3.2. Effect of Decoupling Ratio and Coupling Media on EDC Blasting

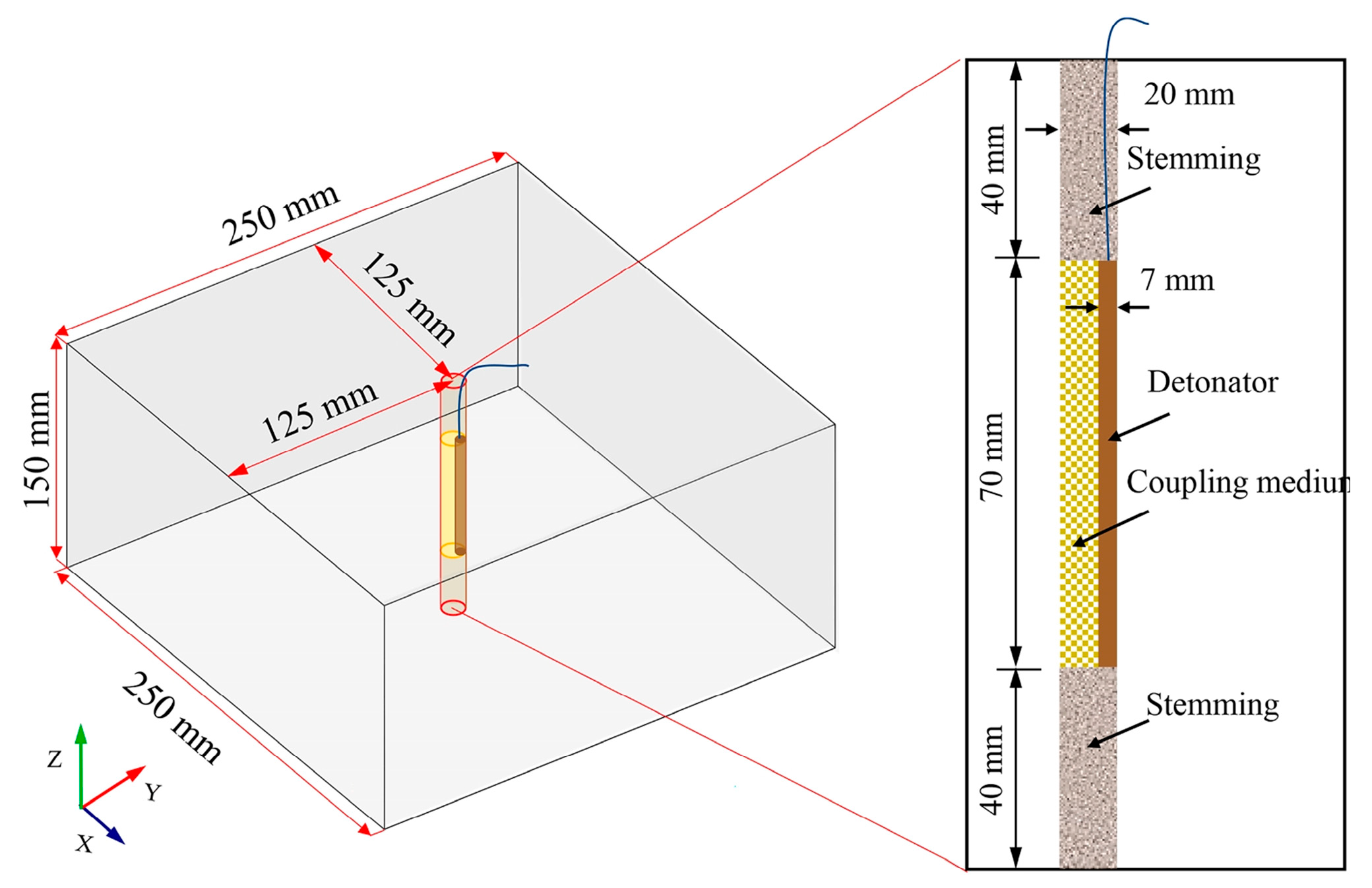

Following the calibration of the material model, numerical simulations were conducted to examine the EDC blasting process under various decoupling ratios and coupling media conditions. The corresponding patterns of pressure propagation and damage evolution are illustrated in

