The Effect of Nitrogen Fertilizer Placement and Timing on Winter Wheat Grain Yield and Protein Concentration

Abstract

1. Introduction

2. Methods and Materials

2.1. Experimental Sites and Environmental Characterization

2.2. Treatments and Experimental Design

2.3. Equipment Specifications and Calibration Protocols

2.4. Trial Management

2.5. Harvest Procedures and Sample Analysis

2.6. Data Analysis

3. Results

3.1. Grain Yield Nitrogen Application Methods

3.2. Grain Yield Response to Application Timing

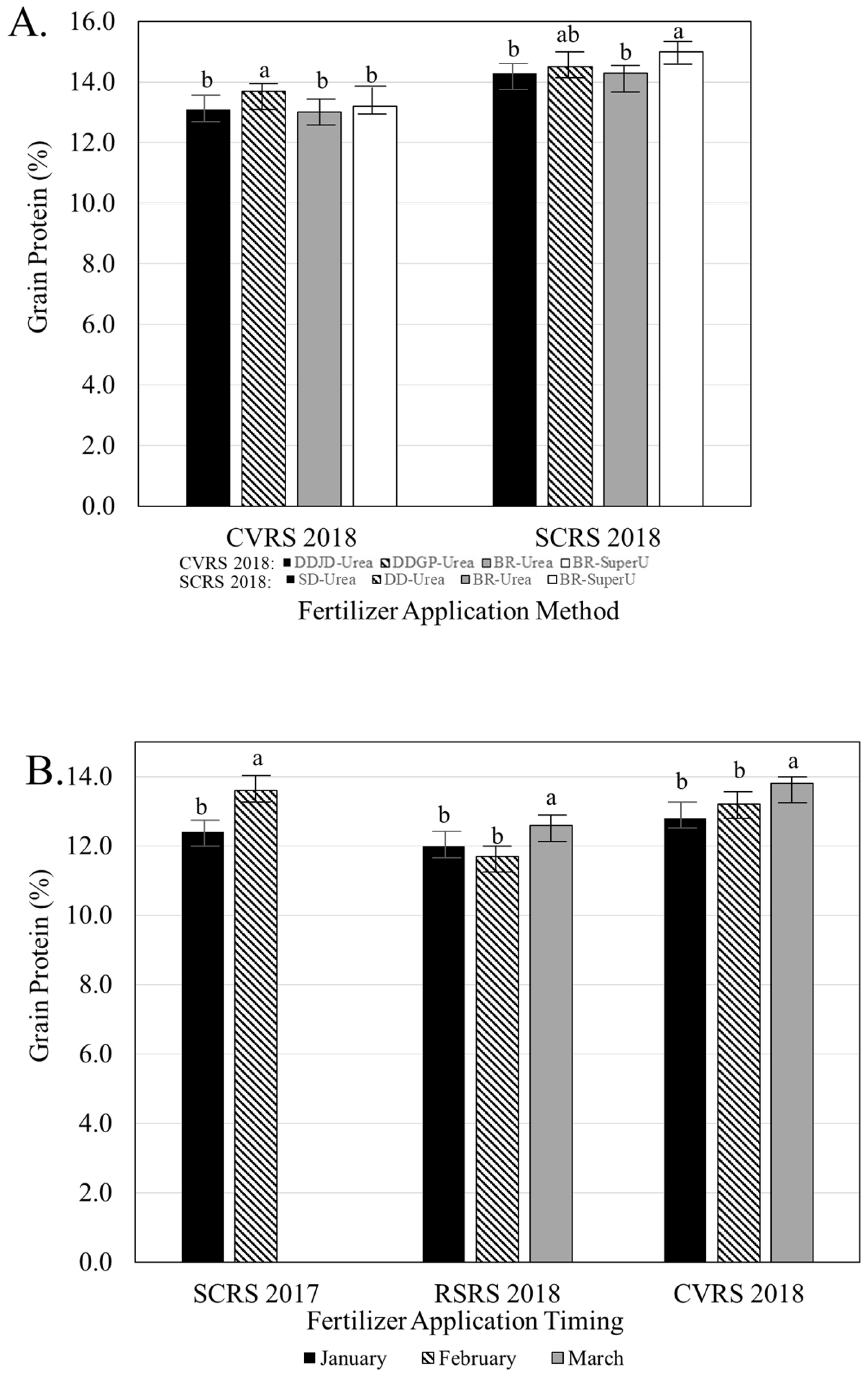

3.3. Grain Protein Content Response to Nitrogen Treatments

3.3.1. Protein Response to Application Methods

3.3.2. Protein Response to Application Timing

4. Discussion

4.1. Nitrogen Placement Effects on Grain Yield

4.2. Equipment Performance and Placement Efficacy

4.3. Enhanced Efficiency Fertilizer Performance

4.4. Application Timing Effects

4.5. Environmental Risk Assessment and Management Implications

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Omara, P.; Aula, L.; Oyebiyi, F.; Raun, W.R. World cereal nitrogen use efficiency trends: Review and current knowledge. Agrosyst. Geosci. Environ. 2019, 2, 1–8. [Google Scholar] [CrossRef]

- Walsh, O.; Raun, W.; Klatt, A.; Solie, J. Effect of delayed nitrogen fertilization on maize (Zea mays L.) Grain yields and nitrogen use efficiency. J. Plant Nutr. 2012, 35, 538–555. [Google Scholar] [CrossRef]

- Zhu, X.; Guo, W.; Ding, J.; Li, C.; Feng, C.; Peng, Y. Enhancing nitrogen use efficiency by combinations of nitrogen application amount and time in wheat. J. Plant Nutr. 2011, 34, 1747–1761. [Google Scholar] [CrossRef]

- Raun, W.R.; Solie, J.B.; Johnson, G.V.; Stone, M.L.; Mullen, R.W.; Freeman, K.W.; Thomason, W.E.; Lukina, E.V. Improving nitrogen use efficiency in cereal grain production with optical sensing and variable rate application. Agron. J. 2002, 94, 815–820. [Google Scholar] [CrossRef]

