The Effect of Shallow Water-Bearing Sand on the Surface Subsidence Characteristics Under Thick Loose Formations

Abstract

1. Introduction

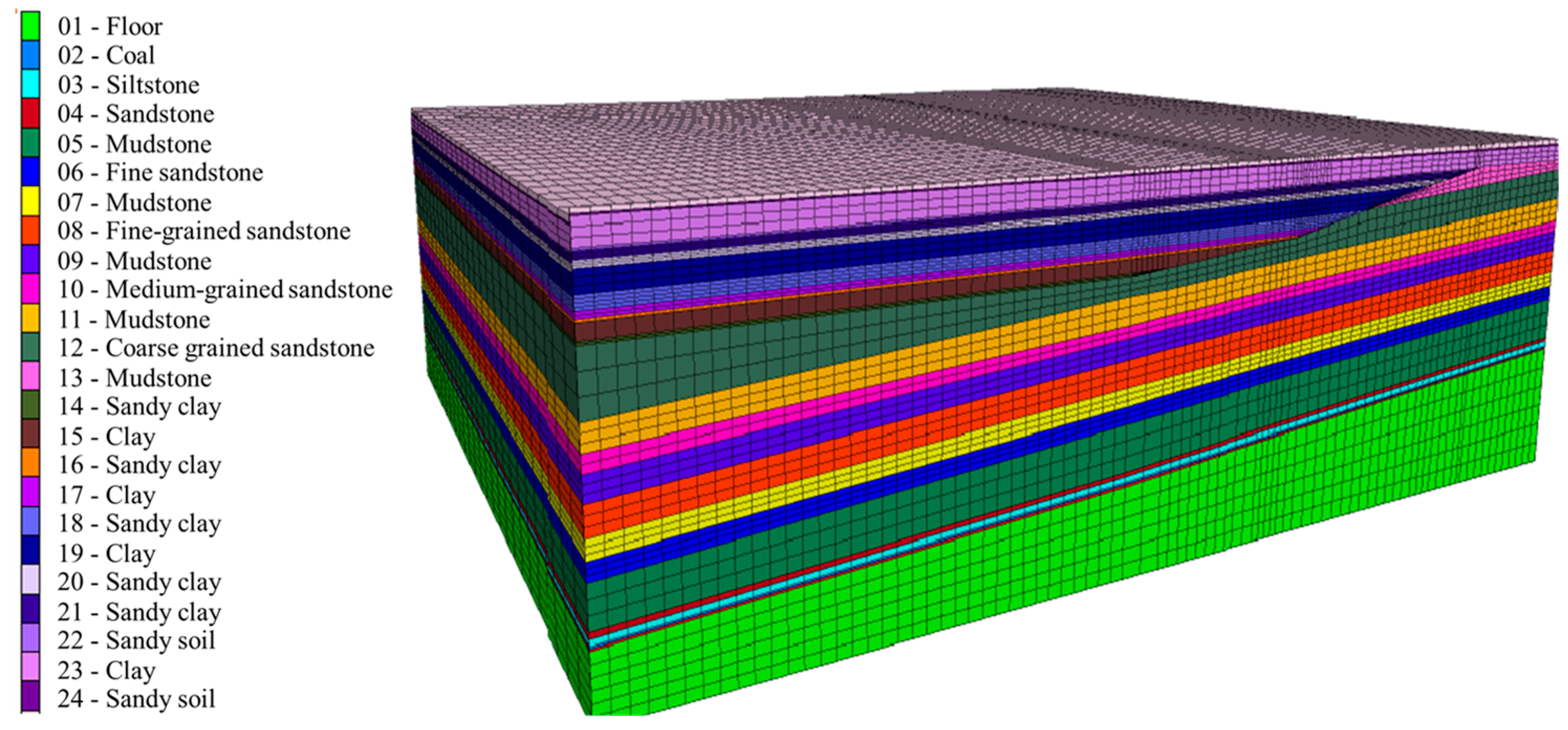

2. Simulation Analysis of Main Controlling Factors of Mining Subsidence

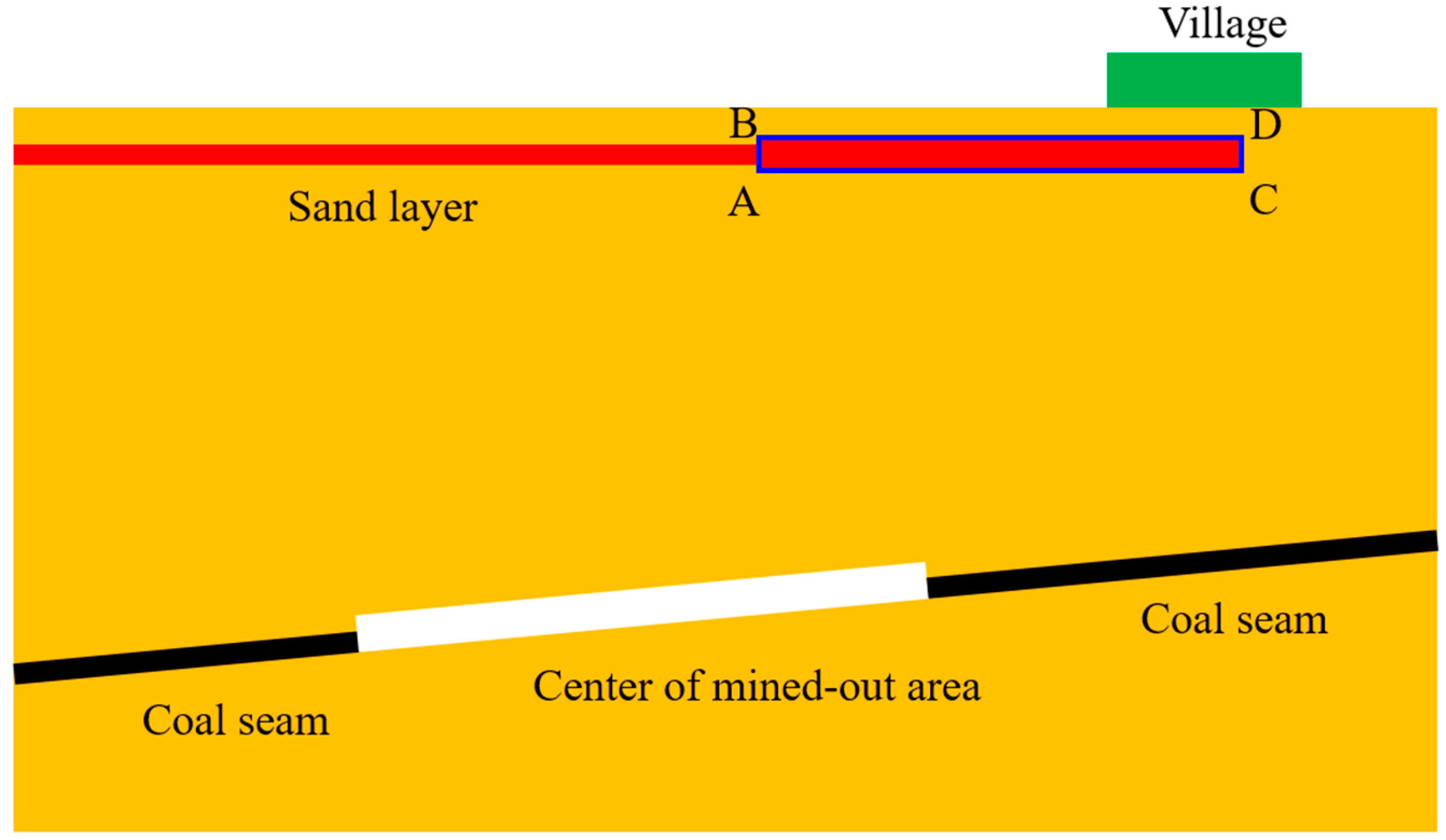