Figure 7. After detonation, the explosive products rapidly expand and exert strong compression on the coupling medium within the borehole, generating a distinct high-pressure zone. At T = 6 μs, the coupled side exhibits a broader high-pressure zone under the minimum decoupling ratio (

K = 20/10). Moreover, the type of coupling medium has a significant effect on pressure distribution. The water medium yields the widest high-pressure region, while the air medium produces the narrowest. As the pressure continues to propagate, the air and sand media exhibit notable asymmetry in the pressure field, leading to the emergence of a pressure eccentricity effect. In contrast, the water medium shows a more uniform distribution due to its lower compressibility. Under shock wave loading, the borehole wall rock initially undergoes compression and crushing, forming a crushed zone (0.8 ≤

D ≤ 1). As energy dissipates, the radial compressive stress becomes insufficient to cause additional failure, while the circumferential tensile stress remains above the rock’s tensile strength, promoting the extension of radial cracks from the edge of the crushed zone. In addition, wave reflection at the free surface generates radial tensile stresses that initiate circumferential cracks, ultimately producing a complete damage zone. The simulation results indicate that the final damage pattern differs significantly depending on the coupling medium. Under water coupling, the cracks are densely and uniformly distributed, with bilateral expansion of the damage zone. By contrast, under air or sand coupling, the damage zone is clearly biased toward the coupled side, while the decoupled side exhibits a more asymmetric damage pattern due to uneven pressure loading.

Figure 8 presents the damage patterns and associated fracture networks of the rock mass under EDC blasting conditions. Both the charge diameter and the type of coupling medium significantly influence the resulting damage pattern. Although radial cracks emanating from the blast center are observed under three coupling media, under air and sand coupling conditions, the fracture networks appear more sparse and asymmetric, with most cracks concentrated on the side closer to the explosive charge, as shown in

Figure 8a,b. In contrast, water coupling generates a dense and intersecting fracture network on both the coupled and decoupled sides, due to its higher energy transfer efficiency, as shown in

Figure 8c. Moreover, as the decoupling ratio increases, the extent of energy dissipation becomes more substantial, leading to a marked decrease in both the number and length of cracks observed on the specimen surface.

To quantitatively assess the extent of blast-induced rock damage and the asymmetry in the fracture pattern, the volume ratios of the crushed zone (

Vcru/

Vr), crack zone (

Vcra/

Vr), and total damage zone (

Vd/

Vr) around the borehole were calculated. As shown in

Figure 9, the damage zone includes both the crushed and cracked zones [

47]. Additionally, the fracture eccentricity

δ was defined as the volume ratio between the coupled side and the decoupled side for each damage region. Specifically,

δcru,

δcra, and

δd represent the eccentricity of the crushed zone, crack zone, and total damage zone, respectively. A value of

δ > 1 indicates that the damage is concentrated on the coupled side, reflecting the presence of a damage eccentricity effect.

Under identical coupling media, increasing the decoupling ratio

K from 20/10 to 20/4 led to a marked decrease in the volume ratios of all three damage regions. This reduction is primarily due to the decreased charge diameter and increased thickness of the coupling layer, which together enhance energy dissipation and reduce the intensity of the stress wave. Among the three media, water coupling consistently produced the largest damage volumes, followed by sand and then air, indicating that water provides the highest energy transmission efficiency and greatest rock-breaking capacity. Regarding the eccentricity effect, the values of

δ in all damage zones increased with

K under both air and sand coupling. Notably, at

K = 20/4,

δcru > 20 for both media, as the transmitted stress on the decoupled side was too weak to form a significant crushed zone, resulting in an extreme disparity. Additionally,

δd > 1 across all

K values for both air and sand coupling, confirming the consistent presence of a damage eccentricity effect. The decoupling ratio

K = 20/5 was identified as the threshold where the dominance of the eccentricity effect transitions: below this value, air coupling exhibits a more pronounced effect; above it, sand coupling becomes more dominant, as shown in

Figure 9c. In contrast, water coupling did not display a damage eccentricity effect when

K < 20/8. The effect only emerged at larger decoupling ratios, suggesting that eccentric damage under water coupling conditions requires high levels of decoupling. At lower

K values, most of the explosive energy on the coupled side is consumed in forming the crushed zone, while the decoupled side experiences primarily crack initiation and extension. As

K increases, the energy on the coupled side becomes increasingly directed toward crack development and eventually exceeds that on the decoupled side, leading to the onset of the eccentricity effect.