- Stone, M.L.; Solie, J.B.; Raun, W.R.; Whitney, R.W.; Taylor, S.L.; Ringer, J.D. Use of spectral radiance for correcting in-season fertilizer nitrogen deficiencies in winter wheat. Trans. ASAE 1996, 39, 1623–1631. [Google Scholar] [CrossRef]

- Kanampiu, F.K.; Raun, W.R.; Johnson, G.V. Effect of nitrogen rate on plant nitrogen loss in winter wheat varieties. J. Plant Nutr. 1997, 20, 389–404. [Google Scholar] [CrossRef][Green Version]

- Tilman, D.; Cassman, K.G.; Matson, P.A.; Naylor, R.; Polasky, S. Agricultural sustainability and intensive production practices. Nature 2002, 418, 671–677. [Google Scholar] [CrossRef]

- Walsh, O.; Kanke, Y.; Edmonds, D.E.; Raun, W.R. Improving mid-season nitrogen recommendations for winter wheat using soil moisture data. Better Crops 2009, 93, 26–27. [Google Scholar]

- Meng, Q.; Yue, S.; Hou, P.; Cui, Z.; Chen, X. Improving yield and nitrogen use efficiency simultaneously for maize and wheat in China: A review. Pedosphere 2016, 26, 137–147. [Google Scholar] [CrossRef]

- Abiola, S.O.; Lacasa, J.; Carver, B.F.; Arnall, B.D.; Ciampitti, I.A.; de Oliveira Silva, A. Nitrogen uptake dynamics of high and low protein wheat genotypes. Front. Plant Sci. 2024, 15, 1493901. [Google Scholar] [CrossRef]

- Malhi, S.; Grant, C.A.; Johnston, A.M.; Gill, K.S. Nitrogen fertilization management for no-till cereal production in the Canadian Great Plains: A review. Soil Tillage Res. 2001, 60, 101–122. [Google Scholar] [CrossRef]

- Cameron, K.C.; Di, H.J.; Moir, J.L. Nitrogen losses from the soil/plant system: A review. Ann. Appl. Biol. 2013, 162, 145–173. [Google Scholar] [CrossRef]

- Pan, B.; Lam, S.K.; Mosier, A.; Luo, Y.; Chen, D. Ammonia volatilization from synthetic fertilizers and its mitigation strategies: A global synthesis. Agric. Ecosyst. Environ. 2016, 232, 283–289. [Google Scholar] [CrossRef]

