Research on Ship Carbon-Emission Monitoring Technology and Suggestions on Low-Carbon Shipping Supervision System

Abstract

1. Introduction

2. Ship Carbon Monitoring and Carbon Calculation Methods

2.1. Indirect Monitoring

2.1.1. BDN Tracking and Periodic Fuel Tank Inventory Checks

2.1.2. Bunker Fuel Oil-Tank Monitoring Onboard

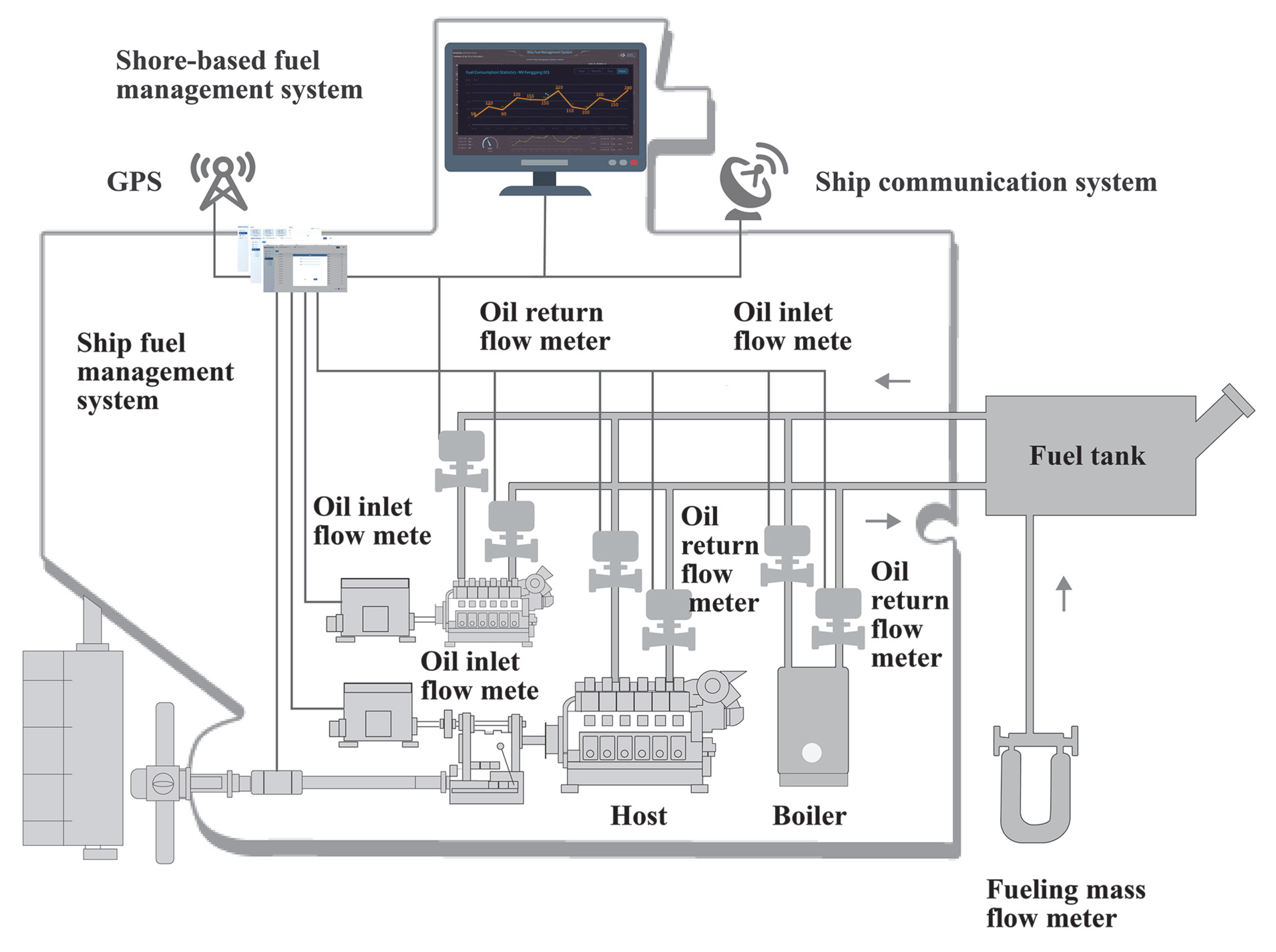

2.1.3. Flow-Meter Monitoring for Fuel Combustion Processes

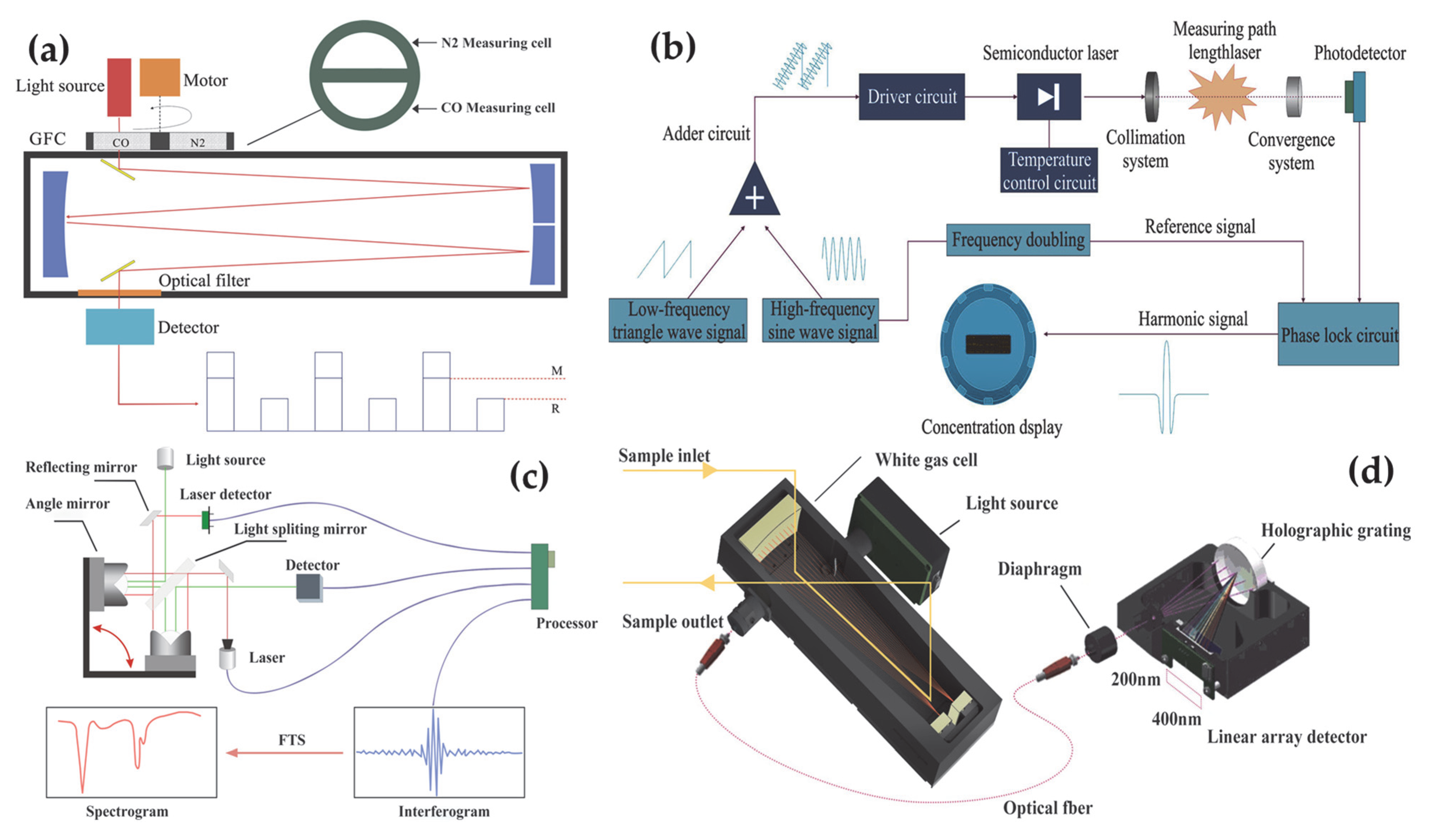

2.2. Direct Monitoring

2.3. Comparative Analysis of Monitoring Techniques

3. Suggestions for Developing a Low-Carbon Shipping Supervision System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IMO. Fourth IMO GCG Study 2020; IMO: Chiba, Japan, 2021; p. 29. [Google Scholar]

- Li, W.; Liang, J.; Zhang, L. Study on ship carbon emission regulation and low carbon shipping measures. Mar. Equip. Mater. Mark. 2024, 32, 85–87. [Google Scholar]

- Zeng, Q.; Zhang, C.; Liu, L. International Regulations on Shipping Carbon Intensity and Port State Control. China Marit. Saf. 2022, 12, 61–62. [Google Scholar]

- Official Journal of the European Union. Regulation (EU) 2023/957 of the European Parliament and of the Council of 10 May 2023; Official Journal of the European Union: Luxembourg, 2023. [Google Scholar]

