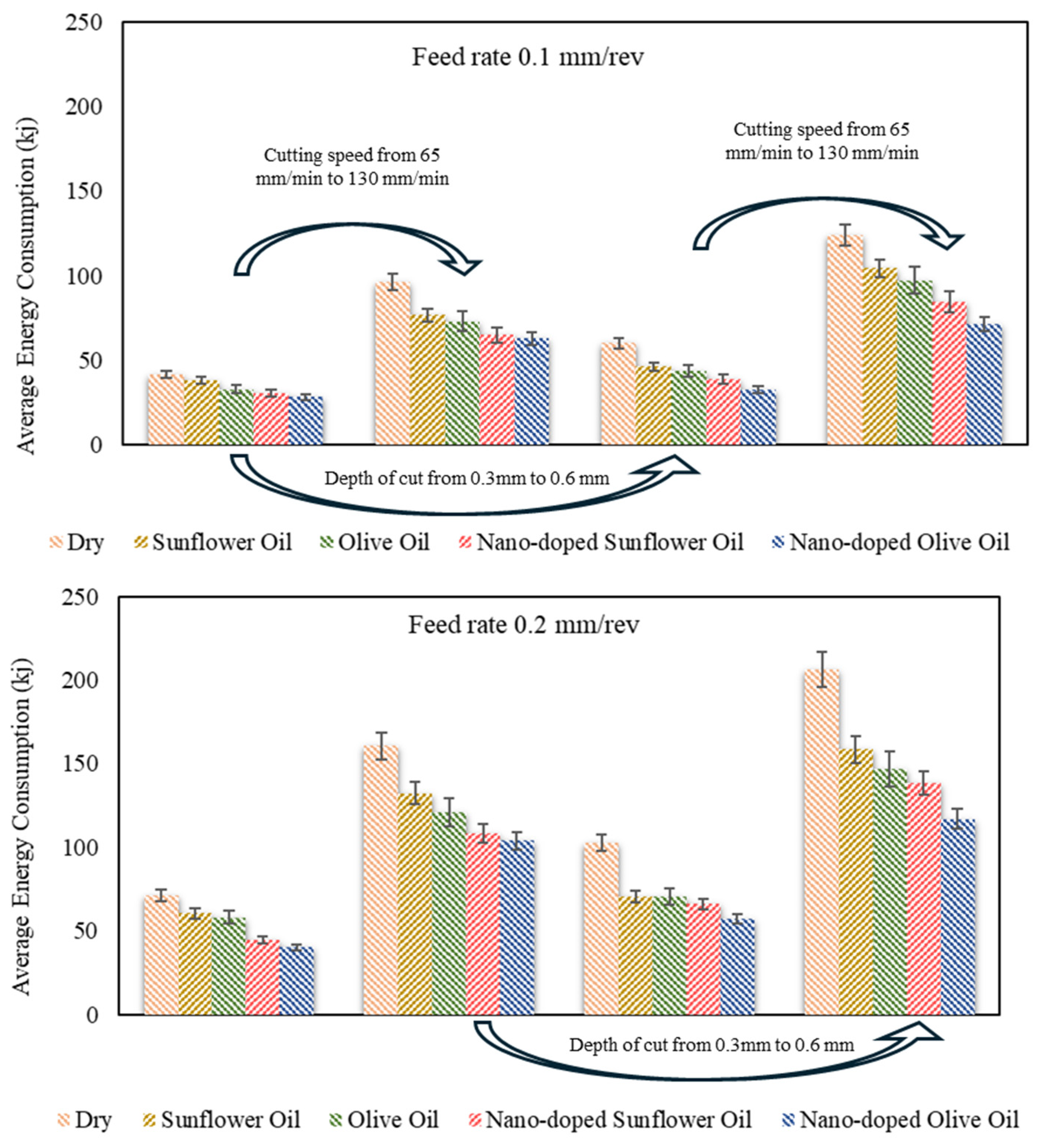

3.6. Energy Consumption

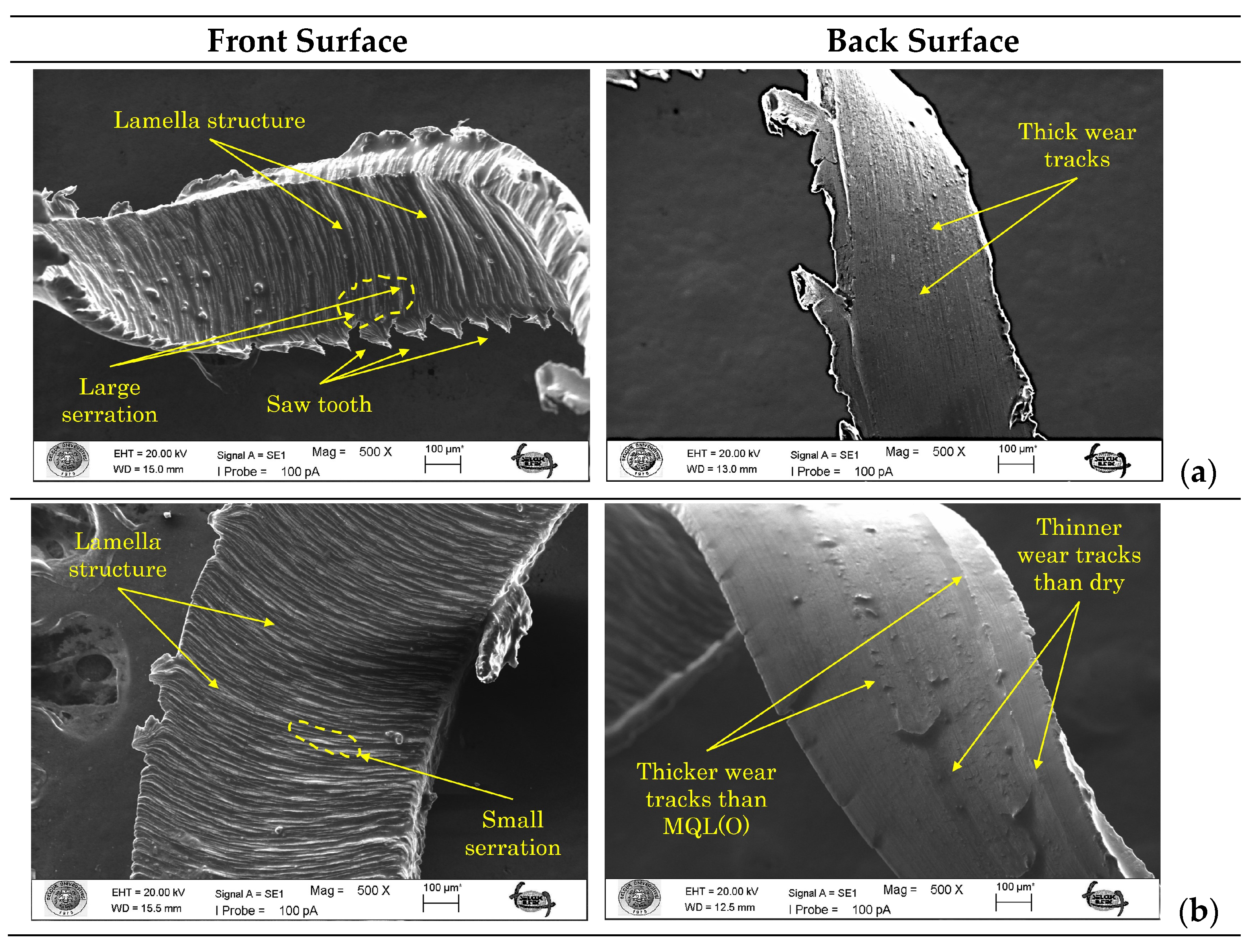

3.7. Chip Morphology

4. Conclusions and Future Recommendations

- Pure sunflower oil has the lowest viscosity at 42.69 cS, while pure olive oil has a viscosity of 67.71 cS, representing a 59% increase. The incorporation of nano-SiO2 into pure oils has resulted in a viscosity increase of 86.88 cS for nano-MQL(nS) and 115.62 cS for nano-MQL(nO). The viscosity of nano-MQL(nO) fluids was determined to be 33% greater than that of nano-MQL(nS) fluids.

- The average values are often seen to be 1.39, 1.02, 0.71, 0.62, and 0.60, according to the sequence of the working environment depicted in the figure. The most significant percentage change is observed in the trial conducted in a dry environment with nano-MQL (nO). The rate of change is 56.80%, and the outcomes from the study utilizing nano-MQL (nO) are superior. Overall, the cutting speed constitutes 12.8%, the feed rate 87.8%, and the cutting depth 31.14%.

- The surface variations in the input parameters are quantified as follows: 63.17% attributed to the feed rate, 8.78% to the cutting speed, and 28.39% to the cutting depth, irrespective of the assessment setting. The average values for dry, sunflower oil, olive oil, nano-doped sunflower oil, and nano-doped olive oil, based on the cutting circumstances, are 65.68, 52.05, 48.90, 43.63, and 38.75, respectively, without parameter separation. The most significant alteration seen was a 41% reduction in roughness when contrasting dry machining with nano-MQL(nO) machining.