- Volk, G.M. Volatile loss of ammonia following surface application of urea to turf or bare soils. Agron. J. 1959, 51, 746–749. [Google Scholar] [CrossRef]

- Jones, C.A.; Koenig, R.T.; Ellsworth, J.W.; Brown, B.D.; Jackson, G.D. Management of urea fertilizer to minimize volatilization. MSU Ext. 2007, 1–12. [Google Scholar]

- Bundy, L.G. Managing urea-containing fertilizers. In Proceedings of the Fertilizer Dealer Meeting, Madison, WI, USA, 27 November–6 December 2001; pp. 1–6. [Google Scholar]

- Rector, N. Managing Nitrogen Fertilizer for Greatest Efficiency. 2009. Available online: https://msu-prod.dotcms.cloud/news/managing_nitrogen_fertilizer_for_greatest_efficiency#:~:text=Several%20research%20studies%20have%20found,can%20hydrolyze%20within%202%20days (accessed on 23 July 2025).

- Mohammed, Y.A.; Chen, C.; Jensen, T. Urease and Nitrification Inhibitors Impact on Winter Wheat Fertilizer Timing, Yield, and Protein Content. Agron. J. 2016, 108, 905–912. [Google Scholar] [CrossRef]

- Sommer, S.G.; Schjoerring, J.K.; Denmead, O.T. Ammonia emission from mineral fertilizers and fertilized crops. Adv. Agron. 2004, 82, 557–622. [Google Scholar]

- Rochette, P.; Angers, D.A.; Chantigny, M.H.; Gasser, M.O.; MacDonald, J.D.; Pelster, D.E.; Bertrand, N. Ammonia volatilization and nitrogen retention: How deep to incorporate urea? J. Environ. Qual. 2013, 42, 1635–1642. [Google Scholar] [CrossRef]

- Rochette, P.; MacDonald, J.D.; Angers, D.A.; Chantigny, M.H.; Gasser, M.O.; Bertrand, N. Banding of urea increased ammonia volatilization in a dry acidic soil. J. Environ. Qual. 2009, 38, 1383–1390. [Google Scholar] [CrossRef]

- Weber, E.A.; Graeff, S.; Koller, W.D.; Hermann, W.; Merkt, N.; Claupein, W. Impact of nitrogen amount and timing on the potential of acrylamide formation in winter wheat (Triticum aestivum L.). Field Crops Res. 2008, 106, 44–52. [Google Scholar] [CrossRef]

- Montemurro, F. Different nitrogen fertilization sources, soil tillage, and crop rotations in winter wheat: Effect on yield, quality, and nitrogen utilization. J. Plant Nutr. 2009, 32, 1–18. [Google Scholar] [CrossRef]

- Abiola, S.O.; Sharry, R.; Bushong, J.; Arnall, D.B. Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement. Agriculture 2025, 15, 812. [Google Scholar] [CrossRef]

- Mulvaney, R.L. Nitrogen—Inorganic Forms. In Methods of Soil Analysis; Sparks, D.L., Page, A.L., Helmke, P.A., Loeppert, R.H., Soltanpour, P.N., Tabatabai, M.A., Johnston, C.T., Sumner, M.E., Eds.; Wiley: Hoboken, NJ, USA, 1996. [Google Scholar] [CrossRef]

- Mehlich, A. Mehlich 3 soil test extractant: A modification of Mehlich 2 extractant. Commun. Soil Sci. Plant Anal. 1984, 15, 1409–1416. [Google Scholar] [CrossRef]

- Sikora, F.J. A Buffer that Mimics the SMP Buffer for Determining Lime Requirement of Soil. Soil Sci. Soc. Am. J. 2006, 70, 474–486. [Google Scholar] [CrossRef]

- Woodley, A.L.; Drury, C.F.; Yang, X.Y.; Phillips, L.A.; Reynolds, D.W.; Calder, W.; Oloya, T.O. Ammonia volatilization, nitrous oxide emissions, and corn yields as influenced by nitrogen placement and enhanced efficiency fertilizers. Soil Sci. Soc. Am. J. 2020, 84, 1327–1341. [Google Scholar] [CrossRef]