- Chinese Classification Society (CCS). Shipping Low-Carbon Development Outlook 2023; Chinese Classification Society (CCS): Beijing, China, 2023. [Google Scholar]

- Cao, Z. Thoughts on collection and management of ship energy consumption data. Transp. Enterp. Manag. 2023, 38, 60–62. [Google Scholar]

- Chinese Classification Society (CCS). Implementation Guidelines for the Monitoring, Reporting and Verification of CO2 Emissions from Ships; Chinese Classification Society (CCS): Beijing, China, 2018. [Google Scholar]

- Chinese Classification Society (CCS). Guidelines for the Calculation and Certification of the Full Life Cycle Greenhouse Gas Emission Intensity of Marine Fuels; Chinese Classification Society (CCS): Beijing, China, 2023. [Google Scholar]

- Li, W.; Sun, X.; Li, H. Research on the status quo and construction of supervision system of carbon emission from ships in China. China Water Transp. 2021, 3, 122–125. [Google Scholar]

- Zhang, S.; Zuo, C.; Huang, Z. Comparative analysis of EU MRV regulations and IMO fuel consumption collection mechanism for ships. China Water Transp. 2017, 17, 79–81. [Google Scholar]

- IMO. Resolution MEPC.281: 2016 Guidelines for the Development of a Ship Energy Efficiency Management Plan (SEEMP); IMO: Chiba, Japan, 2020; p. 5. [Google Scholar]

- IMO. Circular MEPC.1/Circ.795: Guidelines for Verification of Ship Fuel Consumption Data; IMO: Chiba, Japan, 2021; p. 2. [Google Scholar]

- ISO 8217:2017; Petroleum Products—Fuels (class F)—Specifications of Marine Fuels. International Organization for Standardization: Geneva, Switzerland, 2017.

- Deng, S.; Mi, Z. A review on carbon emissions of global shipping. Mar. Dev. 2023, 1, 4. [Google Scholar] [CrossRef]

- Karjalainen, P.; Teinilä, K.; Kuittinen, N.; Aakko-Saksa, P.; Bloss, M.; Vesala, H.; Pettinen, R.; Saarikoski, S.; Jalkanen, J.-P.; Timonen, H. Real-world particle emissions and secondary aerosol formation from a diesel oxidation catalyst and scrubber equipped ship operating with two fuels in a SECA area. Environ. Pollut. 2022, 292 Pt A, 118278. [Google Scholar] [CrossRef] [PubMed]

- Wijaya, T.; Tjahjowidodo, T.; Thepsithar, P. Real time ship exhaust gas monitoring for compliance to SOx and NOx regulation and CO2 footprint. Sun Above Horiz. Meteoric Rise Sol. Ind. 2014, 5, 201. [Google Scholar]