- The temperature variations attributable to machinability variables were identified as follows: a 1.2% increase from cutting speed, a 4.01% increase from feed rate, and a 2.27% increase from increased depth of cut, irrespective of operating circumstances. In this instance, elevated parameter values result in increased temperature readings. The percentage variations, independent of the parameters and based on the working environment, were identified as a 2.61% reduction between dry and MQL(S), a 1.01% reduction between MQL(S) and MQL(O), a 2.14% reduction between olive oil and nano-doped sunflower oil, and a final 0.5% reduction between nano-MQL(nS) and nano-MQL(nO). The most significant alteration occurred between dry and nano-MQL (nO), reflecting a decrease of 6.12%.

- Tool wear diminishes while employing nano-MQL (nS or nO) and pure MQL in contrast to dry cutting. Tool wear is reduced in MQL and nano-MQL procedures compared to dry machining, as the cooling fluids containing nanoparticles effectively lower the temperature in the cutting zone and diminish wear. In the nano-MQL(nO) approach, the cooling fluid penetrates the cutting region more efficiently than in the nano-MQL(nS) method. This decreases the cutting temperature and minimizes tool wear.

- The variations in energy consumption based on processing parameters were 117.56% for cutting speed, 63.08% for feed rate, and 27.20% for the depth of cut. The data indicated an increase, and it was seen that when the parameters elevated, energy usage correspondingly increased. The working circumstances were quantified as 20.38%, 6.42%, 10.35%, and 10.90% sequentially.

- The chips produced in pure MQLs and nano-MQL(nS)-nano-MQL(nO) exhibited greater smoothness and reduced roughness relative to those fabricated under dry circumstances, with diminished gaps between the rough edges. The chips produced in nanofluid environments exhibited greater smoothness and conformed more closely to the required shape compared to those manufactured in MQL environments. Upon examination of the cutting surfaces of the chips, it was seen that the surfaces under MQL and nanofluid conditions exhibited more smoothness, correlating with the surface roughness measurements. The chips exhibited excellent surface quality and smoothness when evaluated in nanofluid environments.

- Determining the ideal concentrations of nano-additives used is important both for the effectiveness of the lubricant and for preventing viscosity problems. In addition, how tool wear changes in long-term machining processes can provide a better understanding of the effects of different nano-additive lubricants on tool life.

- The effect of nano-lubricants on heat dissipation can be investigated more deeply using thermal imaging techniques or simulations that detail the temperature distribution in the cutting zone. In addition, a detailed life cycle analysis on the cost-effectiveness and environmental impacts of nano-additive lubricants will contribute to sustainable production processes.

- In order to contribute to sustainability, using data such as cutting force, temperature, and surface roughness can be utilized with machine learning and artificial intelligence models to determine the most appropriate cutting parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guimarães, M.; Saciotto, V.; He, Q.; DePaiva, J.M.; Diniz, A.; Veldhuis, S. Optimizing Machining Efficiency in High-Speed Milling of Super Duplex Stainless Steel with SiAlON Ceramic Inserts. Machines 2024, 12, 349. [Google Scholar] [CrossRef]

- Matuszak, J.; Zaleski, K.; Zyśko, A. Investigation of the Impact of High-Speed Machining in the Milling Process of Titanium Alloy on Tool Wear, Surface Layer Properties, and Fatigue Life of the Machined Object. Materials 2023, 16, 5361. [Google Scholar] [CrossRef] [PubMed]

- Kuntoğlu, M. Measurement and Analysis of Sustainable Indicators in Machining of ARMOX 500T Armor Steel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7330–7349. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Kuntoğlu, M. Evaluation of the Role of Dry and MQL Regimes on Machining and Sustainability Index of Strenx 900 Steel. Lubricants 2022, 10, 301. [Google Scholar] [CrossRef]

- Kuntoglu, M. Machining Induced Tribological Investigations in Sustainable Milling of Hardox 500 Steel: A New Approach of Measurement Science. Measurement 2022, 201, 111715. [Google Scholar] [CrossRef]

- Binali, R.; Patange, A.D.; Kuntoğlu, M.; Mikolajczyk, T.; Salur, E. Energy Saving by Parametric Optimization and Advanced Lubri-Cooling Techniques in the Machining of Composites and Superalloys: A Systematic Review. Energies 2022, 15, 8313. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Qu, L.; Wang, X. Optimization of Tool Wear and Cutting Parameters in SCCO2-MQL Ultrasonic Vibration Milling of SiCp/Al Composites. Machines 2024, 12, 646. [Google Scholar] [CrossRef]