2.1. Scheme Design

2.2. Analysis of Subsidence Characteristics and Main Controlling Factors

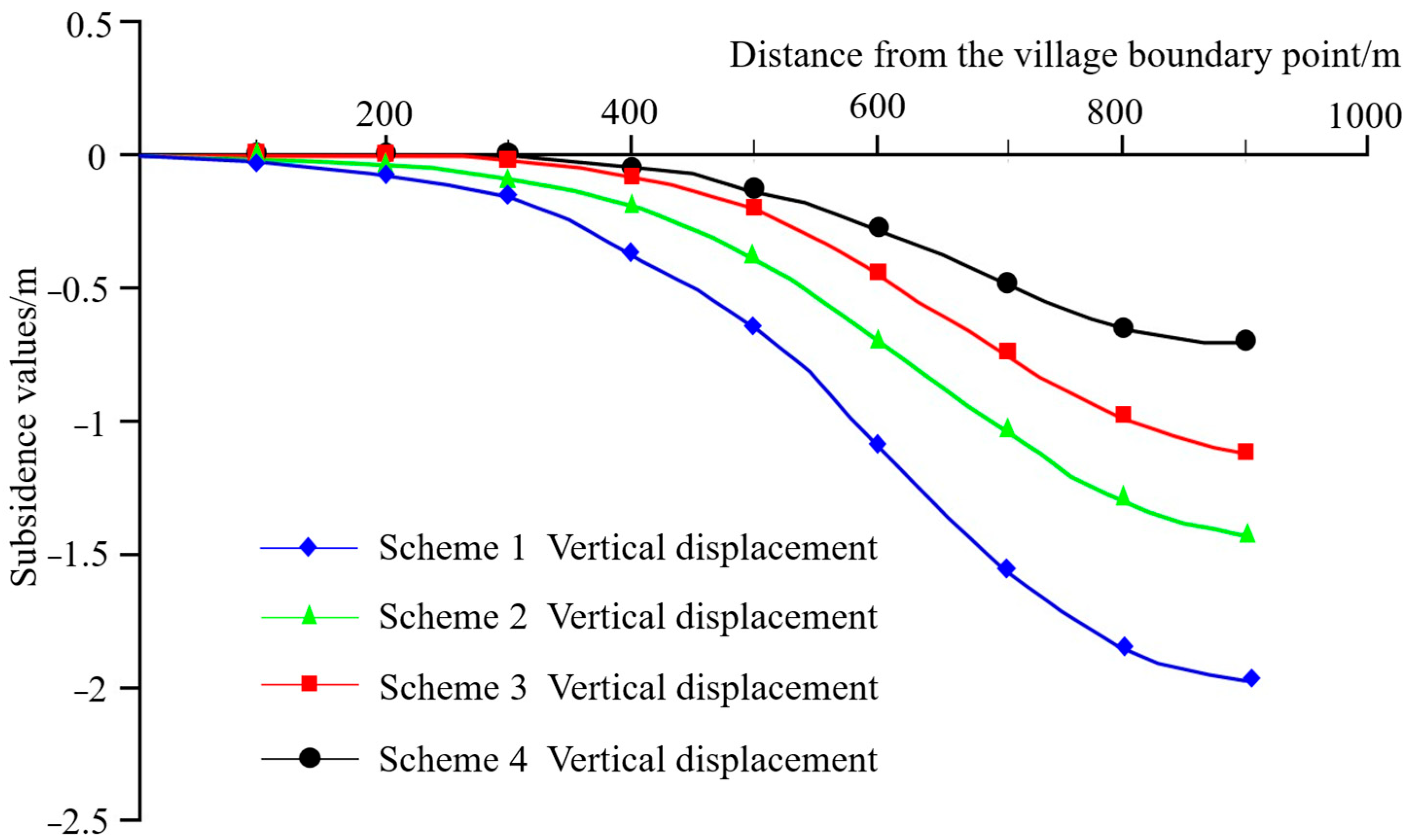

2.2.1. Subsidence Value

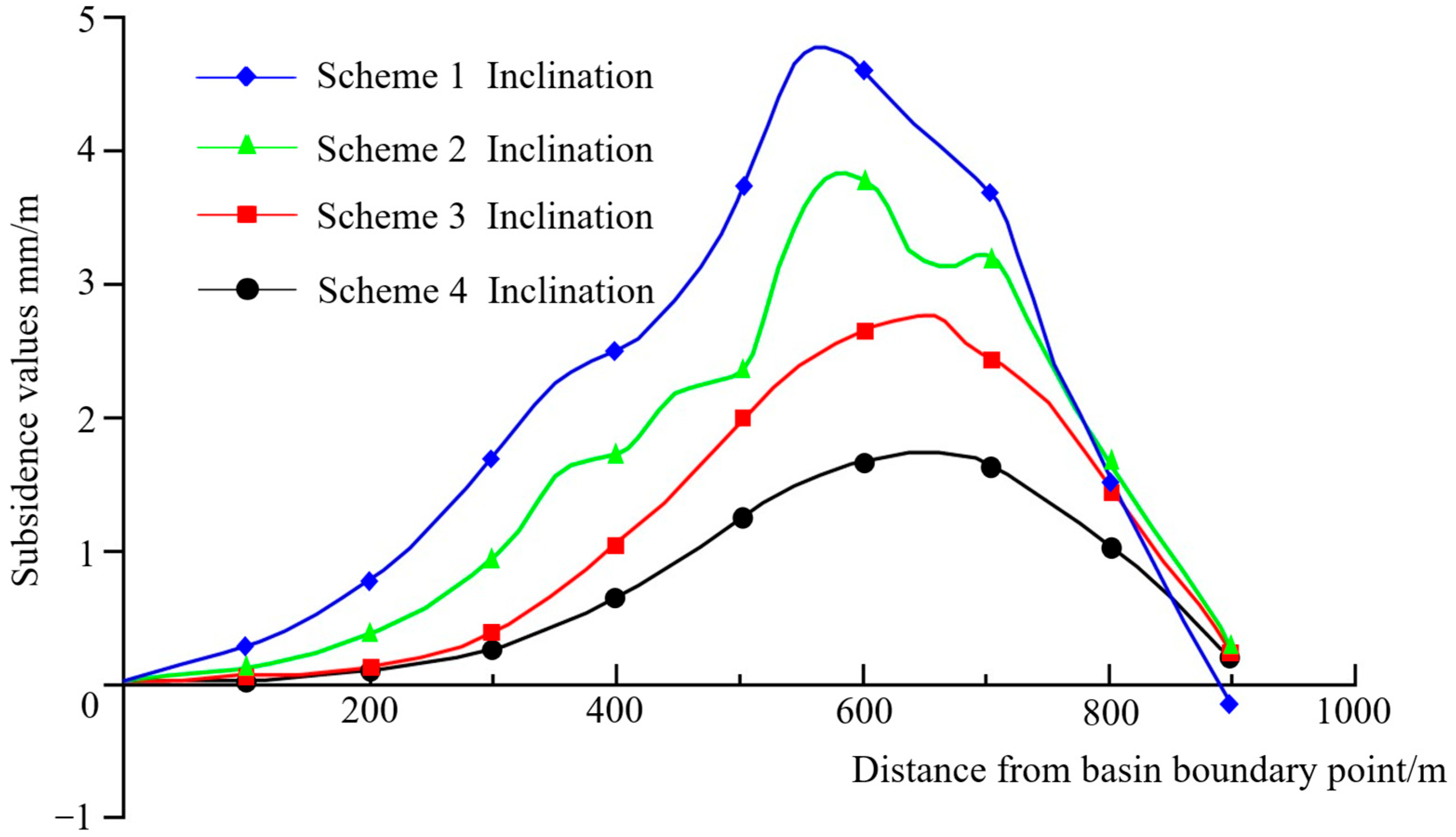

2.2.2. Inclination Value

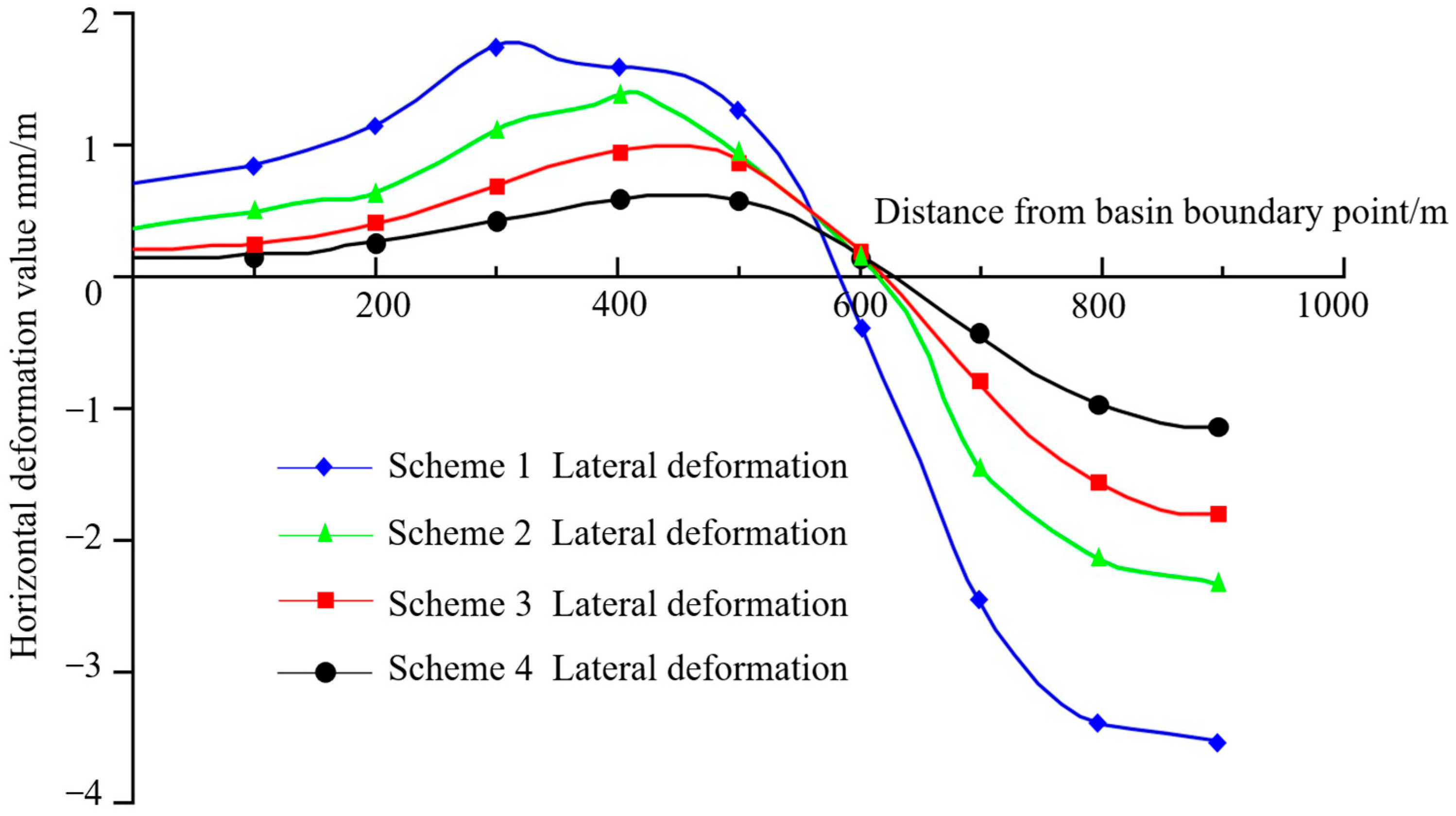