- Hu, Y. Study on Compliance Assessment of Ship Exhaust Emissions in China’s ECA (Emission Control Area). Master’s Thesis, World Maritime University, Dalian, China, 2019. [Google Scholar]

- Hörandner, L.; Duldner-Borca, B.; Beil, D.; Putz-Egger, L.-M. Measurement Techniques, Calculation Methods, and Reduction Measures for Greenhouse Gas Emissions in Inland Navigation-A Preliminary Study. Sustainability 2024, 16, 3007. [Google Scholar] [CrossRef]

- Corbett, J.J.; Fischbeck, P.S.; Pandis, S.N. Global nitrogen and sulfur inventories for oceangoing ships. J. Geophys. Res. Atmos. 1999, 104, 3457–3470. [Google Scholar] [CrossRef]

- Endresen, Ø.; Sørgård, E.; Sundet, J.K.; Dalsøren, S.B.; Isaksen, I.S.A.; Berglen, T.F.; Gravir, G. Emission from international sea transportation and environmental impact. J. Geophys. Res. Atoms. 2003, 108, 4560. [Google Scholar] [CrossRef]

- Fuentes, G. Generating bunkering statistics from AIS data: A machine learning approach. Transp. Res. Part E Logist. Transp. Rev. 2021, 155, 102495. [Google Scholar] [CrossRef]

- Shi, X.; Xi, Q.; Zhang, Z.; Yang, Z. Methods for monitoring carbon emissions from ships: A practical perspective. Environ. Dev. 2025, 55, 101192. [Google Scholar] [CrossRef]

- Li, C.; Yuan, Z.; Ou, J.; Fan, X.; Ye, S.; Xiao, T.; Shi, Y.; Huang, Z.; Ng, S.K.; Zhong, Z.; et al. An AIS-based high-resolution ship emission inventory and its uncertainty in Pearl River Delta region, China. Sci. Total Environ. 2016, 573, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Song, S. Ship emissions inventory, social cost and eco-efficiency in Shanghai Yangshan port. Atmos. Environ. 2014, 82, 288–297. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2021: The Physical Science Basis. In Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021; p. 352. [Google Scholar]

- Zhang, H.; Wu, J.X.; Shen, Z.P. Radiative forcing and global warming potential of perfluorocarbons and sulfur hexafluoride. Sci. China Earth Sci. 2011, 54, 764–772. [Google Scholar] [CrossRef]

- Committee for the preparation of the Second National Assessment Report on Climate Change. The Second National Assessment Report on Climate Change; Science Press: Beijing, China, 2011; p. 26. [Google Scholar]

- El-Safoury, M.; Dufner, M.; Weber, C.; Schmitt, K.; Pernau, H.-F.; Willing, B.; Wöllenstein, J. On-Board Monitoring of SO2 Ship Emissions Using Resonant Photoacoustic Gas Detection in the UV Range. Sensors 2021, 21, 4468. [Google Scholar] [CrossRef] [PubMed]

- Notteboom, T.; Carriou, P. Fuel surcharge practices of container shipping lines: Is it about cost recovery or revenue making? In Proceedings of the 2009 International Association of Maritime Economists (IAME) Conference, Copenhagen, Denmark, 24–26 June 2009. [Google Scholar]

- EN 15267-3:2023; Air Quality—Assessment of Air Quality Monitoring Equipment—Part 3: Performance Criteria and Test Procedures for Automated Measuring Systems for Monitoring Emissions from Stationary Sources. European Committee for Standardization: Brussels, Belgium, 2023.

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization: Geneva, Switzerland, 2017.