- Li, J.; Hu, W.; Chau, H.W.; Beare, M.; Cichota, R.; Teixeira, E.; Moore, T.; Di, H.; Cameron, K.; Guo, J.; et al. Response of nitrate leaching to no-tillage is dependent on soil, climate, and management factors: A global meta-analysis. Glob. Change Biol. 2023, 29, 2172–2187. [Google Scholar] [CrossRef]

- Zhu, L.; Sun, H.; Liu, L.; Zhang, K.; Zhang, Y.; Li, A.; Bai, Z.; Wang, G.; Liu, X.; Dong, H.; et al. Optimizing crop yields while minimizing environmental impact through deep placement of nitrogen fertilizer. J. Integr. Agric. 2025, 24, 36–60. [Google Scholar] [CrossRef]

- Chien, S.H.; Prochnow, L.I.; Cantarella, A.H. Recent developments of fertilizer production and use to improve nutrient efficiency and minimize environmental impacts. Adv. Agron. 2009, 102, 267–322. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.I.; Rahman, A.; Loladze, I.; Das, S.; Kim, P.J. Subsurface fertilization boosts crop yields and lowers greenhouse gas emissions: A global meta-analysis. Sci. Total Environ. 2023, 876, 162712. [Google Scholar] [CrossRef]

- Friedrich, T. The role of no or minimum mechanical soil disturbance in Conservation Agriculture systems. In Advances in Conservation Agriculture; Burleigh Dodds Science Publishing: Sawston, UK, 2020; pp. 155–178. [Google Scholar]

- Zhong, G.; Li, H.; He, J.; Wang, Q.; Lu, C.; Wang, C.; Tong, Z.; Cui, D.; He, D. Design and test of single-disc opener for no-till planter based on support cutting. Agriculture 2023, 13, 1635. [Google Scholar] [CrossRef]

- Pelster, D.E.; Watt, D.; Strachan, I.B.; Rochette, P.; Bertrand, N.; Chantigny, M.H. Effects of initial soil moisture, clod size, and clay content on ammonia volatilization after subsurface band application of urea. J. Environ. Qual. 2019, 48, 549–558. [Google Scholar] [CrossRef]

- Murray, J.R.; Tullberg, J.N.; Basnet, B.B. Planters and Their Components: Types, Attributes, Functional Requirements, Classification and Description. 2006. Available online: https://www.aciar.gov.au/publication/books-and-manuals/planters-and-their-components-types-attributes-functional-requirements-classification (accessed on 25 July 2025).

- Hu, K.; Zhao, P.; Wu, K.; Yang, H.; Yang, Q.; Fan, M.; Long, G. Reduced and deep application of controlled-release urea maintained yield and improved nitrogen-use efficiency. Field Crops Res. 2023, 295, 108876. [Google Scholar] [CrossRef]

- Motasim, A.M.; Samsuri, A.W.; Nabayi, A.; Akter, A.; Haque, M.A.; Sukor, A.S.A.; Adibah, A.M. Urea application in soil: Processes, losses, and alternatives—A review. Discov. Agric. 2024, 2, 42. [Google Scholar] [CrossRef]

- Rochette, P.; Angers, D.A.; Chantigny, M.H.; MacDonald, J.D.; Gasser, M.O.; Bertrand, N. Reducing ammonia volatilization in a no-till soil by incorporating urea and pig slurry in shallow bands. Nutr. Cycl. Agroecosyst. 2009, 84, 71–80. [Google Scholar] [CrossRef]

- Cantarella, H.; Otto, R.; Soares, J.R.; de Brito Silva, A.G. Agronomic efficiency of NBPT as a urease inhibitor: A review. J. Adv. Res. 2018, 13, 19–27. [Google Scholar] [CrossRef]

- Chakrabarti, B.; Bhatia, A.; Sharma, S.; Tomer, R.; Sharma, A.; Paul, A.; Kumar, V.; Sutton, M.A. Nitrification and urease inhibitors reduce gaseous N losses and improve nitrogen use efficiency in wheat exposed to elevated CO2 and temperature. Front. Sustain. Food Syst. 2024, 8, 1460994. [Google Scholar] [CrossRef]