2.2.3. Horizontal Deformation

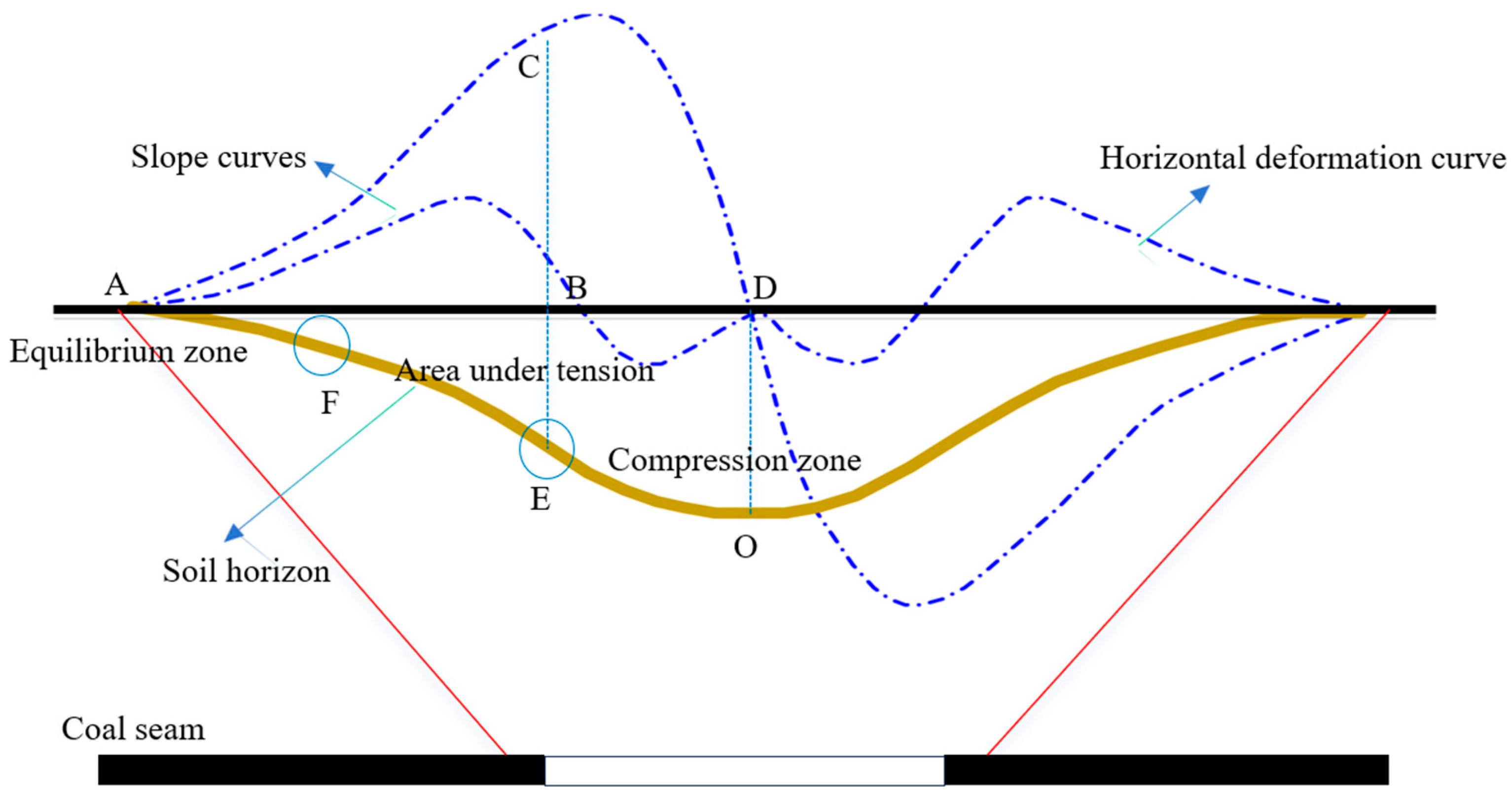

2.3. Influence of Water-Saturated Sand Interbed on Surface Subsidence

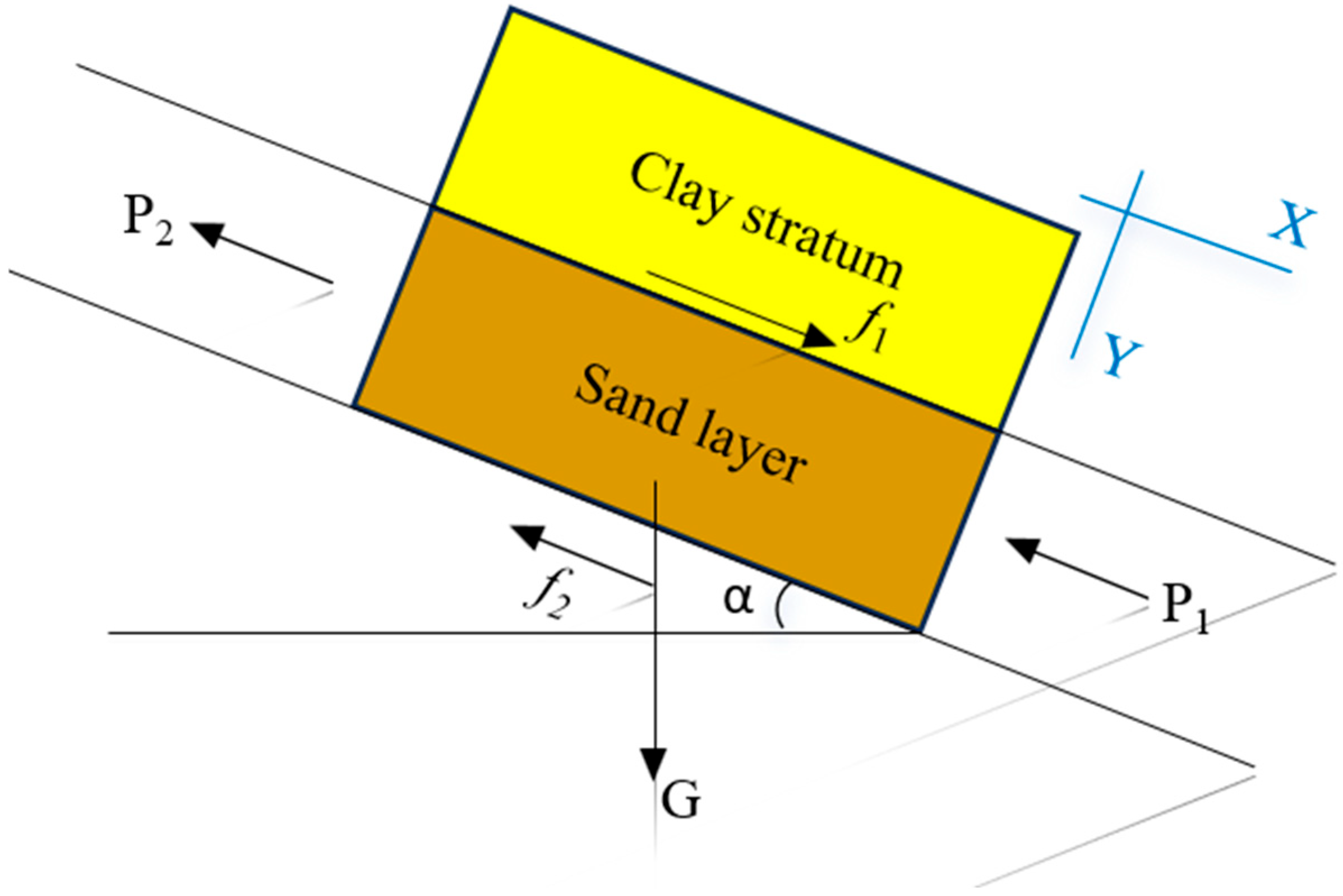

3. Mechanical Model of Sandy Soil Layer

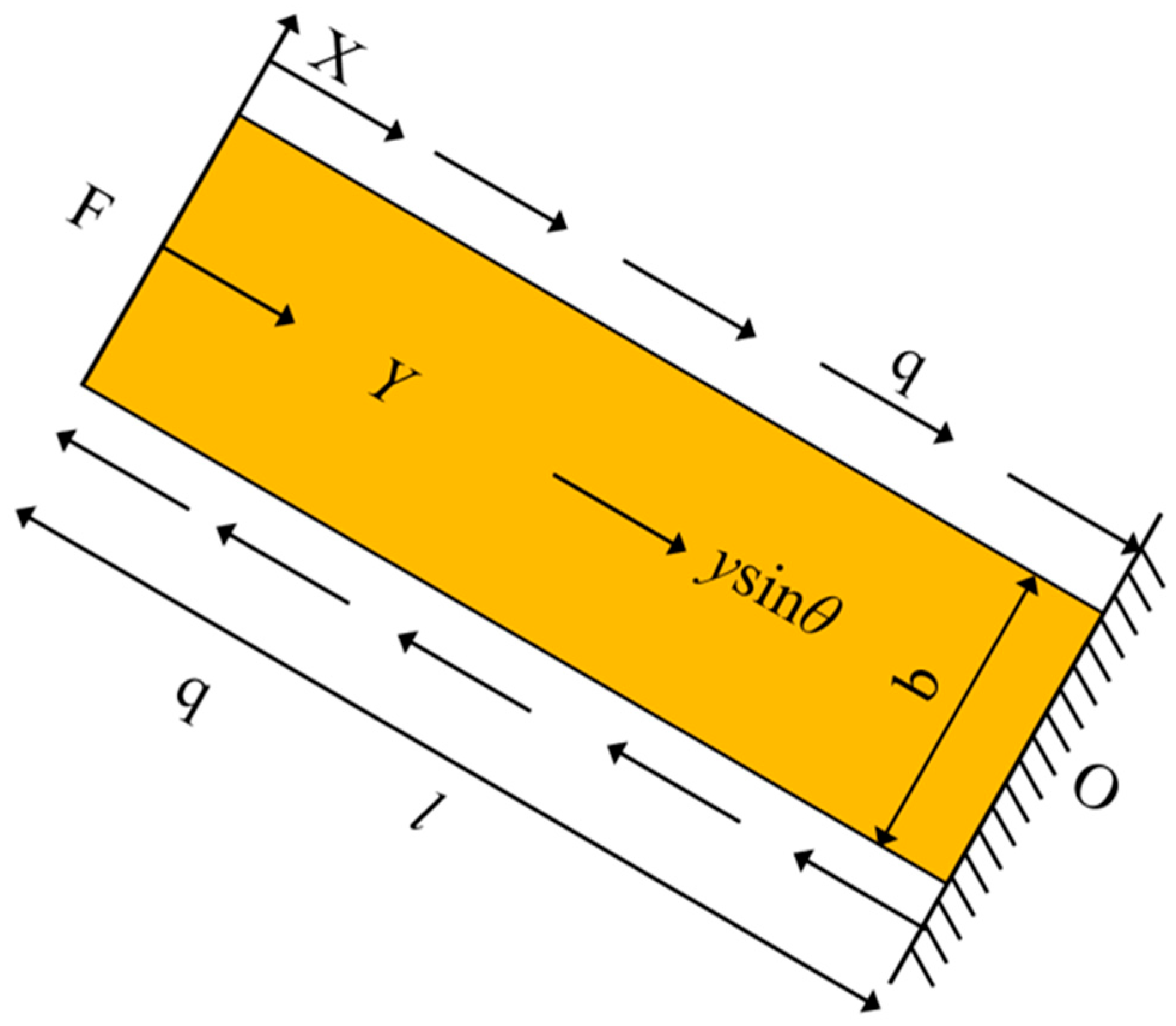

