Abstract

Erosion caused by sediment-laden flow significantly affects the efficiency and durability of Francis turbines. In this study, the Euler–Lagrange multi-phase flow model was employed to simulate solid-liquid two-phase flow with different sediment particle sizes to analyze erosion characteristics in turbine components. The results show that the maximum erosion rate of the runner blades is positively correlated with particle impact velocity, confirming that impact velocity is the dominant factor influencing local material removal. The total erosion rate of the runner blades, guide vanes, and draft tube corresponds closely with vorticity, indicating that vortex-induced flow separation accelerates particle–wall collisions and intensifies erosion. Both vorticity and erosion exhibit a nonlinear variation with particle size, reaching a minimum at 0.05 mm. These findings establish clear qualitative and quantitative relationships between erosion and key flow parameters, providing theoretical guidance for understanding and mitigating sediment-induced wear in Francis turbines.

1. Introduction

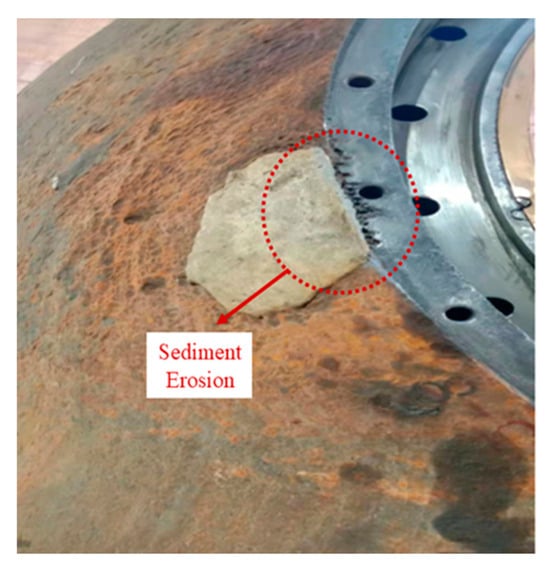

Francis turbines are core energy-conversion units in hydropower stations, requiring structural integrity to ensure operational stability and economic efficiency [1]. Under silt-laden river conditions, prolonged operation subjects turbines to solid particle erosion, where particle size distribution predominantly governs erosion severity [2,3]. Figure 1 illustrates erosion damage patterns on turbine components, revealing that variations in particle trajectory dynamics, impact frequency, and force magnitude yield heterogeneous erosion topographies across surfaces. Specifically, larger sediment particles generate localized severe erosion zones on blades and guide vanes due to elevated kinetic energy and impact forces. Conversely, finer sediment fractions cause widespread mild erosion and fatigue damage through high-frequency impacts. Furthermore, sediment trajectory behavior modulated by flow-field characteristics intensifies erosion complexity and diversification.

Figure 1.

Sediment erosion in the turbine components.

The theory of solid–liquid two-phase flow forms the fundamental basis for investigating sediment transport and the erosion mechanisms of hydraulic machinery. With the advancement of computational fluid dynamics, it has been extensively applied to the numerical simulation of pumps, turbines, and other hydraulic machines, providing an effective tool for elucidating the internal flow characteristics of sediment-laden flows. Wei et al. [4] utilized Discrete Phase Modelling to examine solid particle erosion characteristics under variable speed operations, performing comparative analyses against synchronous speed operations to quantify rotational dynamics induced erosion rate deviations. Zhang et al. [5] employed CFD to numerically simulate and analyze the three-dimensional, steady, incompressible, turbulent solid–liquid two-phase flow in a low-specific-speed centrifugal pump. Their study was based on the mixture model of solid–liquid two-phase flow in combination with the RNG k-ε two-equation turbulence model, which fully accounts for the effects of rotation and curvature, thereby offering valuable insights for subsequent numerical investigations of solid–liquid two-phase flows. Huang et al. [6] performed transient simulations of sediment erosion evolution across entire turbine flow passages, contrasting turbulent characteristics between single-phase and solid–liquid two-phase flow regimes. This research quantified sediment mass flow rate and particle morphology effects on erosive damage distribution in guide vanes and runners, analyzing deformation amplitudes and time-dependent erosion progression. Li et al. [7] conducted a series of numerical simulations on solid–liquid two-phase flow in intersecting fractures based on the two-fluid model and particle flow dynamics theory. Xue et al. [8] analyzed sediment volume fraction and erosion rate correlations, establishing spatial distribution patterns of sediment-induced erosion within hydro turbine flow passages.

The sediment erosion characteristics of Francis turbines, as an important research direction based on solid–liquid two-phase flow dynamics, have attracted extensive attention and in-depth investigation from scholars worldwide. Poudel et al. [9] predicted sediment erosion through numerical simulation and optimized turbine design to extend service life. Acharya et al. [10] examined distinct spatial locations and their corresponding sediment erosion effects in turbines exhibiting complex secondary flows. Wei et al. [11] considered the actual sediment gradation and emphasized the erosion mechanism from the perspective of flow structure. Numerical simulation results revealed a significant correlation between the erosion distribution and the formation location of inter-blade vortices, which is strongly influenced by operating conditions. Thapa et al. [12] reported that the primary measures to mitigate failures caused by sediment erosion include the development of wear-resistant alloys, the application of surface coatings on components, and the optimization of hydraulic design. In Francis turbines, erosion enlarges the clearance between guide vanes and panels, thereby inducing cross-clearance flow. This cross-clearance flow, together with other secondary flows, disrupts the velocity distribution at the runner inlet. Chitrakar et al. [13] elucidated the synergistic characteristics of sediment particles and vortex structures, whose combined effects can lead to greater hydraulic losses, unit vibrations, fatigue issues, and component failures. Cruzatty et al. [14] conducted a characterization of sediment particles in the Pastaza River to determine their physical properties, enabling more accurate predictions of their impact on turbine flow passages. The erosion rate under various operating conditions was calculated using a coupled liquid-solid two-phase flow numerical simulation with an erosion model, revealing the wear distribution patterns across different turbine components.

A critical aspect of sediment-induced erosion in hydraulic turbines is understanding the coupling mechanism between erosion (a wall-boundary phenomenon) and vortex formation (a flow-separation phenomenon) [15]. Erosion occurs when sediment particles collide with turbine surfaces, causing material removal through both impact and friction forces. Conversely, vortex formation, driven by flow separation, strongly influences the trajectories and velocities of sediment particles within the turbine. These two phenomena are intricately linked, with vortex structures altering the local flow field and significantly impacting particle behavior, including velocity, impact angle, and frequency of collisions with turbine surfaces. Therefore, accurate prediction of erosion patterns requires precise resolution of vortex structures, particularly in regions of strong vortex activity. Incorporating this interplay between vorticity and erosion provides valuable insights into optimizing turbine design to reduce erosion damage and improve turbine performance, which is the focus of the current study.