- Zerooğlu, T.; Değirmenci, Ü.; Şap, S. A Study on the Machinability and Environmental Effects of Milling AISI 5140 Steel in Sustainable Cutting Environments. Machines 2024, 12, 436. [Google Scholar] [CrossRef]

- Şap, S. Understanding the Machinability and Energy Consumption of Al-Based Hybrid Composites under Sustainable Conditions. Lubricants 2023, 11, 111. [Google Scholar] [CrossRef]

- Günay, M.; Korkmaz, M.E. Understanding the Relationship between Surface Quality and Chip Morphology under Sustainable Cutting Environments. Materials 2024, 17, 1826. [Google Scholar] [CrossRef]

- Ross, N.S.; Ananth, M.B.J.; Mashinini, P.M.; Ji, H.; Chinnasamy, M.; Palaniappan, S.K.; Gupta, M.K.; Vashishtha, G. Mitigating Tribological Challenges in Machining Additively Manufactured Stainless Steel with Cryogenic-MQL Hybrid Technology. Tribol. Int. 2024, 193, 109343. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Şap, S.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S. Tool Wear, Surface Roughness, Cutting Temperature and Chips Morphology Evaluation of Al/TiN Coated Carbide Cutting Tools in Milling of Cu–B–CrC Based Ceramic Matrix Composites. J. Mater. Res. Technol. 2022, 16, 1243–1259. [Google Scholar] [CrossRef]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Performance Evaluation of Nanofluid-Based Minimum Quantity Lubrication Grinding of Ni-Cr Alloy under the Influence of CuO Nanoparticles. Adv. Manuf. 2021, 9, 580–591. [Google Scholar] [CrossRef]

- Ross, N.S.; Ganesh, M.; Ananth, M.B.J.; Kumar, M.; Rai, R.; Gupta, M.K.; Korkmaz, M.E. Development and Potential Use of MWCNT Suspended in Vegetable Oil as a Cutting Fluid in Machining of Monel 400. J. Mol. Liq. 2023, 382, 121853. [Google Scholar] [CrossRef]

- Seyedzavvar, M.; Abbasi, H.; Kiyasatfar, M.; Ilkhchi, R.N. Investigation on Tribological Performance of CuO Vegetable-Oil Based Nanofluids for Grinding Operations. Adv. Manuf. 2020, 8, 344–360. [Google Scholar] [CrossRef]

- Özdemir, M.T.; Demirsöz, R.; Polat, R. Enhancing Wear Resistance of Inconel 601 through Pack Alumunizing Coating and Advanced Lubrication Environments. Discov. Mater. 2025, 5, 27. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Ercan, H.; Sarıkaya, M. An Attempt towards Green Machining of Ni-Based Hastelloy C4 Alloy: Effect of Vegetable Oils and Their Combination with TiO2 and SiO2 Nanoparticles on Outputs. Sustain. Mater. Technol. 2023, 37, e00668. [Google Scholar] [CrossRef]

- Duan, Z.-J.; Wang, S.-S.; Shi, S.-Y.; Liu, J.-Y.; Li, Y.-H.; Wang, Z.-H.; Li, C.-H.; Zhou, Y.-Y.; Song, J.-L.; Liu, X. Surface Quality Evaluation of Cold Plasma and NMQL Multi-Field Coupling Eco-Friendly Micro-Milling 7075-T6 Aluminum Alloy. Adv. Manuf. 2025, 13, 69–87. [Google Scholar] [CrossRef]

- Aligholami, M.; Shafiei, S.; Akbari, M.; Moodley, M.; Veeredhi, V.R.; Mthunzi, P.; Maaza, M. MoS2-Based Nanofluid Using Pulsed Laser Ablation in Liquid for Concentrating Solar Power Plant: Thermophysical Study. Sol. Energy 2024, 280, 112876. [Google Scholar] [CrossRef]

- Jiao, C.; Chen, H.; Ruan, X.; Cai, Q.; Chen, L.; Yi, J.; Yu, J.; Nishimura, K.; Jiang, N.; Cai, T. Biomimetic Joints Inspired Soft and Hard Combined 2D Diamond Solvent-Free Nanofluids with Multi-Layer Structure for Superior Lubrication. Carbon N. Y. 2024, 230, 119692. [Google Scholar] [CrossRef]