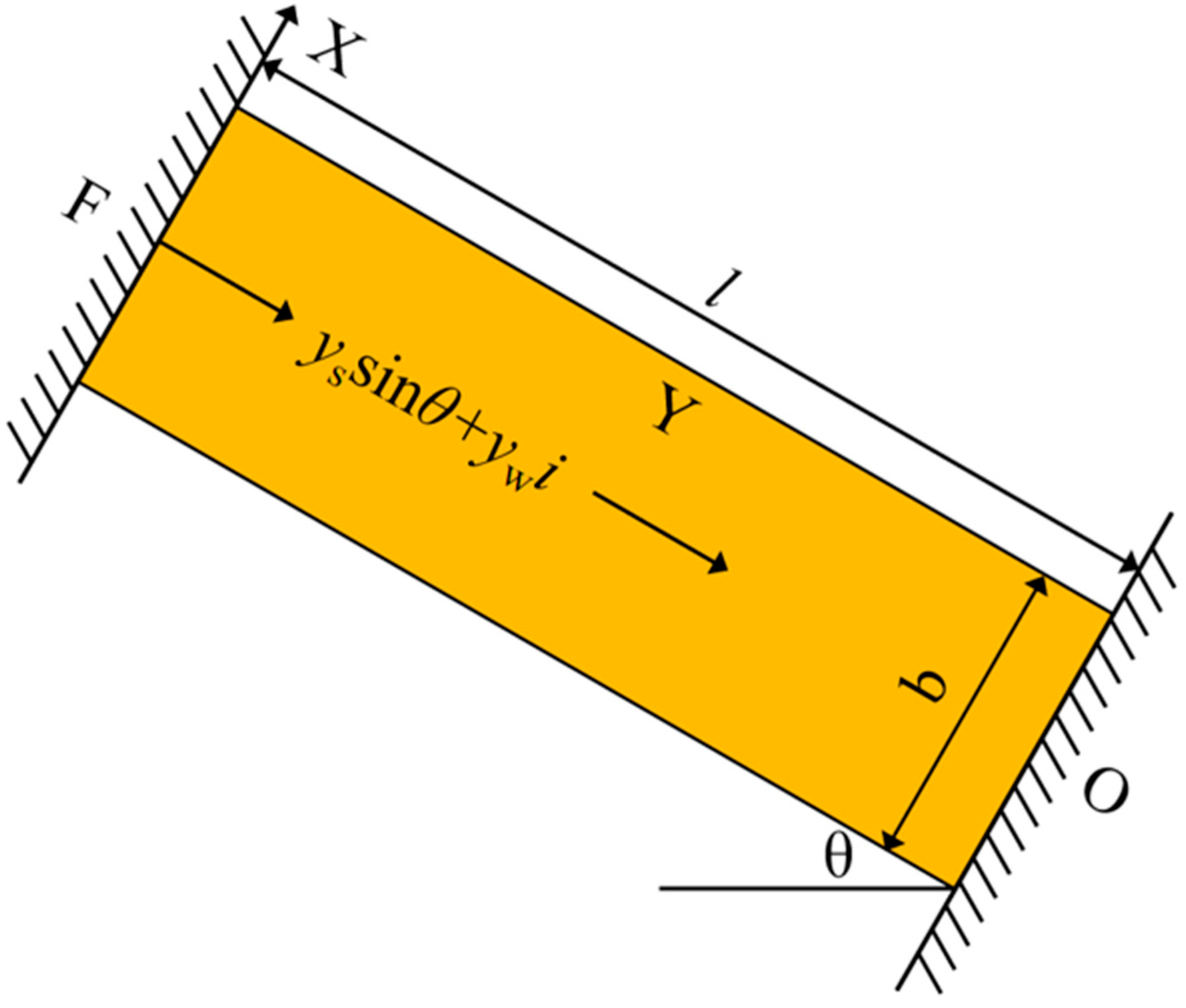

3.1. Stress State Analysis

3.2. Establishment of Mechanical Model

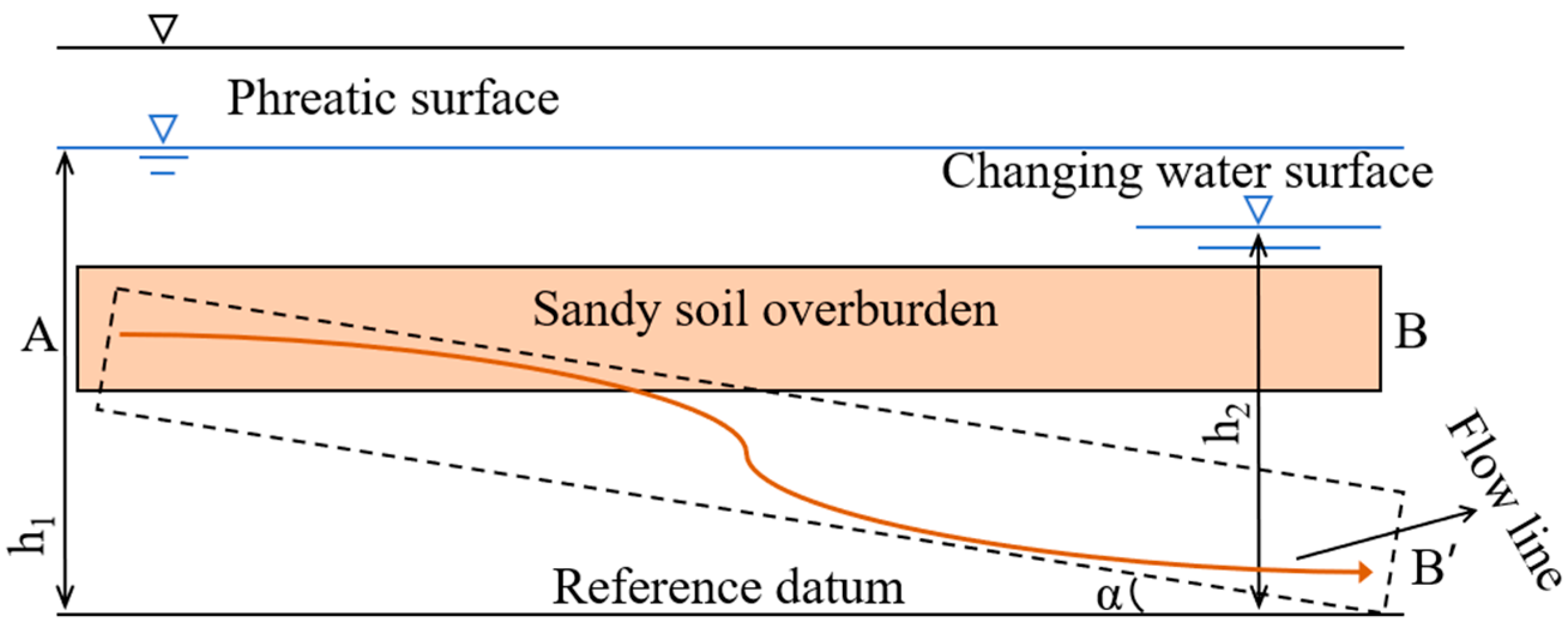

3.3. Seepage Model

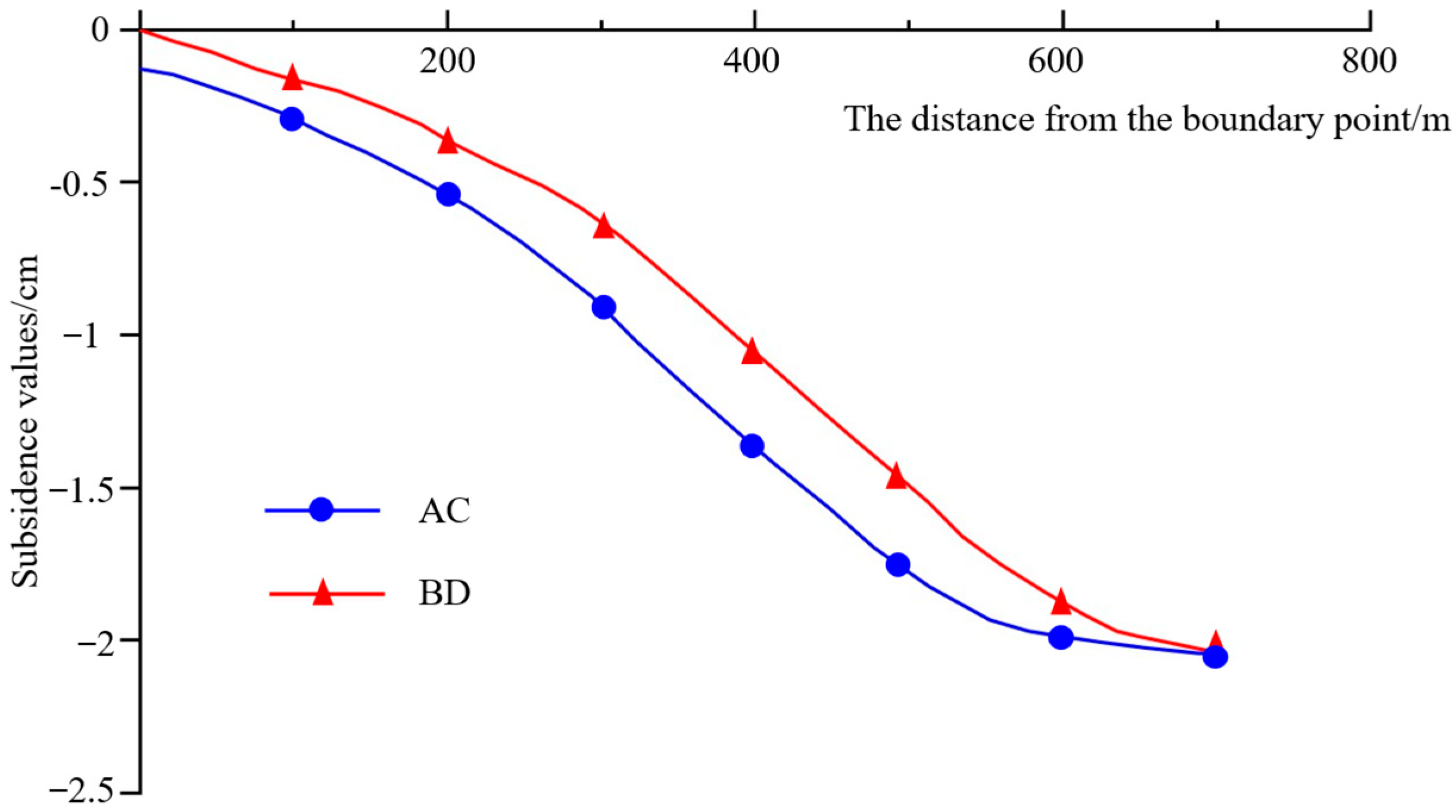

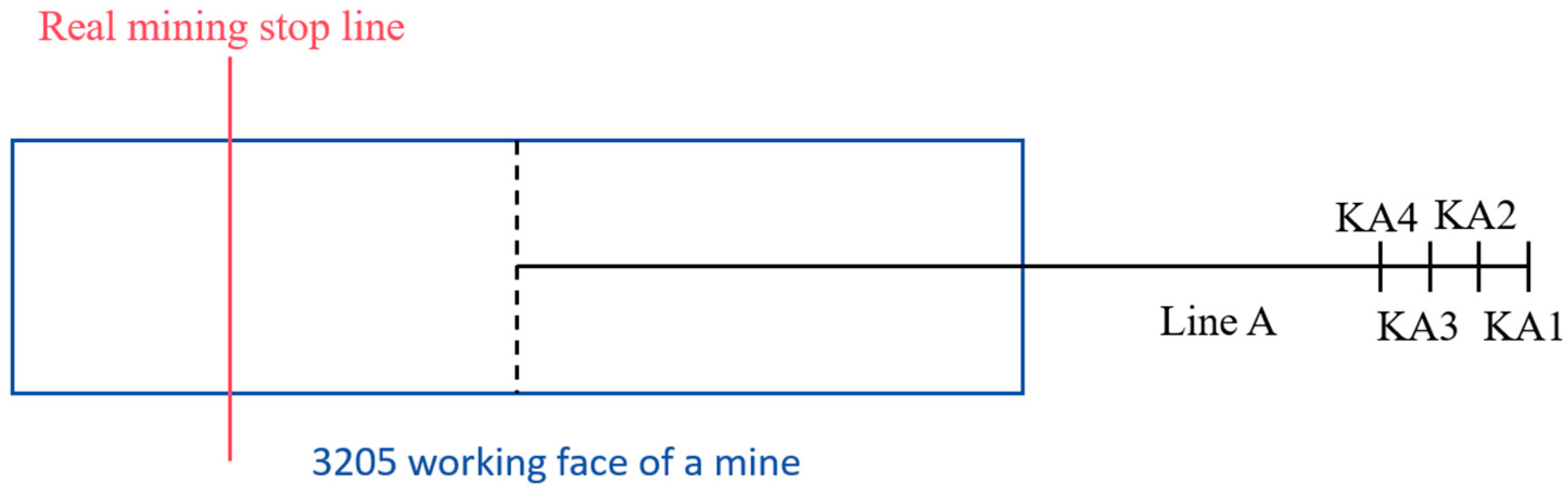