This study, employing a multi-phase numerical approach, investigates the effects of sediment particle size and vortex dynamics on the erosion of key turbine components. By analyzing the relationship between vorticity and erosion, this research aims to contribute to a deeper understanding of sediment erosion mechanisms and offer theoretical support for turbine design improvements.

2. Numerical Simulation

2.1. Mathematical Model

2.1.1. Governing Equation

The motion of the continuous fluid phase within the Francis turbine was governed by the three-dimensional, incompressible Navier–Stokes (N-S) equations, which express the conservation of mass and momentum for Newtonian fluids [16]. These equations can describe transient velocity and pressure distributions with high fidelity, thereby providing a robust foundation for analyzing internal hydraulic behavior under sediment-laden conditions. The governing equations are formulated as follows:

where u is the velocity vector, p is the pressure, ρ denotes the fluid density, μ is the dynamic viscosity, and μt represents the turbulent eddy viscosity. The source term St accounts for the momentum exchange between the fluid and solid phases.

This formulation effectively captures both viscous and inertial effects within the complex flow passages of hydraulic machinery. Similar formulations have been validated in recent CFD analyses of sediment-fluid interactions in turbomachinery by Song et al. [17], confirming the suitability of the N-S framework for erosion prediction in multi-stage centrifugal pumps operating under solid–liquid two-phase conditions. The Navier–Stokes equations were solved using the SIMPLEC algorithm for pressure–velocity coupling, and a second-order upwind scheme for spatial discretization to ensure stability and accuracy [18].

2.1.2. Turbulence Model

To accurately resolve flow separation and vortex formation near solid boundaries, the Shear Stress Transport (SST) k-ω turbulence model was employed. This model blends the advantages of the k-ω formulation near the wall and the k-ε model in the free stream, ensuring reliable prediction of turbulent kinetic energy and dissipation across different flow regions [19,20].

The SST k-ω model effectively captures the adverse pressure gradient and boundary layer behavior typical in the rotating passages of Francis turbines. Its hybrid approach enables accurate reproduction of both near-wall viscous effects and free-shear flow turbulence. Song et al. [17] also confirmed that the SST k-ω model provides superior numerical stability and physical realism for simulating erosion-prone turbulent structures in pumps and turbines.

2.1.3. Particle Track Model

Sediment particles are treated as discrete entities dispersed within the continuous water phase, and their trajectories are computed in the Lagrange reference frame [21]. This Lagrange approach, validated by Song et al. [17] and others, provides a high-resolution description of solid particle behavior in multi-phase flow and has demonstrated strong agreement with experimental erosion patterns in hydraulic components.

2.1.4. Erosion Model

The prediction of material loss due to particle impacts was conducted using the Tabakoff erosion model, which is widely applied in sediment-laden turbine analyses [22]. The erosion rate E is determined by the empirical relationship between particle impact velocity, impact angle, and surface material properties:

where VP is the particle impact velocity, γ is the impact angle, and V1, V2, and V3 are model constants calibrated for material response. The function f(γ) represents the angular dependence of erosion intensity. This model accurately describes the complex particle-surface collision behavior under rotating flow fields and has been verified in hydraulic machinery studies for its predictive capability. Recent findings by Song et al. [17] highlighted that incorporating realistic wall–particle collision angles and particle restitution coefficients significantly enhances erosion prediction accuracy in centrifugal pumps, a principle that also applies to turbine erosion evaluation.

Adopting this refined erosion framework thus improves the reliability of numerical assessment for sediment-induced wear in Francis turbines. This study aims to investigate the erosion effects of sediment particle size on various components of the hydraulic turbine. In this paper, the average sediment particle diameters selected are 0.02 mm, 0.05 mm, and 0.2 mm, with a sediment density of 2300 kg/m3, a sediment concentration of 10 kg/m3.

2.2. Numerical Simulation Model Setup

2.2.1. Geometric Model

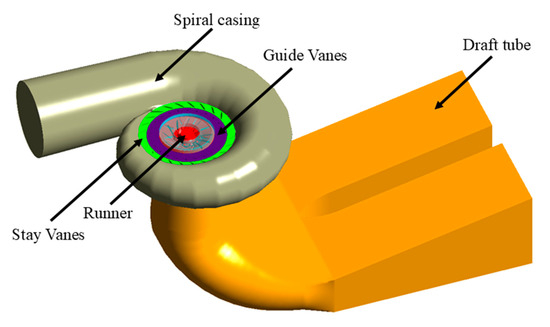

The simulation model is a Francis turbine consisting of five components: the spiral casing, runner, stay vanes, guide vanes, and draft tube (Figure 2). The runner has a diameter of 2.8 m and 13 blades. The main operating and design parameters of the turbine are listed in Table 1.

Figure 2.

Simulation model of the Francis turbine.

Table 1.

Main operating and design parameters of the Francis Turbine.

2.2.2. Mesh Generation

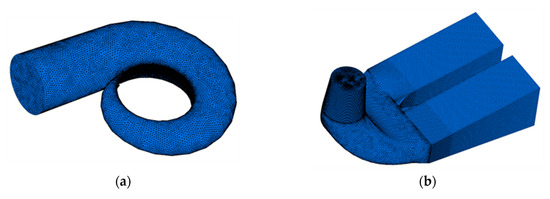

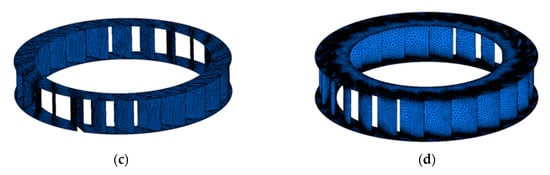

The simulation model is meshed using Ansys Mesh 2022 R1 software, with a hybrid generation of unstructured and structured grids, as shown in Figure 3.

Figure 3.

Three-dimensional flow passage model grid. (a) Spiral casing; (b) draft tube; (c) stay vane; (d) guide vane.