These findings indicate that the degree of rock damage and the corresponding eccentricity effect under EDC blasting are jointly governed by the decoupling ratio K and the coupling medium. For engineering applications, the decoupling ratio K and the coupling medium should be selected based on the excavation requirements: If the goal is to enhance the damage eccentricity effect, air or sand coupling is recommended. When K < 20/5, air coupling exhibits the most pronounced eccentricity effect, with the lowest damage on the decoupled side, making it ideal for protecting the surrounding rock. When K ≥ 20/5, sand coupling produces a stronger eccentricity effect, and the rock-breaking capacity on the coupled side is enhanced. Notably, even under high K values, air coupling still results in the least damage on the decoupled side, making it suitable for scenarios requiring the preservation of rock integrity on the decoupled side. When both eccentric damage and overall crushing efficiency are desired, water coupling is a suitable choice, although a higher decoupling ratio should be used to minimize energy transfer to the decoupled side.

To further investigate the pressure propagation behavior within the rock under EDC conditions, pressure–time histories at target points A and B were plotted for decoupling ratios

K = 20/9, 20/7, and 20/5, as shown in

Figure 10. On the coupled side, the borehole wall is first subjected to the incident shock wave, resulting in a rapid rise to peak pressure followed by sharp attenuation. This behavior is primarily influenced by the energy absorption of the crushed zone. Multiple stress wave reflections at the borehole interface generate secondary local peaks, thereby extending the duration of pressure loading.

On the decoupled side, the pressure rise is significantly delayed compared with the coupled side, and the delay increases with larger decoupling ratios. This is attributed to the thickening of the coupling medium layer, which increases the travel path of the stress wave, reduces its propagation speed, and delays the arrival time. As a result, both the peak pressure and loading rate decrease markedly. Among the three media, air exhibits the lowest peak pressure, the most pronounced delay, and the least energy transfer efficiency. The pressure difference between the coupled and decoupled sides is greatest under air coupling, leading to an apparent asymmetry in the resulting damage, as shown in

Figure 10a. By contrast, water coupling exhibits the highest peak pressure, fastest propagation speed, and shortest arrival time. The smallest pressure difference between the two sides is observed in this case, suggesting a more uniform pressure distribution, as shown in

Figure 10c. This facilitates the development of a coherent and evenly distributed crack network, enhancing overall crushing efficiency. Moreover, the pressure duration on the decoupled side increases in the order: air < sand < water. Liu et al. [

20] attributed this trend to differences in wave reflection frequency and attenuation characteristics at the borehole wall. The degree of stress wave attenuation is closely related to the porosity of the coupling medium—higher porosity in air leads to greater attenuation. Regardless of the medium, increasing the decoupling ratio reduces the charge diameter and total explosive energy, which in turn lowers the peak pressures on both sides of the borehole and shortens the overall pressure duration.

In summary, the peak borehole wall pressure, loading rate, and pressure duration are jointly governed by the decoupling ratio and the physical characteristics of the coupling medium. As the decoupling ratio K increases or as the medium porosity becomes higher, the pressure distribution along the borehole wall becomes increasingly uneven. This leads to greater differences in pressure response between the coupled and decoupled sides, which in turn amplifies the disparity in damage extent across the borehole. These findings are consistent with the damage pattern observations discussed in the preceding section.

According to the numerical simulation results of EDC blasting, a clear distinction in peak pressure attenuation behavior was observed between the coupled and decoupled sides. To quantitatively describe the attenuation of peak borehole wall pressure along the radial and axial directions of the unloaded section, a power function was used to fit the peak pressure data under various EDC configurations [

25,

37,

48,

49]. The fitting results are presented in

Figure 11 and

Table 7.

where

PM is the peak pressure at the measurement point,

Pb is the initial peak pressure at the borehole wall,

RM is the distance from the measurement point to the borehole center O, and

R0 is the borehole radius.

LM denotes the perpendicular distance from the measurement point to the explosive center O

e, and

L0 represents half the length of the charge.