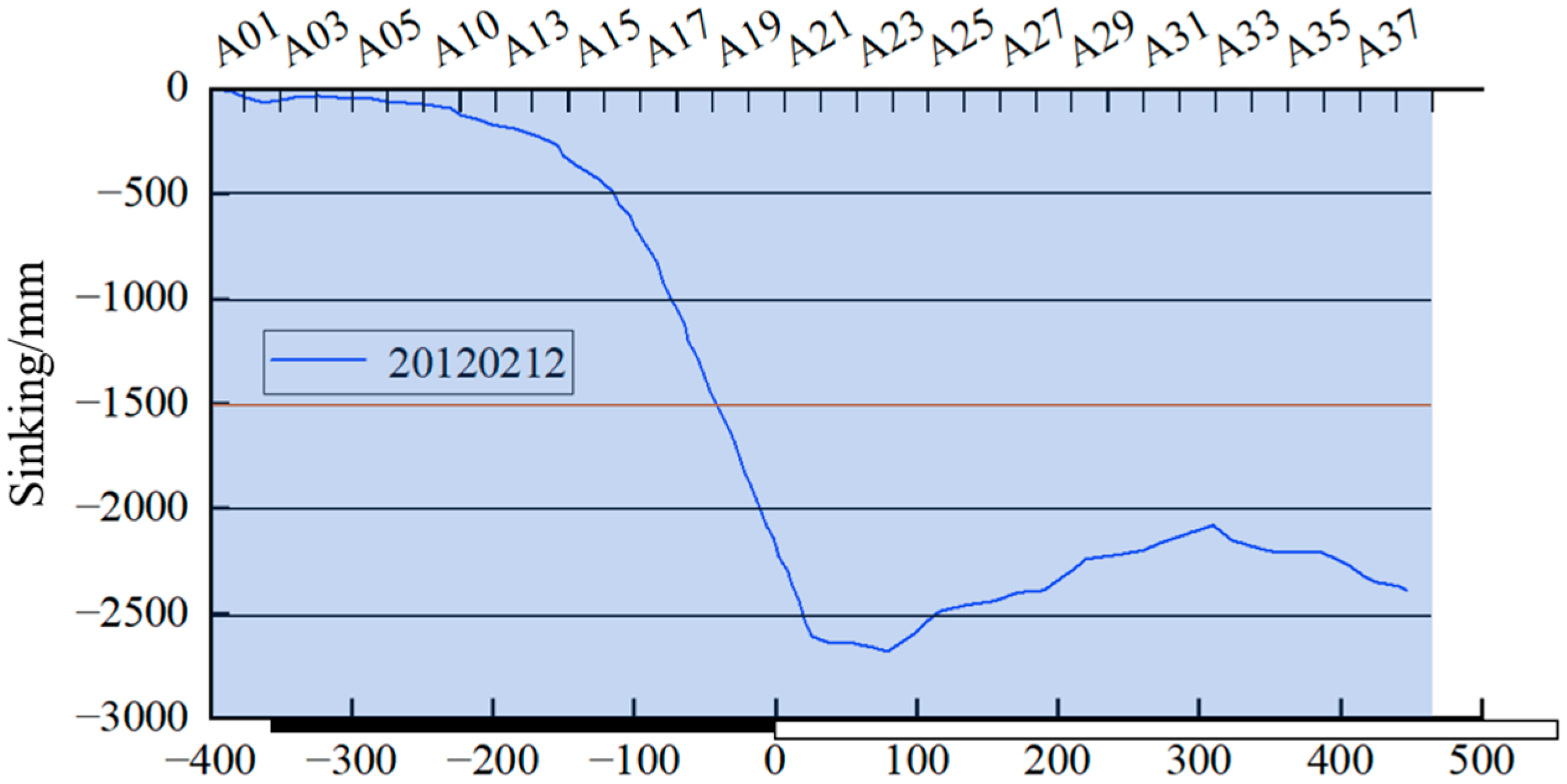

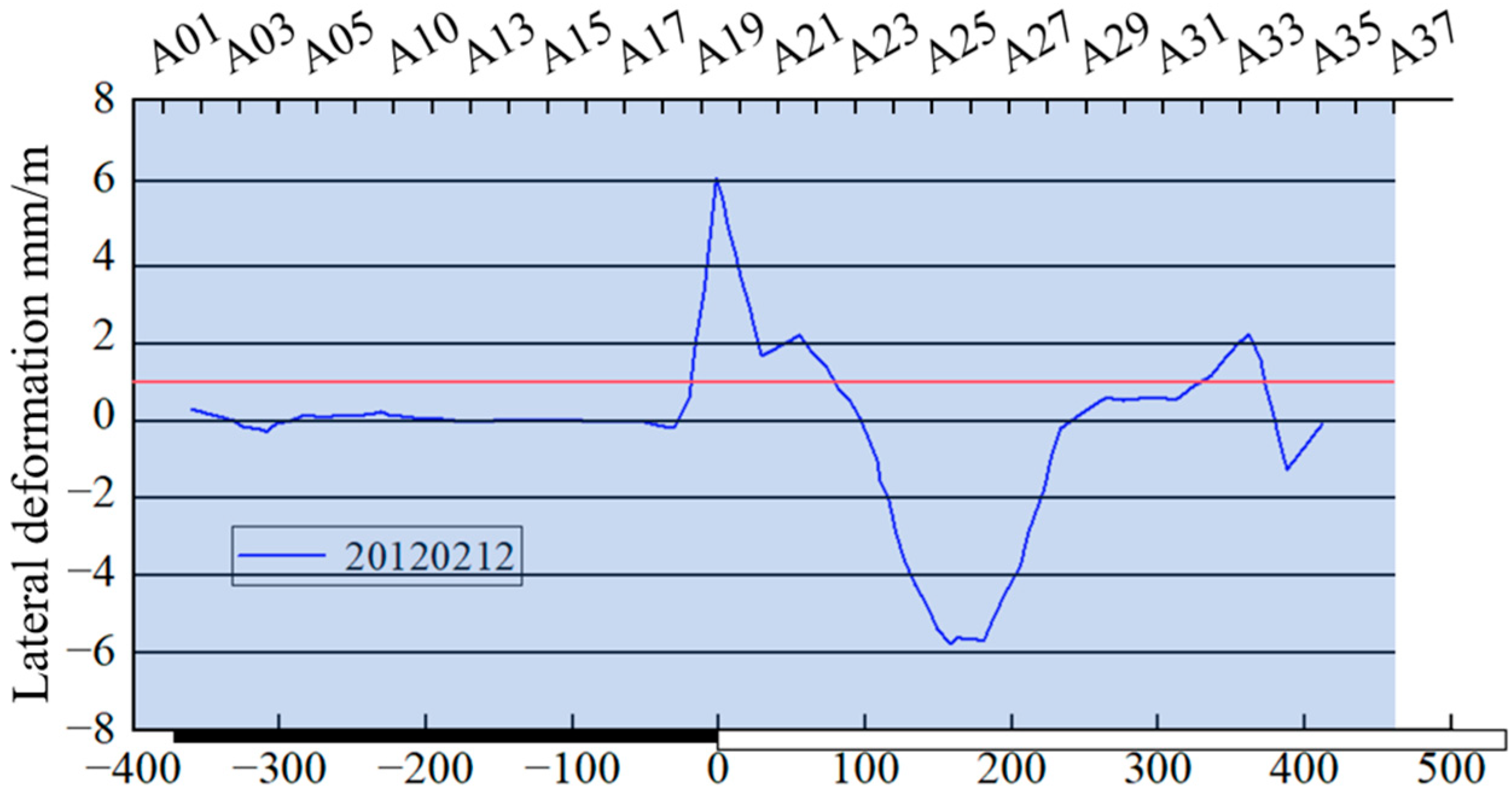

4. Engineering Verification

5. Conclusions and Prospect

- (1)

- By using FLAC3D numerical simulation to compare mining height, loose layer thickness, thin sand layer and whether seepage consolidation is considered, it is found that the change in unconsolidated layer thickness has a great influence on the maximum settlement value, inclination value and horizontal deformation value, which is the main reason for the increase in surface settlement range and building damage degree.

- (2)