- Lasisi, A.A.; Akinremi, O.O.; Kumaragamage, D. Efficacy of a new N-(n-butyl) thiophosphoric triamide formulation in reducing ammonia volatilization from urea-based fertilizers. Can. J. Soil Sci. 2019, 99, 395–405. [Google Scholar] [CrossRef]

- Zanin, L.; Tomasi, N.; Zamboni, A.; Varanini, Z.; Pinton, R. The urease inhibitor NBPT negatively affects DUR3-mediated uptake and assimilation of urea in maize roots. Front. Plant Sci. 2015, 6, 1007. [Google Scholar] [CrossRef]

- Byrne, M.P.; Tobin, J.T.; Forrestal, P.J.; Danaher, M.; Nkwonta, C.G.; Richards, K.; Cummins, E.; Hogan, S.A.; O’Callaghan, T.F. Urease and nitrification inhibitors—As mitigation tools for greenhouse gas emissions in sustainable dairy systems: A review. Sustainability 2020, 12, 6018. [Google Scholar] [CrossRef]

- Chen, Q.; Song, Y.; An, Y.; Lu, Y.; Zhong, G. Mechanisms and Impact of rhizosphere microbial metabolites on crop health, traits, functional components: A comprehensive review. Molecules 2024, 29, 5922. [Google Scholar] [CrossRef]

- Schaefer, S.C.; Hollibaugh, J.T. Temperature decouples ammonium and nitrite oxidation in coastal waters. Environ. Sci. Technol. 2017, 51, 3157–3164. [Google Scholar] [CrossRef]

- Cui, P.; Sheng, X.; Chen, Z.; Ning, Q.; Zhang, H.; Lu, H.; Zhang, H. Optimizing one-time nitrogen fertilization for rice production using controlled-release urea and urease inhibitors. Agronomy 2023, 14, 67. [Google Scholar] [CrossRef]

- Abalos, D.; Jeffery, S.; Sanz-Cobena, A.; Guardia, G.; Vallejo, A. Meta-analysis of the effect of urease and nitrification inhibitors on crop productivity and nitrogen use efficiency. Agric. Ecosyst. Environ. 2014, 189, 136–144. [Google Scholar] [CrossRef]

- Sieling, K.; Kage, H. Apparent fertilizer N recovery and the relationship between grain yield and grain protein concentration of different winter wheat varieties in a long-term field trial. Eur. J. Agron. 2021, 124, 126246. [Google Scholar] [CrossRef]

- Meloni, R.; Cordero, E.; Capo, L.; Reyneri, A.; Sacco, D.; Blandino, M. Optimizing nitrogen rates for winter wheat using in-season crop N status indicators. Field Crops Res. 2024, 318, 109545. [Google Scholar] [CrossRef]

- Deng, T.; Wang, J.H.; Gao, Z.; Shen, S.; Liang, X.G.; Zhao, X.; Chen, X.M.; Wu, G.; Wang, X.; Zhou, S.L. Late split-application with reduced nitrogen fertilizer increases yield by mediating source–sink relations during the grain filling stage in summer maize. Plants 2023, 12, 625. [Google Scholar] [CrossRef]

- Souza, J.L.B.; Antonangelo, J.A.; de Oliveira Silva, A.; Reed, V.; Arnall, B. Recover of grain yield and protein with fertilizer application post nitrogen stress in winter wheat (Triticum aestivum L.). Agronomy 2022, 12, 2024. [Google Scholar] [CrossRef]

- Sangha, L.; Shortridge, J.; Frame, W. The impact of nitrogen treatment and short-term weather forecast data in irrigation scheduling of corn and cotton on water and nutrient use efficiency in humid climates. Agric. Water Manag. 2023, 283, 108314. [Google Scholar] [CrossRef]

- Bogard, M.; Jourdan, M.; Allard, V.; Martre, P.; Perretant, M.R.; Ravel, C.; Heumez, E.; Orford, S.; Snape, J.; Griffiths, S.; et al. Anthesis date mainly explained correlations between post-anthesis leaf senescence, grain yield, and grain protein concentration in a winter wheat population segregating for flowering time QTLs. J. Exp. Bot. 2011, 62, 3621–3636. [Google Scholar] [CrossRef] [PubMed]