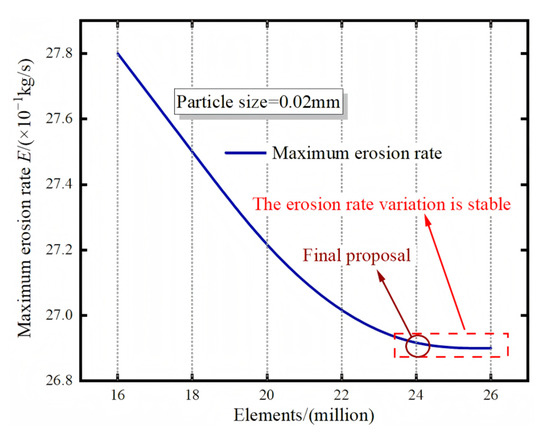

Figure 4 shows the mesh independence verification. As can be seen from the figure, with the increase in mesh number, the maximum erosion rate of the turbine decreases. The maximum erosion rate refers to a specific part of a component in the hydraulic turbine unit, as obtained from the numerical simulation. When the mesh number is between 24 million and 26 million elements, the maximum erosion rate of the turbine remains relatively stable, with fluctuations within 1%. To balance simulation accuracy and resource efficiency, a mesh quantity of 24 million elements was ultimately chosen.

Figure 4.

Maximum erosion rate of turbine with different mesh numbers.

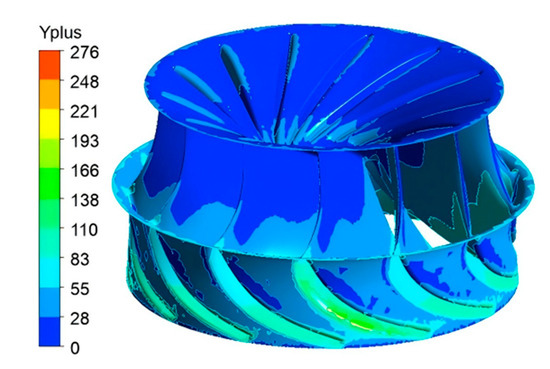

In the boundary layer, it is mainly the viscous force that dominates, while the inertial force can almost be ignored. We use the y+ value in this area for evaluation:

where u* is the friction velocity near the wall, y is the spacing between the first grid node and the wall, and v is the kinematic viscosity of the fluid. The wall friction velocity is given by , where tw is the wall shear stress.

As shown in Figure 5, the maximum value is 276, which suggests that the mesh of the boundary layer is acceptable [23].

Figure 5.

y+ value of boundary layer on runner wall.

2.2.3. Establishment of Simulation Mode

The inlet boundary condition was the mass flow rate at the rated flow, and the outlet boundary condition was the total pressure outlet, with the relative static pressure set to zero [24]. The fluid was normal-temperature water, and the solid was a particle. The wall surface adopted a no-slip boundary condition, and the junction interface with the runner was set as a dynamic-static interface. In contrast, other interfaces were set as static-static interfaces. The inlet turbulence intensity was set to 5%, and sediment particles with diameters of 0.02 mm, 0.05 mm, and 0.2 mm were defined at the inlet.

For boundary interaction, walls were treated with the “reflect” condition based on the Tabakoff model, while particles reaching the outlet boundary were treated as “escape.” This ensures accurate control of particle–wall collisions and exit flow balance.

3. Results and Discussion

In this study, numerical simulation was employed to investigate the erosion characteristics of various components in a Francis turbine. A comprehensive analysis will be discussed in the subsequent sections.

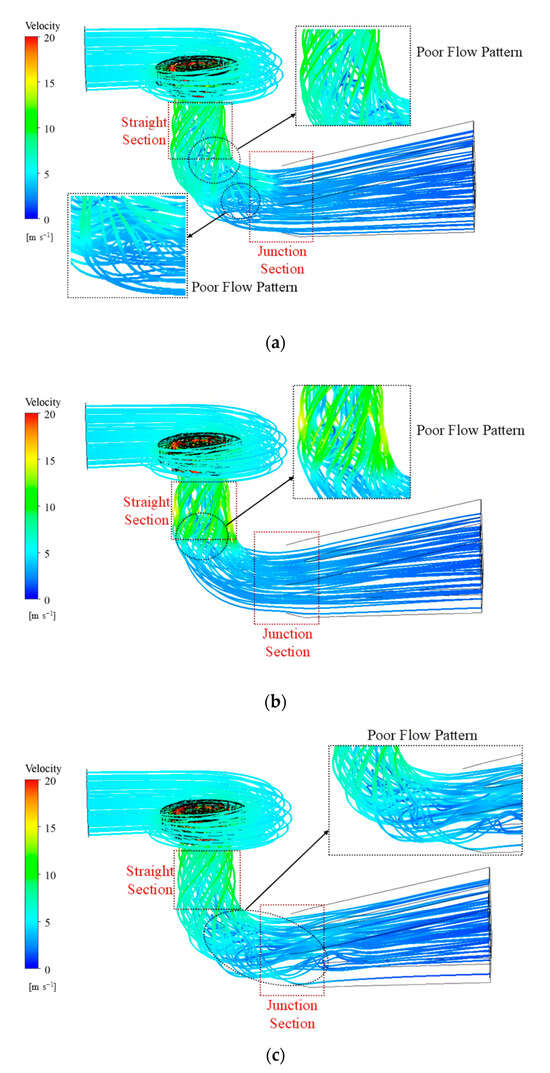

3.1. Effect of Sediment Particle Size on Flow Pattern

Figure 6 illustrates the flow pattern distribution within the unit flow passage under different sediment particle size conditions. The results indicate that the high-velocity regions are mainly concentrated in the guide vanes and runner zones, with significant variations in flow velocity observed across different components inside the turbine unit. Due to its relatively low velocity and simple geometry, the spiral casing section exhibits favorable flow characteristics and smooth water motion under all particle size conditions. In contrast, the flow field in the draft tube is less uniform, with varying degrees of recirculation vortex. This is primarily attributed to the relatively high velocity in the draft tube region, where the fluid is prone to disturbance and flow separation due to the contraction or change in the passage geometry. From the perspective of overall flow characteristics, the flow pattern is most stable when the sediment particle diameter is 0.05 mm. When the diameter decreases to 0.02 mm, adverse flow phenomena in the draft tube are primarily concentrated in the cone and bend sections. As the diameter increases to 0.2 mm, flow instabilities shift to the bifurcation region. This phenomenon suggests that excessively large or small particle sizes can significantly affect the mainstream flow behavior, among which the overall flow pattern is optimal under the condition of a 0.05 mm particle diameter.

Figure 6.

Distribution of three-dimensional flow pattern in the units under different sediment particle sizes. (a) d = 0.02 mm; (b) d = 0.05 mm; (c) d = 0.2 mm.