- Soltan, Y.I.; Nasser, M.S.; Almomani, F.; Mahmoud, K.A.; Onaizi, S.A. Thermal Conductivity of Different Materials Nanofluids Nanofluids of MXenes, Metal Organic Frameworks, and Other Nanostructured Materials in Heat Transfer Applications: Review. J. Mater. Res. Technol. 2024, 31, 2723–2761. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Yilmaz, H.; Ross, N.S.; Boy, M.; Sivalingam, V.K.; Chan, C.K.; Raman, J. Towards Specific Cutting Energy Analysis in the Machining of Inconel 601 Alloy under Sustainable Cooling Conditions. J. Mater. Res. Technol. 2023, 27, 4074–4087. [Google Scholar] [CrossRef]

- Ramanan, K.V.; Ramesh Babu, S.; Jebaraj, M.; Nimel Sworna Ross, K. Face Turning of Incoloy 800 under MQL and Nano-MQL Environments. Mater. Manuf. Process. 2021, 36, 1769–1780. [Google Scholar] [CrossRef]

- Chu, A.; Li, C.; Zhou, Z.; Liu, B.; Zhang, Y.; Yang, M.; Gao, T.; Liu, M.; Zhang, N.; Dambatta, Y.S.; et al. Nanofluids Minimal Quantity Lubrication Machining: From Mechanisms to Application. Lubricants 2023, 11, 422. [Google Scholar] [CrossRef]

- Kulkarni, H.B.; Nadakatti, M.M.; Kulkarni, S.C.; Kulkarni, R.M. Investigations on Effect of Nanofluid Based Minimum Quantity Lubrication Technique for Surface Milling of Al7075-T6 Aerospace Alloy. Mater. Today Proc. 2020, 27, 251–256. [Google Scholar] [CrossRef]

- Kishore Joshi, K.; Behera, R.K. Anurag Effect of Minimum Quantity Lubrication with Al2O3 Nanofluid on Surface Roughness and Its Prediction Using Hybrid Fuzzy Controller in Turning Operation of Inconel 600. Mater. Today Proc. 2018, 5, 20660–20668. [Google Scholar] [CrossRef]

- Pasam, V.K.; Srikant Revuru, R.; Gugulothu, S. Comparing the Performance & Viability of Nano and Microfluids in Minimum Quantity Lubrication for Machining AISI1040 Steel. Mater. Today Proc. 2018, 5, 8016–8024. [Google Scholar] [CrossRef]

- Gutnichenko, O.; Bushlya, V.; Bihagen, S.; Ståhl, J.-E. Influence of Graphite Nanoadditives to Vegetable-Based Oil on Machining Performance When MQCL Assisted Hard Turning. Procedia CIRP 2018, 77, 437–440. [Google Scholar] [CrossRef]

- Lv, T.; Huang, S.; Liu, E.; Ma, Y.; Xu, X. Tribological and Machining Characteristics of an Electrostatic Minimum Quantity Lubrication (EMQL) Technology Using Graphene Nano-Lubricants as Cutting Fluids. J. Manuf. Process. 2018, 34, 225–237. [Google Scholar] [CrossRef]

- Samylingam, L.; Anamalai, K.; Kadirgama, K.; Samykano, M.; Ramasamy, D.; Noor, M.M.; Najafi, G.; Rahman, M.M.; Xian, H.W.; Che Sidik, N.A. Thermal Analysis of Cellulose Nanocrystal-Ethylene Glycol Nanofluid Coolant. Int. J. Heat Mass Transf. 2018, 127, 173–181. [Google Scholar] [CrossRef]

- Sekhar, K.C.; Rama Reddy, V.V.; Srikiran, S.; Daniel, M.; Kumar, S. Investigating the Effect of Nano Crystalline MoS2 Particles on the Surface Integrity of Turned Components. Mater. Today Proc. 2017, 4, 7527–7532. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R.; Singh, R.K. Investigation into Performance of SiO2 Nanoparticle Based Cutting Fluid in Machining Process. Mater. Today Proc. 2017, 4, 133–141. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Singh, R.K.; Dixit, A.R. Tribological Investigation of TiO2 Nanoparticle Based Cutting Fluid in Machining under Minimum Quantity Lubrication (MQL). Mater. Today Proc. 2016, 3, 2155–2162. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R.; Rai, A.; Kumar, A. Characterization and Experimental Investigation of Al2O3 Nanoparticle Based Cutting Fluid in Turning of AISI 1040 Steel under Minimum Quantity Lubrication (MQL). Mater. Today Proc. 2016, 3, 1899–1906. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wojciechowski, S.; Michalski, M.; Legutko, S. The Influence of the Cooling Conditions on the Cutting Tool Wear and the Chip Formation Mechanism. J. Manuf. Process. 2016, 24, 107–115. [Google Scholar] [CrossRef]