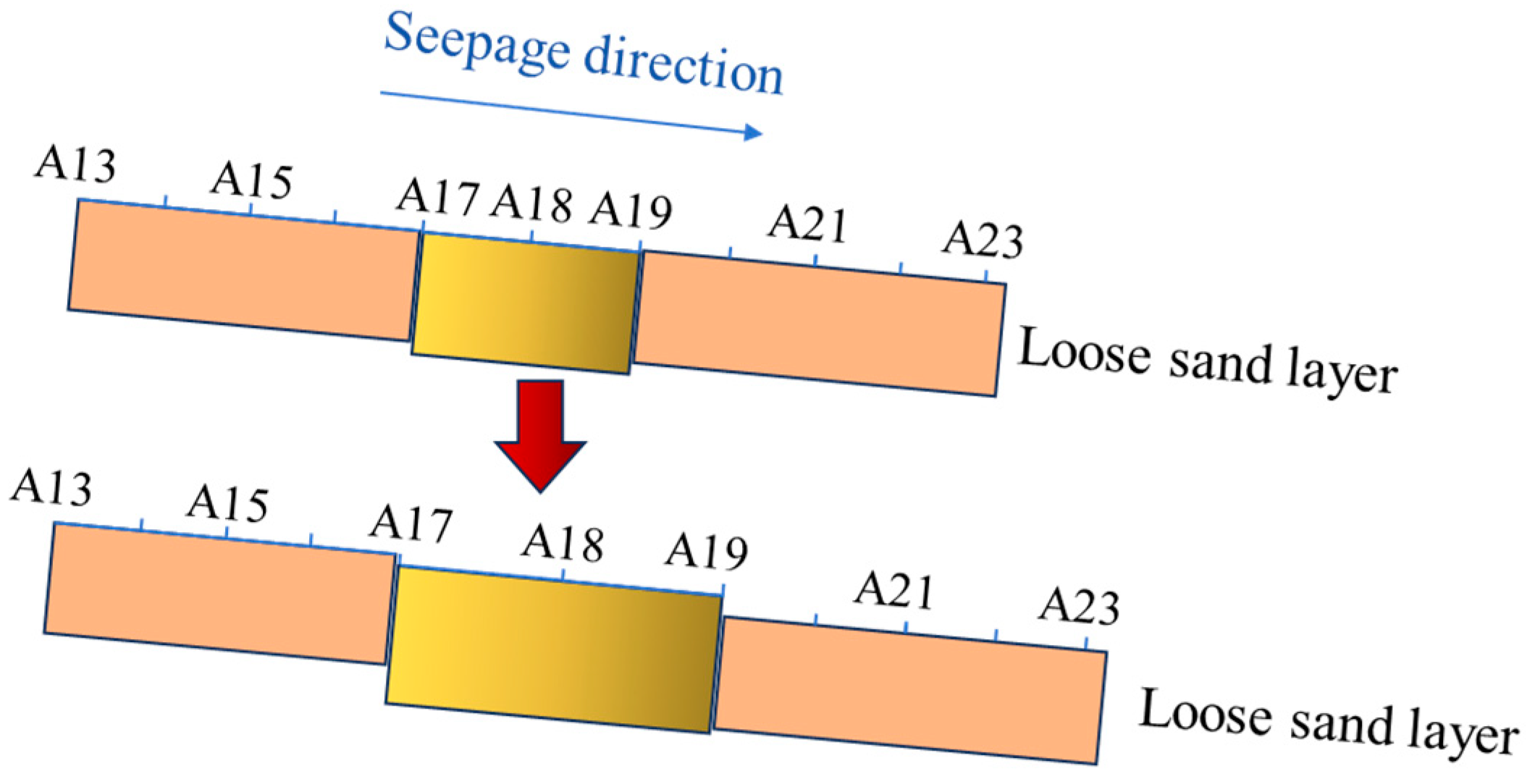

- After the water-bearing sand-interbedded soil layer is affected by mining, the subsidence value caused by seepage consolidation can be ignored; however, the interlayer horizontal movement value is relatively large, which increases the influence scope of surface subsidence. When the sandy soil layer reaches the critical hydraulic gradient, due to the small friction force between the sandy soil layer and the upper and lower contact surfaces, it is prone to large overall movement along the downhill direction of the basin, i.e., a “soil flow phenomenon” occurs.

- (3)

- By establishing a mechanical model of the sandy soil layer, the relationship between the stress state of the soil layer and surface deformation is reasonably explained. When the sand interbed is unsaturated soil, dislocation occurs between the upper and lower surfaces; the dislocation value of the upper and lower surfaces during the subsidence process is , which is proportional to the thickness and interlayer friction force. When the sand interbed is a saturated soil mass, a soil flow phenomenon occurs when the critical hydraulic gradient is reached, and the sandy soil layer shows overall movement; however, due to the absence of friction force on the bottom surface of the overlying soil layer, large displacement occurs, eventually leading to cracks on the surface.

- (4)

- Taking the 3205 working face of a certain mine as an example, the mining subsidence characteristics in its strike direction are studied. The analysis of monitoring data shows that under the influence of mining, the sandy soil layer in the unconsolidated layer moves integrally along the downhill direction of the basin (seepage direction), and a large displacement difference is generated with adjacent strata, causing discontinuous horizontal deformation. The measured results verify the regular conclusions of numerical simulation and theoretical analysis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.C.; Dai, H.Y. Subsidence Control and Special Mining; China University of Mining and Technology Press: Xuzhou, China, 2017. [Google Scholar]

- Gai, Q.; He, M.; Gao, Y.; Li, S. Mechanism of Floor Damage Reduction in Non-pillar Mining with Automatically Formed Roadway: A Model Test Study. Rock Mech. Rock Eng. 2025, 58, 9573–9600. [Google Scholar] [CrossRef]

- Apanowicz, B.; Milczarek, W.; Kowalski, A. Advanced InSAR-SBAS Method for Determining the Extent of Mining-Induced Deformations. Geocarto Int. 2025, 40, 2523428. [Google Scholar] [CrossRef]

- Dudek, M.; Sroka, A.; Tajdus, K.; Misa, R.; Mrochen, D. Assessment and Duration of the Surface Subsidence after the End of Mining Operations. Energies 2022, 15, 8711. [Google Scholar] [CrossRef]

- Tan, Z.X.; Wang, Z.S.; Li, Y.J.; Sun, X.M.; Deng, K.Z. Field Research on Ground Subsidence Rules of Intensive Fully-Mechanized Mining by Sublevel Caving. J. Min. Saf. Eng. 2008, 1, 59–62. [Google Scholar]

- Dudek, M.; Mrochen, D.; Sroka, A.; Tajdus, K. Integrating the Finite Element Method with Python Scripting to Assess Mining Impacts on Surface Deformations. Appl. Sci. 2024, 14, 7797. [Google Scholar] [CrossRef]

- Yu, X.Y.; Li, B.B.; Li, R.B.; Duan, W.S.; Liu, P.L. Analysis of Mining Damage in Huge Thick Collapsible Loess of Western China. J. China Univ. Min. Technol. 2008, 37, 43–47. [Google Scholar]

- Chen, J.J.; Chen, Y.; Guo, W.B.; Zou, Y.F. Study on Surface Movement Law Under the Condition of Thick Unconsolidated Strata. Coal Sci. Technol. 2013, 41, 95–97. [Google Scholar] [CrossRef]

- Xu, Y.C.; Cao, G.M.; Pan, H.B.; Chang, J.L.; Du, M.Z.; Hu, X.L. Analysis of Abnormal Reasons of Surface Deformation of Huoerxinhe Coal Mine. Coal Min. Technol. 2017, 22, 61–64. [Google Scholar] [CrossRef]

- Adhikary, D.P.; Guo, H. Modelling of Longwall Mining-Induced Strata Permeability Change. Rock. Mech. Rock. Eng. 2015, 48, 345–359. [Google Scholar] [CrossRef]

- Singh, R.; Rao, N.S.; Narayan, I.D.; Kumar, N.; Doley, T.; Bandyopadhyay, D.; Kisku, D.K. Application of 3D Numerical Simulations to Forecast Mine Seepage and Groundwater Flow Conditions with Respect to Progressive Coal Mining Activity. Environ. Dev. Sustain. 2024, 26, 22367–22388. [Google Scholar] [CrossRef]

- Park, J.; Lee, D.Y.; Kim, H.; Woo, N.C. Effects of Dry and Heavy Rainfall Periods on Arsenic Species and Behaviour in the Aquatic Environment Adjacent a Mining Area in South Korea. J. Hazard. Mater. 2023, 441, 129968. [Google Scholar] [CrossRef]

- Ge, C.; Li, P.; Zhang, M.; Yang, M. Identification of Surface Subsidence Risk in Deep Foundation Pits Using a Mamba Fusion Model. Eng. Appl. Artif. Intell. 2025, 161, 112077. [Google Scholar] [CrossRef]

- Xu, Q.; Li, P.; Xu, C.; Wang, S.; Zhang, S. Investigation of the Spatial Distribution of Tunnel Seepage under Varying Drainage Capacities in Water-Abundant Regions. Undergr. Space 2025, 23, 343–361. [Google Scholar] [CrossRef]

- Cui, X.; Li, P.; Wang, C.; Ge, Z.; Li, S.; Di, Q. Effect of Seepage Flow on Face Stability for a Tunnel in Water-Rich Silty Clay Overlying Sandy Cobble Strata. Tunn. Undergr. Space Technol. 2025, 161, 106539. [Google Scholar] [CrossRef]

- Cui, X.; Li, P.; Ge, Z.; Li, S.; Chen, Y. Experimental Study on Face Stability of Shield Tunnel in Water-Rich Inclined Composite Strata Considering Different Inclination Angles. Appl. Ocean Res. 2025, 154, 104323. [Google Scholar] [CrossRef]

- Cieslik, K.; Milczarek, W.; Warchala, E.; Kosydor, P.; Rozek, R. Identifying Factors Influencing Surface Deformations from Underground Mining Using SAR Data, Machine Learning, and the SHAP Method. Remote Sens. 2024, 16, 2428. [Google Scholar] [CrossRef]

- Zhao, G.B.; Guo, W.B.; Lou, G.Z.; Ma, Z.B. Simulation of high-strength mining strata and surface movement in thick and loose layers. China Saf. Sci. J. 2008, 28, 130–136. [Google Scholar] [CrossRef]

- Zuo, J.P.; Sun, Y.J.; Wang, J.T.; Shi, Y.; Wen, J.H. Mechanical and numerical analysis of “analogous hyperbola” movement of overlying strata after full mining extraction. J. Min. Saf. Eng. 2018, 35, 71–77. [Google Scholar] [CrossRef]

- Zuo, J.P.; Sun, Y.J.; Qian, M.G. Movement mechanism and analogous hyperbola model of overlying strata with thick alluvium. J. China Coal Soc. 2017, 42, 1372–1379. [Google Scholar] [CrossRef]

- Wan, Z.H.; Zheng, S.Y.; Ii, L.; Guo, Q.K.; Liu, Z.; Miao, W.; Xu, Y.C. Microseismic response characteristics of thin bedrock and thick loose layer working face in Jiaozuo mining area. J. Min. Strat. Control Eng. 1–10. [CrossRef]