3.2. Analysis of the Whole Erosion in the Turbine

According to the preceding analysis, the high-velocity flow regions within the unit are primarily concentrated in the guide vanes and runner zones, whereas the internal flow pattern of the draft tube exhibits poor uniformity. Sediment particle size is a critical parameter influencing the erosion characteristics of hydraulic machinery [25,26].

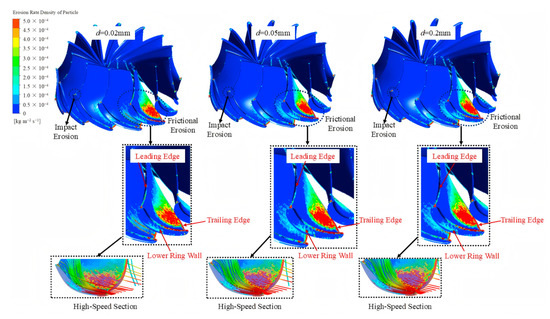

Figure 7 presents the erosion distribution characteristics of runner blades under different particle size conditions. The results indicate that as particle size increases, the area of erosion rate distribution expands, and the spatial distribution undergoes noticeable changes. Specifically, erosion intensity increases from the leading edge to the trailing edge of the blade. Among these regions, the lower ring wall and trailing edge experience the most severe erosion, primarily due to the highest local velocity. It is noteworthy that increasing particle size causes high-erosion zones to shift toward the trailing edge, mainly because larger particles, under strong inertial and centrifugal forces, are more likely to detach from the blade surface.

Figure 7.

Distribution of sediment erosion rate at the blades of the runner.

Erosion mechanism analysis reveals that impact erosion dominates on the leading edge, while frictional erosion is more prominent on the blade surface. This distinction arises from the flow behavior of sediment-laden water within the runner passage: high-velocity flow carries sediment particles that impact the leading edge and subsequently produce continuous friction along the blade surface. Accurate identification of these erosion characteristics provides important theoretical support for determining the types of erosion in hydraulic turbines.

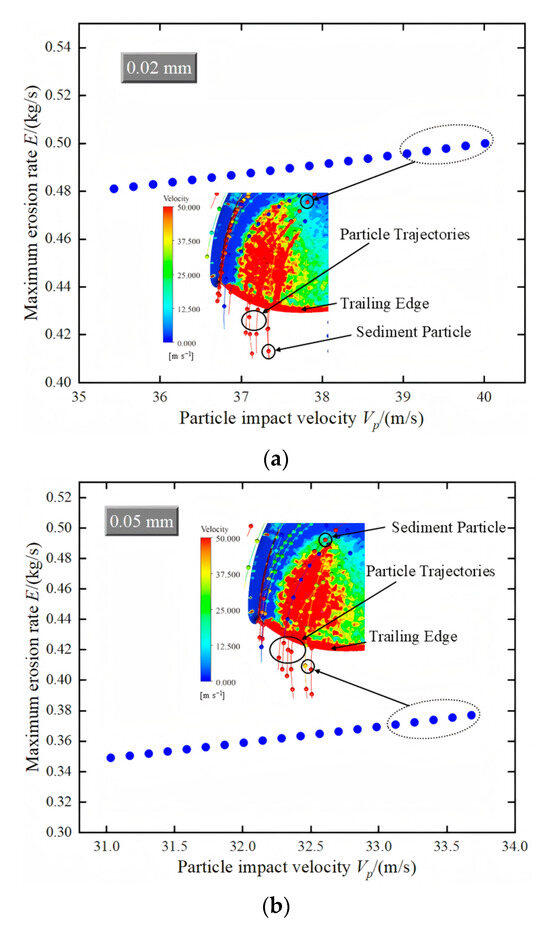

Figure 8 shows the maximum erosion rate and sediment particle impact velocity at the blades of the runner under different sediment particle sizes. The results show that the maximum erosion rate exhibits a nonlinear variation with sediment particle size, first decreasing and then increasing, reaching its minimum at a particle diameter of 0.05 mm. As illustrated in Figure 8, the impact velocity is positively correlated with the maximum erosion rate, indicating that the kinetic energy of particle impacts is the dominant factor controlling material loss on the blade surface. Specifically, when the particle diameter is 0.02 mm, the impact velocity ranges between 35 m/s and 40 m/s, and the corresponding maximum erosion rate is approximately 0.48–0.50 kg/s. For 0.05 mm particles, the impact velocity remains around 35–40 m/s, but the maximum erosion rate decreases to 0.34–0.37 kg/s, representing the lowest erosion intensity among the cases. When the particle diameter increases to 0.2 mm, the impact velocity rises to 40–48 m/s, and the maximum erosion rate correspondingly increases to 0.50–0.53 kg/s. These results demonstrate a clear positive correlation between impact velocity and erosion rate, confirming that higher particle impact velocity leads to more severe material removal. The variation in impact velocity with particle size also explains the observed non-linear erosion trend within the Francis turbine flow passage.

Figure 8.

Maximum erosion rate and sediment particle impact velocity at the blades of the runner under different sediment particle sizes. (a) d = 0.02 mm; (b) d = 0.05 mm; (c) d = 0.2 mm.