- Guo, S.; Li, C.; Zhang, Y.; Wang, Y.; Li, B.; Yang, M.; Zhang, X.; Liu, G. Experimental Evaluation of the Lubrication Performance of Mixtures of Castor Oil with Other Vegetable Oils in MQL Grinding of Nickel-Based Alloy. J. Clean. Prod. 2017, 140, 1060–1076. [Google Scholar] [CrossRef]

- Uslu, G.; Korkmaz, M.E.; Elkilani, R.H.R.; Gupta, M.K.; Vashishtha, G. Investigation of Tribological Properties of Inconel 601 under Environmentally Friendly MQL and Nano-Fluid MQL with Pack Boronizing. Lubricants 2024, 12, 353. [Google Scholar] [CrossRef]

- Yurtkuran, H.; Korkmaz, M.E.; Gupta, M.K.; Yılmaz, H.; Günay, M.; Vashishtha, G. Prediction of Power Consumption and Its Signals in Sustainable Turning of PH13-8Mo Steel with Different Machine Learning Models. Int. J. Adv. Manuf. Technol. 2024, 133, 2171–2188. [Google Scholar] [CrossRef]

- Çakır Şencan, A.; Çelik, M.; Selayet Saraç, E.N. The Effect of Nanofluids Used in the MQL Technique Applied in Turning Process on Machining Performance: A Review on Eco-Friendly Machining. Manuf. Technol. Appl. 2021, 2, 47–66. [Google Scholar] [CrossRef]

- Duan, L.; Zhan, S.; Jia, D.; Zhang, W.; Yang, T.; Duan, H. Tribological Properties and Lubrication Mechanism of Manganese Phosphate Trihydrate as Lubricant Additives. Tribol. Int. 2023, 185, 108547. [Google Scholar] [CrossRef]

- Binali, R.; Demirpolat, H.; Kuntoğlu, M.; Salur, E. Different Aspects of Machinability in Turning of AISI 304 Stainless Steel: A Sustainable Approach with MQL Technology. Metals 2023, 13, 1088. [Google Scholar] [CrossRef]

- Demirpolat, H.; Kaya, K.; Binali, R.; Kuntoğlu, M. Investigation of the Effects of Machining Parameters on Surface Roughness, Cutting Temperature and Cutting Force in Turning AISI 52100 Bearing Steel. Manuf. Technol. Appl. 2023, 4, 179–189. [Google Scholar] [CrossRef]

- Al-Tameemi, H.A.; Al-Dulaimi, T.; Awe, M.O.; Sharma, S.; Pimenov, D.Y.; Koklu, U.; Giasin, K. Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy. Materials 2021, 14, 1783. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-C.; Wu, K.-D.; Shih, W.-C.; Hsu, P.-K.; Hung, J.-P. Prediction of Surface Roughness Based on Cutting Parameters and Machining Vibration in End Milling Using Regression Method and Artificial Neural Network. Appl. Sci. 2020, 10, 3941. [Google Scholar] [CrossRef]

- Binali, R. Experimental and Machine Learning Comparison for Measurement the Machinability of Nickel Based Alloy in Pursuit of Sustainability. Measurement 2024, 236, 115142. [Google Scholar] [CrossRef]

- Saha, S.; Deb, S.; Bandyopadhyay, P.P. Progressive Wear Based Tool Failure Analysis during Dry and MQL Assisted Sustainable Micro-Milling. Int. J. Mech. Sci. 2021, 212, 106844. [Google Scholar] [CrossRef]

- Yılmaz, B.; Uzun, G.; Güllü, A. The Effects of Cutting Parameters on the Thrust Force, Cutting Moment and Cutting Temperature in Drilling Process Applied to Ti6Al4V Material. Manuf. Technol. Appl. 2020, 1, 1–8. [Google Scholar]

- Singh, J.; Gill, S.S.; Dogra, M.; Singh, R. A Review on Cutting Fluids Used in Machining Processes. Eng. Res. Express 2021, 3, 012002. [Google Scholar] [CrossRef]

- Selvan, P.; Jebakani, D.; Jeyasubramanian, K.; Jones Joseph Jebaraj, D. Enhancement of Thermal Conductivity of Water Based Individual and Hybrid SiO2/Ag Nanofluids with the Usage of Calcium Carbonate Nano Particles as Stabilizing Agent. J. Mol. Liq. 2022, 345, 117846. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Zhu, J.; Wang, X.; Mo, J.; Ding, S. Investigation of Machining Ti-6Al-4V with Graphene Oxide Nanofluids: Tool Wear, Cutting Forces and Cutting Vibration. J. Manuf. Process. 2020, 49, 35–49. [Google Scholar] [CrossRef]