- Powlson, D.S.; Dawson, C.J. Use of ammonium sulphate as a sulphur fertilizer: Implications for ammonia volatilization. Soil Use Manag. 2022, 38, 622–634. [Google Scholar] [CrossRef]

- Tamagno, S.; Eagle, A.J.; McLellan, E.L.; van Kessel, C.; Linquist, B.A.; Ladha, J.K.; Pittelkow, C.M. Quantifying N leaching losses as a function of N balance: A path to sustainable food supply chains. Agric. Ecosyst. Environ. 2022, 324, 107714. [Google Scholar] [CrossRef]

- Smith, A.P.; Johnson, I.R.; Schwenke, G.; Lam, S.K.; Suter, H.C.; Eckard, R.J. Predicting ammonia volatilization from fertilized pastures used for grazing. Agric. For. Meteorol. 2020, 287, 107952. [Google Scholar] [CrossRef]

| Location a | Year | Soil Mapping Unit | Taxonomic Classification | pH b | BI c | NO3-N d | P e | K e | Latitude | Longitude |

|---|---|---|---|---|---|---|---|---|---|---|

| -mg kg−1 | dec. degrees | |||||||||

| SCRS | 2017 | Dale silt loam, 0 to 1 percent slopes, rarely flooded | Dale: Fine-silty, mixed, superactive, thermic Pachic Haplustolls | 6.6 | N/A | 13 | 32 | 256 | 35.0410 N | 97.9077 W |

| SCRS | 2018 | McLain silty clay loam, 0 to 1 percent slopes, rarely flooded | McLain: Fine, mixed, superactive, thermic Pachic Argiustolls | 5.8 | 7.0 | 14 | 22 | 182 | 35.0410 N | 97.9077 W |

| RSRS | 2017 | Grant silt loam, 1 to 3 percent slopes | Grant: Fine-silty, mixed, superactive, thermic Udic Argiustolls | 5.0 | 6.8 | 23 | 34 | 245 | 36.3893 N | 97.1053 W |

| RSRS | 2018 | Grant silt loam, 1 to 3 percent slopes | Grant: Fine-silty, mixed, superactive, thermic Udic Argiustolls | 5.6 | 7.0 | 10 | 25 | 139 | 36.3893 N | 97.1053 W |

| CVRS | 2017 | Teller loam, 0 to 1 percent slopes | Teller: Fine-loamy, mixed, active, thermic Udic Argiustolls | 5.6 | 6.6 | 16 | 18 | 148 | 35.9858 N | 97.0473 W |

| CVRS | 2018 | Teller loam, 0 to 1 percent slopes | Teller: Fine-loamy, mixed, active, thermic Udic Argiustolls | 4.7 | 6.7 | 9 | 34 | 135 | 35.9858 N | 97.0473 W |

| Precipitation (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Location a | Year | Sept. | Oct. | Nov. | Dec. | Jan. | Feb. | Mar. | Apr. | May | Total |