α is the pressure attenuation index.

From the coefficient of determination

R2 in

Table 7, it can be seen that the fitting performance is generally better on the coupled side. The

R2 values in the radial direction are mostly above 0.99, and those in the axial direction exceed 0.96. In contrast, the

R2 values on the decoupled side are relatively lower, particularly under water coupling at low

K values, where the value in the radial direction approaches 0.90. This deviation is likely caused by enhanced reflected waves under low-K water conditions, which locally increase pressure and result in slight deviations from the power function trend, as illustrated in

Figure 11c,f. Nevertheless, the current fitting curves adequately describe the overall pressure decay characteristics. The variation in the attenuation index

α with respect to the decoupling ratio

K is shown in

Figure 12. On the coupled side, both the radial direction and axial direction attenuation indices increase with

K for three media, indicating stronger stress wave attenuation as the charge diameter decreases and the coupling layer thickens. Among them, air coupling exhibits the most significant attenuation, with

α increasing from 1.68 to 2.563 in the radial direction and from 4.733 to 7.477 in the axial direction. This suggests that explosive pressure attenuates rapidly in the near-field borehole wall region and that axial propagation is severely limited, as shown in

Figure 11a,d. Sand coupling follows, with

α increasing from 1.434 to 1.931 in the radial direction and from 2.197 to 5.382 in the axial direction. Water coupling shows the slowest attenuation, with

α increasing from 1.403 to 1.859 in the radial direction and from 1.592 to 3.162 in the axial direction, demonstrating superior far-field pressure transmission capabilities, as shown in

Figure 11c,f.

Compared with the coupled side, the pressure decay rate on the decoupled side is lower, less influenced by the decoupling ratio

K, and more sensitive to the coupling medium. Under air coupling, the attenuation index

α remains relatively stable in both the radial and axial directions, ranging from 0.942 to 0.995 and from 0.902 to 1.312, respectively. This can be attributed to the lower peak pressure on the decoupled side, resulting in a smaller crushed zone, as shown in

Figure 11a,d. In contrast, sand medium exhibits greater fluctuations in the attenuation index

α, with values ranging from 1.244 to 1.629 in the radial direction and from 1.459 to 2.204 in the axial direction. Water coupling yields the most consistent attenuation behavior, with the attenuation index

α increasing from 0.996 to 1.088 in the radial direction and from 1.241 to 1.480 in the axial direction. These results suggest that water coupling maintains better long-range pressure transmission characteristics even on the decoupled side.

Furthermore, the attenuation index in the axial direction is generally higher than that in the radial direction, indicating that the pressure decays more rapidly along the axial path. These findings demonstrate that selecting an appropriate combination of decoupling ratio K and coupling medium can effectively regulate the propagation range of the pressure wave, mitigate the impact on non-target areas, and ultimately contribute to a more controllable and efficient blasting outcome.

3.3. Effect of Eccentricity Coefficient on EDC Blasting

Building on the previous analysis, the influence of explosive position on blast pressure distribution and damage pattern under different coupling medium conditions was further investigated. To quantitatively describe the explosive position within the borehole, the eccentricity coefficient

Ee was defined as the ratio of the distance from the charge center to the borehole center to the difference between the borehole diameter and the charge diameter. Four representative values were selected, 0, 1/3, 2/3, and 1, corresponding to a progression from concentric placement to full contact with the borehole wall.

Figure 13 illustrates the pressure evolution and crack propagation process for different eccentricity coefficients under the condition of

K = 20/5. At the onset of detonation, the blast pressure wave exhibits an ellipsoidal, outward-expanding pattern. When

Ee = 0 (concentric loading), both the explosion pressure field and the resulting damage zone are symmetrically distributed around the borehole center. As

Ee increases, the center of gravity of the pressure and damage distributions shifts progressively toward the eccentric side. This is manifested as an enlarged pressure field and an expanded damage zone on the coupled side of the borehole.