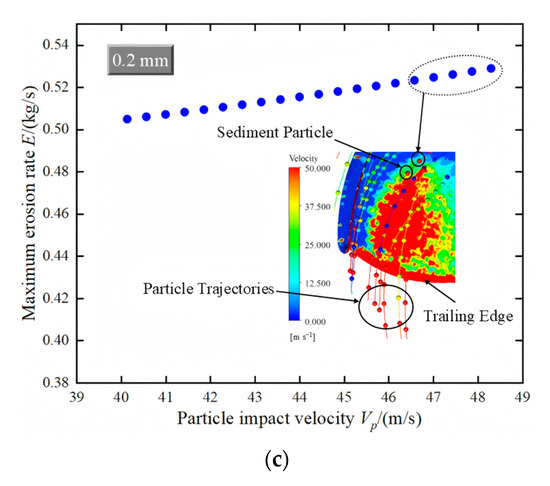

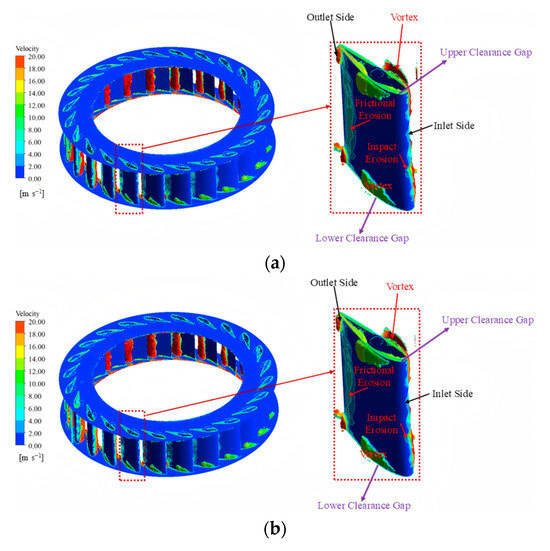

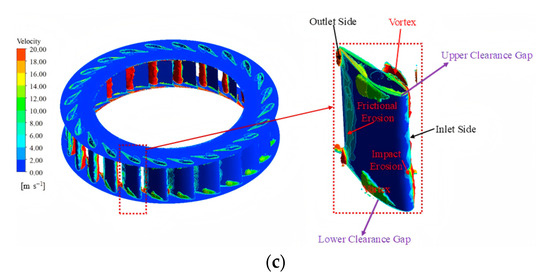

Unlike the runner structure, the guide vanes require a necessary clearance between their upper and lower end surfaces in the design to ensure flexible operation. However, this structural configuration, functioning as a special micro-channel within the turbine flow passage, also provides a pathway for the intrusion of sediment-laden water. Clearance gap erosion is a primary failure mode of the guide vanes in hydraulic turbines [27,28]. Its mechanism is a compound erosion process induced by high-velocity sediment-laden flow passing through the vane clearance, involving the synergistic effects of erosive wear and abrasive wear [29]. Figure 9 presents the typical erosion distribution characteristics of the guide vanes under different sediment particle size conditions. The erosion areas are mainly concentrated at the upper and lower clearance gaps of the vanes, as well as at the inlet and outlet sides. The inlet side exhibits typical impact erosion, resulting from oblique particle collisions with the surface, while the outlet side is predominantly governed by frictional erosion. This differentiated erosion pattern is closely associated with the dynamic characteristics of the flow field.

Figure 9.

Distribution of sediment erosion rate of the guide vanes.

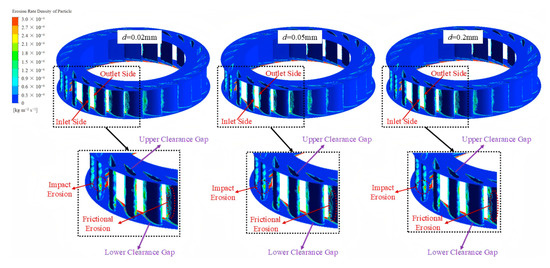

Figure 10 reveals the differentiated evolution patterns of the maximum erosion rate among various turbine components. The study shows that the guide vanes and runner experience the most severe erosion, though their erosion characteristics differ significantly. The maximum erosion rate of the runner exhibits a non-monotonic trend with changing sediment particle size, decreasing initially and then increasing, reaching a minimum at d = 0.05 mm. In contrast, the maximum erosion rate of the guide vanes shows a negative correlation with particle size, registering 2.604 kg/s at d = 0.05 mm, which is 6.92 times higher than that of the runner under the same condition. Notably, the ratio of guide vanes’ maximum erosion rates at d = 0.02 mm (2.693 kg/s) and d = 0.2 mm is only 1.08, indicating a tendency toward stabilization. For the lower ring component, the maximum erosion rate at d = 0.05 mm is 0.213 kg/s, differing by only 10% from its extremum value, also exhibiting a stable trend. The evolution of erosion rates for the runner blades and the up crown displays similar patterns—initially decreasing and then increasing with particle size. These phenomena underscore the risk that, under long-term operation in highly sediment-laden conditions, the runner and guide vanes may suffer severe erosion damage due to the lack of effective protective measures.

Figure 10.

Maximum erosion rate of the unit under different sediment particle sizes.

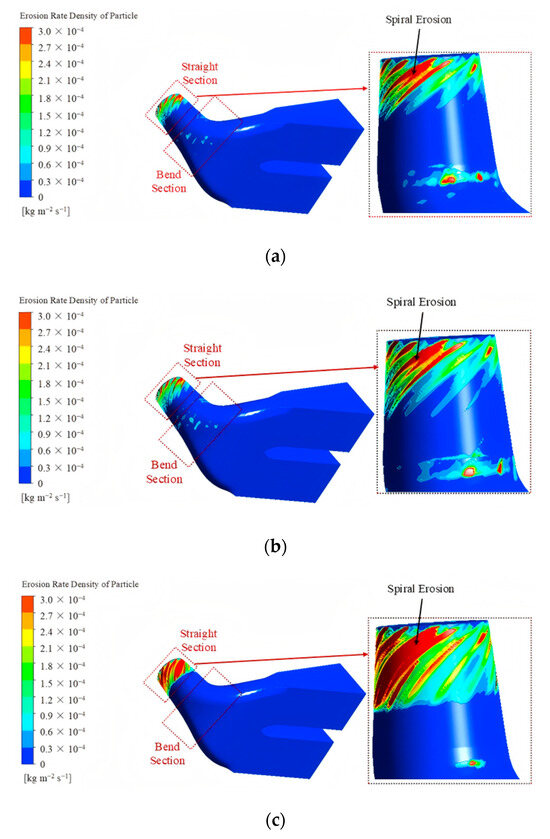

Figure 11 illustrates the spatial distribution characteristics of erosion in the draft tube under different sediment particle size conditions. The results indicate that erosion is primarily concentrated in the straight section of the draft tube, where the high-erosion regions exhibit a typical spiral distribution pattern. As the sediment particle size increases, the straight section shows the following notable changes: a significant expansion of the eroded area, an increase in the width of the spiral erosion bands, and an intensification of the non-uniformity in erosion distribution. Meanwhile, the erosion extent in the bend section of the draft tube tends to decrease with increasing particle size. This phenomenon can be attributed to the fact that larger sediment particles, influenced by both inertial and gravitational forces, are more likely to accumulate in the straight section. This leads to a significantly higher frequency of particle collisions in that region, resulting in more severe erosion damage.

Figure 11.

Distribution of sediment erosion rate of the draft tube. (a) d = 0.02 mm; (b) d = 0.05 mm; (c) d = 0.2 mm.