- Ahmed, W.; Hegab, H.; Kishawy, H.A.; Mohany, A. Estimation of Temperature in Machining with Self-Propelled Rotary Tools Using Finite Element Method. J. Manuf. Process. 2021, 61, 100–110. [Google Scholar] [CrossRef]

- Abouridouane, M.; Bergs, T.; Schraknepper, D.; Wirtz, G. Friction Behavior in Metal Cutting: Modeling and Simulation. Procedia CIRP 2021, 102, 405–410. [Google Scholar] [CrossRef]

- Rezende, B.A.; Magalhães, F.d.C.; Campos Rubio, J.C. Study of the Measurement and Mathematical Modelling of Temperature in Turning by Means Equivalent Thermal Conductivity. Measurement 2020, 152, 107275. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Hu, J.; Wan, Y. Tool Coating Effects on Cutting Temperature during Metal Cutting Processes: Comprehensive Review and Future Research Directions. Mech. Syst. Signal Process. 2021, 150, 107302. [Google Scholar] [CrossRef]

- Ogedengbe, T.S.; Okediji, A.P.; Yussouf, A.A.; Aderoba, O.A.; Abiola, O.A.; Alabi, I.O.; Alonge, O.I. The Effects of Heat Generation on Cutting Tool and Machined Workpiece. J. Phys. Conf. Ser. 2019, 1378, 022012. [Google Scholar] [CrossRef]

- Sayuti, M.; Sarhan, A.A.D.; Salem, F. Novel Uses of SiO2 Nano-Lubrication System in Hard Turning Process of Hardened Steel AISI4140 for Less Tool Wear, Surface Roughness and Oil Consumption. J. Clean. Prod. 2014, 67, 265–276. [Google Scholar] [CrossRef]

- Yurtkuran, H. An Evaluation on Machinability Characteristics of Titanium and Nickel Based Superalloys Used in Aerospace Industry. Manuf. Technol. Appl. 2021, 2, 10–29. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A.; El Mansori, M. Pressure-Induced Critical Influences on Workpiece-Tool Thermal Interaction in High Speed Dry Machining of Titanium. In AIP Conference Proceedings; American Institute of Physics: New York, NY, USA, 2012; pp. 424–440. [Google Scholar]

- Kuntoğlu, M.; Kaya, K.; Binali, R. Investigation of Surface Roughness Changes in The Machining of Carbon Steel Under Sustainable Conditions. Int. Conf. Pioneer Innov. Stud. 2023, 1, 163–167. [Google Scholar] [CrossRef]

- Demir, İ.; Kıvak, T.; Şirin, Ş. Performance Evaluation of CuO Nanofluids with Different Surfactants in the Milling of AISI 329 Duplex Stainless Steel. Manuf. Technol. Appl. 2022, 3, 9–21. [Google Scholar] [CrossRef]

- Deshpande, S.; Deshpande, Y. A Review On Cooling Systems Used In Machining Processes. Mater. Today Proc. 2019, 18, 5019–5031. [Google Scholar] [CrossRef]

- Maruda, R.W.; Szczotkarz, N.; Michalski, M.; Arkusz, K.; Wojciechowski, S.; Niesłony, P.; Khanna, N.; Królczyk, G.M. Evaluation of Tool Wear during Turning of Ti6Al4V Alloy Applying MQL Technique with Cu Nanoparticles Diversified in Terms of Size. Wear 2023, 532–533, 205111. [Google Scholar] [CrossRef]

- Kshitij, G.; Khanna, N.; Yıldırım, Ç.V.; Dağlı, S.; Sarıkaya, M. Resource Conservation and Sustainable Development in the Metal Cutting Industry within the Framework of the Green Economy Concept: An Overview and Case Study. Sustain. Mater. Technol. 2022, 34, e00507. [Google Scholar] [CrossRef]

- Shah, P.; Bhat, P.; Khanna, N. Life Cycle Assessment of Drilling Inconel 718 Using Cryogenic Cutting Fluids While Considering Sustainability Parameters. Sustain. Energy Technol. Assess. 2021, 43, 100950. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Şap, S.; Uzun, M.; Kuntoğlu, M.; Salur, E.; Karabiber, A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Estimation, Optimization and Analysis Based Investigation of the Energy Consumption in Machinability of Ceramic-Based Metal Matrix Composite Materials. J. Mater. Res. Technol. 2022, 17, 2987–2998. [Google Scholar] [CrossRef]