- MEPC.384(79); 2022 Guidelines for the Development of a Ship Energy Efficiency Management Plan (SEEMP). International Maritime Organization: London, UK, 2022.

| Fuel Types | Carbon Factors (Ton of CO2/Ton of Fuel) |

|---|---|

| Heavy oil (ISO 8217 [13] Grades RME~RMK) | 3.114 |

| Light oil (ISO 8217 Grades RMA~RMD) | 3.151 |

| diesel (ISO 8217 Grades DMX~DMB) | 3.206 |

| LPG (propane) | 3 |

| LPG (butane) | 3.03 |

| LNG | 2.75 |

| Methanol | 1.375 |

| Ethanol | 1.913 |

| Ultra-low sulfur fuel oil (ISO 8217 DMA~DMZ) | 3.206 |

| Ultra-low sulfur fuel oil (ISO 8217 RMA~RMD) | 3.151 |

| Biofuel blend 1 | 2.284 |

| Green fuels (ammonia and hydrogen) | 0 |

| No. | Item | Details |

|---|---|---|

| 1 | Recipient of fuel | Clarify the name of the ship that accepts fuel and IMO number |

| 2 | Name of the product | List the types of fuel provided |

| 3 | Quantity | Record the total amount of fuel supplied (metric tons) |

| 4 | Intensity | Provide the density value of fuel at 15 degrees Celsius (in kg/m3) |

| 5 | Sulfur content | Indicate the sulfur content of the fuel, which is a key indicator for environment (unit: % m/m) |

| 6 | Supplier declaration | Measure the liquid level and oil temperature of fuel tanks, the longitudinal and transverse tilt of the ship’s hull each time when the ship is at berth, bunkering oil, arrives or departs from the port. |

| Monitoring Method | Monitoring GHG | Accuracy of Carbon Accounting | Accuracy of Measure | Real time Performance | Feasibility | Cost | |

|---|---|---|---|---|---|---|---|

| Indirect method | BDN | CO2 | low | —— | obtained annually, lagging | Cannot monitor carbon emission sources and new GHG separately | No |

| Bunker Fuel Oil-Tank Monitoring Onboard | CO2 | low | 5% | lagging | Cannot monitor carbon emission sources and new GHG separately | 1000~4200 USD | |

| Flow Meters | CO2 | relatively high | 2% | in real time | cannot monitor new GHG | 4200–15,000 USD | |

| Direct method | Online Monitoring | CO2, CH4, N2O | high | 1~2% | in real time | Can monitor carbon emission sources and new GHG separately | 80,000–104,200 USD |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Qiu, M.; Li, Y.; Tang, H.; Wu, R.; Yu, Z.; Zhang, Y.; Ye, S.; Zheng, C.; Qu, Y.; et al. Research on Ship Carbon-Emission Monitoring Technology and Suggestions on Low-Carbon Shipping Supervision System. Atmosphere 2025, 16, 773. https://doi.org/10.3390/atmos16070773

Li M, Qiu M, Li Y, Tang H, Wu R, Yu Z, Zhang Y, Ye S, Zheng C, Qu Y, et al. Research on Ship Carbon-Emission Monitoring Technology and Suggestions on Low-Carbon Shipping Supervision System. Atmosphere. 2025; 16(7):773. https://doi.org/10.3390/atmos16070773

Chicago/Turabian StyleLi, Mingjun, Mengchun Qiu, Yue Li, Huaiwu Tang, Rui Wu, Zhiwei Yu, Yonglin Zhang, Shanshan Ye, Chaohui Zheng, Ying Qu, and et al. 2025. "Research on Ship Carbon-Emission Monitoring Technology and Suggestions on Low-Carbon Shipping Supervision System" Atmosphere 16, no. 7: 773. https://doi.org/10.3390/atmos16070773

APA StyleLi, M., Qiu, M., Li, Y., Tang, H., Wu, R., Yu, Z., Zhang, Y., Ye, S., Zheng, C., Qu, Y., Zhang, L., Xu, T., Cheng, R., Zhou, C., Cheng, J., & Liang, D. (2025). Research on Ship Carbon-Emission Monitoring Technology and Suggestions on Low-Carbon Shipping Supervision System. Atmosphere, 16(7), 773. https://doi.org/10.3390/atmos16070773