- Meng, X.J.; Li, Y.; Zhang, G.C.; Guo, L.F.; Li, Q.W.; Shen, S.B.; Chen, M.; Zhou, G.L.; Lv, K. The evolution law of overburden structure movement in mining under extremely thick loose layer and unequal thickness bedrock. J. Min. Strat. Control. Eng. 2024, 6, 115–129. [Google Scholar] [CrossRef]

- Ji, Y.L.; Zhang, S.P.; Zhu, H.H.; Zhang, Z.Y.; Song, X.Z.; Wang, L. Friction-seepage coupling mechanism and control technology of rock mass interface in deep ground engineering: Review and prospect. J. Min. Strat. Control Eng. 1–50. [CrossRef]

- Liu, Y.X.; Dai, H.Y.; Jiang, Y.D. Model Test for Mining-Induced Movement Law of Rock and Soil Mass Under Thick Unconsolidated Layers. J. Min. Saf. Eng. 2012, 29, 700–706. [Google Scholar]

- Xu, L.J.; Zhu, N.; Ma, R.Z.; Liu, X.P. Water loss settlement simulation of thick unconsolidated confined aquifer layer. J. Min. Saf. Eng. 2015, 32, 821–826. [Google Scholar] [CrossRef]

- Yi, S.H.; Zheng, Z.G.; Teng, Y.H. Surface Subsidence Rule and Mechanism of Full-mechanized Caving Mining Face under Thick Loose Bed. Coal Min. Technol. 2011, 16, 9–12. [Google Scholar] [CrossRef]

- Liu, C.J. Study on the Law of Surface Movement and Deformation in the Third Panel Mining of Tingnan Coal Mine. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2019. [Google Scholar]

- Li, X.L.; Guo, W.B.; Zhao, G.B. Study on influence of compression characteristics of super thick alluvium on mining subsidence. China Saf. Sci. J. 2018, 28, 135–141. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Liu, H.L.; Zhao, K. Influential factors on surface subsidence in stripe mining under thick unconsolidated layers and thin bedrock. J. Min. Saf. Eng. 2016, 33, 1065–1071. [Google Scholar] [CrossRef]

- Bai, B.; Zhang, W.Q. Study on Time Series Model of Loose Layer Settlement in Thick Loose Layer Mining. Coal Technol. 2018, 37, 176–177. [Google Scholar] [CrossRef]

- Wang, C.H. Study on Geological Characteristics and Surface Subsidence Law of Coal Seam Mining Under Thick Loose Layer. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2018. [Google Scholar]

- He, Y.; Zhang, J.; Yang, T.; Wu, J.; Gao, S.; Sun, J. Study on the Bearing Structure of Key Strata and the Linkage Evolution Mechanism of Surface Subsidence in Shallow Coal Seam Mining. Appl. Sci. 2024, 14, 9608. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, H.; Gao, R.; Zhao, Y. Surface Subsidence Characteristics of Mining Panel Layout Configuration with Multi-Seam Longwall Mining. Processes 2023, 11, 1590. [Google Scholar] [CrossRef]

- Li, D.; Cheng, S.; Liu, N.; Liu, Z.; Sun, Y. Numerical Simulation Study on the Distribution Characteristics of Precipitation Seepage Field in Water-Rich Ultra-Thick Sand and Gravel Layer. Water 2023, 15, 3720. [Google Scholar] [CrossRef]

- He, Q.; Liu, H.; Wei, L.; Zhang, Z. Analysis of the Driving Factors for Land Subsidence in the Northern Anhui Plain: A Case Study of Bozhou City. Water 2025, 17, 1854. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Li, S.; Gao, Y. Study on strike failure characteristics of floor in a new type of pillarless gob-side entry retaining technology above confined water. Tunn. Undergr. Space Technol. 2025, 161, 106596. [Google Scholar] [CrossRef]

- Bai, E.; Guo, W.; Tan, Y.; Huang, G.; Guo, M.; Ma, Z. Roadway Backfill Mining with Super-High-Water Material to Protect Surface Buildings: A Case Study. Appl. Sci. 2020, 10, 107. [Google Scholar] [CrossRef]

- Gai, Q.; Gao, Y.; Zhang, X.; He, M. A new method for evaluating floor spatial failure characteristics and water inrush risk based on microseismic monitoring. Rock. Mech. Rock. Eng. 2024, 57, 2847–2875. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Gao, Y.; Fei, Y. Research on floor failure characteristics of dip direction in non-pillar mining with automatically formed roadway above confined water. Eng. Geol. 2025, 344, 107844. [Google Scholar] [CrossRef]

- Chen, C.; Hu, Z.Q. Current status and progress on the application of key stratum theory in mining subsidence. J. Min. Sci. Technol. 2017, 2, 209–218. [Google Scholar] [CrossRef]

- Yang, X.; Kang, X.; He, M.; Wang, Y.; Zhang, J.; Shi, Z.; Chen, Y. Development Characteristics and Prediction Methods of the “Three Zones” in Overlying Strata Under the 110 Mining Method. Rock Mech. Bull. 2026, 5, 100234. [Google Scholar] [CrossRef]

- Hou, S.; He, M.; Yang, J.; Zhang, J.; Wang, Y.; Kang, X.H.; Han, Z.; Du, F.K. A Green Coal Mining Method for Protecting Roadways and Overlying Strata. Rock Mech. Bull. 2025, 4, 100192. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.W.; Zhu, Z.B.; Deng, D.X.; Jiang, N.S. Integrative Solution of Stress Evolution in Overburden Roof Strata During the Coal Seam Mining by Application of Complex Variable Functions Methodology. Rock Mech. Bull. 2026, 5, 100236. [Google Scholar] [CrossRef]

| Material Type | Density (kg/m3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Cohesion (MPa) | Friction Angle (°) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Floor | 2600 | 12 | 7.5 | 4.5 | 34 | 2.2 |

| Coal seam | 1400 | 2.8 | 1.6 | 2 | 30 | 1.4 |

| Siltstone | 2620 | 15 | 11 | 6 | 35 | 3.2 |

| Sandstone | 2650 | 18 | 13 | 8.5 | 40 | 4.5 |

| Mudstone | 2500 | 10 | 6.5 | 3.5 | 30 | 1.8 |

| Fine sandstone | 2620 | 16 | 11.5 | 6.8 | 36 | 3.5 |

| Medium Sandstone | 2660 | 22 | 15 | 10.5 | 40 | 5.2 |

| Coarse sandstone | 2680 | 26 | 18.5 | 12.5 | 43 | 6.0 |

| Sandy clay | 2000 | 0.15 | 0.08 | 0.1 | 26 | 0.05 |

| Clay | 1850 | 0.08 | 0.04 | 0.06 | 22 | 0.03 |

| Sandy soil | 1900 | 0.25 | 0.15 | 0.005 | 34 | 0.03 |

| Scheme | Height Mining (m) | Thickness of Loose Layer (m) | Thin Layer of Sand | Seepage Consolidation |

|---|---|---|---|---|

| 1 | 6 | 40–160 | Nil | Leave out |

| 2 | 3 | 40–160 | Nil | Leave out |

| 3 | 6 | 68 | Nil | Leave out |

| 4 | 3 | 68 | Nil | Leave out |

| 5 | 6 | 68 | 3 m | Consideration |

| Serial Number | Scheme 1 | Scheme 2 | Scheme 3 | Scheme 4 | Scheme 5 |

|---|---|---|---|---|---|

| Maximum surface subsidence/m | 1.9 | 1.4 | 1.2 | 0.8 | 1.2 |

| Maximum tilt value (mm/m) | 4.7 | 3.8 | 2.8 | 1.6 | 2.8 |

| House damage level | II | II | I | I | I |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Q.; Gai, Q.; Song, H.; Gao, Y.; Xu, X.; Ma, Q.; Gao, H.; Li, Z. The Effect of Shallow Water-Bearing Sand on the Surface Subsidence Characteristics Under Thick Loose Formations. Water 2025, 17, 3156. https://doi.org/10.3390/w17213156

Fu Q, Gai Q, Song H, Gao Y, Xu X, Ma Q, Gao H, Li Z. The Effect of Shallow Water-Bearing Sand on the Surface Subsidence Characteristics Under Thick Loose Formations. Water. 2025; 17(21):3156. https://doi.org/10.3390/w17213156

Chicago/Turabian StyleFu, Qiang, Qiukai Gai, Hongxu Song, Yubing Gao, Xiaoding Xu, Qing Ma, Hainan Gao, and Zhun Li. 2025. "The Effect of Shallow Water-Bearing Sand on the Surface Subsidence Characteristics Under Thick Loose Formations" Water 17, no. 21: 3156. https://doi.org/10.3390/w17213156

APA StyleFu, Q., Gai, Q., Song, H., Gao, Y., Xu, X., Ma, Q., Gao, H., & Li, Z. (2025). The Effect of Shallow Water-Bearing Sand on the Surface Subsidence Characteristics Under Thick Loose Formations. Water, 17(21), 3156. https://doi.org/10.3390/w17213156