| SCRS | 2017 | 89 | 7 | 70 | 23 | 45 | 70 | 108 | 131 | 57 | 600 |

| SCRS | 2018 | 152 | 88 | 3 | 28 | 4 | 75 | 14 | 43 | 164 | 571 |

| RSRS | 2017 | 132 | 65 | 9 | 10 | 60 | 53 | 80 | 148 | 82 | 639 |

| RSRS | 2018 | 54 | 58 | 4 | 2 | 0 | 34 | 24 | 0 | 80 | 253 |

| CVRS | 2017 | 60 | 54 | 55 | 12 | 67 | 50 | 60 | 230 | 101 | 690 |

| CVRS | 2018 | 69 | 144 | 7 | 16 | 4 | 83 | 20 | 66 | 100 | 507 |

| Location a | Year | Type of Disc Opener | Brand of Drill b |

|---|---|---|---|

| SCRS | 2017 | Single-Disc | John Deere 1590 |

| Double-Disc | Kinkaid 2010 | ||

| 2018 | Single-Disc | John Deere 1590 | |

| Double-Disc | Kinkaid 2010 | ||

| RSRS | 2017 | Single-Disc | TYE |

| 2018 | Single-Disc | TYE | |

| Double-Disc | John Deere 1560 | ||

| CVRS | 2017 | Double-Disc | John Deere 450 |

| 2018 | Double-Disc | John Deere 450 | |

| Double-Disc | Great Plains 1006NT |

| Location a | Year | Timing 1 | Timing 2 | Timing 3 |

|---|---|---|---|---|

| SCRS | 2017 | 27 January 2017 | 28 February 2017 | N/A |

| 2018 | 9 January 2018 | 8 February 2018 | 6 March 2018 | |

| RSRS | 2017 | 24 January 2017 | 10 February 2017 | 6 March 2017 |

| 2018 | 10 January 2018 | 8 February 2018 | 13 March 2018 | |

| CVRS | 2017 | 23 January 2018 | 23 February 2018 | N/A |

| 2018 | 8 January 2018 | 5 February 2018 | 3 March 2018 |

| Application Timing | Weather Indicator | SCRS a | RSRS a | CVRS a | |||

|---|---|---|---|---|---|---|---|

| 2017 | 2018 | 2017 | 2018 | 2017 | 2018 | ||

| January | Temperature (°C) | 5.38 | −1.17 | 4.70 | −2.03 | 6.72 | −1.02 |

| Rainfall (mm) | 0.25 | 0.51 | 0.00 | 0.00 | 0.00 | 0.25 | |

| Max Rain Intensity (mm h−1) | 3.05 | 3.05 | 0.00 | 0.00 | 0.00 | 3.05 | |

| Soil Moisture Calibrated Delta-T at 5 cm (°C) | 1.46 | 1.50 | 1.55 | 2.46 | 1.60 | 1.86 | |

| February | Temperature (°C) | 12.84 | 4.77 | 10.32 | 3.76 | 10.40 | 0.76 |

| Rainfall (mm) | 0.51 | 5.59 | 51.56 | 5.59 | 0.00 | 0.00 | |

| Max Rain Intensity (mm h−1) | 3.05 | 3.05 | 67.06 | 6.10 | 0.00 | 0.00 | |

| Soil Moisture Calibrated Delta-T at 5 cm (°C) | 1.70 | 2.40 | 1.61 | 2.65 | 1.67 | 1.46 | |

| March | Temperature (°C) | N/A | 9.27 | 7.97 | 10.29 | N/A | 9.71 |

| Rainfall (mm) | N/A | 0.00 | 5.59 | 14.73 | N/A | 0.25 | |

| Max Rain Intensity (mm h−1) | N/A | 0.00 | 6.10 | 54.86 | N/A | 3.05 | |

| Soil Moisture Calibrated Delta-T at 5 cm (°C) | N/A | 1.40 | 1.66 | 1.76 | N/A | 1.46 | |