3.3. Effect of Vortex on the Sediment Erosion in the Turbine

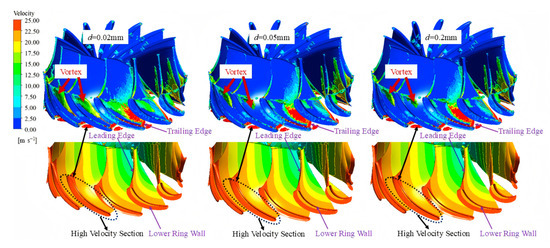

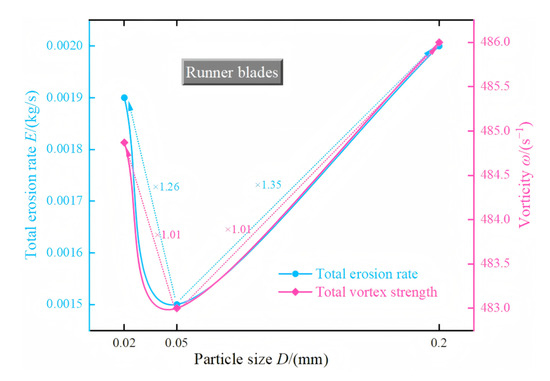

The previous section analyzed the distribution of erosion rates across different components. For the runner, its internal flow field characteristics under high-speed rotation play a crucial role in sediment erosion. To further elucidate the erosion mechanism of the turbine flow-passage components, vortex analysis based on the Q-criterion (with a threshold of 0.01 s−2) was conducted. As shown in Figure 12, distinct vortex structures are observed on the lower ring wall of the runner. In the previous section, a systematic analysis of the maximum erosion rate of different flow-passage components was conducted. To further quantitatively investigate the key factors influencing the erosion rate, the present study extracted and established the correlation between the total erosion rate of each component and the vorticity, as shown in Figure 13.

Figure 12.

Vortex flow and erosion at the blades of the runner.

Figure 13.

Total erosion and vorticity of the runner.

The vorticity was defined as the integral of the vorticity magnitude over regions satisfying the Q-criterion threshold. This quantity characterizes the overall rotational intensity of the flow and directly correlates with vortex-induced wall shear and erosion zones.

The total erosion rate of the runner blades follows a distinct trend with sediment particle size, correlating closely with vorticity. Specifically, when the particle diameter is 0.02 mm, the vorticity is approximately 485 s−1, and the total erosion rate reaches 0.00181 kg/s. At 0.05 mm, the vorticity is slightly lower at 483 s−1, resulting in a corresponding erosion rate of 0.0015 kg/s, which is the minimum observed in this study. As the particle diameter increases to 0.2 mm, the vorticity increases slightly to 486 s−1, and the total erosion rate rises to 0.0020 kg/s, showing a clear positive correlation between vortex intensity and erosion. This relationship suggests that the strength of vortex structures plays a crucial role in driving erosion. The increased vorticity results in more pronounced flow separation and stronger shear forces acting on the blade surfaces, thereby intensifying particle-wall collisions. In particular, the higher vorticity at 0.2 mm particles leads to more concentrated sediment accumulation at the lower ring wall, where the relative velocity (highlighted in red in Figure 12) is significantly higher than in other regions. The vortex structures enhance the kinetic energy of the particles, particularly in regions where flow separation occurs, promoting higher velocity impacts on the blades. This phenomenon explains the higher erosion rates in areas associated with stronger vortex flows. The interaction of sediment particles with the blades in these high-vortex zones results in substantial frictional erosion, particularly at the lower ring wall, which is most susceptible to damage due to its high local relative velocity. The correlation between vorticity and total erosion rate was identified empirically based on numerical results, indicating that stronger vortex structures promote higher total erosion.

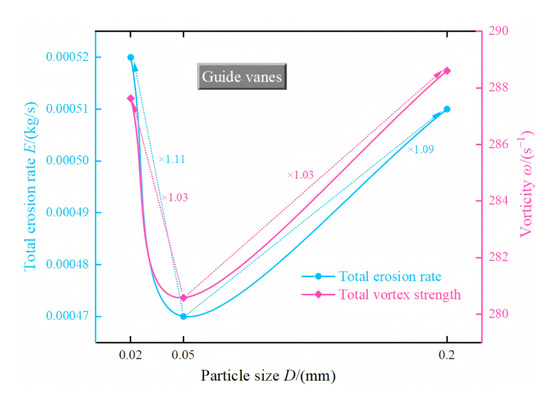

Rajkarnikar conducted experimental studies on the erosion of Francis turbines under laboratory conditions. Localized erosion was observed at both the inlet and outlet of the guide vanes, similar to that seen in the original vanes [30]. As shown in Figure 14, this phenomenon is primarily attributed to vortex flow and high-velocity regions within the guide vanes. Figure 15 shows the relationship between the total erosion rate and vorticity of the guide vanes.

Figure 14.

Vortex flow and erosion in the guide vanes. (a) d = 0.02 mm; (b) d = 0.05 mm; (c) d = 0.2 mm.

Figure 15.

Total erosion and vorticity of the guide vanes.

The total erosion rate of the guide vanes follows a distinct trend with sediment particle size, exhibiting a decrease and then an increase as particle size increases. Specifically, when the particle diameter is 0.02 mm, the vorticity is approximately 287.63 s−1, and the total erosion rate is 5.2 × 10−4 kg/s. At 0.05 mm, the vorticity decreases slightly to 280.58 s−1, with a corresponding total erosion rate of 4.7 × 10−4 kg/s, which represents the lowest erosion value for the guide vanes. When the particle size increases to 0.2 mm, the vorticity increases to 288.61 s−1, and the total erosion rate rises slightly to 5.1 × 10−4 kg/s, demonstrating that vortex intensity is a key factor influencing erosion progression. This trend suggests a direct correlation between vorticity and total erosion in the guide vanes. Increased vorticity leads to enhanced flow separation, which intensifies the interaction between sediment particles and the vane surfaces. The outlet region of the guide vanes primarily experiences frictional erosion, as particles with higher inertia accumulate at the vane outlets, leading to higher impact momentum and more concentrated erosion. This mechanism is particularly pronounced in the upper clearance area, where vortex formation changes the particle trajectories, increasing collision frequency and thereby intensifying the erosion. These findings confirm that the interaction of vortex flows and high-velocity zones within the guide vanes is a primary driver of erosion damage, with vorticity playing a crucial role in modulating the severity and spatial distribution of erosion.