- Naveed, M.; Arslan, A.; Javed, H.M.A.; Manzoor, T.; Quazi, M.M.; Imran, T.; Zulfattah, Z.M.; Khurram, M.; Fattah, I.M.R. State-of-the-Art and Future Perspectives of Environmentally Friendly Machining Using Biodegradable Cutting Fluids. Energies 2021, 14, 4816. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Zhang, X.; Zhang, N.; Dai, J. Experimental Evaluation on Tribological Performance of the Wheel/Workpiece Interface in Minimum Quantity Lubrication Grinding with Different Concentrations of Al2O3 Nanofluids. J. Clean. Prod. 2017, 142, 3571–3583. [Google Scholar] [CrossRef]

- Pérez-Salinas, C.; de Lacalle, L.N.L.; del Olmo, A.; Kumar, C.S. The Relationship between the Cutting-Edge, Tool Wear, and Chip Formation during Inconel 718 Dry Cutting. Int. J. Adv. Manuf. Technol. 2024, 132, 6001–6017. [Google Scholar] [CrossRef]

- Kouam, J.; Songmene, V.; Balazinski, M.; Hendrick, P. Effects of Minimum Quantity Lubricating (MQL) Conditions on Machining of 7075-T6 Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2015, 79, 1325–1334. [Google Scholar] [CrossRef]

- Das, A.; Padhan, S.; Das, S.R.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Performance Assessment and Chip Morphology Evaluation of Austenitic Stainless Steel under Sustainable Machining Conditions. Metals 2021, 11, 1931. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Krolczyk, G.M.; Danish, M.; Singla, A.K.; Khanna, N. Influence of MoS2 and Graphite-Reinforced Nanofluid-MQL on Surface Roughness, Tool Wear, Cutting Temperature and Microhardness in Machining of Inconel 625. CIRP J. Manuf. Sci. Technol. 2023, 41, 225–238. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Günay, M.; Boy, M.; Yaşar, N.; Demirsöz, R.; Ross, K.N.S.; Abbas, Y. Comprehensive Analysis of Tool Wear, Surface Roughness and Chip Morphology in Sustainable Turning of Inconel-601 Alloy. J. Manuf. Process. 2023, 103, 156–167. [Google Scholar] [CrossRef]

- Darshan, C.; Jain, S.; Dogra, M.; Gupta, M.K.; Mia, M.; Haque, R. Influence of Dry and Solid Lubricant-Assisted MQL Cooling Conditions on the Machinability of Inconel 718 Alloy with Textured Tool. Int. J. Adv. Manuf. Technol. 2019, 105, 1835–1849. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Machining Performance Evaluation of Ti6Al4V Alloy with Laser Textured Tools under MQL and Nano-MQL Environments. J. Manuf. Process. 2020, 53, 174–189. [Google Scholar] [CrossRef]

| Description | Value |

|---|---|

| Cutting speed, m/min | 65, 130 |

| Feed rate, mm/rev | 0.1, 0.2 |

| Cutting depth, mm | 0.3, 0.6 |

| Cutting environment | Dry |

| MQL (Sunflower oil) method-MQL(S) | |

| MQL (Olive oil)-MQL(O) | |

| MQL (Sunflower Oil) + 1% SiO2–nano-MQL(nS) | |

| MQL (Olive Oil) + 1% SiO2-nano-MQL(nO) | |

| Lubricant flow rate | 5 bar |

| Property | Value |

|---|---|

| Chemical Formula | SiO2 |

| Crystal Structure | Amorphous |

| Particle Size (nm) | 22 |

| Appearance | White opaque |

| SEM image |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Binali, R.; Korkmaz, M.E.; Özdemir, M.T.; Günay, M. A Holistic Perspective on Sustainable Machining of Al6082: Synergistic Effects of Nano-Enhanced Bio-Lubricants. Machines 2025, 13, 293. https://doi.org/10.3390/machines13040293

Binali R, Korkmaz ME, Özdemir MT, Günay M. A Holistic Perspective on Sustainable Machining of Al6082: Synergistic Effects of Nano-Enhanced Bio-Lubricants. Machines. 2025; 13(4):293. https://doi.org/10.3390/machines13040293

Chicago/Turabian StyleBinali, Rüstem, Mehmet Erdi Korkmaz, Mehmet Tayyip Özdemir, and Mustafa Günay. 2025. "A Holistic Perspective on Sustainable Machining of Al6082: Synergistic Effects of Nano-Enhanced Bio-Lubricants" Machines 13, no. 4: 293. https://doi.org/10.3390/machines13040293

APA StyleBinali, R., Korkmaz, M. E., Özdemir, M. T., & Günay, M. (2025). A Holistic Perspective on Sustainable Machining of Al6082: Synergistic Effects of Nano-Enhanced Bio-Lubricants. Machines, 13(4), 293. https://doi.org/10.3390/machines13040293