| Grain Yield | Grain Protein | |||

|---|---|---|---|---|

| 2017 | 2018 | 2017 | 2018 | |

| p-Value | p-Value | |||

| Method | 0.0479 | 0.4978 | 0.6690 | 0.0975 |

| Timing | 0.0885 | 0.5623 | 0.0061 | 0.4738 |

| Method X Timing | 0.3775 | 0.5394 | 0.1992 | 0.2707 |

| kg ha−1 | % | |||

| January | ||||

| Urea vs. Drilled | −324 | 20 | 0.4 | −0.3 |

| SuperU vs. Drilled | −54 | 155 | 0.7 * | 0.5 |

| SD a vs. DD a | −67 | −169 | −0.4 | −0.6 |

| Urea vs. SuperU | −270 | −135 | −0.2 | −0.8 |

| February | ||||

| Urea vs. Drilled | −984 *** | 229 | −0.4 | −0.7 |

| SuperU vs. Drilled | −364 | −7 | 0.0 | 0.0 |

| SD vs. DD | −67 | −189 | −0.4 | −0.5 |

| Urea vs. SuperU | −627 * | 236 | −0.4 | −0.7 |

| March | ||||

| Urea vs. Drilled | N/A | −243 | N/A | 0.7 |

| SuperU vs. Drilled | N/A | −7 | N/A | 1.2 ** |

| SD vs. DD | N/A | −148 | N/A | 0.4 |

| Urea vs. SuperU | N/A | −236 | N/A | −0.5 |

| Grain Yield | Grain Protein | |||

|---|---|---|---|---|

| 2017 | 2018 | 2017 | 2018 | |

| p-Value | p-Value | |||

| Method | 0.3907 | 0.0275 | 0.4310 | 0.7706 |

| Timing | 0.3880 | 0.9920 | 0.1270 | 0.0097 |

| Method X Timing | 0.2889 | 0.2989 | 0.2958 | 0.3113 |

| kg ha−1 | % | |||

| January | ||||

| Urea vs. Drilled | −303 | 94 | −0.5 | 0.4 |

| SuperU vs. Drilled | −88 | −61 | −0.9 ** | 0.2 |

| SD a vs. DD a | N/A | −290 | N/A | 0.5 |

| Urea vs. SuperU | −222 | 155 | 0.4 | 0.2 |

| February | ||||

| Urea vs. Drilled | −189 | 189 | 0.0 | 0.8 * |

| SuperU vs. Drilled | −438 * | −222 | 0.4 | −0.1 |

| SD vs. DD | N/A | −303 | N/A | −0.4 |

| Urea vs. SuperU | 256 | 404 * | −0.4 | 0.9 * |

| March | ||||

| Urea vs. Drilled | −34 | 61 | −0.4 | −0.6 |

| SuperU vs. Drilled | 189 | 330 * | −0.2 | −0.3 |

| SD vs. DD | N/A | −458 | N/A | −0.5 |

| Urea vs. SuperU | −222 | −270 | −0.2 | −0.3 |

| Grain Yield | Grain Protein | |||

|---|---|---|---|---|

| 2017 | 2018 | 2017 | 2018 | |

| p-Value | p-Value | |||

| Method | 0.2349 | 0.5460 | 0.7221 | 0.0508 |

| Timing | 0.3025 | 0.0379 | 0.1659 | 0.0400 |

| Method X Timing | 0.2722 | 0.5102 | 0.2804 | 0.2265 |

| kg ha−1 | % | |||

| January | ||||

| Urea vs. Drilled | 155 | −13 | −0.3 | −0.6 |

| SuperU vs. Drilled | 115 | −20 | −0.3 | 0.5 |

| DDJD a vs. DDGP a | N/A | 88 | N/A | −0.2 |

| Urea vs. SuperU | 47 | −115 | 0.0 | −1.0 ** |

| February | ||||

| Urea vs. Drilled | −67 | −283 | 0.4 | −0.4 |

| SuperU vs. Drilled | 404 * | 371 | 0.8 | −0.3 |

| DDJD vs. DDGP | N/A | 607 | N/A | −0.5 |

| Urea vs. SuperU | −472 * | −654 * | −0.5 | −0.1 |

| March | ||||

| Urea vs. Drilled | N/A | 391 | N/A | −0.2 |

| SuperU vs. Drilled | N/A | 101 | N/A | −0.6 * |

| DDJD vs. DDGP | N/A | 67 | N/A | −0.8 ** |

| Urea vs. SuperU | N/A | 290 | N/A | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ballagh, B.; Ballagh, A.; Bushong, J.; Arnall, D.B. The Effect of Nitrogen Fertilizer Placement and Timing on Winter Wheat Grain Yield and Protein Concentration. Agronomy 2025, 15, 1890. https://doi.org/10.3390/agronomy15081890

Ballagh B, Ballagh A, Bushong J, Arnall DB. The Effect of Nitrogen Fertilizer Placement and Timing on Winter Wheat Grain Yield and Protein Concentration. Agronomy. 2025; 15(8):1890. https://doi.org/10.3390/agronomy15081890

Chicago/Turabian StyleBallagh, Brent, Anna Ballagh, Jacob Bushong, and Daryl Brian Arnall. 2025. "The Effect of Nitrogen Fertilizer Placement and Timing on Winter Wheat Grain Yield and Protein Concentration" Agronomy 15, no. 8: 1890. https://doi.org/10.3390/agronomy15081890

APA StyleBallagh, B., Ballagh, A., Bushong, J., & Arnall, D. B. (2025). The Effect of Nitrogen Fertilizer Placement and Timing on Winter Wheat Grain Yield and Protein Concentration. Agronomy, 15(8), 1890. https://doi.org/10.3390/agronomy15081890