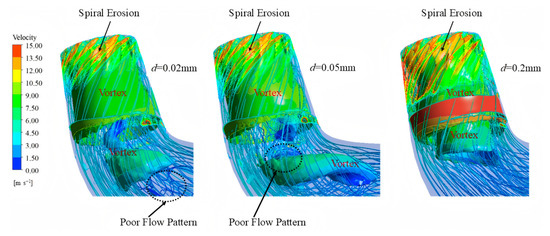

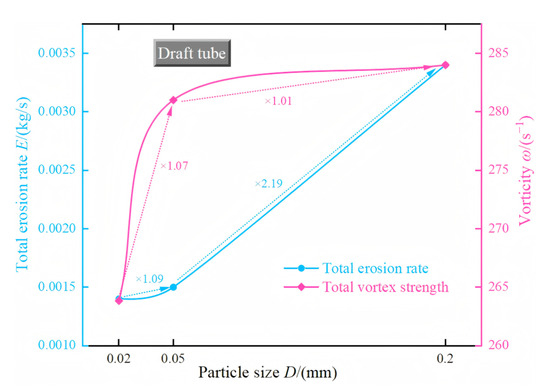

Figure 16 reveals the relationship between vortex structures in the draft tube’s straight section and the corresponding erosion rate. Figure 17 shows the relationship between the total erosion rate and vorticity of the draft tube.

Figure 16.

Vortex flow and erosion in the draft tube.

Figure 17.

Total erosion and vorticity of the draft tube.

The total erosion rate of the draft tube is positively correlated with sediment particle size. Specifically, at d = 0.02 mm, the vorticity is approximately 263.83 s−1, and the total erosion rate is 0.0014 kg/s. When the particle size increases to d = 0.05 mm, the vorticity increases to 281 s−1, and the erosion rate rises slightly to 0.0015 kg/s. At d = 0.2 mm, the vorticity increases further to 284 s−1, and the total erosion rate sharply increases to 0.0034 kg/s, which is 2.43 times the erosion rate at 0.02 mm. This data demonstrates a clear positive correlation between vorticity and total erosion rate, where an increase in vorticity results in a corresponding rise in erosion. The underlying mechanism is that the vortex field accelerates the rotational motion of sediment particles, which in turn increases their kinetic energy and frequency of wall impacts, particularly in the straight section of the draft tube.

Fine particles (d = 0.02 mm and 0.05 mm), dominated mainly by inertial forces, exhibit weak responses to the vortex structures, and as a result, they tend to detach quickly from the wall after impact, moving downstream. These particles, due to their lower inertia, do not accumulate in the straight section but are more influenced by the vortex structures in the bend section, which results in lower erosion rates. In contrast, coarse particles (d = 0.2 mm), influenced by both inertia and gravity, tend to accumulate more in the straight section, leading to higher wall impact frequency and increased erosion rates. Furthermore, the distribution of vortex structures exhibits a strong dependence on particle size. Under conditions with fine particles, vortex structures are predominantly distributed in the bend section, whereas with coarse particles, vortices are concentrated in the straight section, where particle accumulation and erosion are most intense. Sediment particles form characteristic erosion traces along the vortex extension path, validating the scouring effect of vortex structures on the wall surface. This phenomenon reveals the intrinsic coupling between the internal flow field structures and sediment erosion within the draft tube, emphasizing the critical role of vorticity in driving sediment accumulation and intensifying erosion.

4. Conclusions

In this study, the Euler–Lagrange multi-phase flow model was employed to investigate the erosion characteristics of flow-passing components in a Francis turbine under different sediment particle sizes. The main conclusions are as follows:

- Erosion is primarily concentrated in the runner blades, the straight section of the draft tube, and the inlet and outlet regions of the guide vanes. In these specific areas, erosion is particularly severe. The erosion in the straight section of the draft tube intensifies with increasing particle size, where sediment particles, driven by vortex structures, form spiral erosion traces along the wall surface.

- The maximum erosion rate of the runner blades exhibits a clear positive correlation with impact velocity. Specifically, when the particle diameter is 0.02 mm, the impact velocity ranges between 35–40 m/s, resulting in a maximum erosion rate of approximately 0.48–0.50 kg/s. For 0.05 mm particles, the impact velocity remains around 35–40 m/s, but the maximum erosion rate decreases to 0.34–0.37 kg/s, which is the lowest erosion intensity observed. When the particle diameter increases to 0.2 mm, the impact velocity increases to 40–48 m/s, and the maximum erosion rate increases to 0.50–0.53 kg/s, confirming that higher impact velocities lead to more severe material removal from the turbine surfaces.

- The total erosion of the turbine components, particularly the runner blades, guide vanes, and draft tube, is closely aligned with the evolution of vorticity. The locations where vortex structures occur correspond closely with the observed erosion zones. Vortex structures alter the velocity distribution of the flow field and the trajectories of sediment particles, resulting in frequent impact erosion along the lower ring wall and trailing edge of the runner, and at the inlet and outlet of the guide vanes. The increased vorticity accelerates the motion of sediment particles, causing them to accumulate in areas with high vortex intensity, leading to more severe erosion.

Author Contributions

Conceptualization, Y.J. and F.T.; methodology, B.C.; software, B.C.; validation, Y.X., H.L. and Y.J.; formal analysis, B.C.; investigation, B.C.; resources, B.C.; data curation, B.C.; writing—original draft preparation, B.C.; writing—review and editing, Y.J. and F.T.; visualization, Y.X.; supervision, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. SJCX24_2239) and the Open Research Subject of Key Laboratory of Fluid Machinery and Engineering (Xihua University), Sichuan Province (grant number LTJX-2025011). This study was supported by the Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions, the Open Project Program of Engineering Research Center of High-efficiency and Energy-saving Large Axial Flow Pumping Station, Jiangsu Province, Yangzhou University (grant number ECHEAP028).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to thank the JSS-Key-Lab of Hydrodynamic Engineering at Yangzhou University.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CFD | Computational Fluid Dynamics |

| SST k-ω | Shear Stress Transport k-ω (turbulence model) |

| N-S | Navier–Stokes (equations) |

| DPM | Discrete Phase Model |

References

- Krzemianowski, Z.; Przybyliński, T.; Karwacki, J.; Tomaszewski, A. Experimental research of a high specific speed low-head model Francis turbine—A case study with emphasis on flow visualisation under runner using PIV method and energy production analysis. Energy 2025, 334, 137711. [Google Scholar] [CrossRef]

- Nguyen, V.B.; Nguyen, Q.B.; Zhang, Y.; Lim, C.; Khoo, B. Effect of particle size on erosion characteristics. Wear 2016, 348, 126–137. [Google Scholar] [CrossRef]

- Bahadur, S.; Badruddin, R. Erodent particle characterization and the effect of particle size and shape on erosion. Wear 1990, 138, 189–208. [Google Scholar] [CrossRef]

- Wei, X.; Pei, J.; Geng, Q.; Wang, W. Study on the Sediment Wear Characteristics of Variable-Speed Mixed-Flow Hydraulic Turbines. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2025, 53, 101–107+164. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Cui, B.; Zhu, Z.; Dou, H. Numerical simulation and analysis of solid-liquid two-phase flow in centrifugal pump. Chin. J. Mech. Eng. 2013, 26, 53–60. [Google Scholar] [CrossRef]