The corresponding blast-induced fracture networks are shown in

Figure 14. When

Ee = 0, symmetric damage zones are observed on the top surfaces of the rock specimens for all coupling media. Notably, under air coupling, the specimen surface exhibits no visible crushed zone and only a few short radial cracks, primarily due to the high compressibility of air, as previously discussed. As the eccentricity coefficient

Ee increases, the difference in damage between the two sides of the specimen becomes more apparent. Under air and water coupling, the asymmetry is relatively minor, whereas sand coupling displays a pronounced eccentric damage pattern characterized by dense cracking on the coupled side and sparse cracking on the decoupled side.

Figure 15 presents the volume ratios and fracture eccentricity

δ for each damage pattern region under different eccentricity coefficients. It is evident that the explosive position significantly affects the degree of damage eccentricity, while the overall damage volume remains relatively constant. Combined with the pressure–time histories at the monitoring points in

Figure 16, it can be seen that when

Ee = 0, the pressure responses on both sides are nearly identical, resulting in no observable eccentricity in the damage distribution. As

Ee increases, the coupled side experiences more rapid stress loading, higher peak pressure, and a longer duration, leading to an expanded damage zone. In contrast, the decoupled side exhibits delayed pressure transfer, lower peak pressure, and a more limited damage extent. This disparity leads to a continuous increase in the fracture eccentricity

δ. Furthermore, the choice of coupling medium modulates the magnitude of the eccentricity effect. Under water coupling, even moderate eccentricity coefficients (

Ee = 1/3 − 2/3) may result in a reversed eccentricity distribution, thereby weakening the damage asymmetry associated with explosive position. By contrast, air and sand coupling exhibit more prominent eccentricity effects. Among them, air coupling produces stronger asymmetry at lower eccentricity coefficients (

Ee ≤ 1/3), though the growth of

Ee tends to level off at higher values. In sand coupling, the eccentric damage increases more steeply beyond

Ee > 1/3, with a marked rise in the eccentricity of the total damage zone

δd.

The same Equation (12) was employed to fit the decay trend of peak pressure with distance along the radial and axial directions at various eccentricity coefficients. As shown in

Figure 17, the current equation provides a good fit to the pressure attenuation behavior at different explosive positions.

As shown in

Table 8 and

Figure 18, when the eccentricity coefficient

Ee gradually increases from 0 to 1 (the explosive shifts closer to the borehole wall), the distribution of the explosion pressure field begins to exhibit a clear and intensifying eccentricity effect. This pressure decay behavior closely resembles the trend observed under increasing decoupling ratio

K. On the coupled side, the attenuation indices in both radial and axial directions increase significantly with the eccentricity coefficient

Ee. This indicates that near-field pressure decays more rapidly, while attenuation in the far field becomes more gradual. As shown in

Figure 17, most of the explosive energy is directed toward the side where the charge is positioned. Among three coupling media, air coupling shows the most pronounced increase, with the attenuation index

α rising from 1.084 to 2.374 in the radial direction and jumping from 1.513 to 7.016 in the axial direction—indicating sharp stress concentration and limited long-range propagation. Sand coupling follows with a moderate rise: the attenuation index

α increases from 1.149 to 1.818 in the radial direction, and from 1.889 to 4.330 in the axial direction. In contrast, water coupling remains the most stable, with the attenuation index

α changing only from 1.178 to 1.745 in the radial direction and from 1.646 to 2.471 in the axial direction. These results suggest that water as a coupling medium is more favorable for maintaining far-field pressure transmission under eccentric loading.

Compared with the coupled side, the pressure decay rate on the decoupled side is generally lower and shows limited sensitivity to increasing the eccentricity coefficient Ee. Instead, it is more strongly influenced by the properties of the coupling medium. Across all media, the attenuation indices on the decoupled side exhibit relatively small variations, and the coefficients of determination R2 are, in most cases, lower than those of the coupled side. For instance, under air coupling, the attenuation index α ranges from 0.996 to 1.182 in the radial direction, while α ranges from 1.057 to 1.517 in the axial direction. In the case of sand coupling, the radial and axial attenuation indices range from 0.974 to 1.495 and from 0.969 to 1.889, respectively. Water coupling shows the narrowest variation, with the attenuation index α varying between 1.046 and 1.178 in the radial direction and between 1.411 and 1.646 in the axial direction. These results suggest that water as a coupling medium is more favorable for maintaining stable and efficient far-field pressure transmission on the decoupled side under eccentric loading.