- Huang, J.; Yao, J.; Zhang, L. Study on the Evolution Characteristics of Sediment Wear in Mixed-Flow Turbines Based on Erosion-Moving Mesh Coupling. Res. Prog. Hydrodyn. A 2024, 39, 234–243. [Google Scholar]

- Li, P.; Zhang, X.; Lu, X. Numerical simulation on solid-liquid two-phase flow in cross fractures. Chem. Eng. Sci. 2018, 181, 1–18. [Google Scholar] [CrossRef]

- Xue, B.; Li, Y.; Li, Y.; Tang, Z.; Xu, B.; Xu, K.; Zhou, Z.; Yu, Z.; Yao, B.; Pang, J.; et al. Numerical Simulation of Flow Fields and Sediment-Induced Wear in the Francis Turbine. Water 2024, 16, 3148. [Google Scholar] [CrossRef]

- Poudel, R.; Chitrakar, S.; Qian, Z.; Thapa, B. Experimental Investigations of Sediment Erosion in Francis Turbine Using Non-Recirculating Sediment Test Rig. Energy Sci. Eng. 2024, 13, 700–713. [Google Scholar] [CrossRef]

- Acharya, N.; Gautam, S.; Chitrakar, S.; Iliev, I.; Dahlhaug, O.G. Correlating Sediment Erosion in Rotary–Stationary Gaps of Francis Turbines with Complex Flow Patterns. Energies 2024, 17, 5961. [Google Scholar] [CrossRef]

- Wei, X.Y.; Pei, J.; Wang, W.Q.; Yu, Z.F. Numerical study on sediment erosion characteristics of Francis turbine runner. Eng. Fail. Anal. 2024, 161, 108270. [Google Scholar] [CrossRef]

- Thapa, B.S.; Dahlhaug, O.G.; Thapa, B. Sediment erosion in hydro turbines and its effect on the flow around guide vanes of Francis turbine. Renew. Sustain. Energy Rev. 2015, 49, 1100–1113. [Google Scholar] [CrossRef]

- Chitrakar, S.; Neopane, H.P.; Dahlhaug, O.G. Study of the simultaneous effects of secondary flow and sediment erosion in Francis turbines. Renew. Energy 2016, 97, 881–891. [Google Scholar] [CrossRef]

- Cruzatty, C.; Jimenez, D.; Valencia, E.; Zambrano, I.; Mora, C.; Luo, X.; Cando, E. A case study: Sediment erosion in francis turbines operated at the san francisco hydropower plant in ecuador. Energies 2021, 15, 8. [Google Scholar] [CrossRef]

- Karpenko, M. Aircraft hydraulic drive energy losses and operation delay associated with the pipeline and fitting connections. Aviation 2024, 28, 1–8. [Google Scholar] [CrossRef]

- Thapa, B.S.; Dahlhaug, O.G.; Thapa, B. Sediment erosion induced leakage flow from guide vane clearance gap in a low specific speed Francis turbine. Renew. Energy 2017, 107, 253–261. [Google Scholar] [CrossRef]

- Song, X.; Zhu, K.; Wang, Z. Research on the influence of symmetrical installation of blade on the sediment erosion in a multi-stage centrifugal pump. Symmetry 2024, 16, 1636. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Deptuła, A.; Karpenko, M. Navier-Stokes solutions for accelerating pipe flow—A review of analytical models. Energies 2023, 16, 1407. [Google Scholar] [CrossRef]

- Koirala, R.; Thapa, B.; Neopane, H.P.; Zhu, B.; Chhetry, B. Sediment erosion in guide vanes of Francis turbine: A case study of Kaligandaki Hydropower Plant, Nepal. Wear 2016, 362, 53–60. [Google Scholar] [CrossRef]

- Mamazhonov, M.; Shakirov, B.; Matyakubov, B.; Makhmudov, A. Polymer materials used to reduce waterjet wear of pump parts. J. Phys.: Conf. Ser. 2022, 2176, 012048. [Google Scholar] [CrossRef]

- Masoodi, J.H.; Harmain, G.A. A methodology for assessment of erosive wear on a Francis turbine runner. Energy 2017, 118, 644–657. [Google Scholar] [CrossRef]

- Kang, M.W.; Park, N.; Suh, S.H. Numerical study on sediment erosion of Francis turbine with different operating conditions and sediment inflow rates. Procedia Eng. 2016, 157, 457–464. [Google Scholar] [CrossRef]

- Yan, X.; Kan, K.; Zheng, Y.; Chen, H.; Binama, M. Entropy production evaluation within a prototype pump-turbine operated in pump mode for a wide range of flow conditions. Processes 2022, 10, 2058. [Google Scholar] [CrossRef]

- Peng, G.; Wang, Z.; Xiao, Y.; Luo, Y. Abrasion predictions for Francis turbines based on liquid–solid two-phase fluid simulations. Eng. Fail. Anal. 2013, 33, 327–335. [Google Scholar] [CrossRef]

- Tarodiya, R.; Gandhi, B.K. Numerical simulation of a centrifugal slurry pump handling solid-liquid mixture: Effect of solids on flow field and performance. Adv. Powder Technol. 2019, 30, 2225–2239. [Google Scholar] [CrossRef]

- Tarodiya, R.; Gandhi, B.K. Experimental investigation of centrifugal slurry pump casing wear handling solid-liquid mixtures. Wear 2019, 434, 202972. [Google Scholar] [CrossRef]

- Wang, J.; Song, X.; Wang, J.; Wang, Z. Study on the Complex Erosion Characteristics and Specific Influencing Factor Mechanism in a Francis Hydraulic Turbine. Water 2025, 17, 1234. [Google Scholar] [CrossRef]

- Sharma, S.; Gandhi, B.K. Assessment of erosion wear in low specific speed Francis turbine due to particulate flow. Adv. Powder Technol. 2023, 34, 104065. [Google Scholar] [CrossRef]

- Gautam, S.; Neopane, H.P.; Acharya, N.; Chitrakar, S.; Thapa, B.S.; Zhu, B. Sediment erosion in low specific speed francis turbines: A case study on effects and causes. Wear 2020, 442, 203152. [Google Scholar] [CrossRef]

- Rajkarnikar, B.; Neopane, H.P.; Thapa, B.S. Development of rotating disc apparatus for test of sediment-induced erosion in Francis runner blades. Wear 2013, 306, 119–125. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).